Patents

Literature

102results about "Splitting instruments" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Inductive power supply

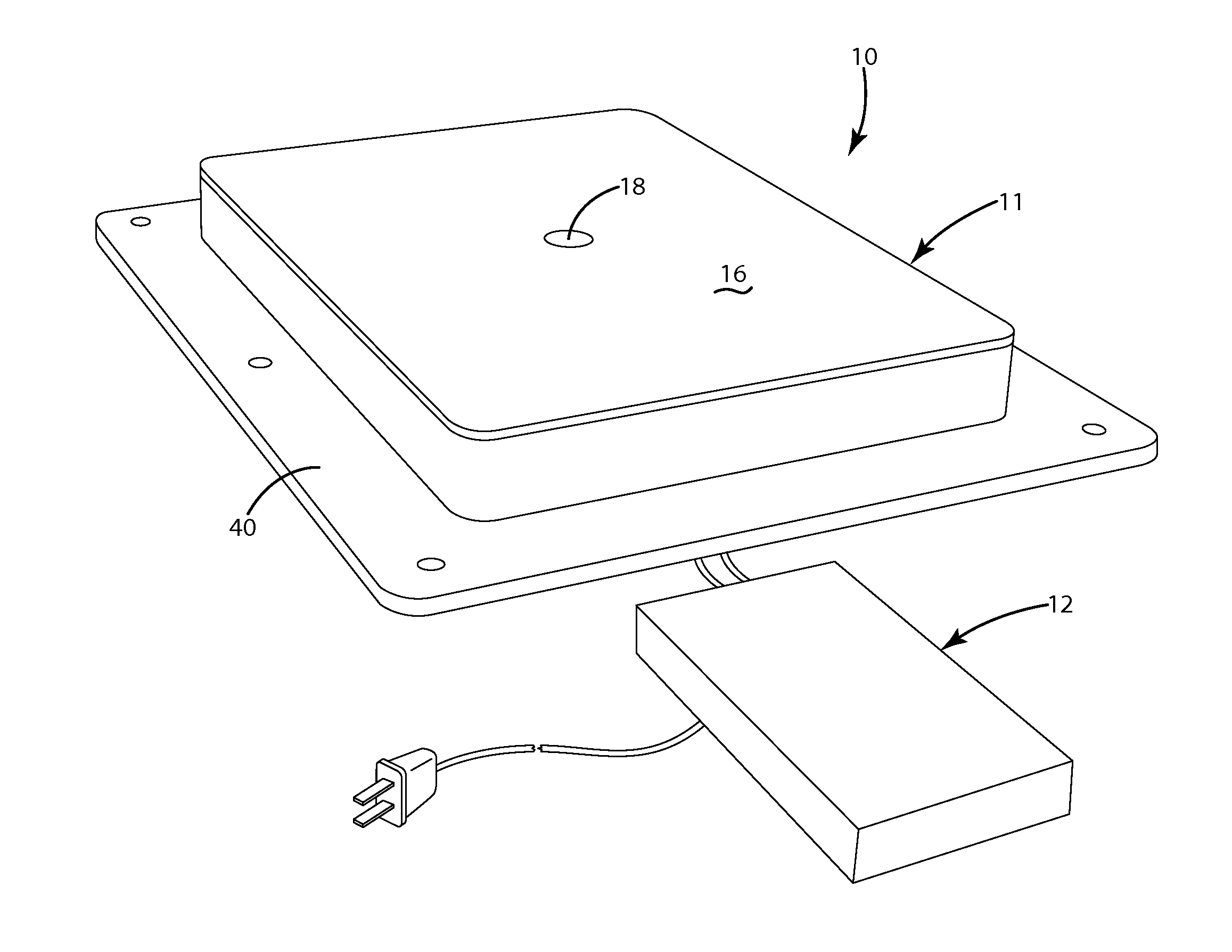

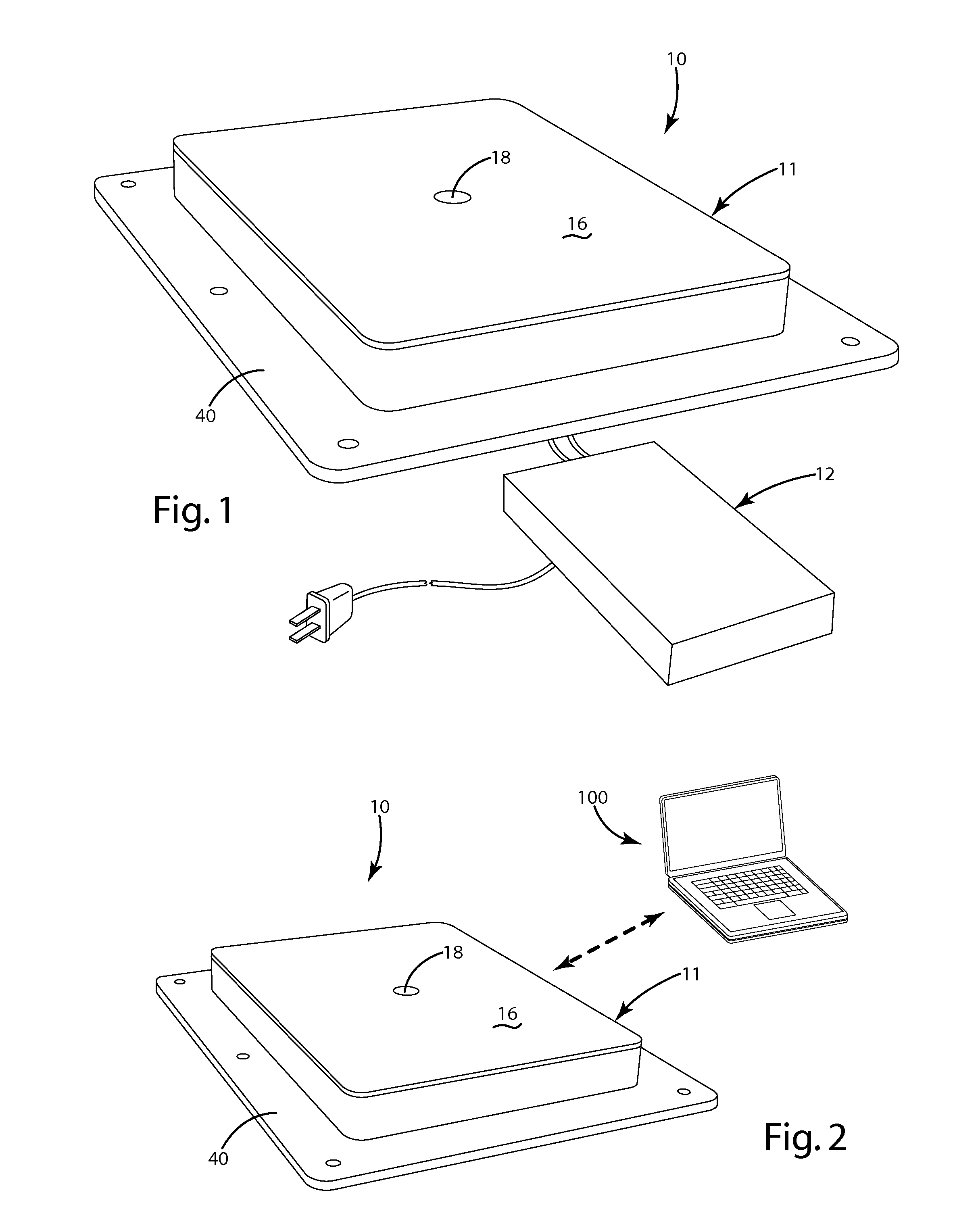

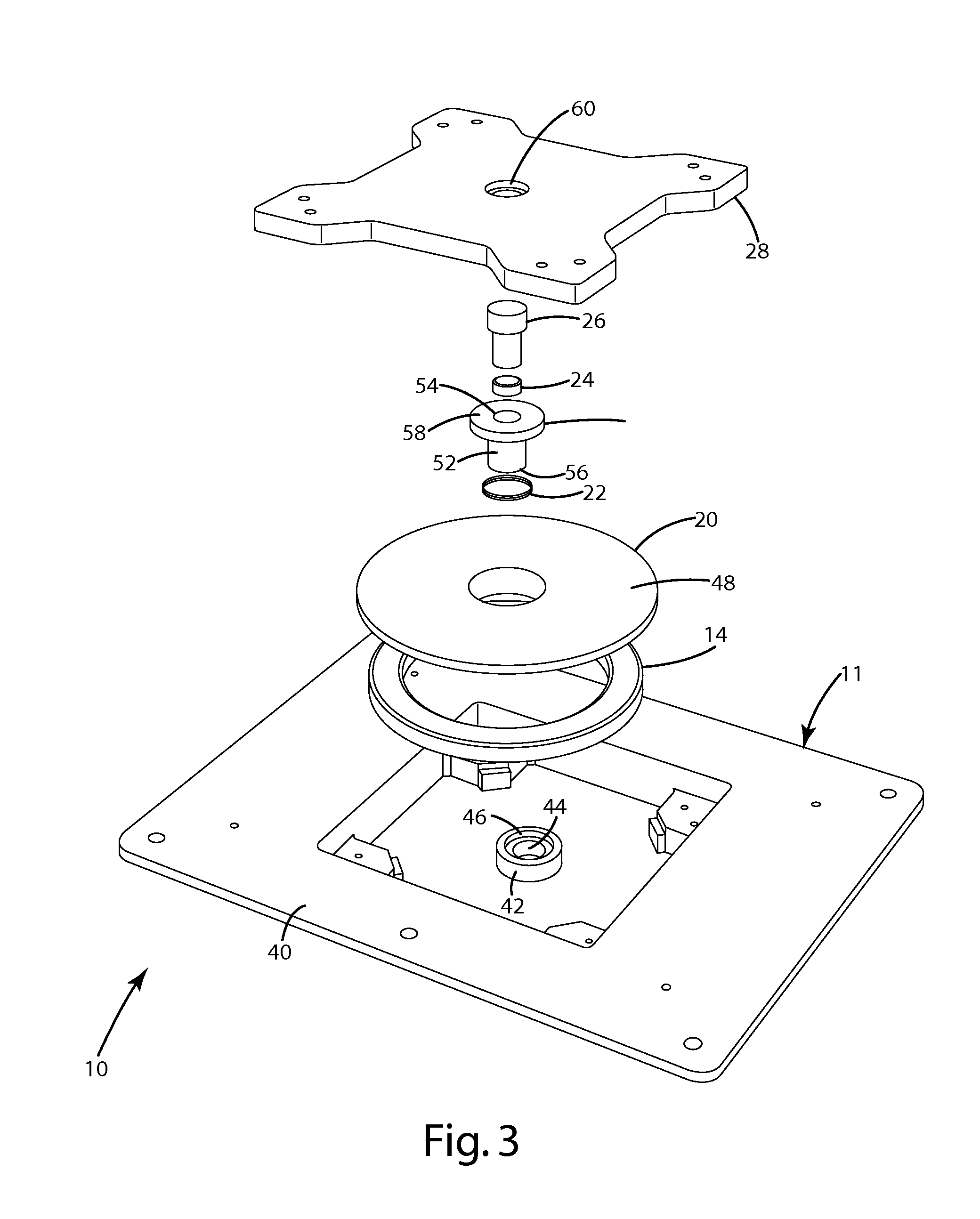

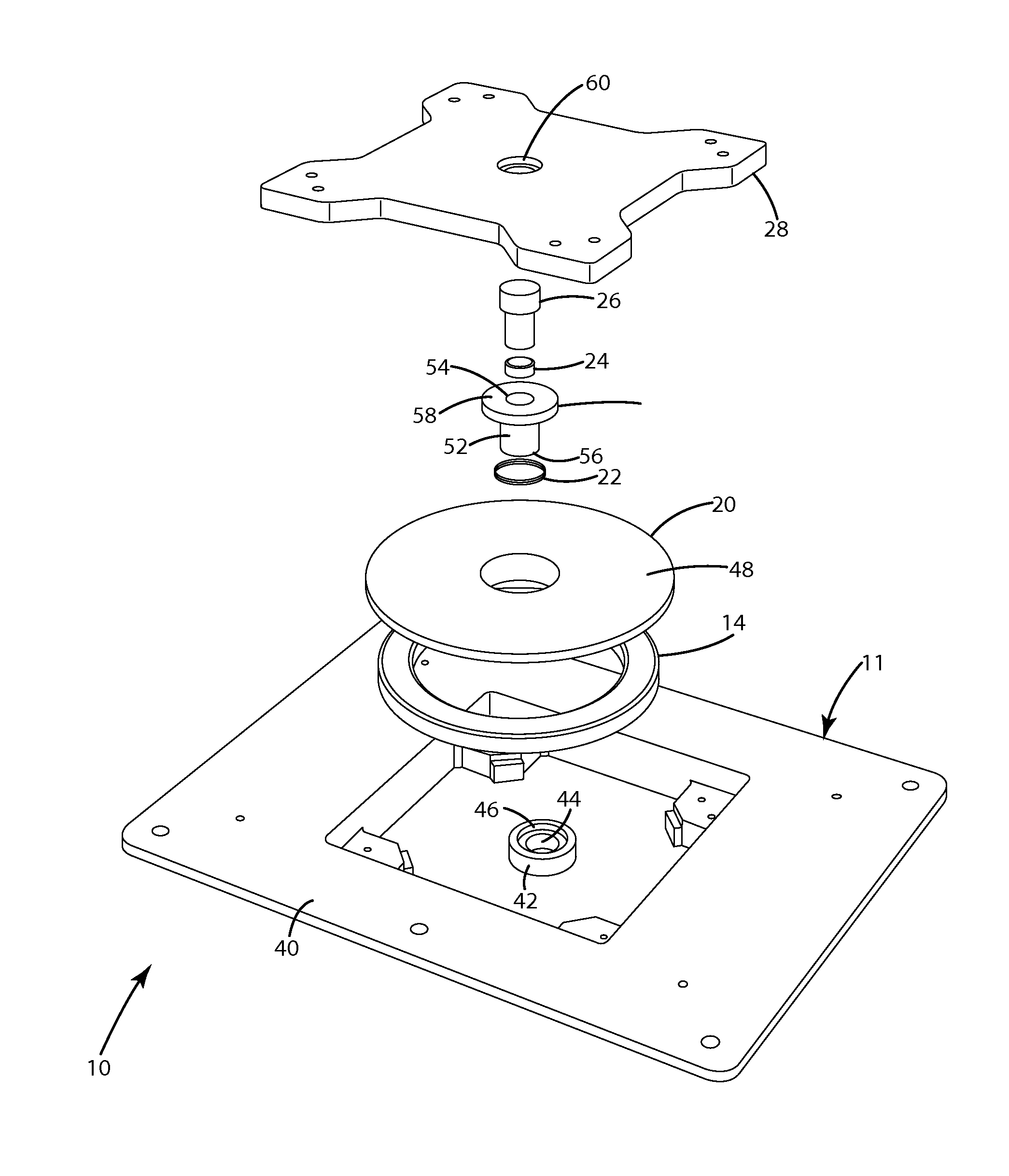

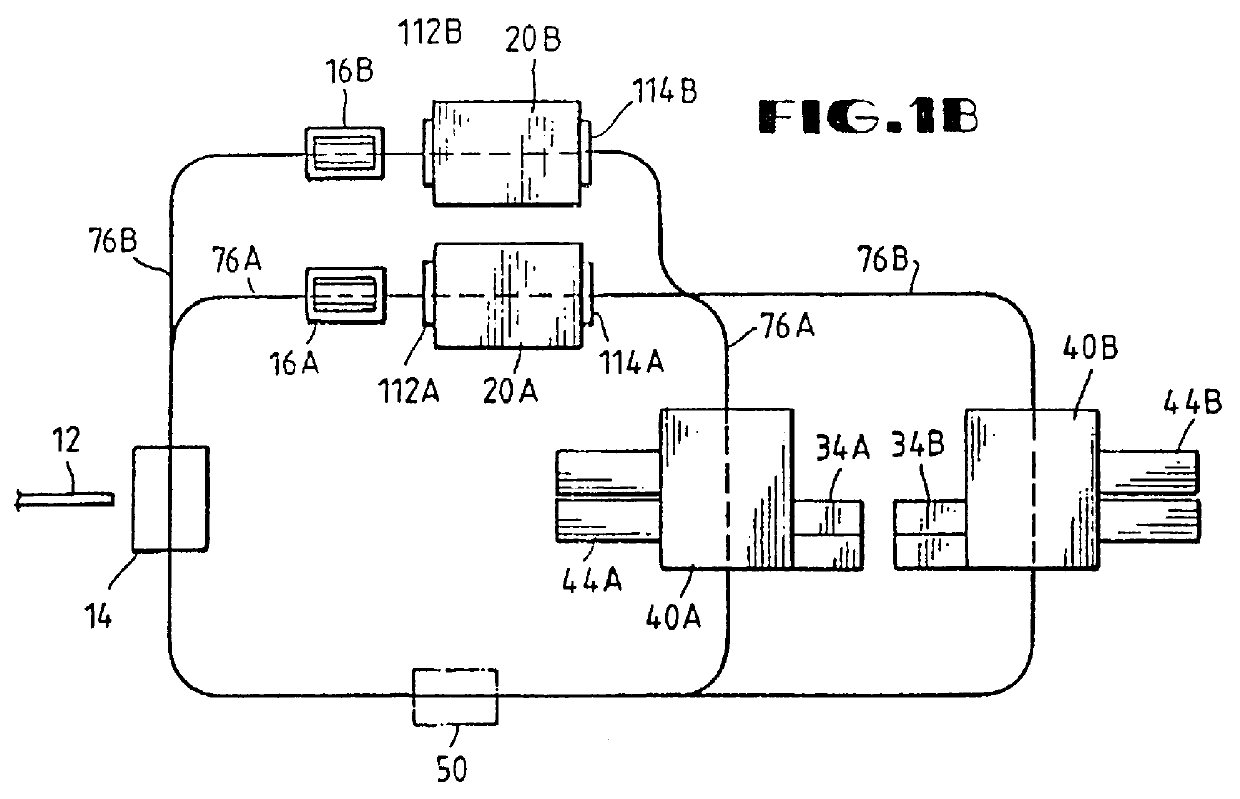

ActiveUS8373310B2Reduced footprintSimple mechanical structureBatteries circuit arrangementsElectromagnetic wave systemCharging stationMajor and minor

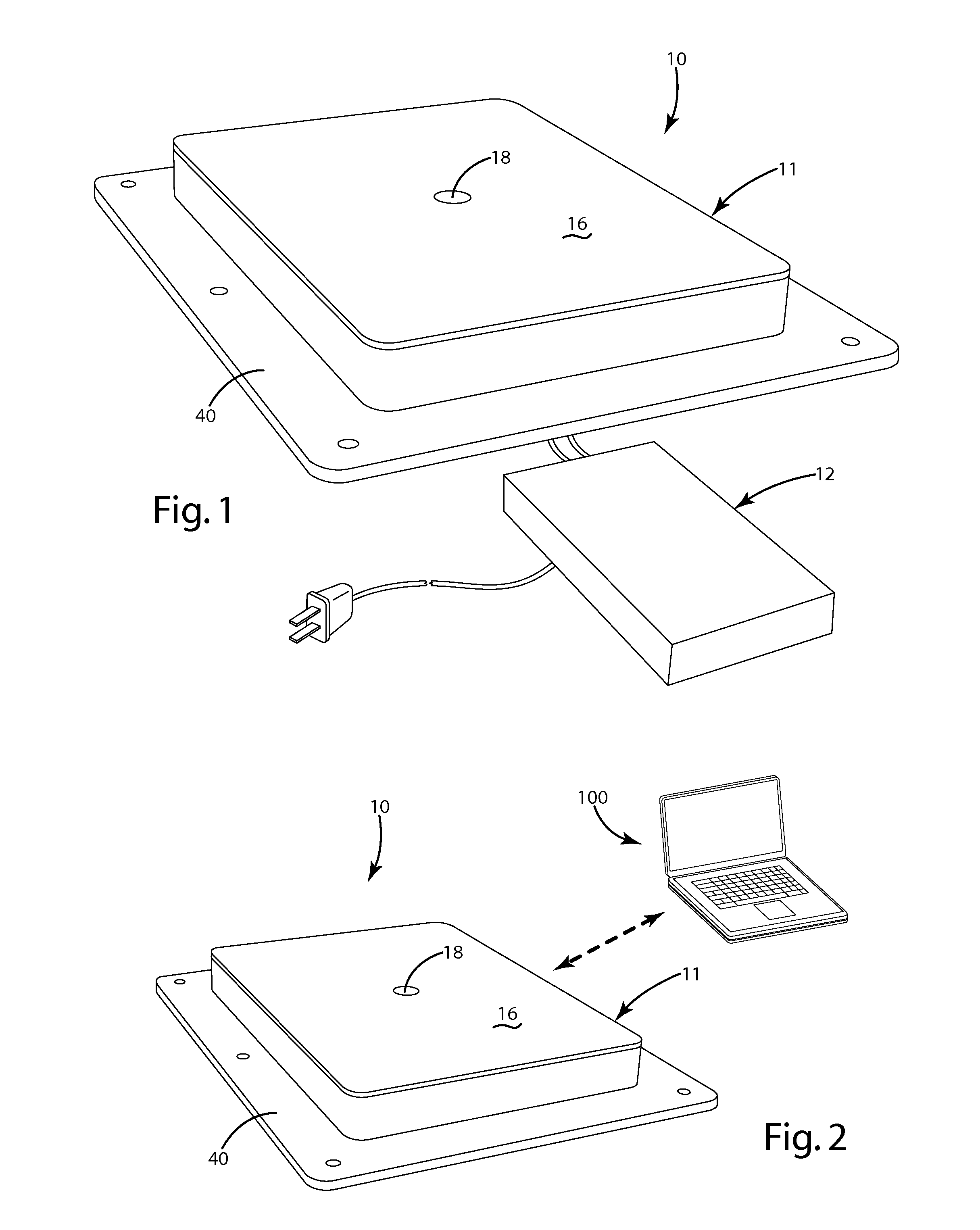

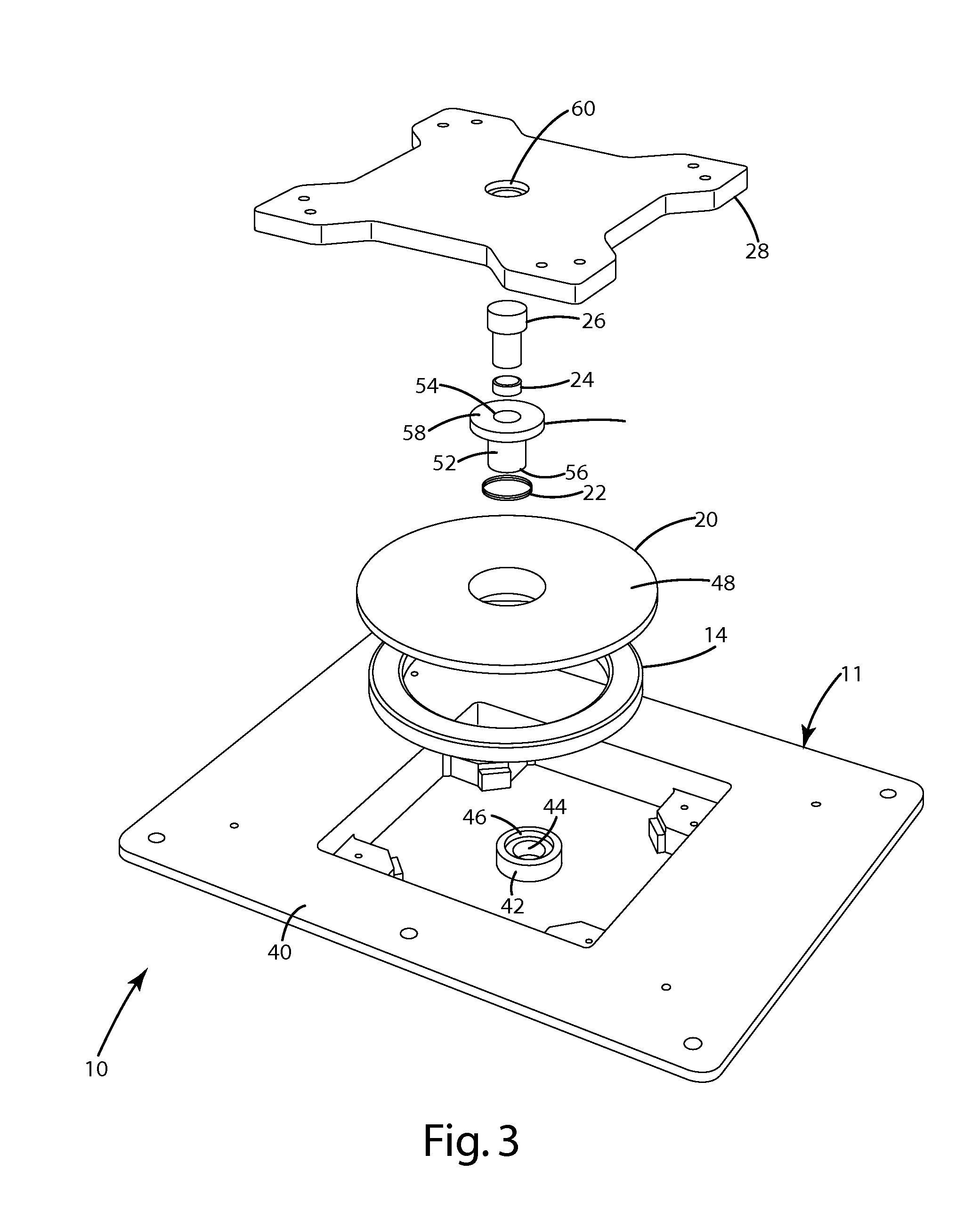

In one aspect, the present invention provides a wireless power supply having a plunger for mechanically interconnecting a remote device with the power supply. The plunger may be extendable / retractable to interfit with the remote device. In a second aspect, the present invention provides a wireless power supply with a movable primary that allows for close alignment between the primary and the secondary when the remote device is disposed within a range of different positions with respect to the charging surface. The movable primary may, for example, be coupled to the remote device by a peg, a plunger or a magnet. Alternatively, the position of the movable primary may be adjusted manually. In a third aspect, the present invention provides a charging bowl having a plurality of charging stations disposed about a common axis. Each charging station may include a movable primary that permits some freedom in positioning of the remote device on the charging surface. In a fourth aspect, the present invention provides a wireless power supply having a manually movable primary.

Owner:PHILIPS IP VENTURES BV

Inductive power supply

ActiveUS20110006611A1Reduced footprintSimple mechanical structureBatteries circuit arrangementsElectromagnetic wave systemCharging stationPlunger

In one aspect, the present invention provides a wireless power supply having a plunger for mechanically interconnecting a remote device with the power supply. The plunger may be extendable / retractable to interfit with the remote device. In a second aspect, the present invention provides a wireless power supply with a movable primary that allows for close alignment between the primary and the secondary when the remote device is disposed within a range of different positions with respect to the charging surface. The movable primary may, for example, be coupled to the remote device by a peg, a plunger or a magnet. Alternatively, the position of the movable primary may be adjusted manually. In a third aspect, the present invention provides a charging bowl having a plurality of charging stations disposed about a common axis. Each charging station may include a movable primary that permits some freedom in positioning of the remote device on the charging surface. In a fourth aspect, the present invention provides a wireless power supply having a manually movable primary.

Owner:PHILIPS IP VENTURES BV

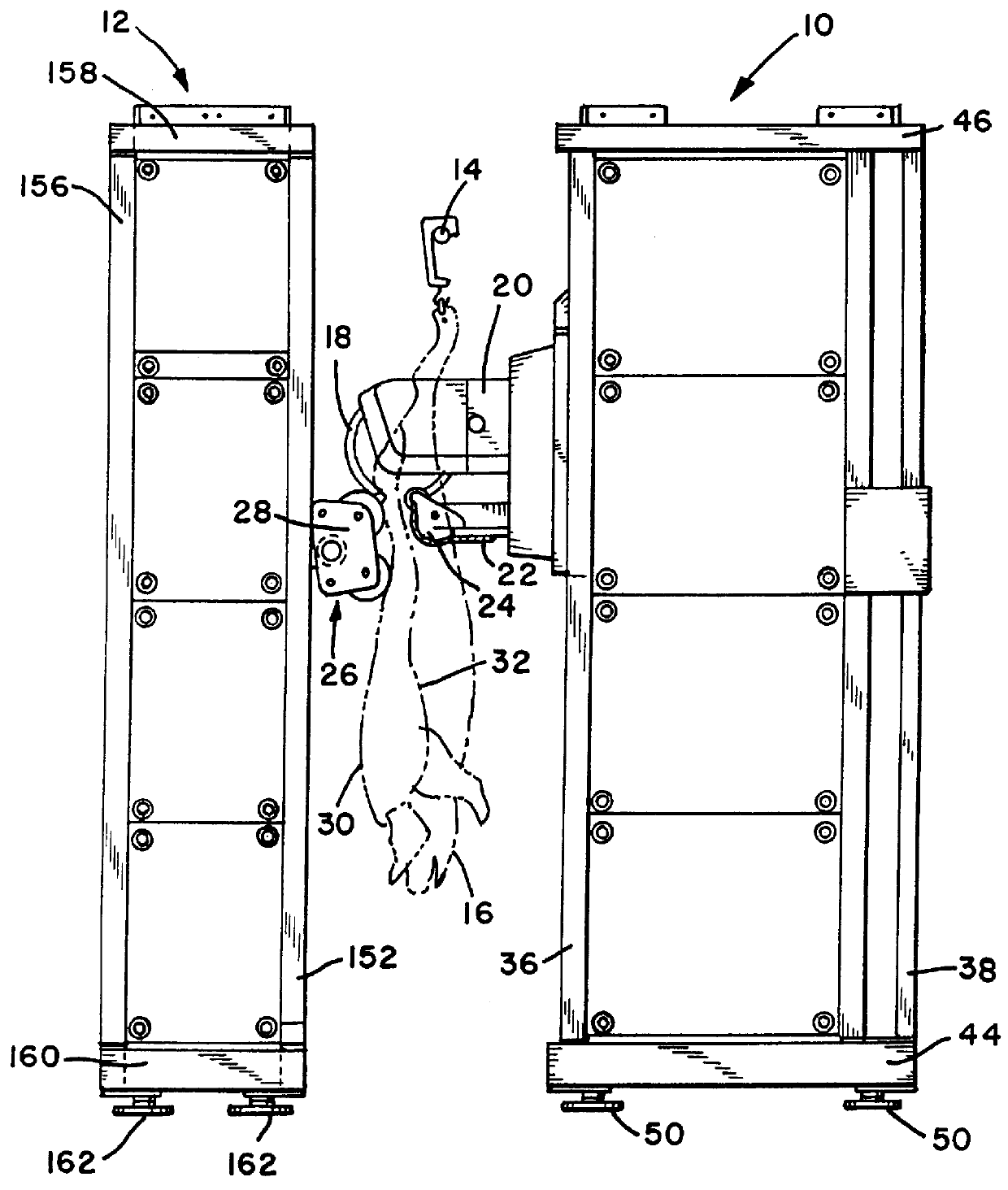

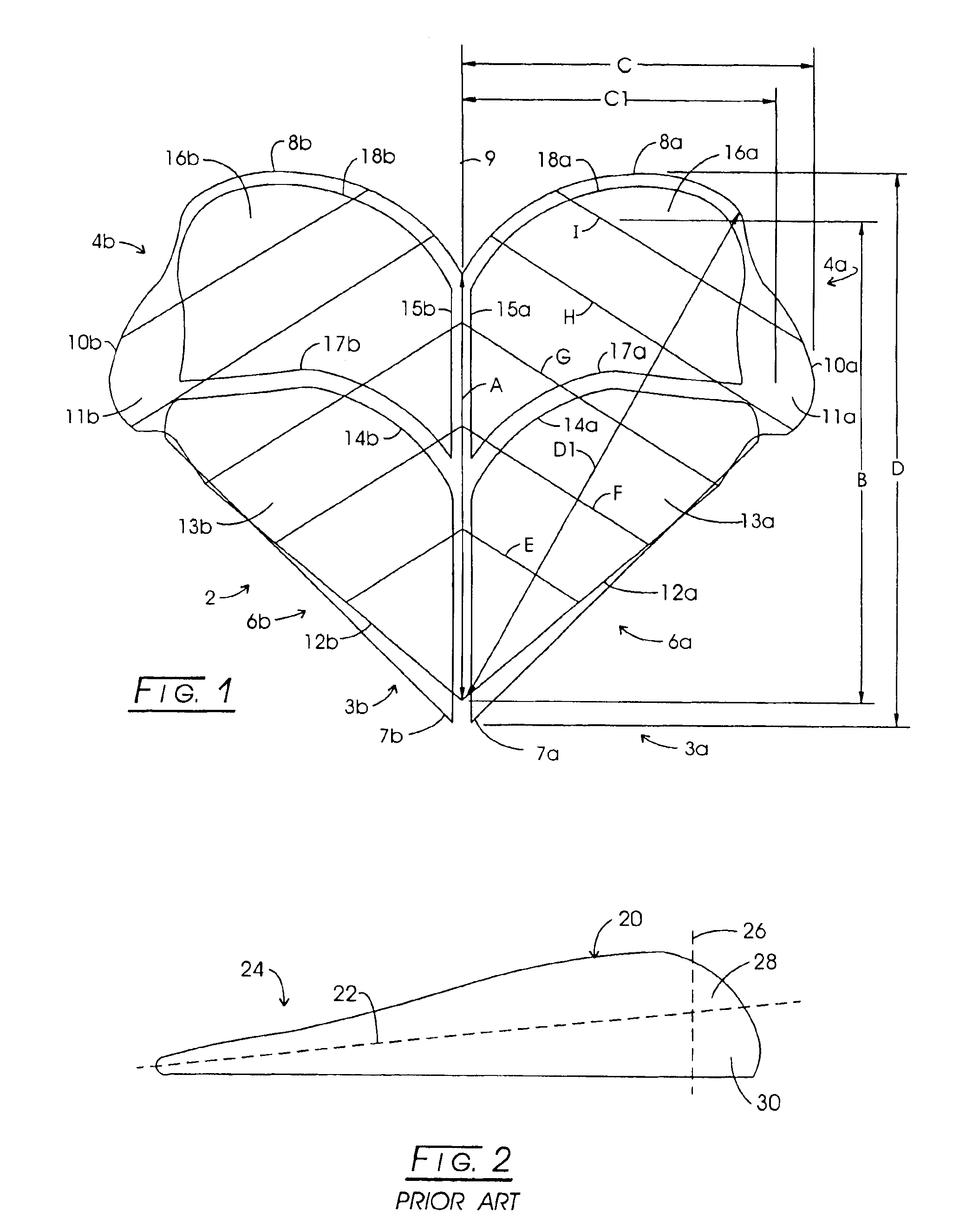

Method and apparatus for automatically segmenting animal carcasses

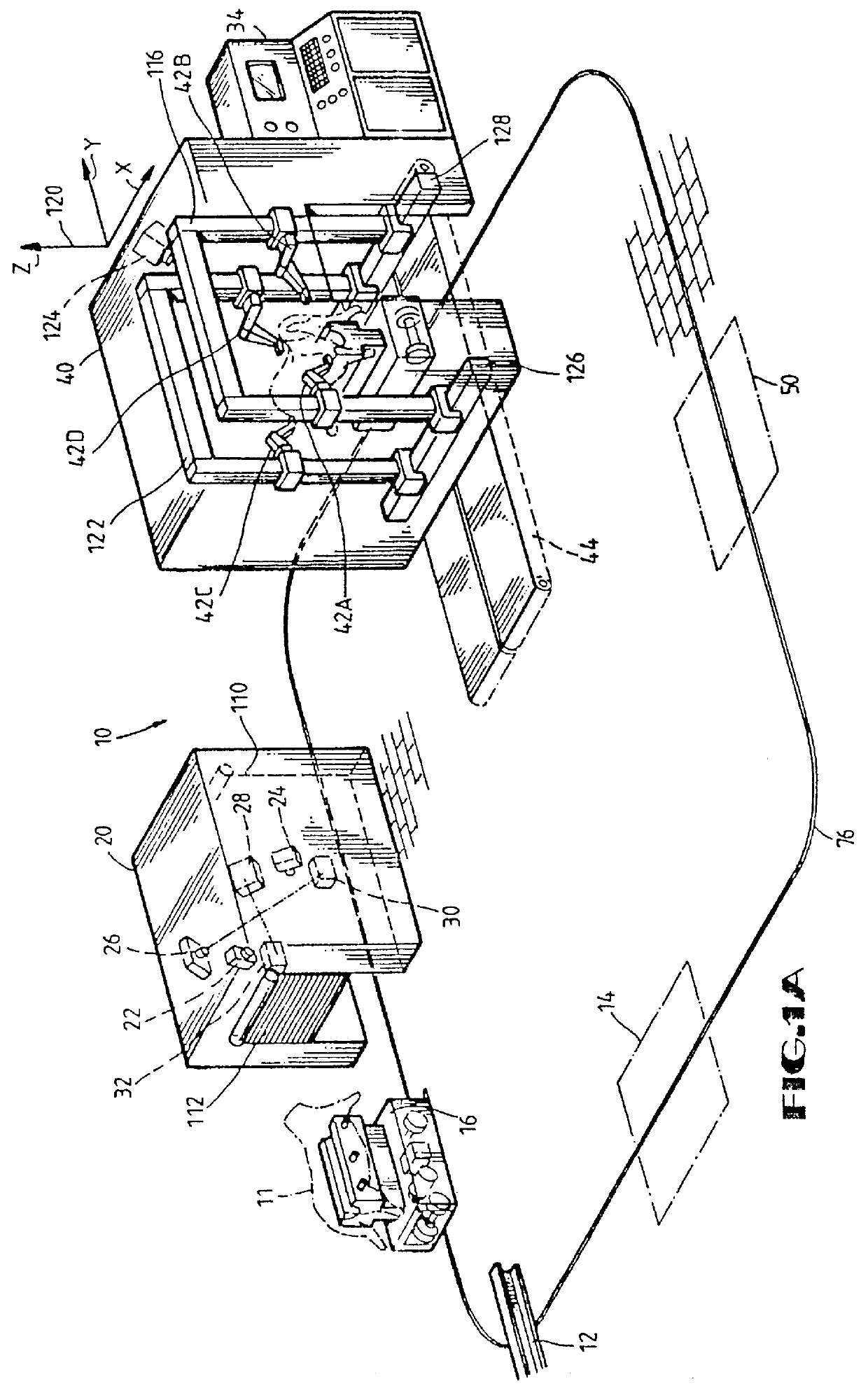

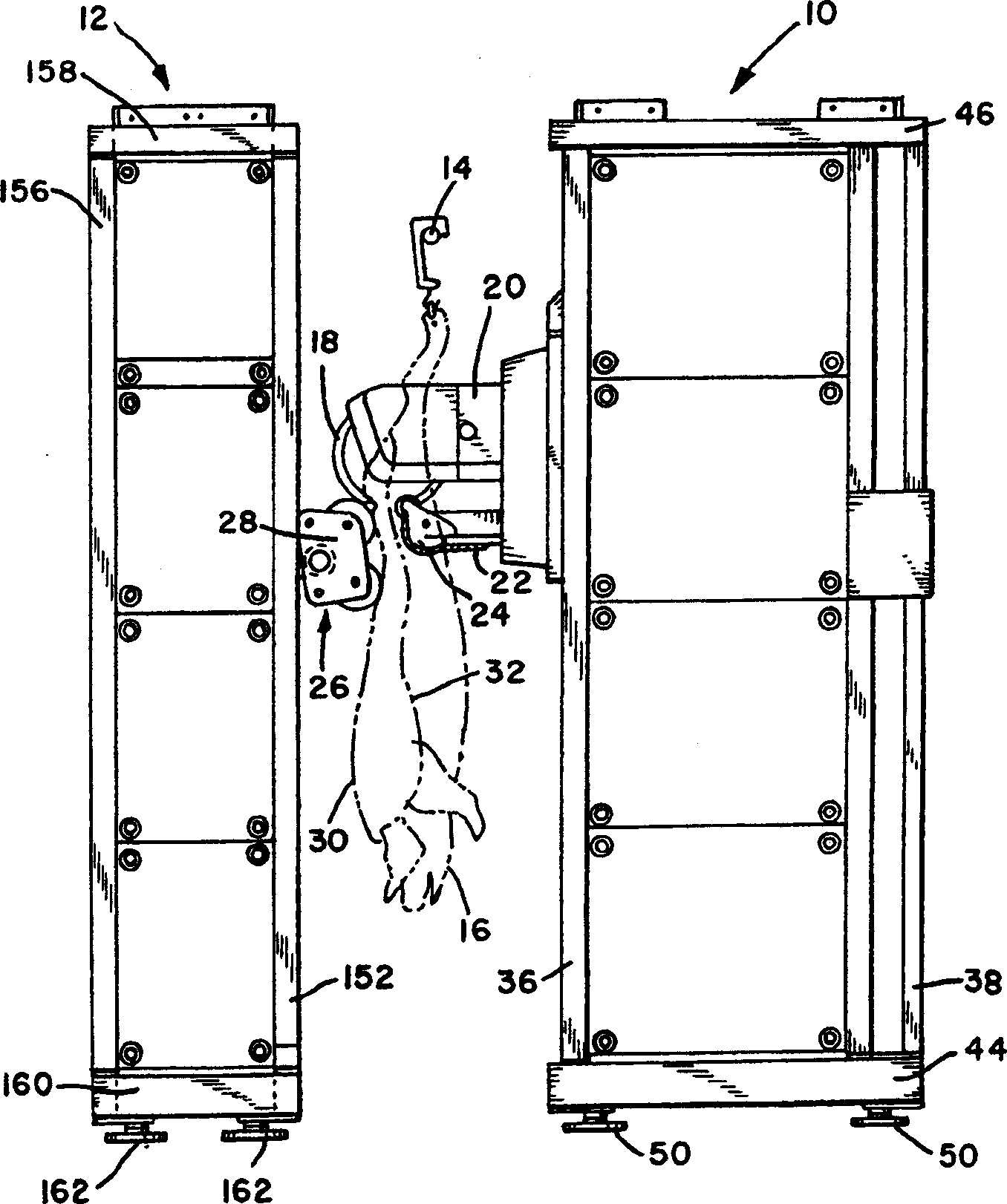

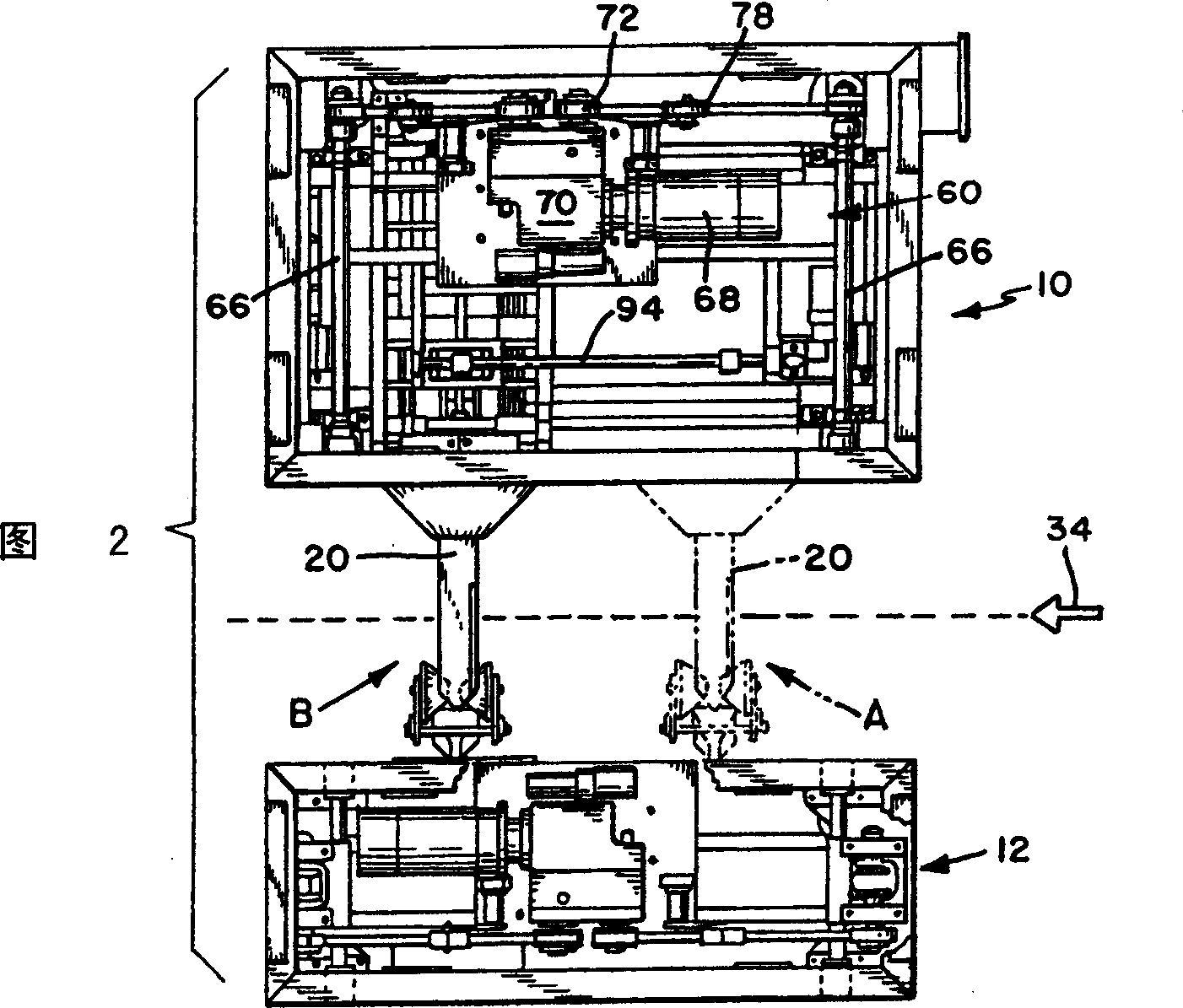

Manually segmenting animal carcasses into primary cuts involves an enormous amount of manual labor and attendant expense. However, known automated systems for segmenting carcasses cannot match the accuracy of expert butchers. The apparatus for segmenting animal carcasses disclosed herein provides an imaging station having a vision system that determines parameters of the interior and / or exterior of the carcass. Using these parameters, a computer determines a cutting path or a plurality of cutting paths for segmenting the carcass. A mounting vehicle, which securely holds the carcass, transports the carcass from the imaging station to a cutting station. In the cutting station, electrically controlled cutting implements, such as high-pressure water jets or lasers, segment the carcass along the determined cutting path or paths.

