Core wire of reinforced stranded wire, wire core of reinforced twisted wire, and reinforced type stranded wire

A reinforced, stranded wire technology, applied to the parts of the conductive core, conductors, insulated cables, etc., can solve the problems of stranded wires that are easy to break, and achieve the effects of increasing fatigue resistance, reducing severe friction, and reducing the degree of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

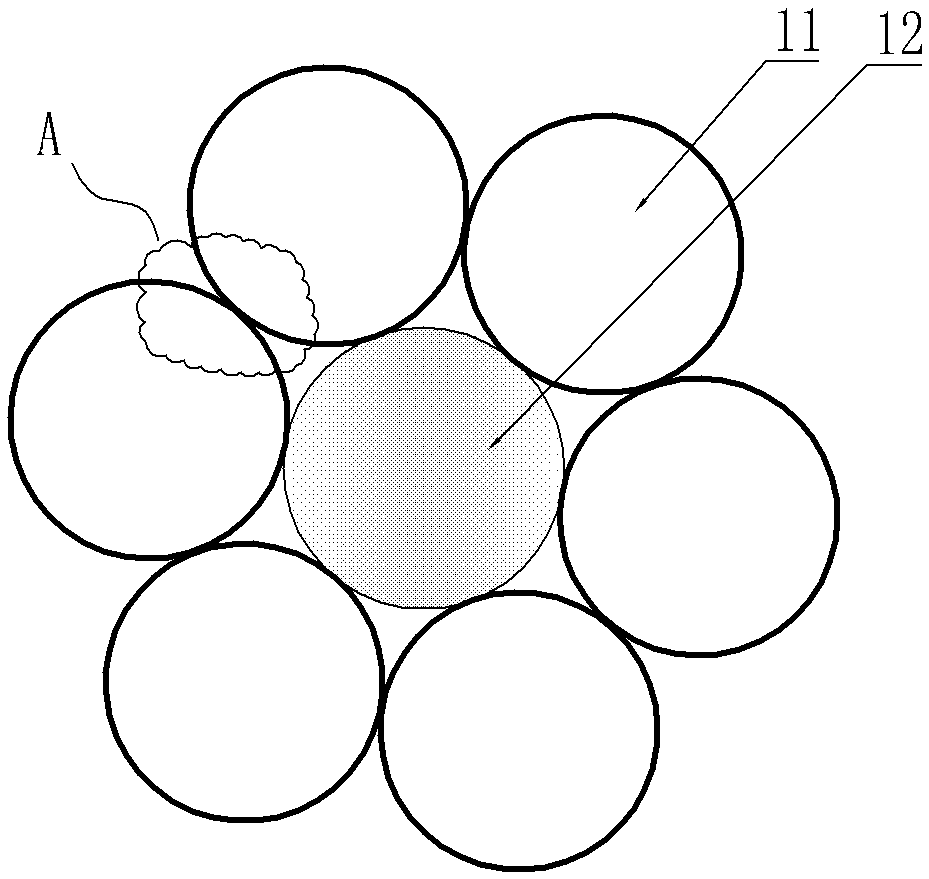

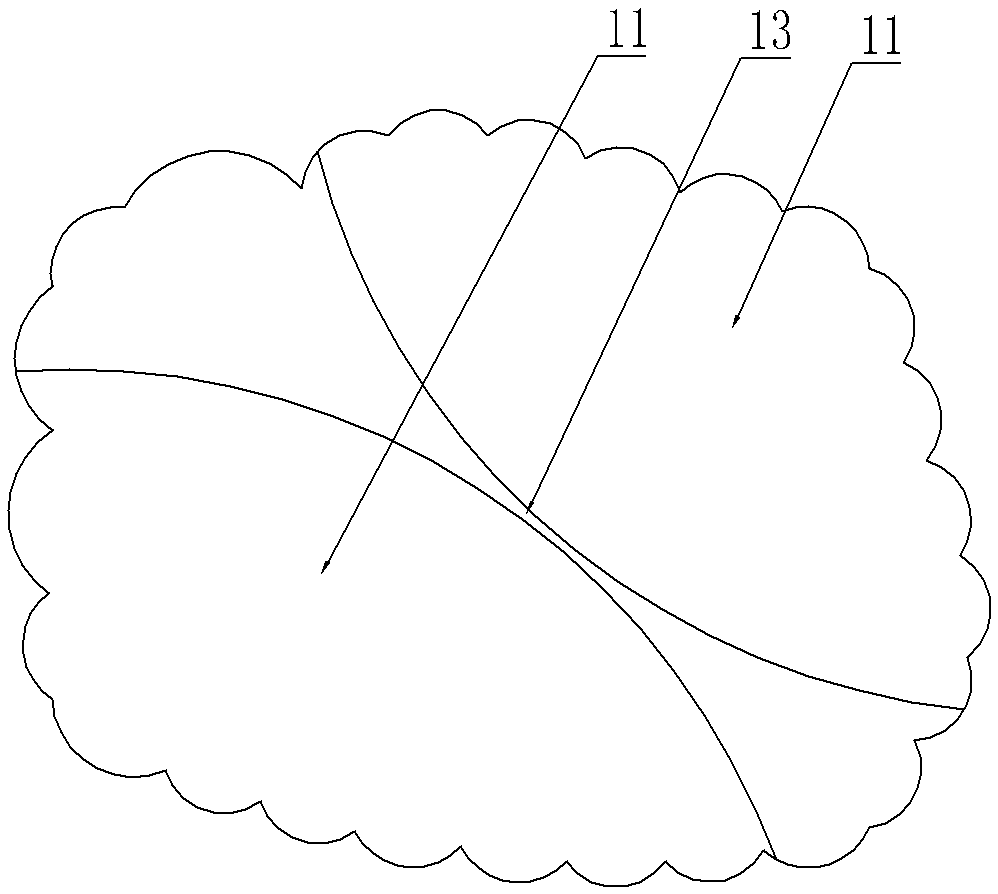

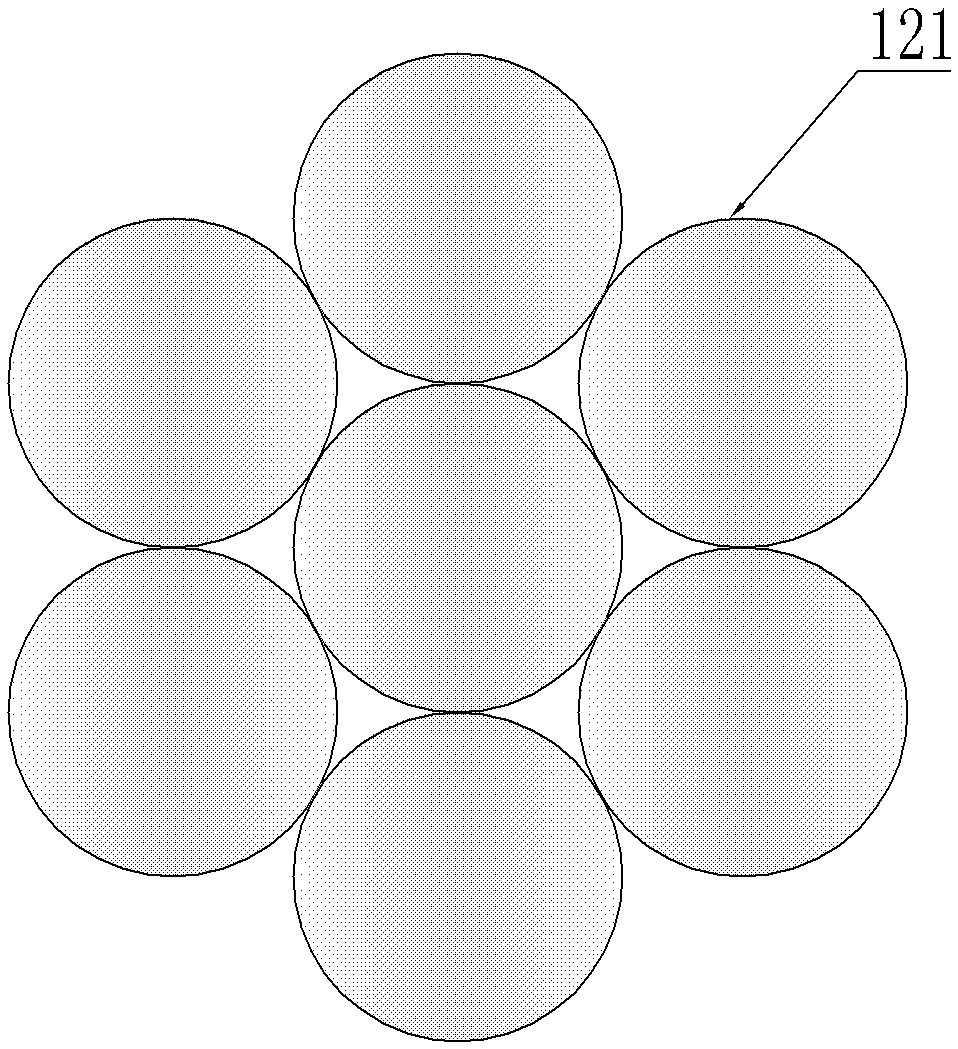

[0017] Such as Figure 1~Figure 3 As shown, the core wire of the reinforced stranded wire includes 1 core strand 12 and 6 side wires 11 evenly twisted on the outer periphery of the core strand. The core strand 12 is provided with 7 core wires 121, of which 6 core wires Twisted on the outer periphery of one core wire, the diameter of the core strand 12 is larger than that of the side wires 11, so that after the side wires 11 are stranded on the outer periphery of the core strand 12, gaps 13 can be provided between adjacent side wires 11 of the same layer.

[0018] Bending test detection:

[0019] Material description: Test group 1: The core wire is made of stainless steel with a diameter of 0.28mm, and the diameter of the core strand is 0.84mm; there are 6 side wires made of pure copper with a diameter of 0.8mm.

[0020] Control group 1: The core strand is a single core wire made of pure copper with a diameter of 0.83 mm; 6 side wires are made of pure copper with a diameter of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com