Patents

Literature

79results about How to "Reduce cutting vibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

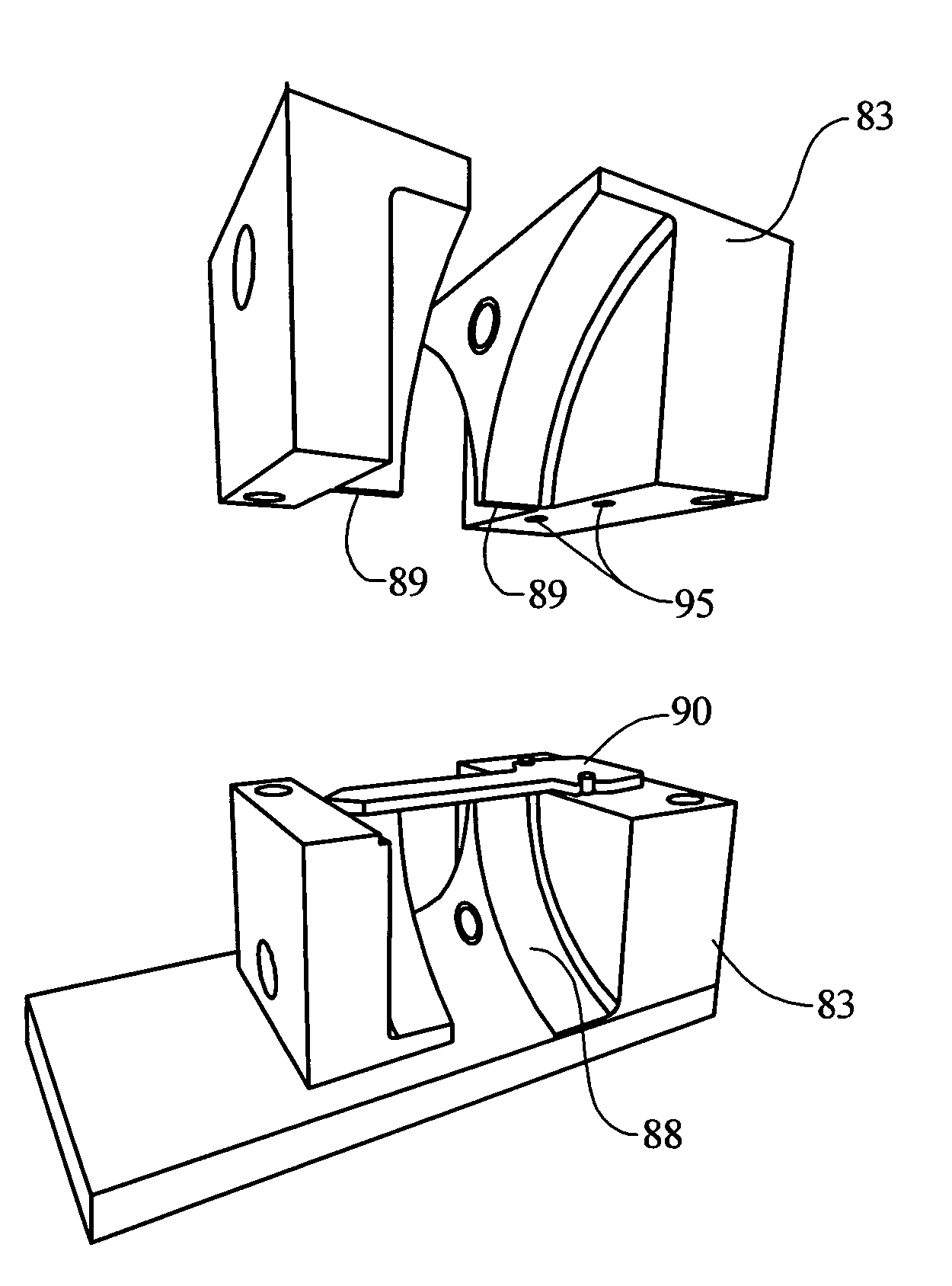

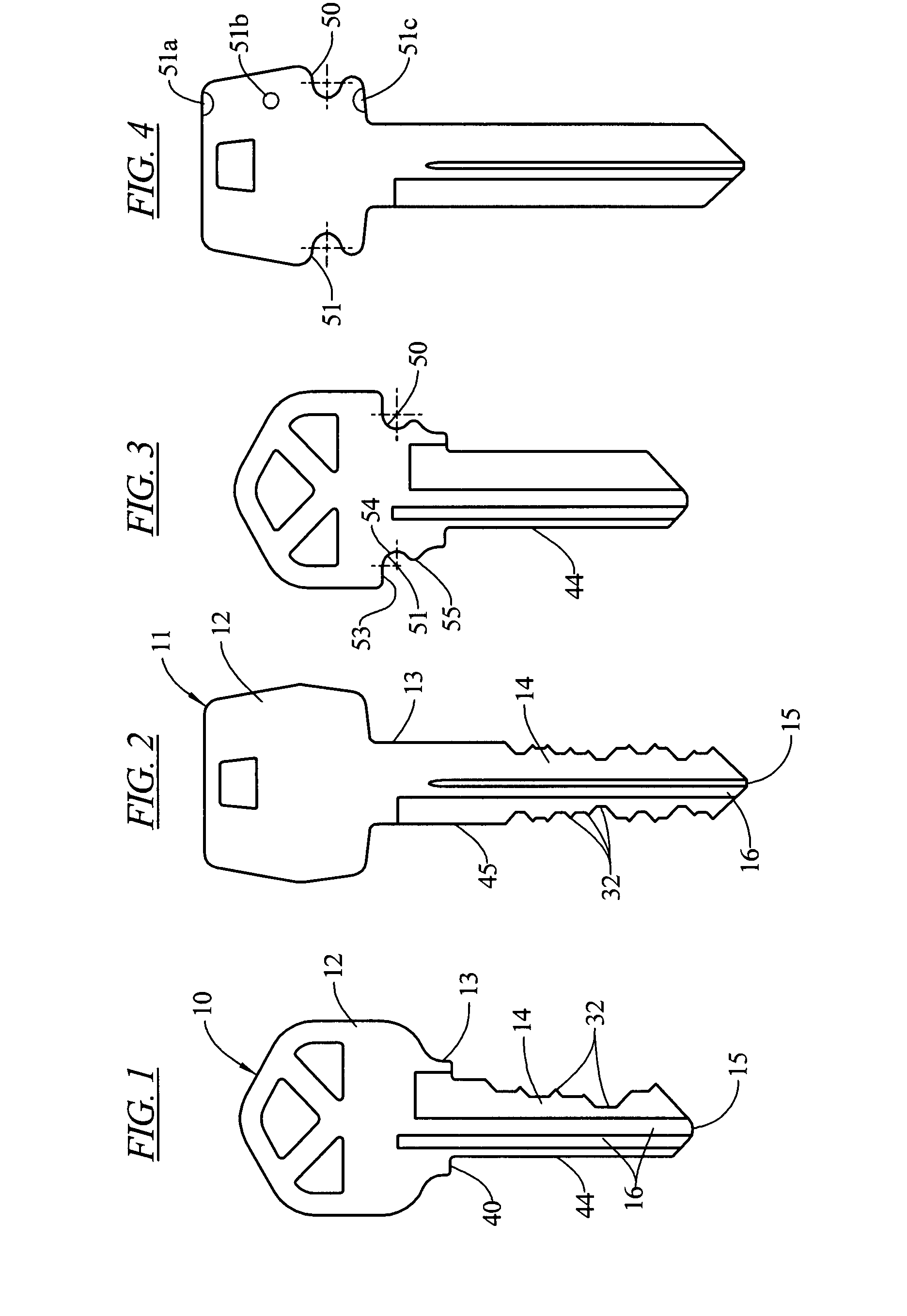

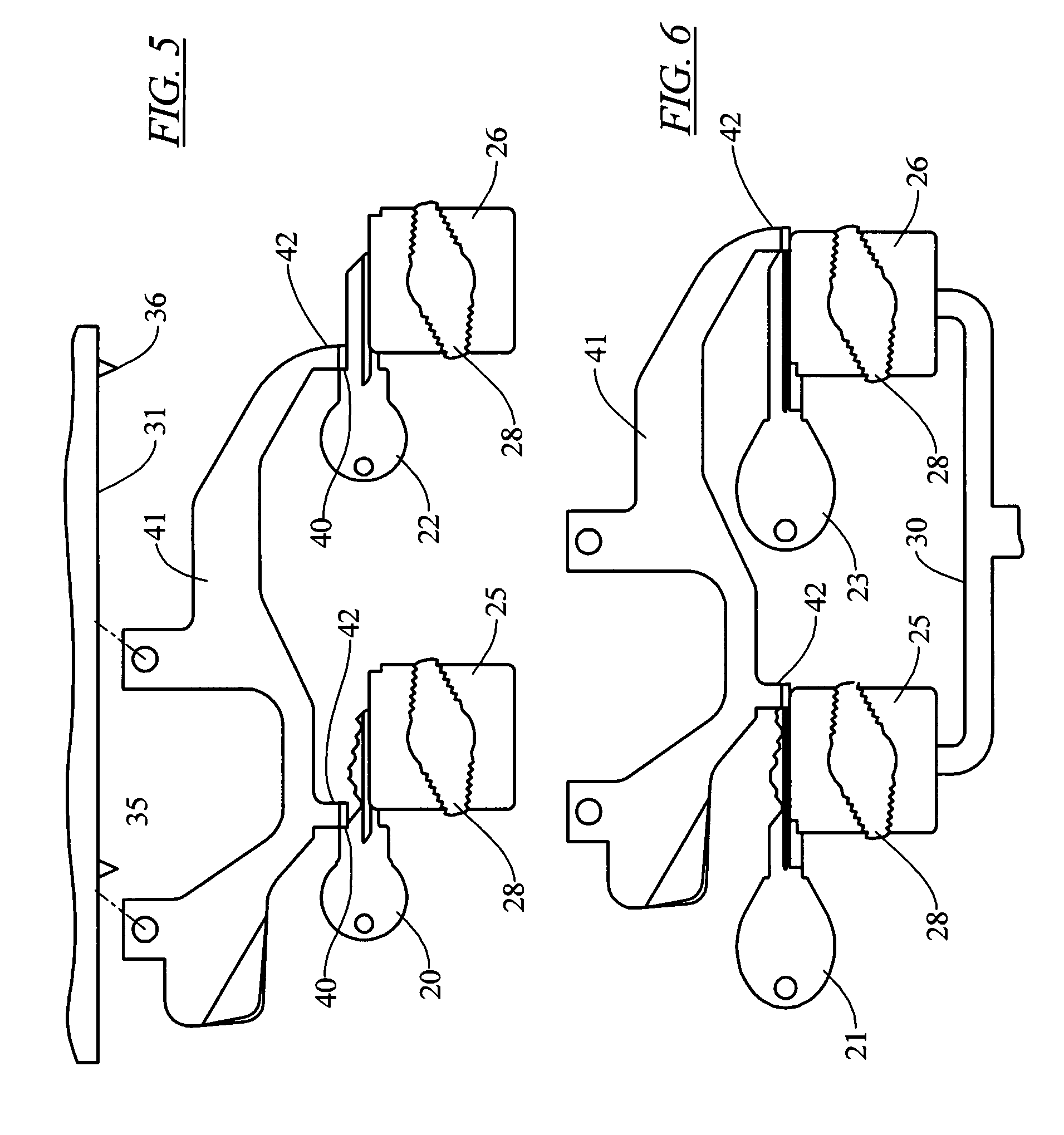

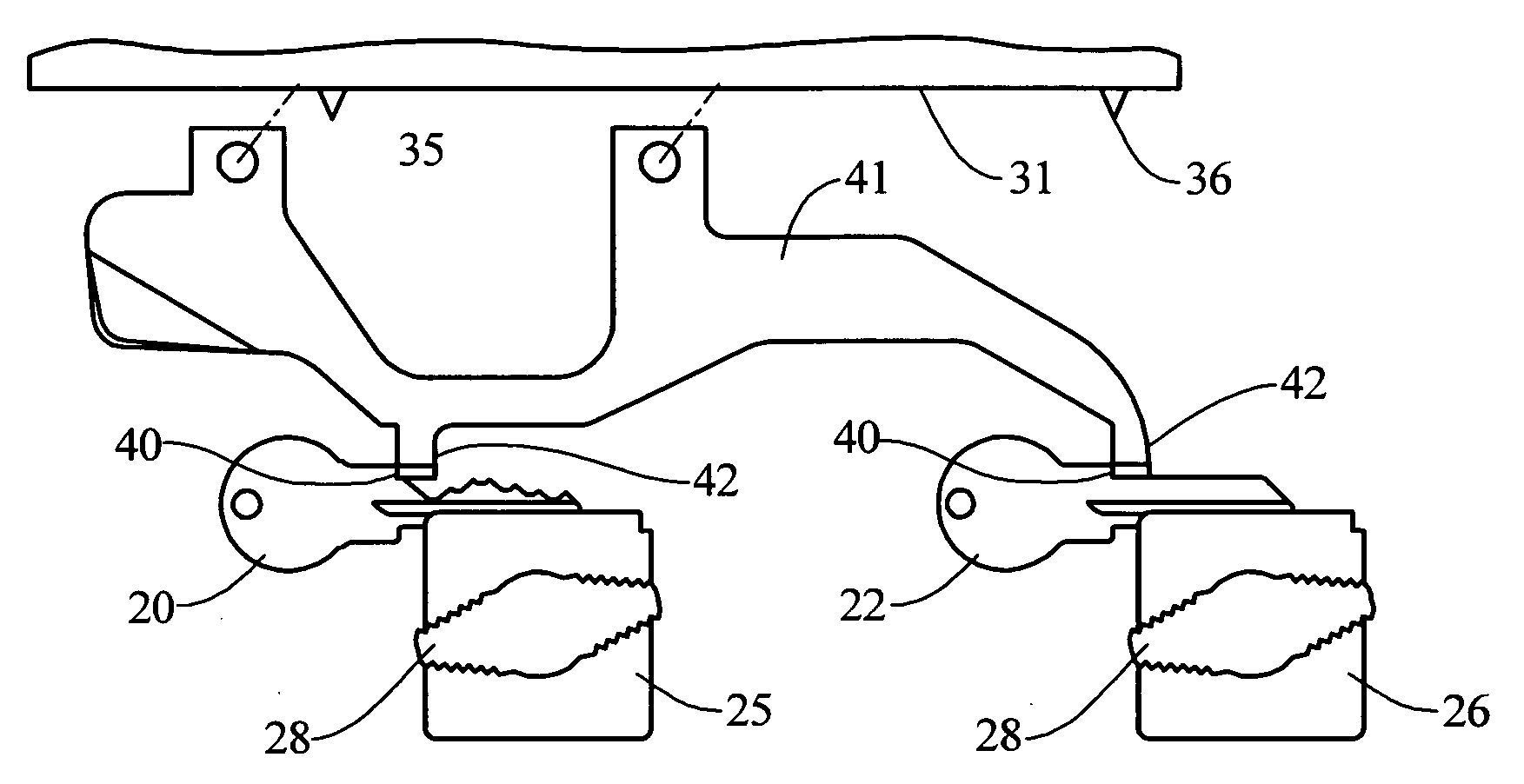

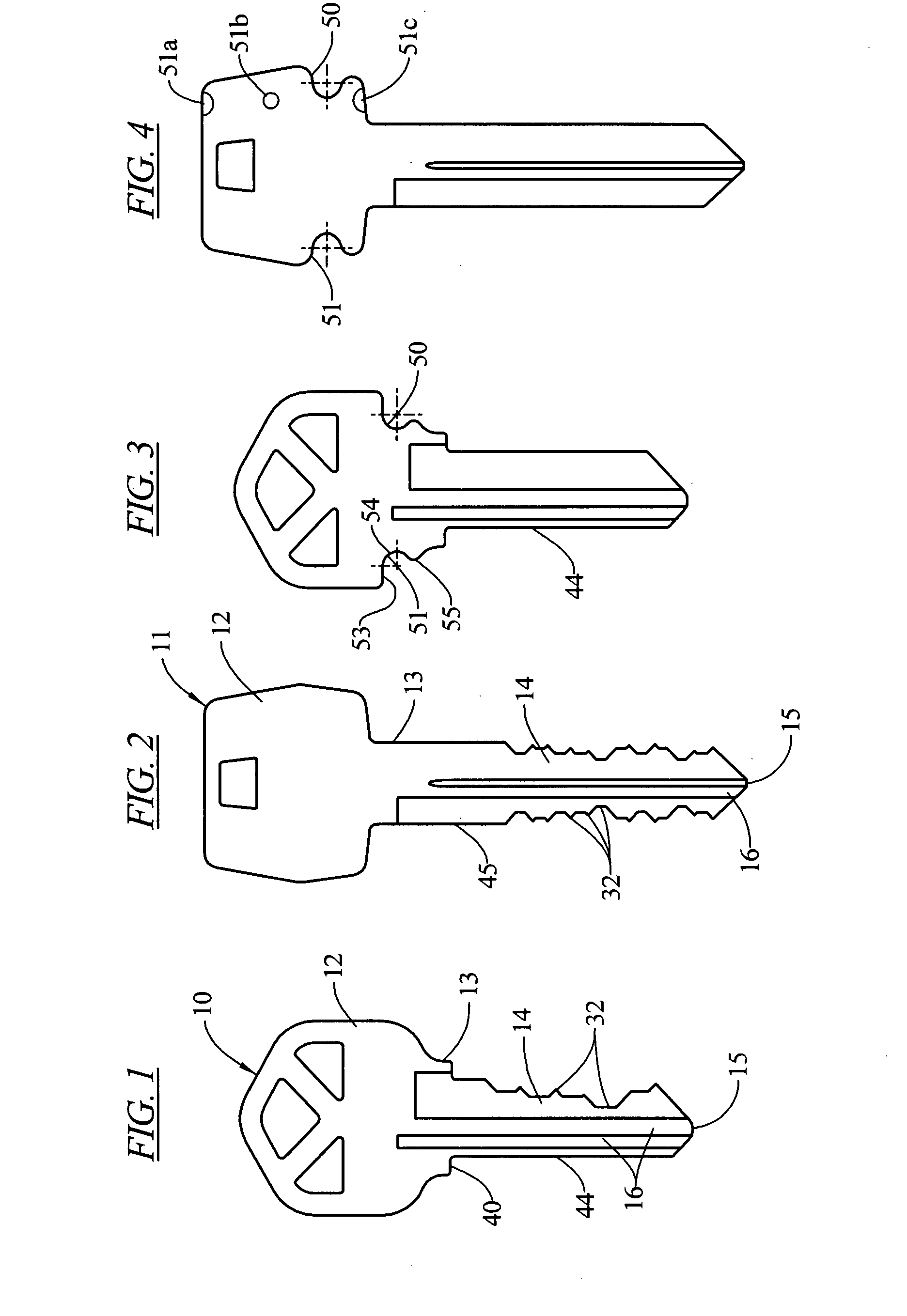

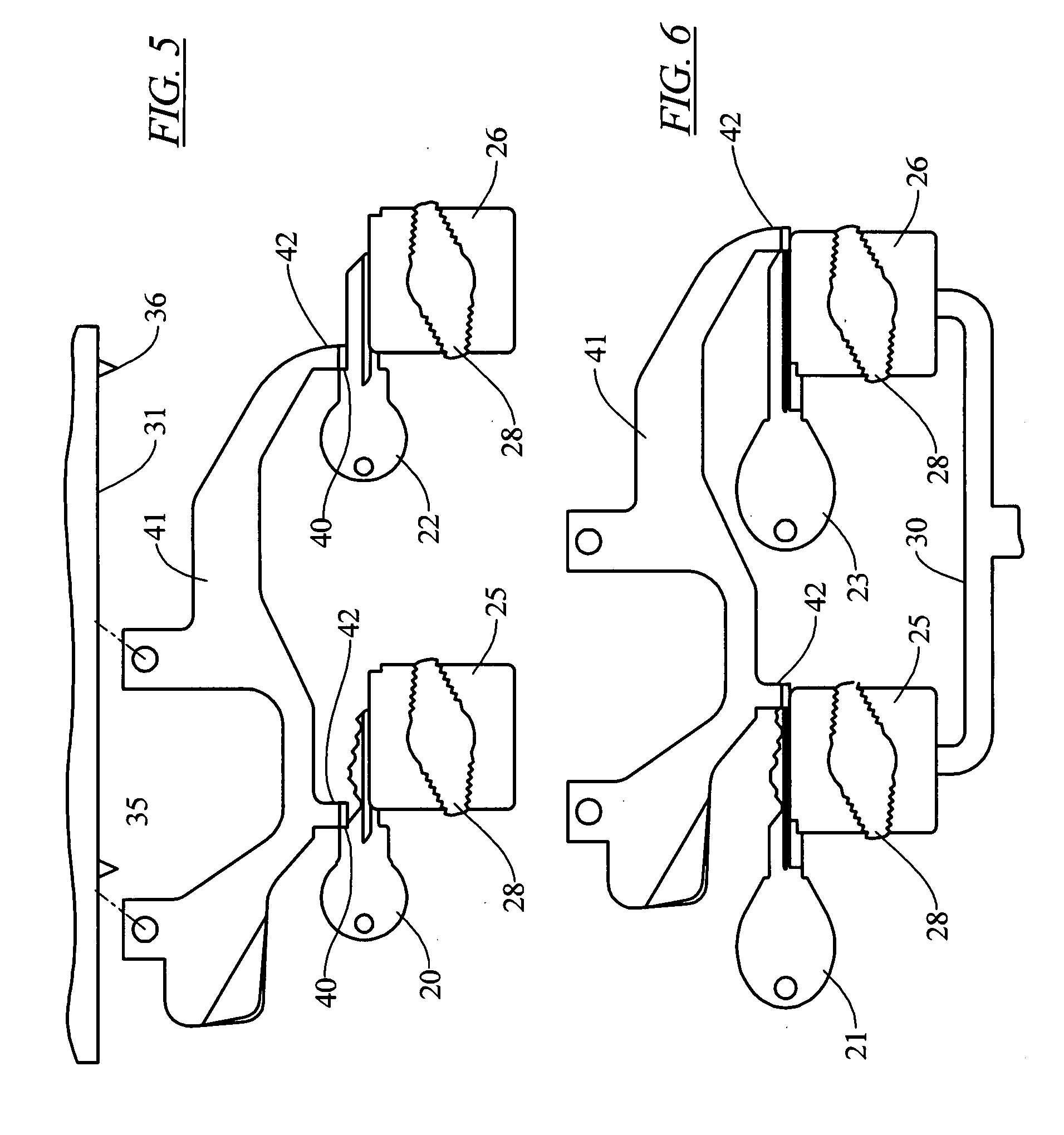

Ez key registration assembly

InactiveUS7918629B2Precise positioningReduce cutting vibrationWorkpiece holdersMilling machinesEngineeringMechanical engineering

A locating system and method for accurately positioning key blanks with respect to a key cutter where the key head is clamped between opposing jaws with the key blade working edges projecting therefrom, the key head is provided with shaped recesses having at least a partially specifically shaped edge wall and wherein at least one jaw member is provided with a projection having a correspondingly shaped sidewall, the pin being positioned with respect to the clamp such that when the key blank head is abutted against the pin with the key blank edge configuration mating to the pin sidewall configuration, the key blade will project from the jaw in a proper position for engagement by either the bitting follower or bitting cutter respectively.