Owner:TEXAS BEEF GROUP +1

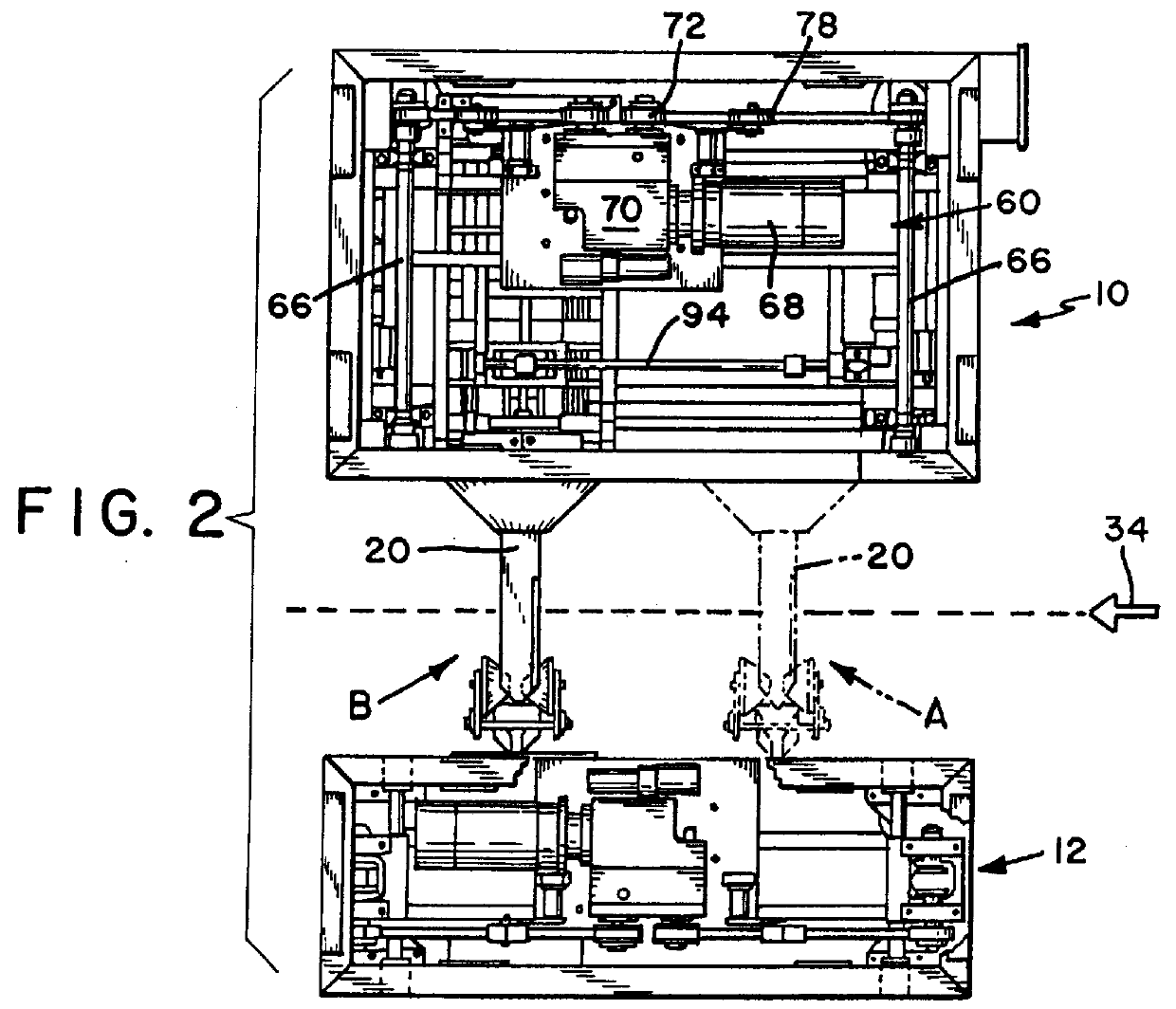

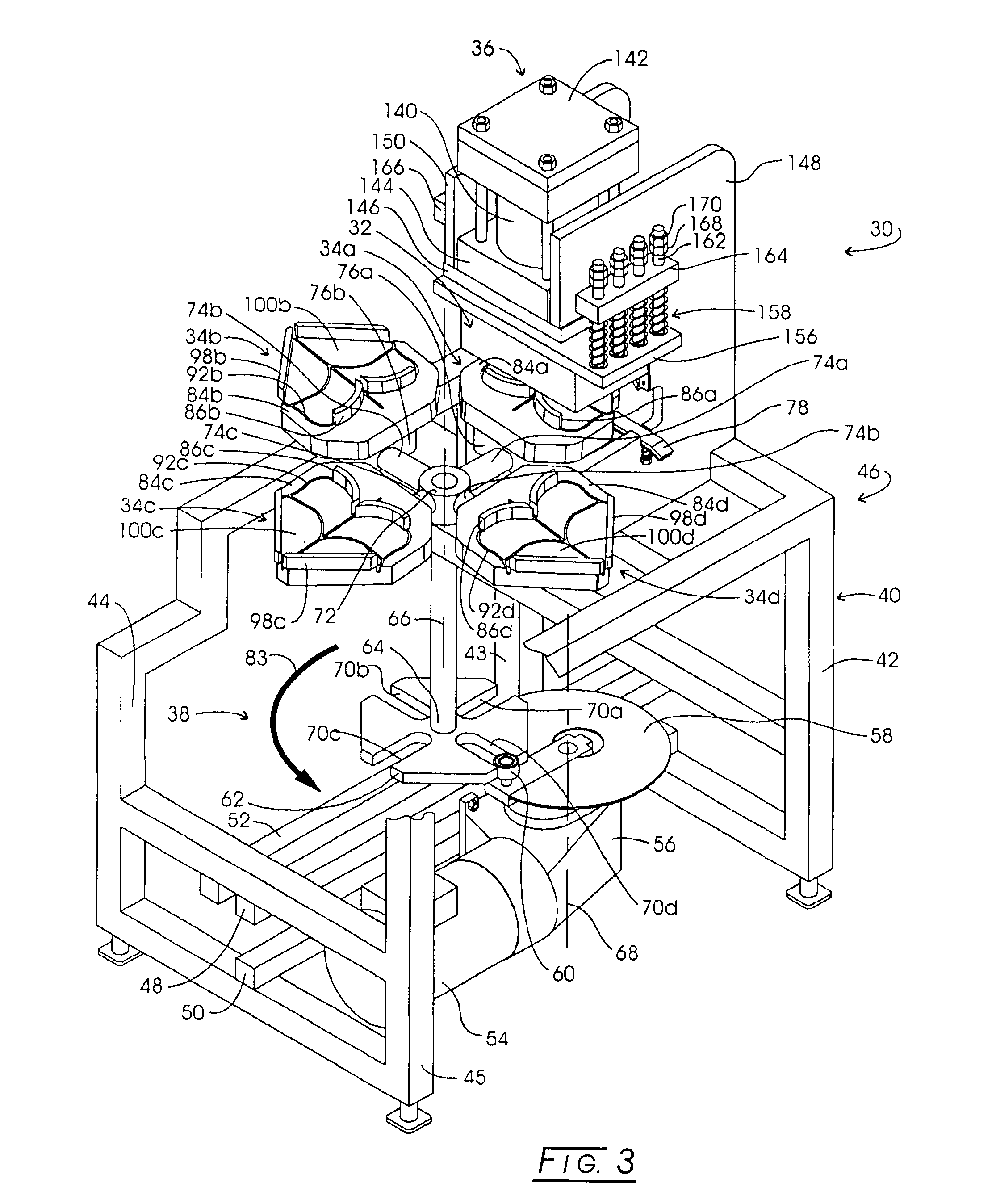

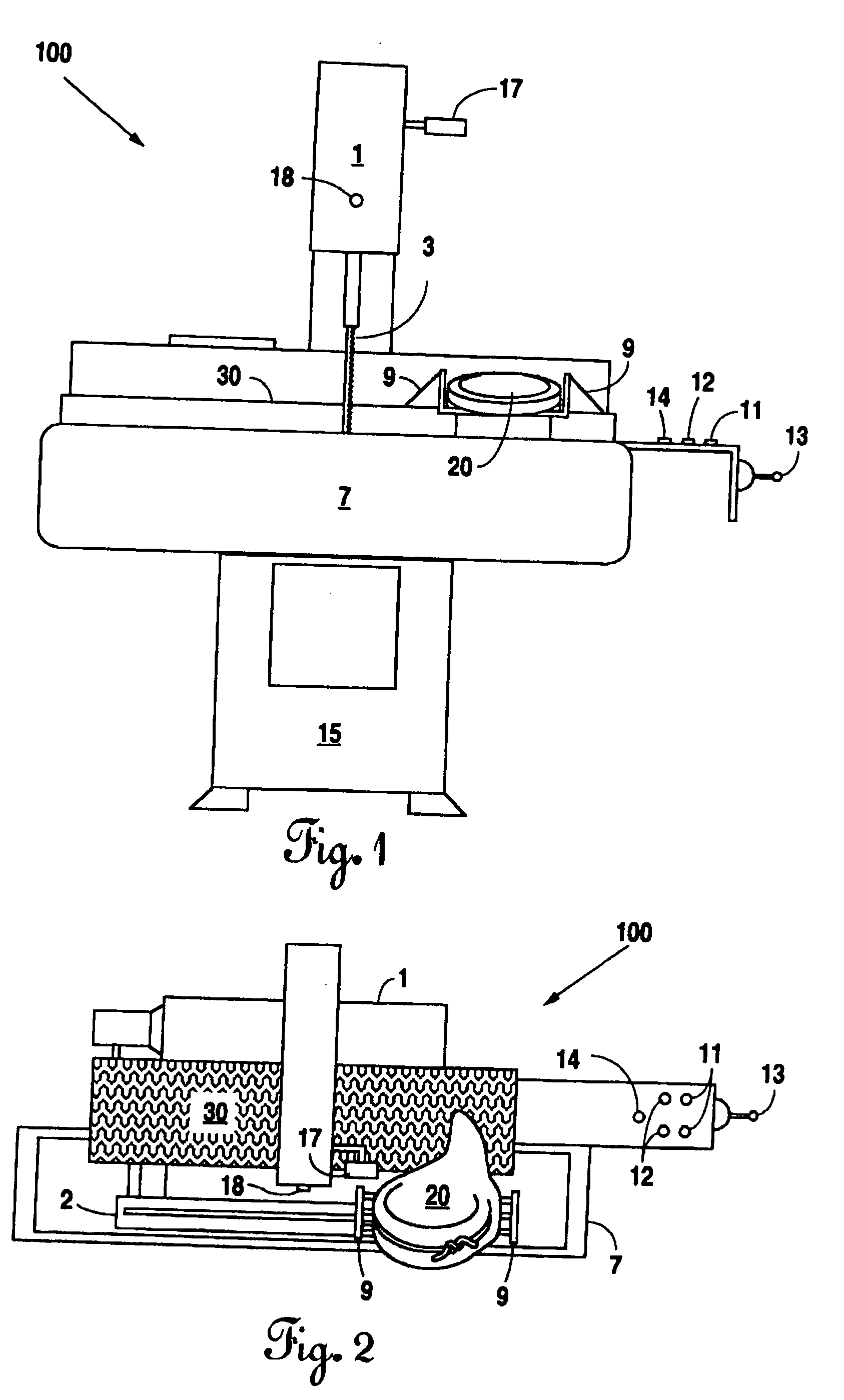

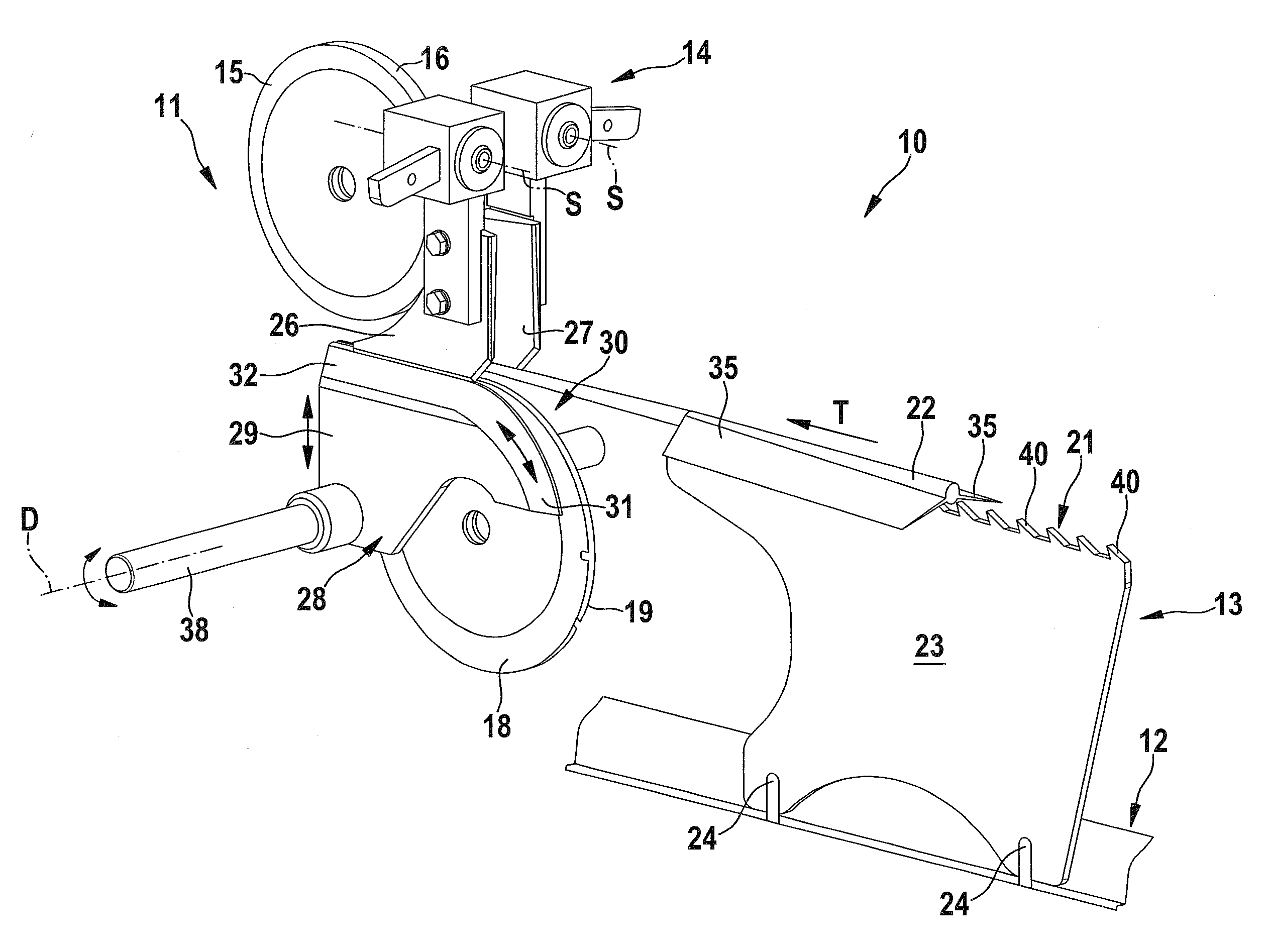

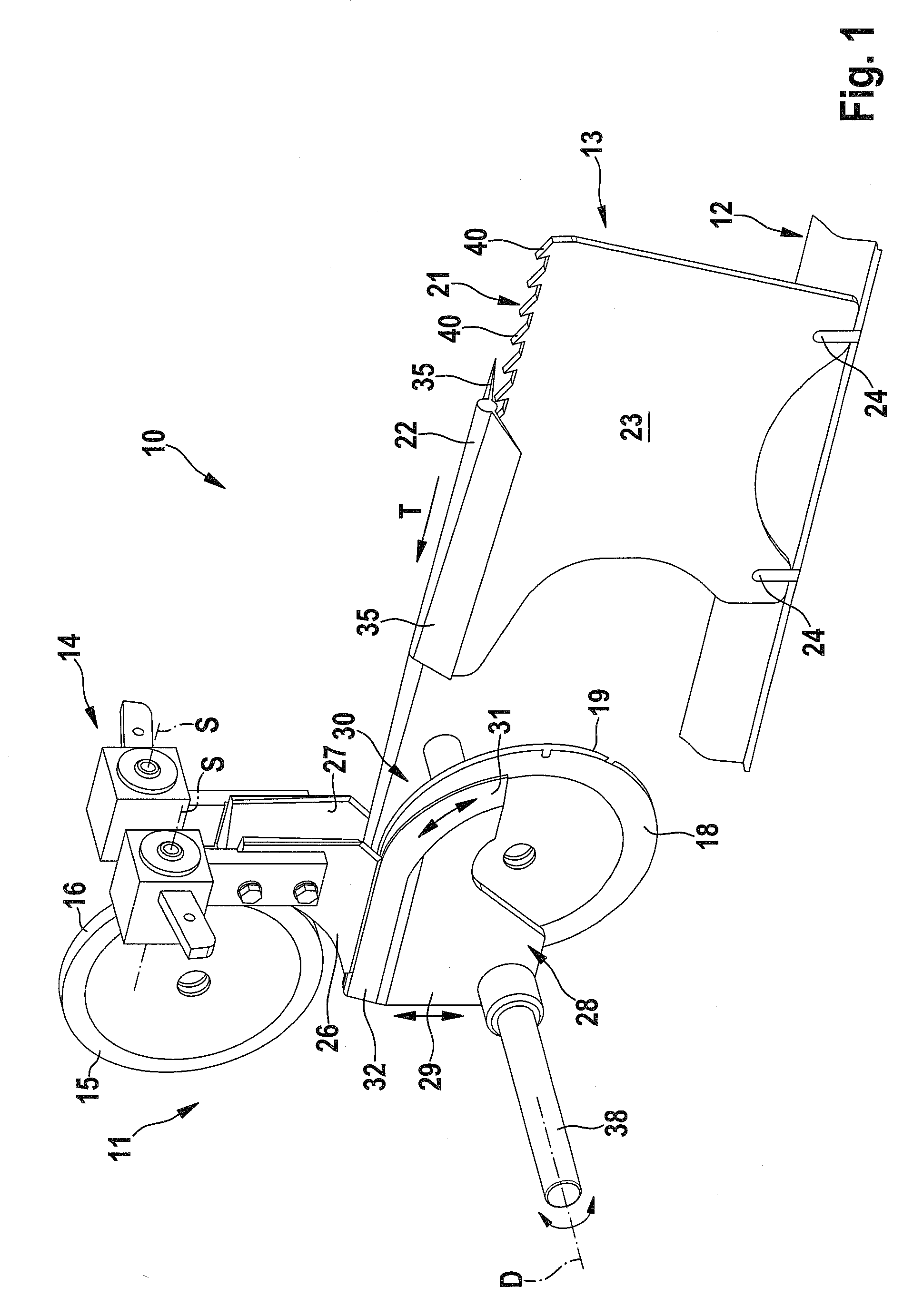

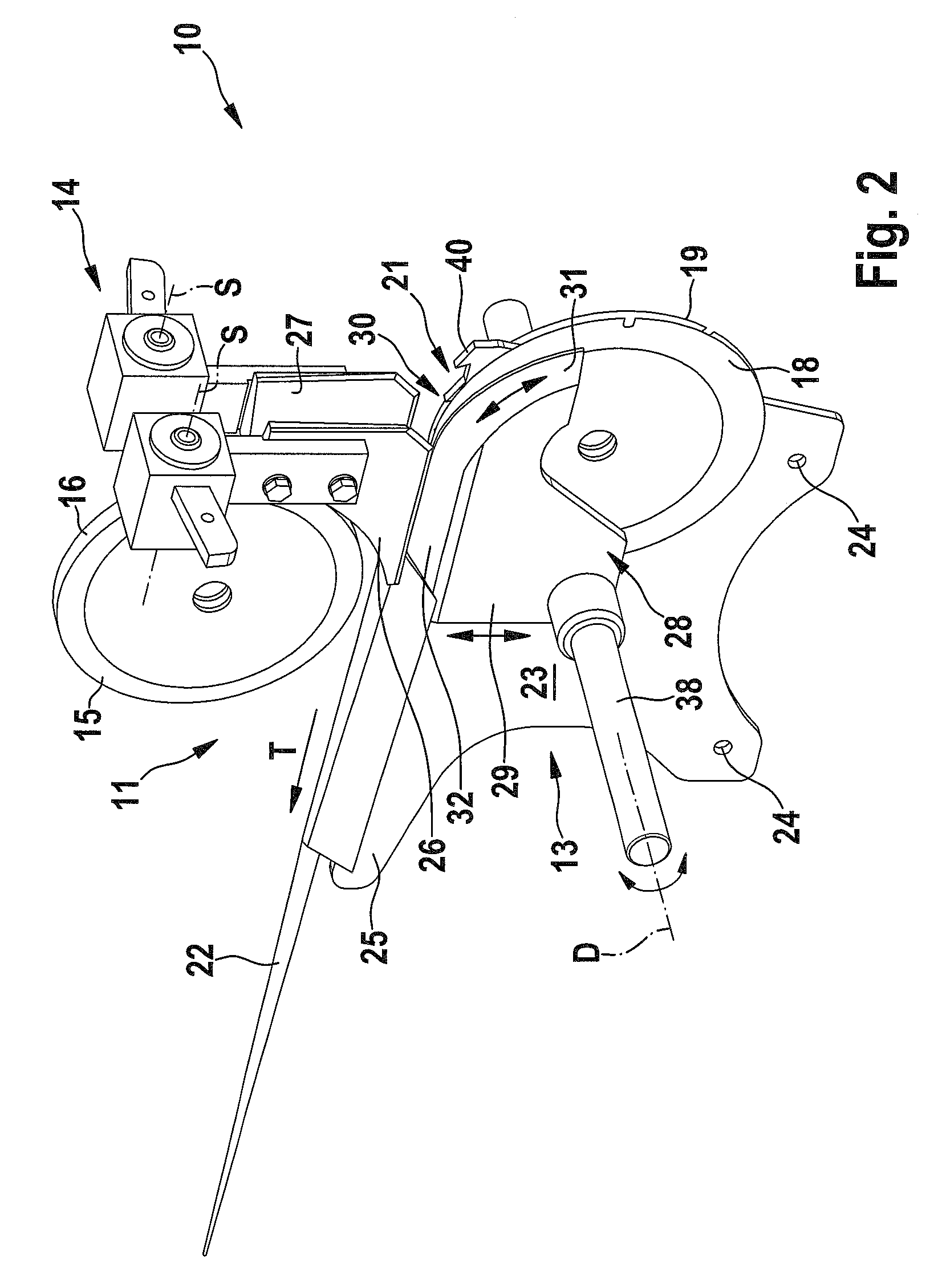

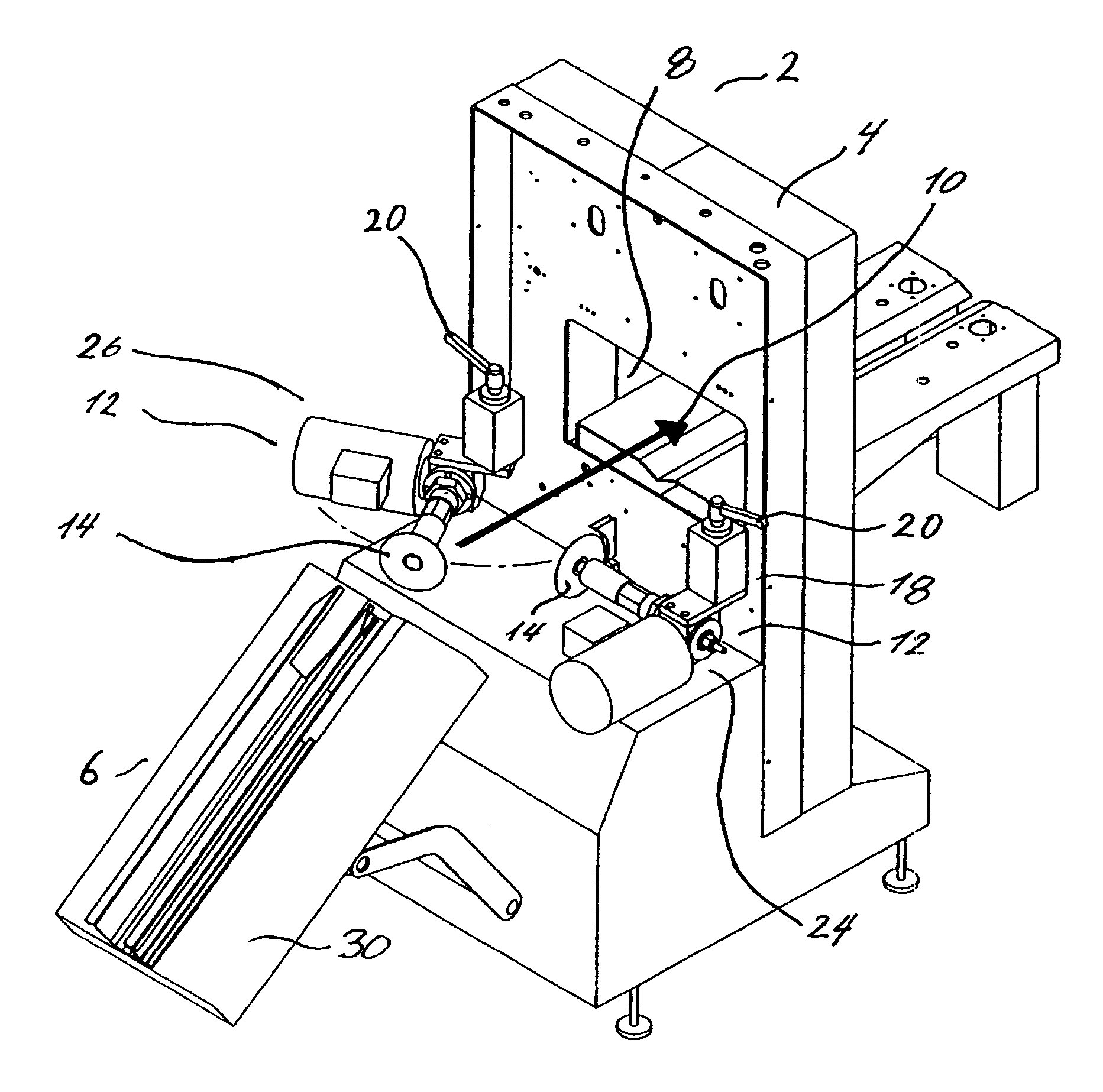

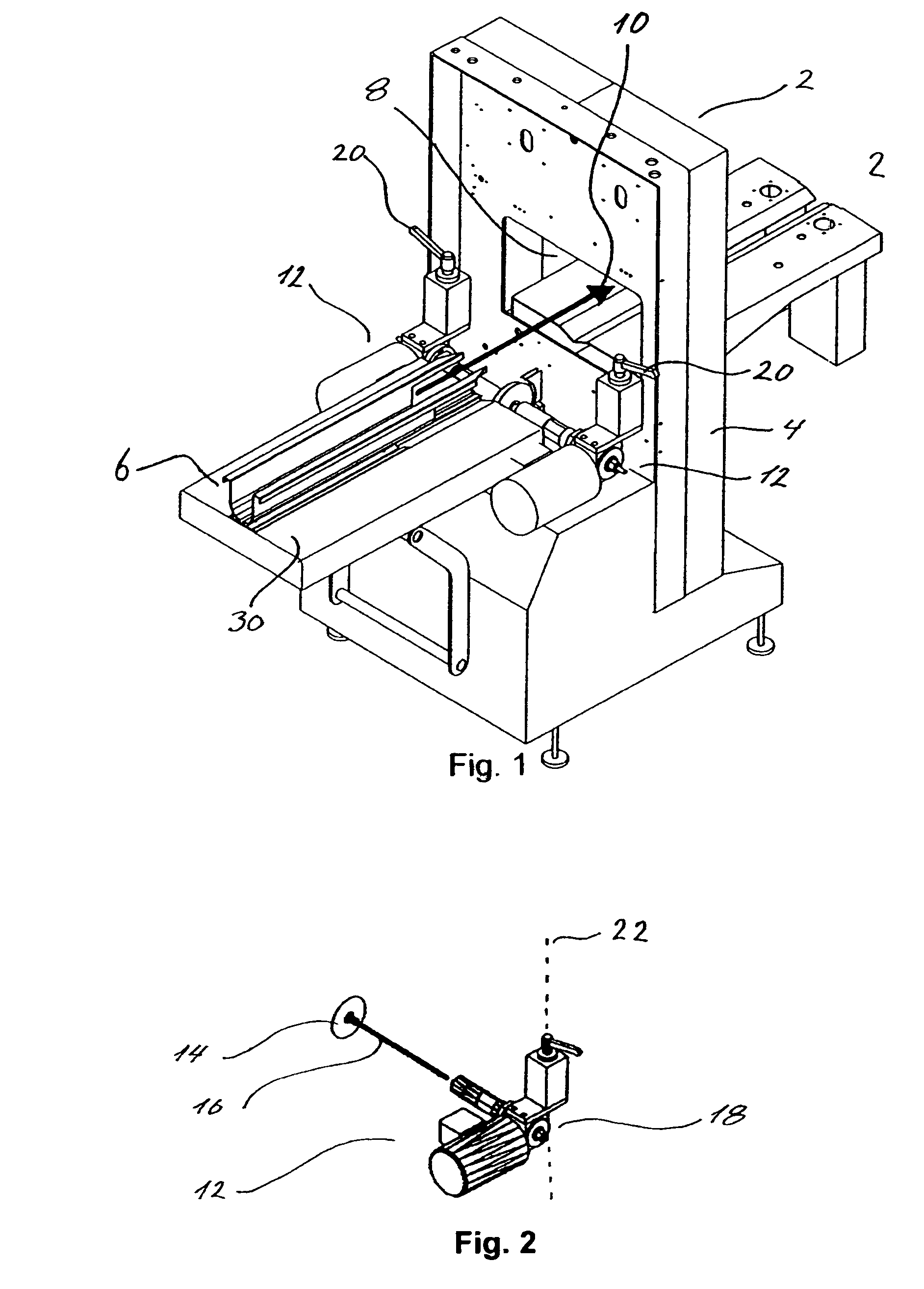

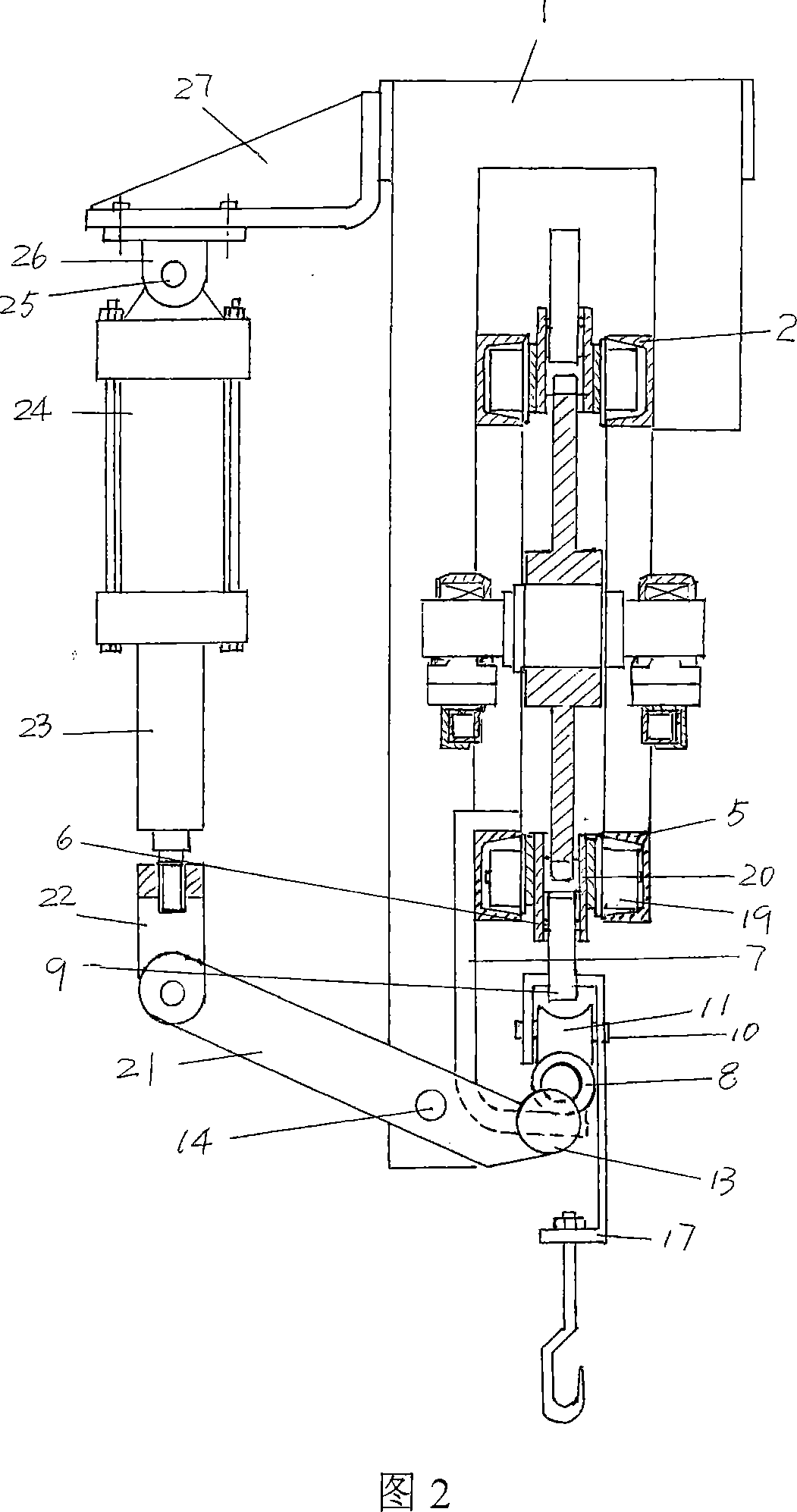

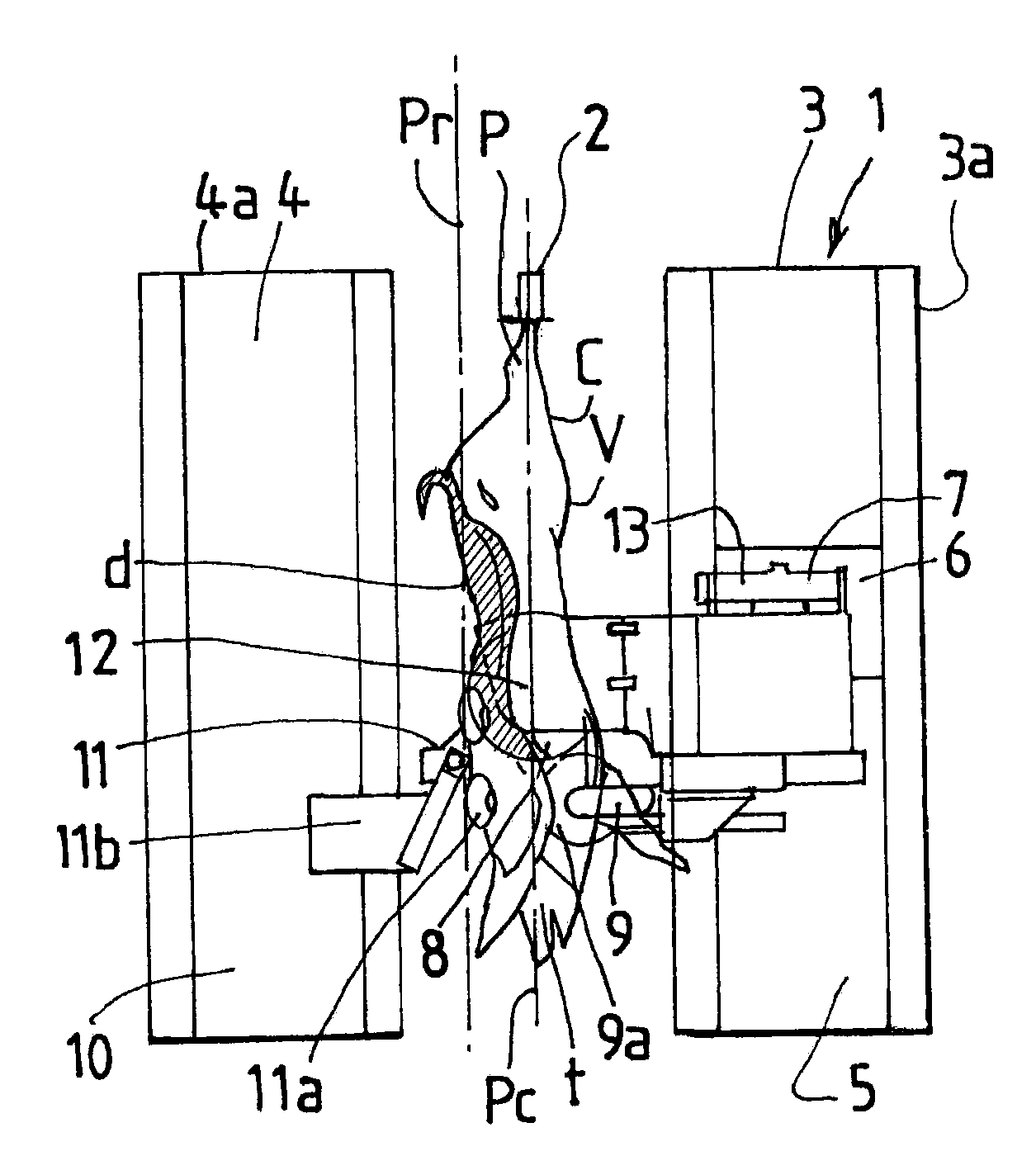

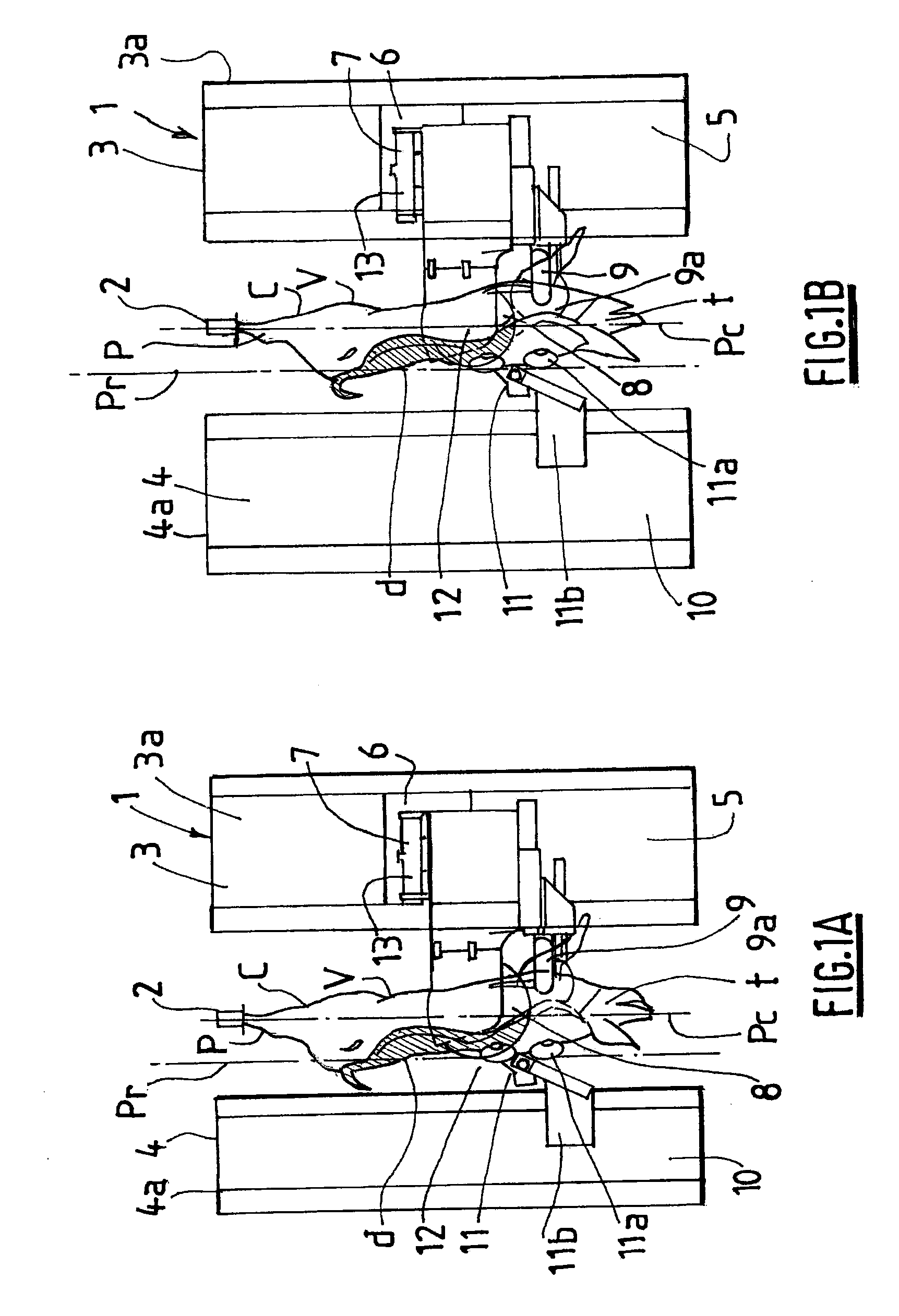

Automated saw for splitting carcasses

InactiveUS6126536AIncrease speedPrecise positioningMeat holding apparatusSplitting instrumentsMechanical engineeringEngineering

