Automatic fifty-fifty splitting robot with single-shaft dual-crank rocking bar mechanism

A technology of crank rocker mechanism and rocker mechanism, which is applied in the direction of splitting tools, etc., can solve the problems of uneven tool wear, large mechanical energy, noise generation, etc., and achieve the effects of improving cutting accuracy, reducing noise, and reducing cutting vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

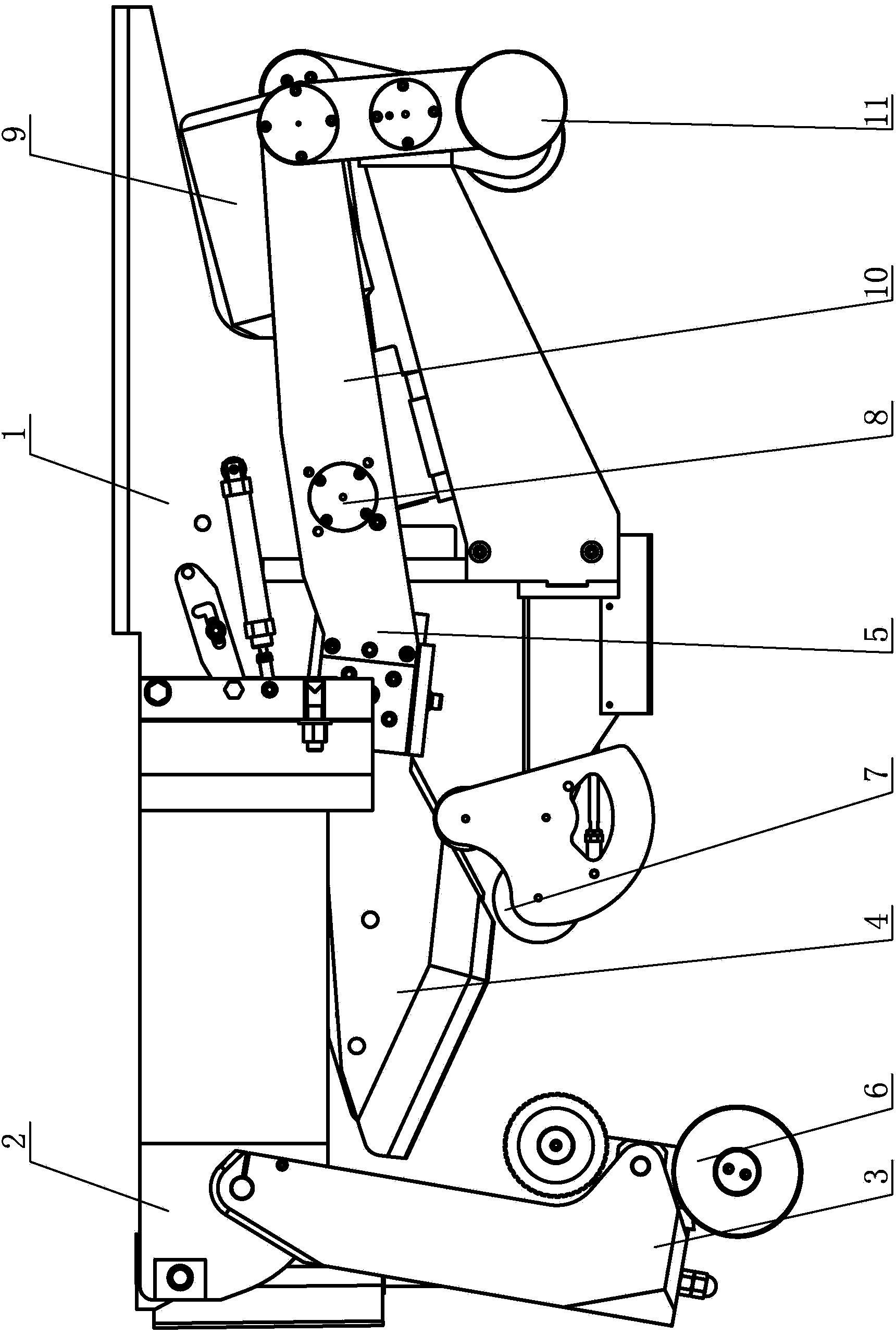

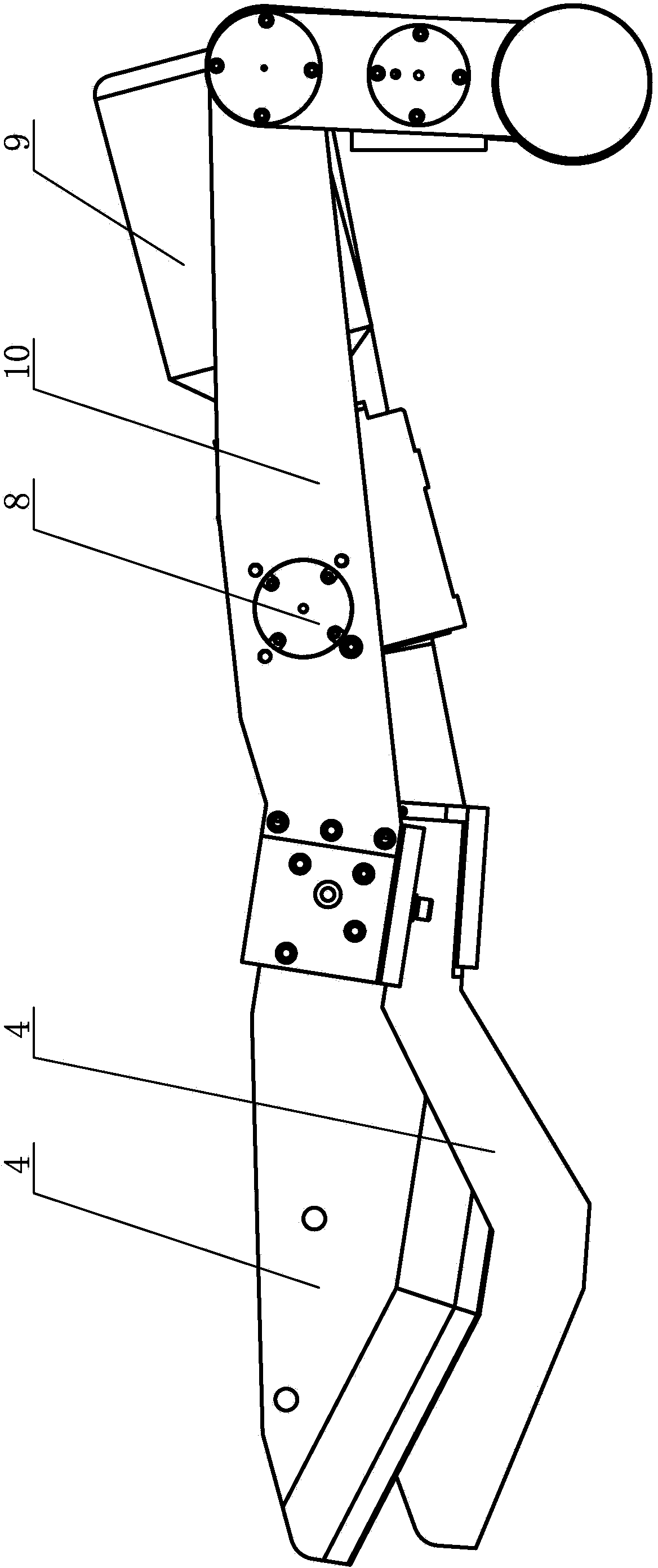

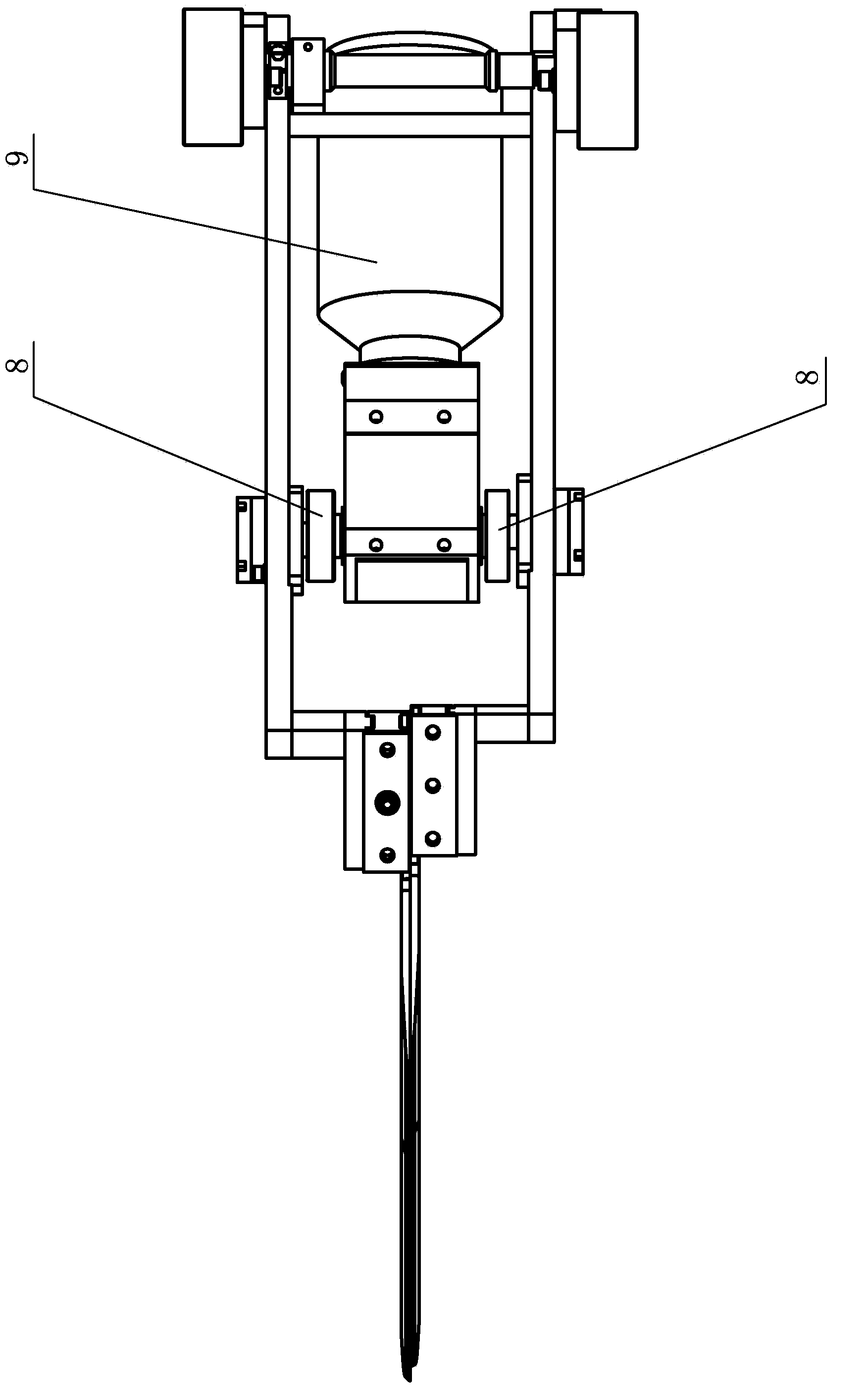

[0010] Specific implementation mode one: combine Figure 1 to Figure 3 Illustrate this embodiment, the automatic half-splitting robot with uniaxial double crank rocker mechanism described in this embodiment includes frame 1, livestock support mechanism, motor 9, two machetes 4, two crank rocker mechanisms 5 and two Crank 8, described livestock support mechanism is installed on the front end of frame 1, and motor 9 is installed on the frame 1, and two cranks 8 are arranged side by side in parallel, and the upper end of