Patents

Literature

35results about How to "Guarantee the quality of the machined surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Finish-milling feeding speed optimizing method based on integral impeller blade shape

ActiveCN103586738AImprove processing efficiencyGuarantee the quality of the machined surfaceAutomatic control devicesWorkpiecesImpellerProcess quality

The invention discloses a finish-milling feeding speed optimizing method based on integral impeller blade shape. The method comprises the steps of generating a finish-machining cutter track source file of a spherical head cutter blade with the radius as RT and based on a spherical head according to a geometrical shape of an integral impeller blade, introducing a single impeller blade model, judging the cross line between a runner and the blade according to the distance between a point on the blade and the center of an impeller, extracting the cross line, discreting the cross line into W points according to equal chord heights, composing a point set U through W points, setting the longitudinal depth acceleration proportion omega between the top end of the blade and the tail end of the blade, sequentially reading and analyzing the cutter track source file generated in the step 1 line by line, and extracting cutter point information of all cutting paths in the cutter track source file generated in the step 1. In addition, the cutter track source file records cutter point coordinates under a processing coordinate system and cutter axis vectors corresponding to the cutter point coordinates. The finish-milling feeding speed optimizing method solves the technical problems that an existing method is low in processing efficiency, poor in processing quality and serious in cutter abrasion.