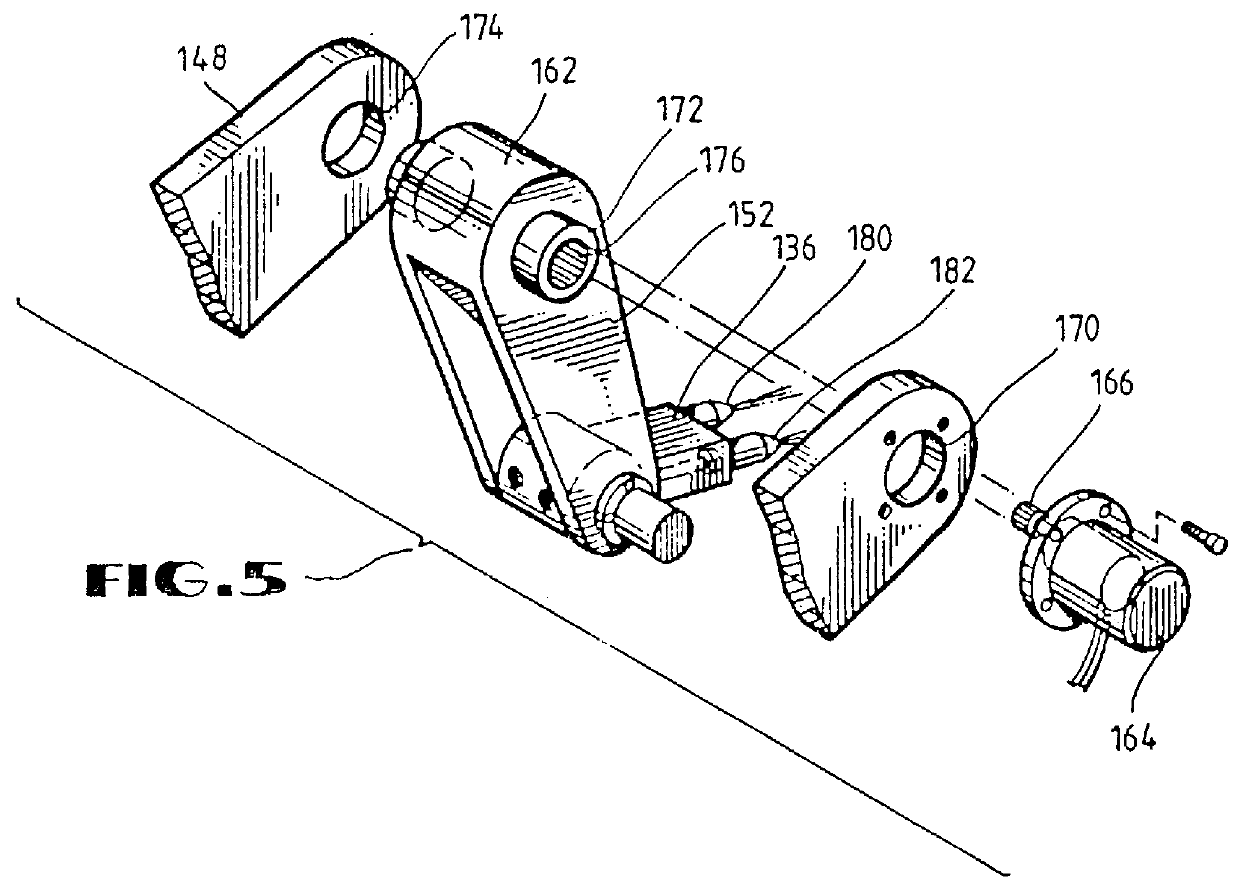

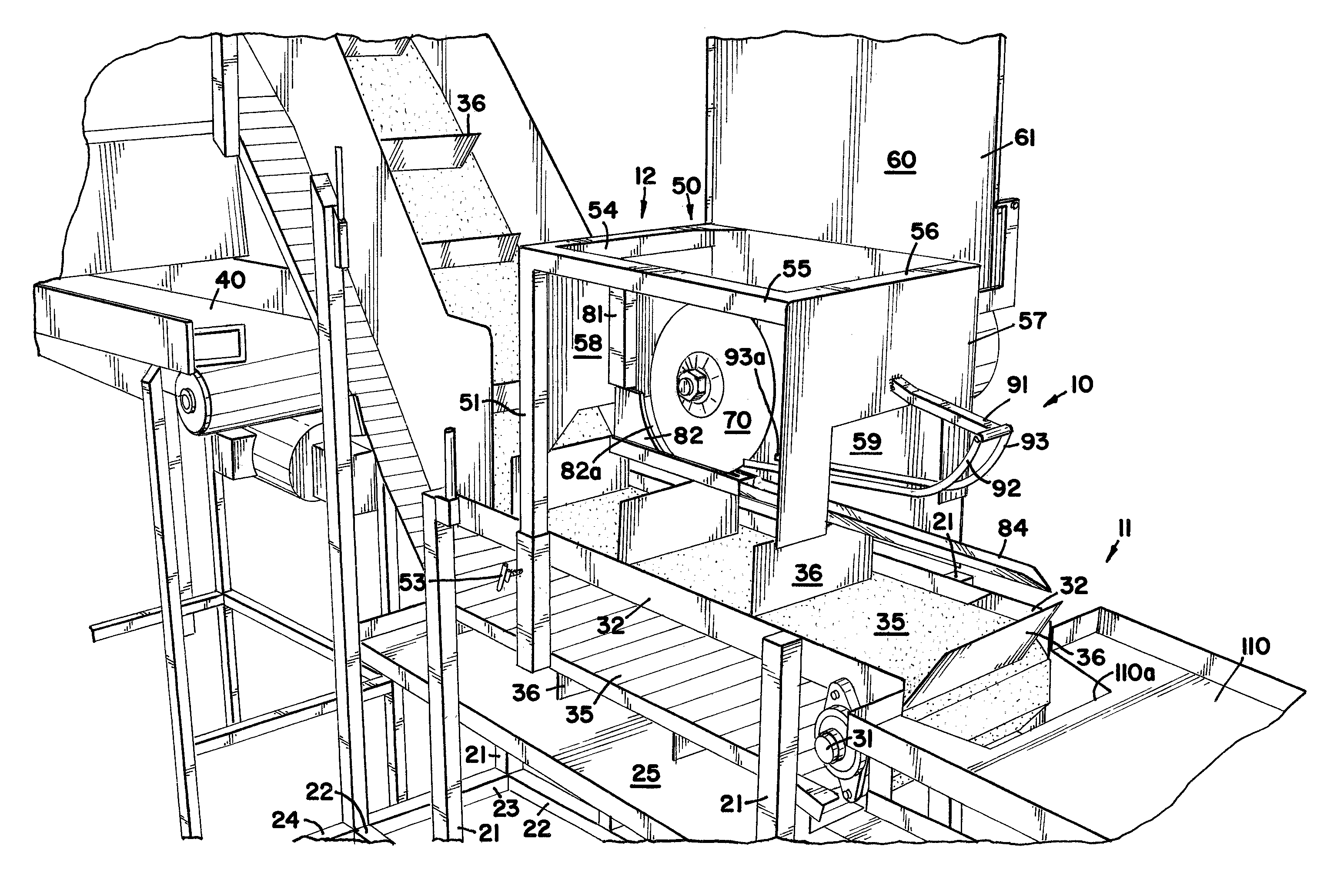

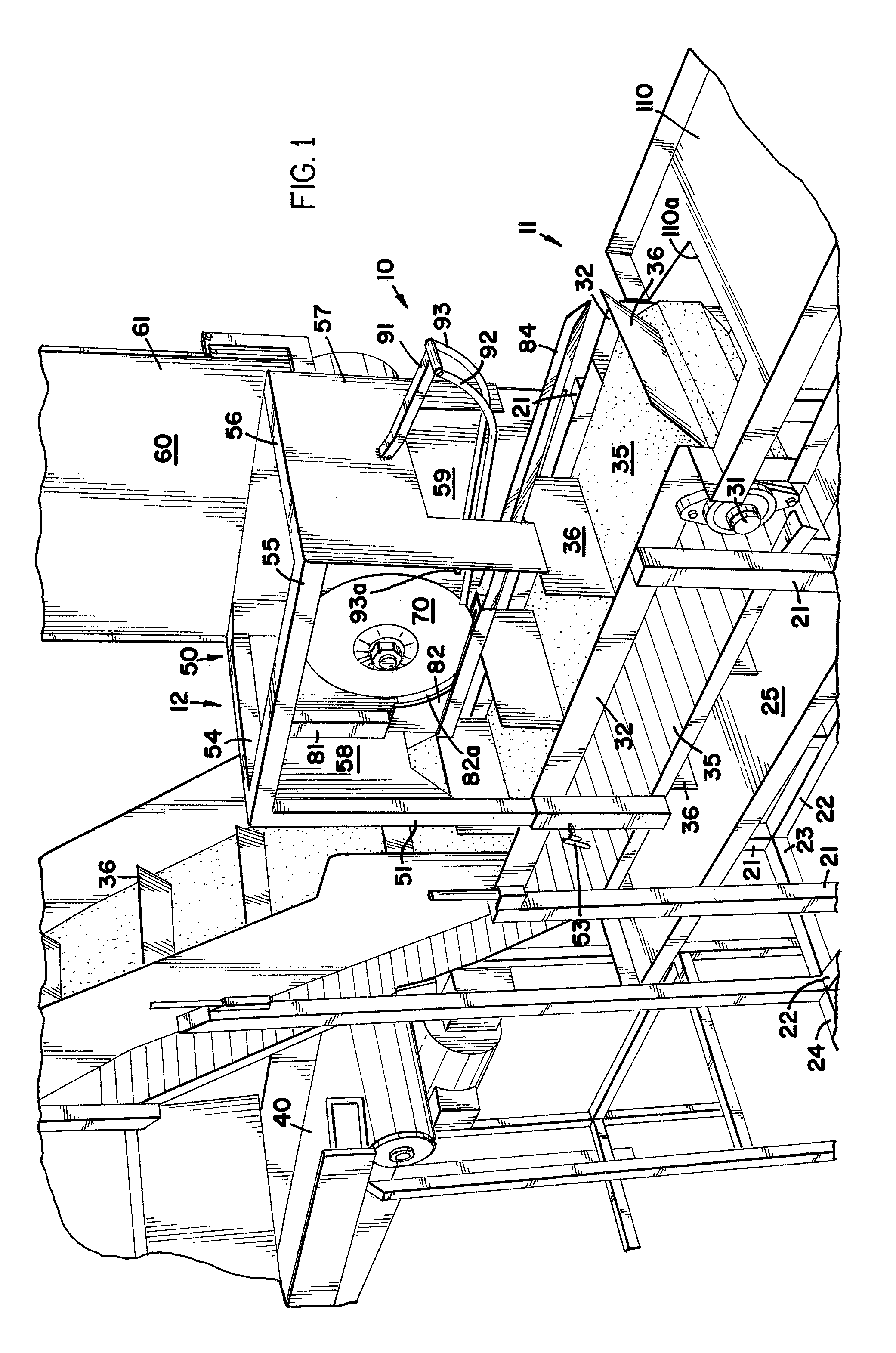

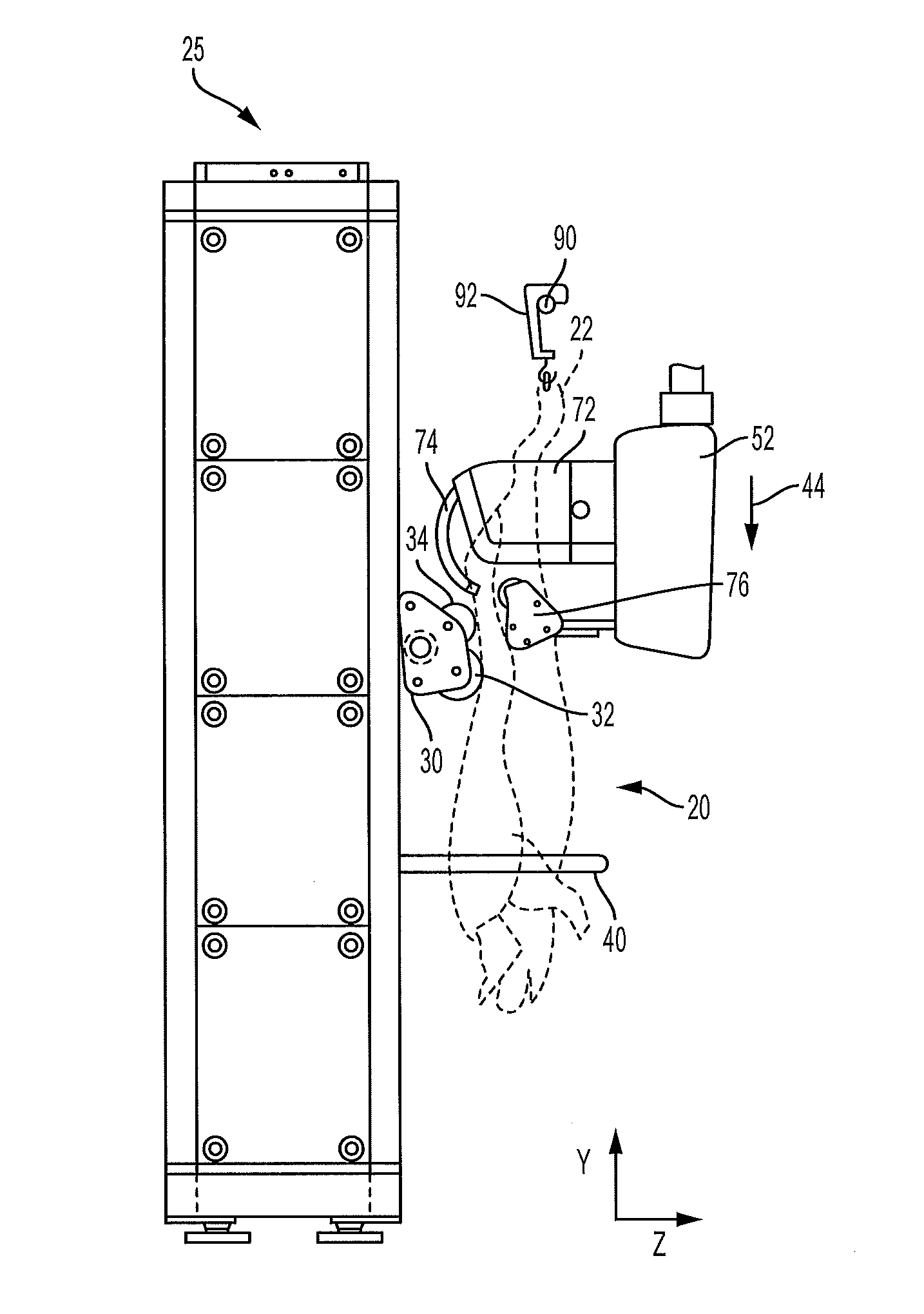

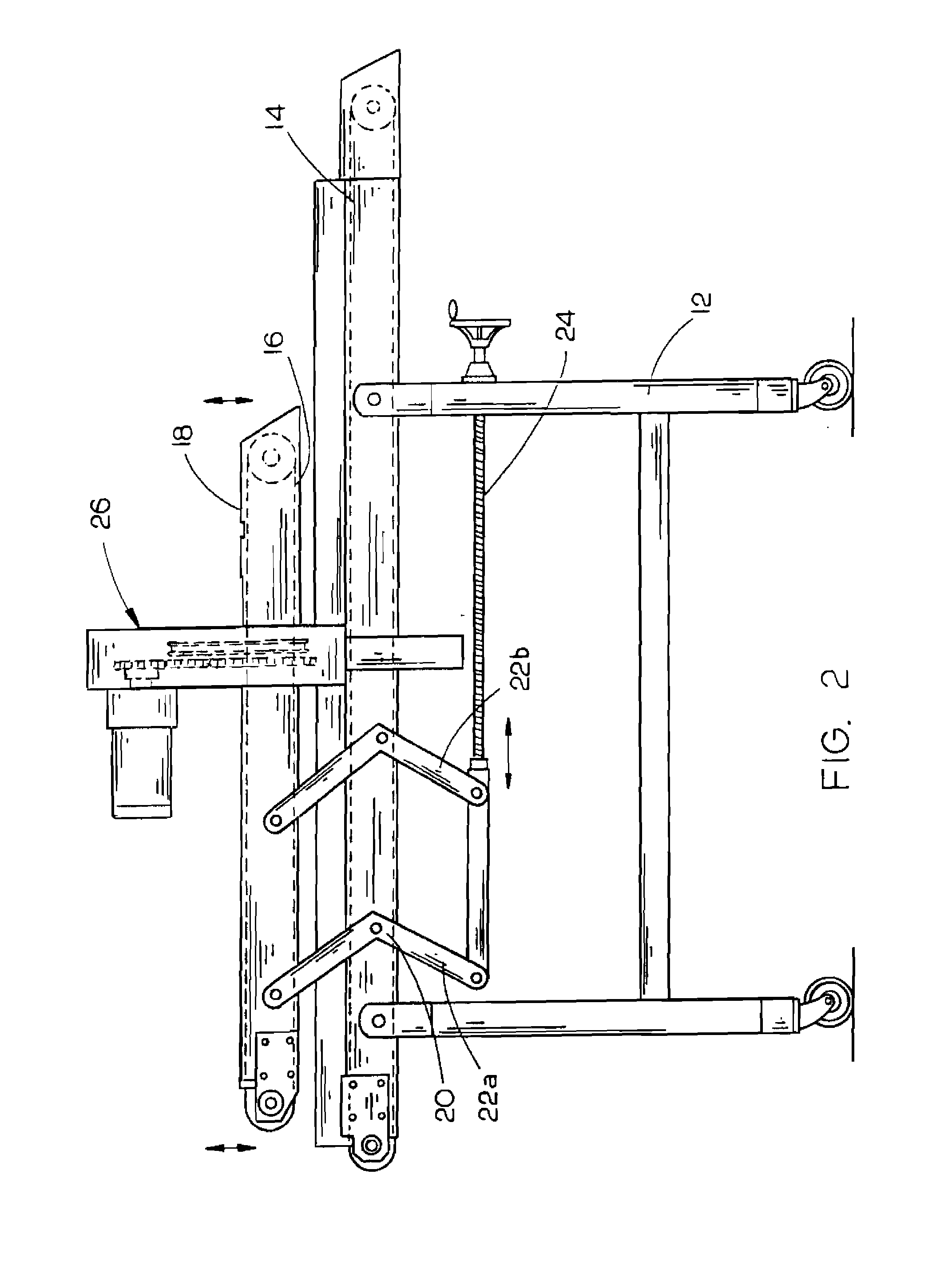

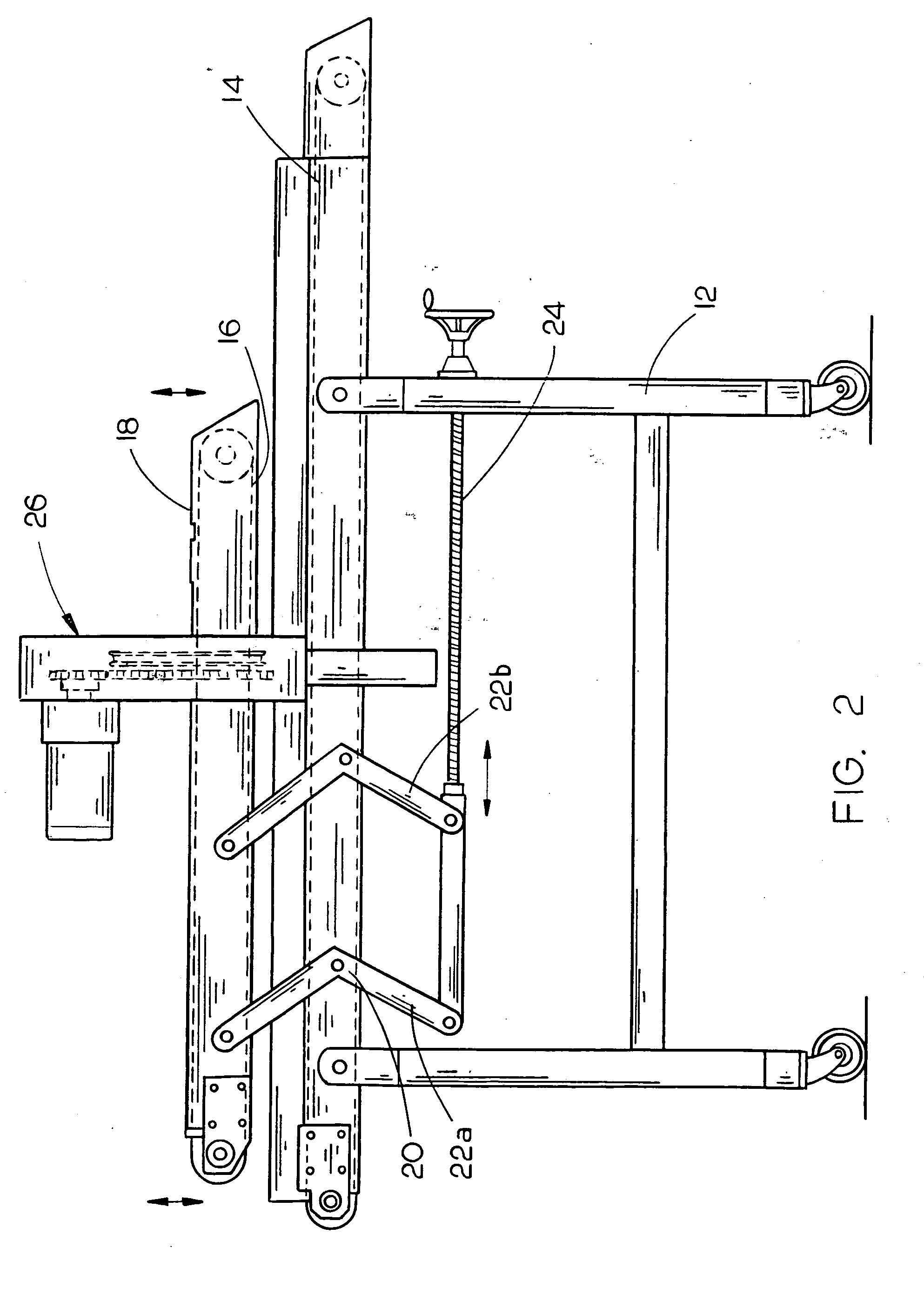

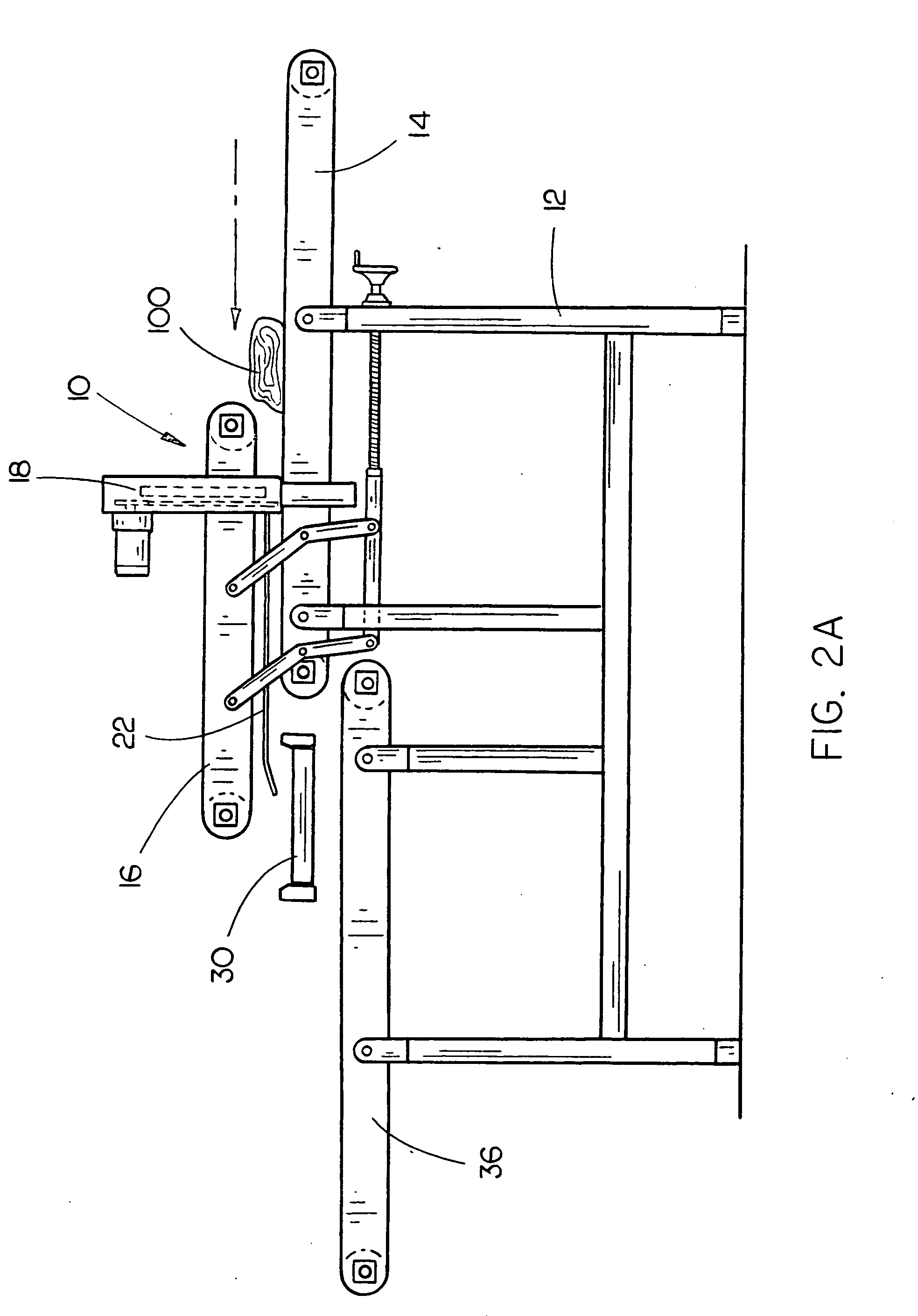

An automated saw for high speed splitting of suspended carcasses, such as hog carcasses, through the backbone as the carcasses continuously move along a carcass rail includes a splitting station and a back roller station located on opposite sides of the carcass rail. The splitting station includes a splitting saw that can be driven in three directions, including horizontally towards a carcass to begin cutting, vertically down to make the cut and horizontally parallel to the carcass rail to match the speed of the moving carcass as the cut is made. A guide roller carried by the splitting station positions the backbone in a known position relative to the saw. The back roller station includes a back roller for positioning the carcass relative to the saw as the cut is made. The back roller is also movable in three directions, including horizontally in to contact the carcass, vertically down, and horizontally parallel to the carcass rail to match the motion of the saw. The back roller and saw are structurally independent, but are accurately driven to maintain the relative position of the saw and the back roller as the cut is made.