Owner:KABA ILCO CORP

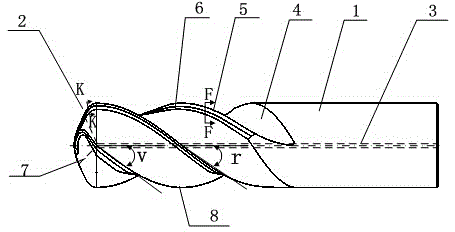

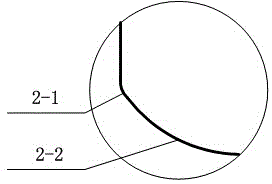

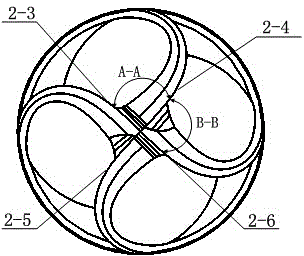

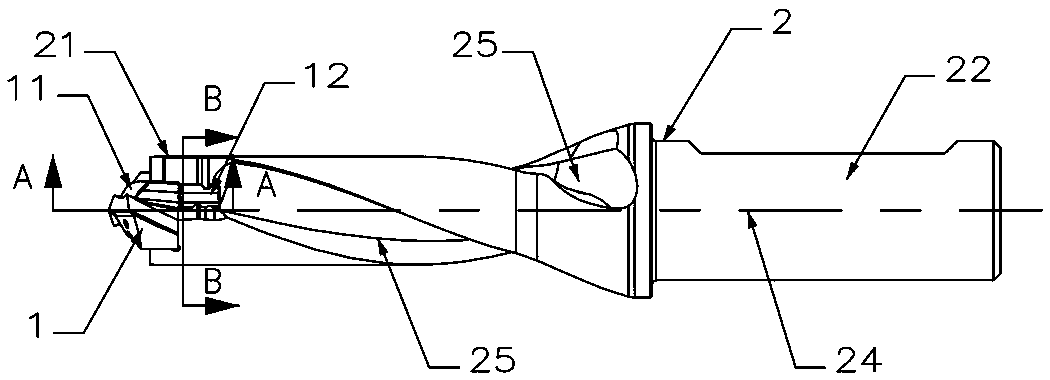

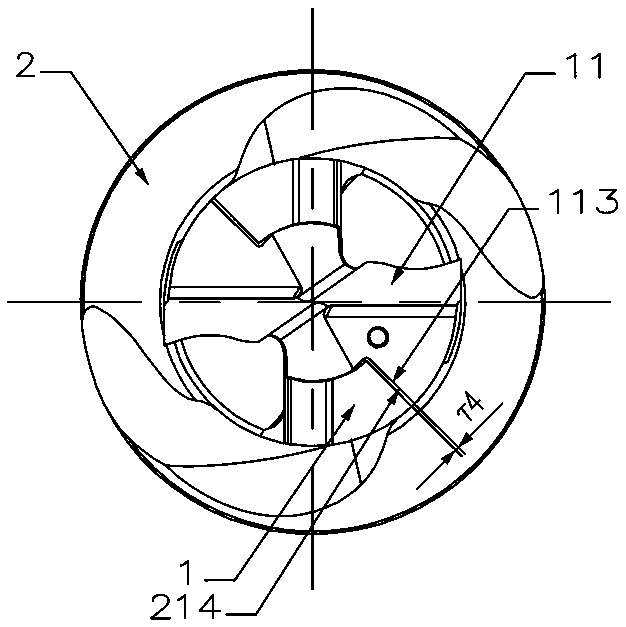

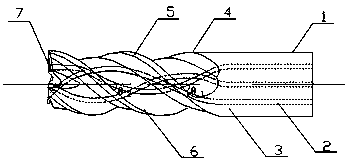

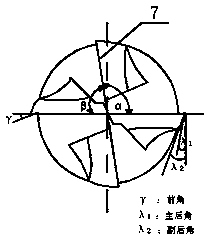

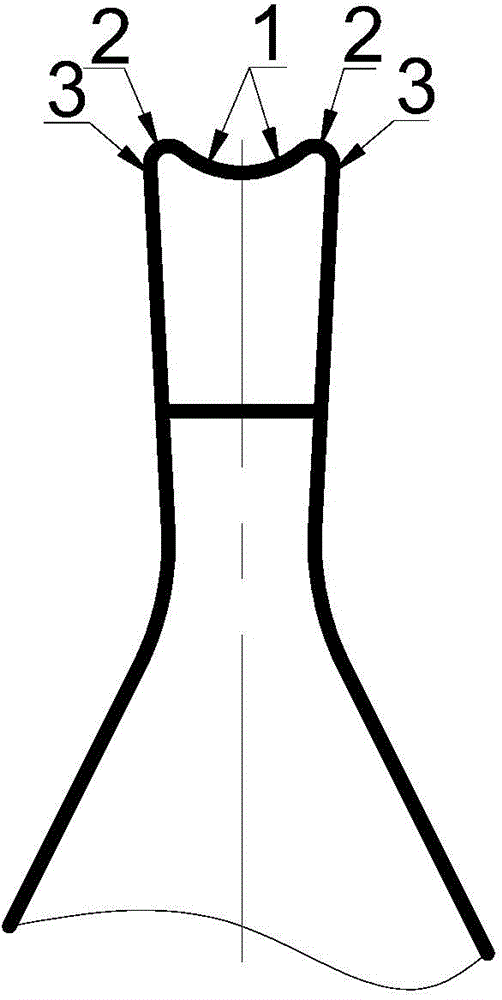

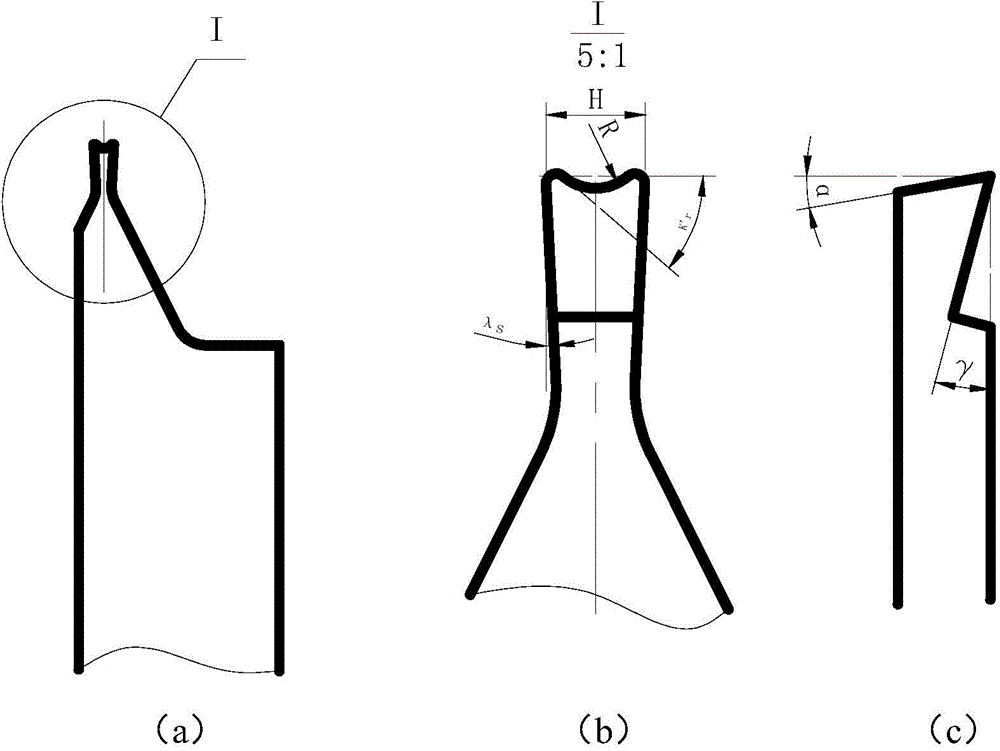

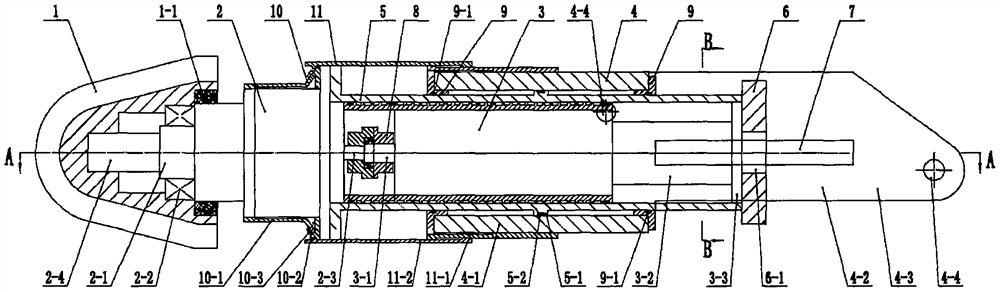

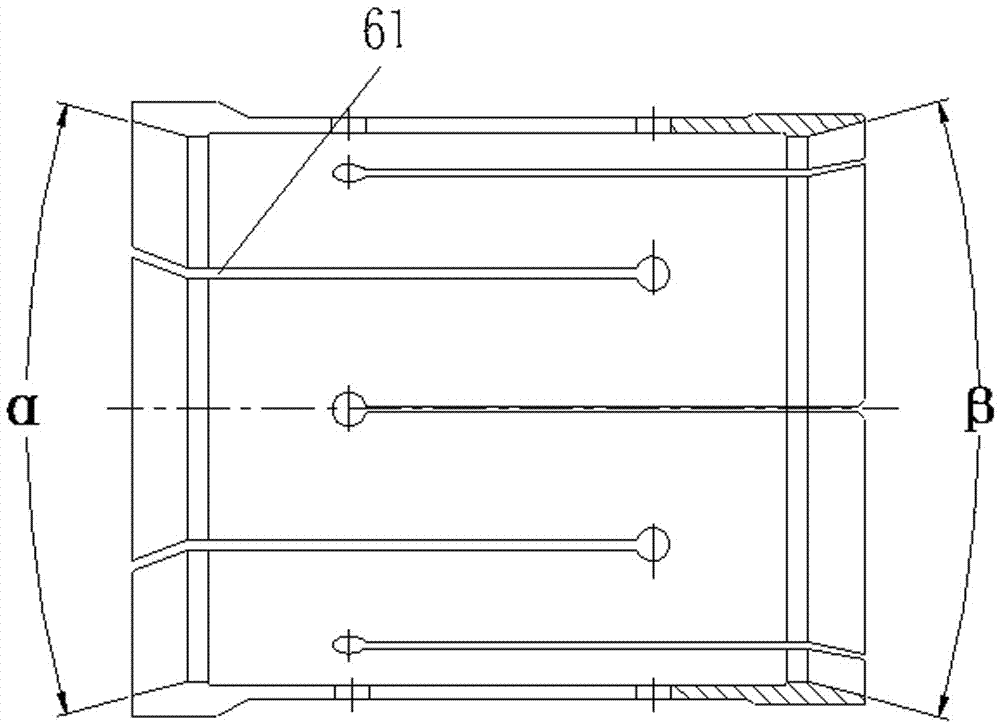

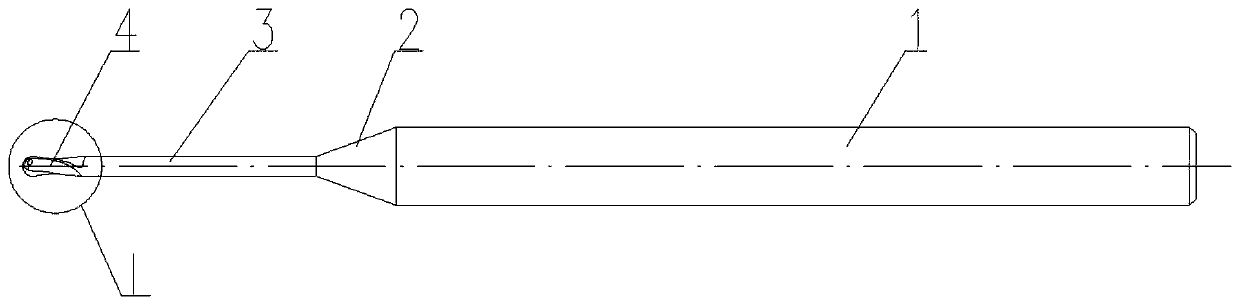

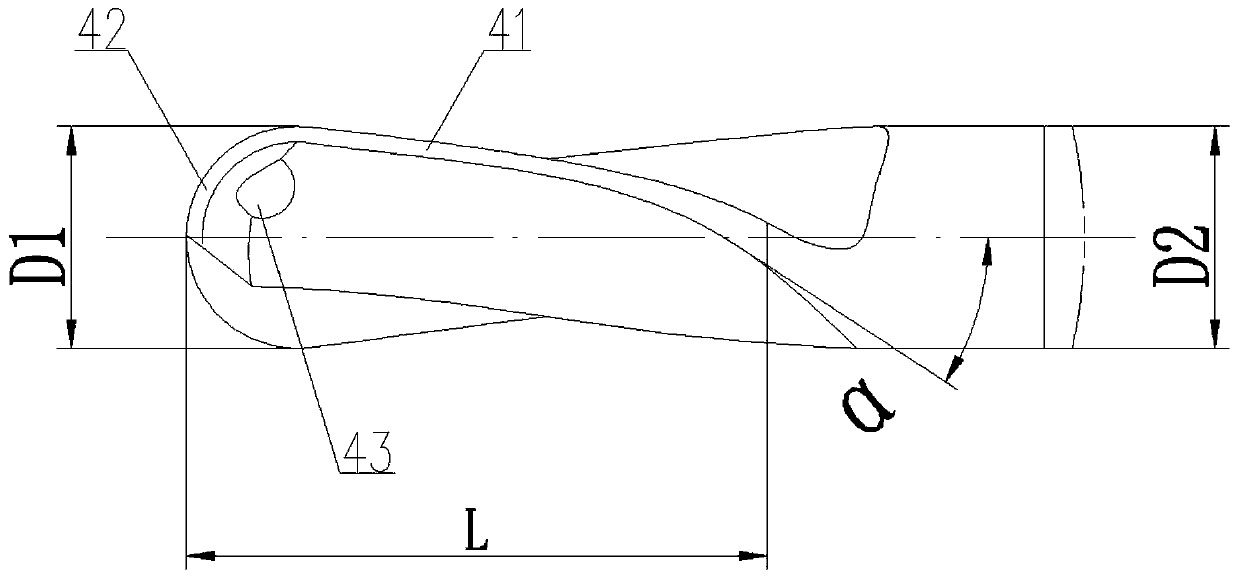

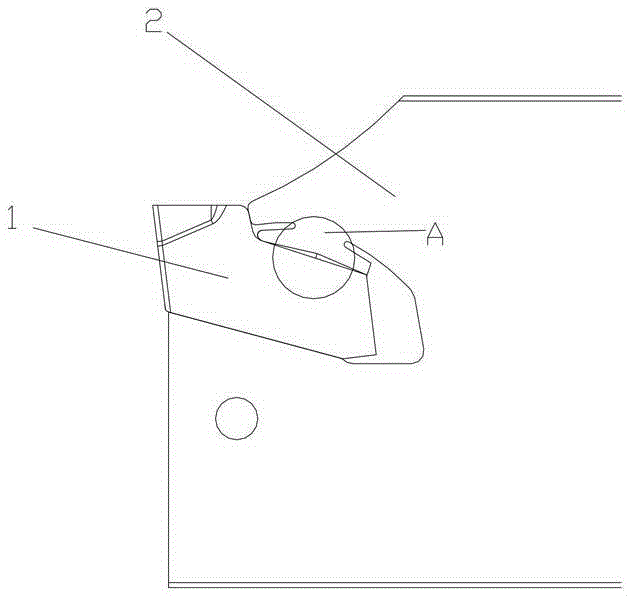

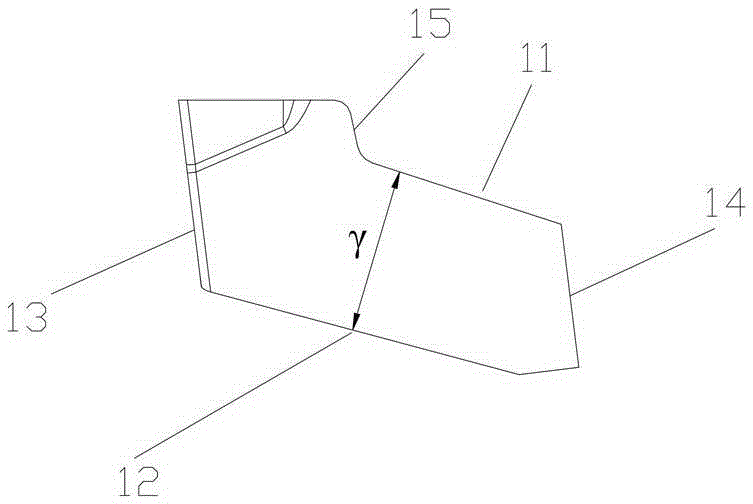

Milling cutter provided with equidistant arc head on eccentric shape flank surface and grinding method

InactiveCN104959667AAvoid vibrationExtend your lifeMilling cuttersWorkpiecesMilling cutterEngineering

The present invention relates to a milling cutter provided with an equidistant arc head on an eccentric shape flank surface and a grinding method, the cutter can reduce the vibration during the process of processing of different hardness of hardened steels for splicing of a mould, the cutter life and workpiece surface quality can be improved, the flank surface shape can be changed, and the cutter tip strength can be improved. The milling cutter is an overall hard alloy end milling cutter. The milling cutter includes a cutter shank (1) and the arc head (2), the arc head includes a large curvature arc (2-1) and a small curvature arc (2-2). Tooth-spacing angles are 87 degrees, 93 degrees, 87 degrees, and 93 degrees, tooth-spacing vertical angles are equal, helix angle (r) is 38 degrees, helix angle (v) is 40 degrees, and cutter end cutting edge flank surface (10) and circumferential cutting edge (6) are in eccentric shape. Front angle is in the range of 0-3 degrees, first clearance angle is in the range of 8-10 degrees, and second clearance angle is in the range of 15-22 degrees. The center position of the cutter is provided with cooling channels (3), the number of the cooling channels is four, and the four cooling channels respectively are located four cutting edge end tooth chip pockets. The present invention also provides a reference for the grinding of the cutter of the type.

Owner:HARBIN UNIV OF SCI & TECH

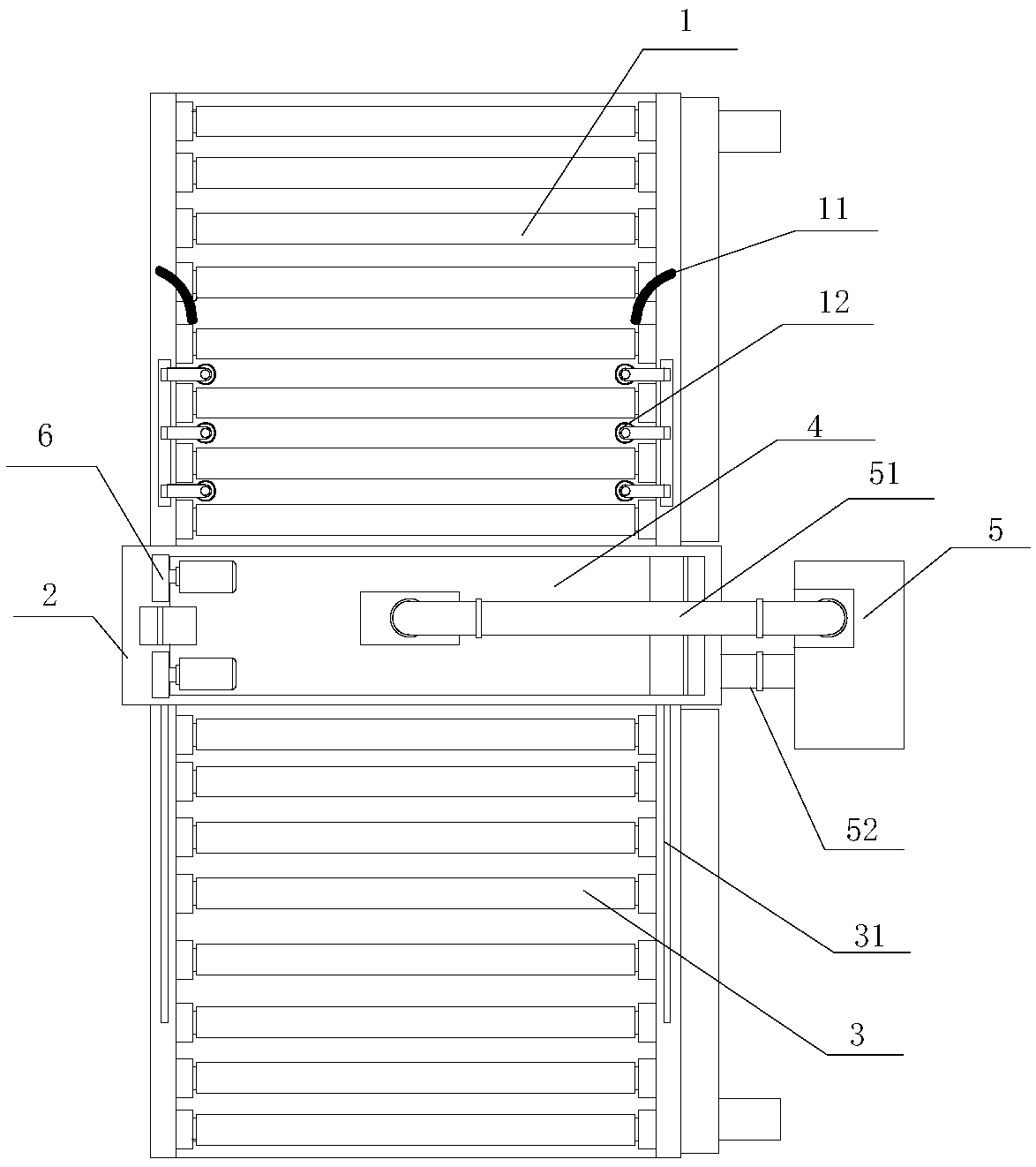

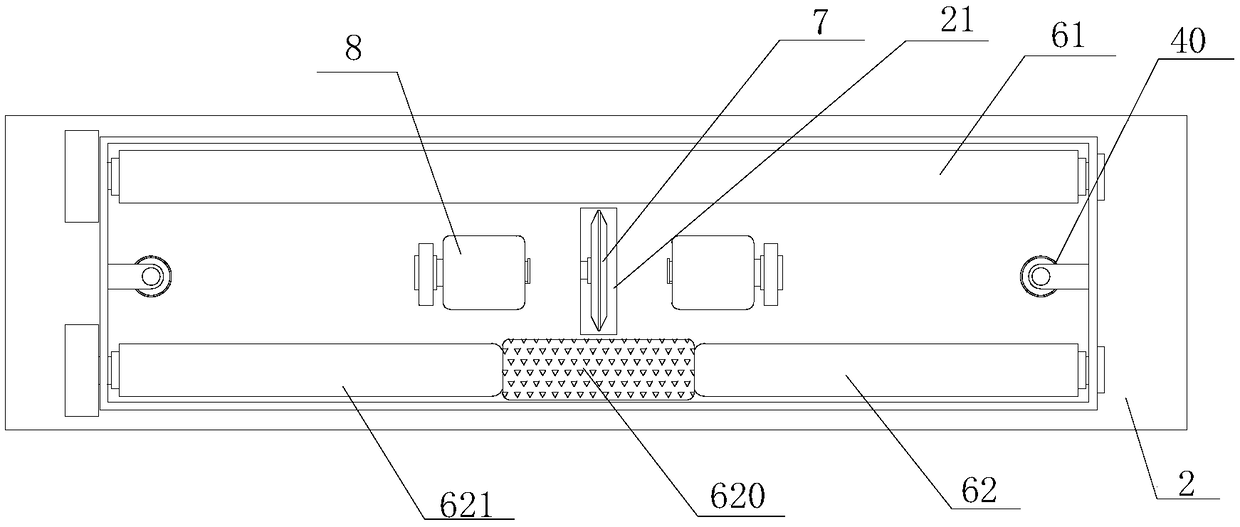

Board material cutting device

InactiveCN109093853AClear in timeAvoid accidental injuryWorking accessoriesStone-like material working toolsEngineeringMechanical engineering

The invention discloses a board material cutting device, which comprises a loaded material conveying roller device, a rack, a discharged material conveying roller device, a dust-proof protective cover, a dust suction device, auxiliary feed roller devices, a cutting device and auxiliary material pressing roller mechanisms, wherein two ends of the rack are independently provided with the loaded material conveying roller device and the discharged material conveying roller device; the dust-proof protective cover is installed above the rack; the auxiliary feed roller devices, the cutting device andthe auxiliary material pressing roller mechanisms are arranged in the dust-proof protective cover; the rack is provided with a knife groove; the cutting device is installed below the rack and is provided with a cutting knife component; the cutting knife component penetrates through the knife groove; and two sides of the cutting knife component are symmetrically provided with auxiliary material pressing roller mechanisms. Through a roller conveying mechanism, the board material is conveyed, the auxiliary feed roller structures and the auxiliary material pressing roller structures can press a wallboard, cutting vibration is reduced, cutting accuracy is improved, and meanwhile, the dust-proof protective cover can be adopted to remove dust generated by cutting in time.

