Method for preparing building material product by clinker-free steel slag gel material and multiple CO2 absorbing techniques

A technology of cementitious materials and building materials, applied in the field of building materials, can solve problems such as low early strength, low wearability, and poor stability, and achieve the effects of improving production efficiency, increasing strength, and improving greenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Select a company with a specific surface area of 300-400m 2 Converter steel slag powder between / kg, add appropriate amount of water (water-solid ratio is 0.15), stir for 240s by conventional stirring method, and use 5MPa pressure to form 2 groups (6 pieces in each group) of test blocks with a size of 40mm×40mm×20mm, One set was placed in a pressure vessel and injected with CO 2 gas that makes CO 2 The air pressure reaches 2bar, and carbonization curing is carried out. After 2 hours, the strength reaches 15.5MPa, and the carbon fixation amount reaches 12.9%. While the other group underwent standard curing, the strength was 0 after 2 hours, and the amount of carbon fixation was 0.

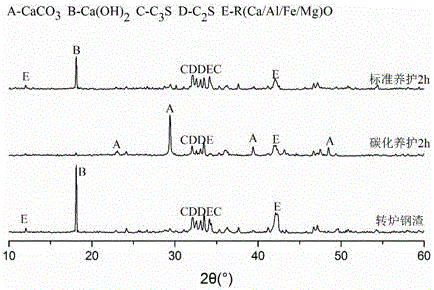

[0029] The XRD patterns of converter steel slag, carbonation curing 2h and standard curing 2h are as follows figure 1 shown. from figure 1 It can be seen that after two hours of carbonization curing, the Ca(OH) in the original steel slag 2 Diffraction peaks disappear, CaCO 3 The inte...

Embodiment 2

[0031] Select a company with a specific surface area of 300-400m 2 Converter steel slag powder between / kg, add appropriate amount of water (water-solid ratio is 0.1), in CO 2 Stir for carbonization in the atmosphere for 240s, then add water with 5% of the mass of steel slag and continue stirring for 120s in the air atmosphere. Formed into 6 test blocks of 40mm×40mm×20mm with 8MPa pressure. Put the group of samples in a pressure vessel, inject CO 2 gas that makes CO 2 The air pressure reaches 2bar and the temperature is 15-25°C for carbonization curing. After 2-8 hours, the maximum strength reaches 10.5MPa, and the maximum carbon fixation capacity reaches 15.2%.

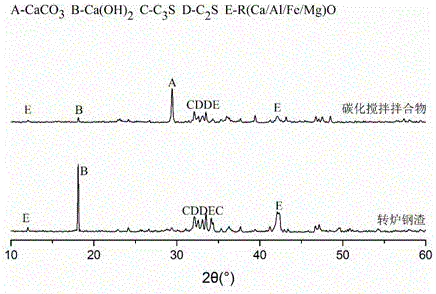

[0032] The XRD patterns of converter steel slag and steel slag mixture samples after carbonization stirring are as follows figure 2 shown. from figure 2 It can be seen that after carbonization stirring, the Ca(OH) in the XRD pattern of steel slag 2 The diffraction peaks of CaCO are obviously weakened, and ...

Embodiment 3

[0034] Select a company with a specific surface area of 300-400m 2 / kg electric furnace steel slag powder, add appropriate amount of water (water-solid ratio is 0.1), in CO 2 Stir for carbonization in the atmosphere for 240s, then add water with 5% of the mass of steel slag and continue stirring for 120s in the air atmosphere. Form 6 test blocks of 40mm×40mm×20mm with 8MPa pressure, place the test blocks in a pressure vessel, and inject CO 2 gas that makes CO 2 The air pressure reaches 2bar, and the temperature is 15-25°C for carbonization curing. After 2-8 hours, the strength reaches 6.8MPa, and the carbon fixation capacity reaches 10.2%. Compared with converter steel slag, the amount of carbon fixation is lower.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com