Owner:JARVIS PROD

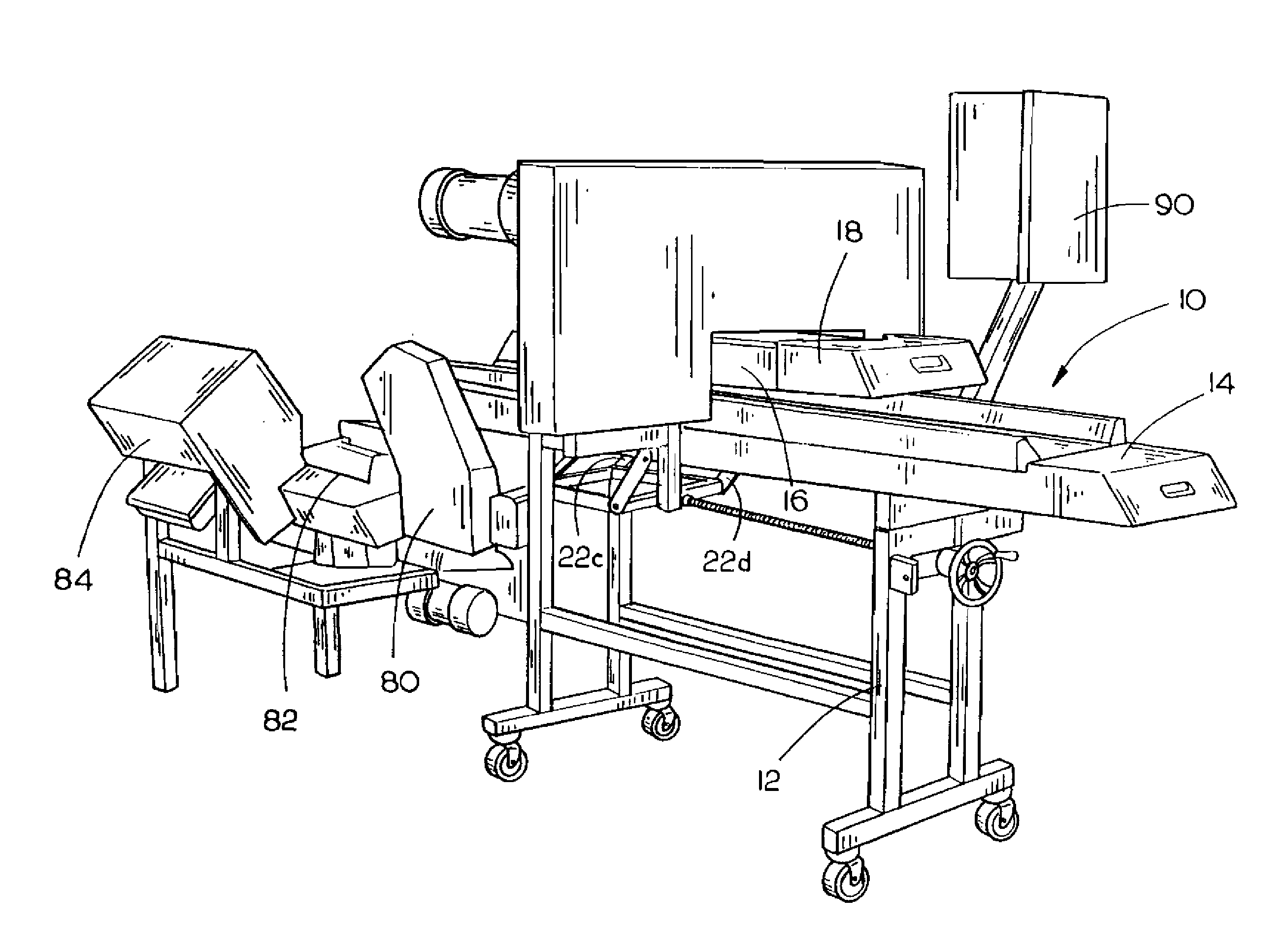

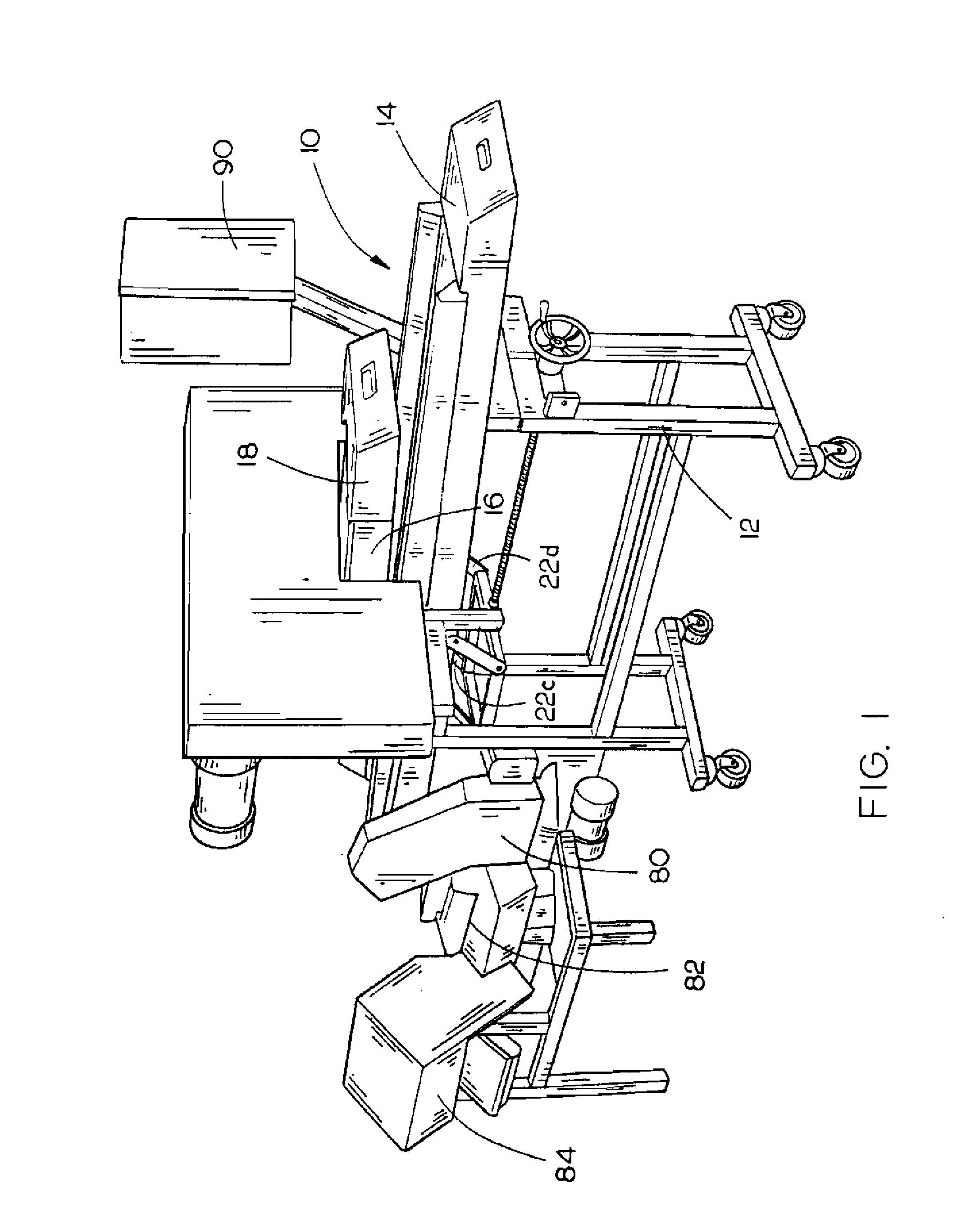

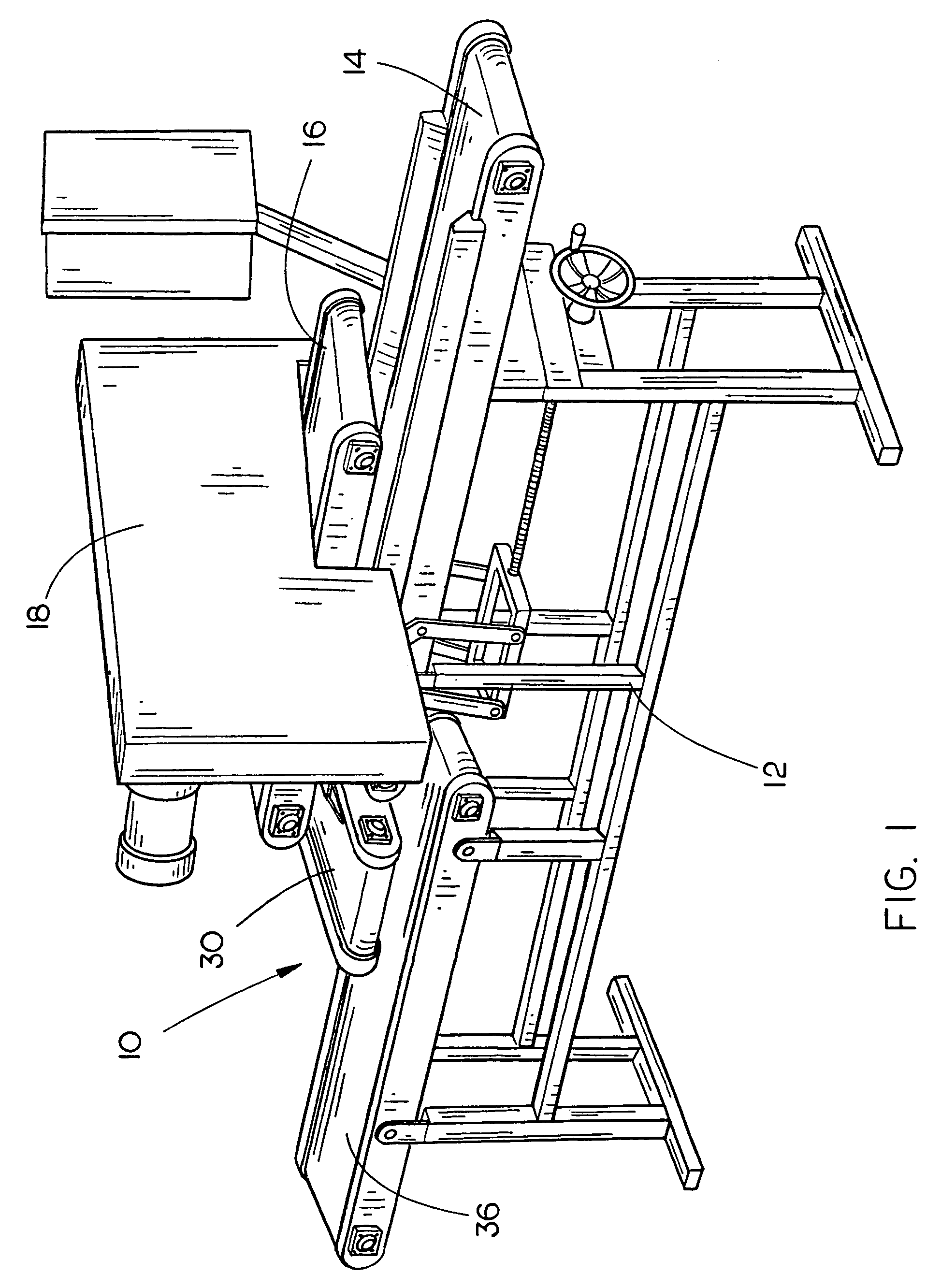

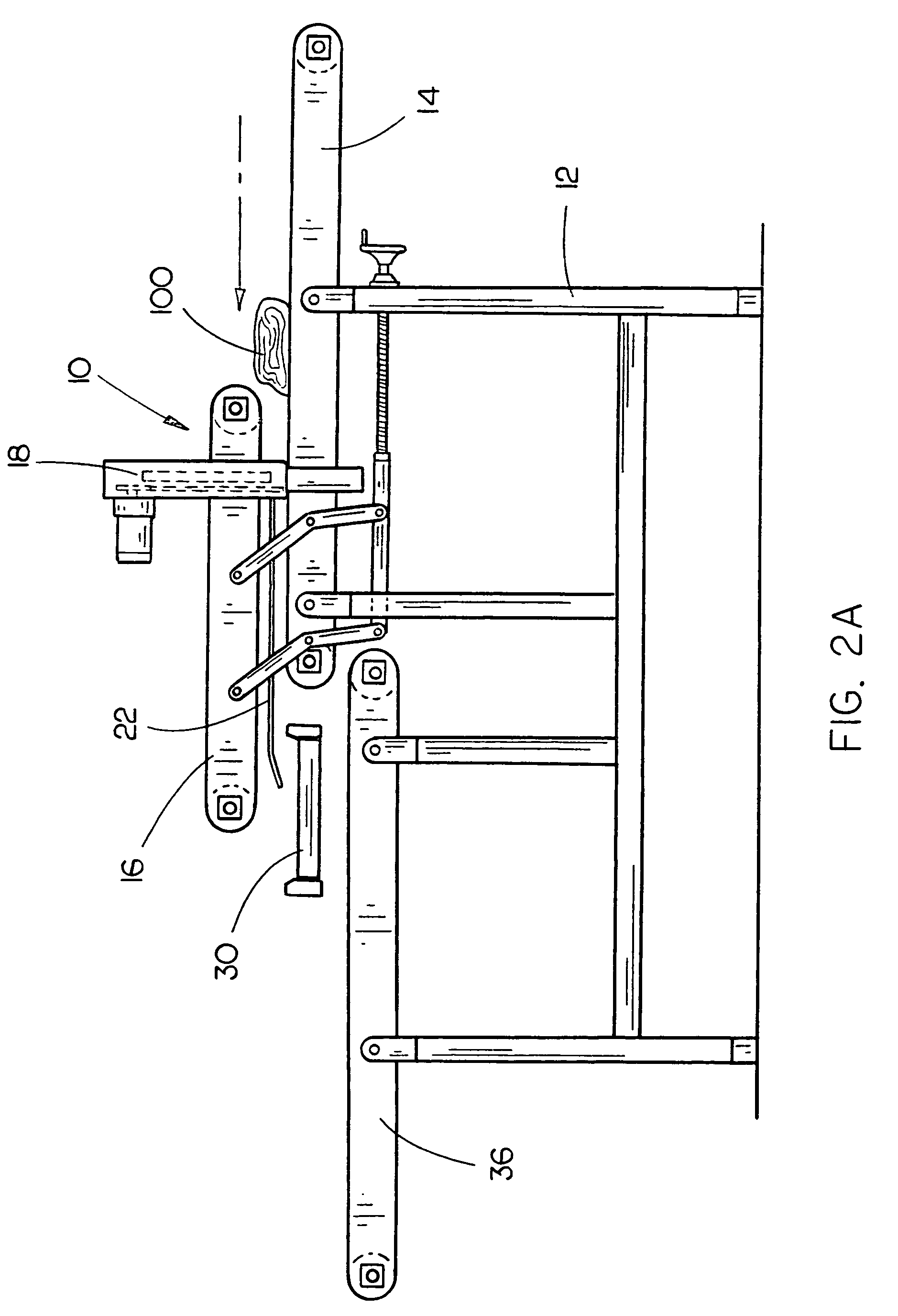

Poultry breast saw apparatus

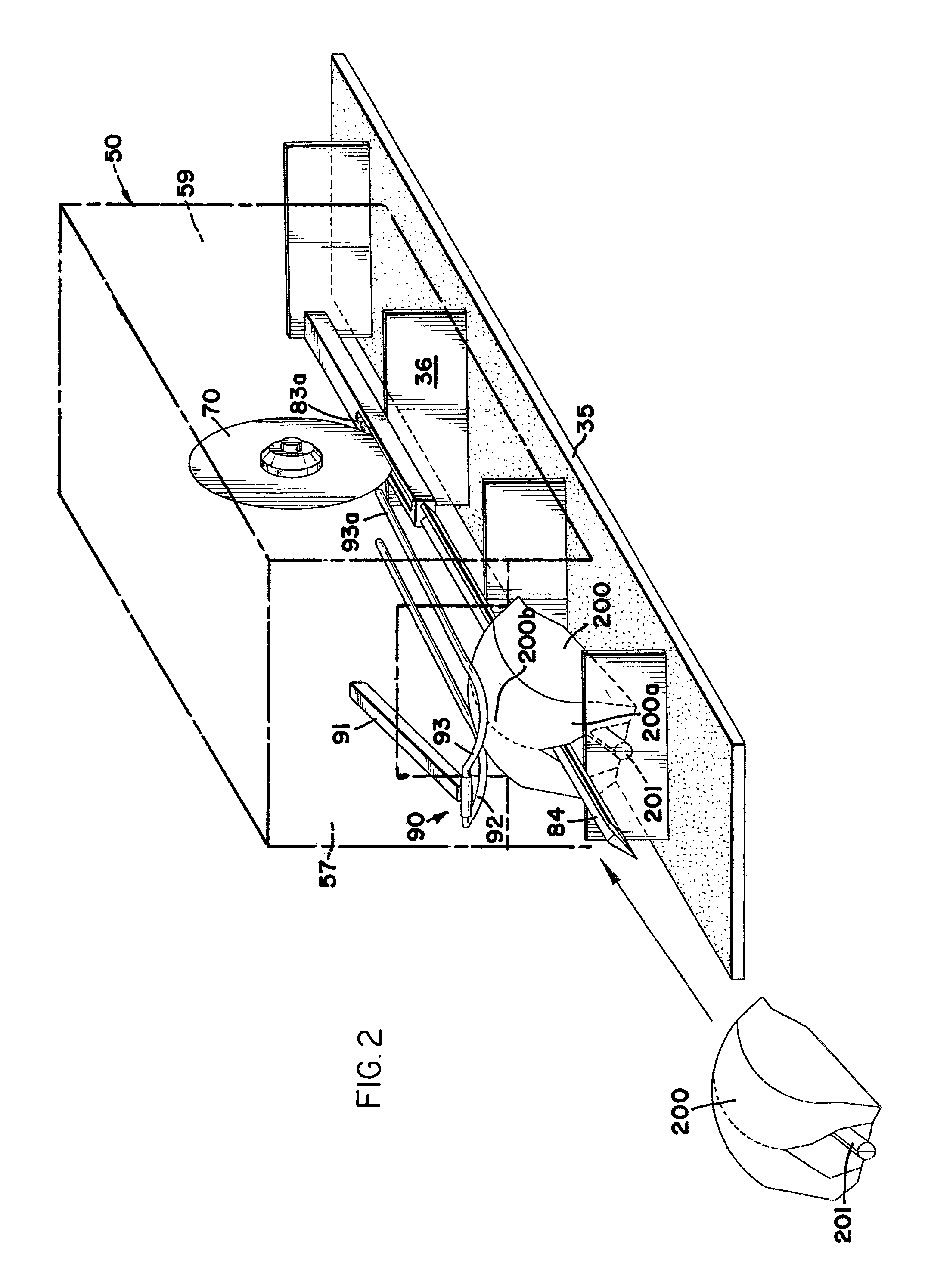

A breast saw apparatus (10) is used for cutting a poultry breast having a keel bone. A conveyor (30) moves the poultry breast through the apparatus (10). A bottom member (80) is supported above the conveyor (30). The bottom member (80) is configured for the poultry breast moving along the bottom member's length and supporting the poultry breast on its keel bone. An elongate top member (90) is positioned above the bottom member (30). A blade (70) is utilized to cut the poultry breast and the poultry breast is held straight between the top member (90) and the bottom member (80) as the poultry breast is moved by the conveyor (30) to the blade (70) for cutting.

Owner:JENNIE O TURKEY STORE

Poultry breast meat apportioning method

InactiveUS6921326B2Increase productionUniform volumeSplitting instrumentsMetal working apparatusBiotechnologyPhysiology

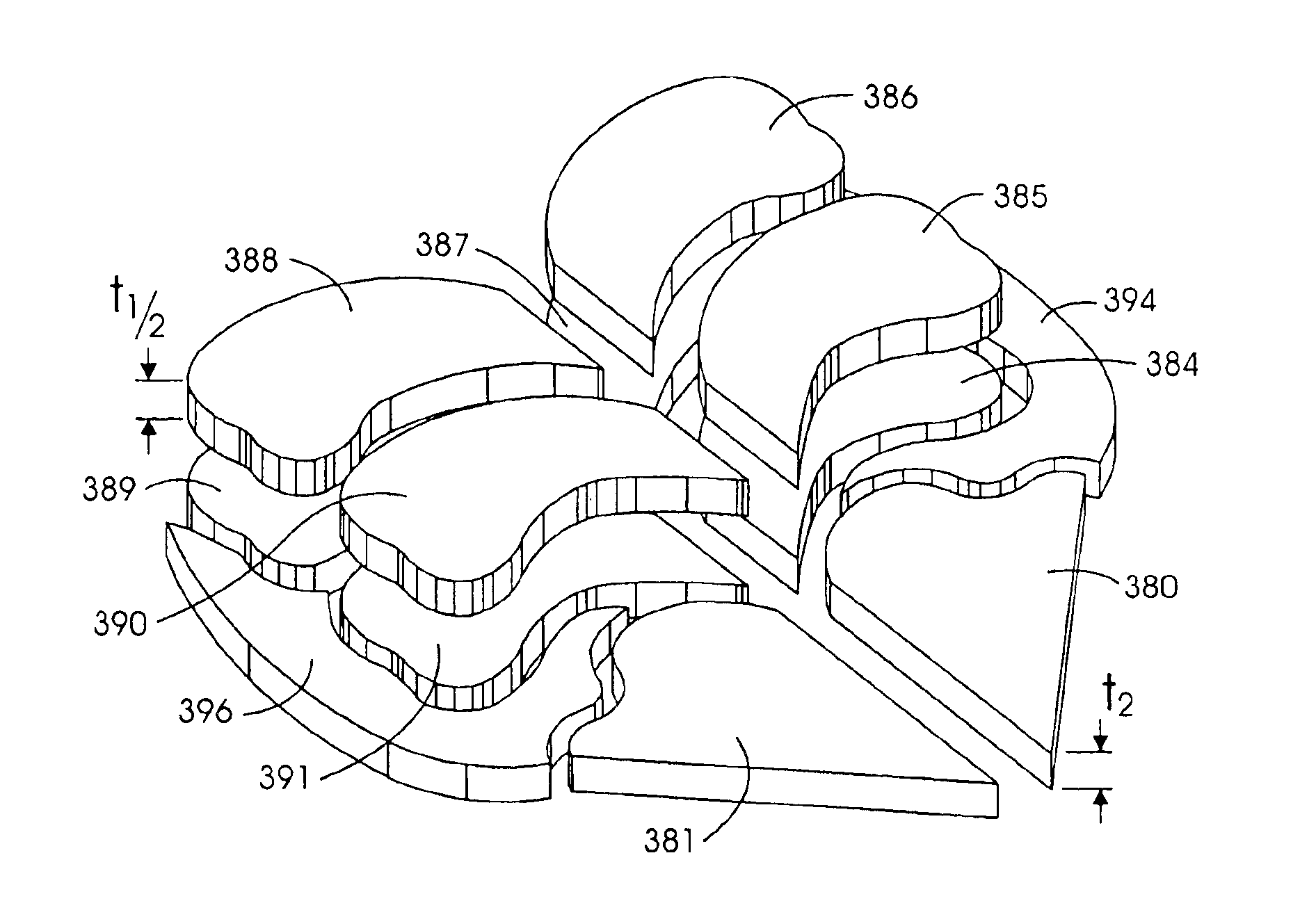

A method for apportioning larger poultry breast wherein two primary meat products are produced by cutting predetermined cutlet shapes from the rearward one half of each breast half. Additionally cut are two or more preparative secondary meat products from the thicker shoulder forward region of each breast half. These preparative secondary meat products are severed horizontally in half to produce four secondary meat products.

Owner:SMITH JEFFREY P

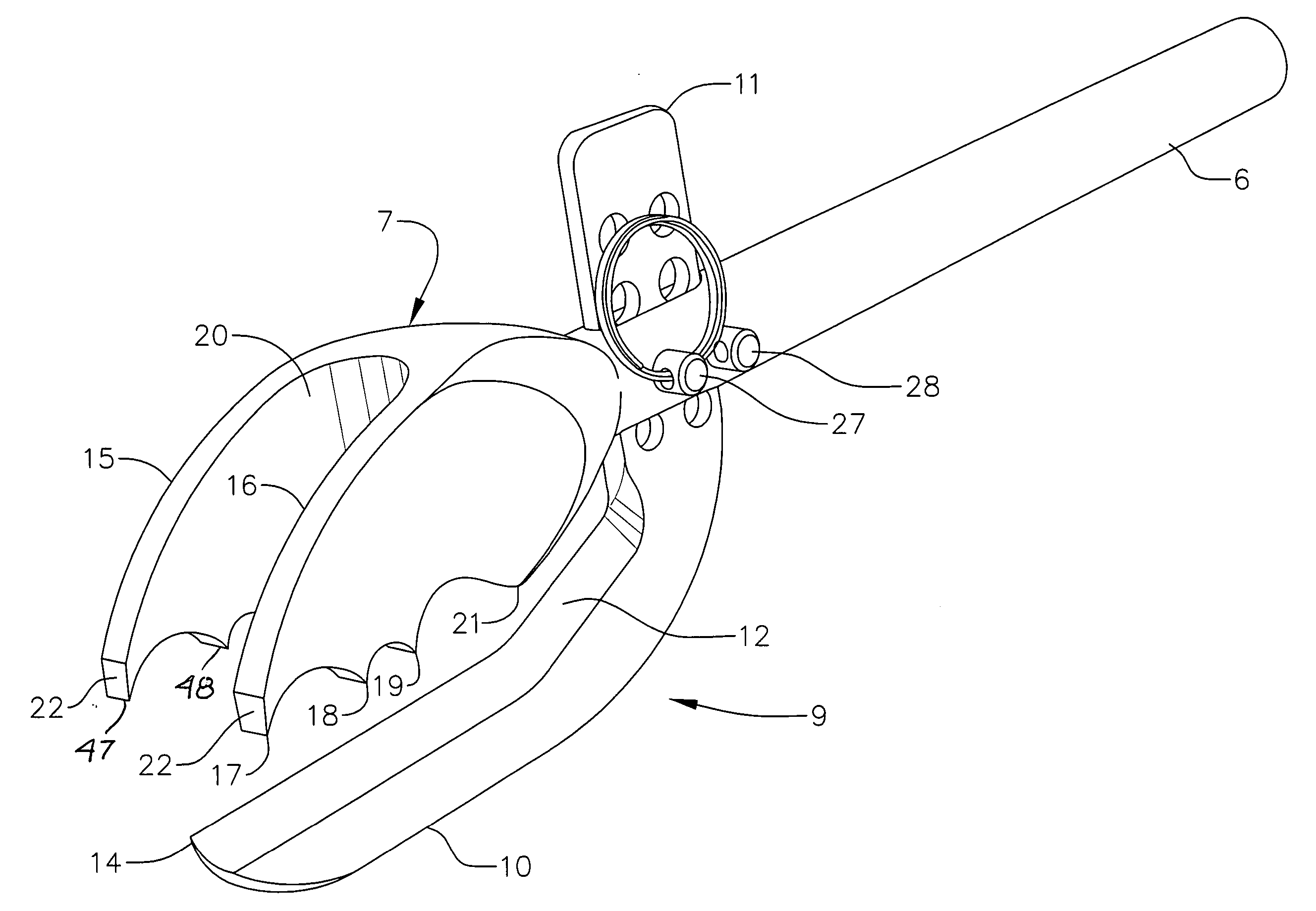

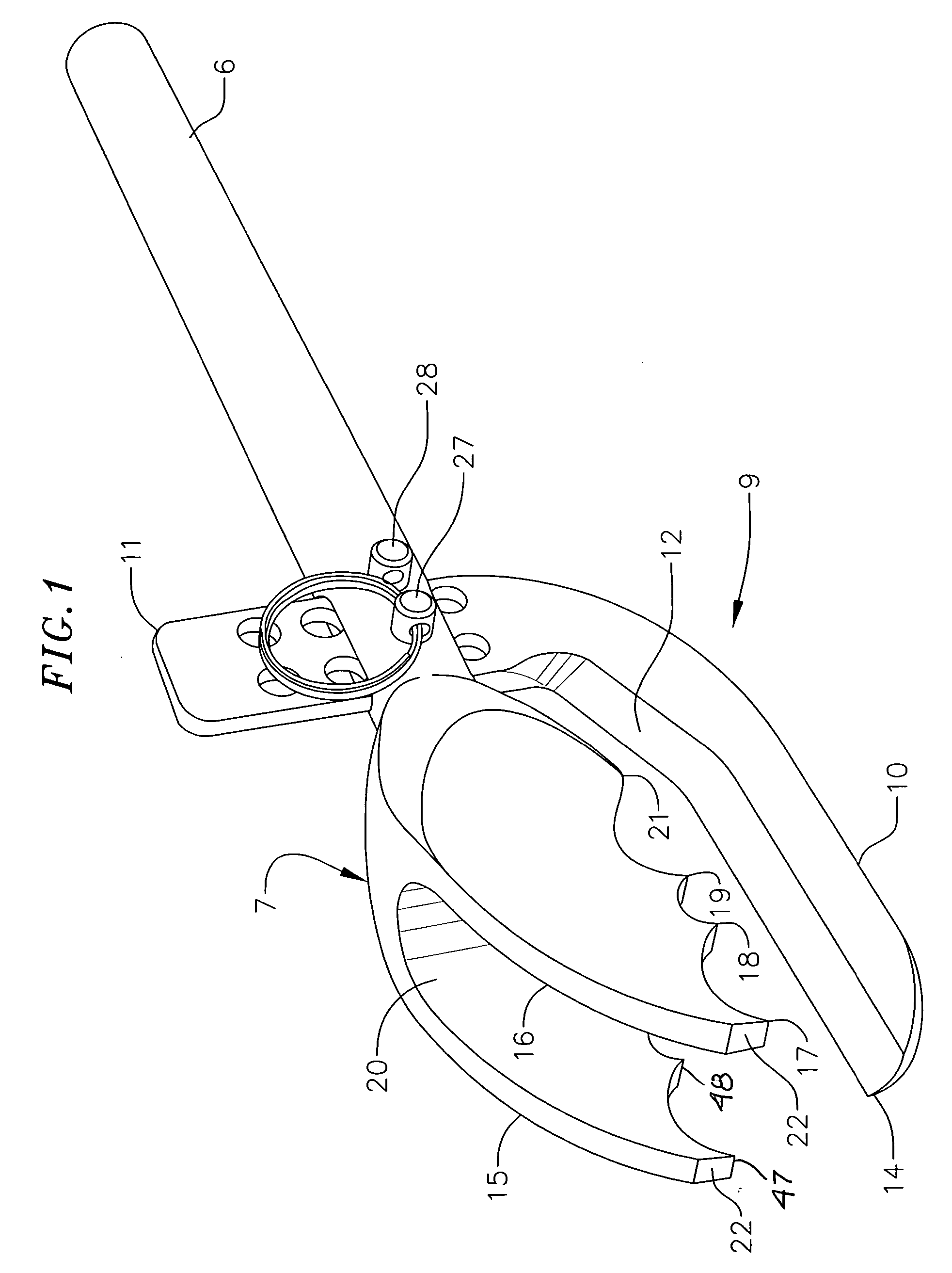

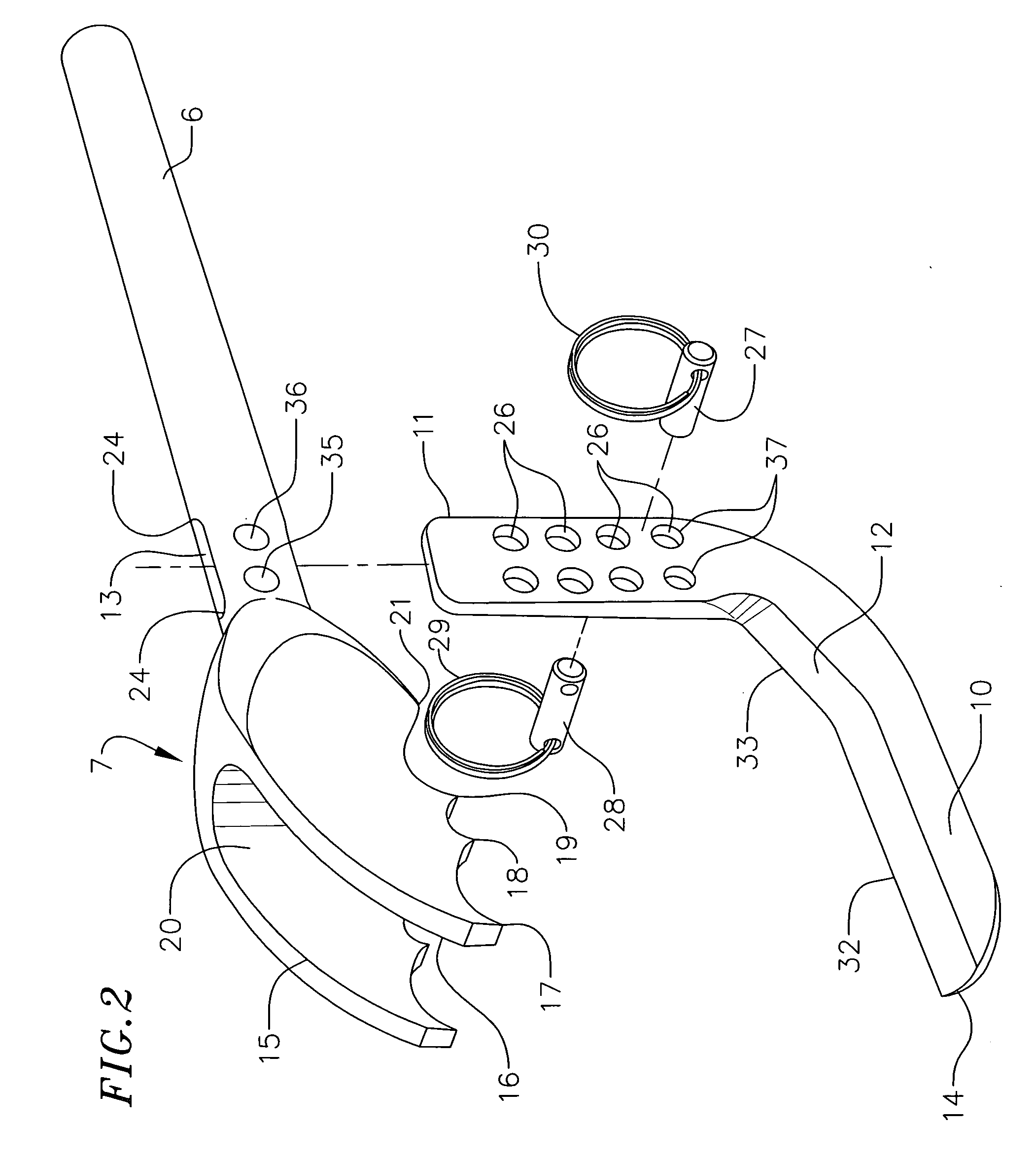

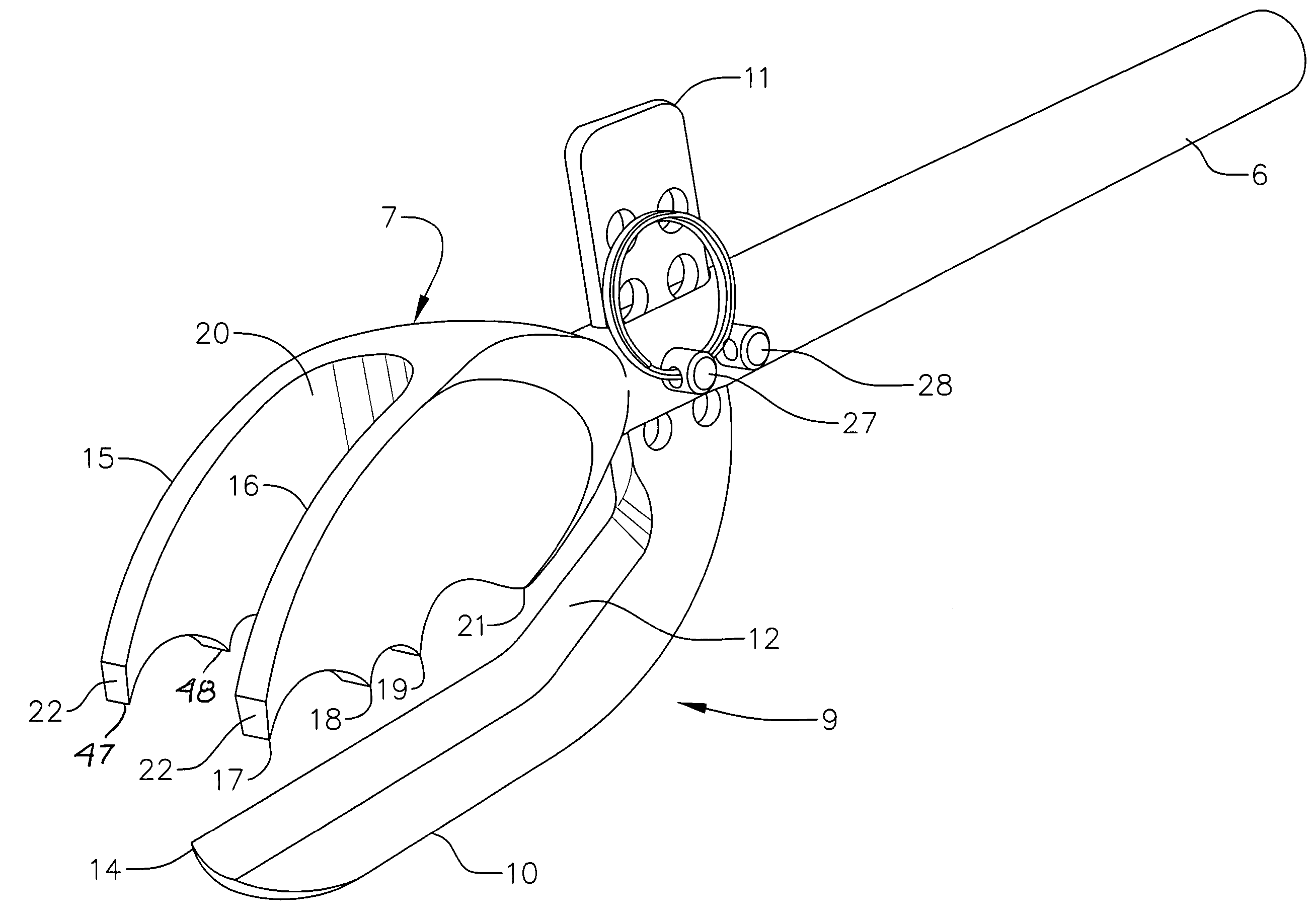

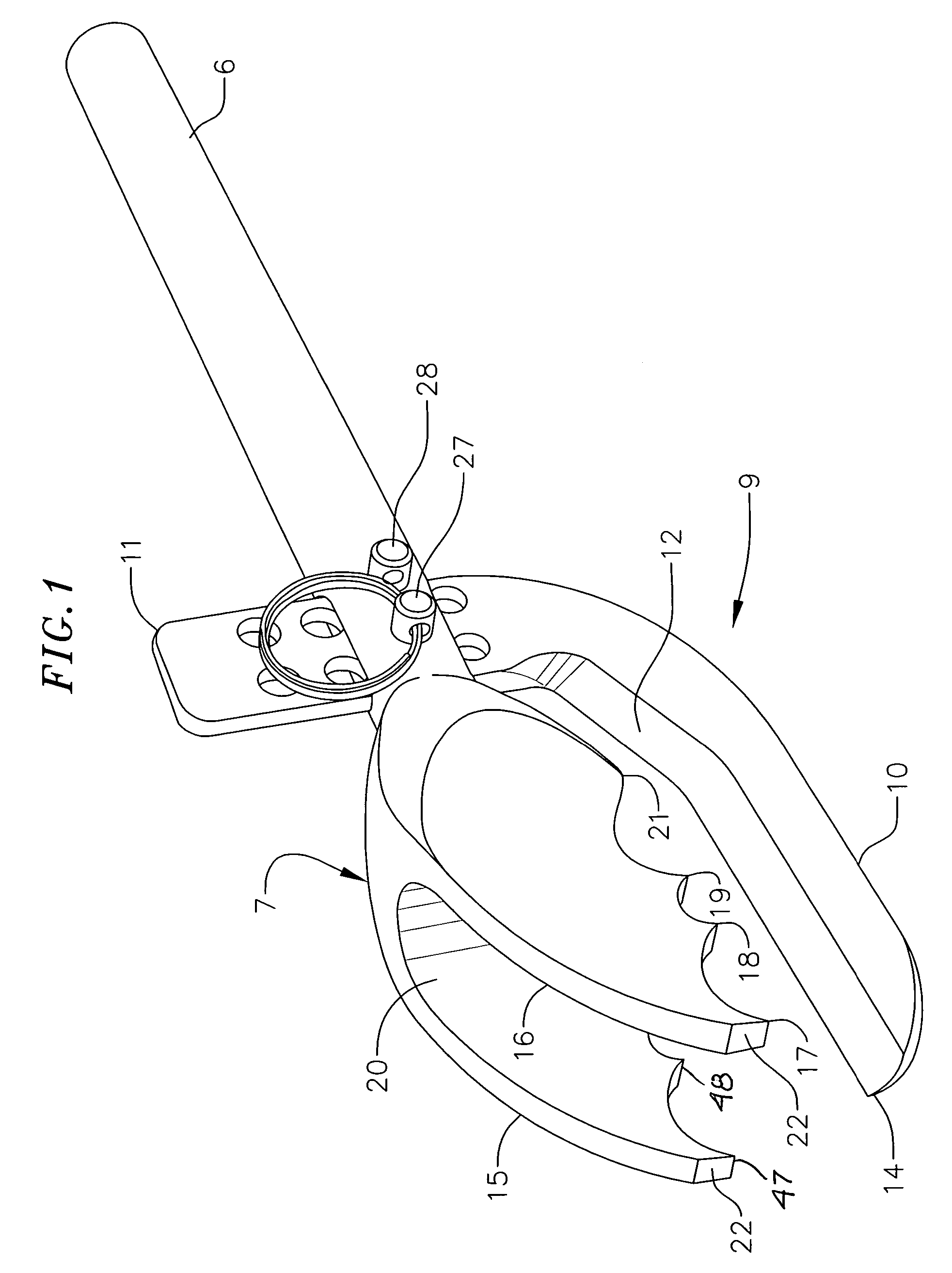

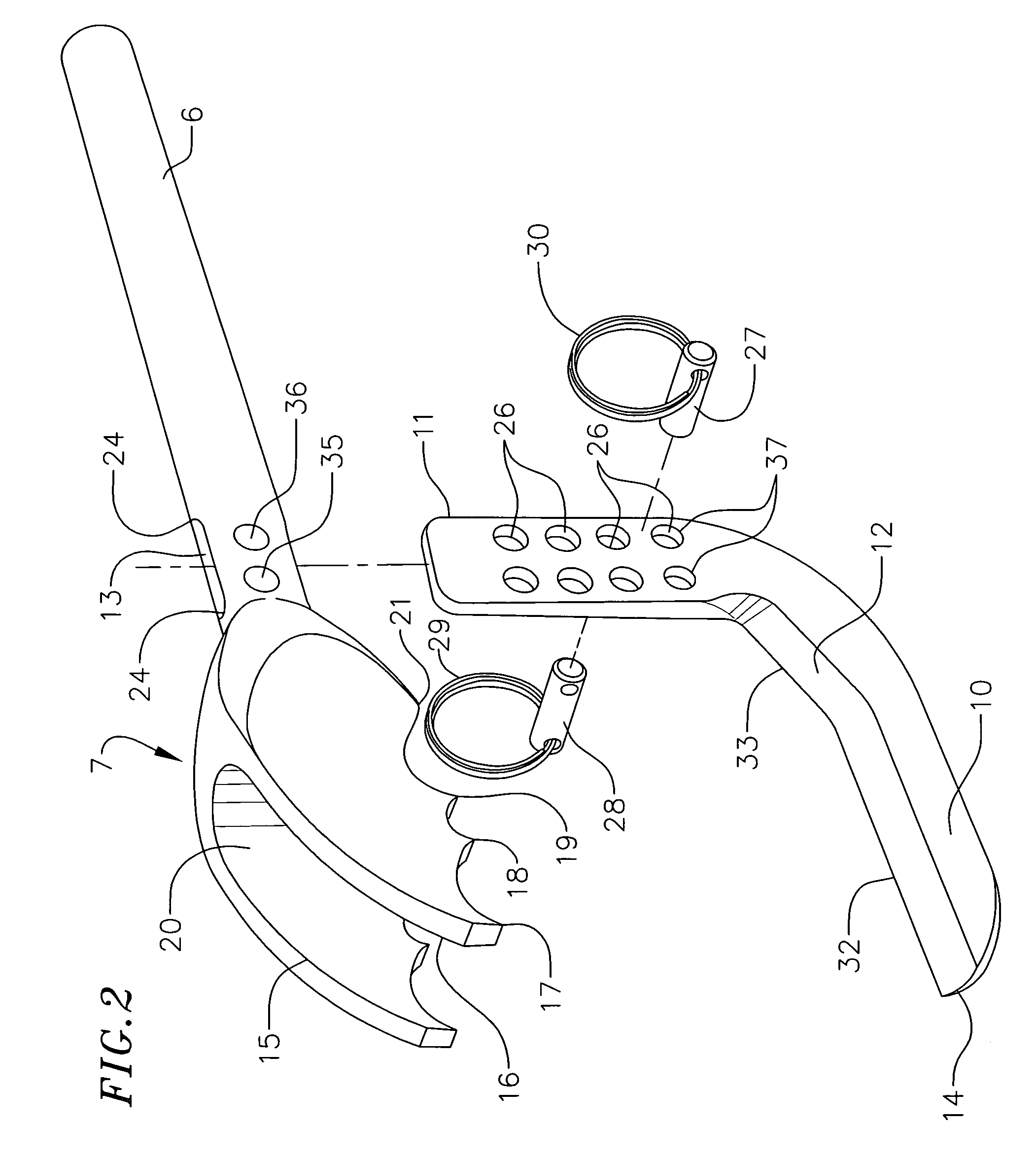

Animal dressing tool

InactiveUS20050227601A1Easy to useSecure attachmentSplitting instrumentsShrimp/lobster processingEngineeringKnife blades

A bladed lever for cutting through or splitting animal bones having a head, a handle and a knife with the head having two sides with a row of teeth at the bottom of each side to grip the bone to be cut or split and the knife having a blade positioned below and between the two sides of the head at a distance to permit the bone to be split to fit between the teeth of the head and the blade of the knife.

Owner:WHETSTONE GREGORY JACK +1

Animal dressing tool

InactiveUS7198562B2Easy to useSecure attachmentSplitting instrumentsShrimp/lobster processingKnife bladesBiomedical engineering

A bladed lever for cutting through or splitting animal bones having a head, a handle and a knife with the head having two sides with a row of teeth at the bottom of each side to grip the bone to be cut or split and the knife having a blade positioned below and between the two sides of the head at a distance to permit the bone to be split to fit between the teeth of the head and the blade of the knife.