Owner:杭州看啊贸易有限公司

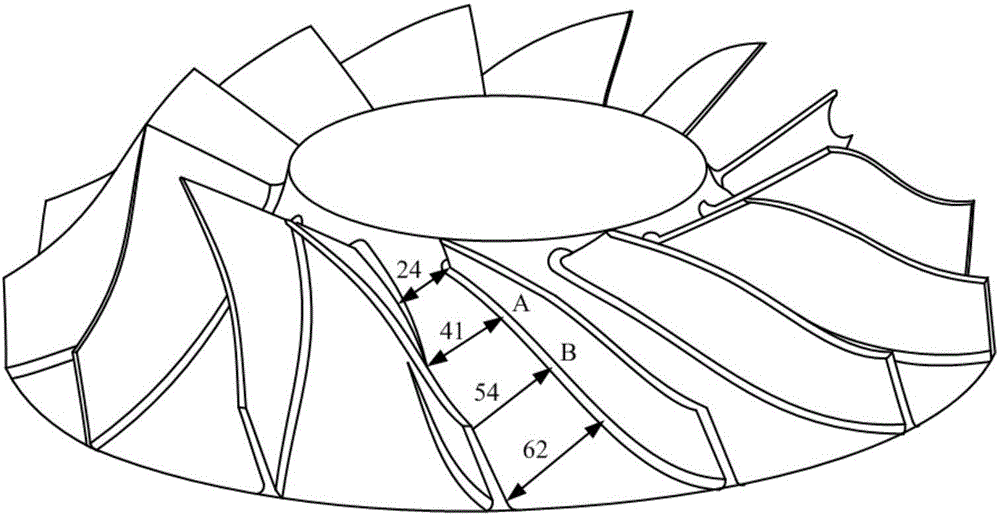

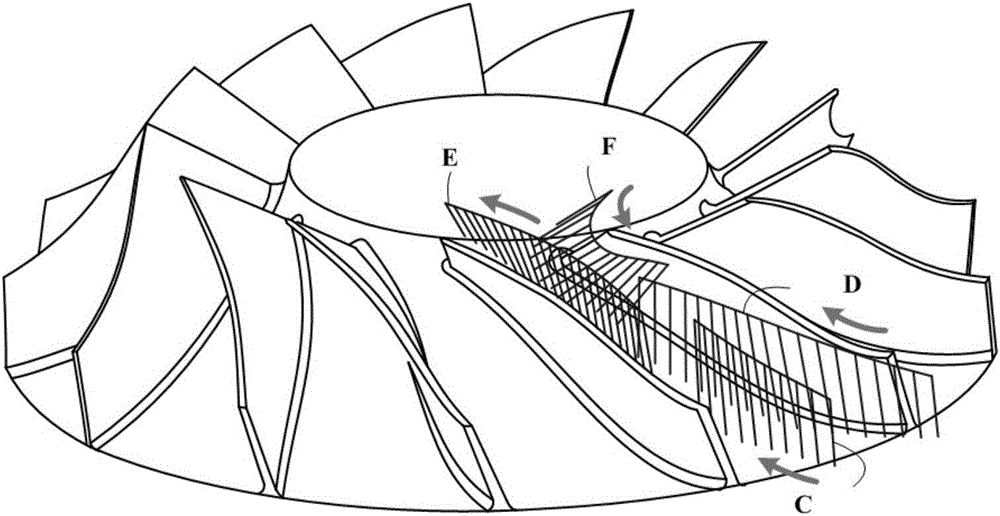

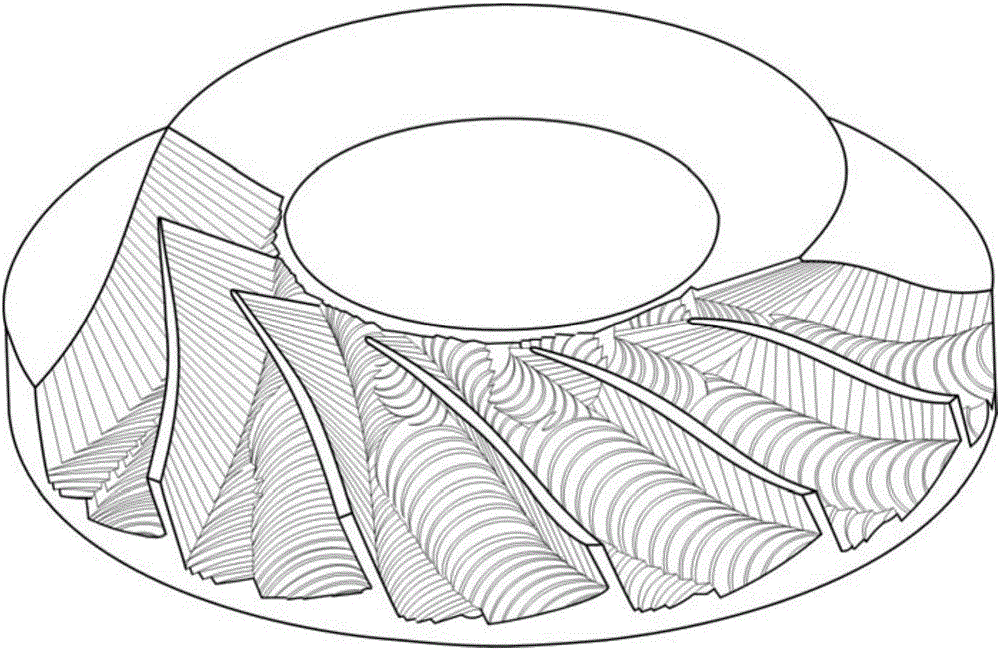

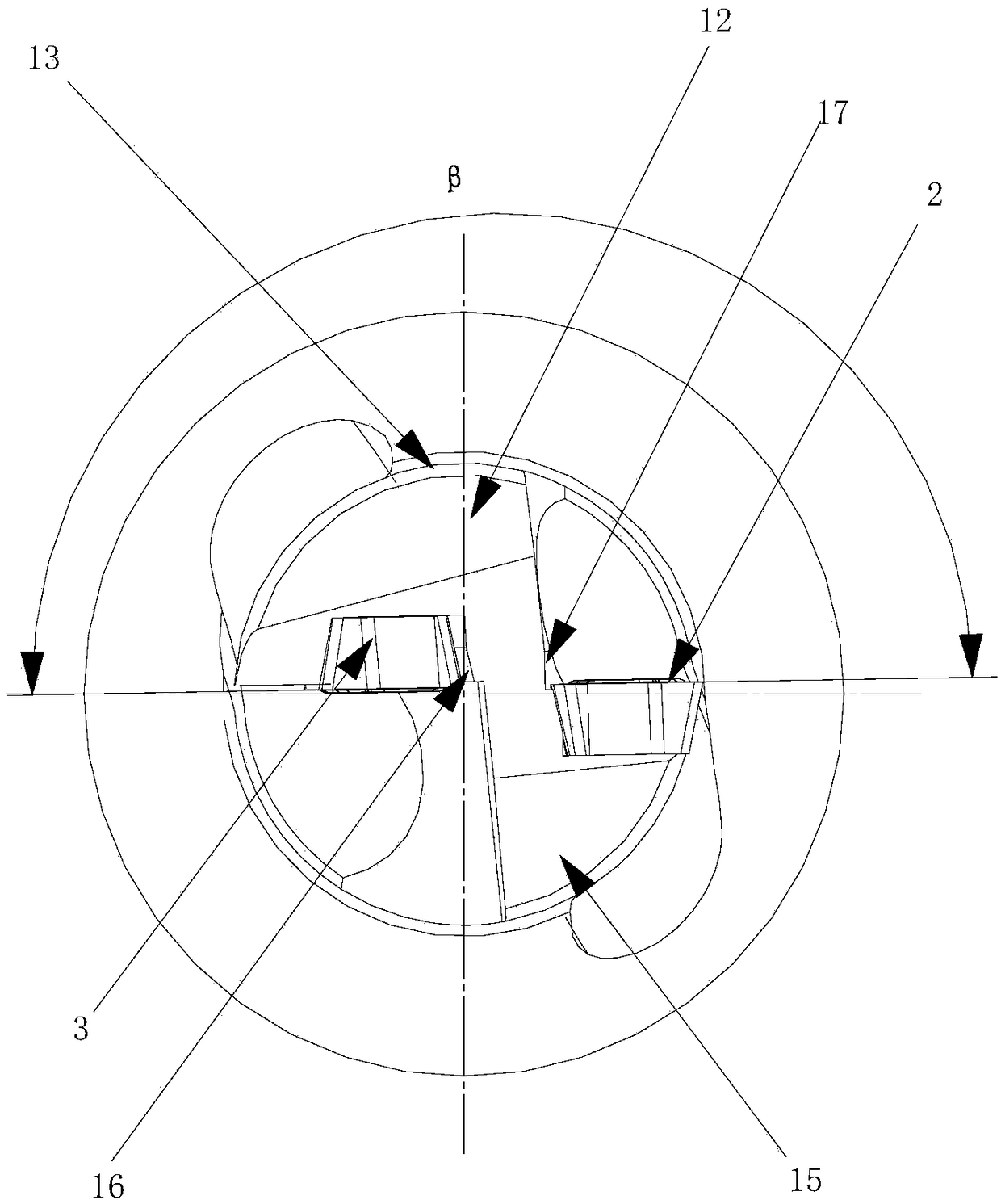

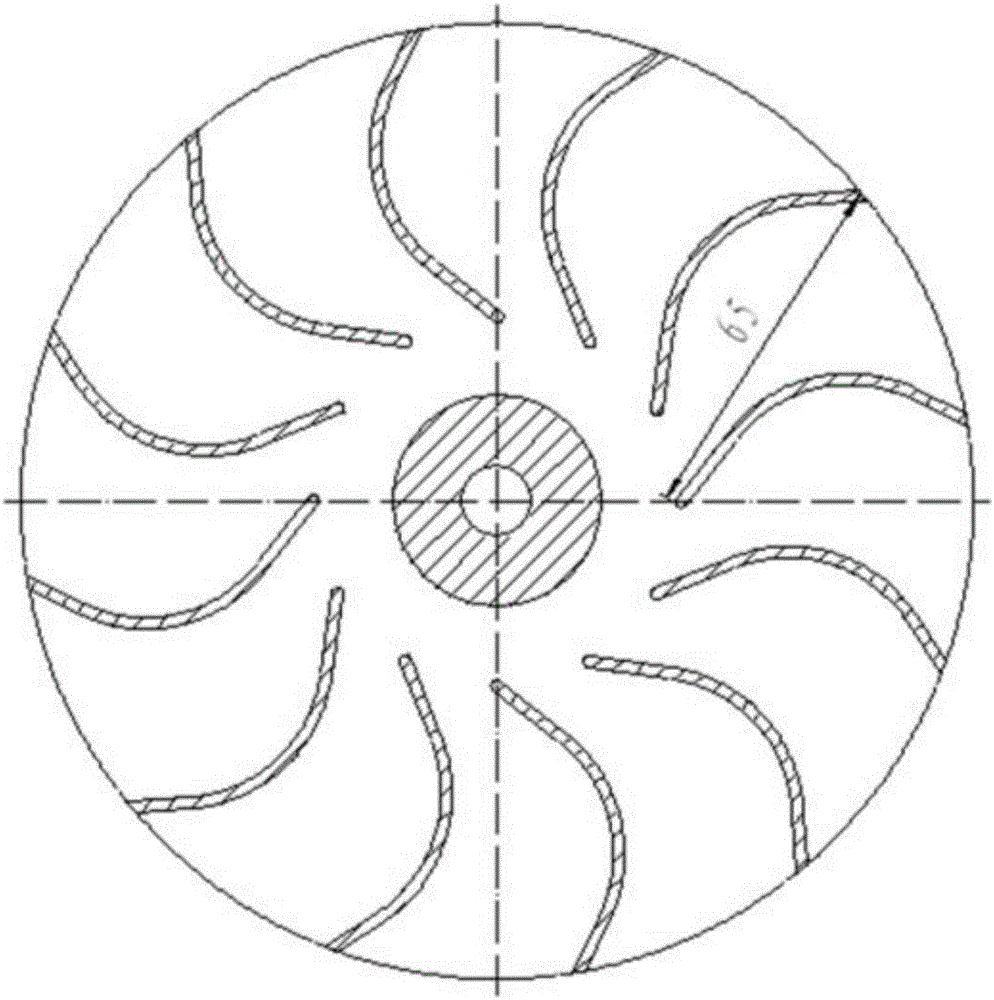

Double-row grooving plunge milling method of integral impeller

ActiveCN106624667AReduce the number of tracesImprove efficiencyWorkpiecesMilling equipment detailsImpellerEngineering

The invention discloses a double-row grooving plunge milling method of an integral impeller. The double-row grooving plunge milling method is characterized by comprising the steps that a double-row plunge milling tool track is planned along blades on the two sides of an impeller runner; the row tool sequence of the tool track is in the inlet and outlet direction of the runner; and the tool diameter is determined according to the bottom width of the cross section of the runner, the runner is segmented, and the bottom width of the cross section of each segment of the runner is larger than one time of the tool diameter and smaller than two times of the tool diameter. According to the method, compared with an existing large feed layer cutting method, the rough machining efficiency of the integral impeller can be improved by 50% or above, plunge milling top tools can be conveniently eliminated, and redundant tool tracks are effectively reduced; and according to the method, the implementation process is simple, CAM software integration is facilitated, and good application prospects are achieved.

Owner:DALIAN UNIV OF TECH

Ez key registration assembly

InactiveUS20080226408A1Reduce cutting vibrationStable positionWorkpiece holdersMilling machinesEngineeringMechanical engineering

A locating system and method for accurately positioning key blanks with respect to a key cutter where the key head is clamped between opposing jaws with the key blade working edges projecting therefrom, the key head is provided with shaped recesses having at least a partially specifically shaped edge wall and wherein at least one jaw member is provided with a projection having a correspondingly shaped sidewall, the pin being positioned with respect to the clamp such that when the key blank head is abutted against the pin with the key blank edge configuration mating to the pin sidewall configuration, the key blade will project from the jaw in a proper position for engagement by either the bitting follower or bitting cutter respectively.

Owner:KABA ILCO CORP

Stably clamping drilling tool

ActiveCN109262027AEasy clampingReduce manufacturing difficultyTransportation and packagingChucksBiomedical engineeringLambda

The invention discloses a stably clamping drilling tool. A projection is spirally twisted into a recess along the direction of a center shaft, an outer circumferential surface is matched with an innercircumferential surface to achieve changing interference magnitude lambda in the cutting part clamping process of a clamping component, and -0.1mm<=lambda<=0.05mm. The drilling tool has the advantages of rapidness in assembly and disassembly, no axial looseness, high positioning precision, simplicity in manufacture, good interchangeability and the like.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Damping cutter bar for turning coarse-pitch threads

InactiveCN109465506ASimple structureEasy to manufacture, process and installThread cutting toolsThread cutting machinesReduction functionMagnet

The invention relates to a damping cutter bar for turning coarse-pitch threads, and belongs to the field of machining. The damping cutter bar comprises a cutter bar shaft, a cutter bar shaft sleeve, an exciting coil, an upper permanent magnet, a lower permanent magnet, a piezoelectric ceramic piece, an end cover, a magnetorheological fluid and the like, wherein the exciting coil is wound on the cutter bar shaft, a coil lead of the exciting coil is connected with the piezoelectric ceramic piece, the magnetorheological fluid is injected into an annular cavity formed by the upper permanent magnetand the lower permanent magnet, and the piezoelectric ceramic piece is arranged in an annular cavity formed by the upper permanent magnet and the cutter bar shaft sleeve. According to the damping cutter bar, vibration can be suppressed when the coarse-pitch threads are turned, ever-changing current is generated by the piezoelectric ceramic piece due to cutting vibration and is transferred to theexciting coil through the coil lead, therefore, an ever-changing magnetic field can be generated by the exciting coil, so that the rigidity and damping of the magnetorheological fluid are quickly changed, the vibration reduction function is realized, and the surface quality of a to-be-processed workpiece is increased.

Owner:HARBIN UNIV OF SCI & TECH

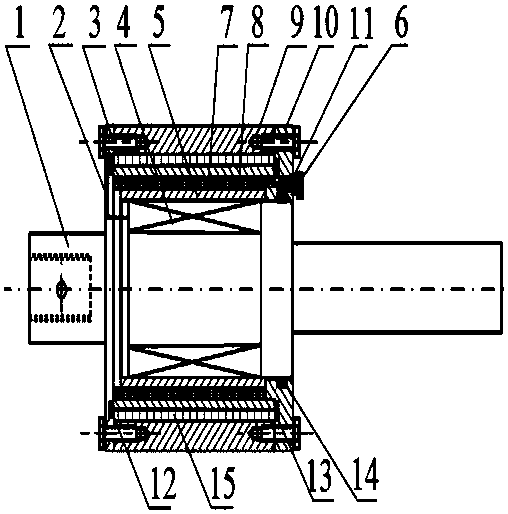

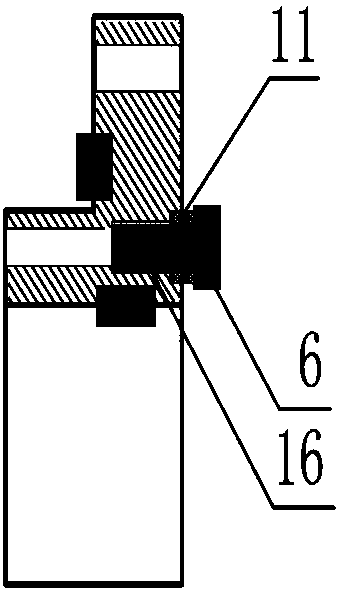

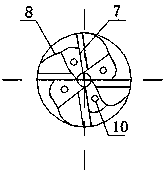

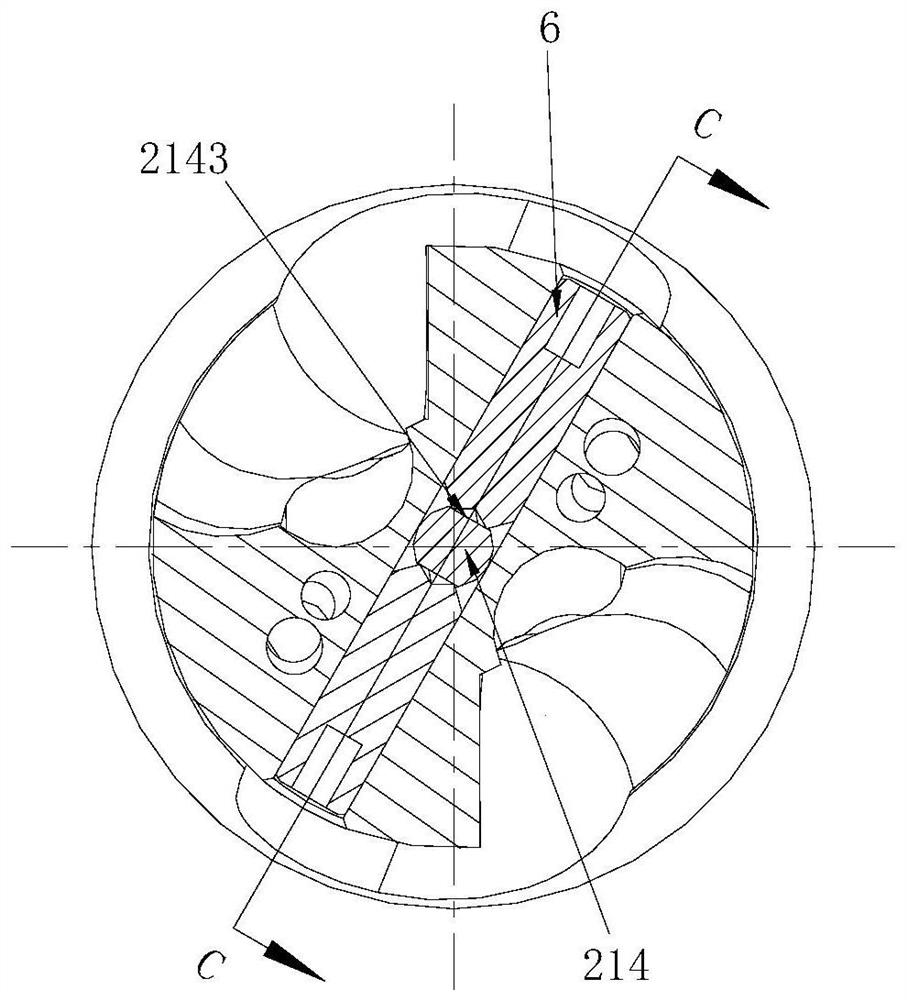

Four-edge end mill having cooling holes and variable spiral unequal tooth pitch

PendingCN109732130AIncrease profitImprove surface finish qualityMilling cuttersMilling cutterWear resistance

The invention discloses a four-edge end mill having cooling holes and the variable spiral unequal tooth pitch. The four-edge end mill comprises a main body of the end mill, a shank part and a millingpart at one end of a shank; four cooling liquid supply holes are formed inside the main body of the end mill; and the milling part at one end of the shank comprises four side cutting edges arranged onthe cylindrical surface of the milling part and four bottom cutting edges arranged on the end surface. The side cutting edges of the end mill adopt the variable spiral angle structures, the bottom cutting edges adopt the arc-shaped structures, the unequal tooth pitch structure is adopted between every two adjacent end tooth edges, and a spiral chip removal groove is formed between each bottom cutting edge and the adjacent side cutting edge. According to the end mill, the edge chipping resistance and the wear resistance of the tool are improved, then the service life of the tool is prolonged,vibration of the tool is reduced during machining, the tool cooling speed is increased, the milling heat and the milling force during machining are reduced, the surface quality of workpieces is improved, and the chip removal effect is obvious.

