Foaming insulation board cutting and forming process

A foam insulation board and molding process technology, applied in the field of sheet material processing, can solve the problems of foam insulation board molding accuracy and quality reduction, cutting tools stuck, internal wrinkles or sags, etc., to reduce the occurrence of cutting jams , Improve the scope of application and reduce the effect of stagnation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

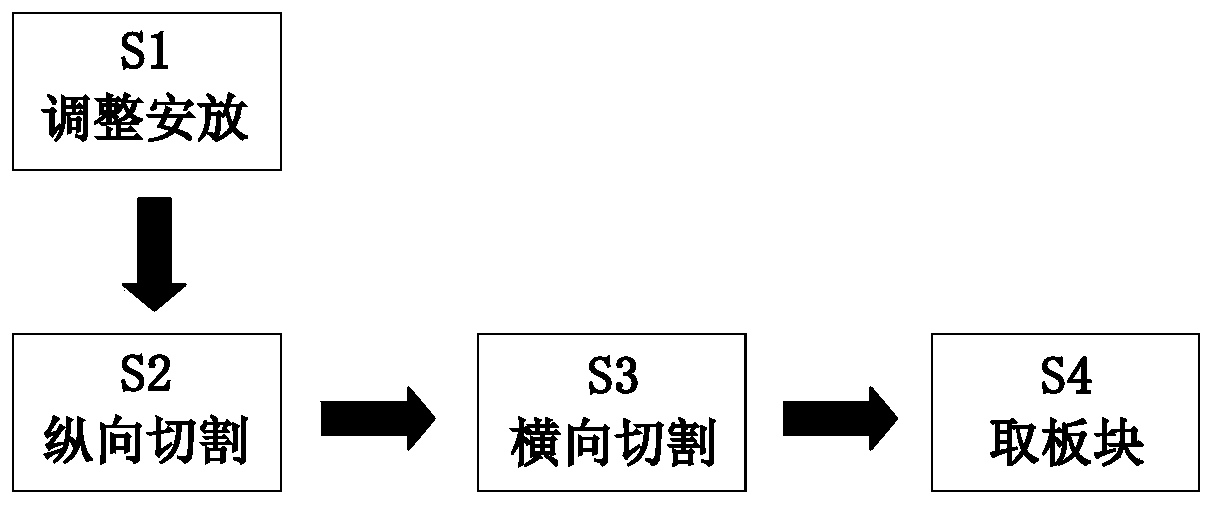

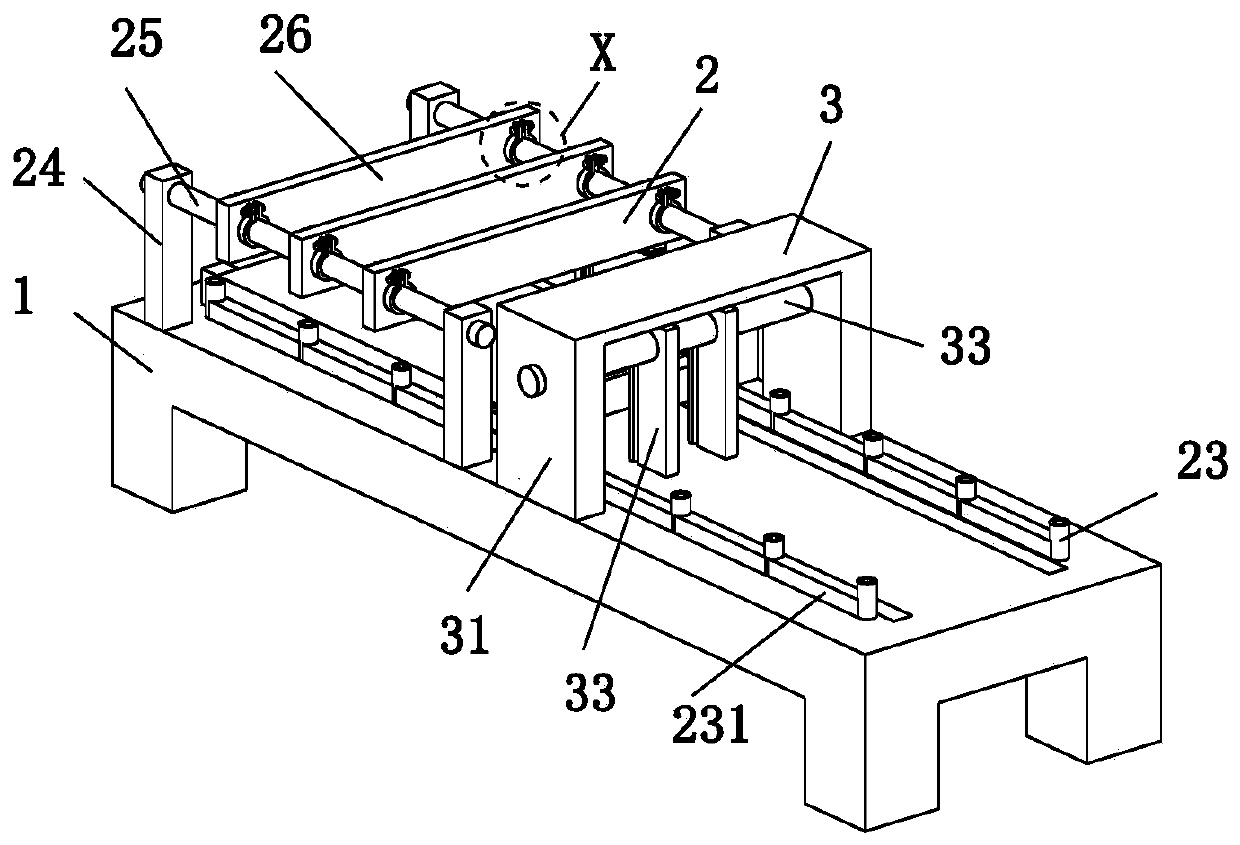

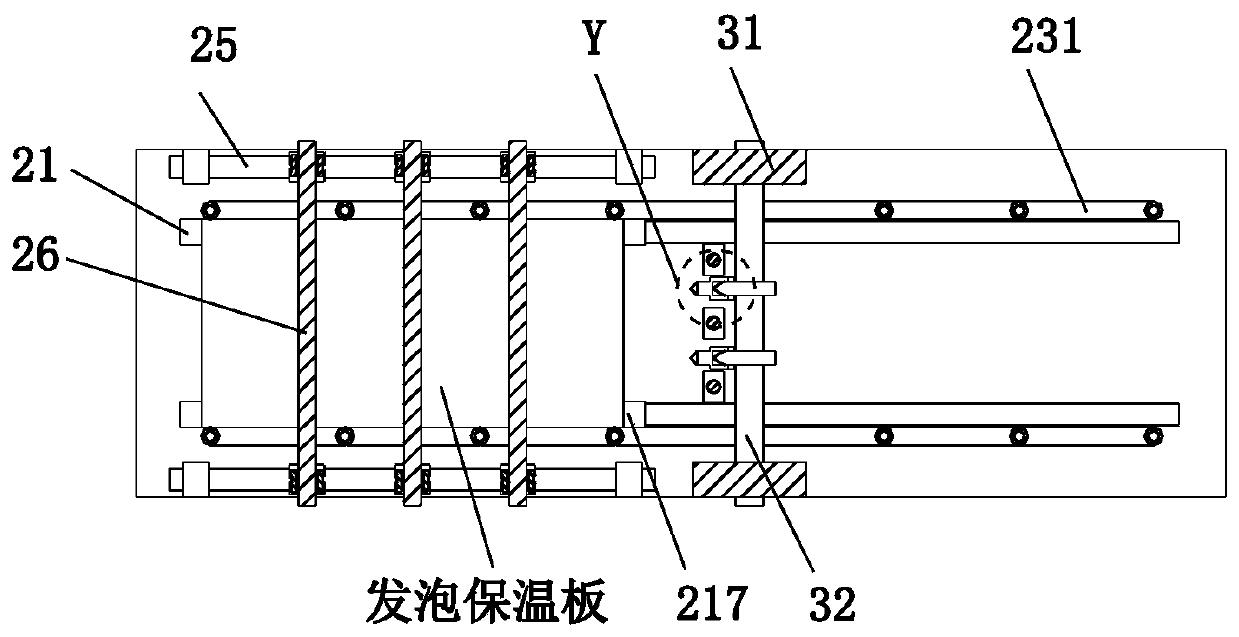

[0041] Such as Figure 1 to Figure 12 As shown, a foam insulation board cutting and forming process uses a foam insulation board cutting and forming device. The foam insulation board cutting and forming device includes a workbench 1, a vertical cutting mechanism 2 and a transverse cutting mechanism 3. The specific molding process when the above-mentioned foam insulation board cutting and forming device cuts and shapes the foam insulation board is as follows:

[0042] S1. Adjustment and placement: Loosen the fastening bolt 262 manually. With the help of the scale line, the worker moves the buckle 261 and the knife plate 26 by a corresponding distance according to the size of the foam insulation board, and then tightens the fastening bolt again. 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com