Owner:WHETSTONE GREGORY JACK +1

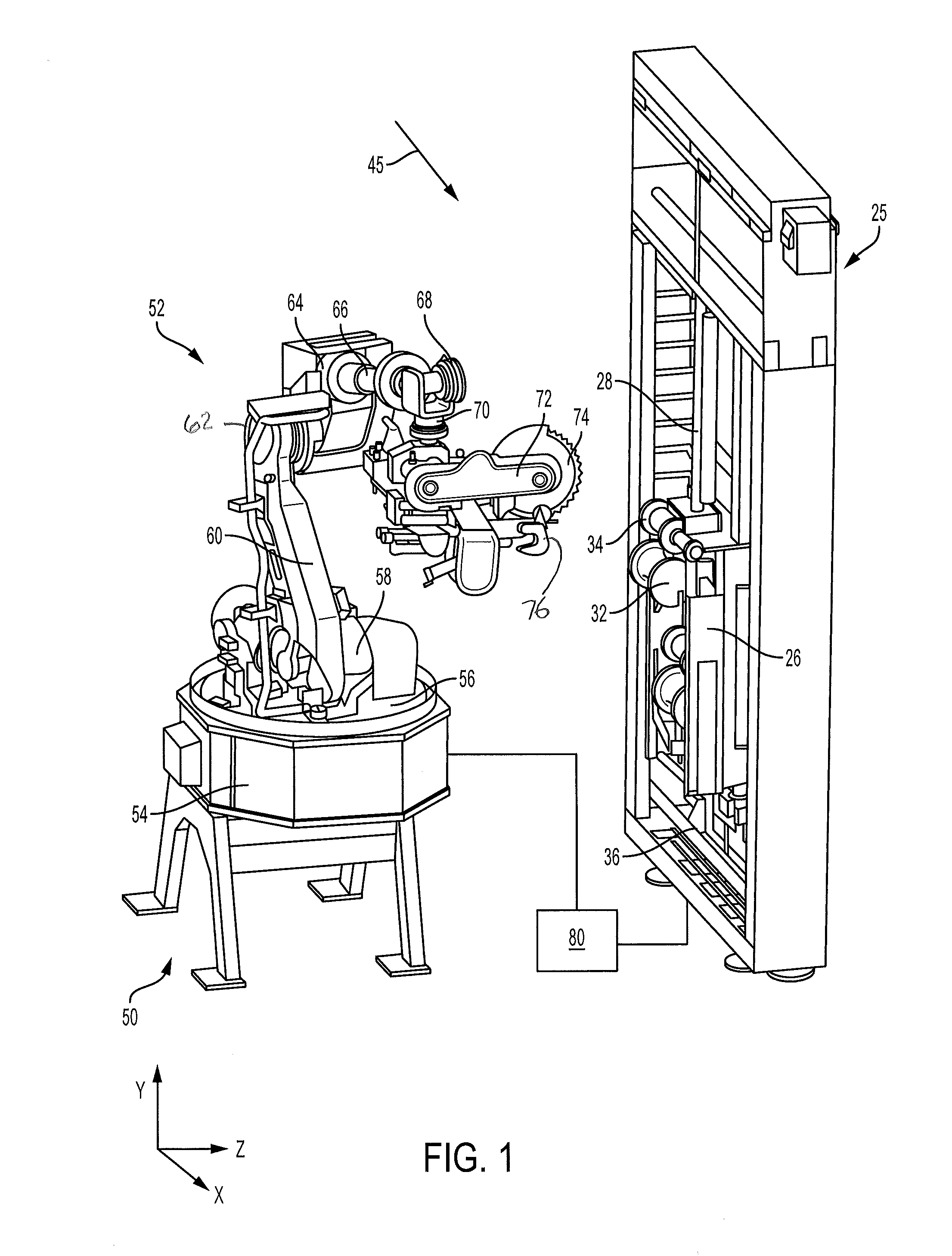

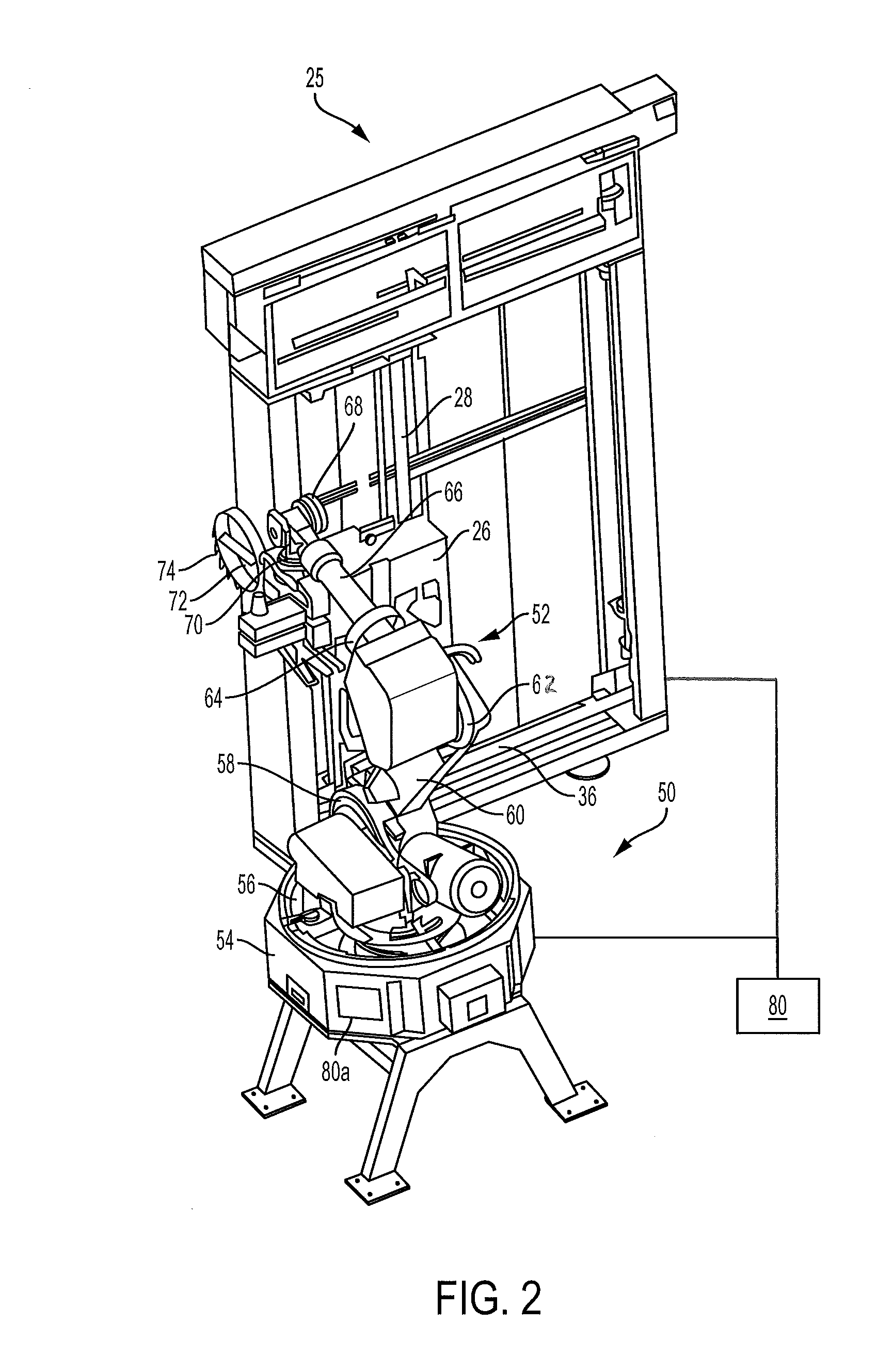

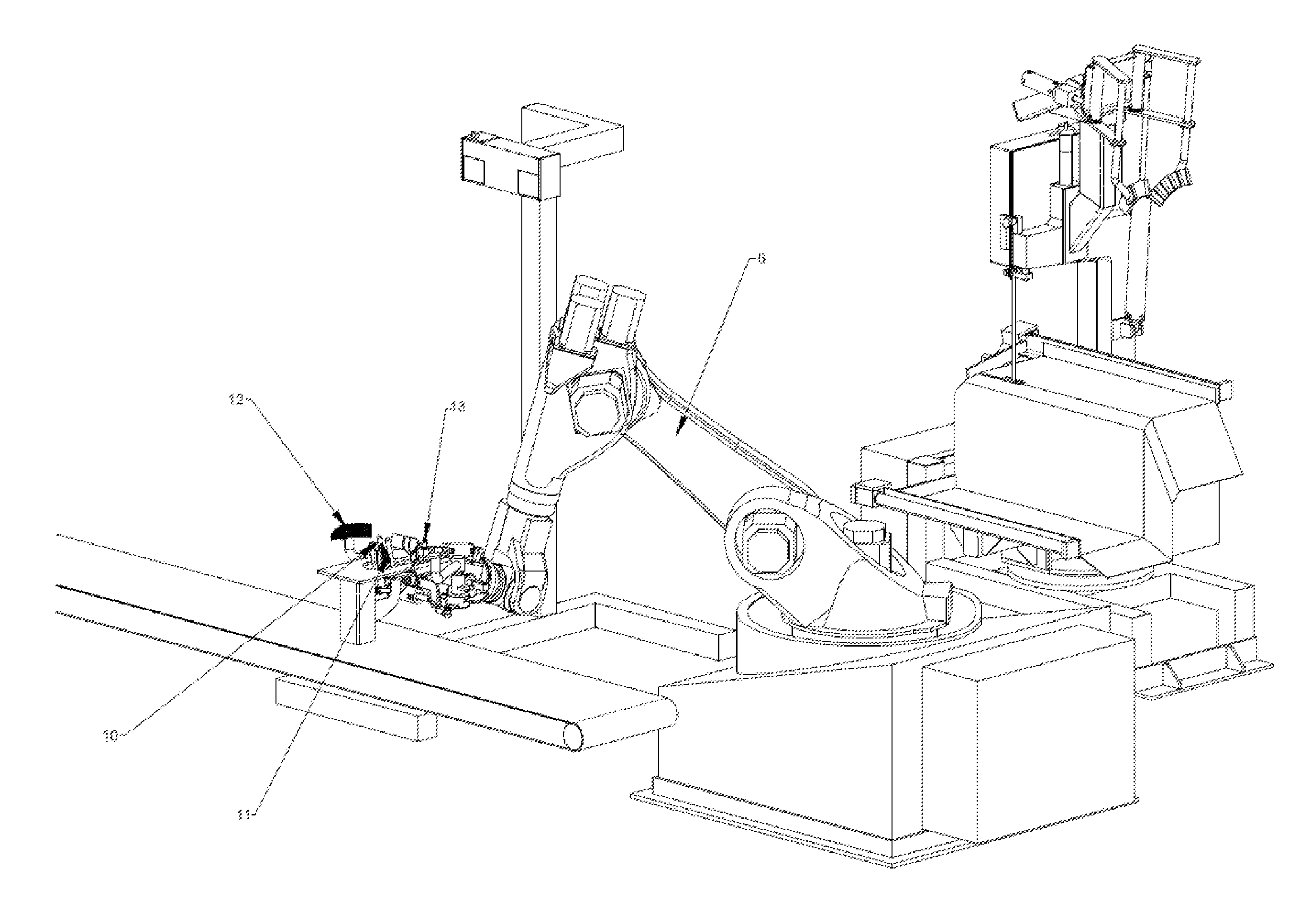

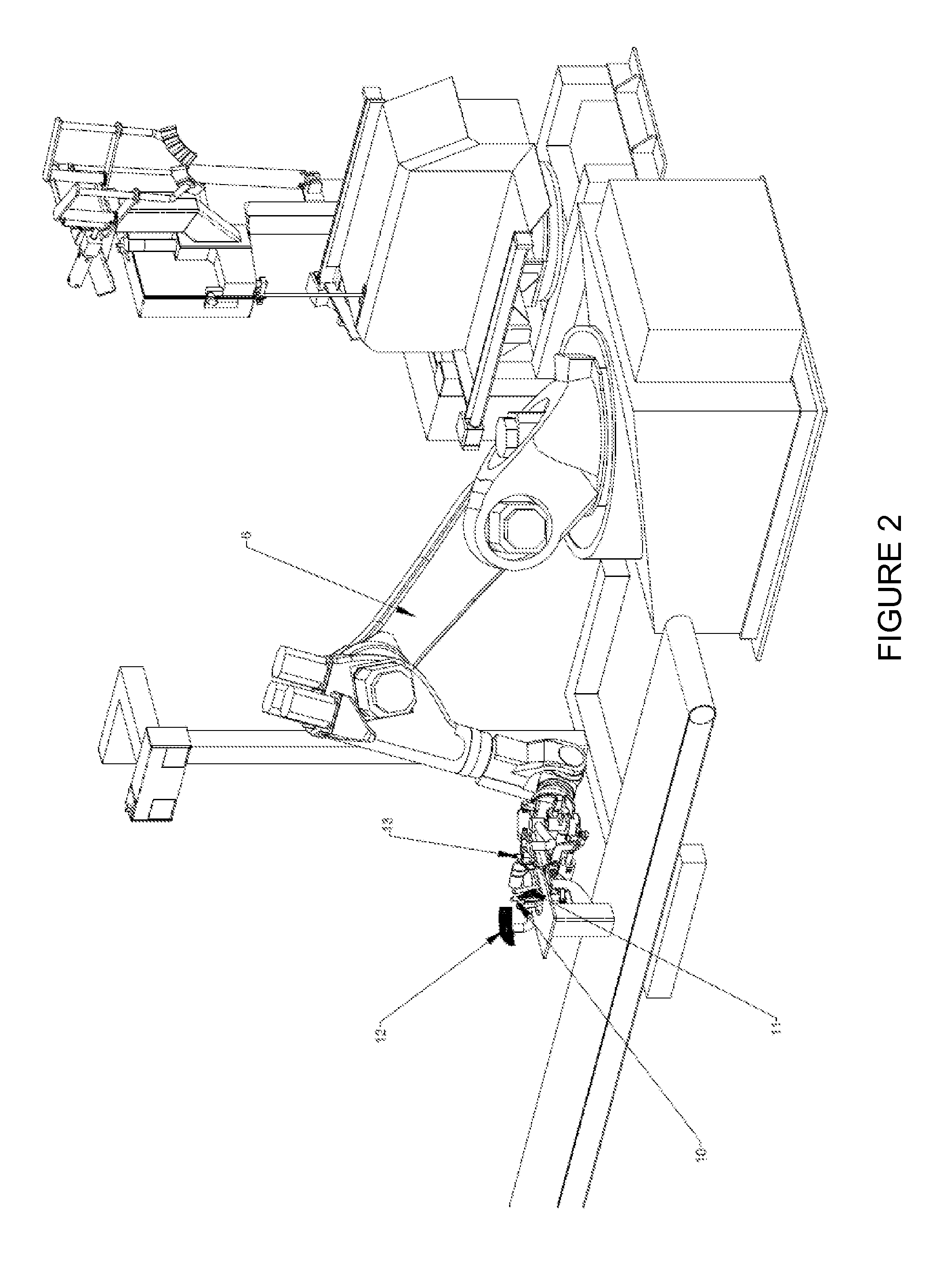

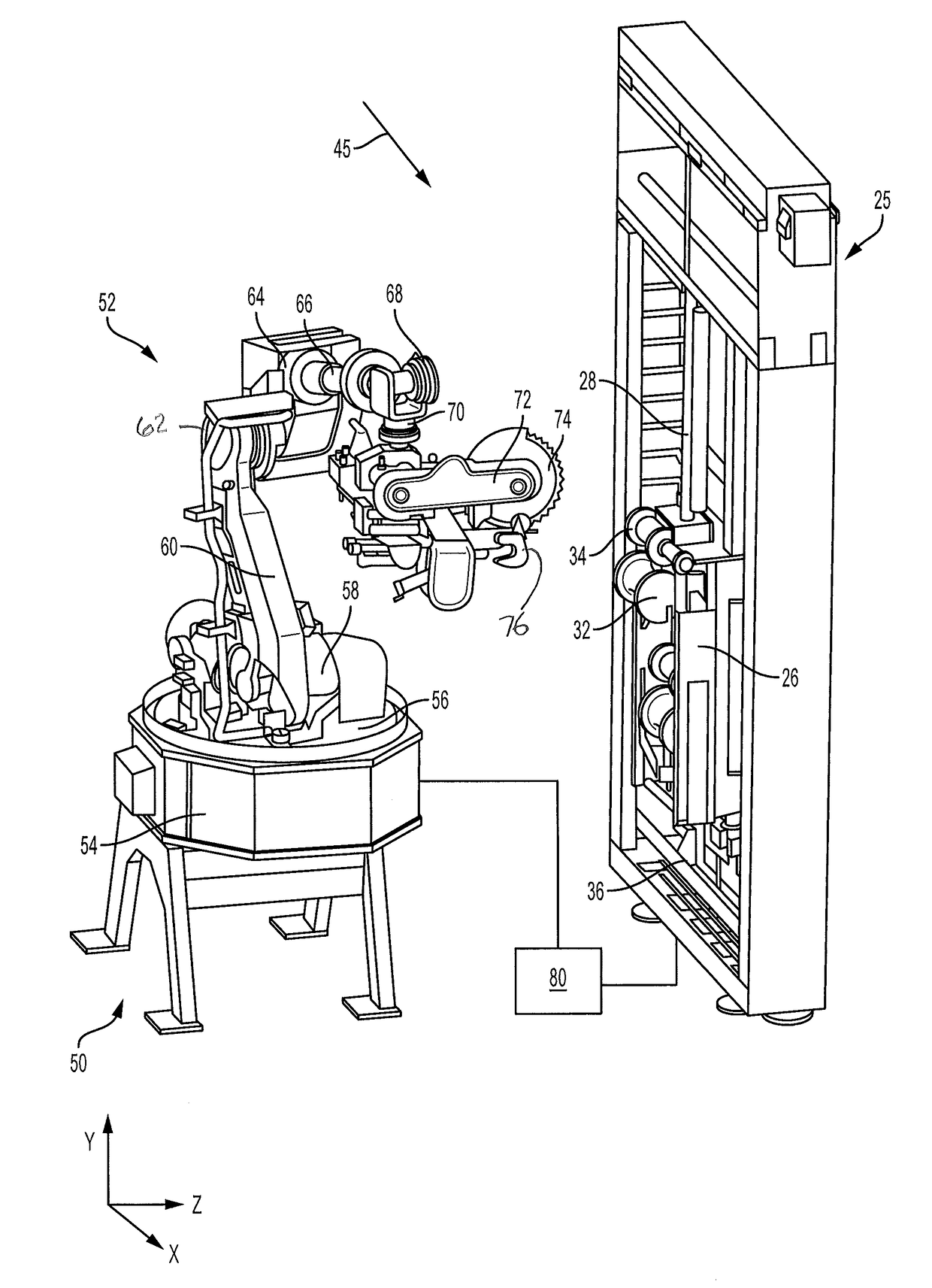

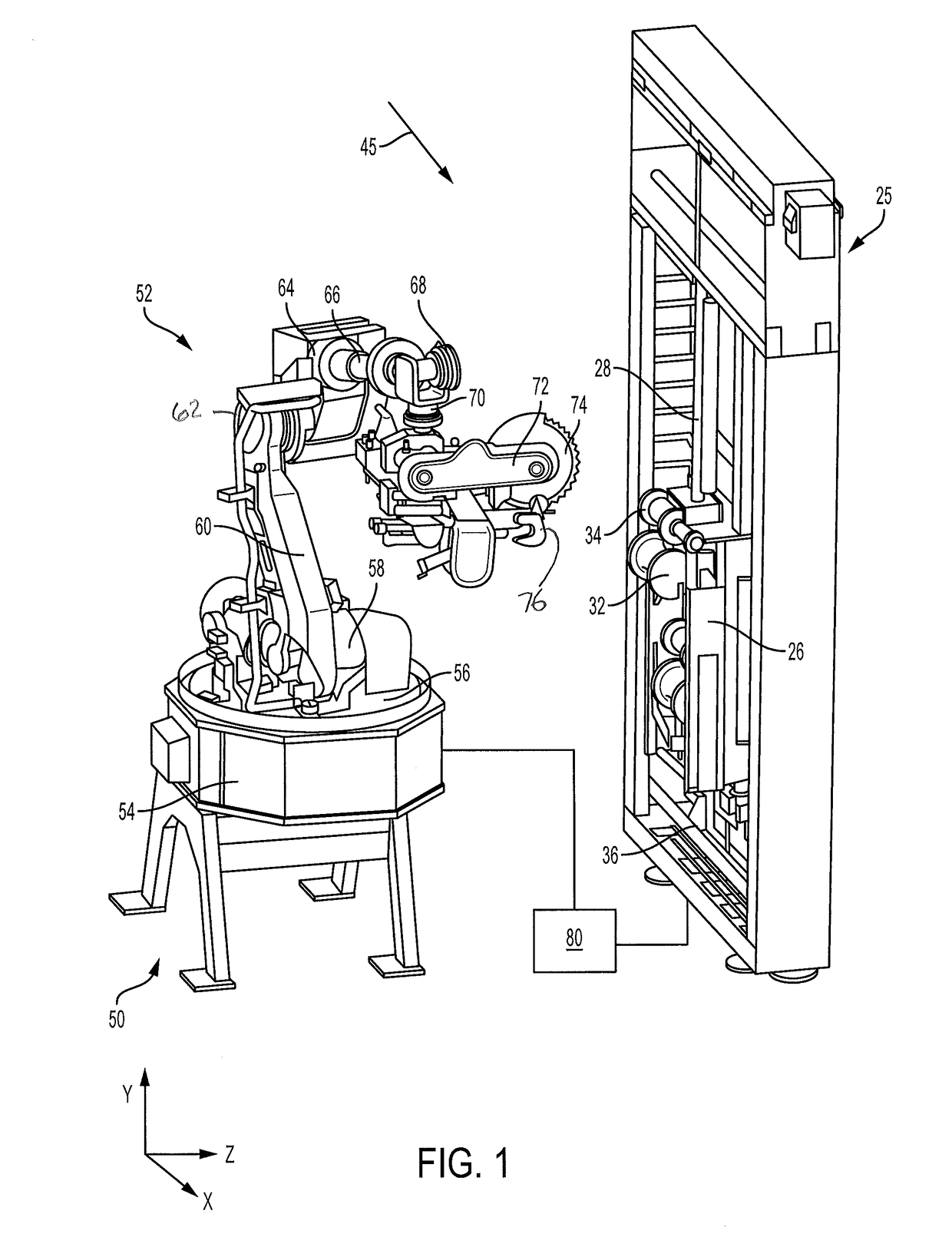

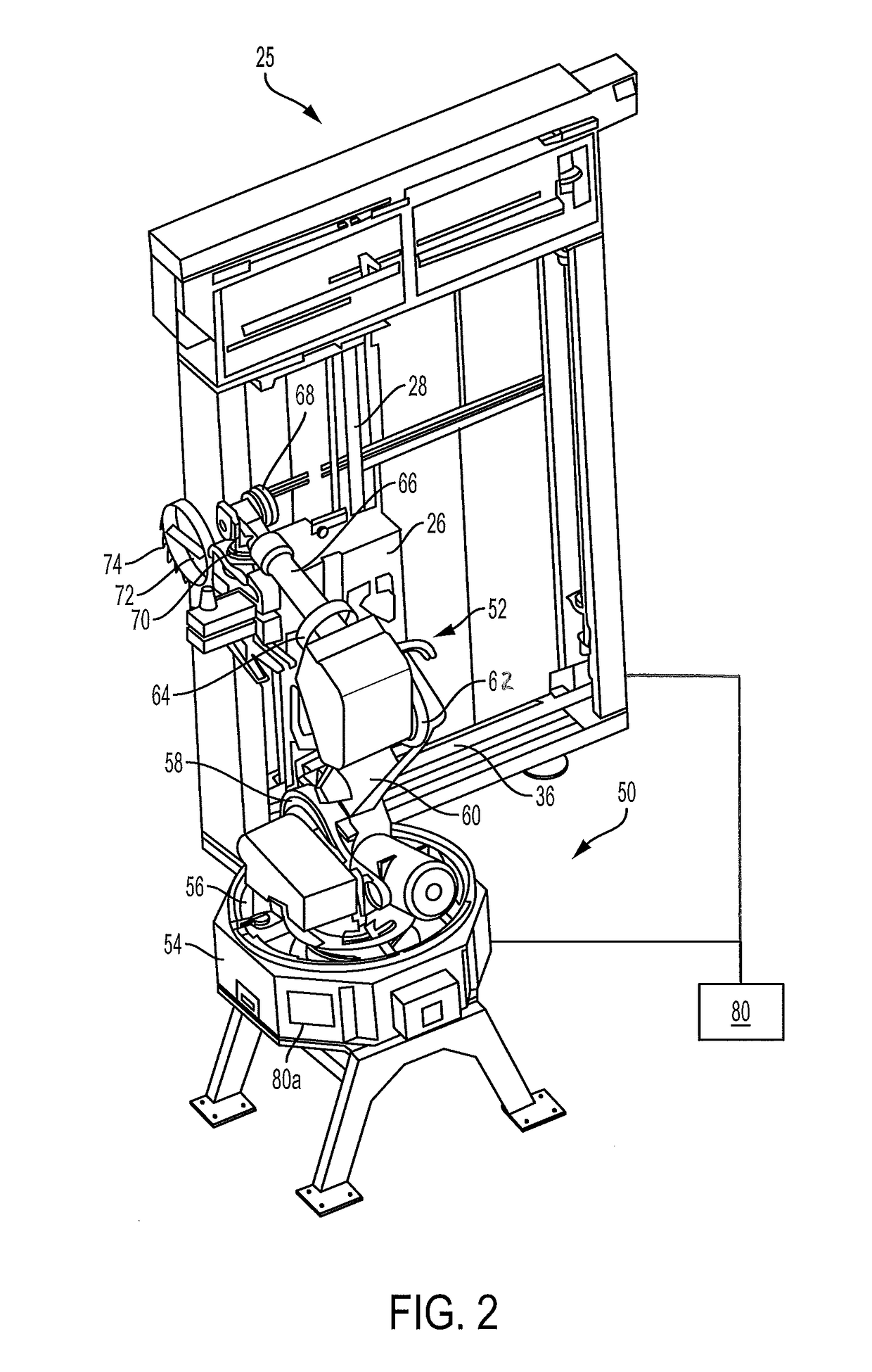

Robotic carcass processing method and system

InactiveUS20170049116A1Keep full controlAnimal feeding devicesSplitting instrumentsRobotic armEngineering

A robotic carcass processing system uses a pair of robotic arms having multiple axes of motion, a saw mounted thereon, and a controller. The controller moves the saw in Cartesian space via inverse kinematics with interpolation control over the multiple axes of the robotic arm to synchronously move the saw relative to a carcass on an assembly line. The controller also determines when one of the robotic arms has moved its saw out of a defined space to indicate that space is clear and to permit the other robotic arm to enter that space. A sensor on the assembly line identifies location of the absence of a supported carcass, a supported carcass that requires special handling, or weight or length of a carcass. The controller sends a signal to the robotic arms to either effect a standard cut or to modify the standard cut at the identified location or carcass.

Owner:JARVIS PROD

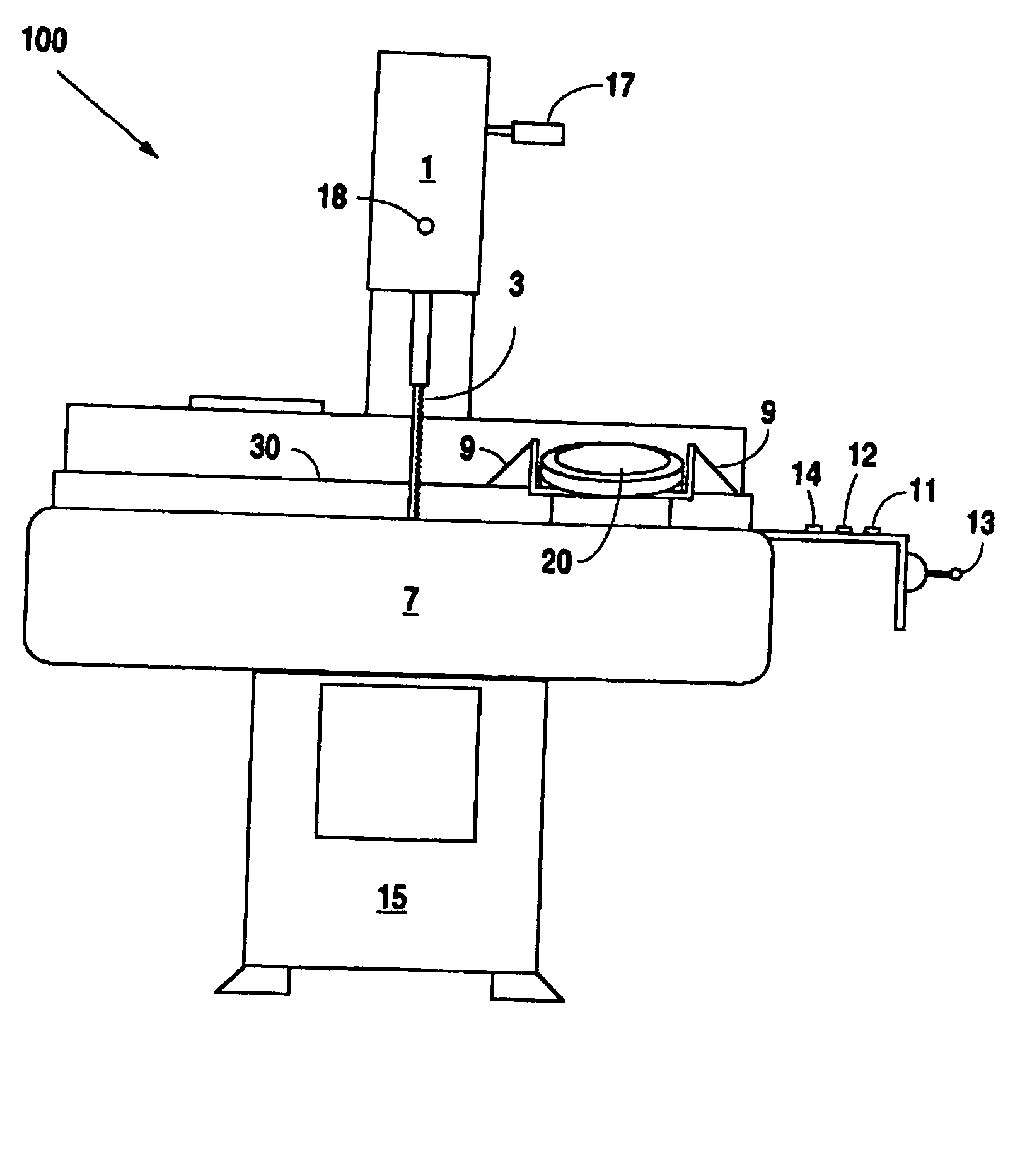

Apparatus and method for cutting meat

InactiveUS20050159094A1Reduce contactReduce injuriesBone cleaning devicesSplitting instrumentsHands freeLaser beams

Apparatus and method for cutting meat that enables a worker to repeatedly and consistently guide a securely clamped carcass through the cutting area of a saw without exposing his or her hands to the saw's cutting implement. The operator sets a carcass in a set of clamps. Tightening of the clamps, alignment of the carcass with respect to the saw blade, and movement of the clamps and carcass through the cutting area is done with controls located on the apparatus at locations safely remote from the cutting area. Alignment, done with a laser beam, is precise and repeatable. Conveyors built into the apparatus carry the useful and scrap parts of the carcass away for convenient and safe disposal. The hands-free cutting operation minimizes human contact with the meat being cut, thereby enhancing hygiene.