Owner:HARBIN UNIV OF SCI & TECH

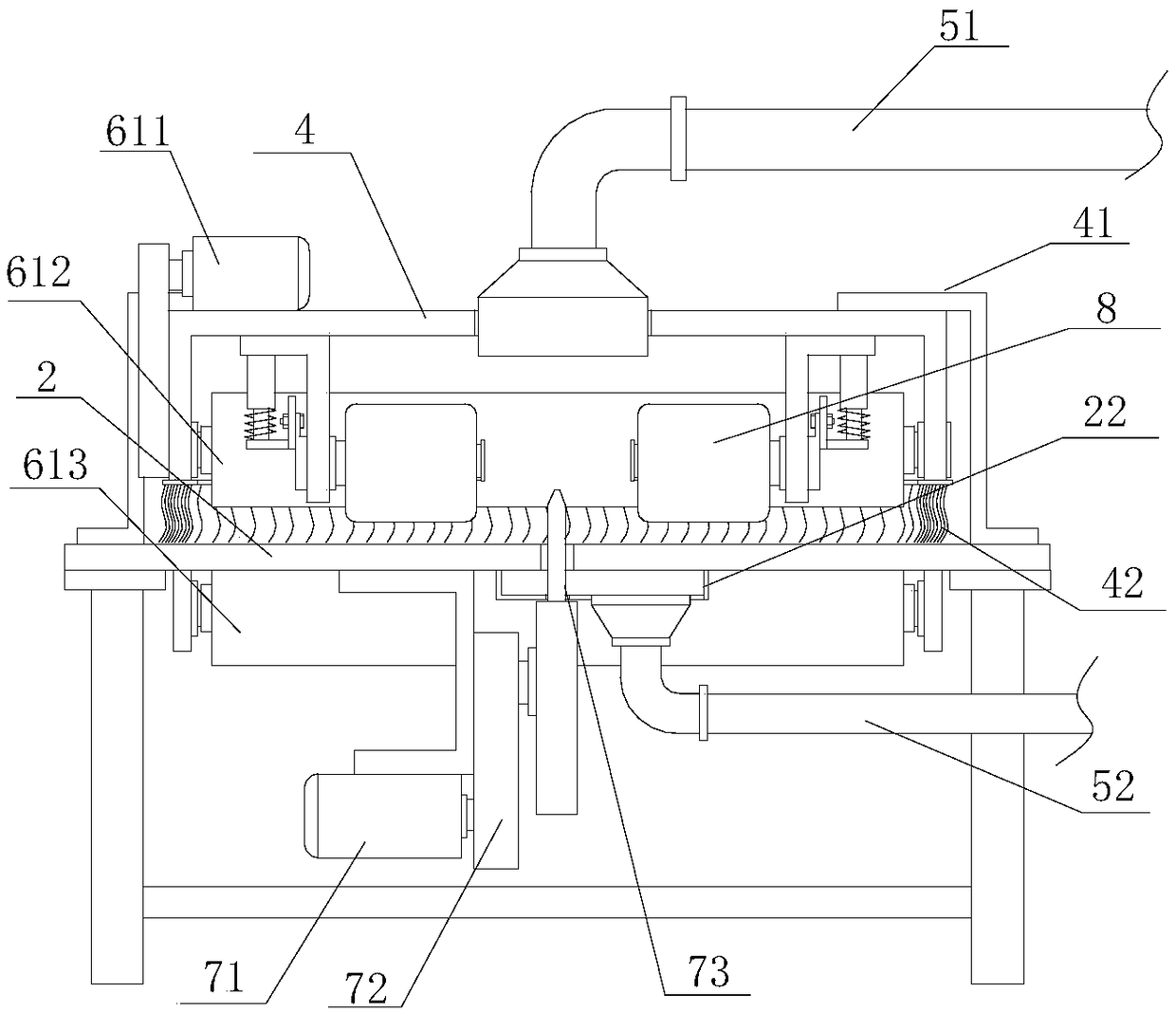

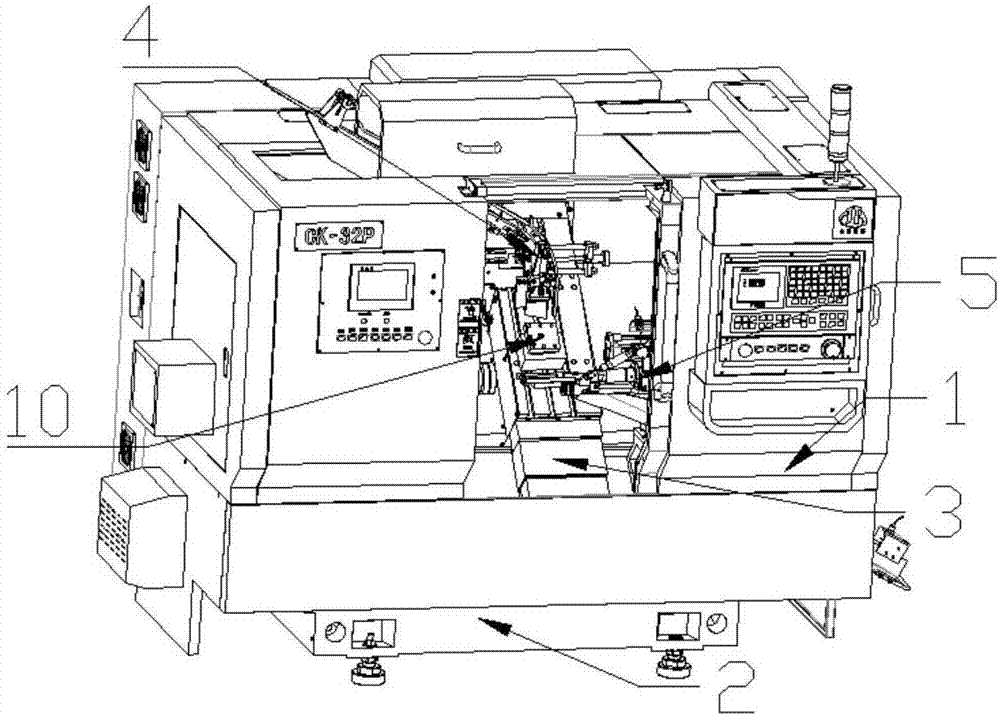

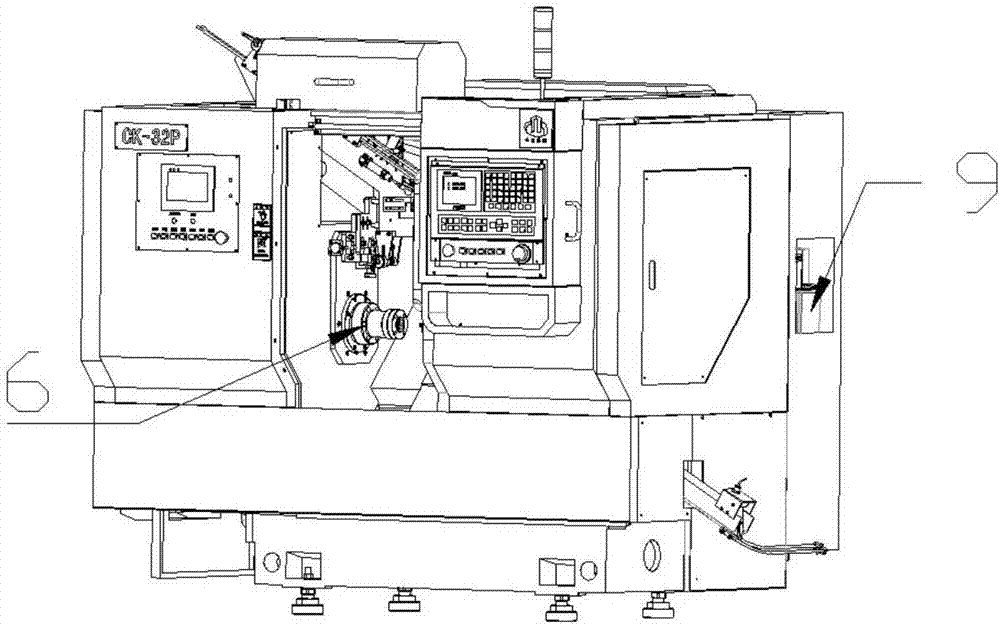

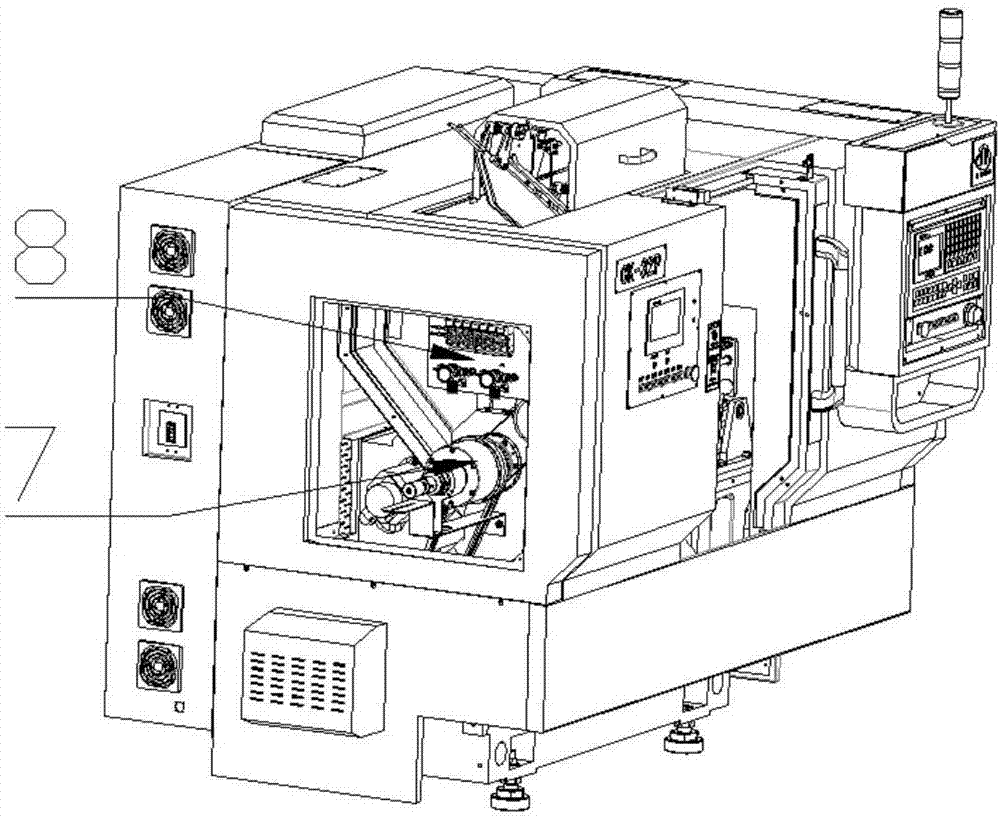

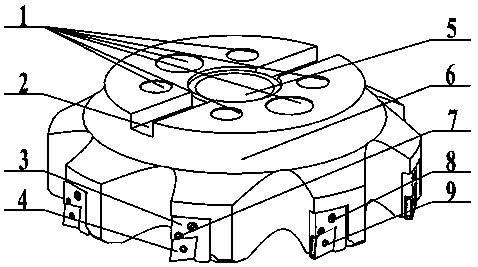

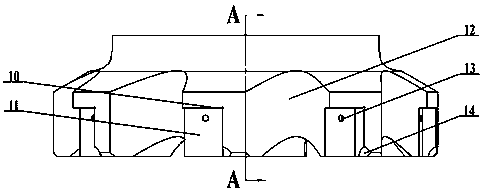

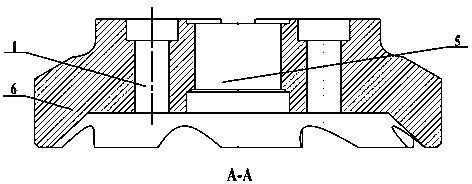

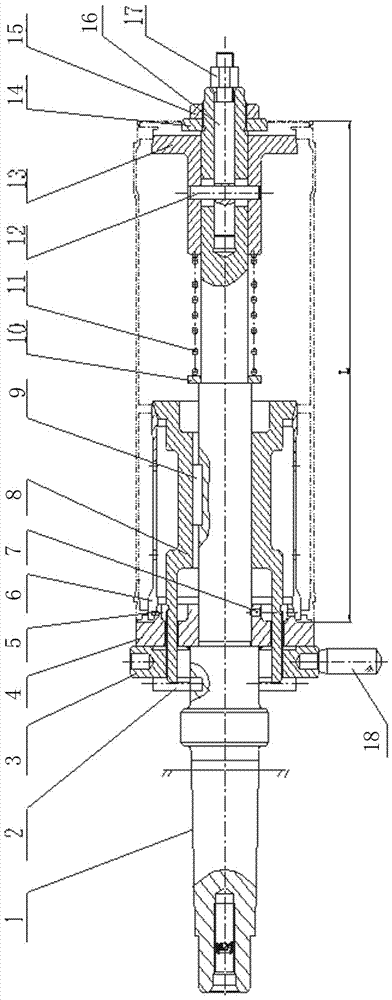

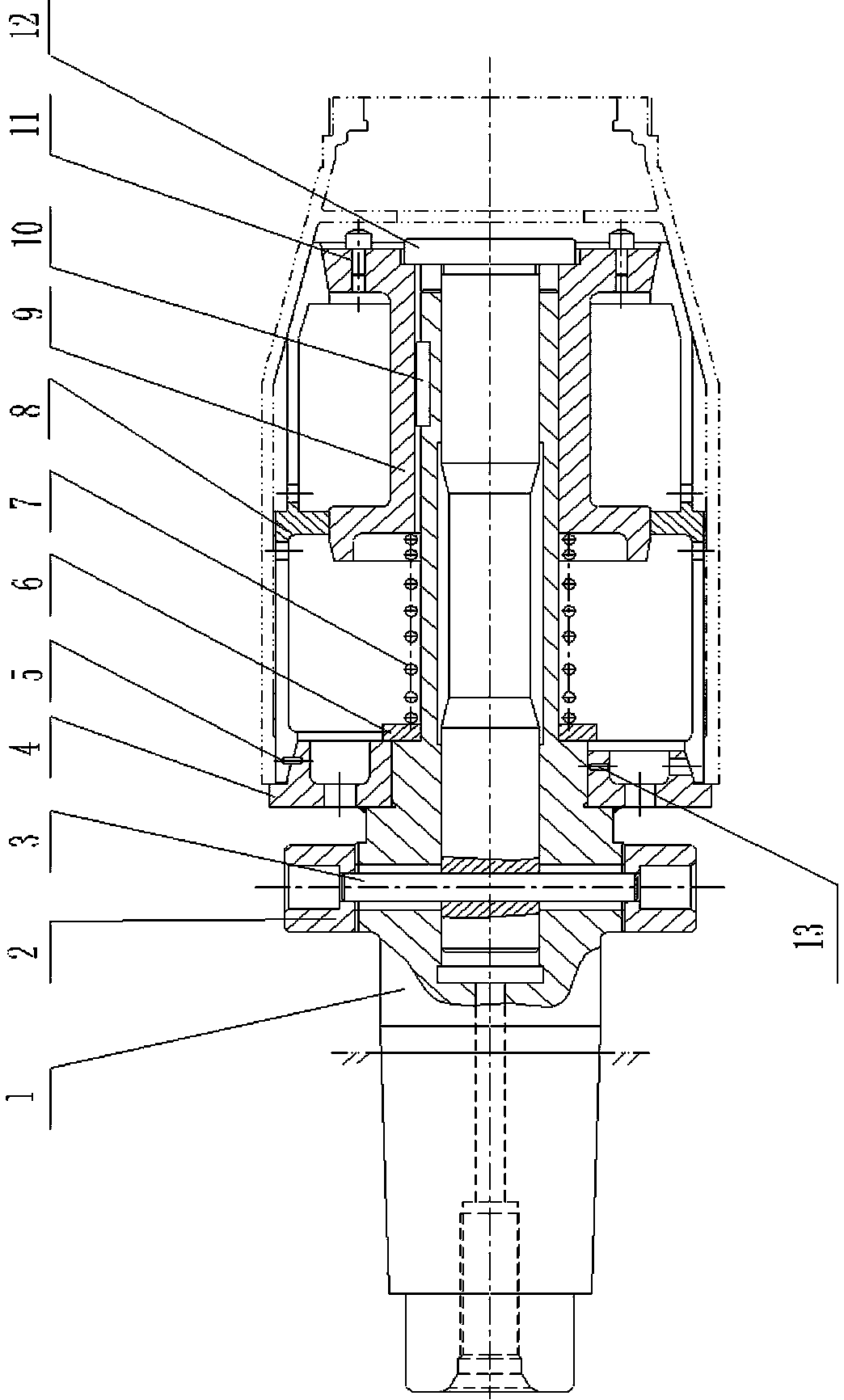

Digital controlled lathe special for engine air valve continuous full-automatic machining and method thereof

ActiveCN107570726ARealize no angle splicingReduce adverse effectsFeeding apparatusChucksThree degrees of freedomEngineering

The invention discloses a digital controlled lathe special for engine air valve continuous full-automatic machining and a machining method thereof. A machine tool of the digital controlled lathe comprises a protective shell assembly, a lathe bed base assembly, a sliding saddle assembly, a material sorting and discharging assembly, a feeding and falling assembly, a main shaft assembly, a material clamping and pushing assembly, a pneumatic system assembly, a lubrication system assembly and a cutter seat assembly; the protective shell assembly protects all parts, the lathe bed base assembly supports all the parts, and three-degree-of-freedom moving of a cutter seat is realized through the sliding saddle assembly; the material sorting and discharging assembly realizes sorting of air valve workpieces and single material discharging, the feeding and falling assembly installs and clamps the air valve workpieces and collects falling finished products, and the workpieces are driven to rotate bythe main shaft assembly; the material clamping and pushing assembly clamps the workpieces and pushes the finished products, the pneumatic system assembly provides the pneumatic force, the lubricationsystem assembly lubricates all relative moving parts, and the cutter seat assembly clamps cutting tools. All the assemblies are coordinative, and full-automatic high-efficiency production of the engine air valves is realized.