Owner:HUAZHONG UNIV OF SCI & TECH

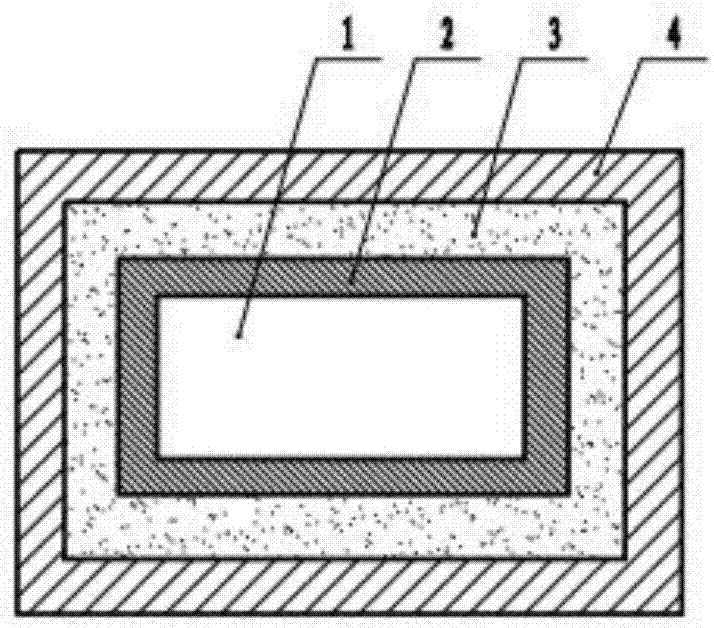

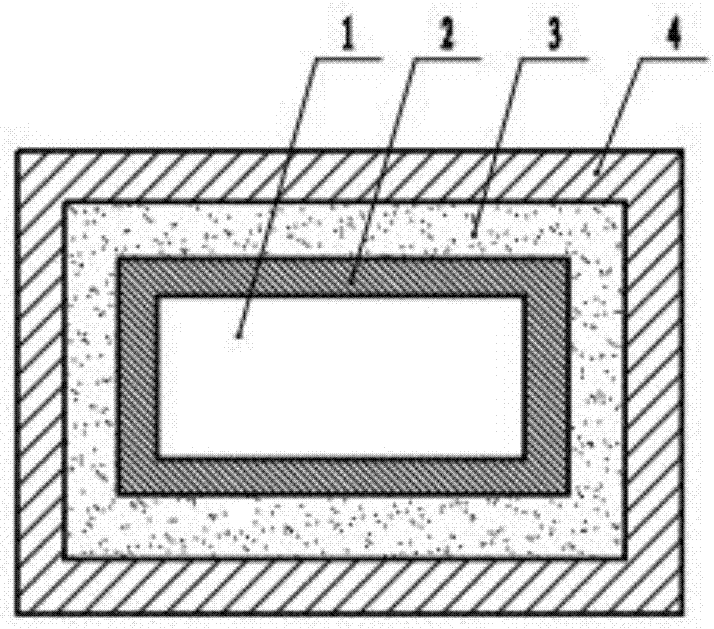

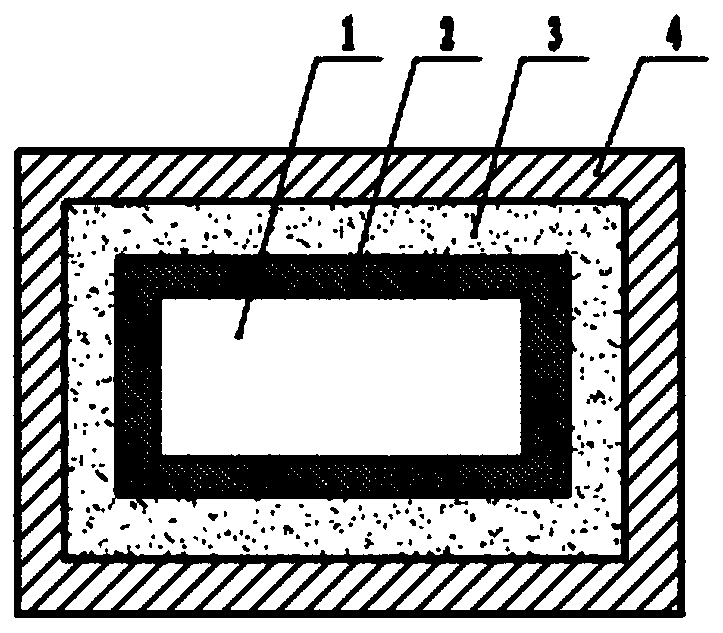

SiZrCN gradient composite coating cutter and preparation method thereof

ActiveCN107177828AHigh hardnessImprove thermal stabilityVacuum evaporation coatingSputtering coatingSputteringHeat stability

The invention belongs to the field of mechanical manufacture cutting cutters, and in particular relates to a SiZrCN gradient composite coating cutter and preparation method thereof. The coating is the SiZrCN gradient composite coating prepared by adopting a composite coating method of unbalanced magnetron sputtering and electric arc plating; the surface of the coating cutter is SiZrCN gradient composite coating with gradually-changed gradient of nitrogen content, a Ti transition layer and a SiZrC transition layer are sequentially arranged between a cutter base body and the coating. By adopting the SiZrCN ultra-hard carbon-nitrogen compound coating, because two metals including Si and Zr are added in the coating at the same time, the nitrogen content of the coating structure component is gradually changed in a gradient manner, so that the cutting machining performance of the cutter can be improved. The coating has high hardness and heat stability, and also has good diffusion prevention and wear prevention performances, good plastic deformation resistance ability and excellent friction and wear resistance property. In the cutting process, the cutter can effectively prevent the occurrence of cracking of cutting edges and hot cracks, guarantee the machining surface quality of the workpieces, and prolong the service life of the cutter by more than 70%.

