Green diode with optical microcavity structure and production thereof

An optical microcavity and diode technology, applied in semiconductor/solid-state device manufacturing, ion implantation plating, coating, etc., can solve the problem of low device brightness, low luminous efficiency and stability, and inevitable redundant holes that do not participate in radiation Composite and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

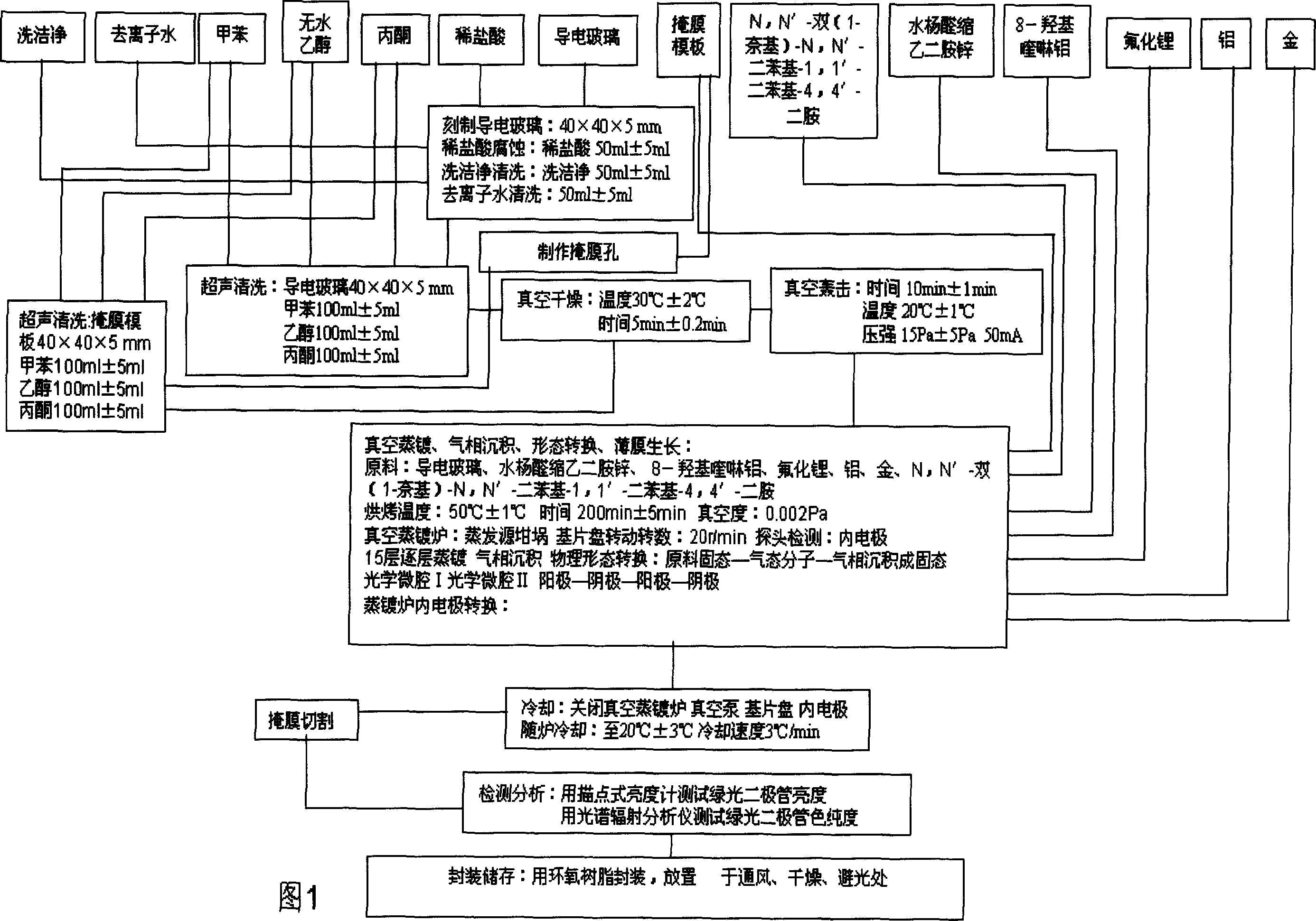

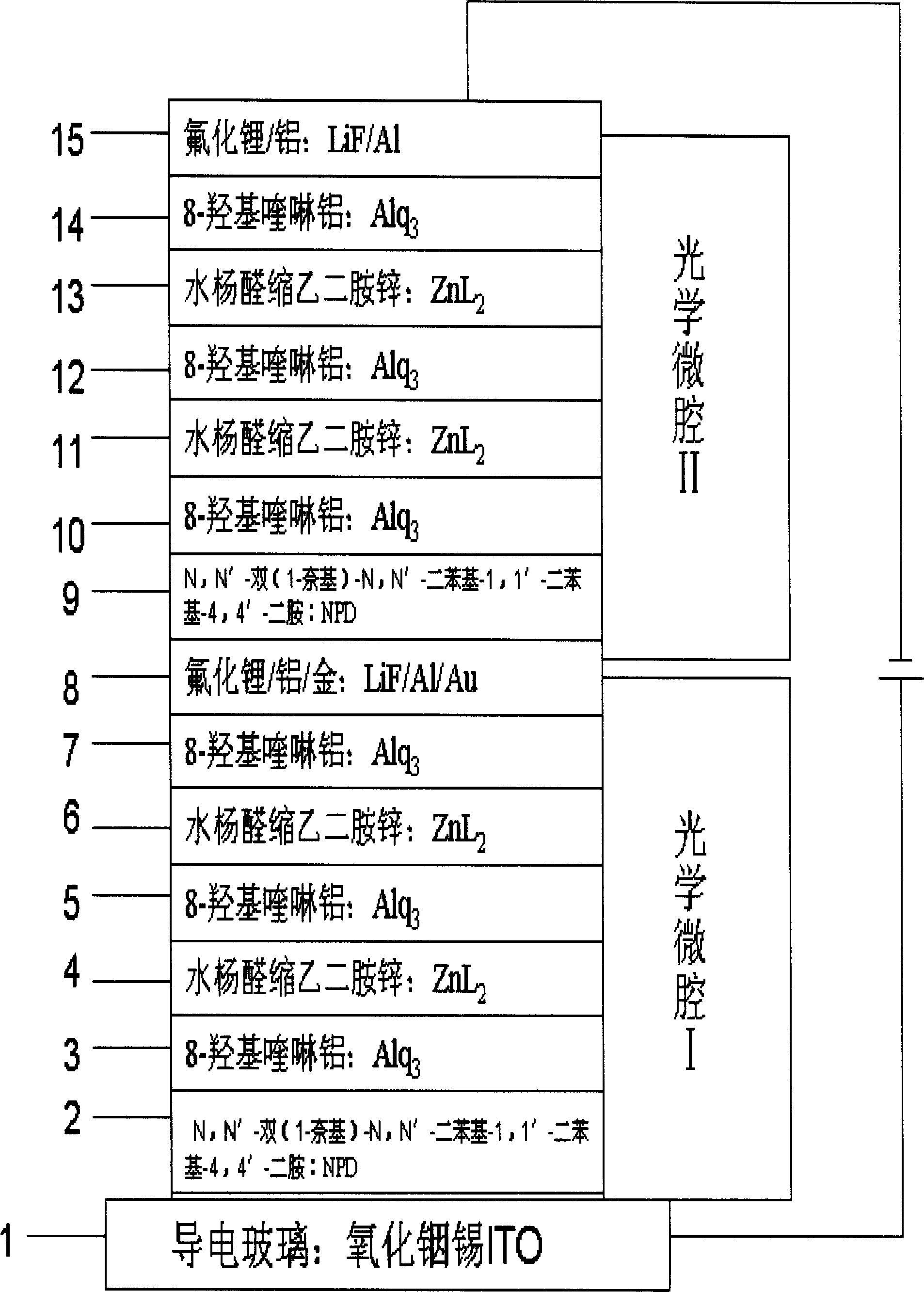

Method used

Image

Examples