Owner:ZHEJIANG JINTANG MACHINE TOOL

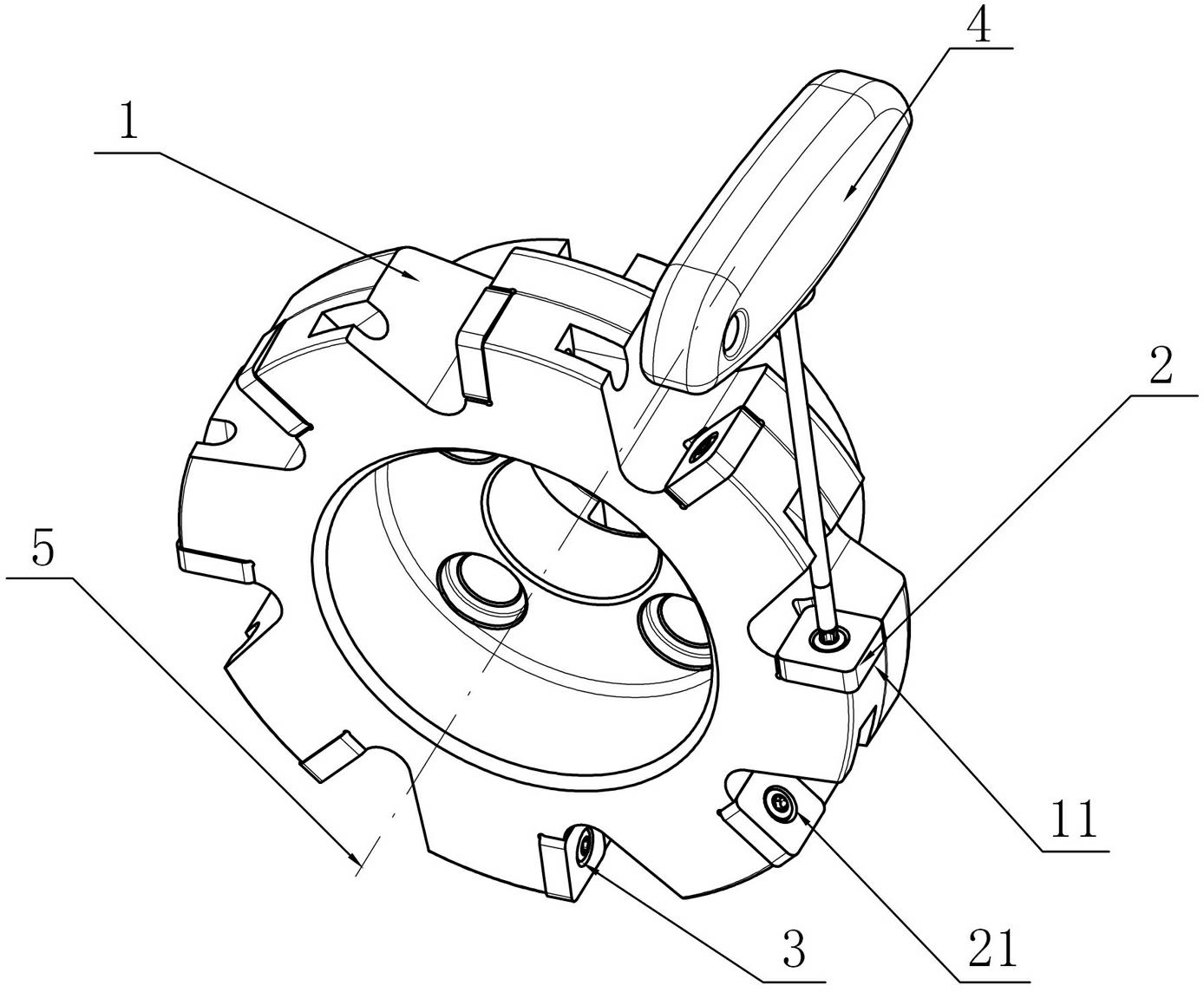

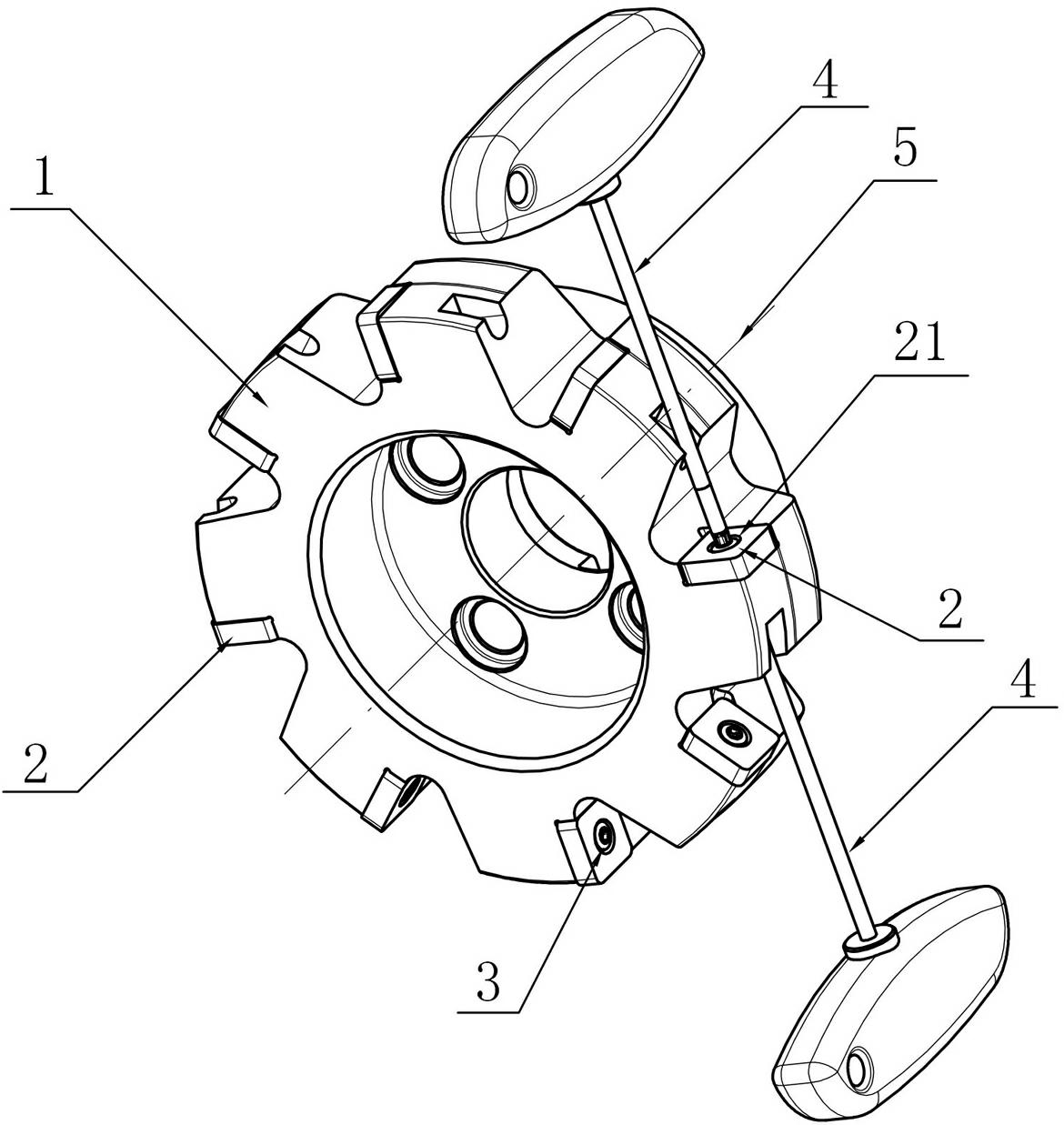

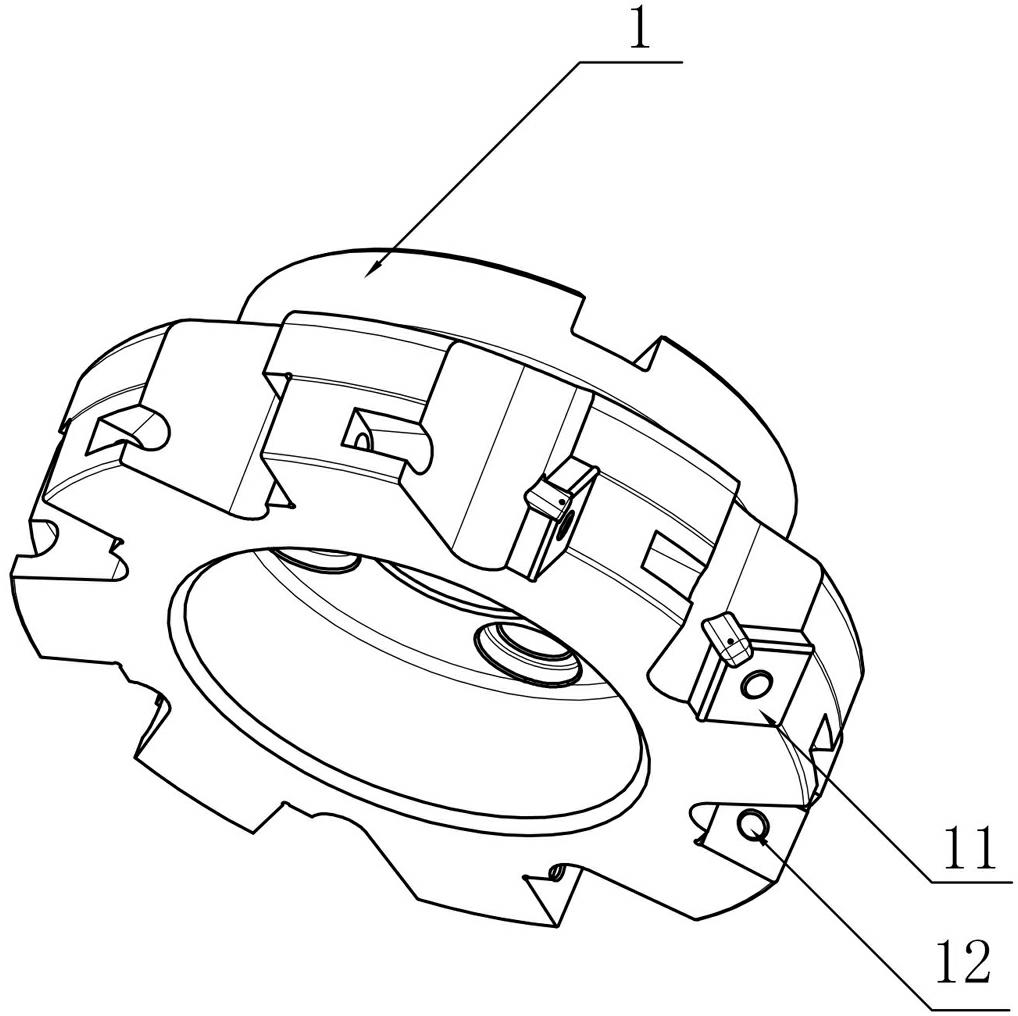

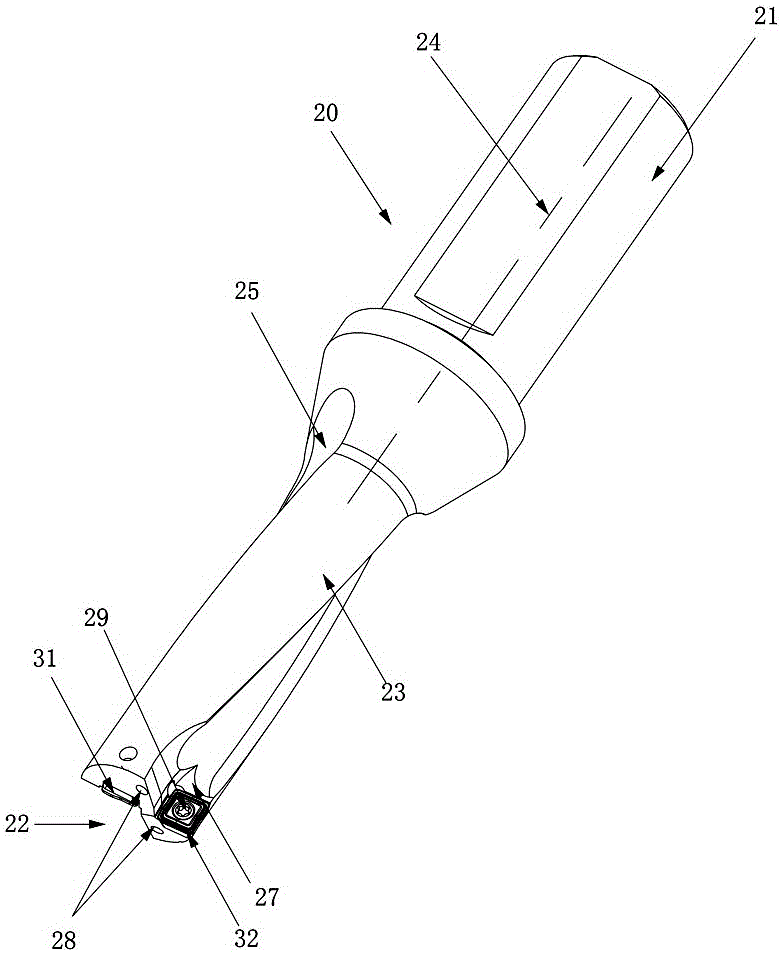

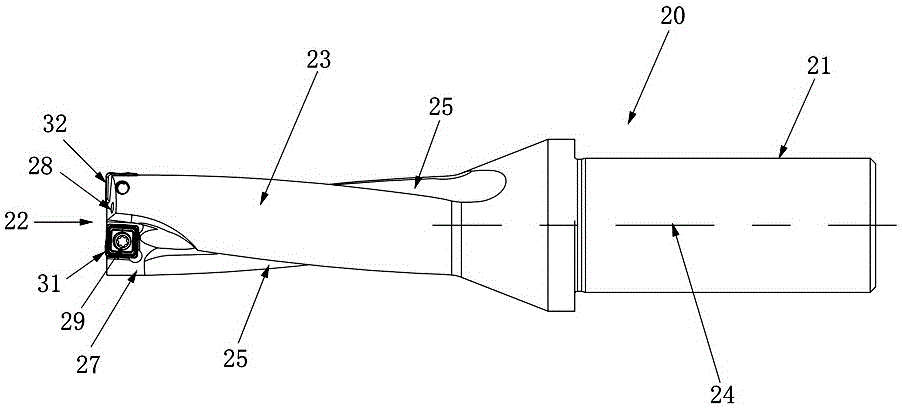

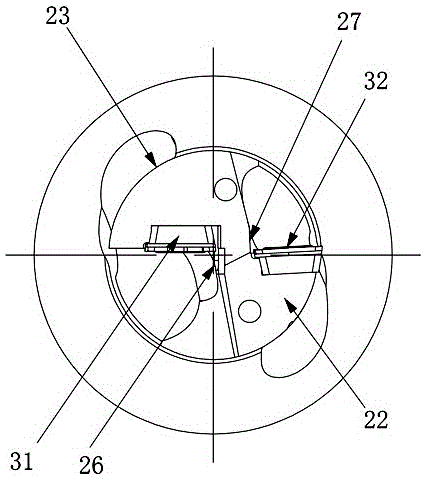

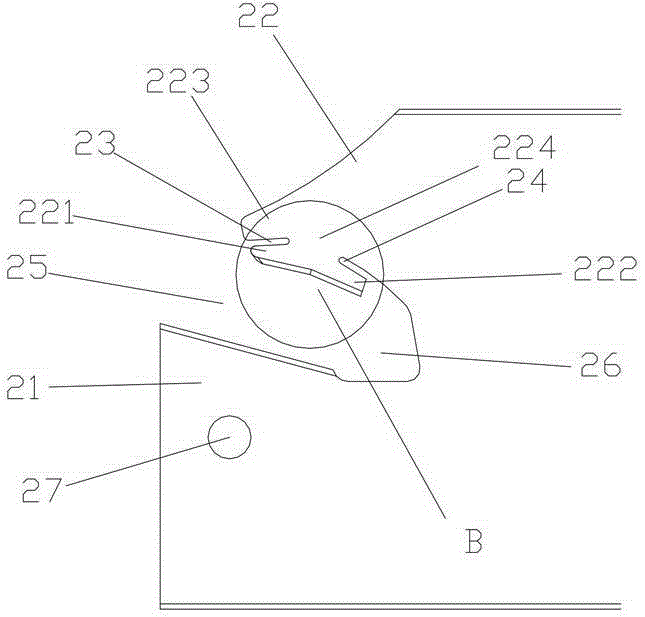

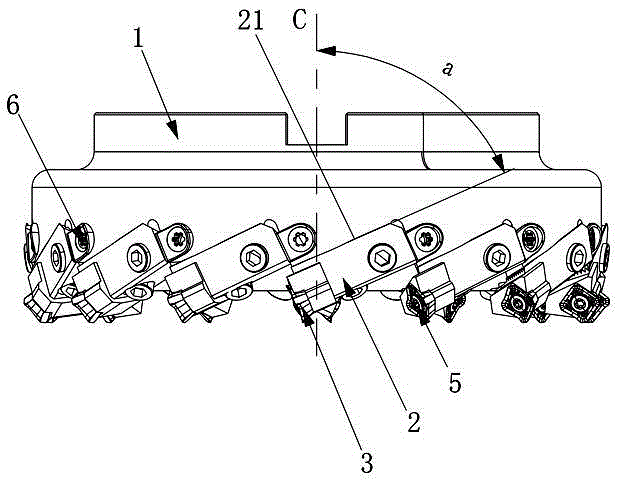

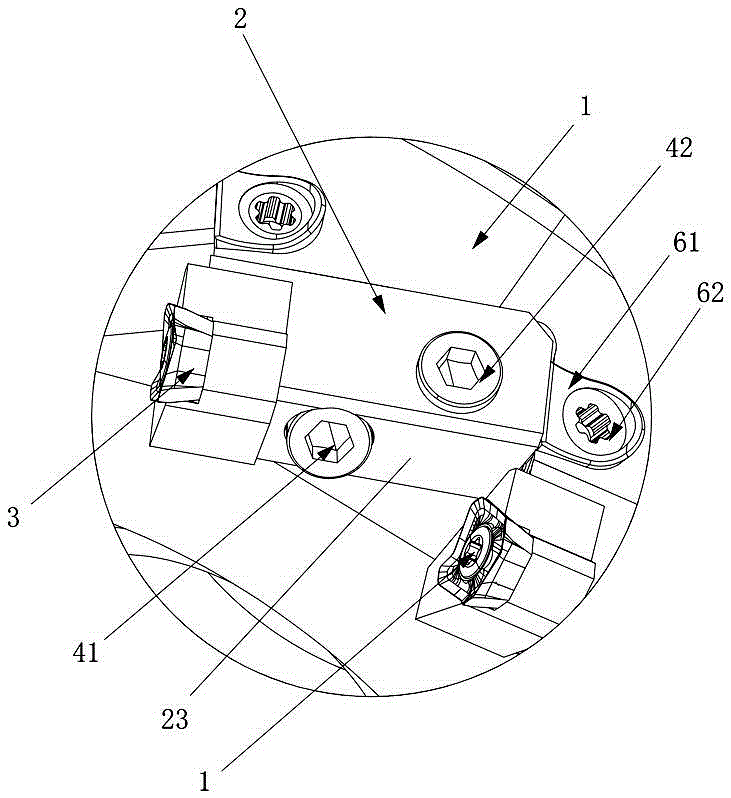

Milling cutter

InactiveCN102601439AImprove cutting stabilityReduce cutting vibrationMilling cuttersMilling cutterCutting force

The invention discloses a milling cutter, comprising a cutter body, cutting blades and a fastening piece, wherein the cutter body is at least provided with a group of cutter grooves; each cutter groove is internally provided with one cutting blade; each cutting blade is provided with a central hole and fastening piece connecting holes are arranged in the bottom surfaces of the cutter grooves; the head part of the fastening piece is pressed into the central hole and the tail part of the fastening piece passes through the central hole to be connected with the fastening piece connecting holes; the tail end of the fastening piece is provided with a first concave hole which is connected with a wrench in an inserting manner; and the fastening piece connecting holes pass through the cutter body. The milling cutter disclosed by the invention has the advantages of simple structure, convenience for attaching and detaching, relatively-increased blade number, high cutting efficiency, small cutting force and small vibration.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

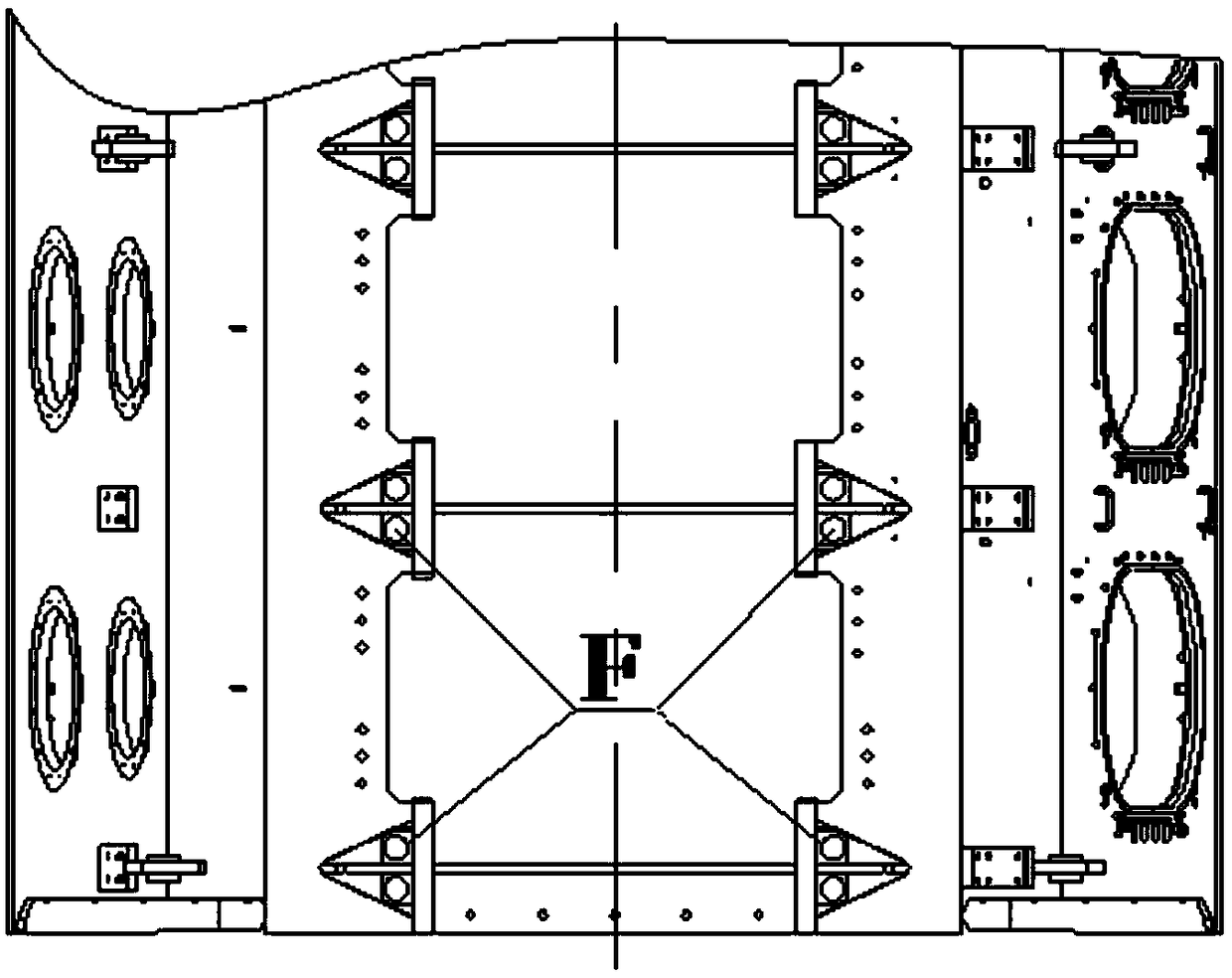

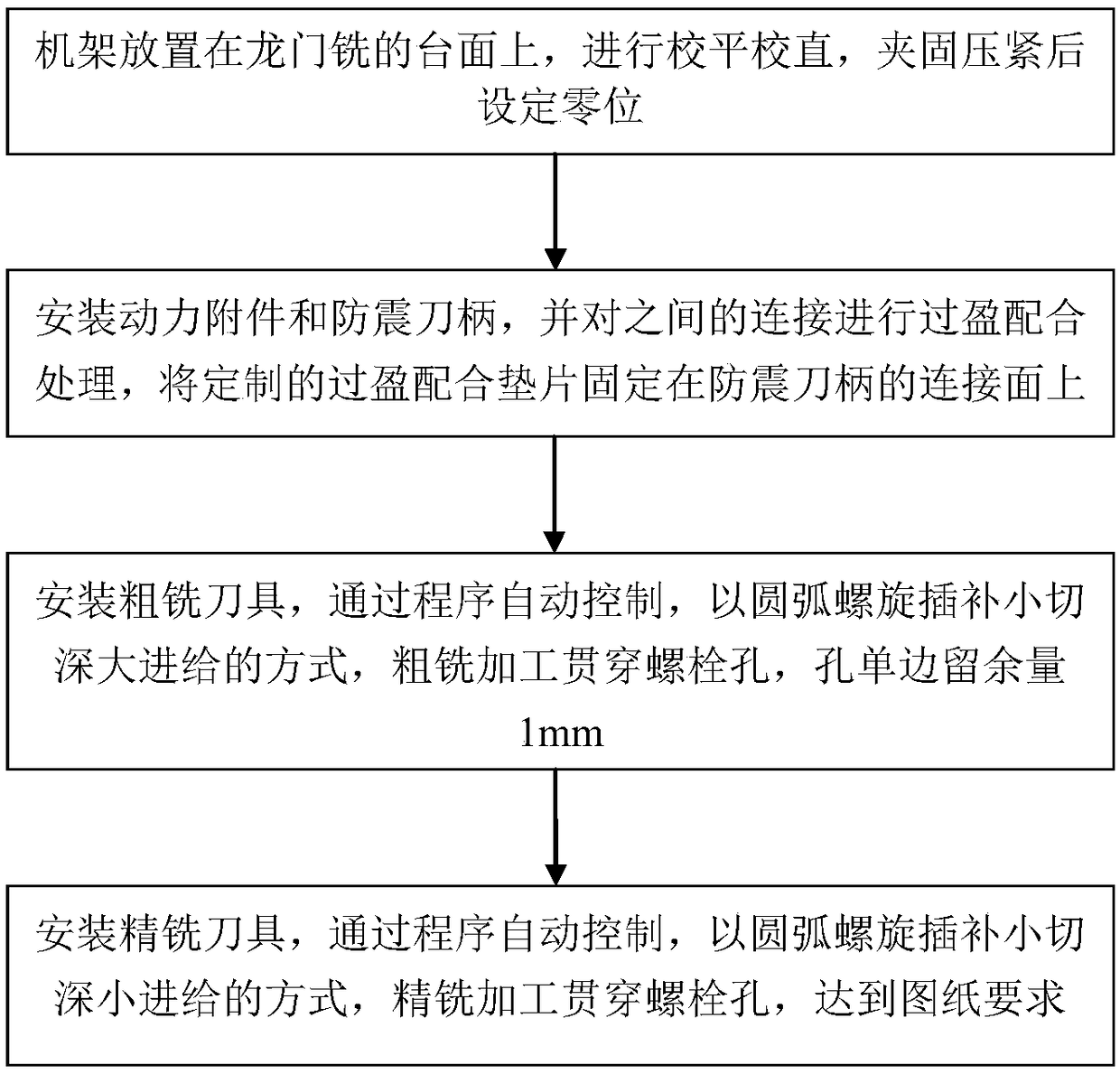

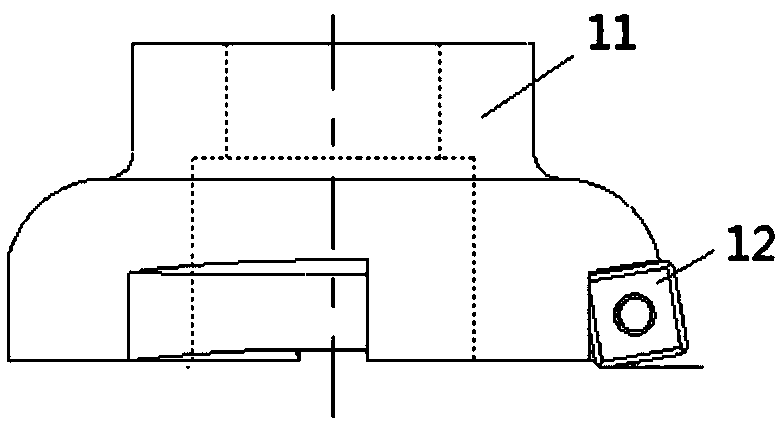

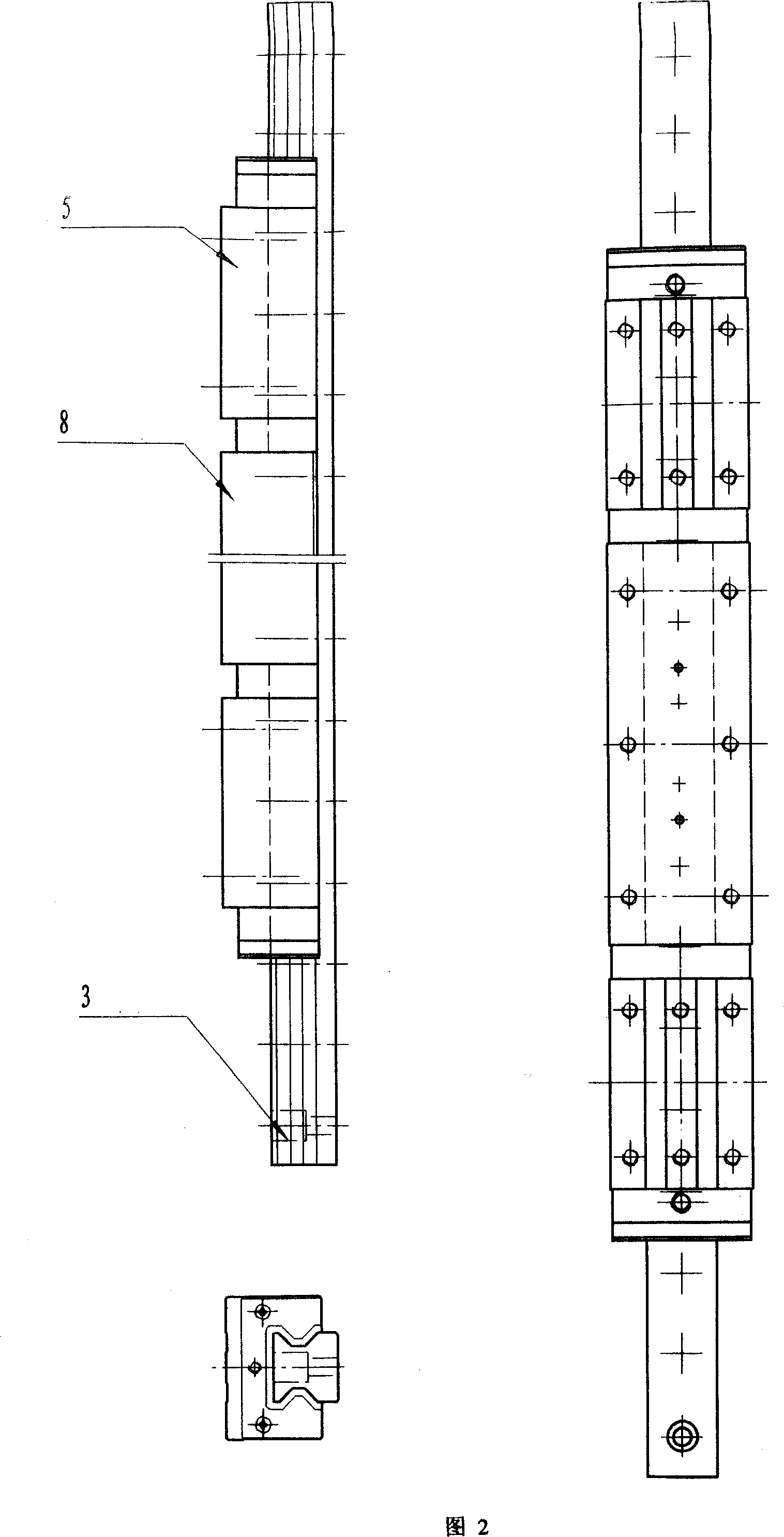

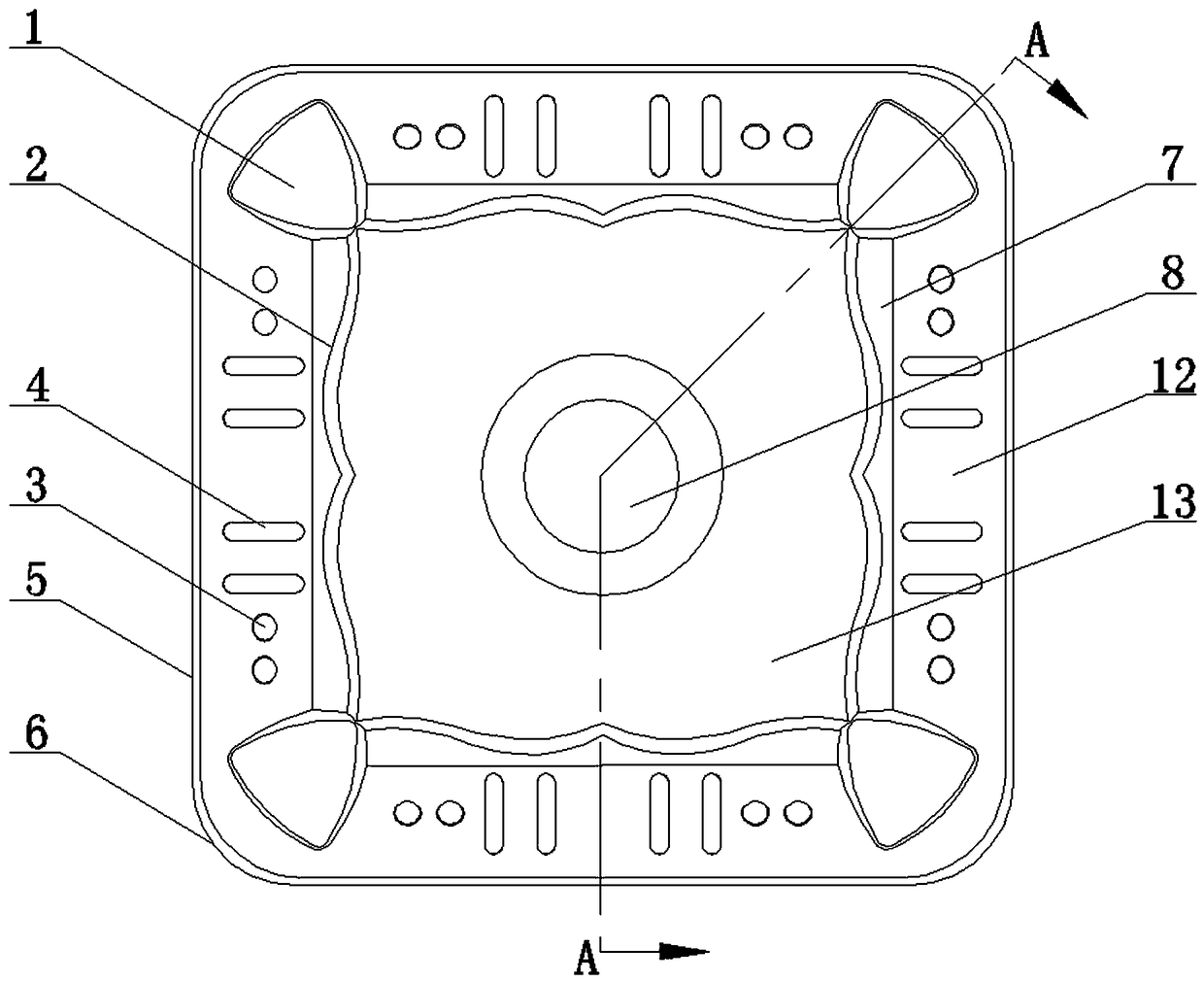

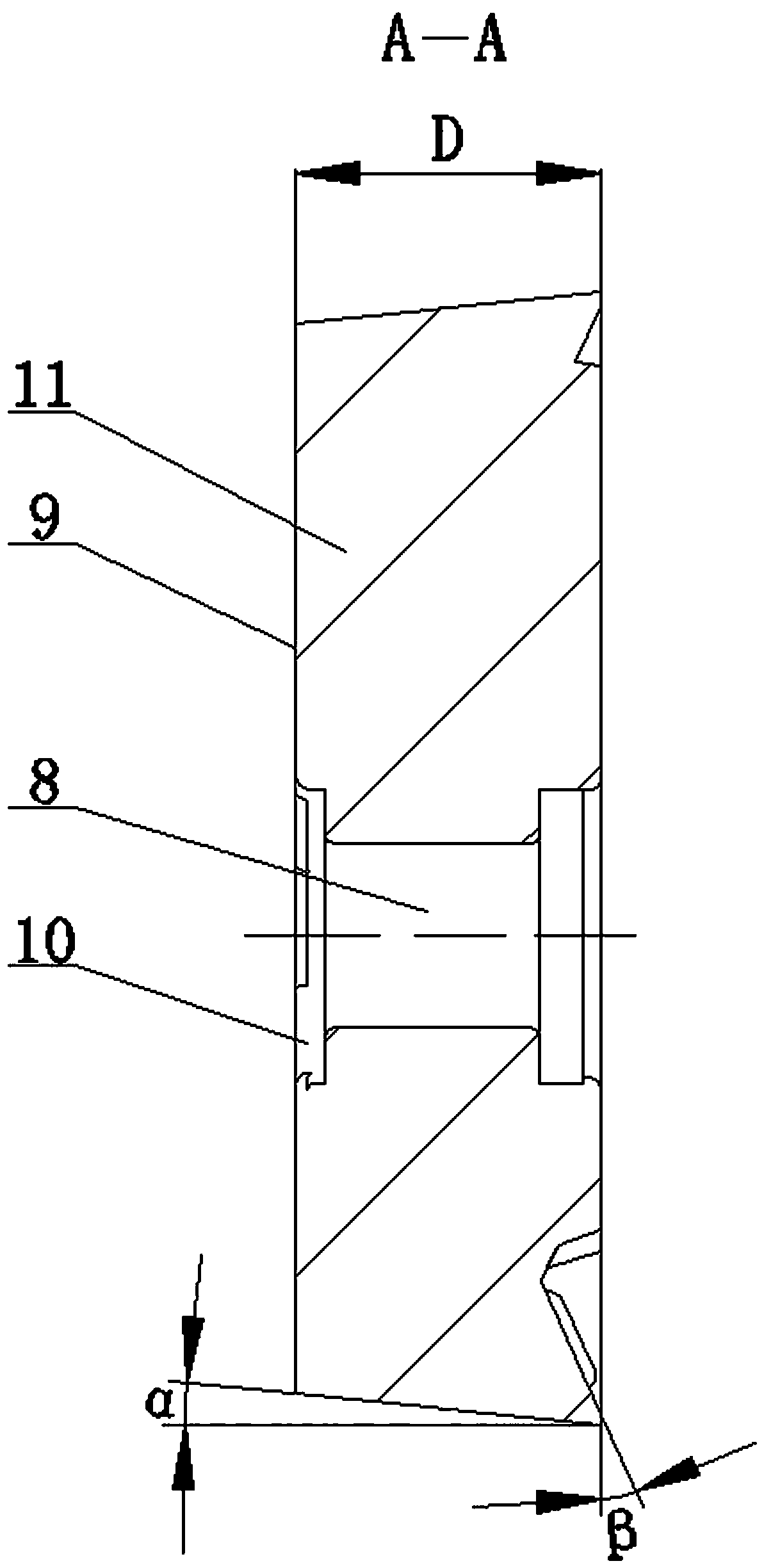

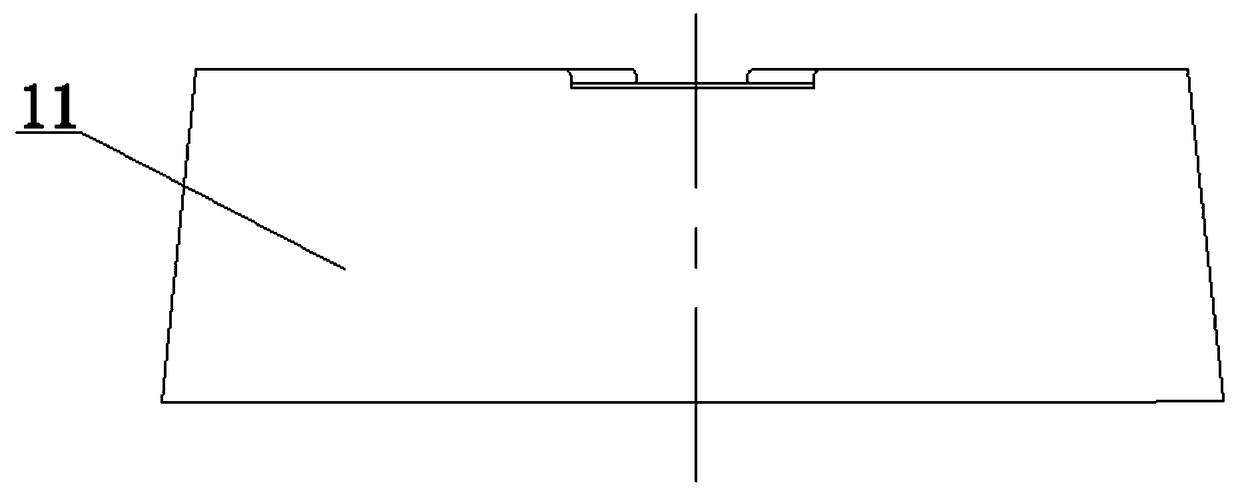

Method for machining diesel engine frame through bolt holes and tools thereof

InactiveCN109262033AImprove rigidityReduce cutting vibrationMilling cuttersMilling equipment detailsNumerical controlInterference fit

A method for machining diesel engine frame through bolt holes and tools thereof are provided. On a numerical control gantry milling machine, a rough milling tool and a finishing milling tool mounted on a shockproof shank connected to a power accessory are successively adopted to automatically complete rough milling and finishing milling of all the through bolt holes in a frame in a circular arc interpolation method according to a numerical control program command; the connection between the shockproof shank and the power accessory is subjected to interference fit processing, that is, the gap size of the connection surface of the shockproof shank and the power accessory is measured when the shockproof shank is first installed, and an interference fit gasket is customized according to the gap size and fixed on the connection surface of the shockproof shank. According to the method, the tool angle is optimized, the high-efficiency continuous full program control automatic machining is achieved, and the effects of small machining tremor, cutting temperature reduction and smooth chip discharge are achieved. Not only the hole wall machining quality is ensured, but also the machining efficiency is improved. The method is suitable for machining of the diesel engine frame through bolt holes and deep holes.