Owner:JINING UNIV

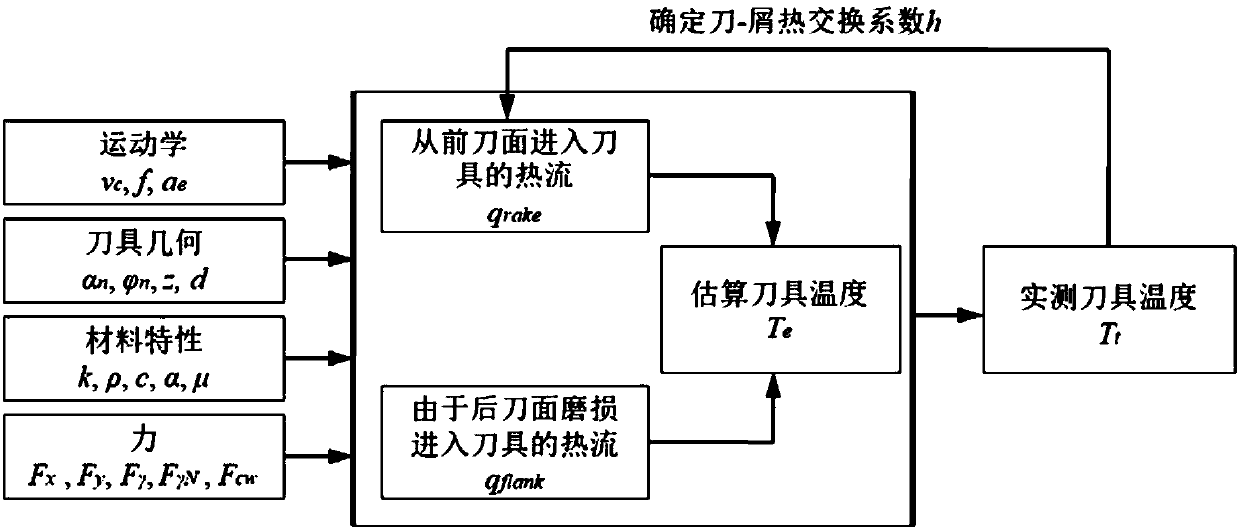

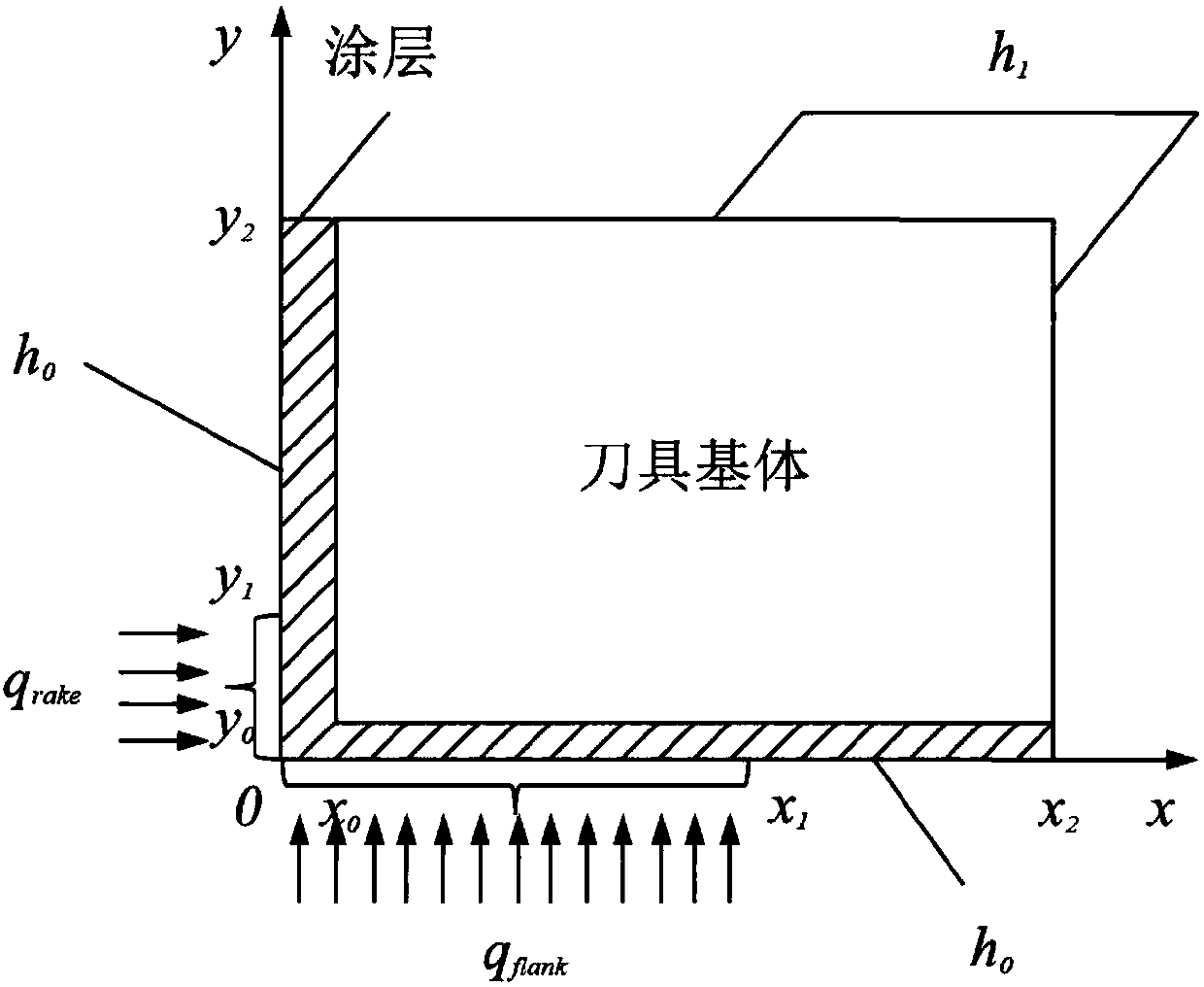

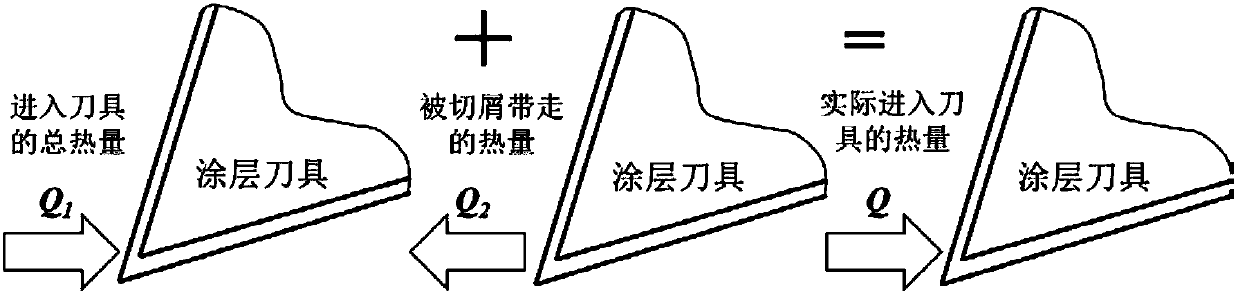

Coating cutter steady-state temperature field predicting method considering cutter rear surface abrasion

InactiveCN108256244AGuarantee the quality of the machined surfaceOptimizing cutting process parametersGeometric CADSpecial data processing applicationsHeat fluxHeat flow

The invention discloses a coating cutter steady-state temperature field predicting method considering cutter rear surface abrasion. By means of the method, firstly, a thermal model used for describingthe coating cutter temperature change in the cutting and machining process is built, secondly, heat flux entering a cutter from the front cutter surface and heat flux entering the cutter due to abrasion of the rear cutter surface are calculated respectively, through cutting experimental data, heat exchange coefficients are estimated to be used for determining the heat flux distribution proportionfor entering chips and the cutter, and then instantaneous cutter temperature distribution under different cutter states is simulated and predicated. Precise cutter temperature prediction in the abrasion state of a coating cutter is easily achieved, by optimizing technology parameters, the service life of the cutter is prolonged, and the machining surface quality of parts is improved.