each crank 8 is respectively connected with one end of crankshaft respectively, and described Crankshaft is connected with the rotating shaft of motor 9 by bevel gear pair, and two crank rocker mechanisms 5 are arranged in parallel side by side, and each machete 4 is respectively respectively connected with the front end of the rocking bar 10 of a crank rocker mechanism 5, and each rocking bar 10 are all hinged with the frame 1, and the lower end of each crank 8 ...

specific Embodiment approach 2

[0012] Specific implementation mode two: combination Figure 1 to Figure 3 Illustrate this embodiment, the livestock support mechanism of the automatic half robot with uniaxial double crank rocker mechanism described in this embodiment includes swing head frame 2, swing frame 3, front guide wheel group 6 and rear guide wheel group 7, swing The rear end of the head frame 2 is connected with the front end of the frame 1, the upper end of the swing frame 3 is hinged with the front end of the swing head frame 2, the front guide wheel group 6 is installed on the lower end of the swing frame 3, and the rear guide wheel group 7 is connected to the swing frame through the mounting frame. Rack l hinged.

[0013] The technical effect of this embodiment is: set in this way, when the swing frame 3 is ready, it is in a horizontal state, and turns to vertical when cutting, and the two front guide wheels of the front guide wheel group 6 are against the spine of the livestock from the outside...

specific Embodiment approach 3

[0014] Specific embodiment three: in conjunction with Fig. 1 to image 3 To illustrate this embodiment, the automatic half-splitting robot with a single-axis double crank-rocker mechanism described in this embodiment also includes two balance weights 11, and each balance weight 11 is installed on a corresponding crank-rocker mechanism 5 the rear end of the rocker 10.

[0015] The technical effect of this embodiment is: such setting, the two balance counterweights 11 balance the inertia force during the movement of the two connecting rods, which is beneficial to reduce cutting vibration and improve cutting precision. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com