Owner:CSSC MES DIESEL

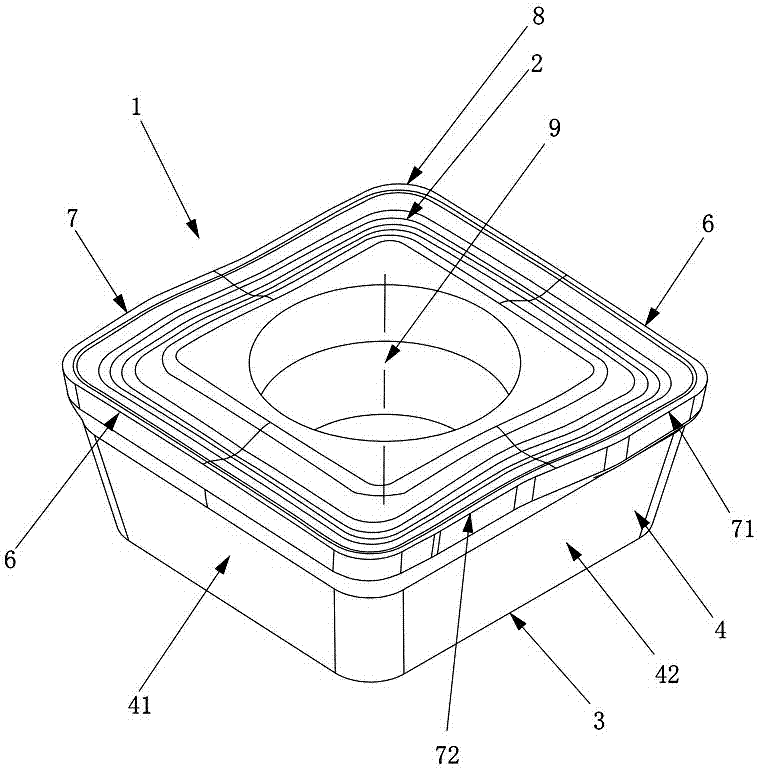

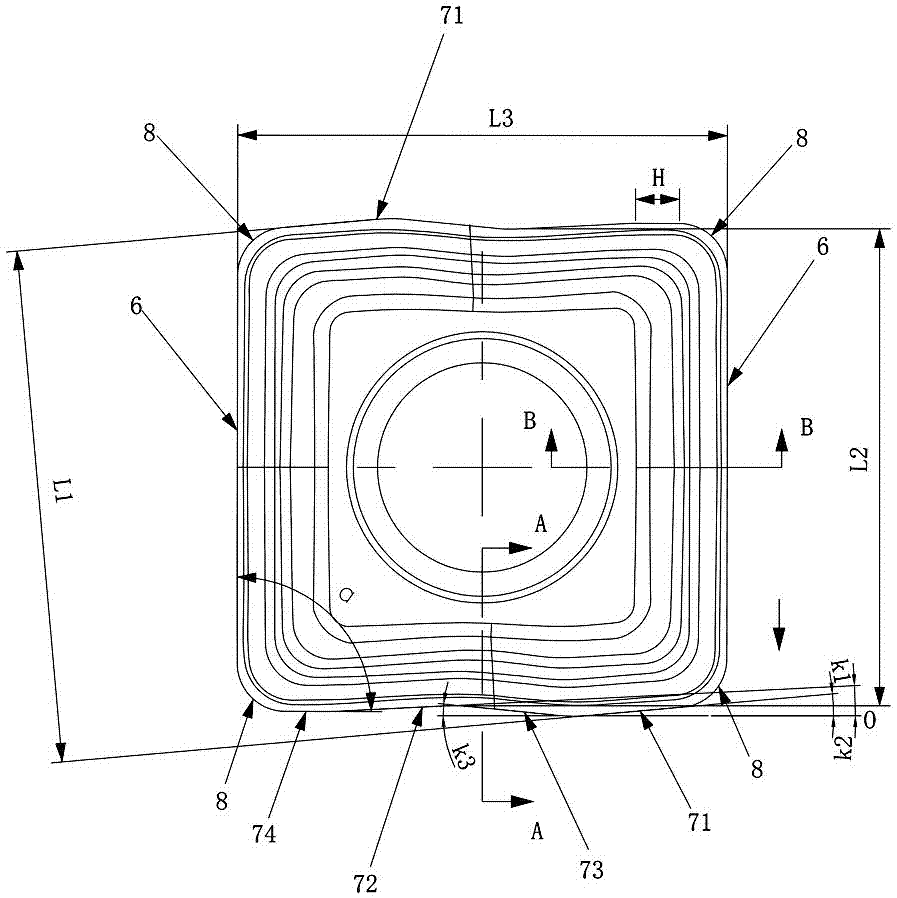

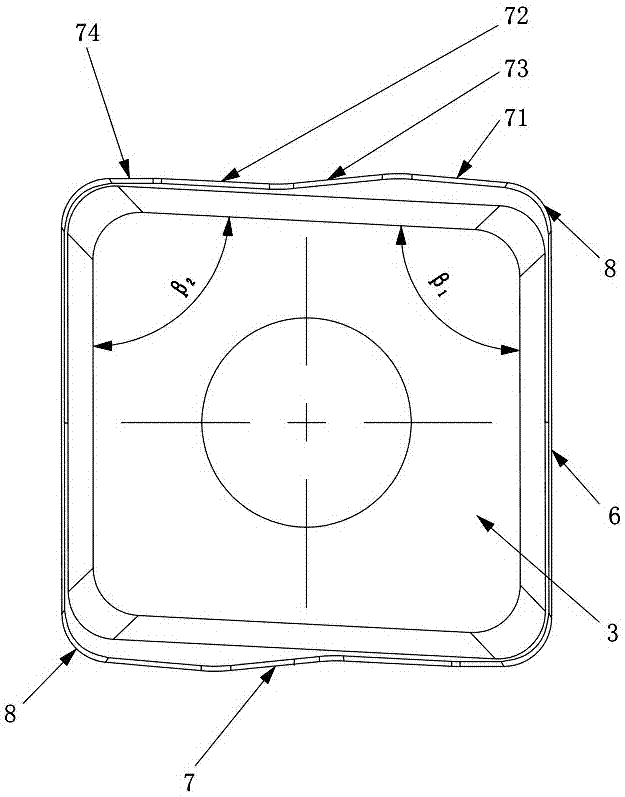

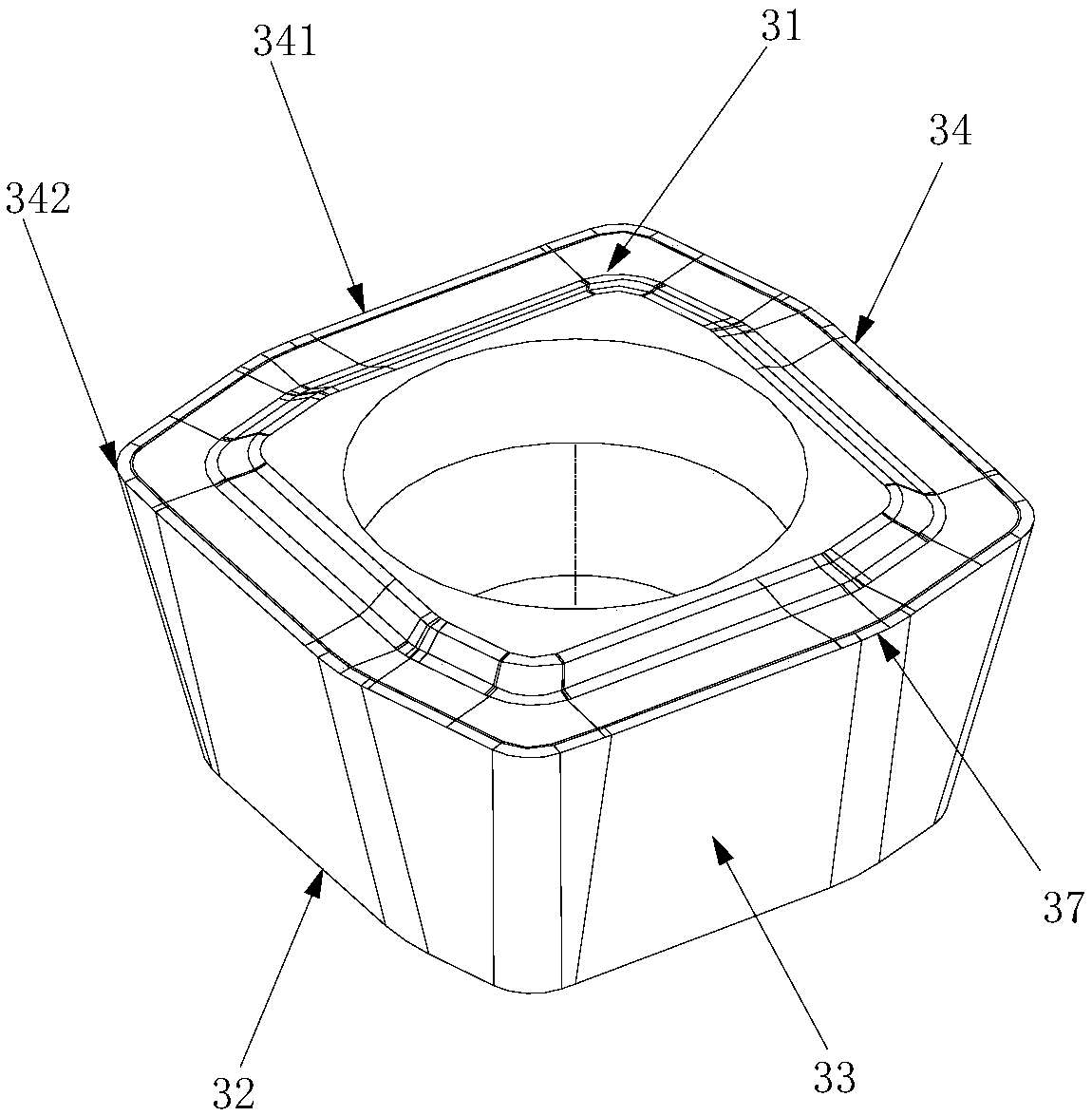

Cutting blade

ActiveCN106975760AReduce cutting vibrationImprove cutting accuracyCutting insertsTurning toolsEngineeringKnife blades

The invention discloses a cutting blade. The cutting blade comprises a plate-shaped blade body which is encircled by an upper surface, a lower surface and a side surface, wherein the upper surface and the lower surface are connected through the side surface; the upper surface and the side surface are intersected to form a plurality of cutting units which have the same structure; a cutting edge unit comprises a secondary cutting edge, a main cutting edge, and a corner cutting edge which is positioned between the secondary cutting edge and the main cutting edge; the secondary cutting edge and the main cutting edge are alternatively arranged in the circumference of the blade body; the main cutting edge comprises a first cutting edge, a second cutting edge, and a transition cutting edge for connecting the first cutting edge and the second cutting edge; the surface, vertical to the feeding direction of the cutting blade in hole drilling processing, is a reference surface O; in the upper surface direction, the secondary cutting edge is provided with one cutting slope, and the first cutting edge, the second cutting edge and the transition cutting edge are correspondingly provided with the cutting slope k1, k2 and k3 which meet the formula seeing the description. The cutting blade has the advantages of being high in cutting accuracy, small in cutting vibration, long in service life, etc.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Turning tool for improving quality of surface of flange end face sealing groove

PendingCN104607673AIncrease the secondary declinationReduce cutting forceCutting insertsTurning toolsMachining deformationEngineering

The invention provides a turning tool for improving the quality of the surface of a flange end face sealing groove. A grooving tool is provided with a main cutting edge, tool nose smoothing edges and auxiliary cutting edges. The main cutting edge, the tool nose smoothers and the auxiliary cutting edges are integrally formed in a grinding mode. According to the main cutting edge of the grooving tool, an original linear common end face grooving turning tool main cutting edge is improved into a concave circular-arc-shaped main cutting edge. According to the two tool nose smoothers, original common end face grooving turning tool nose circular arc radiuses are improved into tool noses with smoothing edges, the surface quality is improved by one time while the same feeding can be ensured. According to the auxiliary cutting edges on the two sides of the grooving tool, the width of an original common end face grooving turning tool is improved to be half of the width of a sealing groove, chip removing is easy, and gear marks are reduced. The turning tool has certain universality and is suitable for machining flange type parts, the machining deformation is small, the surface quality is high, the production period is greatly shortened, the production cost is reduced, and therefore the turning tool can be applied and popularized.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

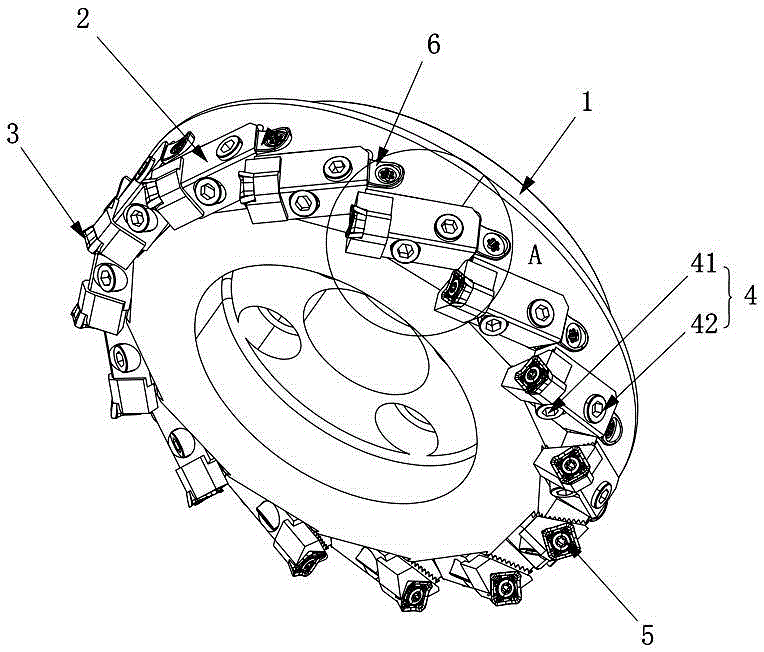

High-efficiency vertically-arranged milling cutterhead and special blades

InactiveCN110315120AEasy to connect and fixAvoid loose connectionsMilling cuttersMachining vibrationsDrive shaft

The invention relates to a high-efficiency vertically-arranged milling cutterhead and special blades, and belongs to the technical field of cutters for metal cutting machining. A main fastening bolt hole is formed in the top of the cutterhead, the cutterhead is connected with a power transmission shaft through a bolt, the cutterhead is positioned through a key slot, so that the cutterhead can be well mounted and fixed on the main shaft, and machining vibration is reduced; a plurality of cutter grooves of vertically-arranged cutter clamps are uniformly formed in the periphery of the cutterhead,and the cutter clamps are locked in the cutter grooves through locking screws; and each cutter clamp is provided with a cutter holder for installing the special blades, the special blades are fixed in cutter holders through pressing screws, and the axial cutting depth of the special blade can be adjusted through eccentric adjusting pins. The special blades and the cutter clamps adopt a vertical installation mode, the operation is simple and convenient, the service life of a cutter can be prolonged, and the production efficiency is improved.

Owner:HARBIN UNIV OF SCI & TECH

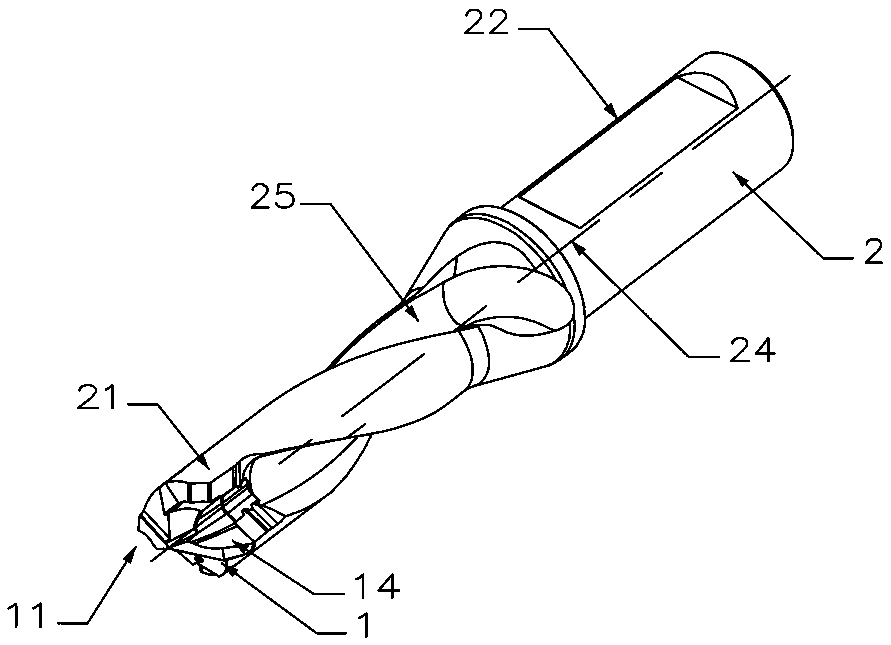

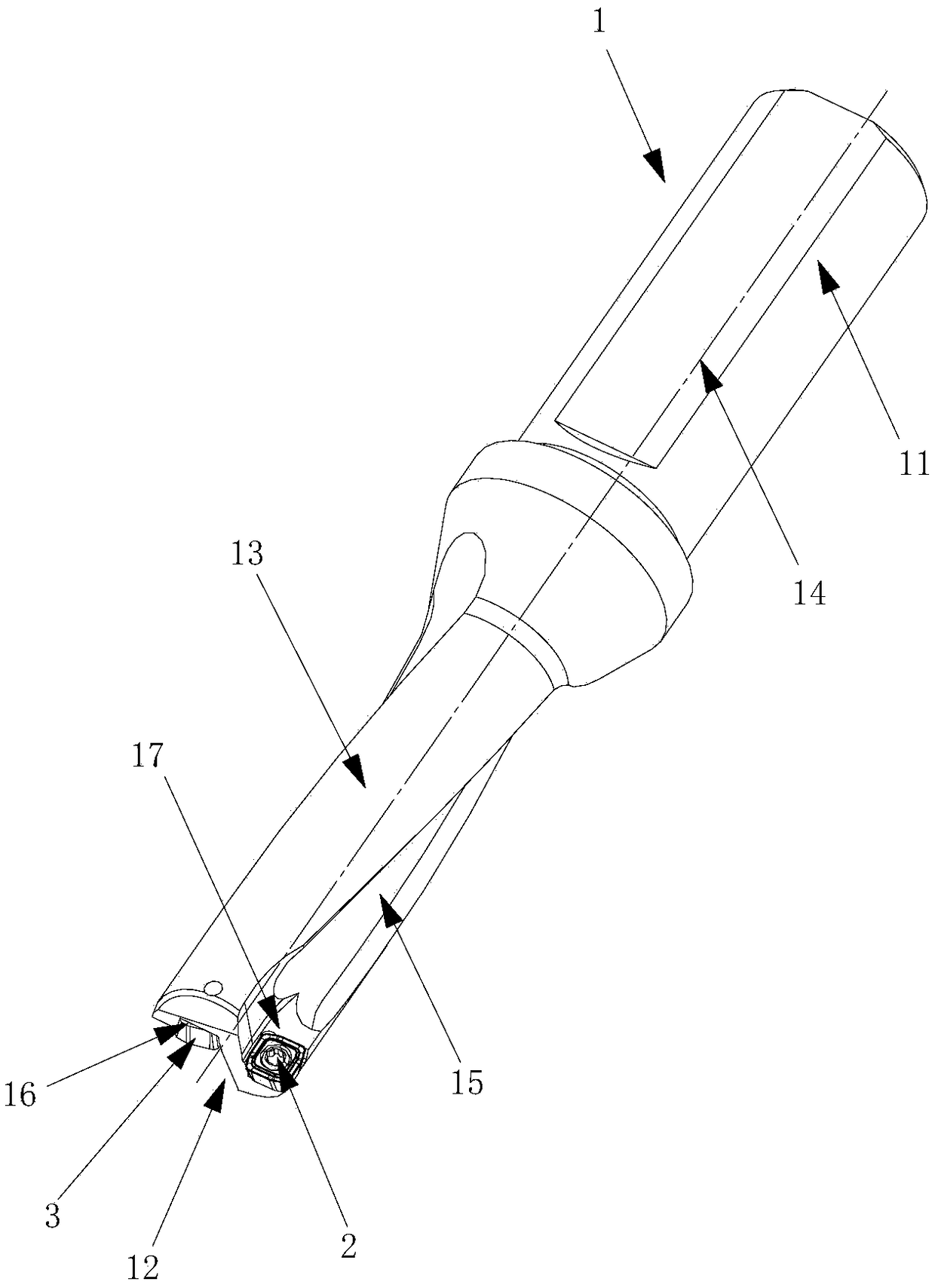

Drilling tool

ActiveCN106694962AReduce manufacturing difficultyReduce crashTransportation and packagingTrepanning drillsEngineeringMachining

The invention discloses a drilling tool. The drilling tool comprises a tool body; the tool body comprises a handle part, a cutting end part and a peripheral surface located between the handle part and the cutting end part; the handle part and the peripheral surface are symmetric about a rotation central axis of the tool body; a central groove and a circumferential groove which both communicate with a spiral groove in the circumferential surface are formed in the cutting end part, wherein the center groove is arranged adjacent to the rotation central axis, and the circumferential groove is arranged adjacent to the peripheral surface; cutting blades are arranged in the central groove and the circumferential groove, wherein the cutting blade arranged in the central groove is an inner blade, the cutting blade arranged in the circumferential grooves is an outer blade, and the inner blade and the outer blade are the same cutting blades; each cutting blade comprises a short cutting edge and a long cutting edge which are adjacent; the edge shape of each short cutting edge is different from the edge shape of the corresponding long cutting edge; the long cutting edge of the inner blade and the short cutting edge of the outer blade are combined to form a complete main cutting edge used for drilling a hole, the inner blade completes machining of a center area of the hole, and the outer blade completes machining of an outer ring area of the hole. The drilling tool has the advantages of being small in cutting vibration, high in machining precision, stable, reliable and the like.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Indexable drilling tool

ActiveCN109158665AMounting dimensions are simply derived fromAchieve double radial balanceTransportation and packagingTrepanning drillsEngineeringKnife blades

The invention discloses an indexable drilling tool. The indexable drilling tool is characterized in that an inner blade is composed of a first upper surface, a first lower surface and a first side surface which is used for connecting the first upper surface with the first lower surface in a surrounding mode, the first upper surface and the first side surface intersect to form a plurality of identical inner cutting edges, during drilling machining, the cutting areas of the inner cutting edges serving as main cutting edges are located between middle inner points and middle outer points on the inner cutting edges, the cutting areas of outer cutting edges serving as main cutting edges are located between peripheral inner points and peripheral outer points on the outer cutting edges, in the feeding direction of the indexable drilling tool, an inner convex cutting part with the maximum cutting depth on the inner cutting edges and the outer cutting edges is arranged between the middle inner points and the middle outer points, the depth differences of the middle inner points and the peripheral outer points relative to the inner convex cutting part are correspondingly H1 and H2, and H1 andH2 should meet the following conditions that H1 is larger than or equal to 0.9H2 and less than or equal to 1.1H2. The indexable drilling tool has the following advantages that the cutting vibration issmall, the radial balance capability, is strong, the machining surface quality is good, and the size precision is high.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