Owner:DUNIVAN STEVEN W

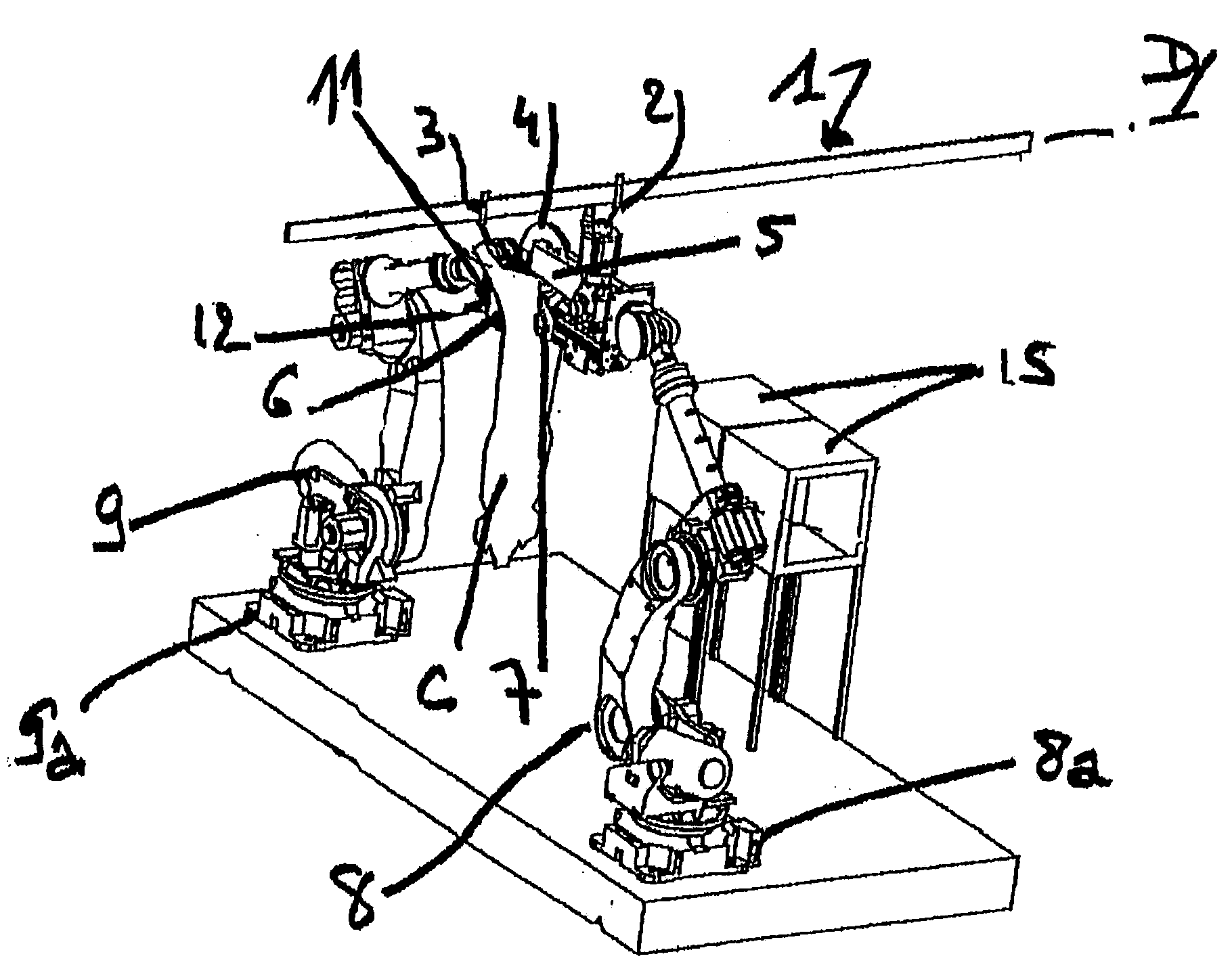

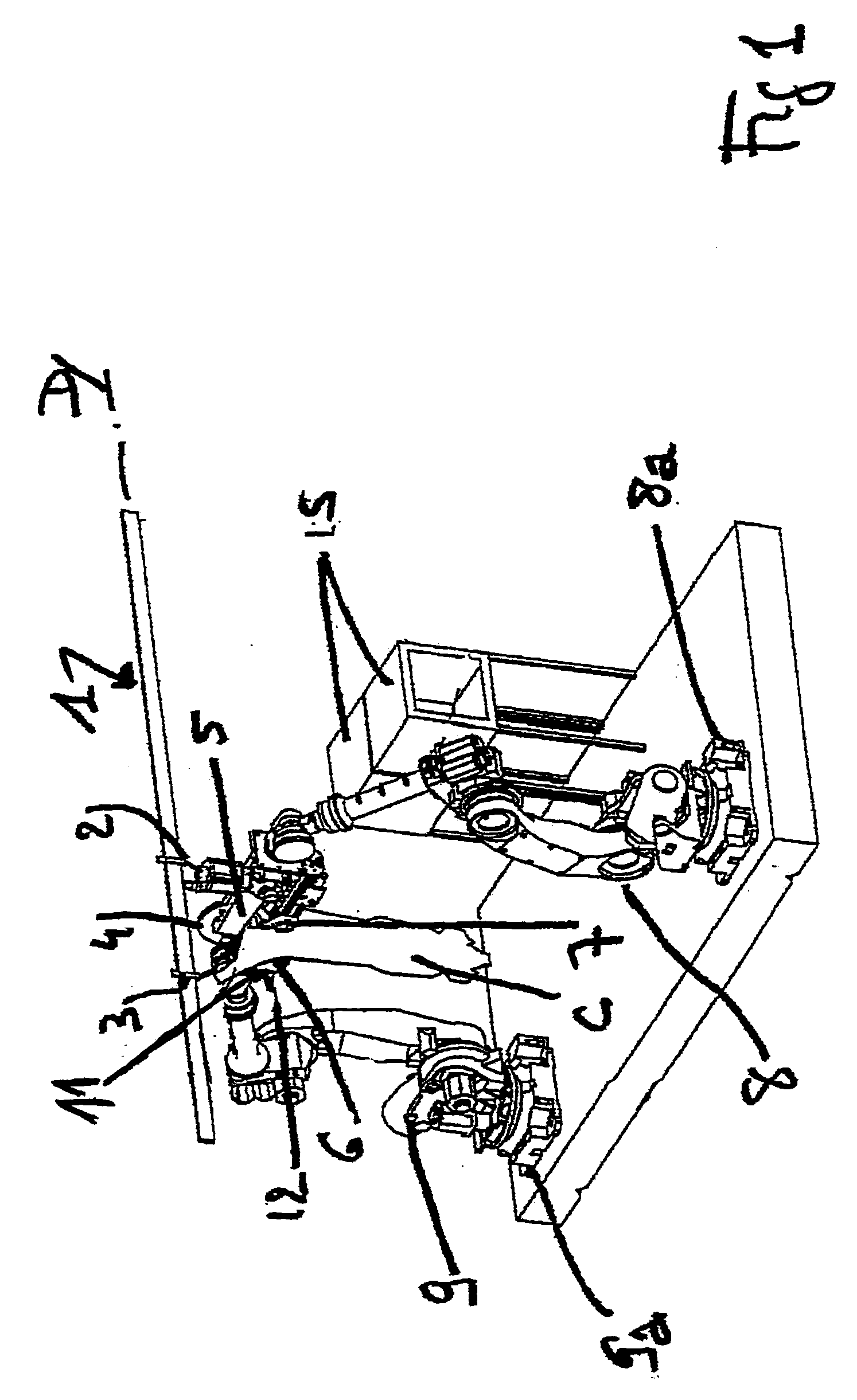

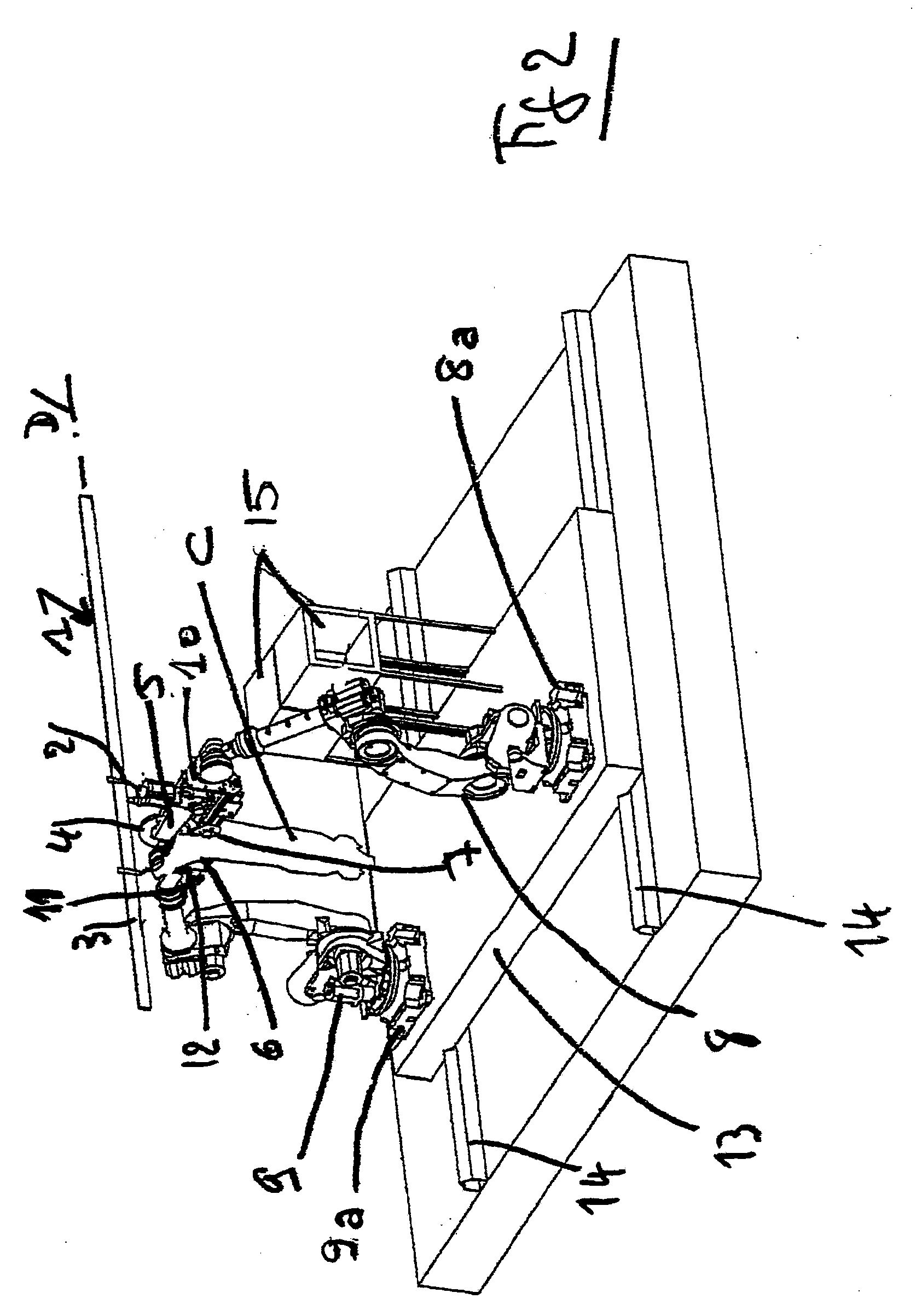

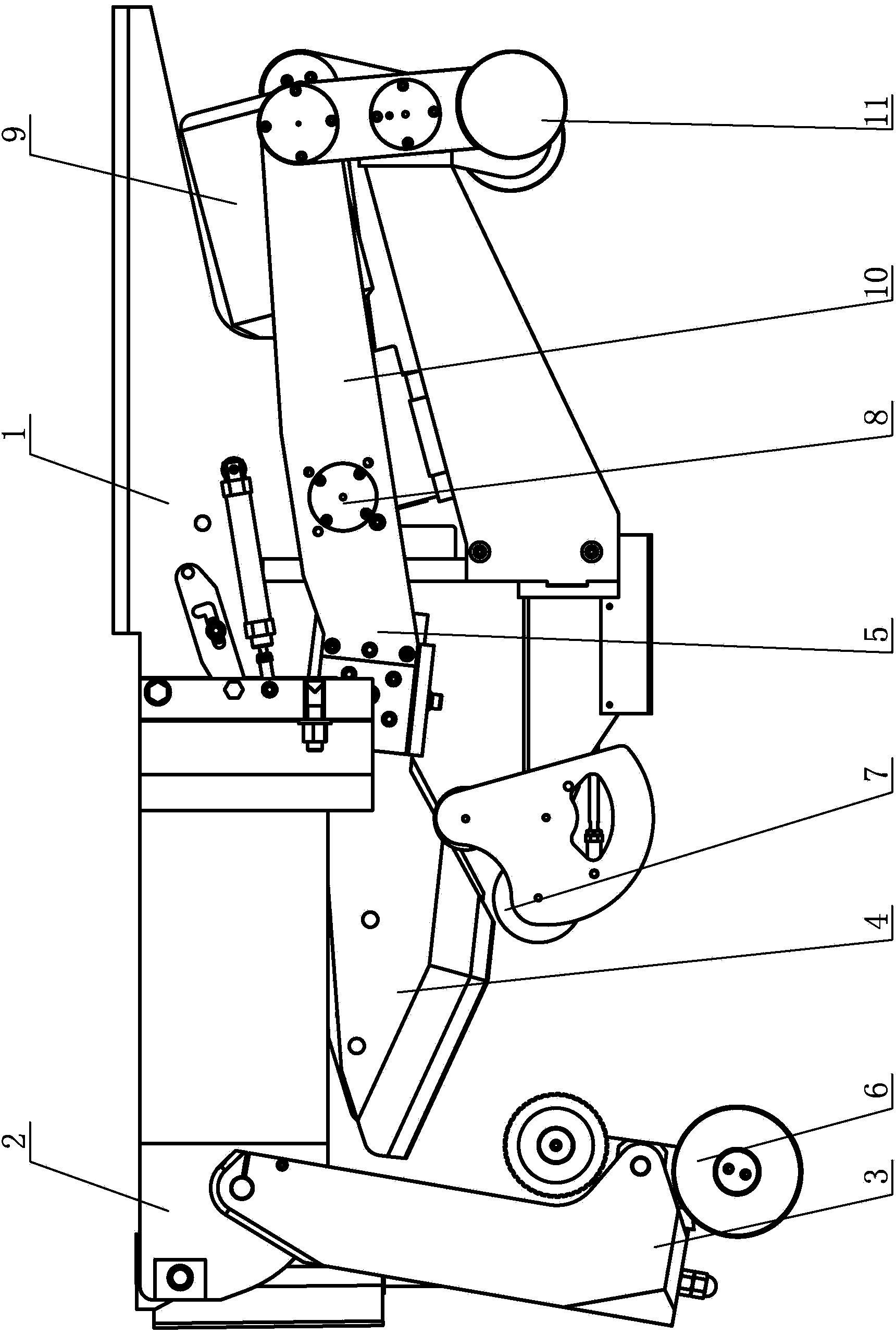

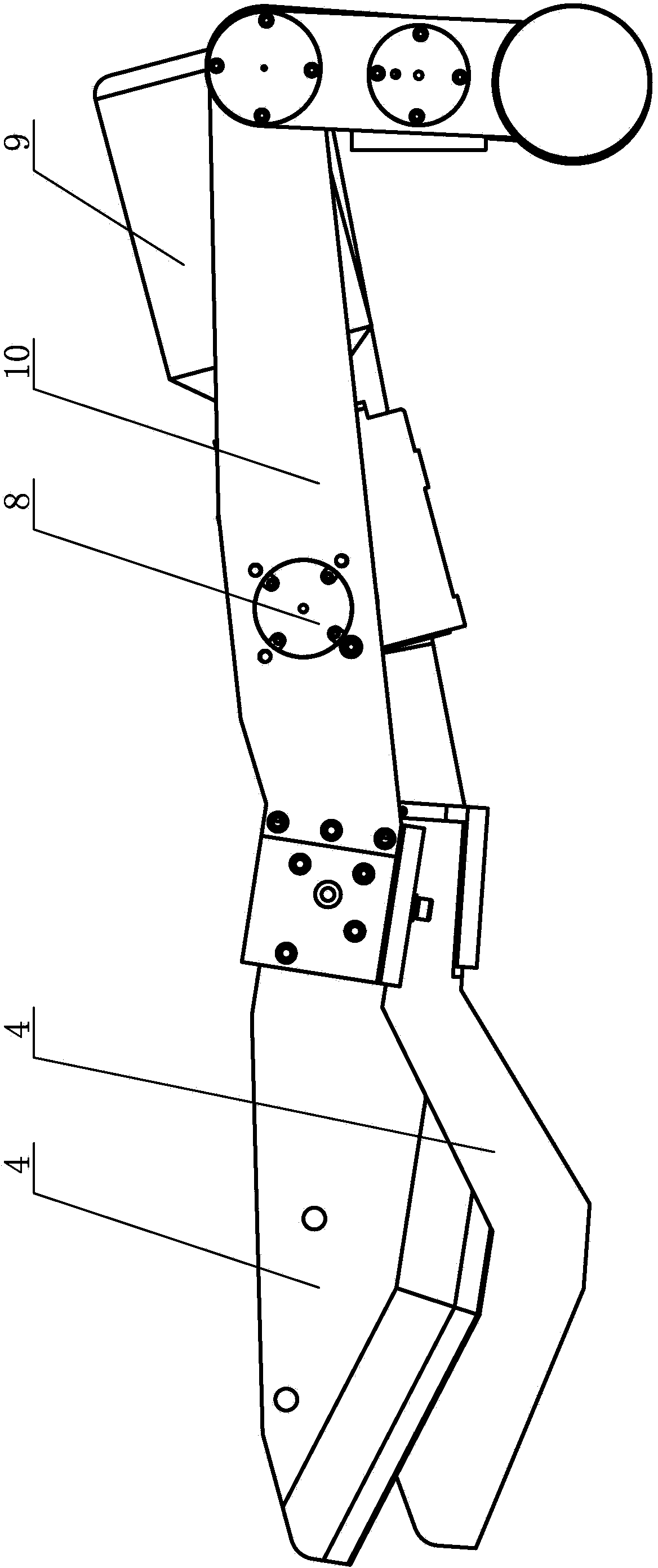

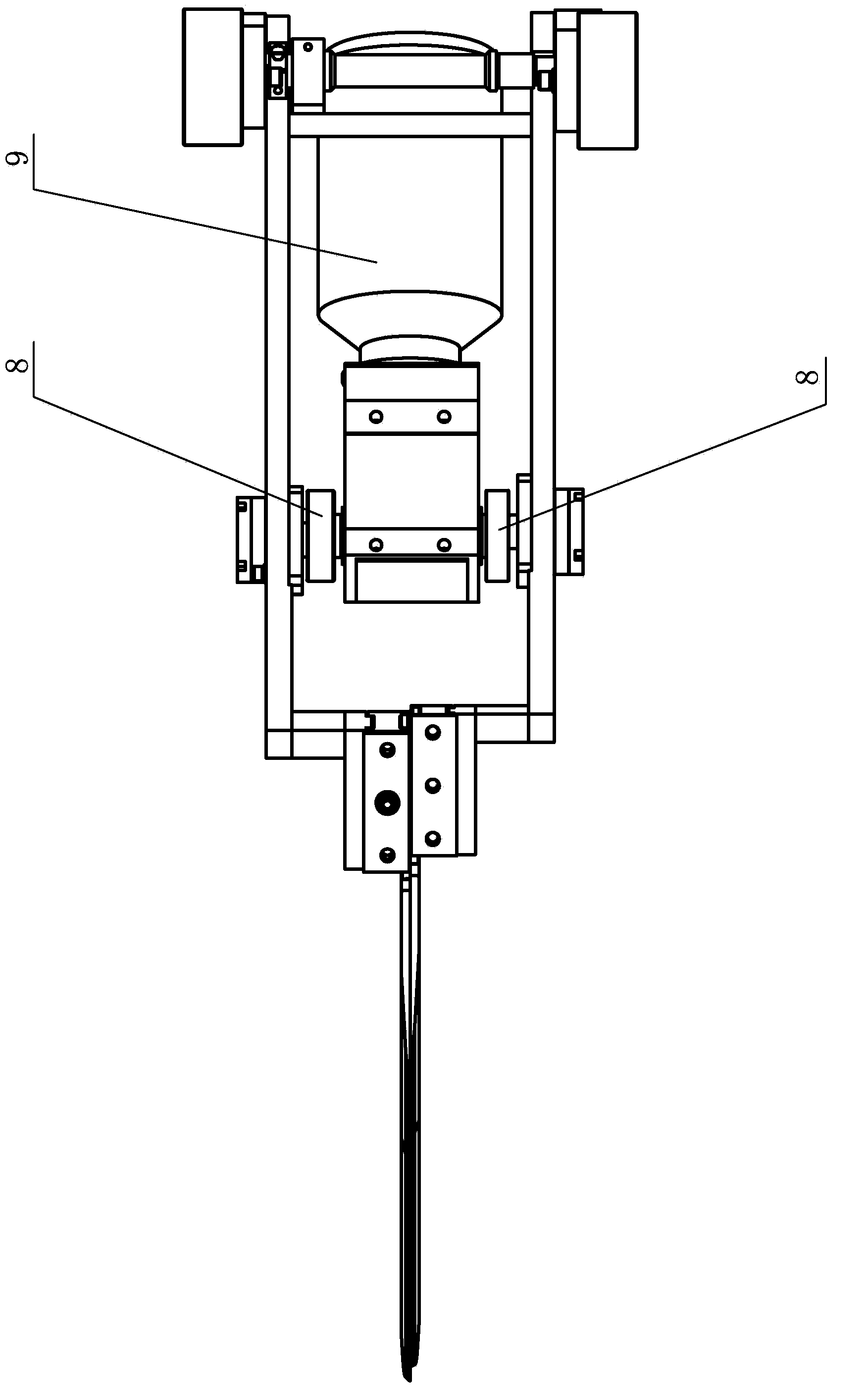

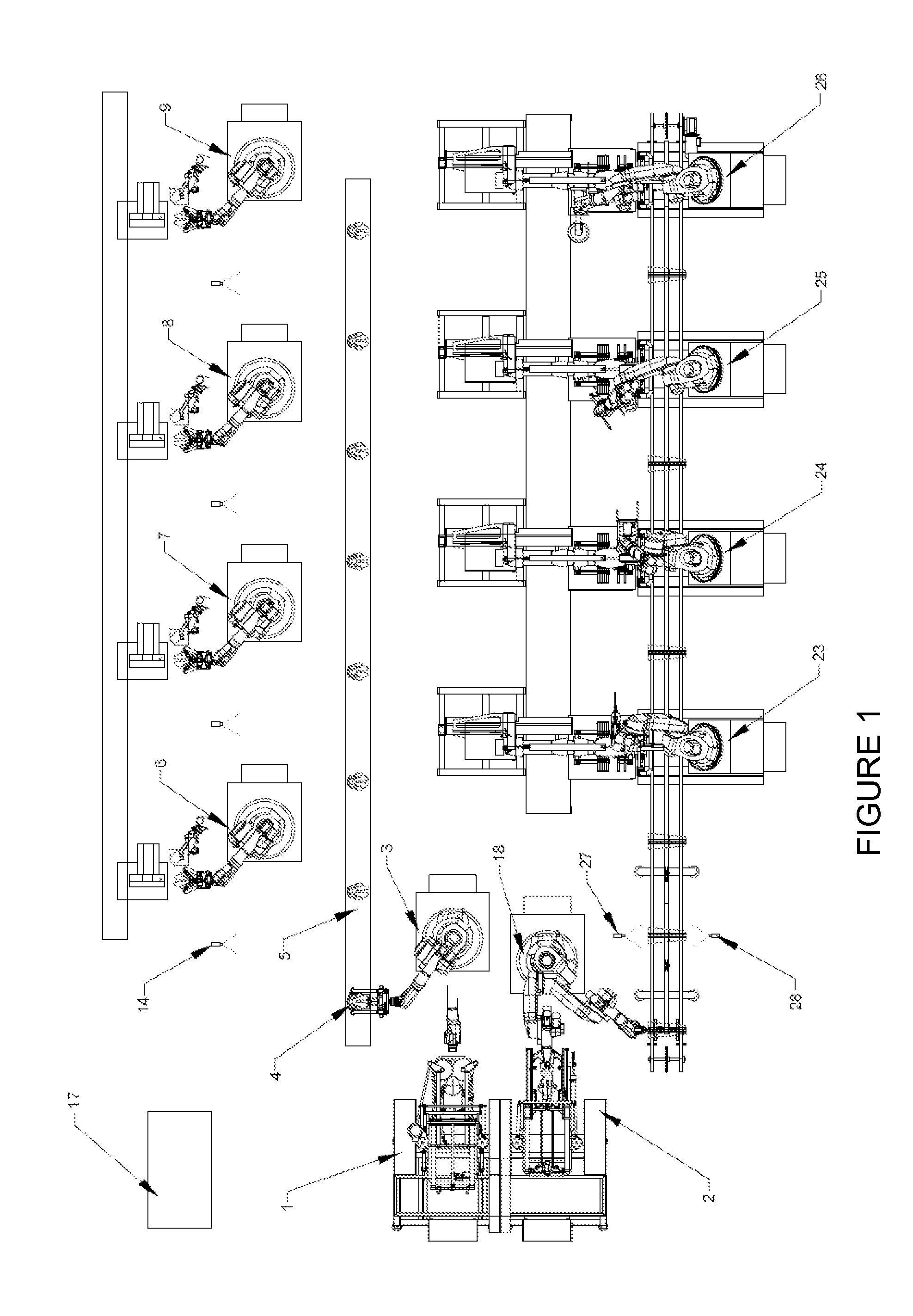

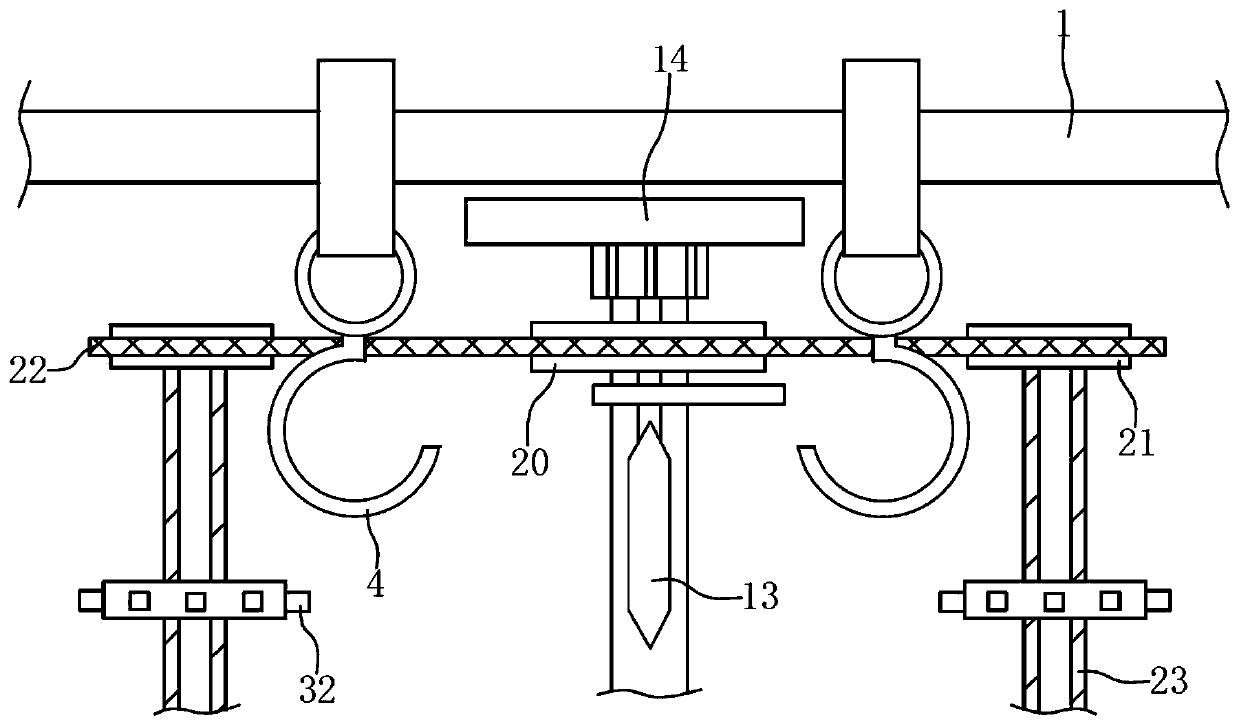

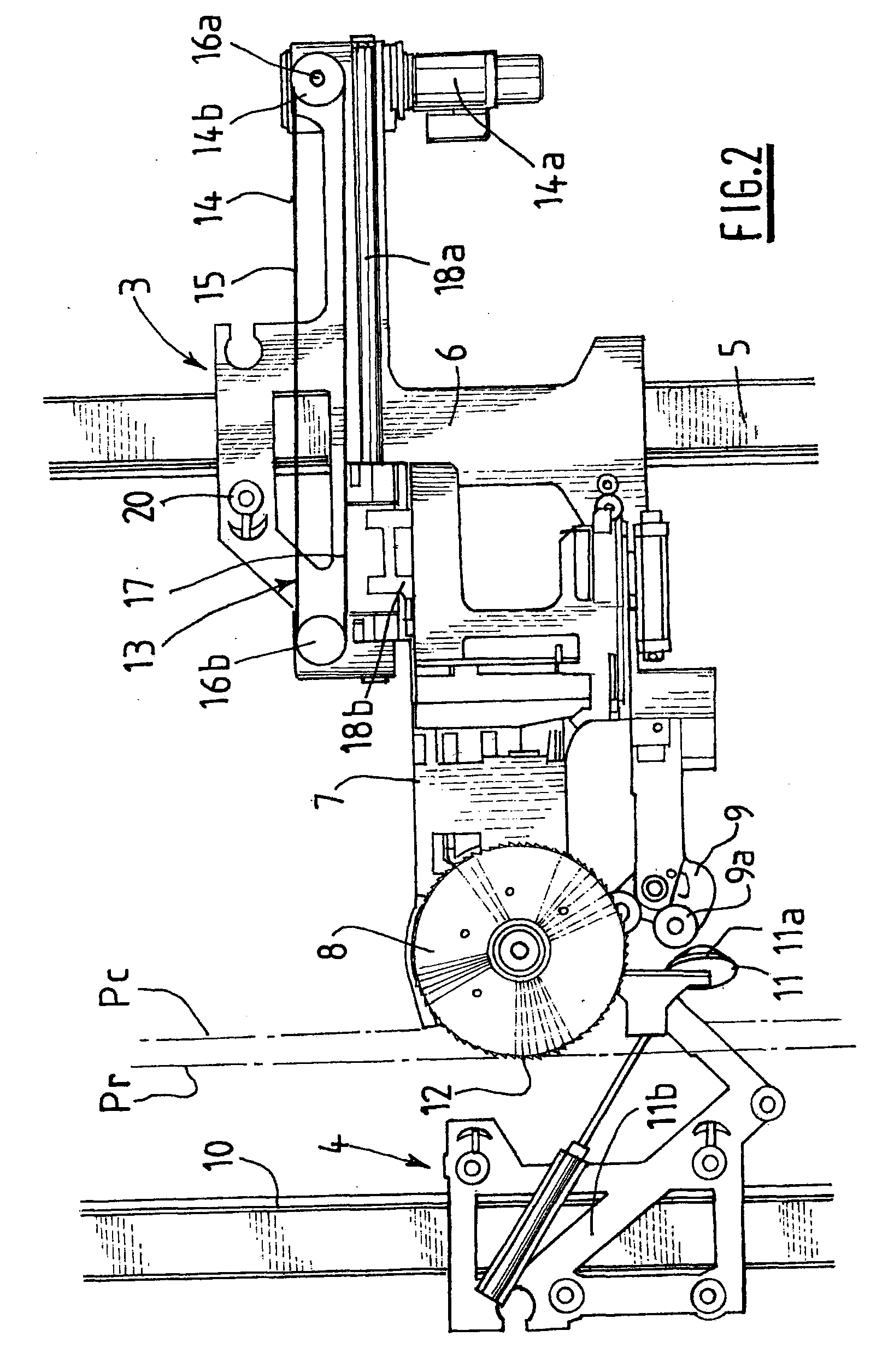

Installation for splitting hog carcasses or equivalent comprising one or more robots

InactiveUS20090124186A1Easy to cleanSplitting instrumentsMeat processing plantsEngineeringMechanical engineering

The installation for splitting hog carcasses or equivalent, comprises support means (1) for carcasses having components (2) for suspending carcasses, a splitting tool (4) supported by a splitting head (5), displaced in a splitting plane, a dorsal support device (6) and a ventral support device (7), suitable for being displaced in the splitting plane and for providing a fixed and predetermined relative positioning of the carcass in relation to the splitting plane, support means for the splitting head (5), support means for the dorsal support device (6) and for the ventral support device (7), motor means for displacing the splitting tool (4), means for displacing the splitting head (5), means for displacing the dorsal support device (6) and the ventral support device (7), control means, and at least one robot (8, 9, 16), supporting at least one portion of the support means for the splitting head (5), of the support means for the dorsal support device (6) and of the support means for the ventral support device (7), and constituting at least in part means for displacing the means that same supports: a splitting head (5), a dorsal support device (6) and ventral support device (7).

Owner:DURAND INT

Apparatus and method for filleting beheaded and gutted fish

ActiveUS8298050B2Improved centringSimpler and cheapSplitting instrumentsFish filletingEngineeringSaddle-shaped

Owner:NORDISCHER MASCHINENBAU RUD BAADER GMBH CO KG

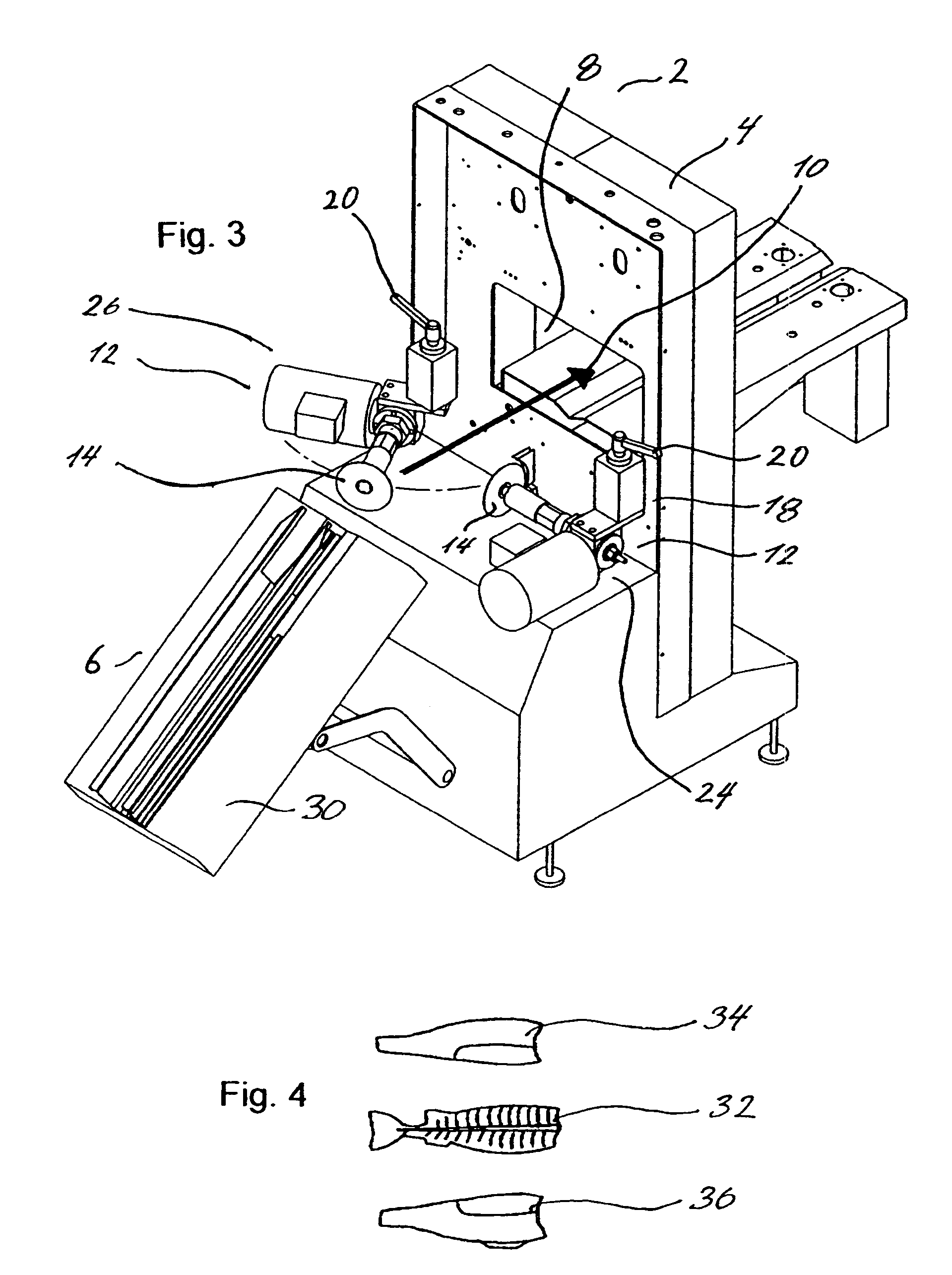

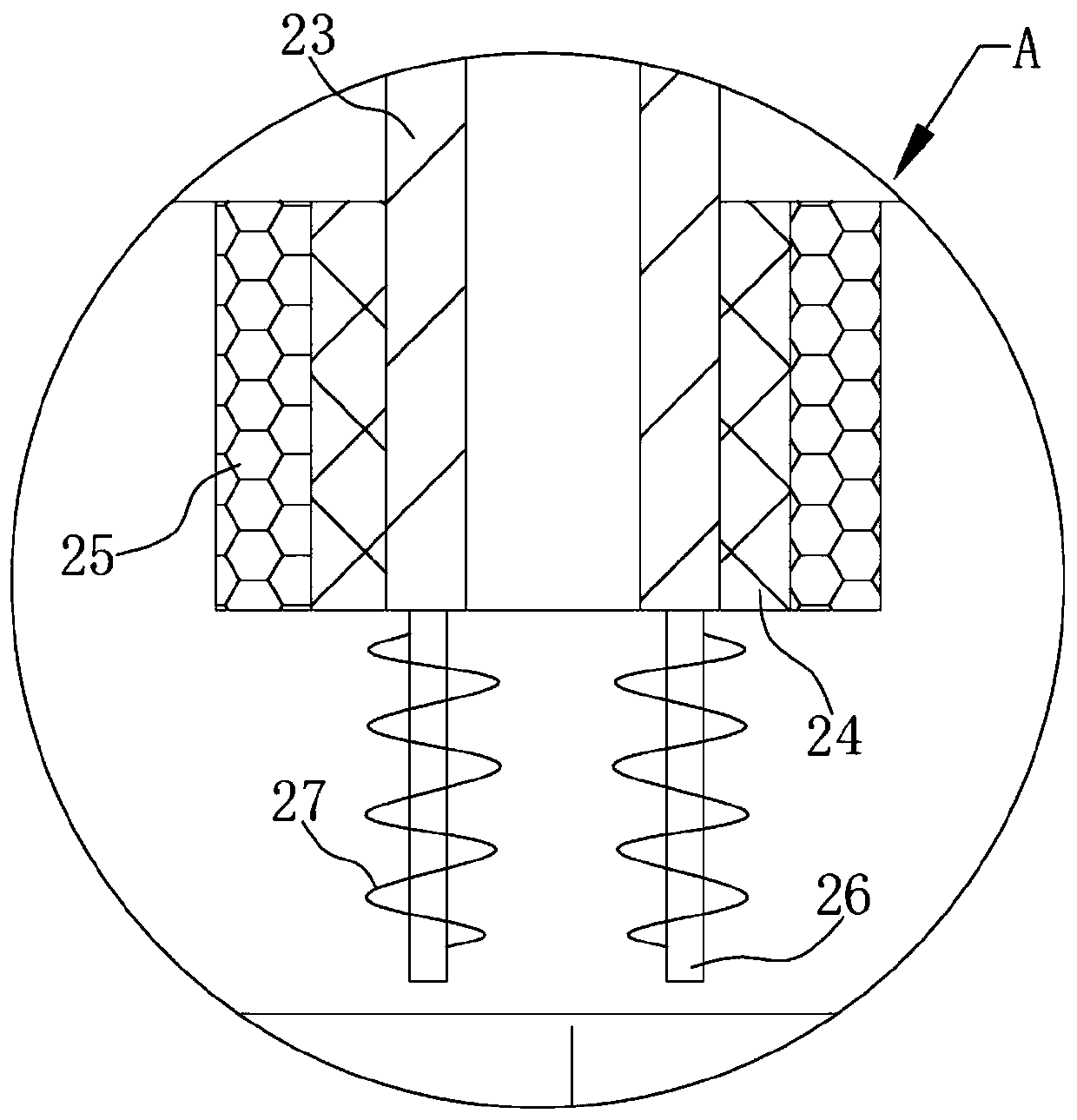

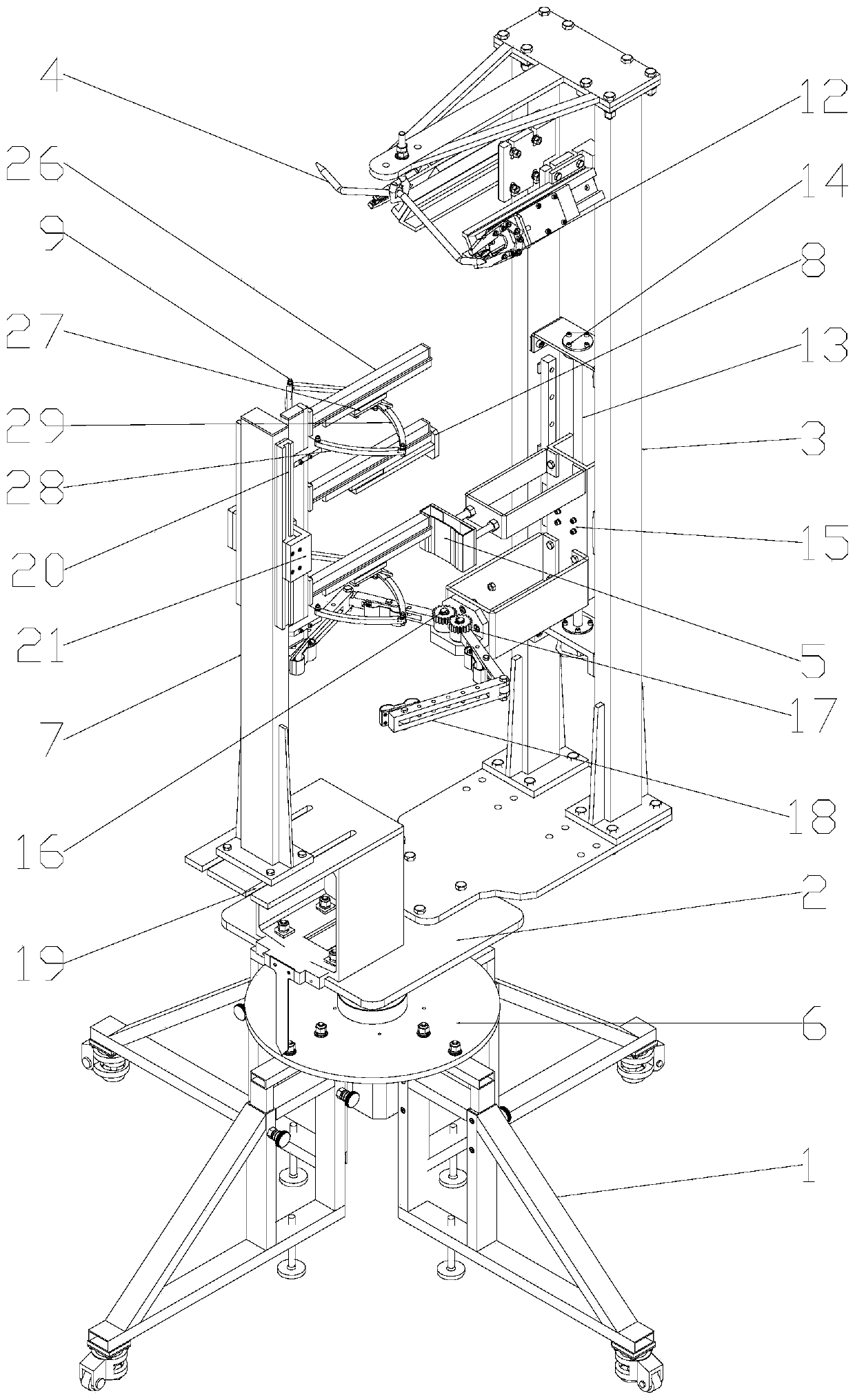

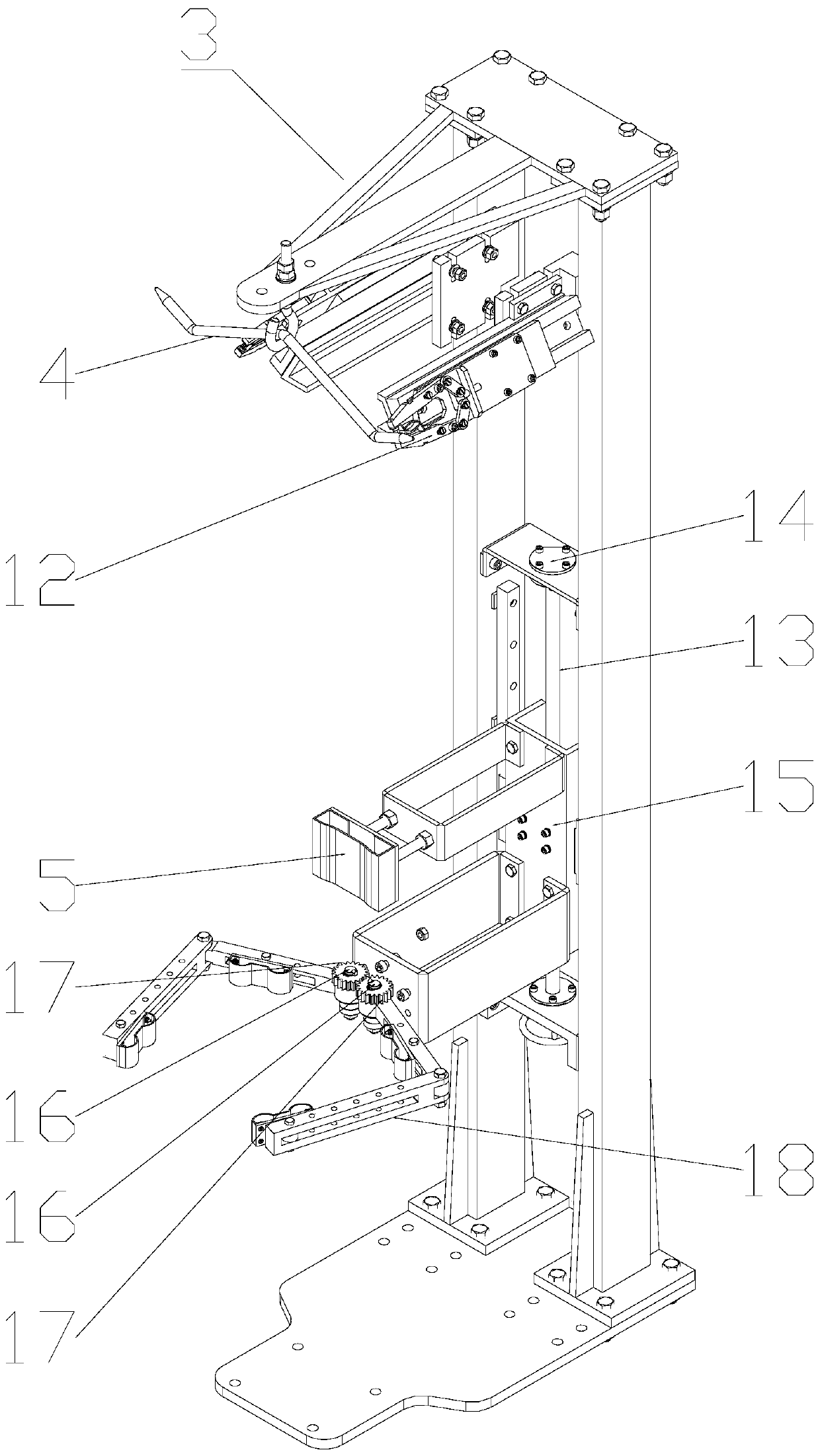

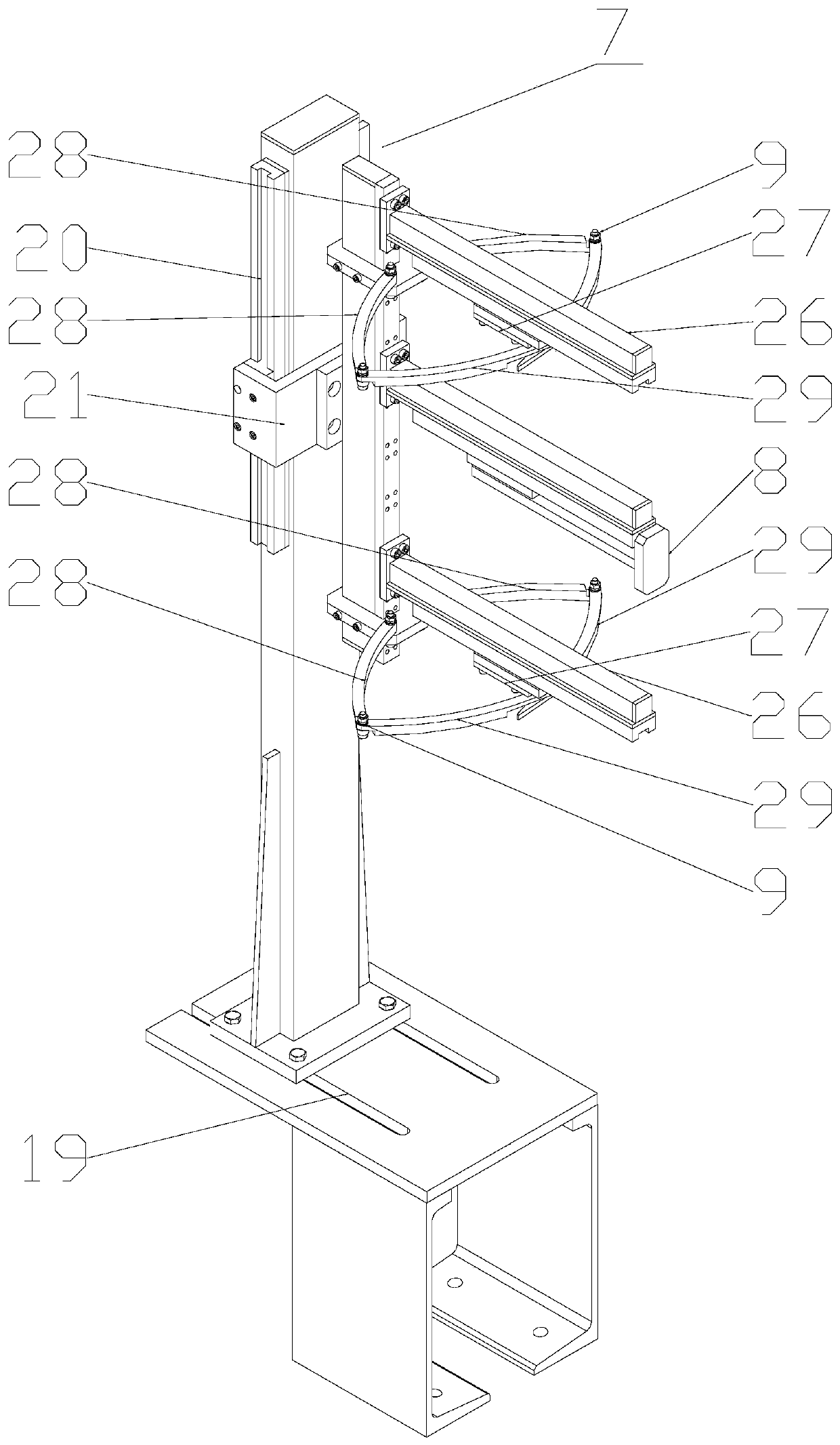

Automatic fifty-fifty splitting robot with single-shaft dual-crank rocking bar mechanism

InactiveCN103444832AReduce severe frictionAvoid violent frictionSplitting instrumentsMechanical energyEngineering

The invention relates to an automatic fifty-fifty splitting robot, in particular to an automatic fifty-fifty splitting robot with a single-shaft dual-crank rocking bar mechanism, and aims to solve the problem that short pillars and guide grooves of existing fifty-fifty splitting equipment slide correspondingly, a large amount of mechanical energy is consumed, noise is produced, and wearing of cutters is uneven. According to the automatic fifty-fifty splitting robot, a livestock supporting mechanism is mounted at the front end of a frame, a motor is mounted on the frame, two cranks are arranged parallelly in a same row, the upper end of each crank is connected to one end of a crankshaft, the crankshaft is connected to a rotary shaft of the motor through a bevel gear pair, two crank rocking bar mechanisms are arranged parallelly in a same row, each splitting cutter is connected to the front end of a rocking bar of one crank rocking bar mechanism, each rocking bar is hinged with the frame, and the lower end of each crank is connected to one corresponding crank rocking bar mechanism. The automatic fifty-fifty splitting robot is used for cutting livestock.

