Livestock ketone body secondary supporting leg device

A carcass and livestock technology, which is applied to the field of secondary leg support devices for livestock carcasses, can solve the problems of ineffectiveness, uneconomical, and increased equipment input costs of slaughtering enterprises, and achieves the effect of saving operators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

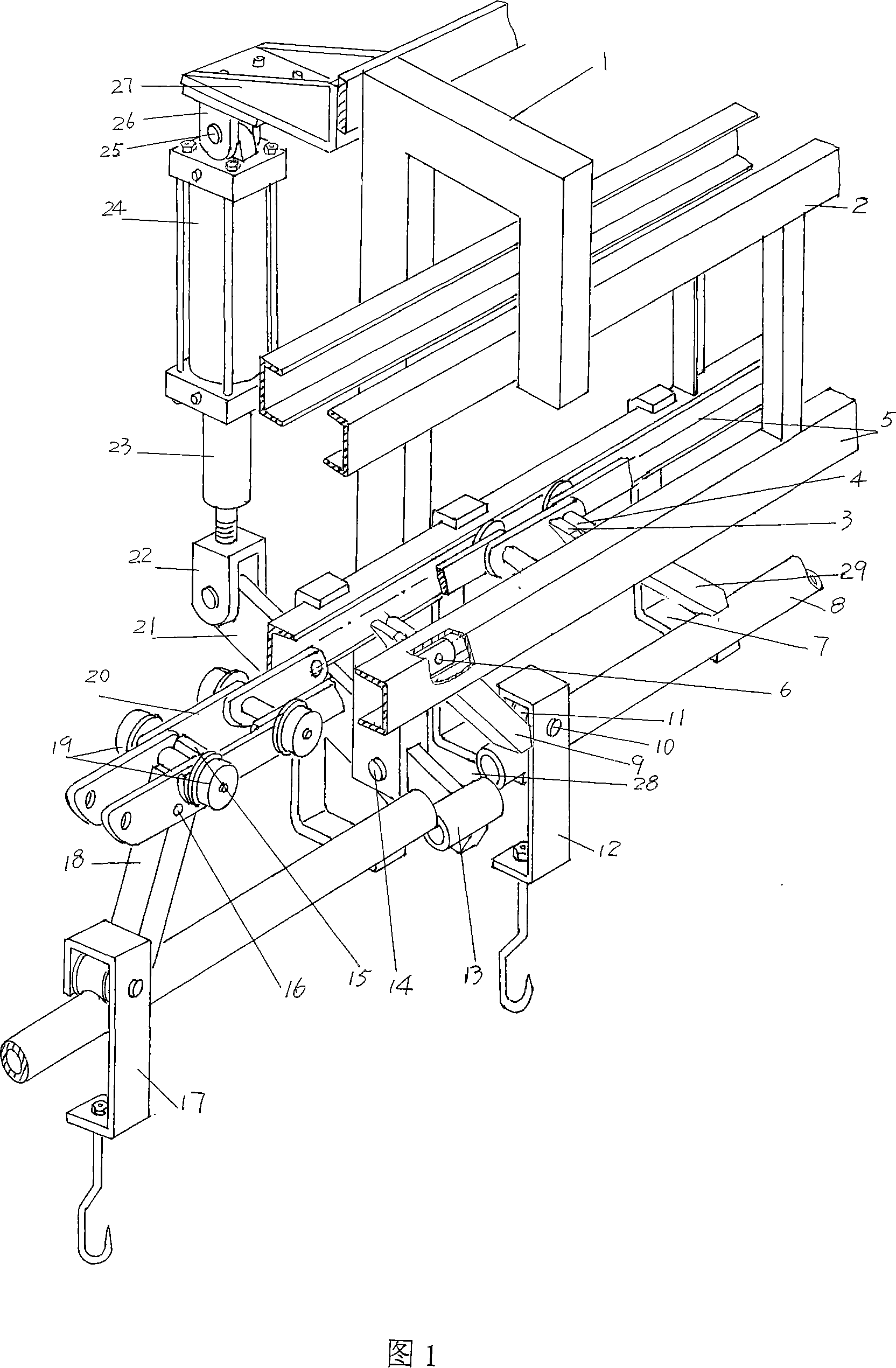

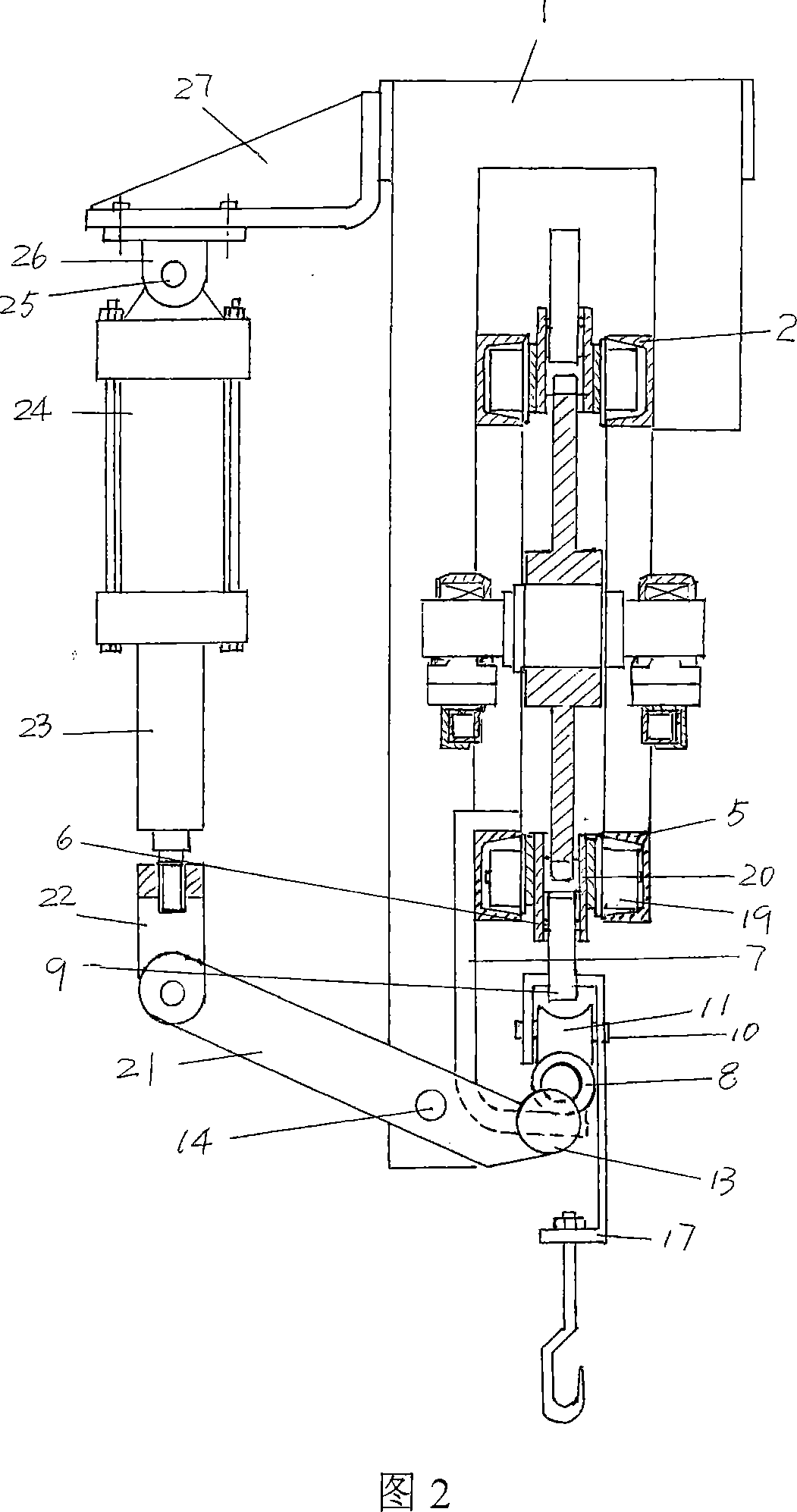

[0014] Please refer to Figure 1 and Figure 2, since the stepping conveyor is widely used in the slaughtering industry and its overall structure is well known in the industry, so the applicant did not show the whole picture of the machine, but only combined with this application model Some components associated with each component of the described livestock carcass secondary leg support device are clearly shown in the figure. As these parts of the stepping conveyor, such as the upper and lower guide rails 2, 5 of the chain, the conveying chain 20 that moves repeatedly along the upper and lower guide rails 2, 5 of the elongated chain, and the pair of pairs pivoted on the conveying chain 20 The front and rear support legs 18, 9 (only a pair are shown in the figure), pass through a group of brackets 7 fixed on the chain lower guide rail 5 in the form of interspersed cloth, and the primary support supported by the group of brackets 7 Leg guide rail 8, a pair of front and rear hooks...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com