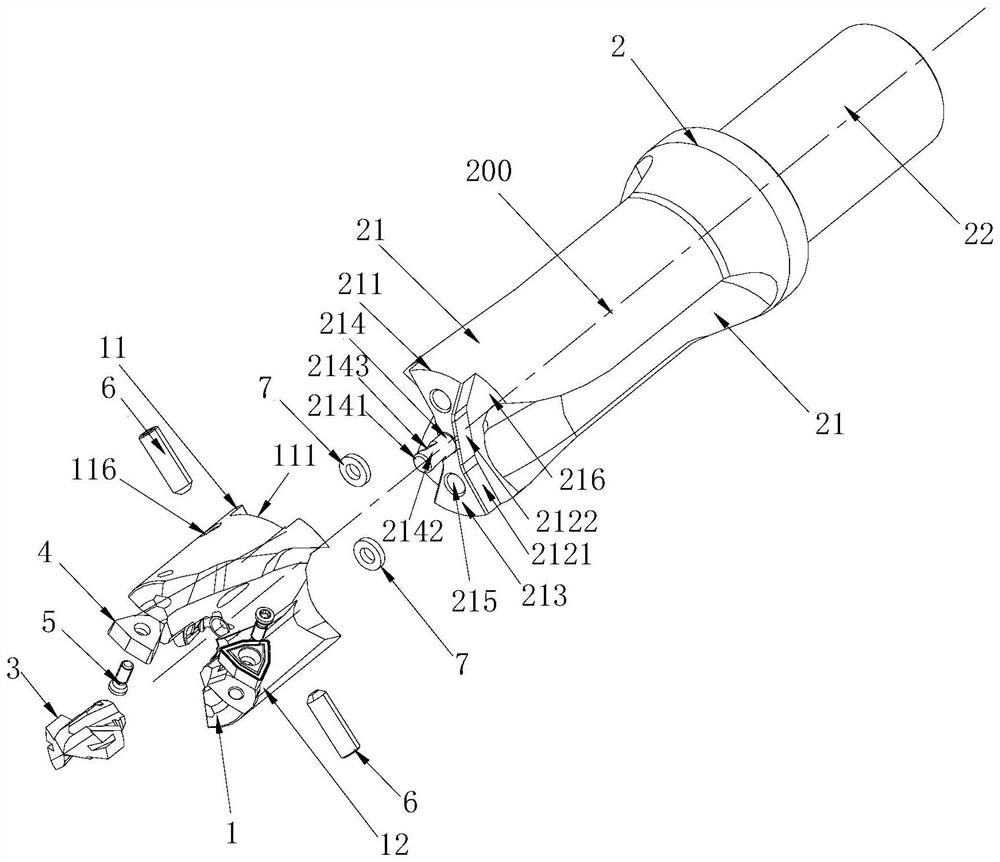

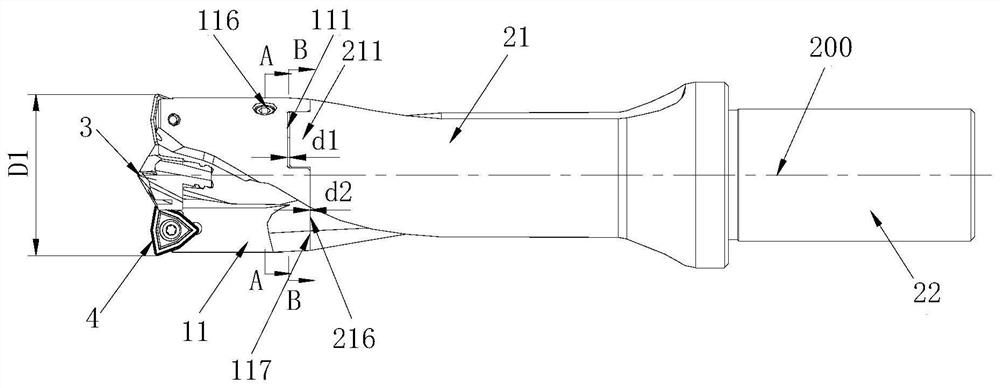

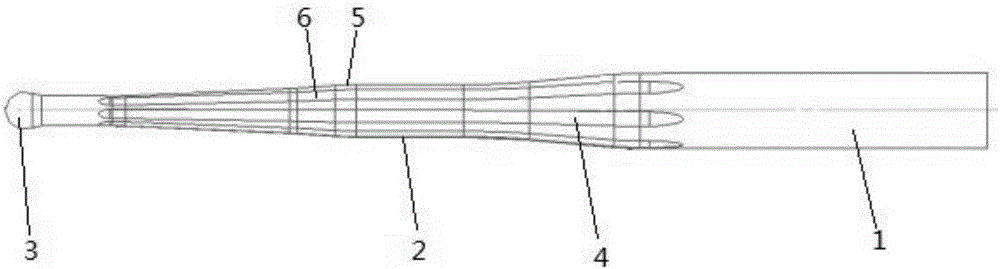

Modular drilling machining tool

ActiveCN112453507AIncreased maximum drilling depthAccurate installation and positioningTransportation and packagingTrepanning drillsEngineeringKnife blades

The invention discloses a modular drilling machining tool. The modular drilling machining tool comprises a cutting component, a clamping component, a center drill tip and two outer cutting blades, wherein the cutting component is provided with a cutting connector part and a cutting part, the clamping component is provided with a clamping connector part and a clamping part, the center drill tip andthe outer cutting blades are installed in the center and the circumferential position of the cutting part correspondingly, the two outer cutting blades are arranged on the two sides of the center drill tip to form a complete cutting unit with the center drill tip, a clamping concave part is arranged on the cutting connector part, a clamping boss is arranged on the clamping connector part, the clamping concave part penetrates through the circumferential face of the cutting connector part, the outer side face of the clamping boss is smoothly connected with the circumferential face of the clamping connector part, when the cutting component is installed on the clamping component in place, the clamping boss is arranged in the clamping recess and matched with the clamping recess to achieve circumferential positioning of the cutting component and the clamping component, and the modular drilling machining tool has the advantages of being convenient to assemble and disassemble, high in positioning strength and precision and the like.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

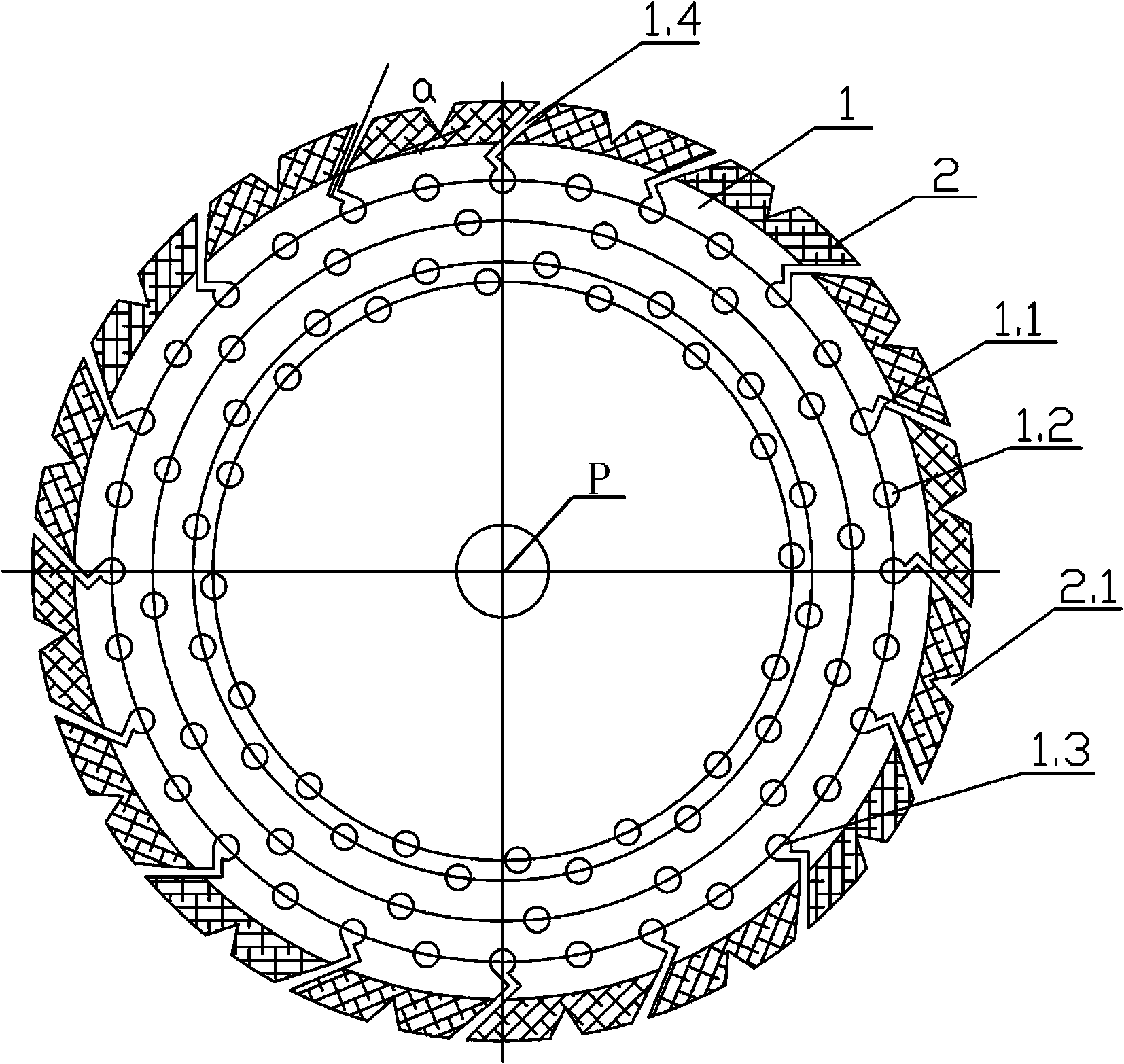

Small low-noise diamond circular saw blade

InactiveCN104108137AReduce cutting vibrationSpeed up coolingMetal sawing toolsStone-like material working toolsTurn angleLow noise

A small low-noise diamond circular saw blade comprises a saw blade base body and a diamond tool bit. The outer edge of the saw blade base body is evenly provided with circular bottom holes and a turn angle water slot with an inclined opening. The cylindrical area of the saw blade base body is provided with holes which are distributed in a staggered mode. The side edge of the diamond tool bit inclines towards the same direction and the tool bit cutting edge is provided with a slot opening. Through the structure, cooling performance is effectively improved when the small diamond circular saw blade conducts cutting at a high speed, the tool bit stress condition and the tooth portion stress condition in the cutting process are improved, cutting noise is lowered, cutting stability is improved, and service life of a blade body is prolonged.

Owner:HEIXUANFENG SAW IND

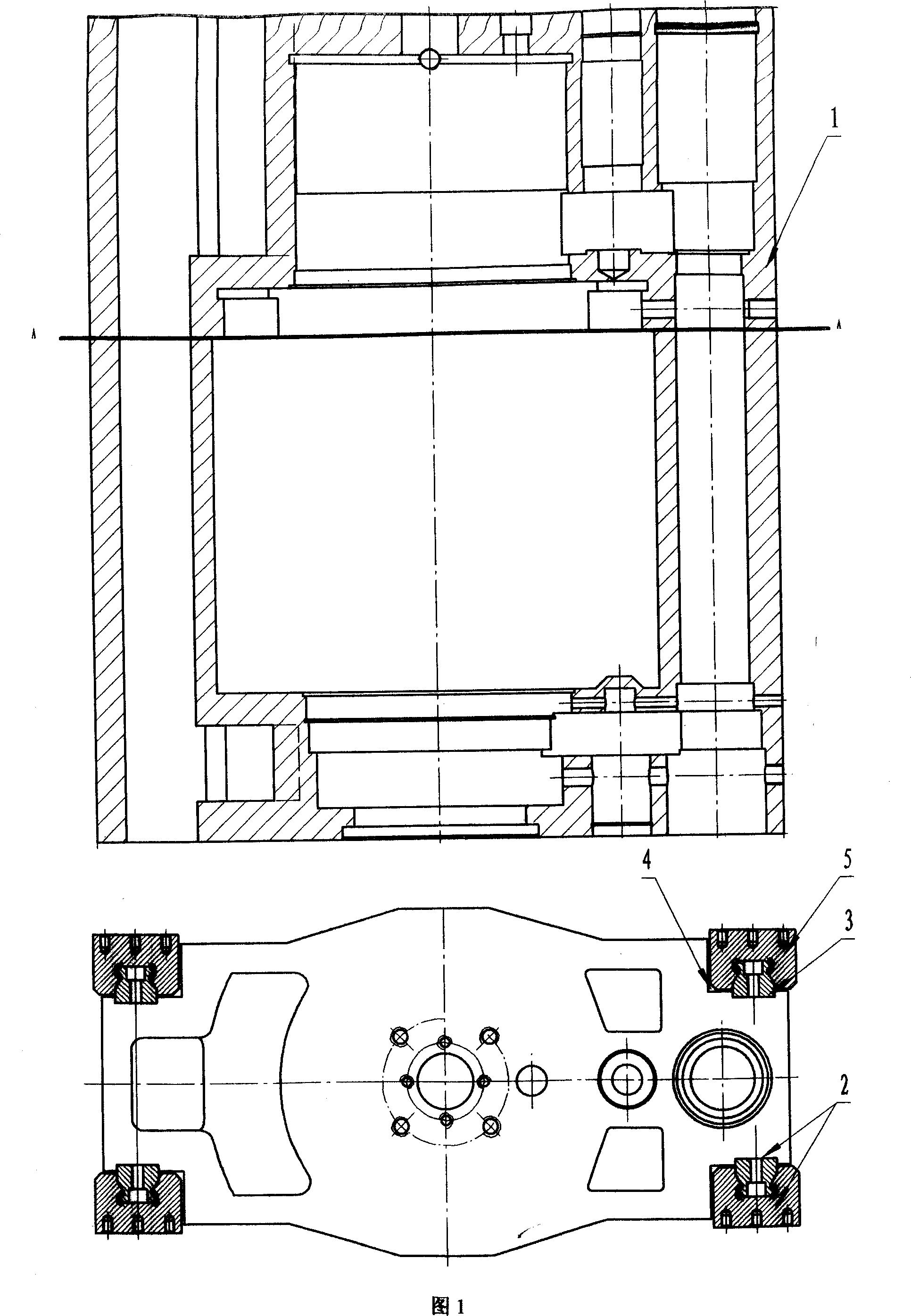

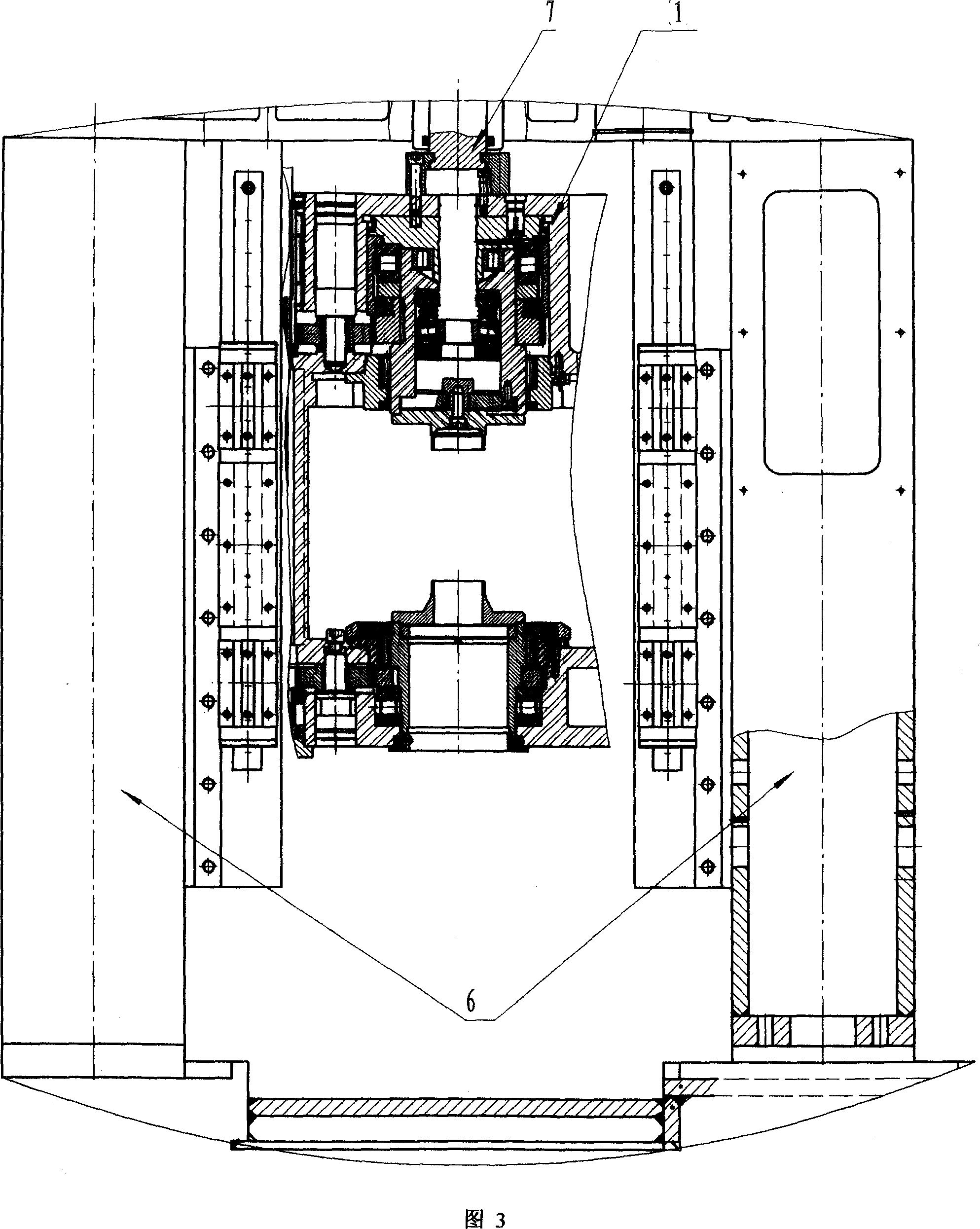

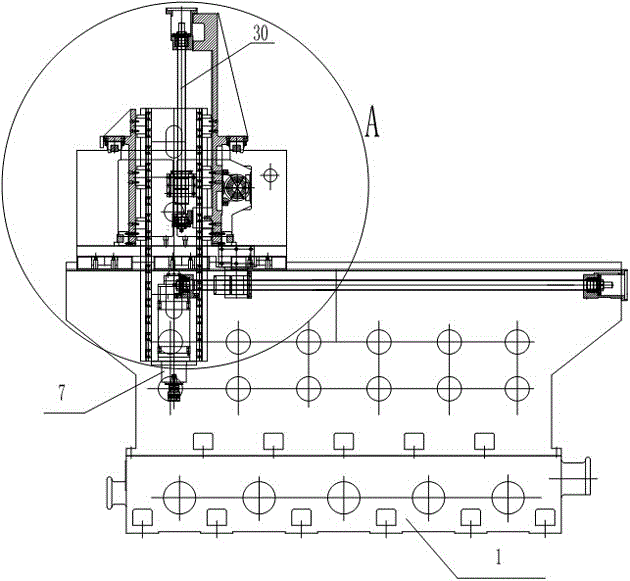

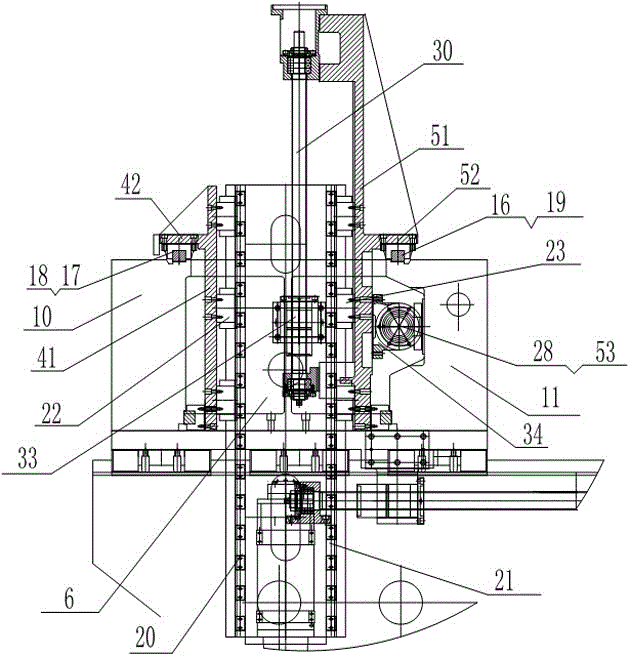

Vertical lathe for profiling internal and external circle of piston ring

The invention relates to an upright piston ring round lathe, wherein its main axle frame is integral; four parts at two shoulders of main axle frame have four roller straight guide tracks; four tracks are fixed at four grooves at two shoulders; eight blocks are fixed at the inner sides of left and right posts; the blocks have enough mounting holes to be mounted on the left and right posts; each two blocks have one damping block between them to reduce the cutting vibration. The invention has compact structure, high accuracy, high producing efficiency and low cost.

Owner:福建东亚机械有限公司

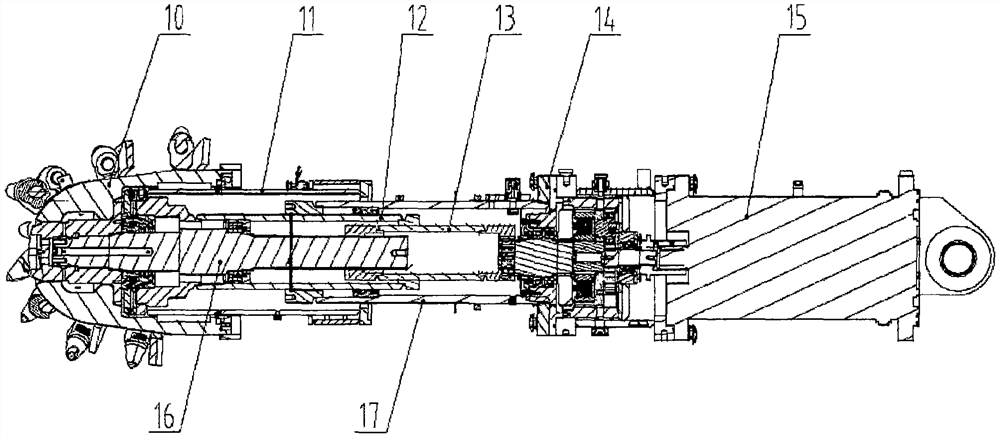

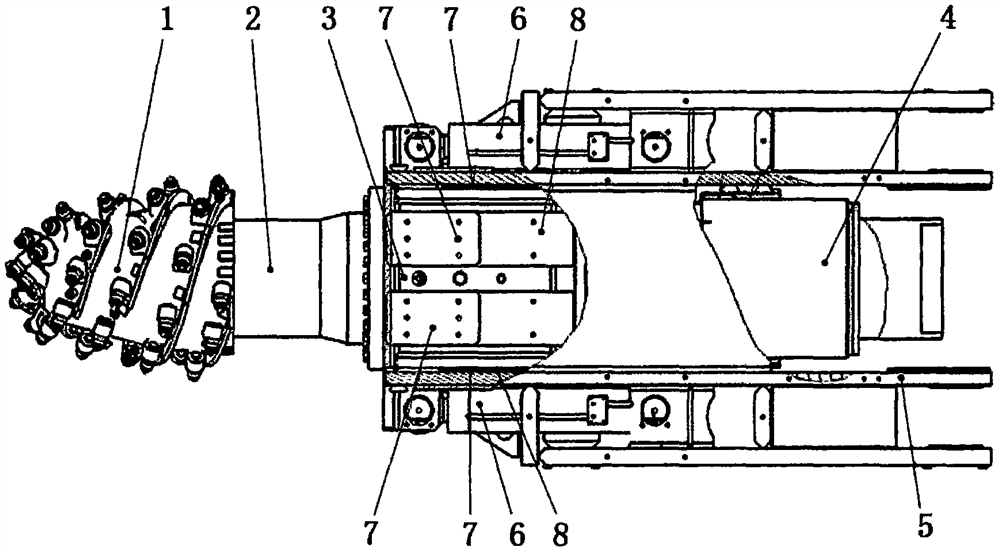

Telescopic cutting device and heading machine

PendingCN112664190AImprove reliabilityReduce supportSlitting machinesTunnelsElectric machineryReducer

The invention discloses a telescopic cutting device and a heading machine. The telescopic cutting device comprises a cutting arm support provided with a cylindrical cylinder barrel, a telescopic sleeve is sleeved with the cylinder barrel in a sliding mode, the cylinder barrel and the telescopic sleeve form a large-diameter hollow oil cylinder telescopic mechanism, a longitudinal guide rail is fixed to the cutting arm support, a guide plate matched with the longitudinal guide rail is fixed to the rear end of the telescopic sleeve, a cylindrical motor is sleeved with the telescopic sleeve, the motor, a speed reducer and a cutting head form an integral cutting power unit through the telescopic sleeve and the guide plate, liquid is supplied to a front cavity and a rear cavity of the cylinder barrel, and integral stretching and retracting of the integral cutting power unit can be achieved. The cutting device has the advantages of large telescopic stroke, simple structure, high mechanical strength and reliable work, after the heading machine is matched with the cutting device, the cutting device has the positioning and cutting capacity, the heading efficiency can be improved, and a foundation can be laid for upgrading a heading and anchoring all-in-one machine.