Owner:WUHAN UNIV OF TECH

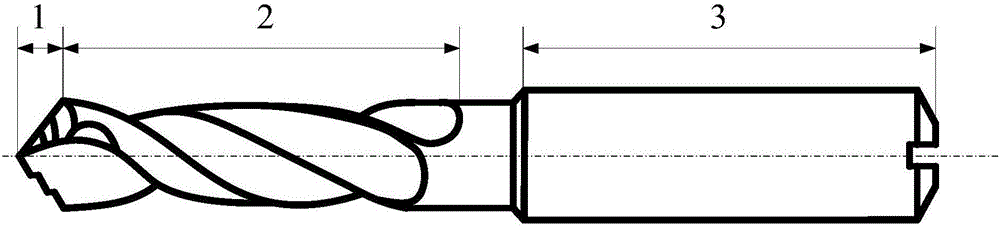

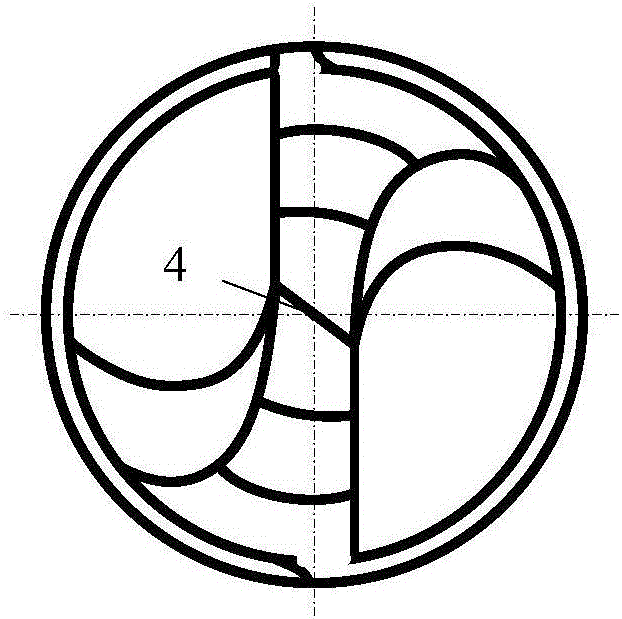

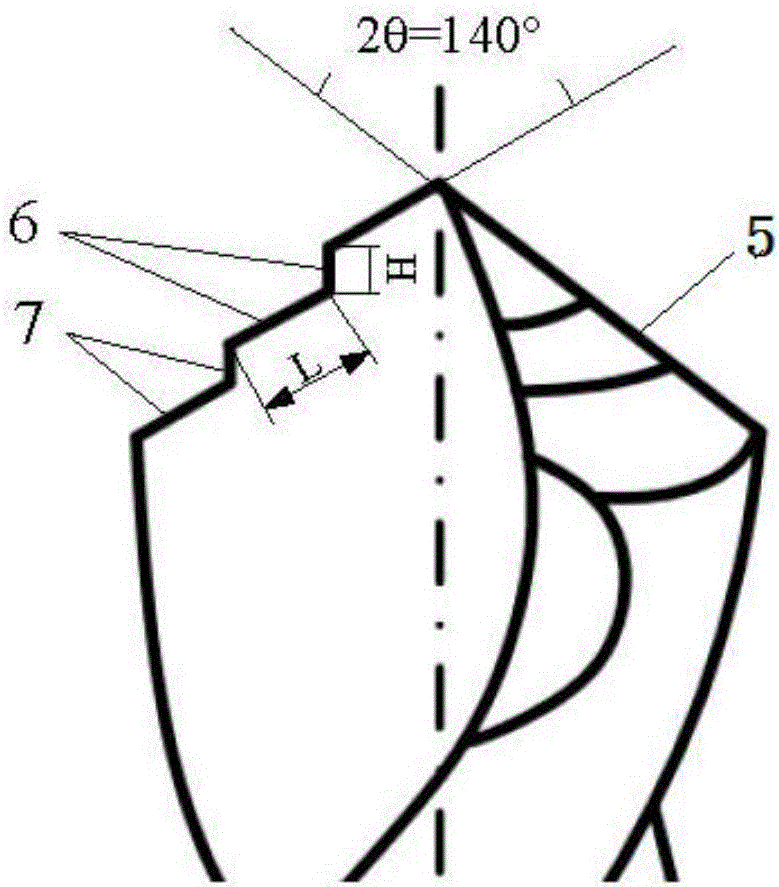

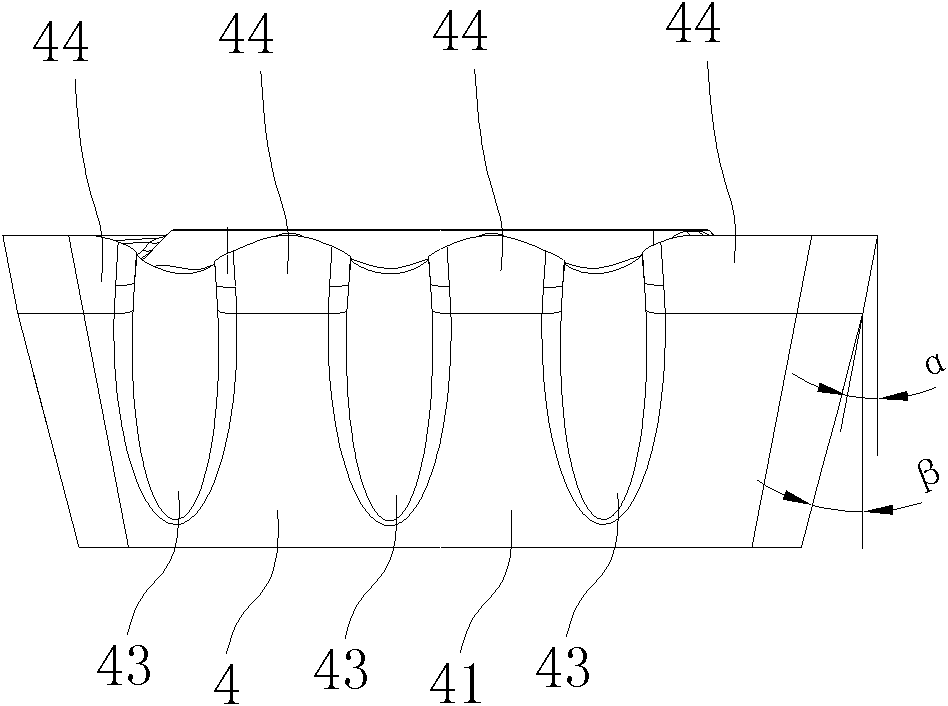

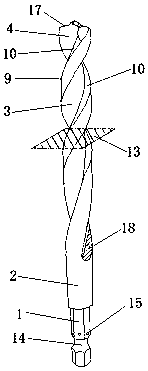

