Premixed pump concrete prepared from coal oil residues and preparation method thereof

A pumping concrete and coal-to-oil technology, which is applied in the comprehensive utilization of solid waste resources and building materials, can solve the problem of low early strength of ready-mixed pumped concrete, high carbon emissions, and slow hydration speed of coal-to-oil residue and other issues, to achieve good durability, reduce carbon emissions, and change the effect of crystal form and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

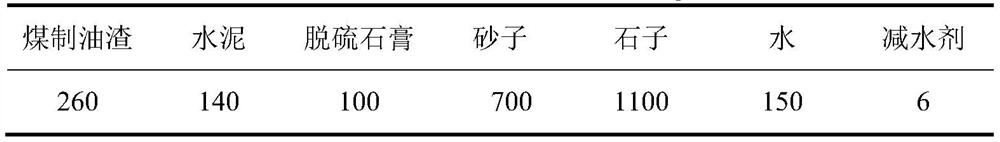

Embodiment 1

[0049] Weigh each raw material according to Table 1, mix and grind cement, coal oil residue and gypsum until the specific surface area is 560m 2 / kg, to prepare the gelled material. The stability test of the cementitious material is carried out in accordance with the provisions of GB / T 1346-2011 "Cement Standard Consistency Water Consumption, Setting Time, and Stability Test Methods". After testing by the cake test method and Raymond clamp method, the stability is qualified .

[0050] The cementitious material is mixed with fine aggregate (sand), coarse aggregate (stone), water reducer (sodium polycarboxylate) and water to obtain concrete.

[0051] Table 1 raw material ratio (unit: g)

[0052]

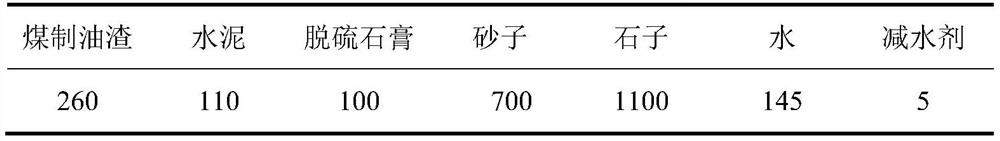

Embodiment 2

[0054] Weigh each raw material according to Table 2, mix and grind cement, coal oil residue and gypsum until the specific surface area is 560m 2 / kg, to prepare the gelled material. The stability test of the cementitious material is carried out in accordance with the provisions of GB / T 1346-2011 "Cement Standard Consistency Water Consumption, Setting Time, and Stability Test Methods". After testing by the cake test method and Raymond clamp method, the stability is qualified .

[0055] The cementitious material is mixed with fine aggregate (sand), coarse aggregate (stone), water reducer (sodium polycarboxylate) and water to obtain concrete.

[0056] Table 2 raw material ratio (unit: g)

[0057]

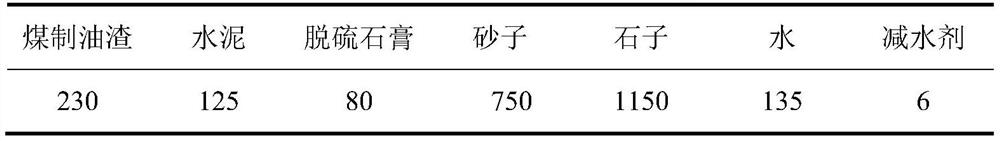

Embodiment 3

[0059] Weigh each raw material according to Table 3, mix and grind cement, coal oil residue and gypsum until the specific surface area is 560m 2 / kg, to prepare the gelled material. The stability test of the cementitious material is carried out in accordance with the provisions of GB / T 1346-2011 "Cement Standard Consistency Water Consumption, Setting Time, and Stability Test Methods". After testing by the cake test method and Raymond clamp method, the stability is qualified .

[0060] Stir and mix the cementitious material with fine aggregate (sand), coarse aggregate (stone), water reducer (sodium potassium polycarboxylate) and water to obtain concrete.

[0061] Table 3 raw material ratio (unit: g)

[0062]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com