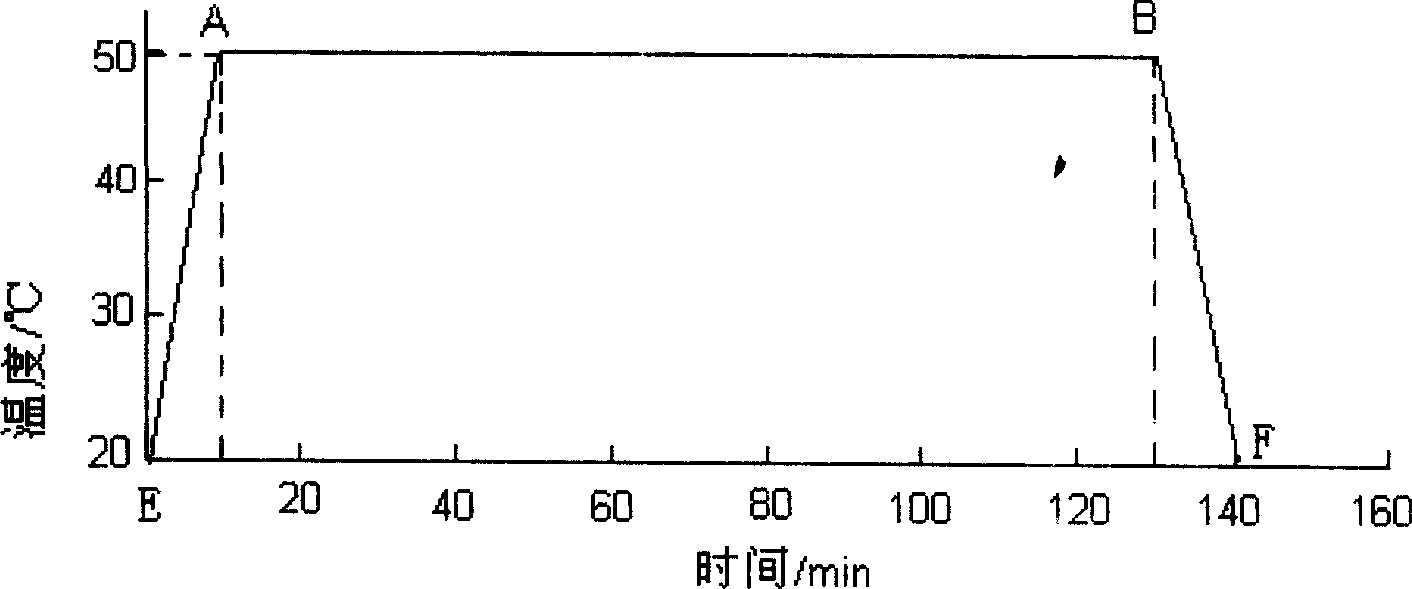

Embodiment 1

[0131] The vacuum evaporation furnace, console, etching equipment, ultrasonic cleaner, vacuum drying oven, beaker, and container used in the preparation are all in quasi-working condition;

[0132] Selected chemical materials; purity, fineness, precision control, material fineness ≥ 300 mesh, conductive glass square resistance 10Ω / □-60Ω / □, transmittance 80-88%, colorless and transparent, 40×40×5mm , scotch tape 40×2×0.08mm;

[0133] Etching conductive glass: test the conductivity of the front and back sides to determine that the front side is the conductive side;

[0134] Make mask holes: engrave 6 equidistant rectangular through-hole mask holes on the mask template, and the size of the mask holes is 2×2×5mm;

[0135] Etching conductive glass: Paste two transparent tapes symmetrically on the conductive surface, then put in a beaker and add 50ml±5ml of dilute hydrochloric acid, etch for 2min±0.2min, wipe the etched conductive glass with a soft material , peel off the transpar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com