Carcass cutting methods and apparatus

a cutting method and animal carcass technology, applied in the field of automatic cutting of animal carcasses, can solve the problems of inability to accurately cut carcasses, difficulty in ensuring carcass quality, and difficulty in ensuring the quality of carcasses,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

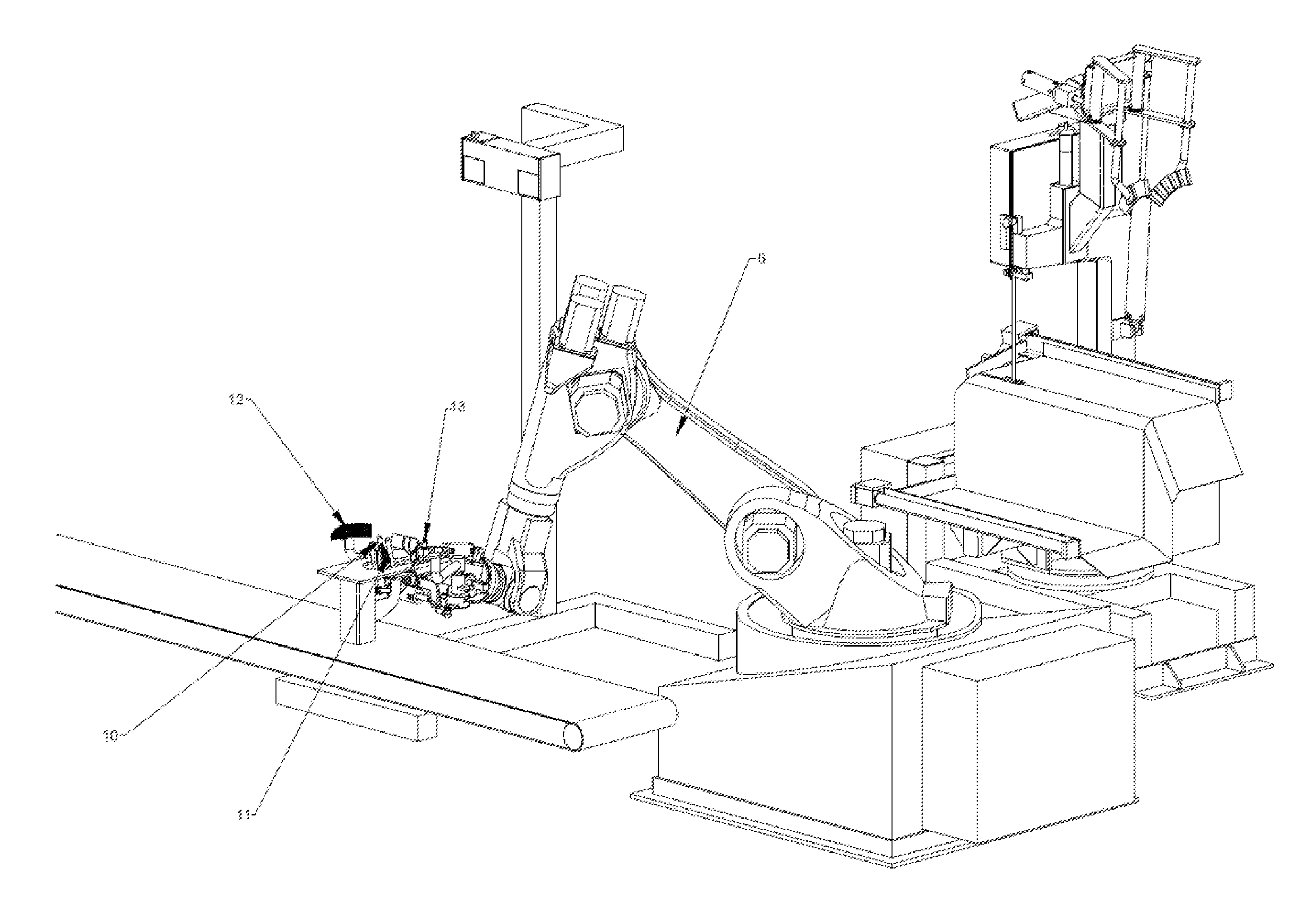

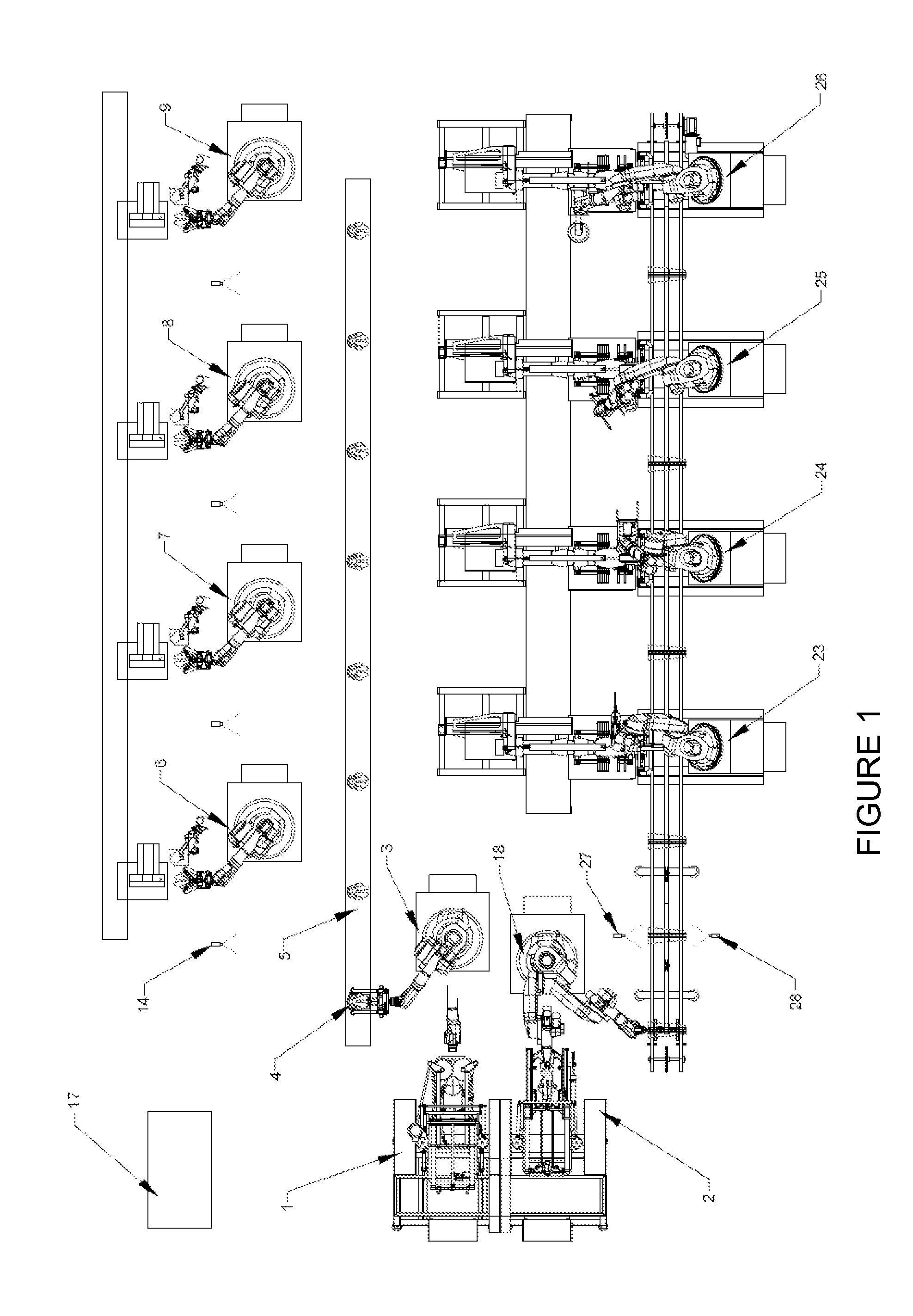

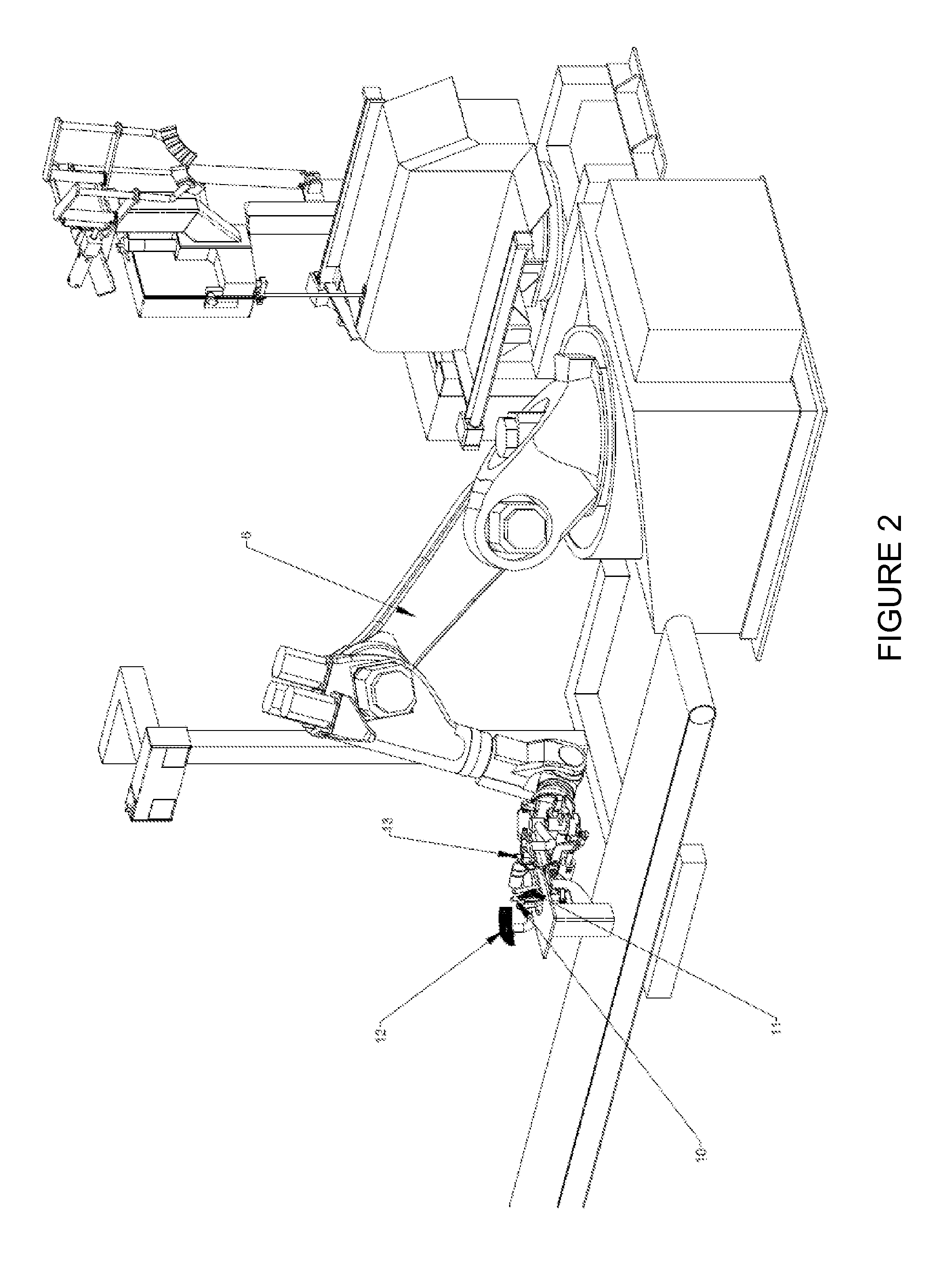

[0022]FIG. 1 shows an integrated system for performing primal cuts and then processing the saddle portions and fore-quarters at a number of stations matched to the processing room capacity. Prior to processing by the system shown in FIG. 1 a carcass may be X-rayed to reveal the internal anatomy of the carcass using a system such as that described in WO 2008010732, the disclosure of which is hereby incorporated by reference. The anatomical information obtained by X-ray imaging may be associated with a carcass and used in subsequent processing as will be described.

[0023]The system shown in FIG. 1 includes a fore-quarter primal cutting station 1 which may utilize a carcass cutter as described in the applicant's prior application GB2445277A, the disclosure of which is hereby incorporated by reference. A saddle cutting station 2 may utilize a carcass cutter as described in the applicant's prior application WO2006 / 135262, the disclosure of which is hereby incorporated by reference.

[0024]A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com