Owner:HARBIN INST OF TECH

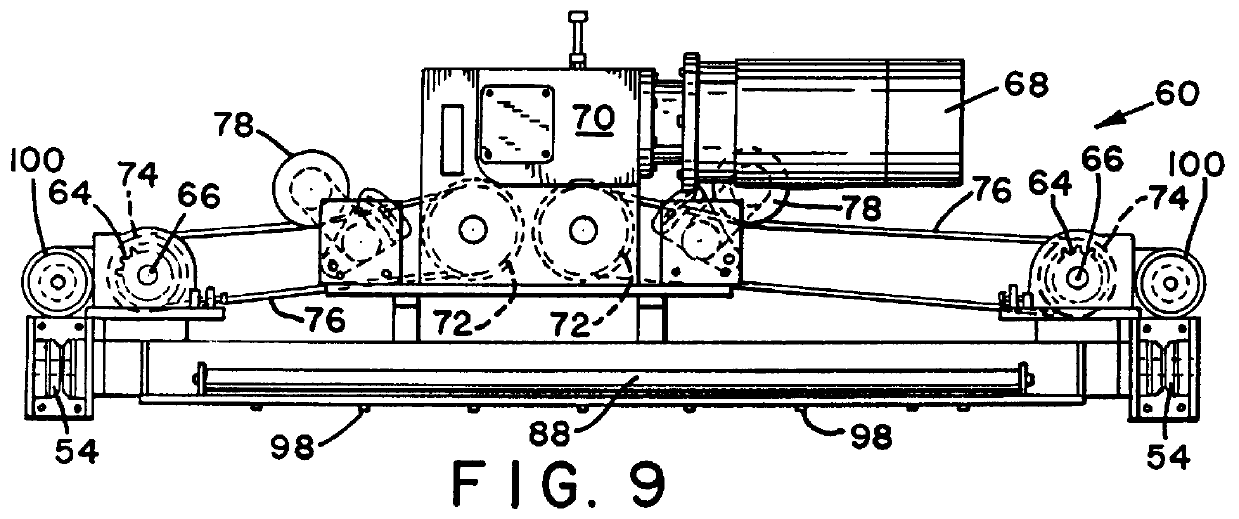

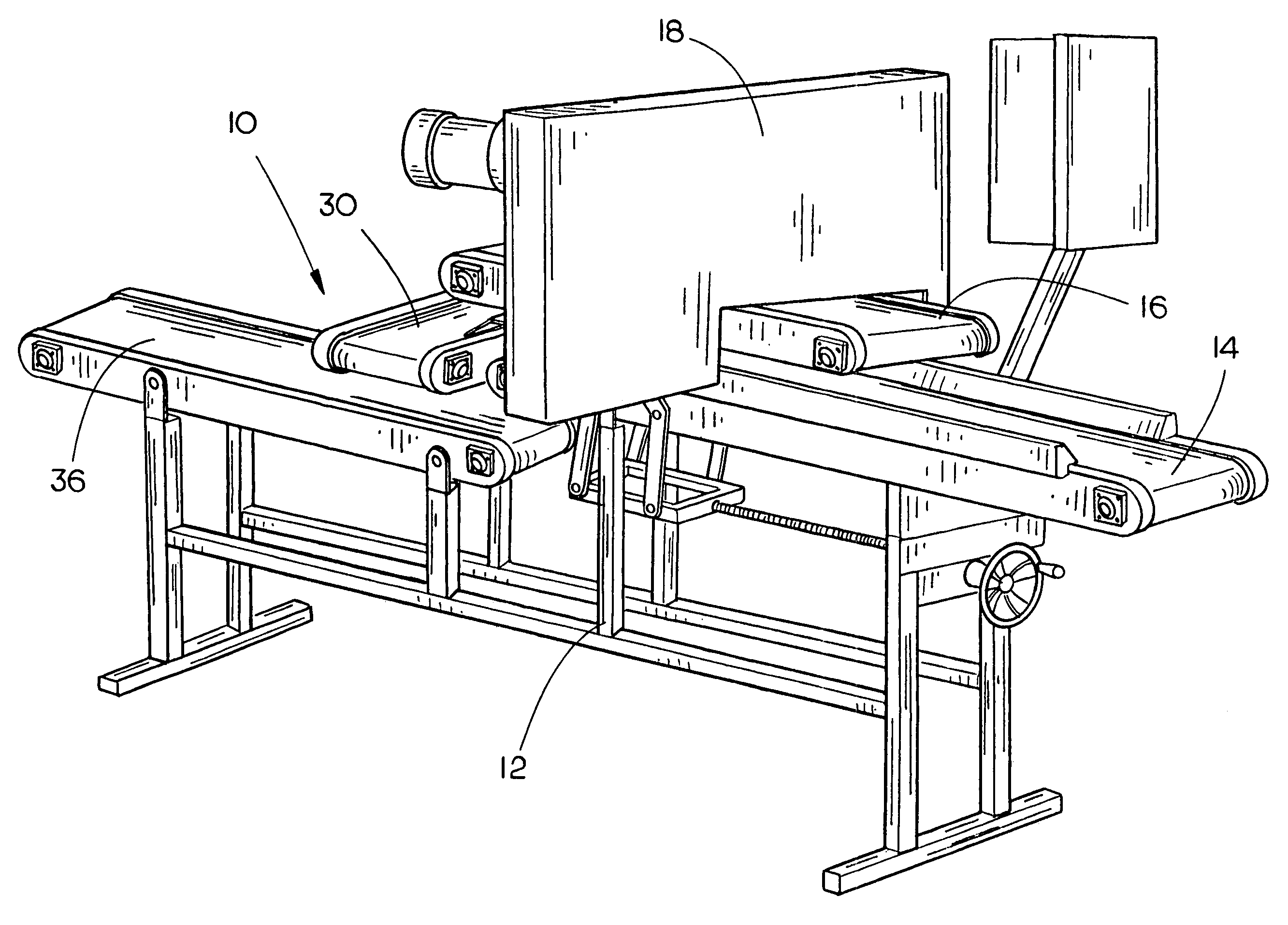

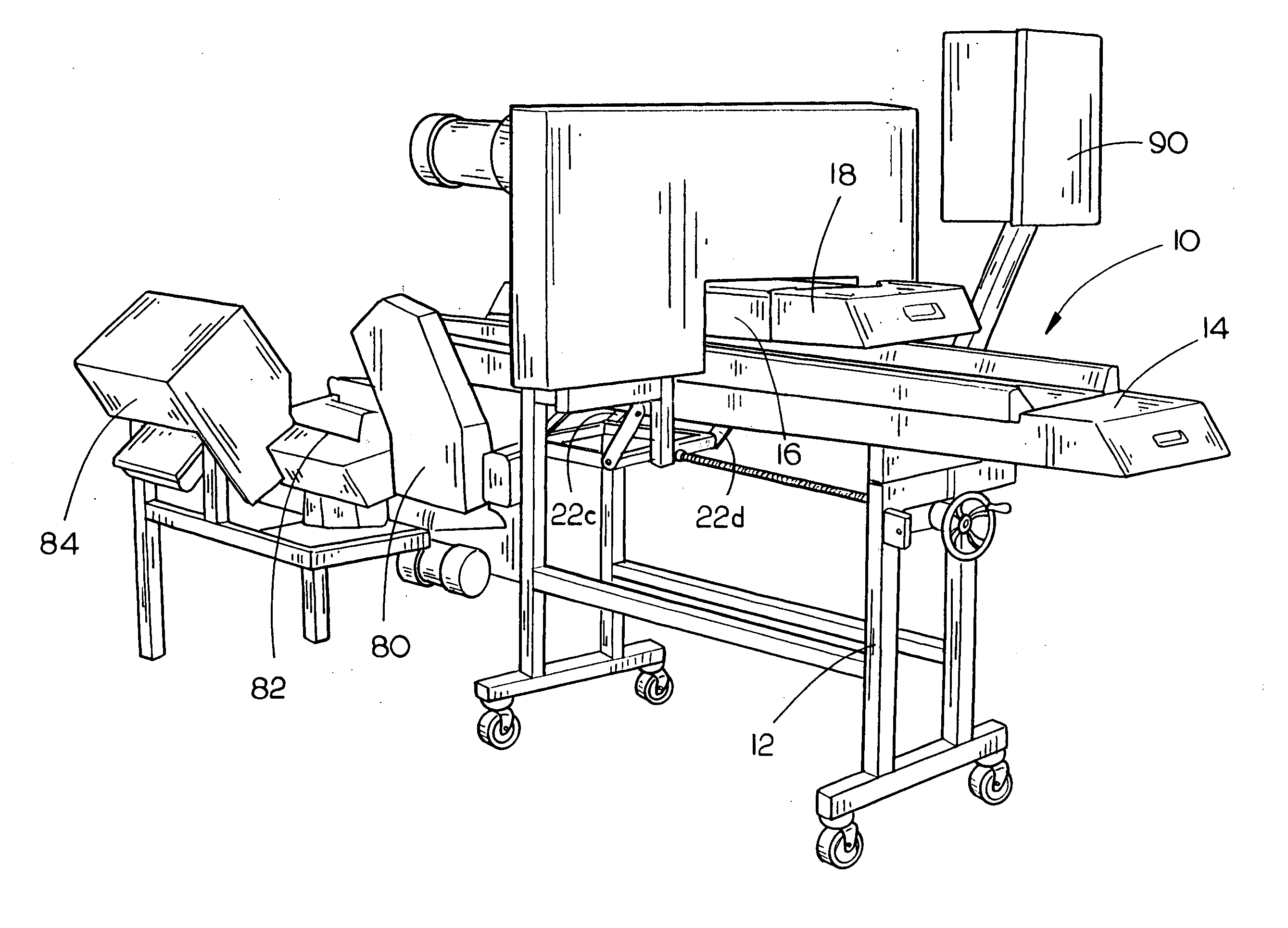

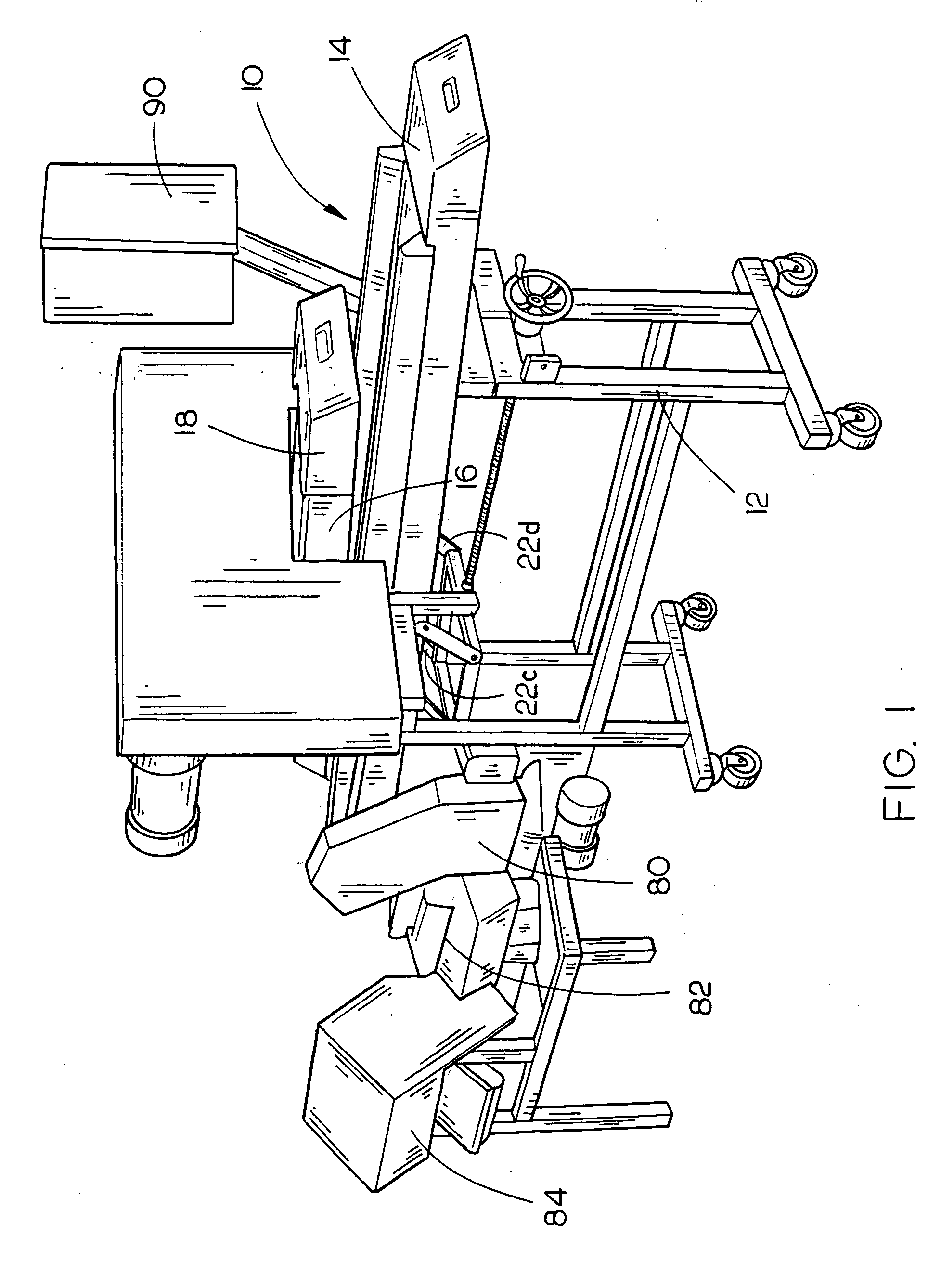

Horizontal Meat Slicer with Bandsaw Blade

InactiveUS20080223228A1Improve cut qualityEliminates the concern of the meat product accidentally twisting or rotatingMetal sawing devicesFruit stoningEngineeringConveyor belt

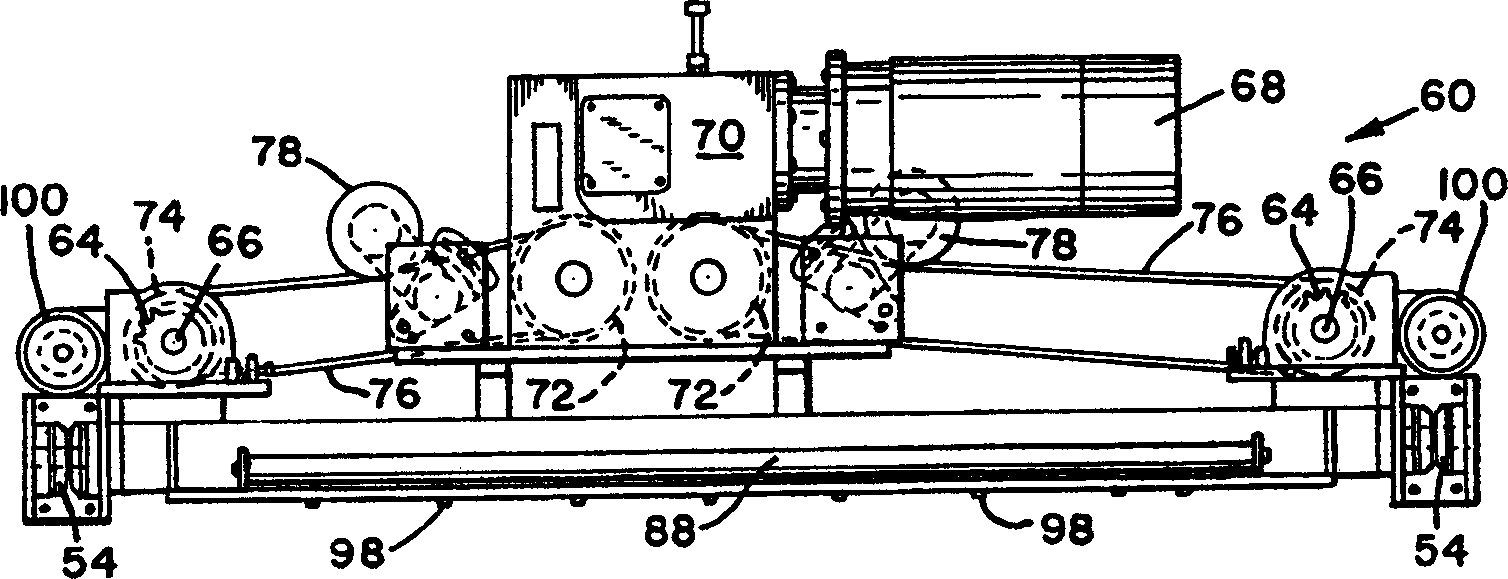

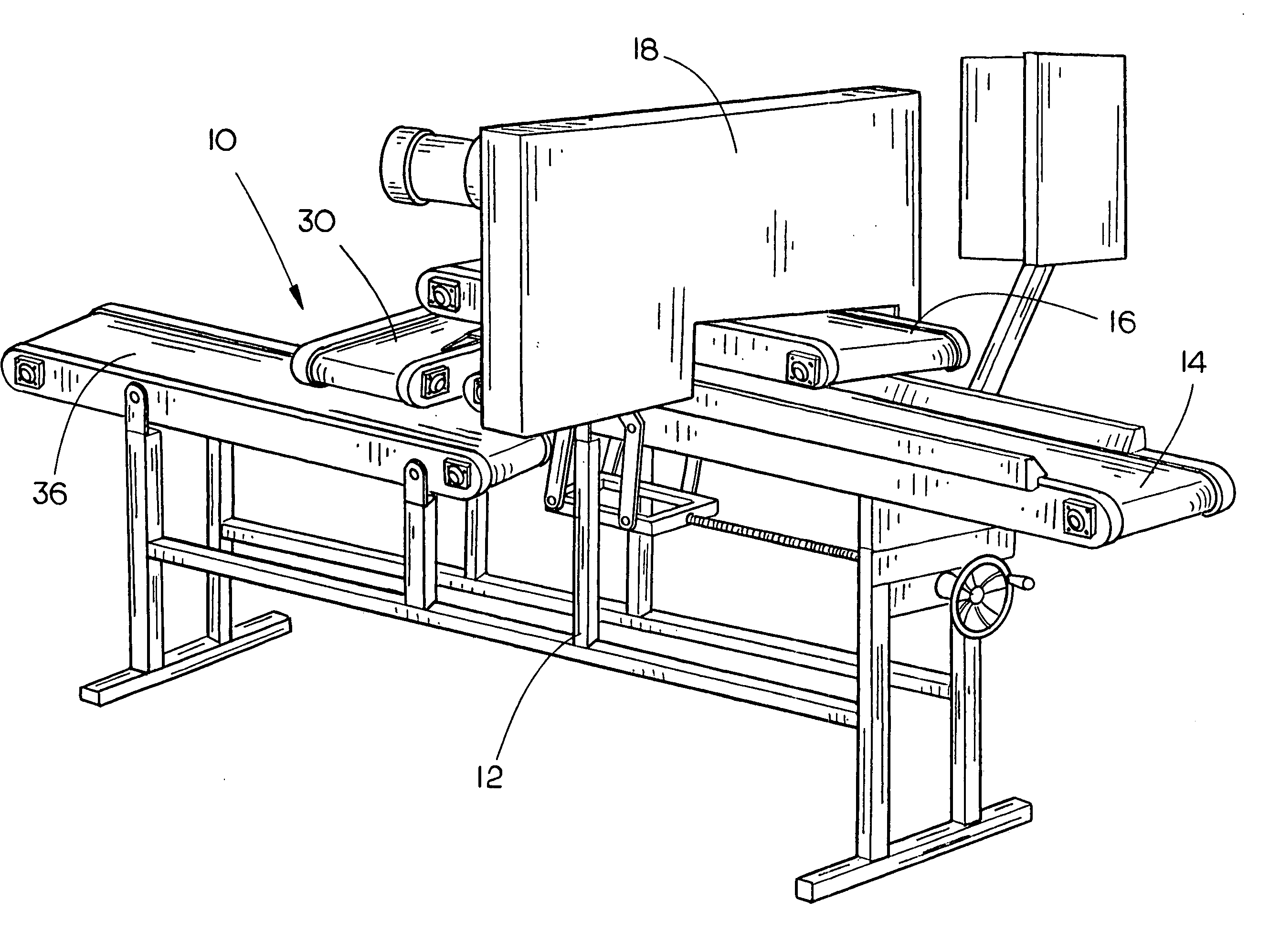

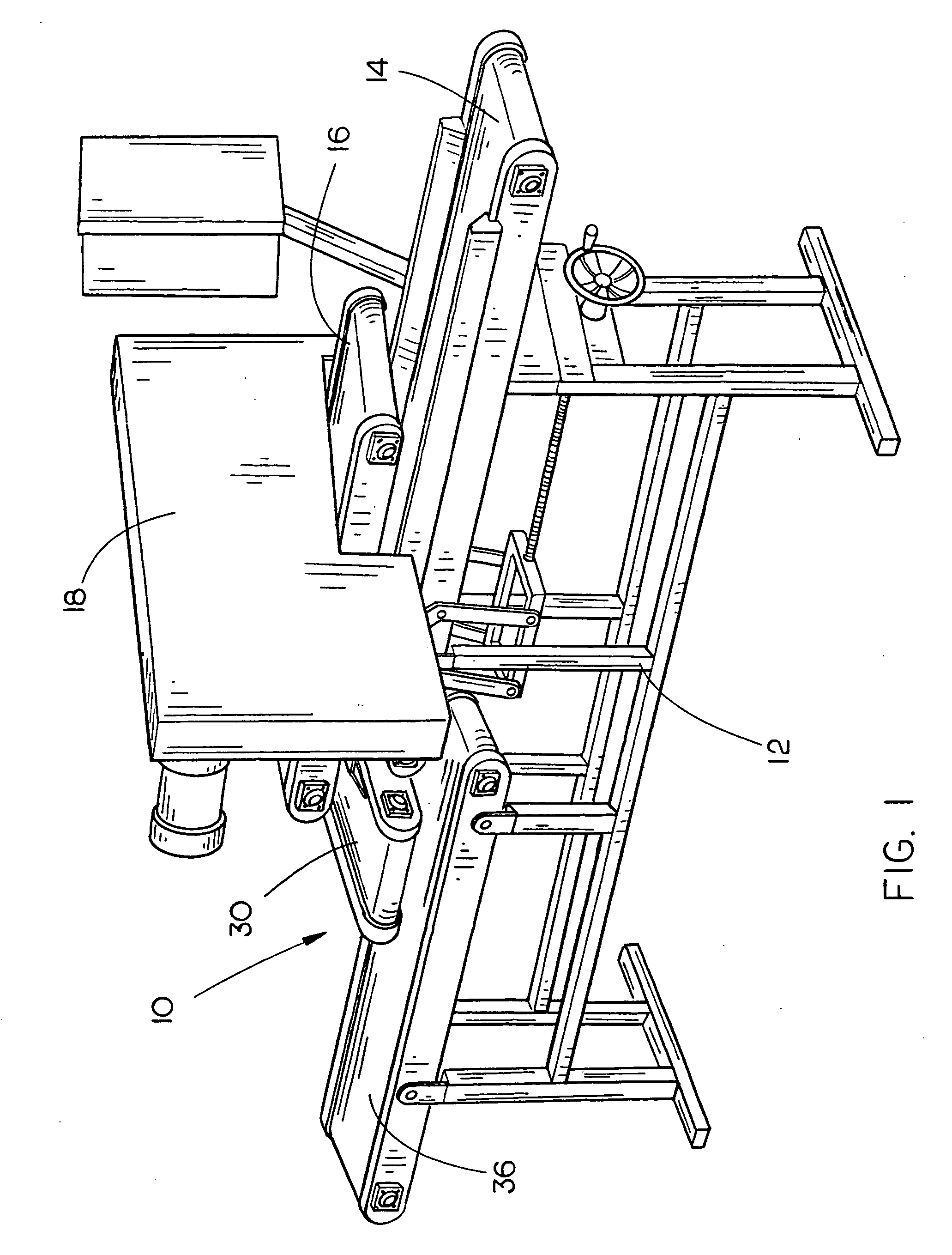

A horizontal meat slicer includes a frame and a lower conveyor belt having forward and rearward ends, the lower conveyor belt operative to receive a meat product thereon and transport it into and through the device. An upper pressing conveyor belt includes forward and rearward ends, the upper pressing conveyor belt and the lower conveyor belt cooperating such that meat product is compressed between the lower conveyor belt and the upper pressing conveyor belt. At least one bandsaw blade is rotatably mounted on the frame, a cutting section of the bandsaw blade traveling between the upper belt and lower belts. Finally, at least one drive device such as a motor is operatively connected to each of the conveyor belts and the bandsaw blade to drive them to pull the meat product through the device and cut the meat product via the cutting edge of the bandsaw blade.

Owner:BIGGS HENRY +1

Automated saw for splitting carcasses

An automated saw for high speed splitting of suspended carcasses, such as hog carcasses, through the backbone as the carcasses continuously move along a carcass rail includes a splitting station and a back roller station located on opposite sides of the carcass rail. The splitting station includes a splitting saw that can be driven in three directions, including horizontally towards a carcass to begin cutting, vertically down to make the cut and horizontally parallel to the carcass rail to match the speed of the moving carcass as the cut is made. A guide roller carried by the splitting station positions the backbone in a known position relative to the saw. The back roller station includes a back roller for positioning the carcass relative to the saw as the cut is made. The back roller is also movable in three directions, including horizontally in to contact the carcass, vertically down, and horizontally parallel to the carcass rail to match the motion of the saw. The back roller and saw are structurally independent, but are accurately driven to maintain the relative position of the saw and the back roller as the cut is made.

Owner:JARVIS PROD

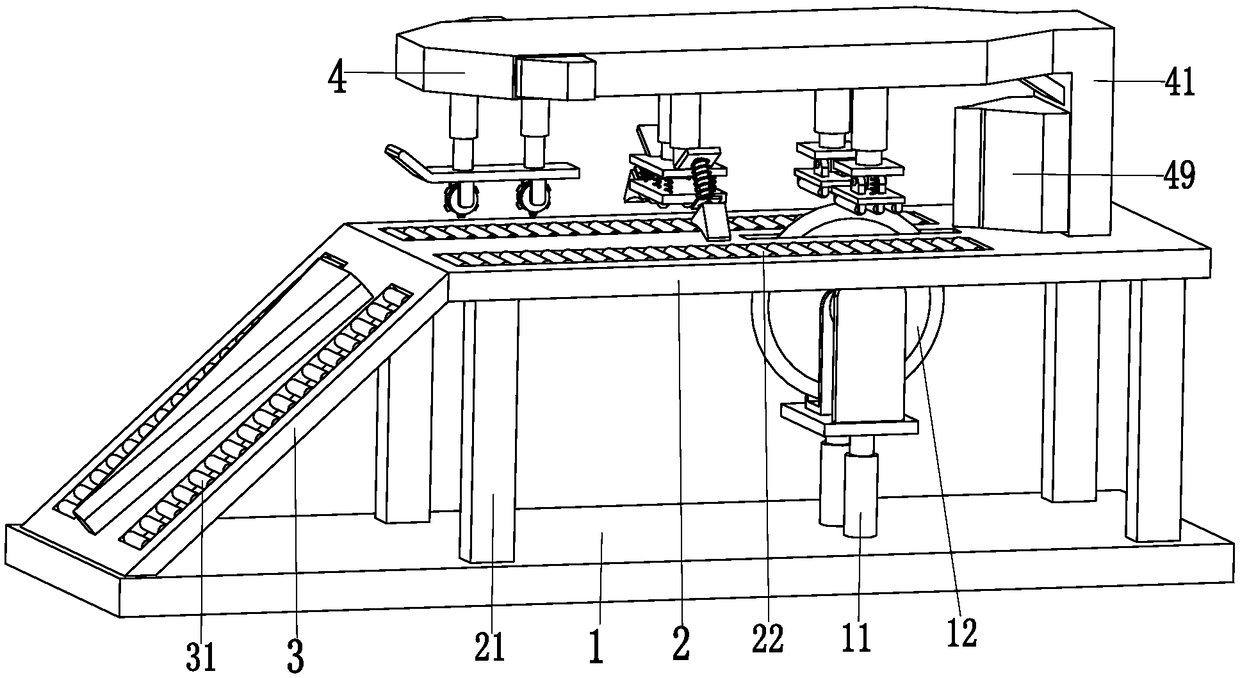

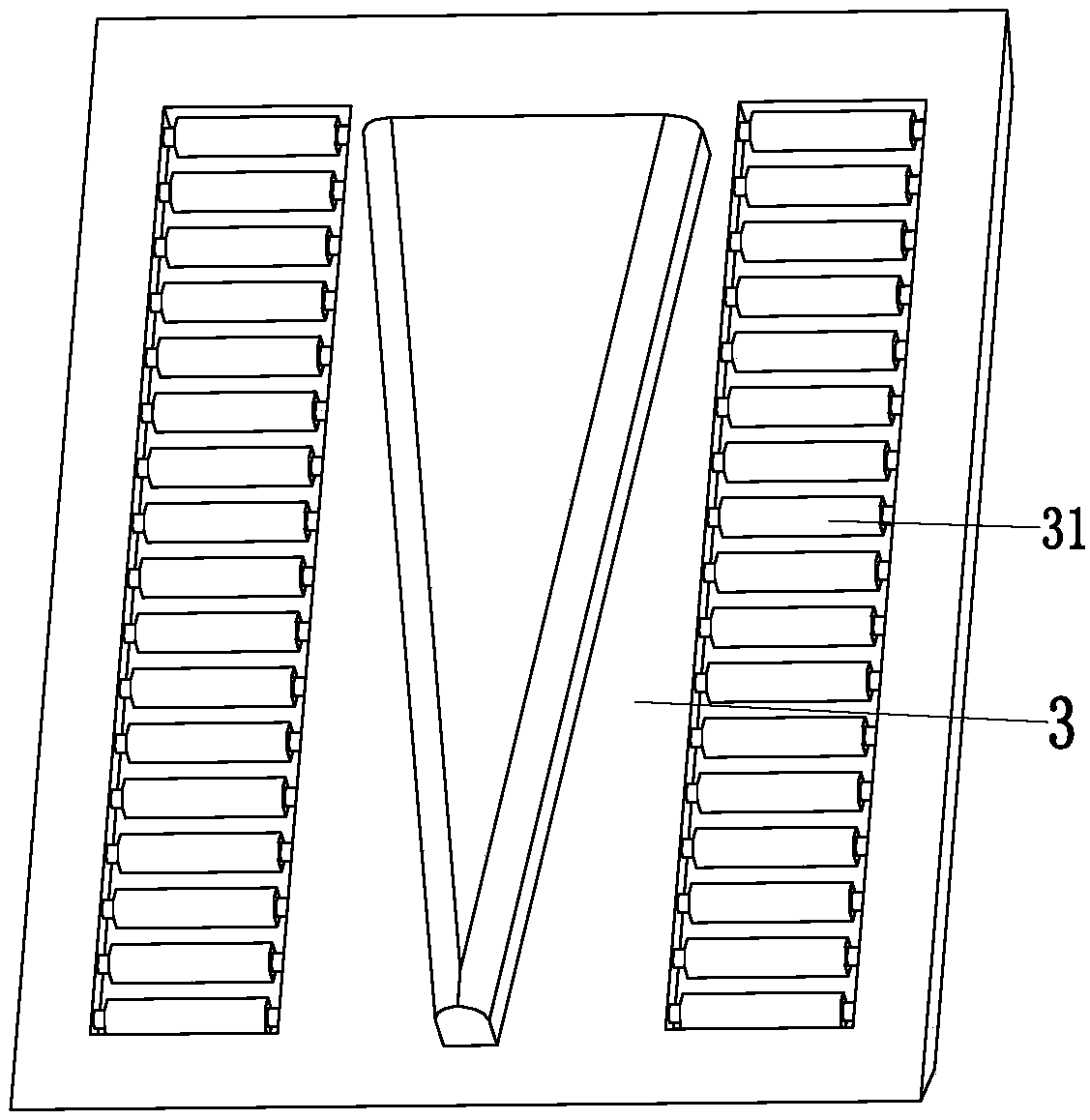

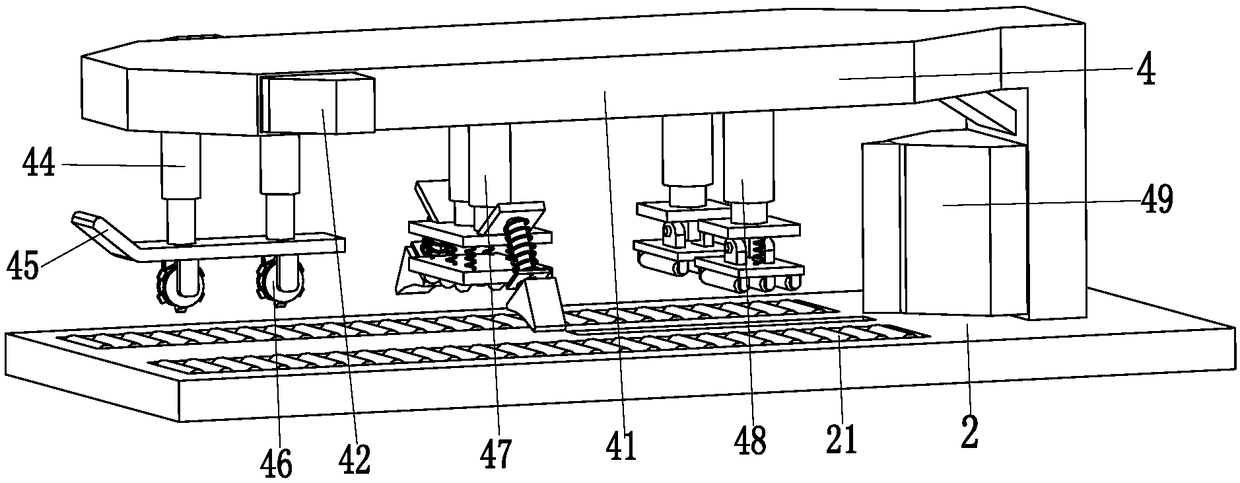

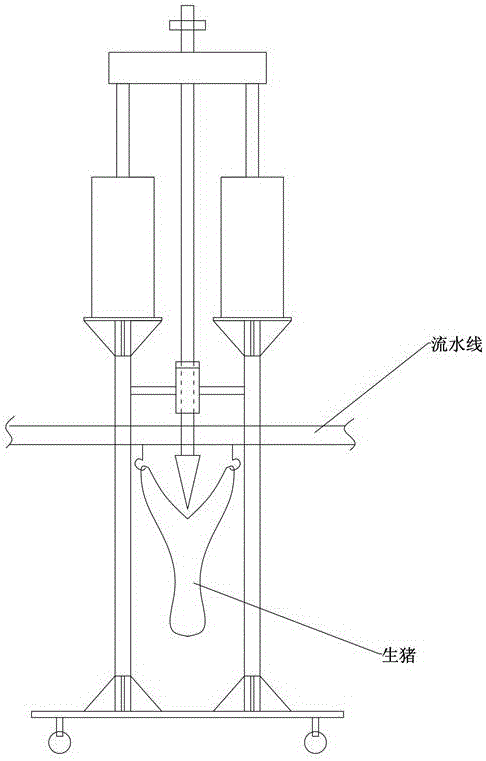

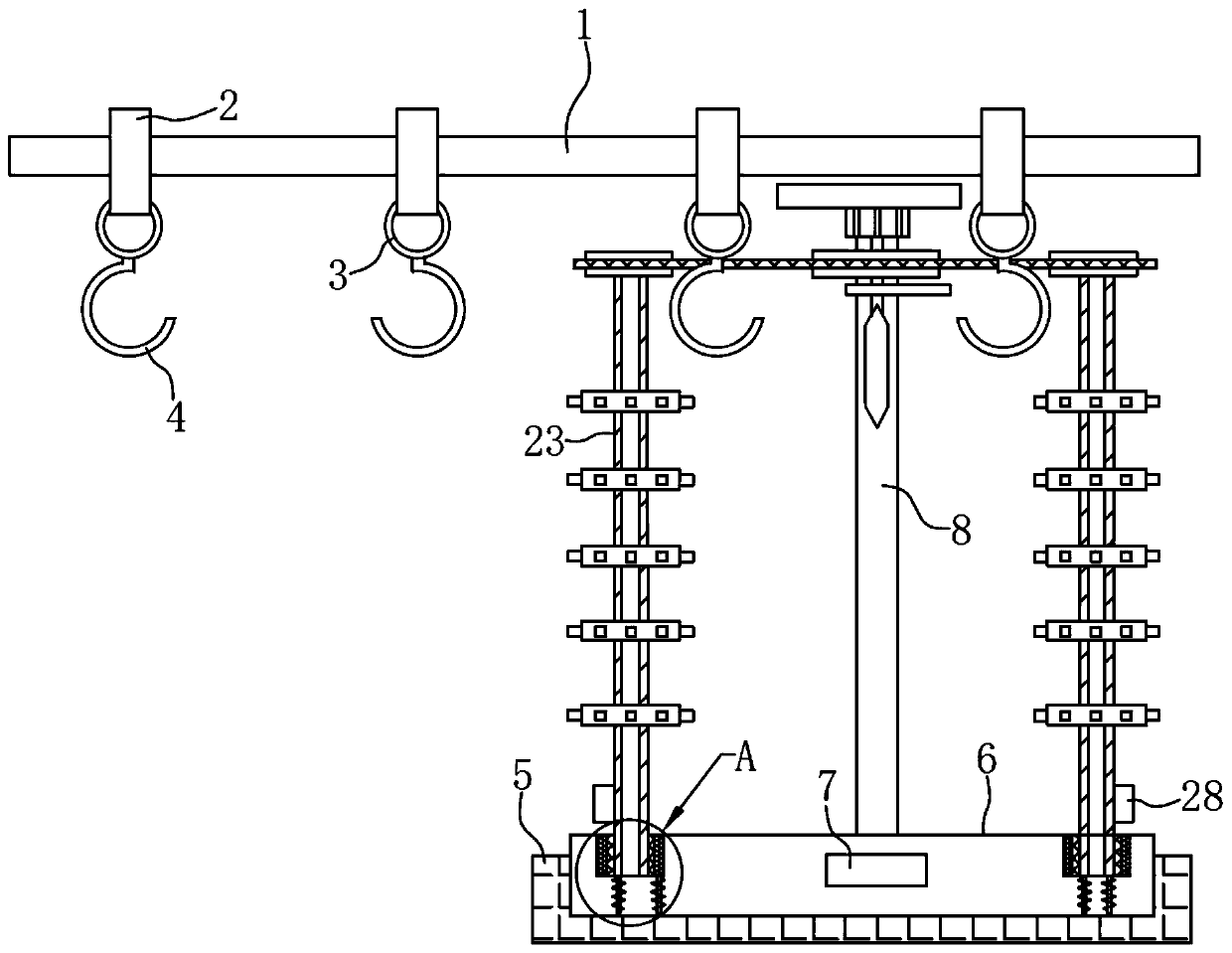

Live pig hanging automatic processing system

ActiveCN109452341APlay a role in the separationAvoid incomplete cuttingSplitting instrumentsSlaughterhouse arrangementsThoracic structureEngineering

The present invention relates to a live pig hanging automatic processing system. The live pig hanging automatic processing system comprises a supporting bottom plate, a cutting plate, a guiding plateand a stablizing device, the cutting plate is arranged on a top part of a right end of the supporting bottom plate, the fixing device is arranged on a top part of the cutting plate, a left end of thecutting plate is connected with a right end of the guiding plate, and a left end of the guiding plate is arranged on a top part of a left end of the supporting bottom plate; and the stablizing devicecomprises a stabilizing bracket, a positioning telescopic body, a positioning spring, positioning push rods, a positioning connecting plate, positioning wheels, an external support mechanism, an extrusion mechanism and a separation guide block. The live pig hanging automatic processing system can solve problems that during live pig half cutting, many people are needed to assist cutting of the livepigs, the live pig half cutting has risks, the live pig half cutting is uneven, the live pig half cutting cuts thoracic cavity of the live pigs and causes waste, the live pig cutting is incomplete, and can achieve functions of positioning conveying and pressing cutting of the live pigs.

Owner:XIAMEN YINXIANG GROUP

Automatic top slice removal device

ActiveUS7096769B2Reduce waste and inefficiencyLong lastingSplitting instrumentsGang saw millsEngineeringConveyor belt

An automatic top slice removal device includes a frame, a lower conveyor belt and an adjustably mounted upper conveyor belt extending generally parallel with and spaced from the lower conveyor belt. A meat product slicing device includes a blade interposed between the upper conveyor belt and the lower conveyor belt to separate a top slice from the remainder of the meat product. A top slice separator plate is adjustably mounted between the upper conveyor belt and the lower conveyor belt and positioned rearwardly adjacent and vertically aligned with the blade and extends rearwards therefrom to maintain separation of the top slice and the remainder of the meat product between the belts. Finally, a top slice removal conveyor belt is positioned rearwards of the top slice separator plate and below the upper conveyor belt to remove the top slice from the remainder of the meat product.

Owner:JOHN BEAN TECH CORP

Horizontal meat slicer with bandsaw blade

InactiveUS20050132863A1Improve cut qualityEliminates the concern of the meat product accidentally twisting or rotatingMetal sawing devicesSplitting instrumentsEngineeringConveyor belt

A horizontal meat slicer includes a frame and a lower conveyor belt having forward and rearward ends, the lower conveyor belt operative to receive a meat product thereon and transport it into and through the device. An upper pressing conveyor belt includes forward and rearward ends, the upper pressing conveyor belt and the lower conveyor belt cooperating such that meat product is compressed between the lower conveyor belt and the upper pressing conveyor belt. At least one bandsaw blade is rotatably mounted on the frame, a cutting section of the bandsaw blade traveling between the upper belt and lower belts. Finally, at least one drive device such as a motor is operatively connected to each of the conveyor belts and the bandsaw blade to drive them to pull the meat product through the device and cut the meat product via the cutting edge of the bandsaw blade.

Owner:BIGGS HENRY +1

Automatic top slice removal device

ActiveUS20050274245A1Reduce wasteReduce inefficienciesSplitting instrumentsGang saw millsEngineeringKnife blades

An automatic top slice removal device includes a frame, a lower conveyor belt and an adjustably mounted upper conveyor belt extending generally parallel with and spaced from the lower conveyor belt. A meat product slicing device includes a blade interposed between the upper conveyor belt and the lower conveyor belt to separate a top slice from the remainder of the meat product. A top slice separator plate is adjustably mounted between the upper conveyor belt and the lower conveyor belt and positioned rearwardly adjacent and vertically aligned with the blade and extends rearwards therefrom to maintain separation of the top slice and the remainder of the meat product between the belts. Finally, a top slice removal conveyor belt is positioned rearwards of the top slice separator plate and below the upper conveyor belt to remove the top slice from the remainder of the meat product.

Owner:JOHN BEAN TECH CORP

Fish filleting machine

ActiveUS6994617B2Easy maintenanceReduce frictionSplitting instrumentsPoultry processingEngineeringFish fillet

A fish-cutting machine for cutting fillets from the backbone of fish (38), the machine comprising a fish support (6), a feed-line for feeding fish through the machine and two mutually adjacent band saws (46) arranged along the feed-line. The band saws functions to cut on respective sides of the backbone of a fish (38) for filleting the abdomen-bone part of the fish and thus for separating the fish into two fish fillets and a carcass. A spine cutting device is arranged along the feed-line (40) and before the band saws (46) in a feeding direction of the feed-line, and the spine cutting device comprise two mutually adjacent cutting blades (14) for cutting of incisions in the spine part of the fish.

Owner:MAREL SALMON

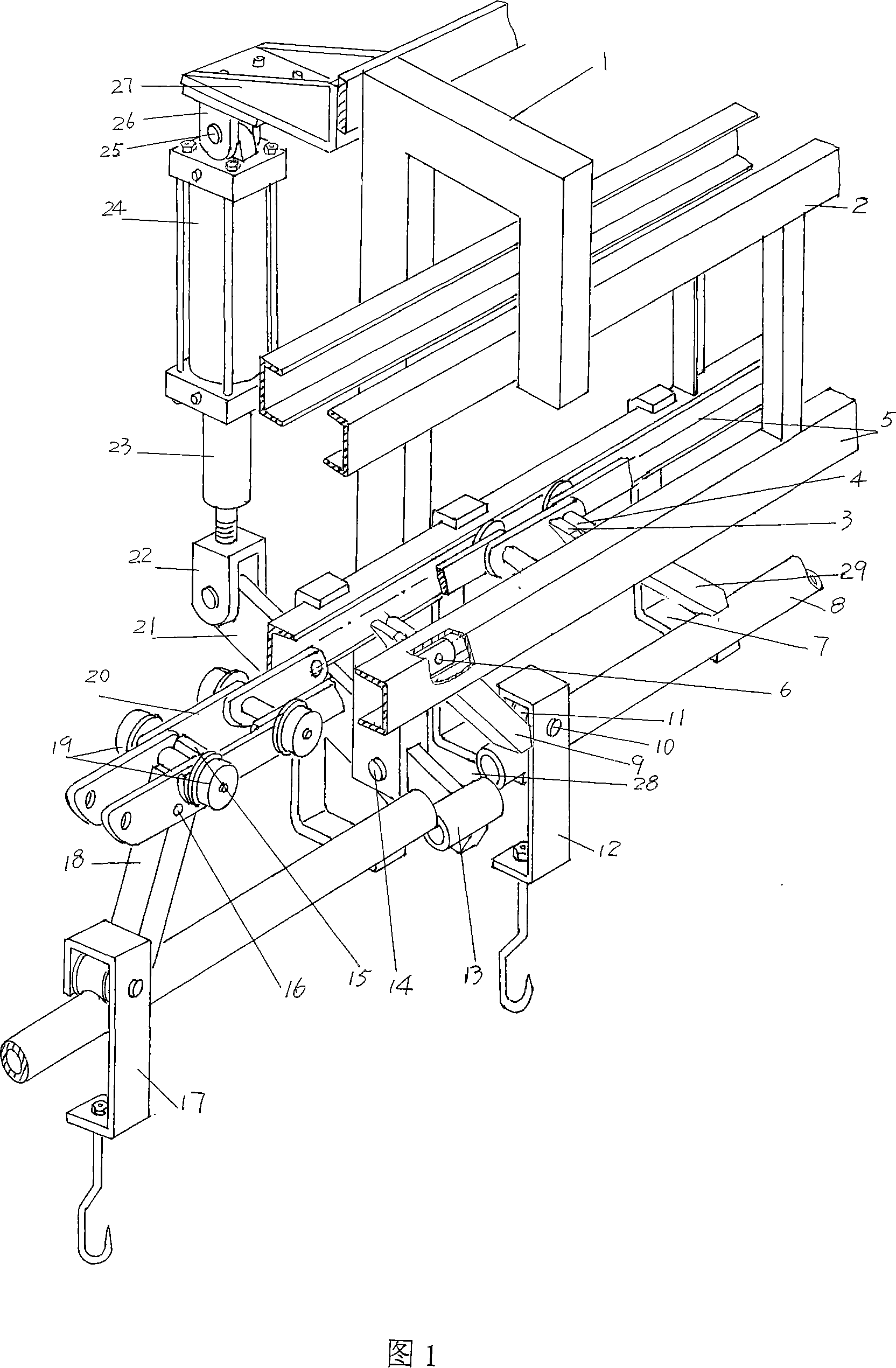

Livestock ketone body secondary supporting leg device

InactiveCN101057601AMeet the secondary leg support requirementsAvoid splittingSplitting instrumentsEngineeringMechanical engineering

The invention relates to a secondary leg-supporting device for livestock, belonging to slaughtering facilities technique, comprising one framework fixed on the chain and lower guide rail on marching type conveyor, one acting vat, the vat body of said vat is connected with chain on the framework, the vat column is hinged with swinging arm, swinging arm is hinged on framework, the other end of swinging arm is equipped with transfer guide rail, said transfer guide rail is corresponding to the break on one-time leg-supporting hook rail of marching type conveyor. It is characterized in that it adds framework, acting vat, swinging arm equipped with transfer rail and break forming one-time leg-supporting hook rail on original marching type conveyor, then it can meet demand of secondary leg supporting, and avoids saw pinching during splitting saw, it needs no additional secondary leg-supporting device, which not only saves operating workers, but also plays effect of original conveyor.

