A kind of preparation method of microecological viable bacteria vitrified freeze-dried shrimp

A micro-ecological and freeze-drying technology, which is used in the forming of food, the function of food ingredients, and the preservation of meat/fish by freezing/cooling, which can solve the problem of no new beneficial ingredients, less nutritional retention of shrimp, and different shapes and sizes. problems, resulting in improved gut health, light weight, easy storage and transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

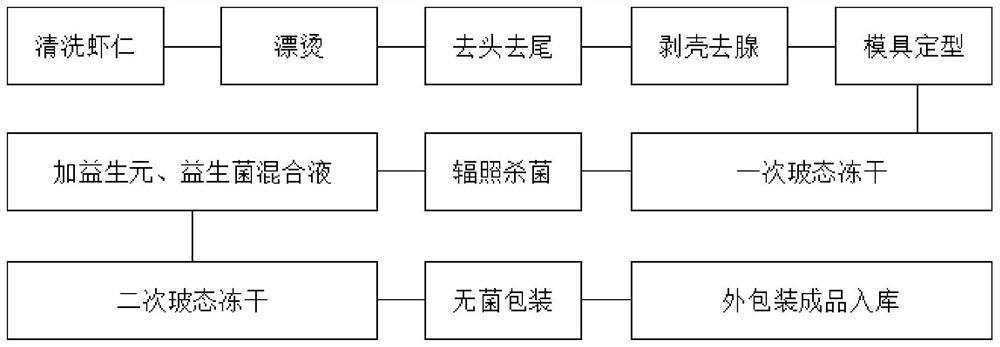

Image

Examples

Embodiment 1

[0033] The present embodiment provides a preparation method of microecological viable bacteria vitrified freeze-dried shrimp, and the preparation method of the shrimp includes the following steps:

[0034] S1, food processing: clean the fresh shrimp to remove the sediment and drain, and then de-head, remove the tail, peel the shrimp shell and remove the intestinal glands after blanching to obtain the shrimp, rinse and drain the shrimp and put it into the mold;

[0035] On the selection of materials in step S1, the fresh shrimp selected can be Penaeus vannamei, basil shrimp, etc.;

[0036] In the present invention, Penaeus vannamei is preferred. In the following process of injecting the mixture of prebiotics and probiotics, the amount of injection is 5-7 mL, preferably 6 mL.

[0037] S2. One-time glassy freeze-drying: place the shrimp together with the mold under the ultra-low temperature condition of -110℃~-60℃ for quick freeze-drying, so that the water molecules in the ingred...

Embodiment 2

[0052] A preparation method of microecological viable bacteria vitrified freeze-dried shrimp, the shrimp is prepared by the preparation method of the above-mentioned embodiment 1.

[0053] The proportion of guaranteed nutritional value of the shrimp (per 100g) is:

[0054] Table 1 Proportion of guaranteed value of nutrient composition of microecological live bacteria in glassy freeze-dried shrimp

[0055] nutrient content proportion protein 82.29% Fat 1.54% moisture 2.3% Ash 2.3% Dietary fiber 0.3%

[0056] By freeze-drying the ingredients by ultra-low temperature freezing, the shape, color and smell of the ingredients are preserved to the greatest extent, and the nutrient retention rate is as high as 96%; and the products are of high quality, light weight, easy to store and transport; After absorbing water, the ingredients basically return to their original form, and the ingredients are natural, green, safe, convenient and nutritio...

Embodiment 3

[0058] In the step S1, a mixer is used in the process of rinsing the shrimp, and the rinsing step here is:

[0059] (1) Pour the unshelled shrimp, water and edible salt into the blender according to the ratio of 1:10:0.05;

[0060] (2) Put a rubber cover on the surface of the stirring rod, and turn on the mixer. At this time, the rotation speed of the stirring rod is 300-500r / min, and the duration of the mixer is 5-10min;

[0061] (3) After the mixer stops working, let the shrimps stand for 15-30min, and finally remove them.

[0062] In step (3), the fished out shrimps are inspected, and some shrimps that are not separated from the shrimp shells are manually extracted, and finally complete shrimps are obtained.

[0063] The above-mentioned method of stirring and cleaning can save the step of peeling the shrimp shell, and use the stirring rod to carry out the shelling operation for most of the shrimp.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com