Base plate fixing device of heater rod bending forming machine

A technology for fixing devices and molding machines, applied in positioning devices, feeding devices, storage devices, etc., can solve problems such as fixing troubles, loose bolts, inconvenient replacement of molding machines, etc., to prevent loosening, increase friction, and facilitate replacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

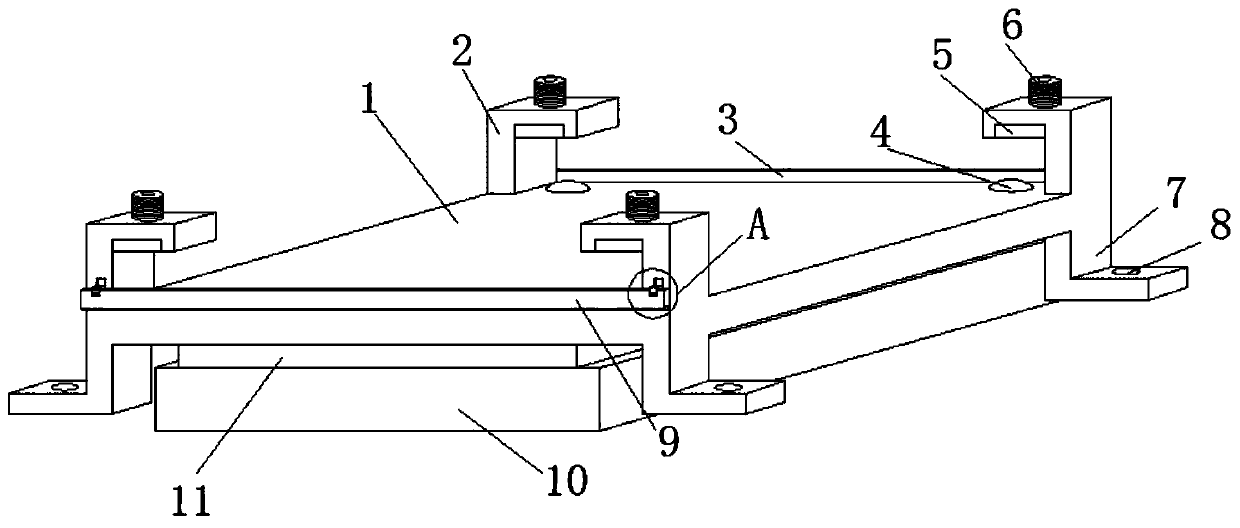

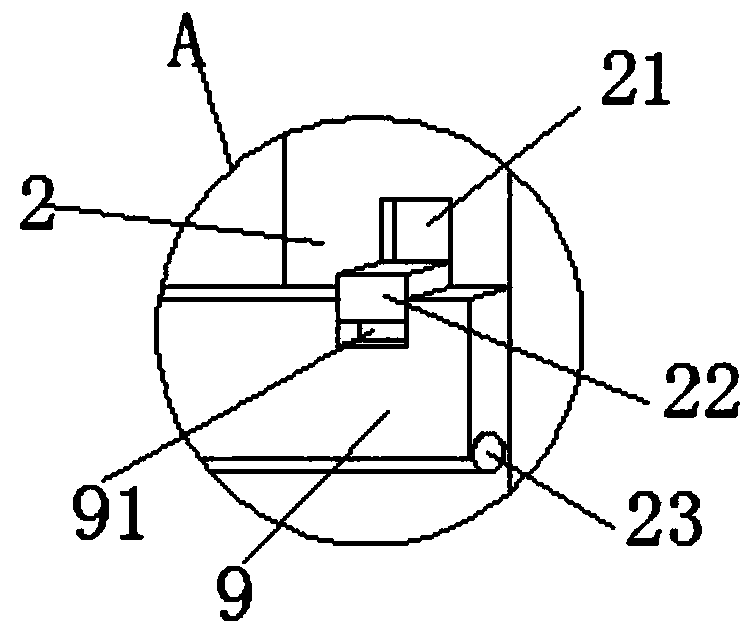

[0026] see figure 1 , Figure 6 , Figure 7 and Figure 8 , this embodiment provides a bottom plate fixing device for a heater rod bending machine, including a base 1, a press frame 2 is fixedly installed on the four corners of the upper end surface of the base 1, and the groove on the inner top of the press frame 2 A briquetting block 5 is installed in the briquetting block 5, and a threaded rod 6 is fixedly installed on the top of the briquetting rod 6. The top of the threaded rod 6 is provided with an inner hexagonal hole, which can regulate the threaded rod 6. The threaded rod 6 runs through the pressure On the top of the frame 2, one end of the base 1 is fixedly equipped with a first baffle 3, and both sides of the first baffle 3 are fixed on the outside of the press frame 2, and the other side of the base 1 is rotatably installed with The second baffle plate 9, the four corners of the lower end of the base 1 are fixedly installed with a mounting frame 7, and the lower...

Embodiment 2

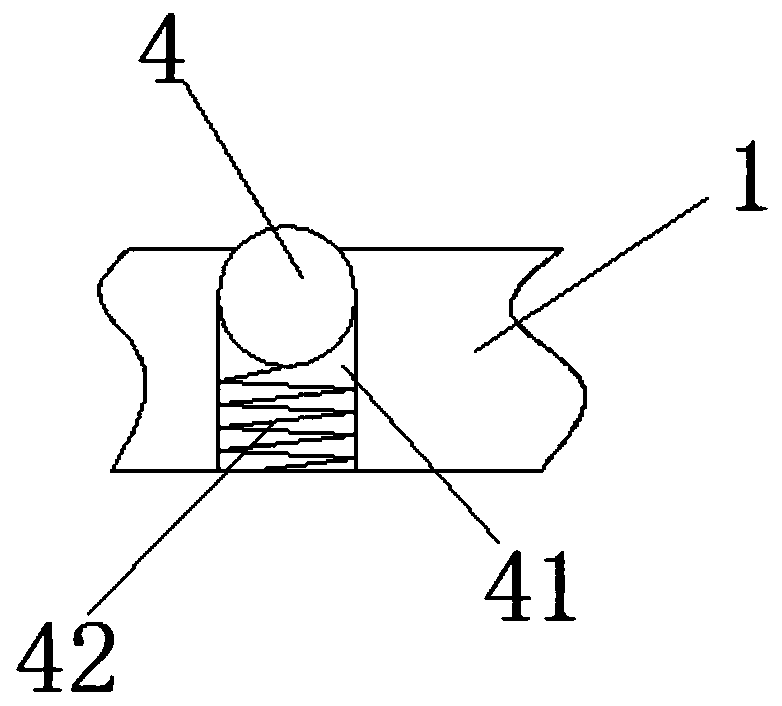

[0030] see Figure 2-5 , made a further improvement on the basis of Example 1: the top ball 4 is installed on the slide of the base 1, the top ball 4 is located on the upper end surface of the base 1 inside the press frame 2, and the upper end surface of the base 1 is provided with A placement groove 41 matched with the top ball 4, the bottom of the placement groove 41 is fixedly equipped with a first spring 42, and the top of the first spring 42 is fixedly welded with the top ball 4, by setting the top ball 4 and the first spring 42. When the base 1 fixes the bottom plate of the molding machine, while the threaded rod 6 and the pressure block 5 exert pressure on the bottom plate of the molding machine, the bottom plate of the molding machine also has pressure on the top ball 4, and the top ball is under the pressure of the first spring 42 Under the action, there will be an upward elastic force on the bottom plate of the molding machine, and the elastic force of the spring wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com