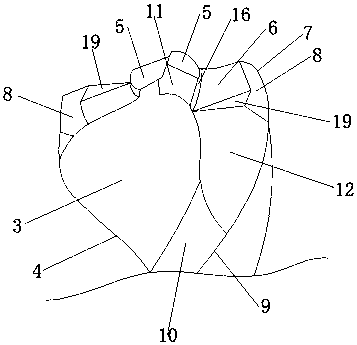

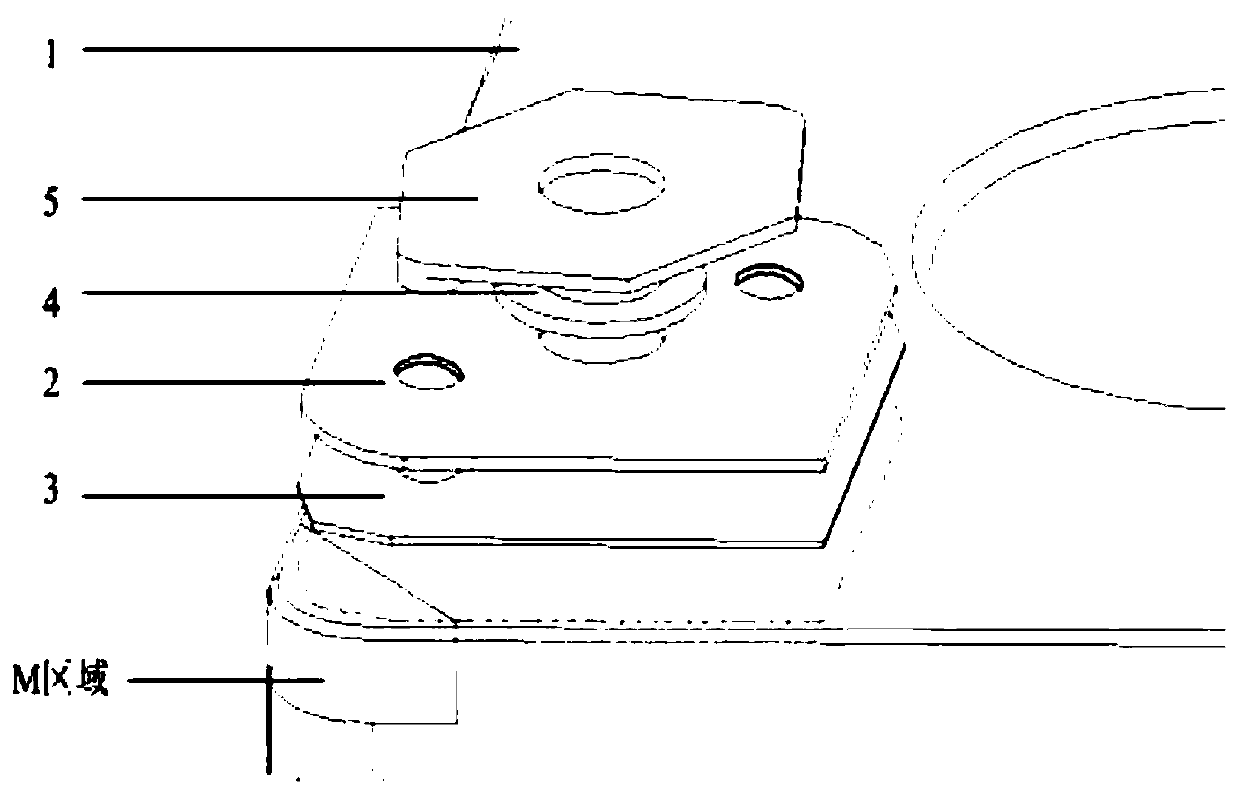

Chip breaking drill bit with step edge type

InactiveCN106001708AReduce contact areaGuaranteed service lifeTransportation and packagingStepped drillsVertical edgeMachined surface

