Broach based on surface micro-pit magnetic adsorption and broaching method thereof

A magnetic adsorption, micro-pit technology, applied in the direction of broach, broaching, metal processing equipment, etc., can solve problems such as excessive load, tool wear, low efficiency, etc., to reduce severe friction, reduce contact area, and improve storage. the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing.

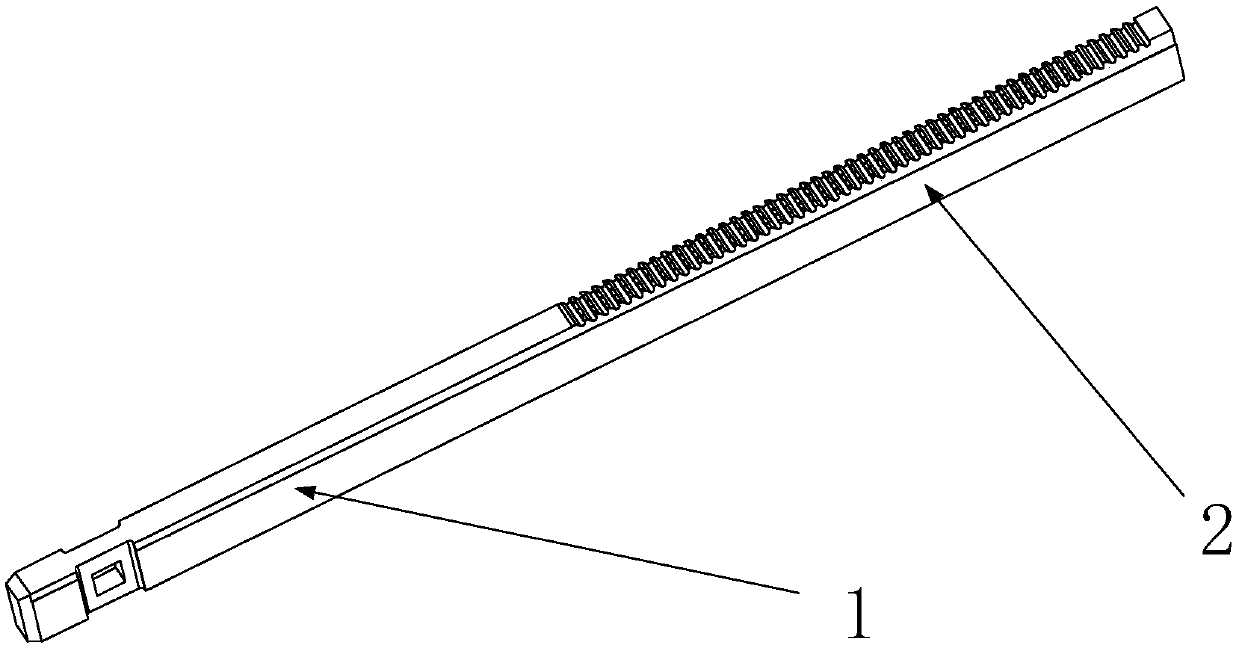

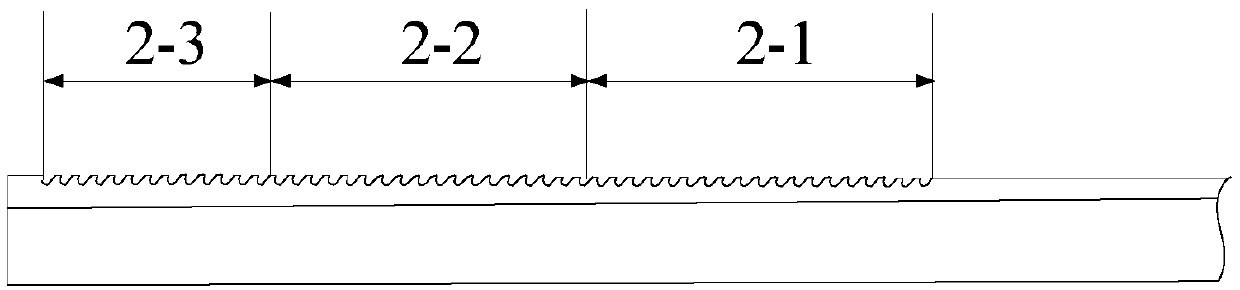

[0033] Such as figure 1 , 2 As shown in and 3, a broach based on surface microstructure and magnetic adsorption includes a handle 1 and a tooth part 2. The cutter tooth part 2 includes a rough drawing section 2-1, a fine drawing section 2-2 and a smoothing section 2-3 arranged in sequence from inside to outside. Rough drawing section 2-1 consists of sequentially arranged n 1 It consists of a rough broach tooth. The fine drawing section 2-2 consists of n arranged in sequence 2 Composed of a fine broach tooth. The smoothing section 2-3 consists of n arranged in sequence 3 Composed of a smoothing knife tooth. Both the rough drawing section 2-1 and the fine drawing section 2-2 are provided with three or four chip dividing grooves. The chip splitter divides the flank of the tooth into four or five split flanks3.

[0034] Such as Figure 4 , 5 As shown in and 6, micro-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com