Owner:牛一村

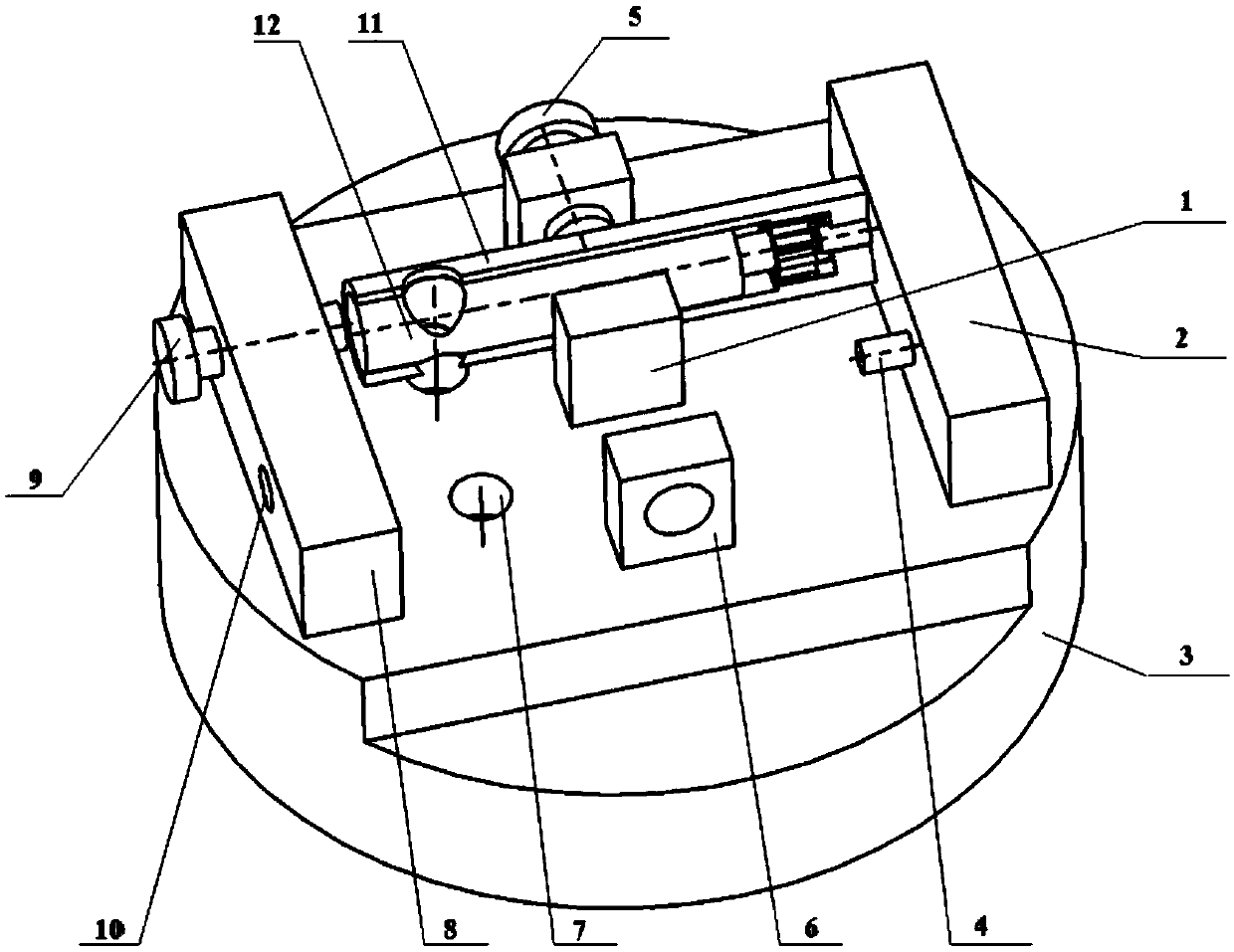

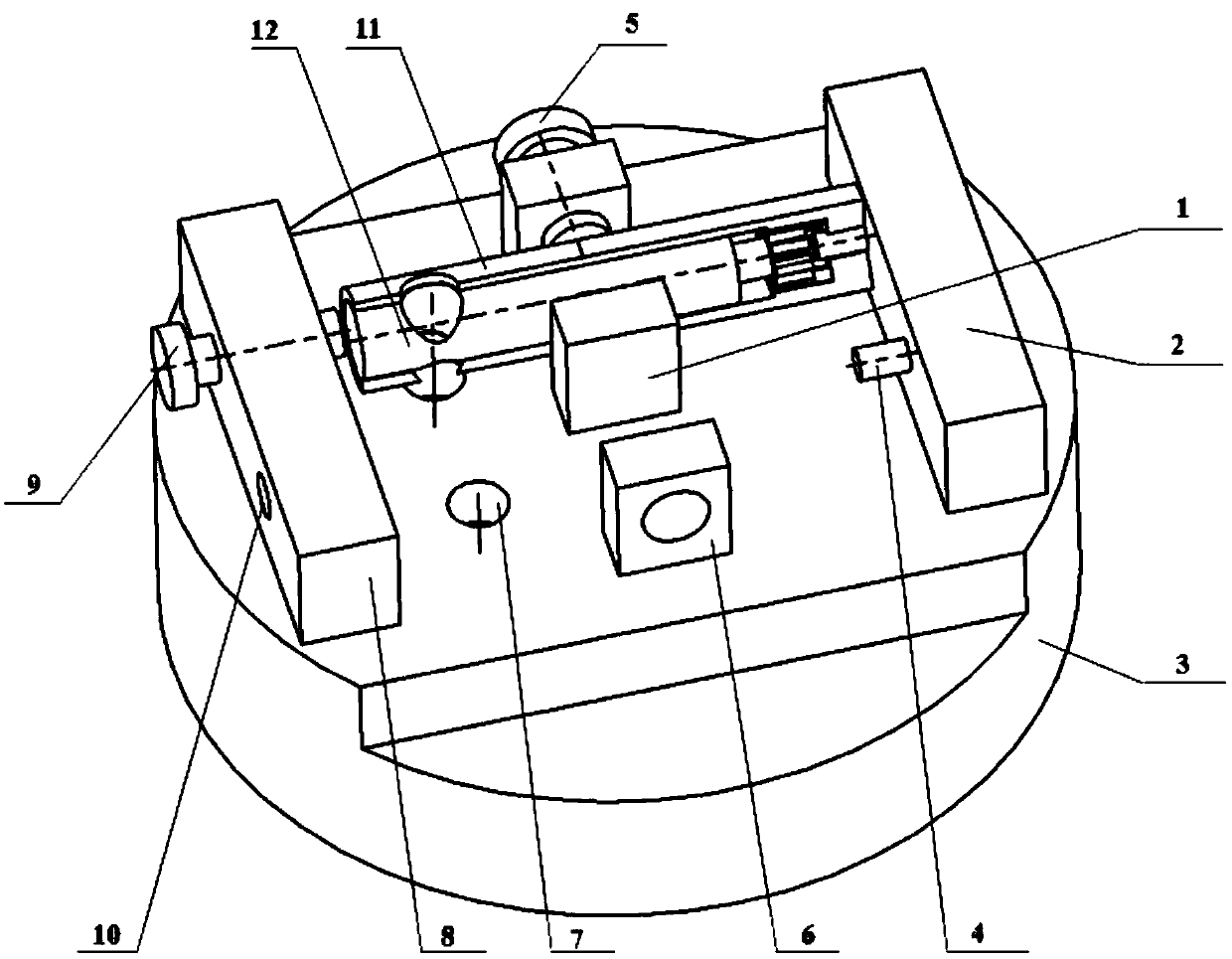

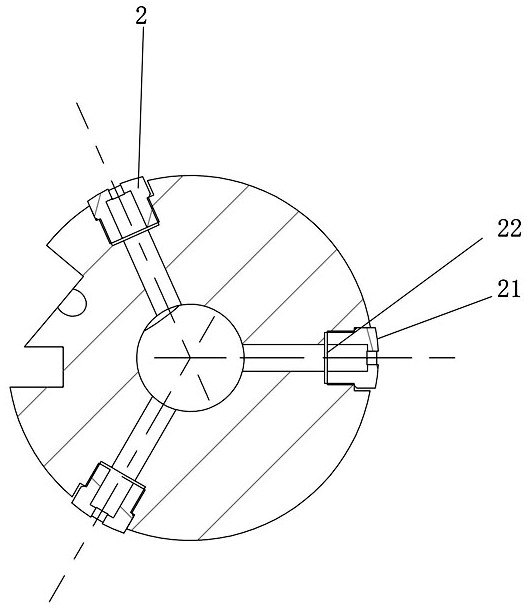

Positioning and centering combination clamping device

PendingCN107234456AUniform wall thickness differenceEasy to operateWork clamping meansPositioning apparatusMachine partsCantilever

The invention discloses a positioning and centering combination clamping device. The positioning and centering combination clamping device comprises a shaft, a big nut, a fixed cone, a rising spring, a movable cone, a centering cone dish and a blocking ring. The fixed cone and the movable cone are arranged on the shaft. The cone surfaces of the fixed cone and the movable cone are arranged oppositely. The front end of the movable cone penetrates through a through hole on the fixed cone and is connected with the big nut. The two ends of the rising spring are correspondingly arranged on the cone surfaces of the fixed cone and the movable cone. The centering cone dish is installed at the back end of the shaft. The back end of the shaft is provided with the blocking ring. The blocking ring is positioned in the axial direction on the shaft through the nut. According to the positioning and centering combination clamping device, a way of rising spring bi-directional positioning clamping is adopted, a rigidity cone dish bearing is designed at the cantilever ends of machined parts in an auxiliary mode, deformation of products caused by machining stress is overcome, the uniform wall thickness difference of the whole section of the machined parts is ensured, and the positioning and centering combination clamping device has the characteristics of being convenient to operate, safe, reliable and the like.

Owner:江南工业集团有限公司

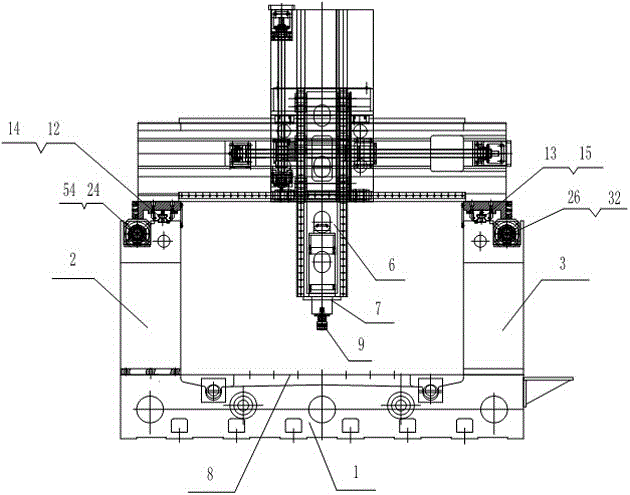

Numerical control high-speed carving and milling machine of bridge type elevated cross beam moving gantry

ActiveCN105562791AVertical stabilityImprove motion rigidityMilling machinesLarge fixed membersNumerical controlBridge type

The invention discloses a numerical control high-speed carving and milling machine of a bridge type elevated cross beam moving gantry. The numerical control high-speed carving and milling machine comprises a base, a left wall, a right wall, a cross beam, a front sliding seat, a rear sliding seat, a ram and a spindle. A workbench is arranged on the base, the left wall and the right wall are arranged on the base in parallel, and the workbench is located between the left wall and the right wall. The two ends of the cross beam are arranged on the left wall and the right wall, and horizontal moving pairs are formed by the two ends of the cross beam, the left wall and the right wall. The front sliding seat and the rear sliding seat are arranged in parallel, a horizontal moving pair is formed by the front portion of the front sliding seat and the cross beam, and a horizontal moving pair is formed by the rear portion of the rear sliding seat and the cross beam. The ram is located between the front sliding seat and the rear sliding seat, a vertical moving pair is formed by the front portion of the ram and the front sliding seat, and a vertical moving pair is formed by the rear portion of the ram and the rear sliding seat. The spindle is arranged on the lower portion of the ram and used for being provided with a carving and milling cutter. The numerical control high-speed carving and milling machine has the beneficial effects that due to the fact that the cross beam in the machine is supported by the left wall and the right wall, the down milling precision and the up milling precision of a workpiece are the same.

Owner:南京诚友数控设备有限公司

A compound insert for turning and milling with wave-shaped chip guide for heavy-duty cutting

InactiveCN106270588BEasily brokenHigh strengthMilling cuttersCutting insertsMachining processComposite blade

Owner:HARBIN UNIV OF SCI & TECH

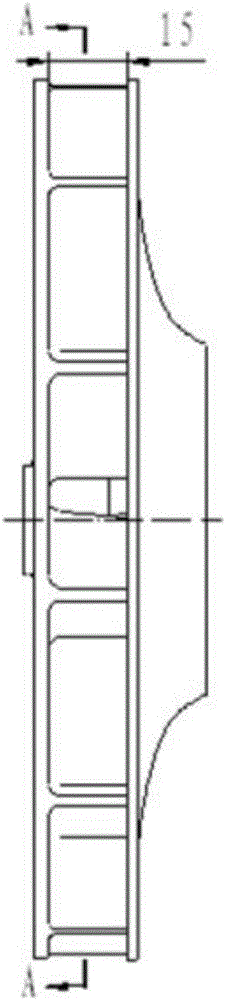

Multistage diameter change milling cutter

InactiveCN106270692AReduce cutting vibrationAvoid interferenceMilling cuttersWorkpiecesMilling cutterProduction quality

The invention discloses a multistage diameter change milling cutter. The multistage diameter change milling cutter comprises a shank; the front end of the shank is a multistage cutter rod with gradually reduced diameter; the front end of the cutter rod is a cutter bit; every two adjacent diameter change sections on the multistage cutter rod are conical transitions; chamfering angles are arranged at one ends, towards the shank, of the conical transitions; and multiple milling grooves are peripherally spaced in the outer wall of the multistage cutter rod. The multistage diameter change milling cutter is excellent in rigidity during cutting, effectively reduces the cutting vibration, can insert the thinner front end thereof into a deeper cavity for machining, enhances the machining adaptability, improves the manufacturing precision of complex curved surface structural parts of narrow deep cavities and deep cavity ultrathin structural parts, improves the machining efficiency, and effectively guarantees the production quality stability.

Owner:GUIZHOU YONGHONG AVIATION MACHINERY

Machining method for through hole in angular combination device

ActiveCN109648257AHigh precisionAvoid interferencePositioning apparatusMetal-working holdersEngineeringMachining process

The invention relates to a machining process for a through hole in an angular combination device, in particular to a machining method for a through hole in an angular combination device. A machining clamp for the through hole in the angular combination device is adopted, and machining of the through hole in the angular combination device is achieved on a high-speed milling machine; a first combination part is positioned and clamped through an axial pressing bolt, an end face positioning block, a lateral pressing bolt and a lateral positioning block, and a through hole in the combination part is machined; and an axial positioning bolt is loosened, a second combination part is in inserted, angular combination is achieved, the pressing bolt is screwed, a tool is switched, a high-speed micro cutting milling method is adopted, and a through hole in the second combination part is machined. By means of the method, matching errors produced by through hole separated machining are well avoided,influences produced by different material cutting on a tool are avoided, the cutting movement phenomenon is reduced fundamentally, and the through hole machining quality is effectively improved.

Owner:JINCHENG NANJING ELECTROMECHANICAL HYDRAULIC PRESSURE ENG RES CENT AVIATION IND OF CHINA

A cutting tool with guiding structure

ActiveCN110860724BThe guiding structure is simple and stable and reliableAvoid rigid contactTransportation and packagingTrepanning drillsEngineeringSupport surface

The invention discloses a cutting tool with a guide structure, which includes a cutting tool body and a long guide bar. A guide cavity matching the guide bar is provided on the surface of the cutting tool body. The guide bar includes a guide support surface, Bottom positioning surface and positioning column. The positioning column is located on the bottom positioning surface. A deep groove cavity is opened on the guiding support surface. The positioning column is provided with a first cooling hole communicating with the deep groove cavity. The guiding cavity includes a bottom supporting surface, a peripheral The receiving surface and the positioning hole, the positioning hole is opened on the bottom supporting surface, the bottom positioning surface is in contact with the bottom supporting surface, the surrounding receiving surface is located on both sides of the bottom supporting surface, the positioning column and the positioning hole are interference fit, and the cutting tool body is also provided with There is a second cooling hole connected to the first cooling hole, which has the advantages of small guiding contact area, small cutting vibration, stability and reliability.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

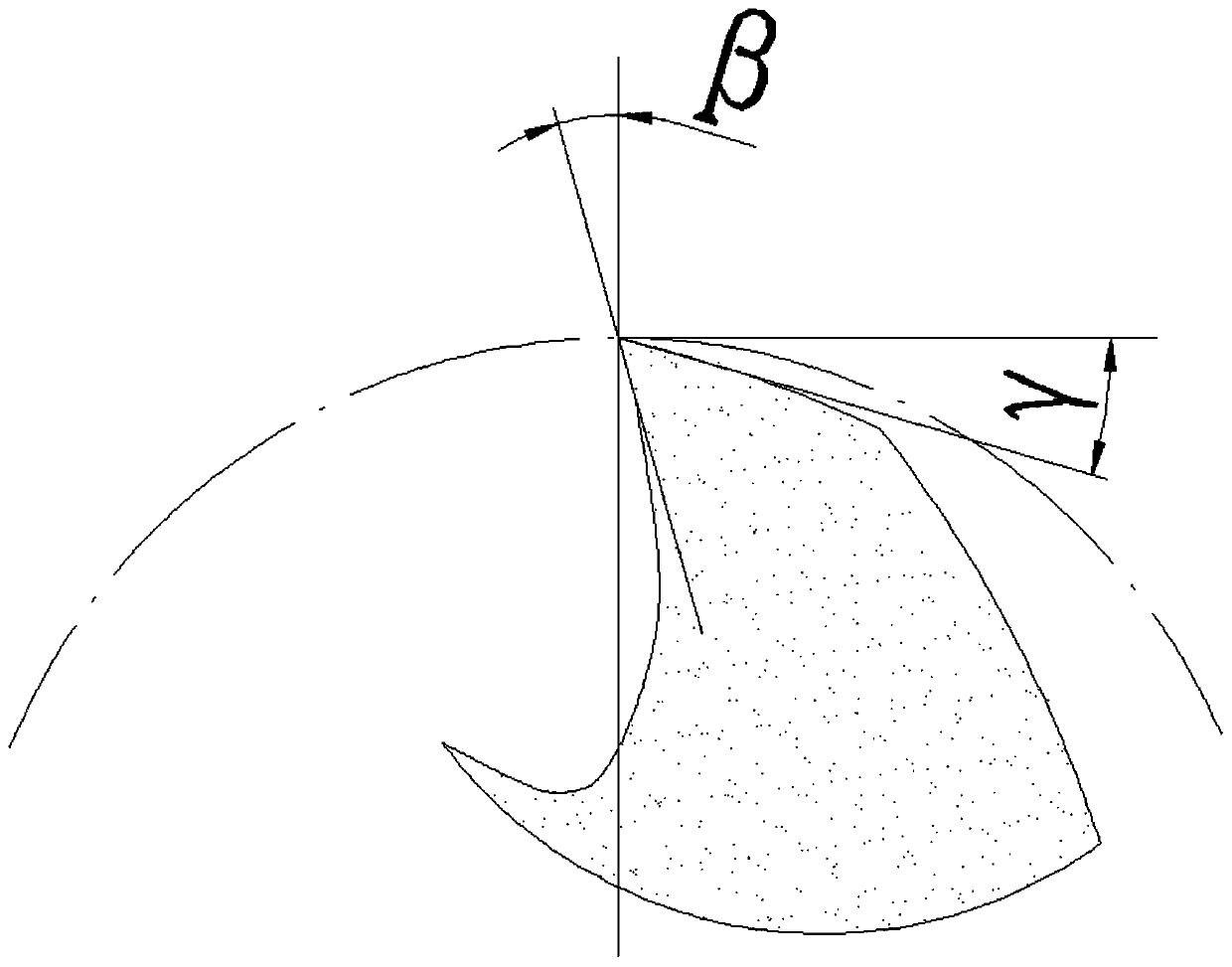

End mill

InactiveCN110508854ANot prone to oxidative chemical reactionsLow thermal conductivityMilling cuttersMilling cutterNeck parts

The invention relates to an end mill which is made of zirconia ceramics. The end mill comprises a handle part, a conical transition part, a neck part and a cutting part which are connected in sequence. The cutting part comprises at least two outer circle blades which spirally extend around the outer side wall of the cutting part, and the spiral angle alpha is controlled to be 25 degrees to 42 degrees. The circumference blade front angle beta of the outer circle blades is controlled to be 5 degrees to 10 degrees, and the circumference blade rear angle gamma of the outer circle blades is controlled to be 12 degrees to 18 degrees. The outer circle blades extend to the end face of the cutting part to form end blades, and the rear angle delta of the end blades is controlled to be 10 degrees to18 degrees. In addition, the outer diameter of the cutting part is D1, the core thickness diameter of the cutting part is d, and d is equal to 65%-70% of D1. Thus, in the practical cutting process, the end mill has the low cutting vibration amount, a cutting edge is not likely to be subjected to an oxidation chemical reaction, and therefore the machining precision and the service life are effectively ensured. In addition, the tripping phenomenon extremely happens in the specific use process of the end mill, and therefore the fine degree of the cutting edge is ensured.

Owner:SUZHOU AHNO PRECISION CUTTING TECH CO LTD

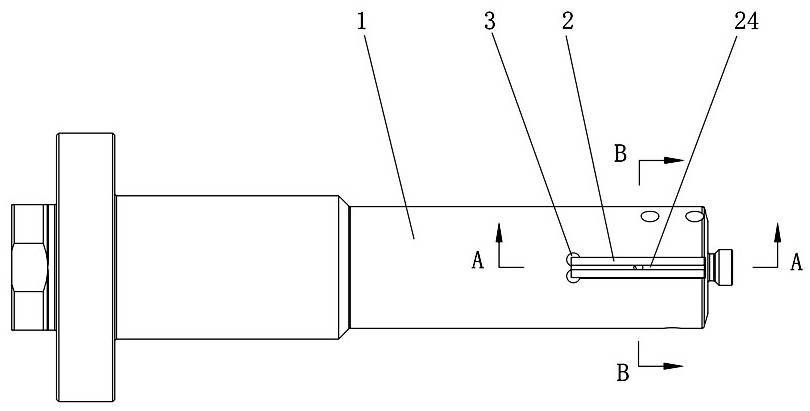

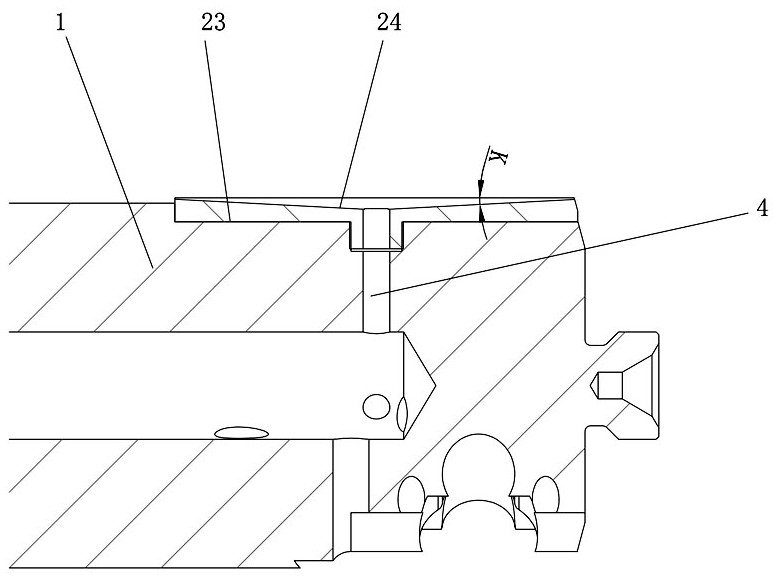

Tapered tension spring clamping device

ActiveCN107584306AUniform wall thickness differenceSimple structurePositioning apparatusMetal-working holdersEngineeringFlange

The invention discloses a tapered tension spring clamping device which is characterized by comprising a shaft, a fixed cone, a spring, a tapered tension spring, a movable cone and a mandrel. The fixedcone is fixedly mounted on the shaft, the movable cone sleeves the shaft, the spring is disposed between the movable cone and the fixed cone, and the spring sleeves the shaft. The mandrel is insertedin a center hole in one end of the shaft and is connected with the shaft through a movable pin. The exposed end of the mandrel is provided with a flange, and the flange can position the movable cone.The movable cone is provided with a material return pin. One end of the tapered tension spring is placed on the conical surface of the fixed cone, and the other end of the tapered tension spring is placed on the conical surface of the movable cone. The tapered tension spring clamping device is simple in structure, convenient to operate, safe and reliable. According to the tapered tension spring clamping device, rigidity of the tapered tension spring clamping device is enhanced, cutting vibration in the processing process is reduced, and processing precision is improved.

Owner:江南工业集团有限公司

Grooving cutter

ActiveCN105345049AGuaranteed limit effectHigh clamping reliabilityCutting insertsTurning toolsEngineeringMechanical engineering

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Rotary machining cutter

ActiveCN105328224AGuarantee the quality of the machined surfaceExtended service lifeCutting insertsTurning toolsMachiningFastener

The invention discloses a rotary machining cutter which comprises a rotary cutter body, wherein cutter slots are formed in the outer edge at the front end of the rotary cutter body; cutter holders are mounted in the cutter slots through cutter holder fastening components; cutting blades are mounted at the head parts of the cutter holders through cutting blade fasteners; adjusting structures are also mounted in the cutter slots; the adjusting structures are located between the tail part surfaces of the cutter holders and the tail part positioning surfaces of the cutter slots; all the surfaces, located between the tail part surfaces and the end surfaces of the cutter holders, of the cutter holders are circumferential surfaces of the cutter holders; each cutter holder fastening component comprises at least two cutter holder fasteners; and the cutter holders are locked by the cutter holder fasteners in different directions of the circumferential surfaces of the cutter holders. The rotary machining cutter provided by the invention has the advantages of positioning stability, strong vibration resistance, long service life, high machining precision and the like.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com