Fully-automatic flexible production equipment and production process of annular lifting belt

A fully automatic and flexible production technology, applied in textile and paper making, cloth feeding mechanism, garment piece transporter, etc., can solve the problems of high product cost, low degree of automation, hidden safety hazards, etc., and achieve rapid control and high turnover. The effect of precision, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

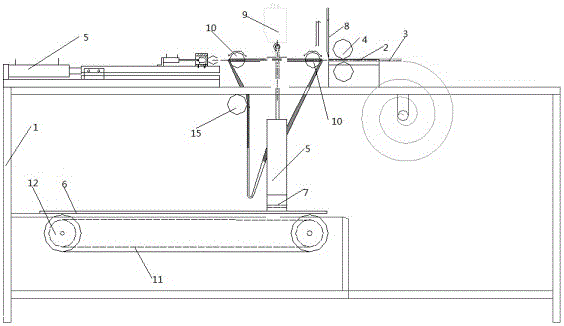

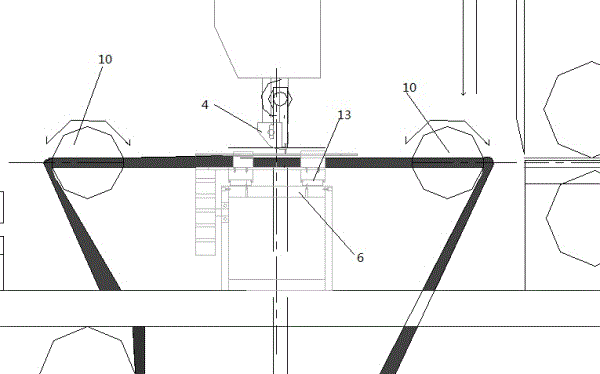

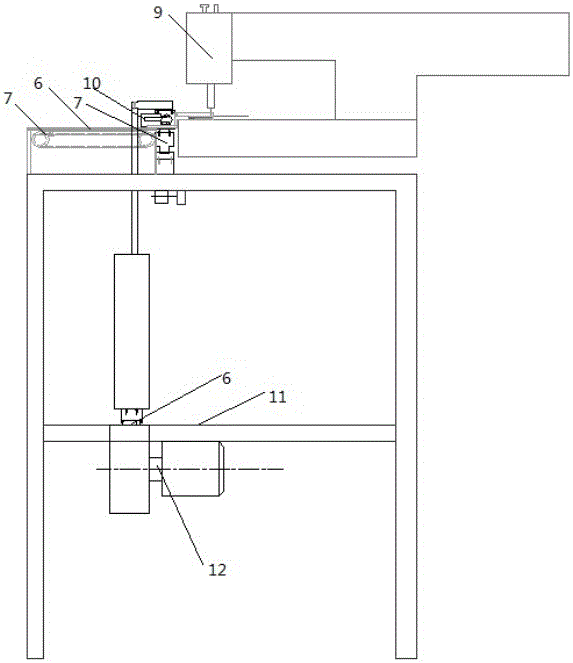

[0019] Refer to attached figure 1 , the present invention provides a fully automated flexible production equipment for a ring-shaped lifting belt and its production process, including three parts: a base, a flat belt cutting system and a flat belt sewing system, the base 1 is provided with a rotating shaft 2, and the rotating shaft is provided with There is a roll of flat belt 3, on which a pinch wheel 4 is arranged, and the pinch wheel 4 compresses the flat belt 3, and the linear cylinder 5 is fixed on the base 1, and the base 1 A guide rail 6 is arranged on the guide rail 6, and a slider 7 is arranged on the guide rail 6. The slider 7 can realize linear reciprocating motion relative to the guide rail 6 fixed on the base 1. A small Cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com