Owner:CHANGSHU SLAUGHTERING EQUIP SET

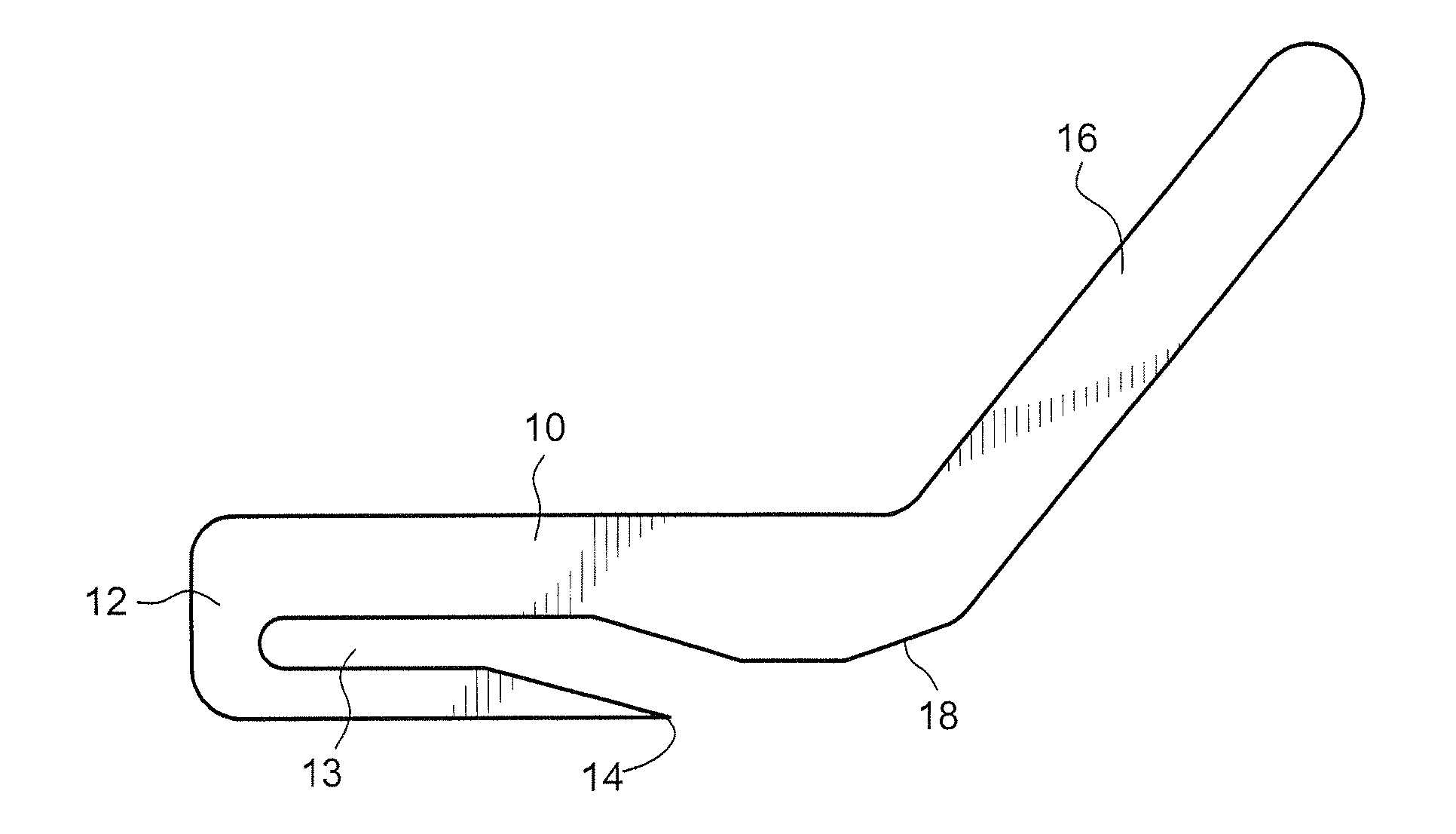

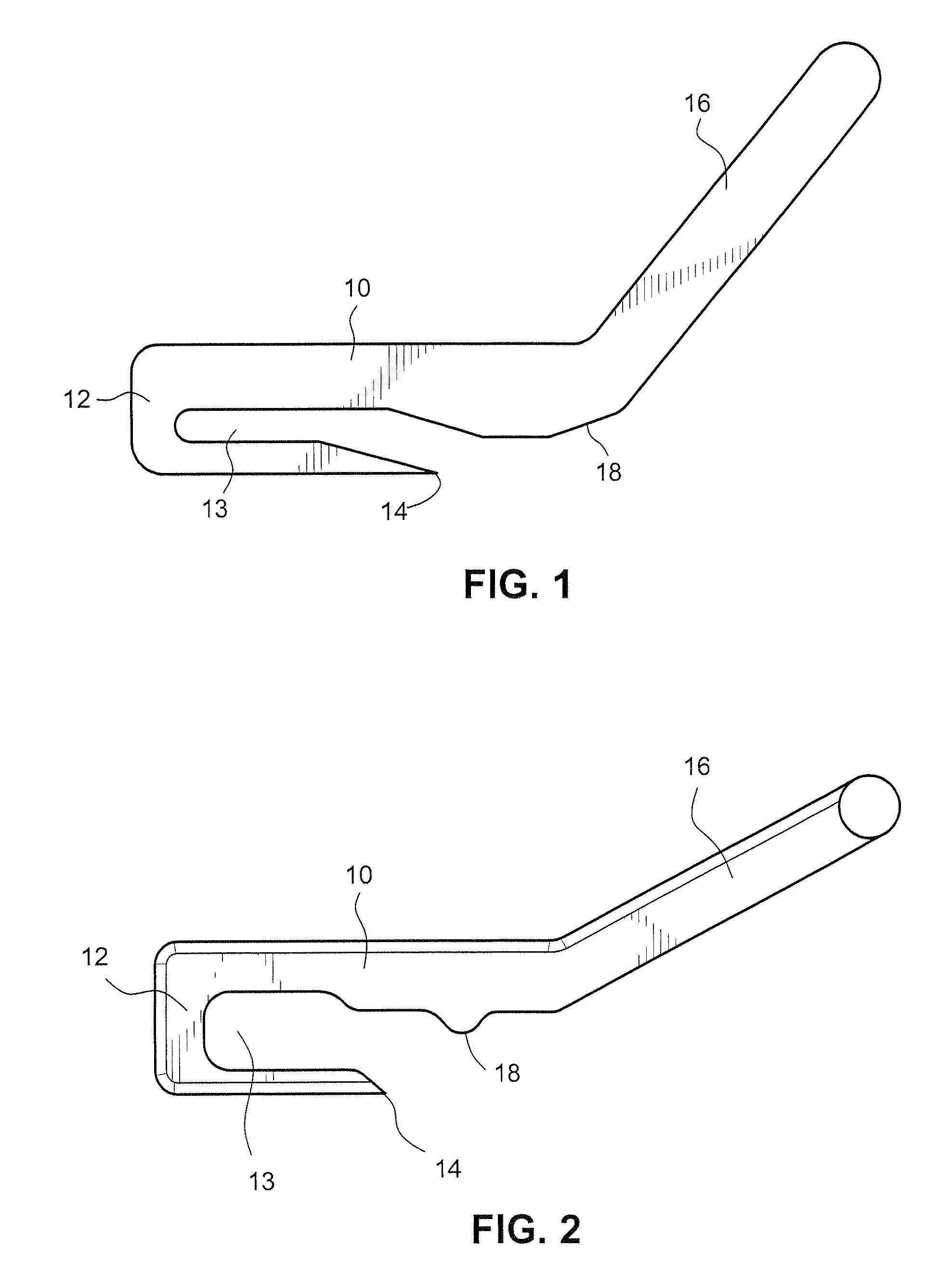

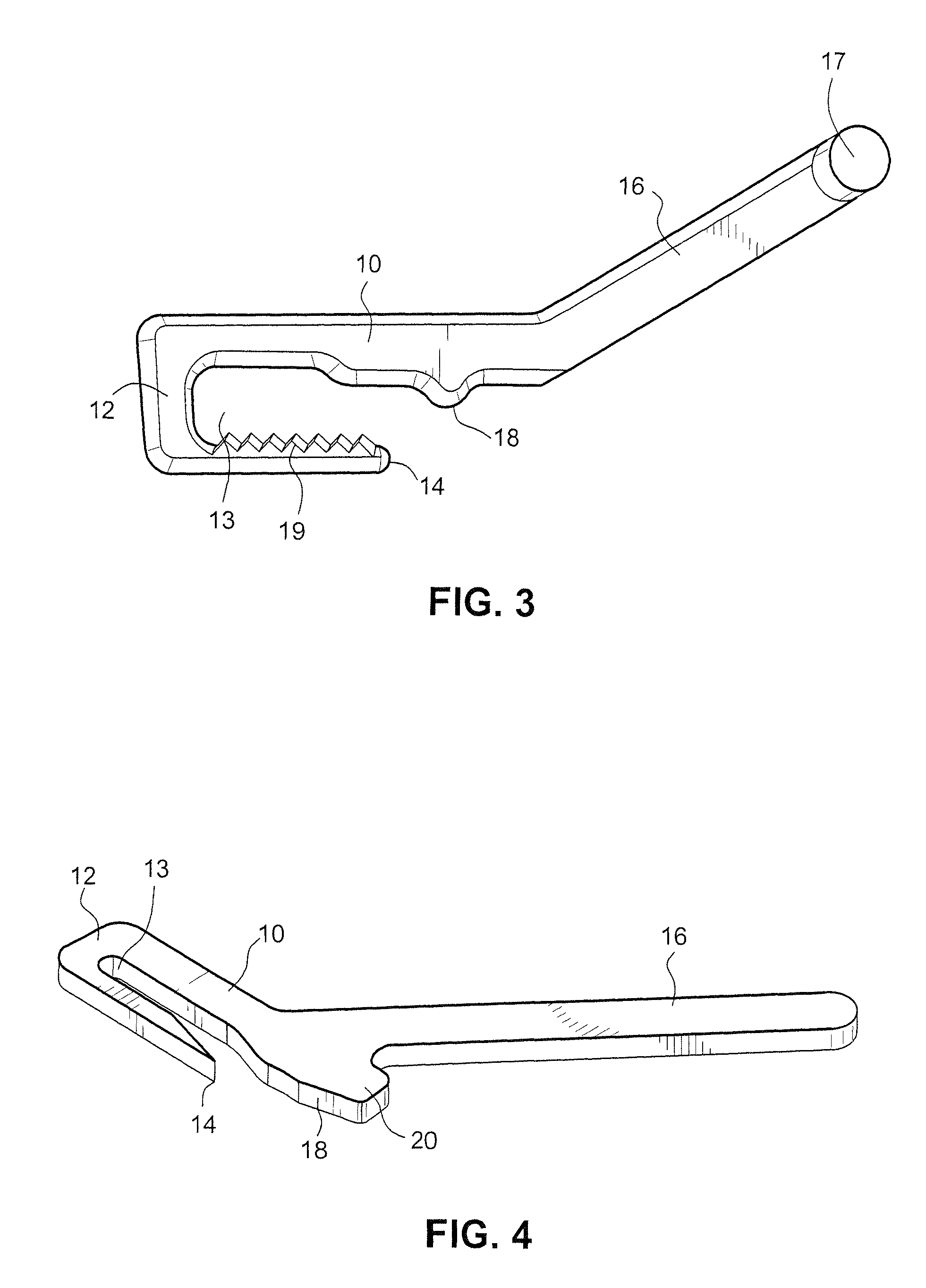

Bone splitting and breaking tool

InactiveUS8235775B1Bone-shears/bone-crushersSplitting instrumentsBiomedical engineeringMetatarsal head

A bone breaking or crushing tool for use by a hunter is designed to break the pelvic bone of a game animal. The bone breaking tool includes a U-shaped body having first and second arms joined by a front end. A handle projects at an angle from an outer side of a first arm of the U-shaped main body. A projection is formed on an inner side of the first arm of the U-shaped main body. The bone breaking tool is configured so that the first and second arms of the U-shaped main body can be slid around either side of a portion of the pelvic bone of a game animal. A hunter can then apply a force to an end of the handle to drive the projection on the inner side of the first arm into the pelvic bone to break or crush the pelvic bone.

Owner:MOY YUEY S

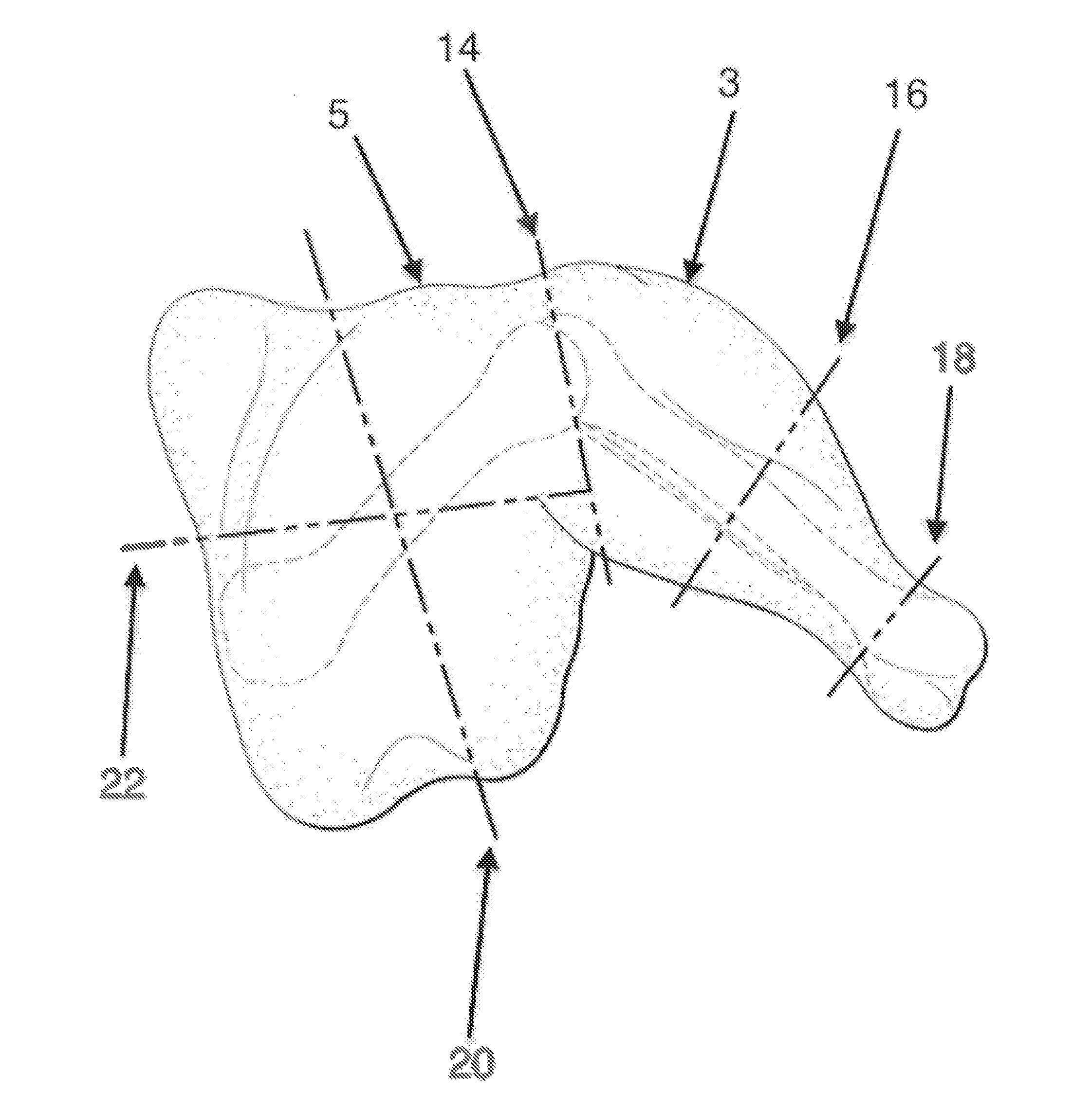

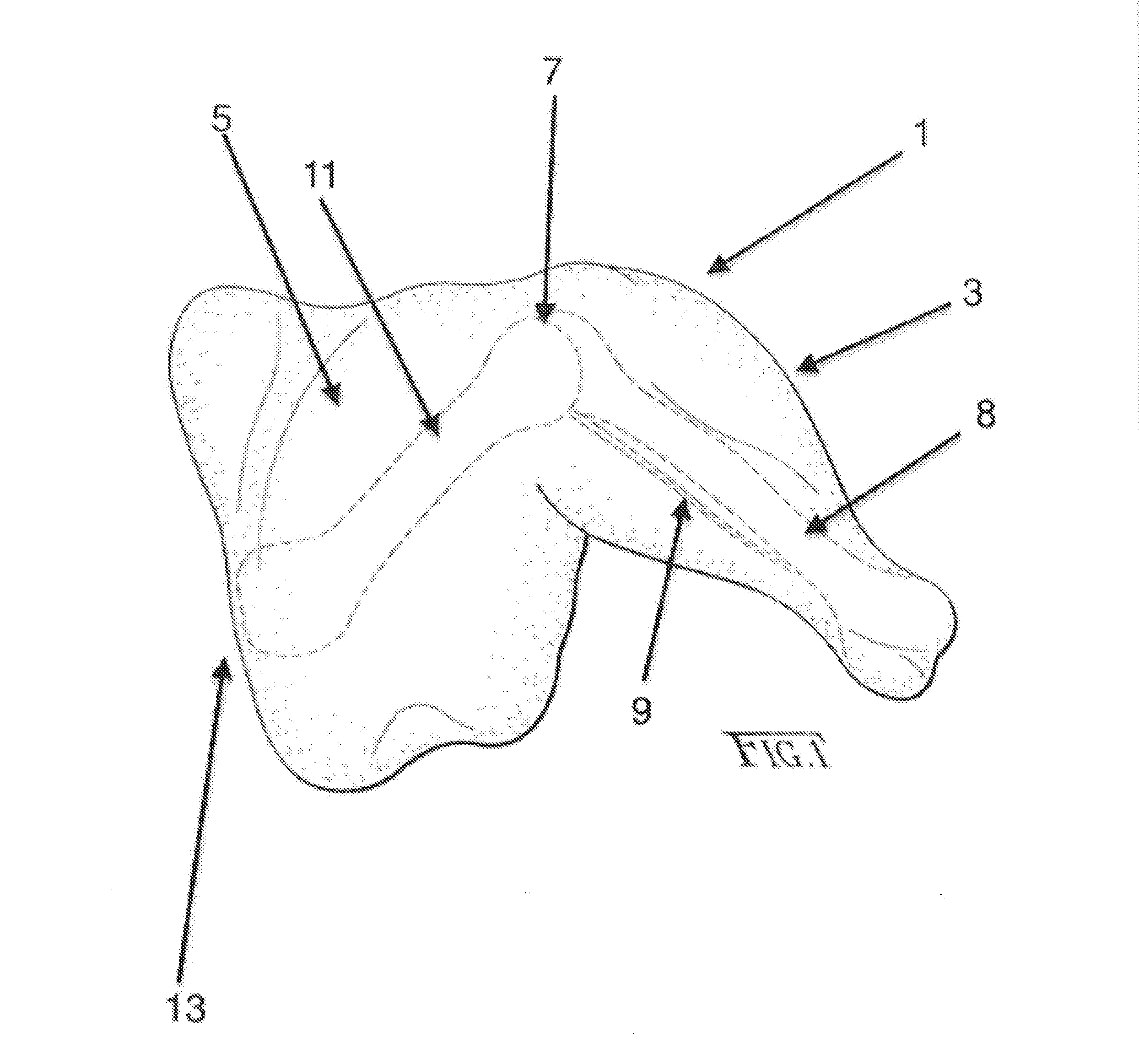

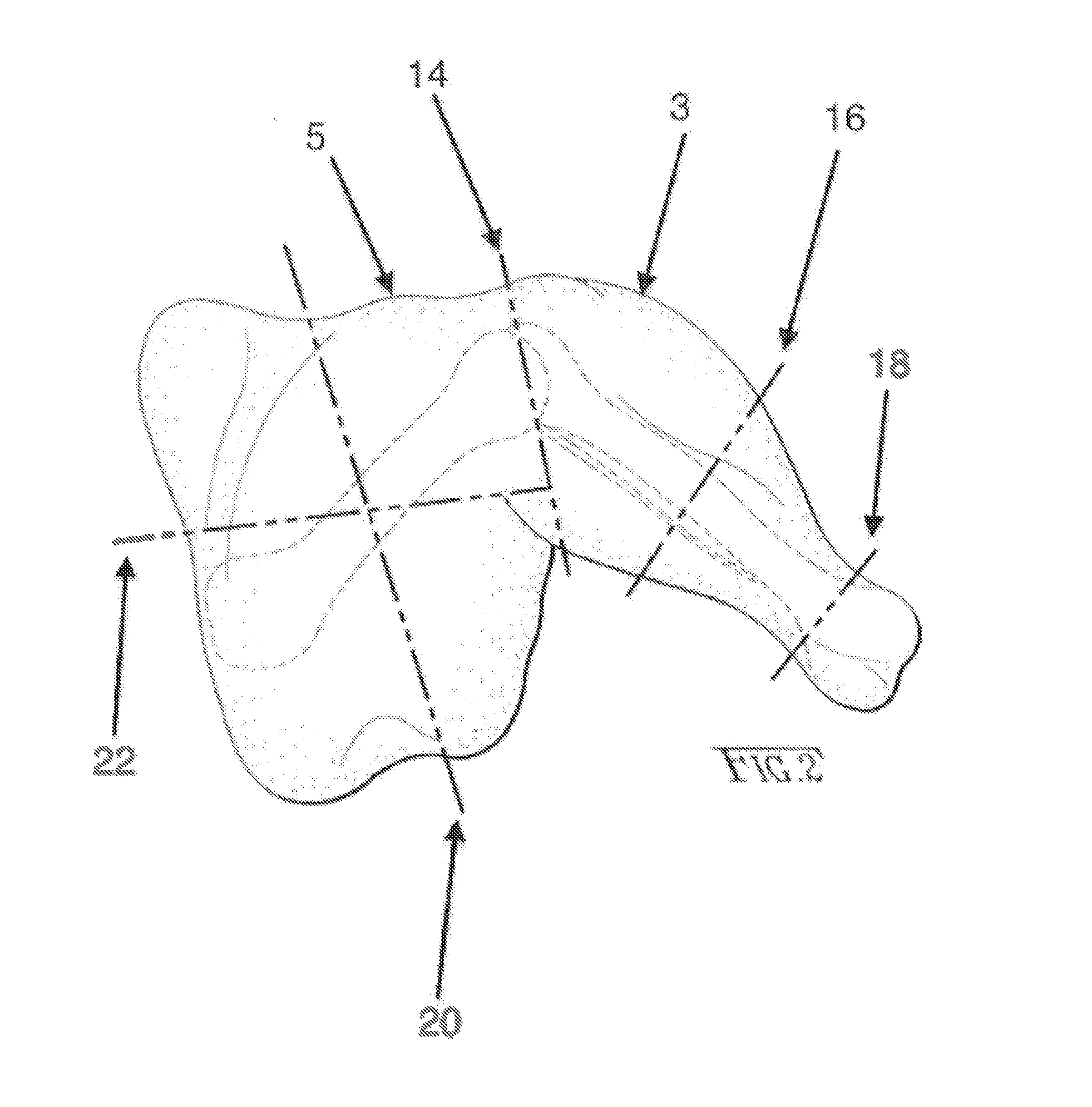

Carcass cutting methods and apparatus

A method and apparatus for performing a longitudinal cut along a saddle section of a carcass. A pair of spaced apart tines are located in one end of a spinal column of the saddle section. The saddle section is then moved relative to a cutting tool to cut longitudinally through the spinal column to cut the saddle section in half with the cutting tool passing between the pair of spaced apart tines.

Owner:ROBOTIC TECH

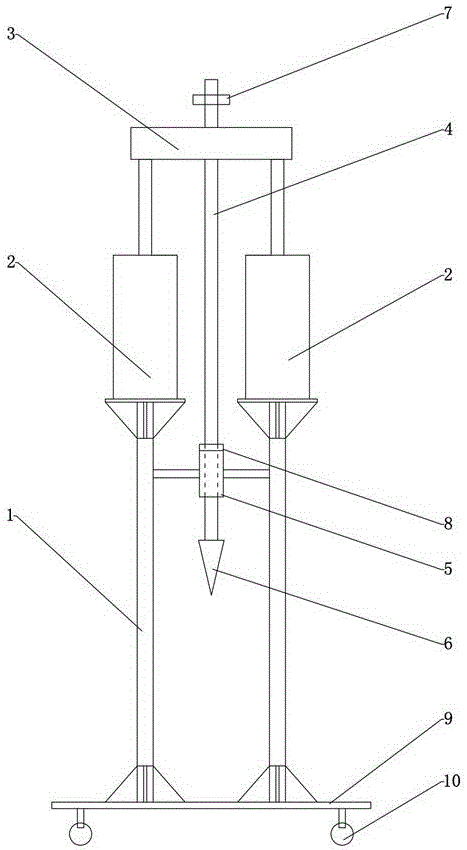

Live pig splitting machine

ActiveCN105851189AReduce labor intensityNo problem affecting meat qualitySplitting instrumentsFree fallingEngineering

The invention discloses a live pig splitting machine. The live pig splitting machine is characterized by comprising two supporting columns, wherein a cylinder is mounted at the top of each supporting column; the tops of piston rods of the two cylinders are respectively connected with electronic hoops; a straight rod shaped knife handle is arranged at the center between the two cylinders in the vertical direction; a guide cylinder is arranged between the two supporting columns and fixedly connected with the supporting columns; the knife handle penetrates through the electronic hoops and the guide cylinder; a knife head is connected with the bottom end of the knife handle. The live pig splitting machine performs splitting operation on a live pig through the free-fall motion of the knife handle and the knife head under the action of gravity, can shorten the splitting time, greatly improves the splitting efficiency, reduces the labor intensity of workers, meanwhile cannot have the problem that bone dregs affect the meat quality, and is low in manufacture cost.

Owner:四川东坡三味农业科技有限公司

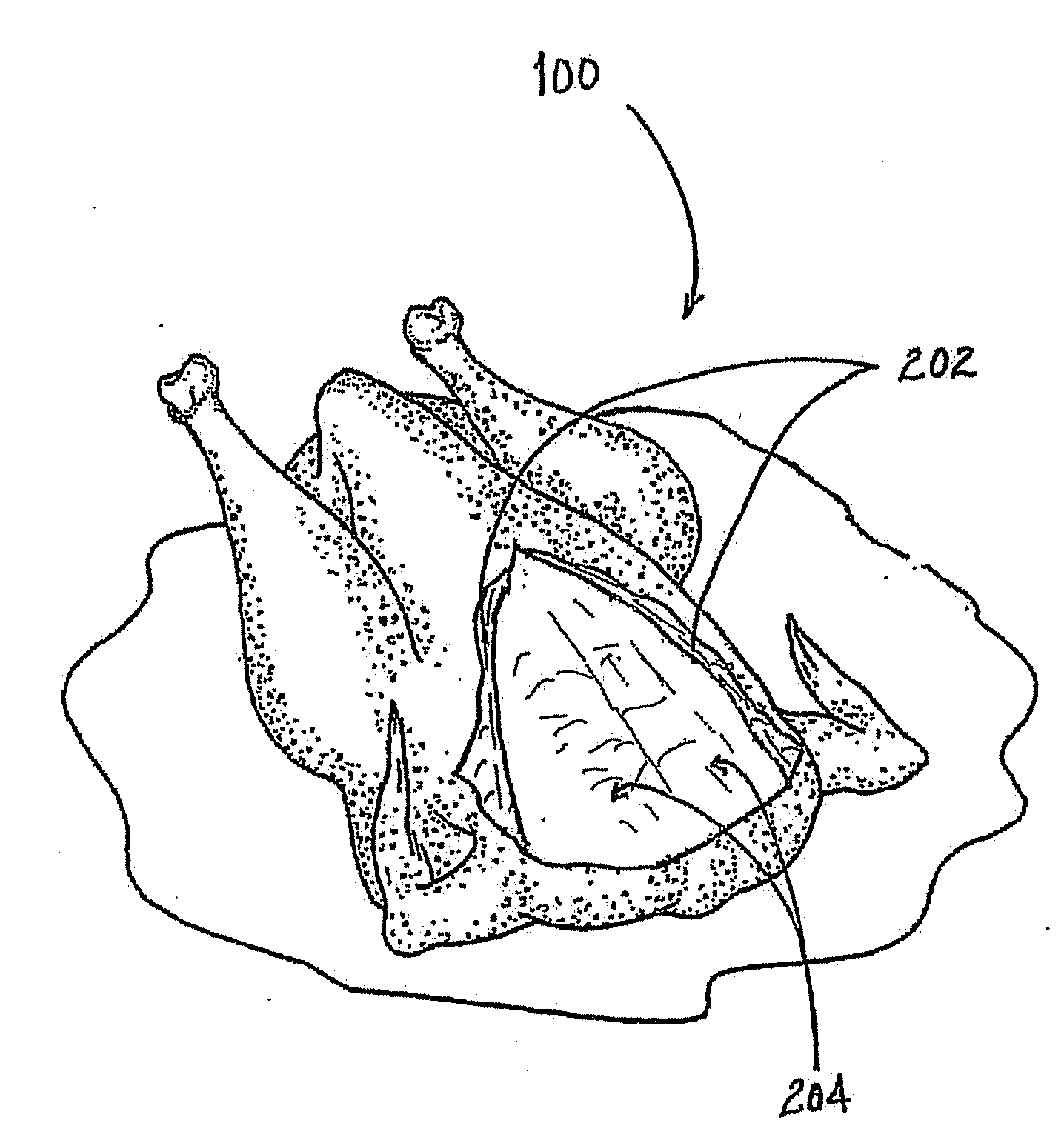

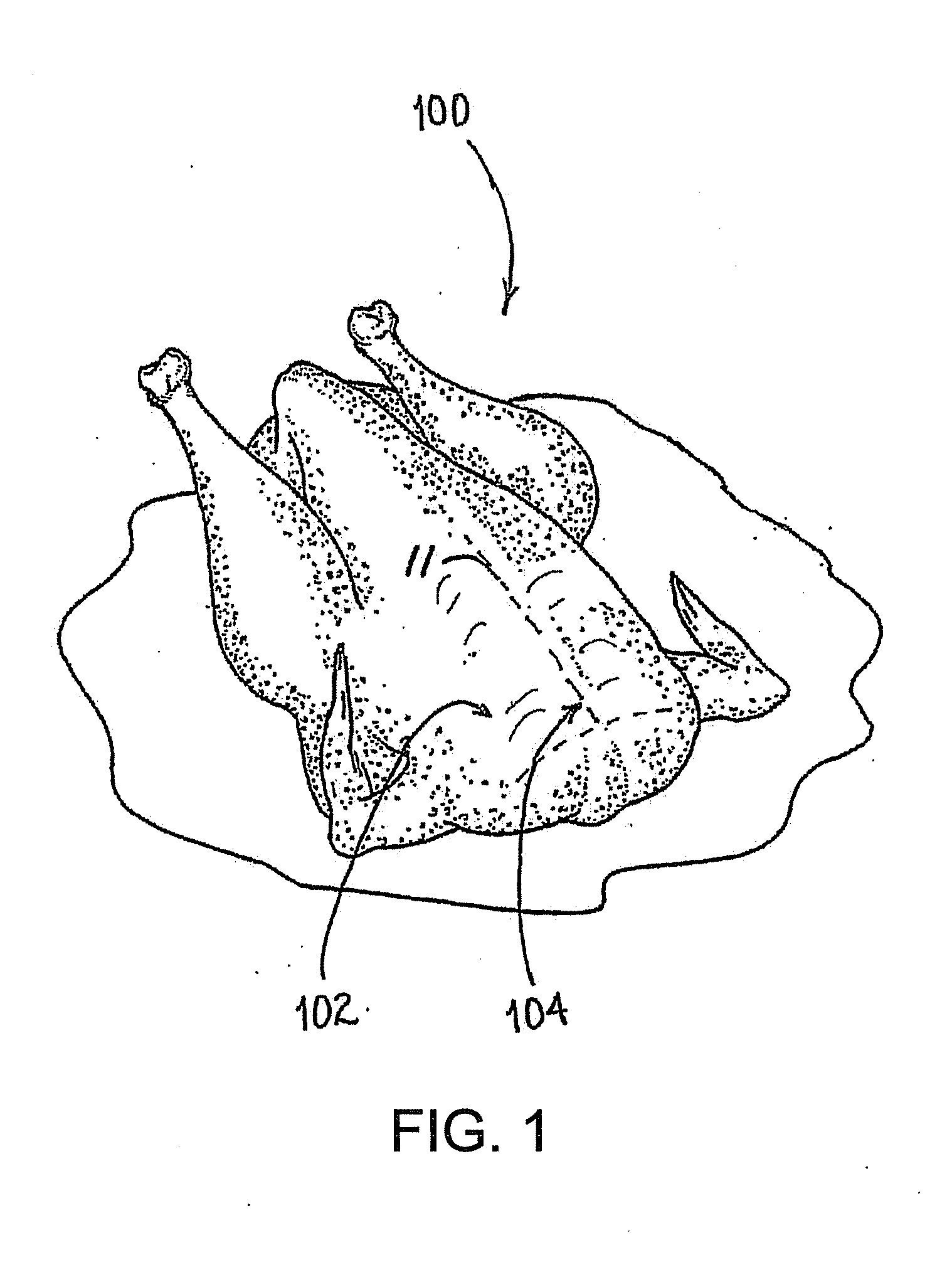

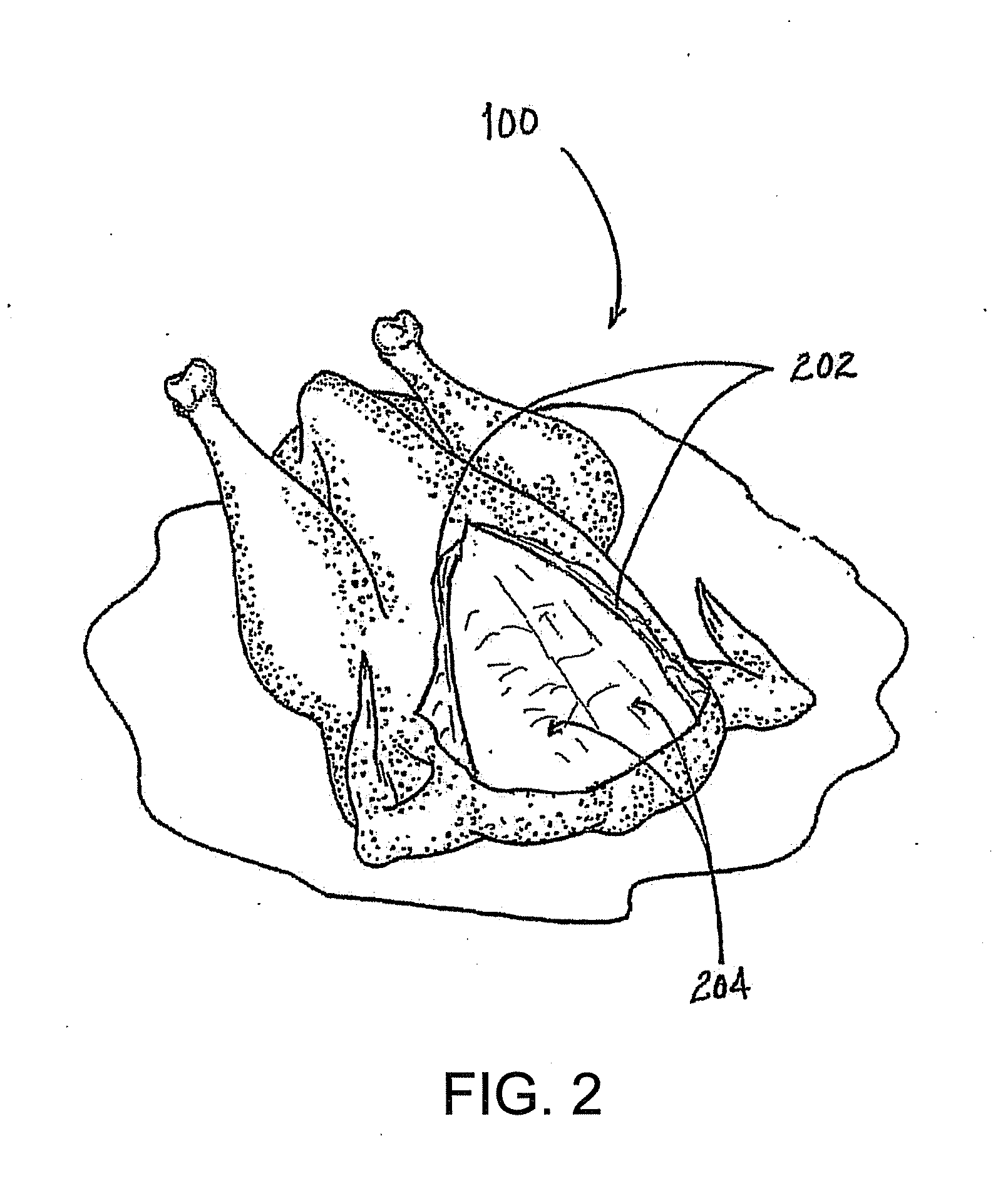

Value whole poultry product and method for manufacture

InactiveUS20090285972A1Improve convenienceAppealing appearancePoultry skinningPoultry deboningPoultry productBreasts skin

An product and method providing for a value whole poultry product meat cut comprising a whole poultry carcass with the breast meat and tenders cut away with the breast skin remaining in tact. The semi-whole bird with the breast and tenders cut away with the breast skin in tact can be netted and / or packaged in a manner to have the look of a whole bird. The semi-whole poultry product can provide all of the normal meat yield to the consumer minus the breast and tender, while enhancing convenience, maintaining the appearance and aesthetic appeal and meeting the potential “per-pound” value of a whole chicken carcass.

Owner:TYSON FOODS

Automatic splitting-in-half device for livestock slaughtering

InactiveCN109699722AEasy to cut in half one by oneNo human assistance requiredSplitting instrumentsMechanical engineeringStain

The invention discloses an automatic splitting-in-half device for livestock slaughtering. The device includes a transfer rod, wherein a plurality of connecting belts are fixedly disposed on the transfer rod, a hook is fixedly disposed on each connecting ring, a sliding block is movably disposed on a sliding rail, one end, far away from the sliding block, of a connecting rod is disposed on a cutting wheel, and one end, far away from a nut seat, of a push rod is fixed on the sliding block; and a driving gear is fixedly arranged on a screw rod in a penetrated mode, and the center of one side, faraway from the transfer rod, of a driven gear is fixedly provided with a cleaning tube. The invention provides the automatic splitting-in-half device for livestock slaughtering. The device can automatically perform splitting-in-half cutting on livestock in turn without manual assistance. During the splitting-in-half cutting, the device, on the one hand, can brush and clean livestock and prevent stain and grimy blood on the skin from affecting the cleanliness of the cutting surface and a cutting knife, and on the other hand, can stir a cleaning liquid. Besides, the above three functions are alldriven by the same rotating motor so as to save energy, to concentrate functions and to be worth promoting.

Owner:BENGBU COLLEGE

Driving of a splitting tool holder for an animal carcass splitting machine

The invention relates to a device for driving a splitting tool holder intended for an animal carcass splitting machine including a main carriage having sliding guide means for a splitting tool holder; a splitting tool holder supporting a splitting tool; means for driving the splitting tool in order to make it operational; operation programming means; means for slidingly driving the tool holder carried by the main carriage and connected to the tool holder and means for controlling said driving means, characterised on the one hand, by electric driving means which can be stopped in one or several adjustable precise known positions considered as reference positions for the splitting tool; on the other hand, in that the control means are able to control not only the operation and stoppage of the electric driving means but also the adjustment in position thereof, in order to adjust the reference position of the splitting tool according to the needs; the reference positions for the splitting tool being selected among the following: initial retracted position, initial splitting position, final splitting position, final retracted position.

Owner:DURAND INT

Sheep carcass clamping mechanism

PendingCN110226617AAvoid swingingHanging stableSplitting instrumentsEngineeringUltimate tensile strength

The invention provides a sheep carcass clamping device. The sheep carcass clamping device comprises a base, a rotating component, a lifting frame and a positioning bracket, wherein the rotating component is rotationally arranged on the base; the lifting frame is arranged at one side of the upper part of the rotating component, the lifting frame is provided with a hook, one side of the lifting frame close to the sheep carcass is provided with a first limiting block and a tightening clamp in the position below the hook, the first limiting block is used for abutting against the sheep carcass, andthe tightening clamp is used for surrounding and clamping the outer side of the sheep carcass; and the positioning bracket is arranged at the other side of the upper part of the rotating component, one side of the positioning bracket close to the sheep carcass is provided with a second limiting block and an inner support frame, the second limiting block is used for abutting against the carcass, and the inner support frame is used for extending into the inner cavity of the sheep carcass to support the sheep carcass from the inside. When the sheep carcass is cut, the rotating component can be rotated to drive the sheep carcass to rotate, and an operator does not need to move and turn over the sheep carcass but only needs to perform the cutting work in the fixed position, thereby obviously improving the working efficiency and reducing the labor intensity of workers.

Owner:浙江浙华智能科技有限公司

Robotic carcass processing method and system

InactiveUS10028514B2Keep full controlAnimal feeding devicesSplitting instrumentsRobotic armDead body

A robotic carcass processing system uses a pair of robotic arms having multiple axes of motion, a saw mounted thereon, and a controller. The controller moves the saw in Cartesian space via inverse kinematics with interpolation control over the multiple axes of the robotic arm to synchronously move the saw relative to a carcass on an assembly line. The controller also determines when one of the robotic arms has moved its saw out of a defined space to indicate that space is clear and to permit the other robotic arm to enter that space. A sensor on the assembly line identifies location of the absence of a supported carcass, a supported carcass that requires special handling, or weight or length of a carcass. The controller sends a signal to the robotic arms to either effect a standard cut or to modify the standard cut at the identified location or carcass.

Owner:JARVIS PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com