Preparation method of core-shell silver nanowire based on conductive polymer

A conductive polymer, silver nanowire technology, applied in nanotechnology, nanotechnology, nanotechnology and other directions for materials and surface science, can solve the problems of high material cost, high cost, high absolute cost, and ensure completeness and density, high controllability and greenness, and the effect of reducing material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

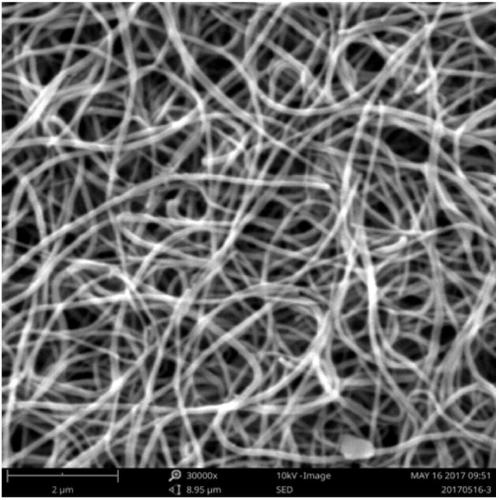

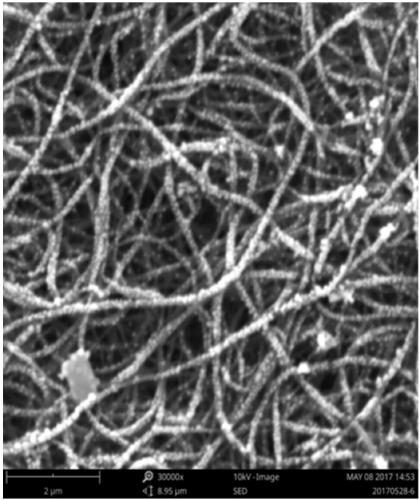

[0030] Pyrrole is stirred and dissolved in 0.2mol / L at room temperature, and pH is 7.4 in the phosphate buffer solution of 7.4, forms the pyrrole solution that molar concentration is 0.1mol / L, then adds naphthalenesulfonic acid, makes the molar concentration of naphthalenesulfonic acid in solution be 10mmol / L to form a conductive polymer nanowire precursor liquid; stir and mix silver nitrate and sodium nitrate at room temperature to prepare a mixed aqueous solution with a molar concentration of silver nitrate of 3mmol / L and a molar concentration of sodium nitrate of 0.2mol / L, and then press 2g Add polyvinylpyrrolidone at / L mass concentration to form a nano-silver precursor liquid; transfer the conductive polymer nanowire precursor liquid to an electrochemical cell, use a stainless steel sheet as a working electrode, a copper sheet as a counter electrode, and a saturated calomel electrode as a reference electrode Form a three-electrode system, constant current method: 0.6mA, th...

Embodiment 2

[0032] Aniline is stirred and dissolved at room temperature in 0.2mol / L, pH is 6.8 in the phosphate buffer solution of 6.8 to form the mixed solution of 0.3mol / L, then add naphthalenesulfonic acid by 20mmol / L to form the precursor liquid of conductive polymer nanowire; silver sulfate Stir and mix with sodium nitrate at room temperature, prepare silver sulfate molar concentration as 6mmol / L, sodium nitrate molar concentration as the mixed aqueous solution of 0.2mol / L, then add polyvinylpyrrolidone by 2g / L mass concentration to form nano-silver precursor liquid; The precursor fluid of the nanowire was transferred to the electrochemical cell, with the stainless steel sheet as the working electrode, the copper sheet as the counter electrode, and the saturated calomel electrode as the reference electrode to form a three-electrode system. Constant voltage method: 1.0V, the polymer formed after 15min The aniline nanowires were centrifuged and washed three times with water; the obtaine...

Embodiment 3

[0034] Stir and dissolve pyrrole at room temperature in a 0.6mol / L, pH 8.0 phosphate buffer solution to form a 0.1mol / L mixed solution, then add camphorsulfonic acid at a molar concentration of 10mmol / L to form a conductive polymer nanowire precursor liquid Stir and mix silver nitrate and sodium nitrate at room temperature, prepare silver nitrate and sodium nitrate mixed aqueous solution with molar concentration of 3mmol / L and 0.6mol / L respectively, then add chitosan to form nano-silver precursor body liquid by 5g / L mass concentration; Transfer the conductive polymer nanowire precursor liquid to the electrochemical cell, use the titanium sheet as the working electrode, the copper sheet as the counter electrode, and the saturated calomel electrode as the reference electrode to form a three-electrode system. Constant current method: 0.6mA after 10min The formed polypyrrole nanowires were centrifuged and washed three times with water; after the obtained polypyrrole nanowires were ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com