A chip breaking drill bit with a step edge type comprises a drill tip, a guide part and a tool handle. The guide part is arranged between the drill tip and the tool handle. The drill tip comprises a chisel edge and two main cutting edges. The chisel edge is located between the two main cutting edges. Each main cutting edge comprises a front tool face and a rear tool face. Each main cutting edge is in a step edge type and comprises a first step edge body and a second step edge body, both of which are composed of a step transverse edge body and a step vertical edge body. According to the drill bit, step structure design is conducted on the main cutting edges, so that the load on unit cutting edge is reduced, the contact area of the rear tool faces of a tool and the machined surface of a workpiece is reduced, and the cutting force is reduced; meanwhile, through the step edge type, the deformation degree of cutting chips can be effectively increased, the cutting chips can be easily broken, smoothly discharged and prevented from twining around the tool, the quality of the machined surface of the workpiece and the service life of the tool are guaranteed, the durability of the tool is improved, and the machining quality and the machining efficiency are guaranteed.

Owner:SHANDONG UNIV

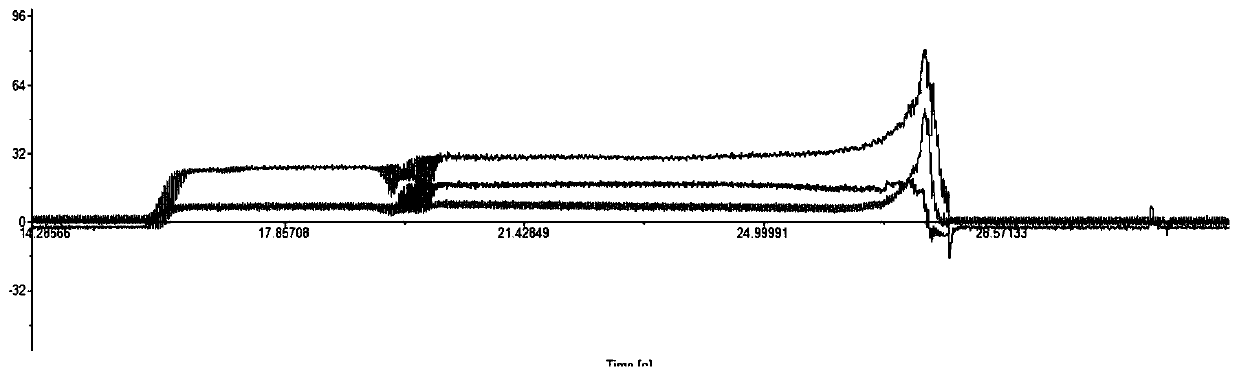

Ultrasonic auxiliary cutting force control method

ActiveCN111151773AReduced cutting force variabilityReduce cutting force amplitudeAutomatic control devicesAuxillary equipmentMaterial removalSurface roughness

The invention provides an ultrasonic auxiliary cutting force control method. The ultrasonic auxiliary cutting force control method comprises the steps of building an ultrasonic auxiliary system, adjusting and controlling ultrasonic vibration parameters and adjusting and controlling cutting force. The step of building the ultrasonic auxiliary system comprises: building a two-dimensional ellipticalultrasonic auxiliary turning system; the step of adjusting and controlling the ultrasonic vibration parameters comprises: carrying out ultrasonic end face turning with different ultrasonic vibration parameters and fixed cutting parameters under the set power supply frequency of the ultrasonic vibration auxiliary system, and obtaining an optimal material removal parameter by measuring the cutting force, observing a material removal mode and the extension / brittleness region cutting parameter range; and the step of adjusting and controlling the cutting force comprises: fixing the ultrasonic vibration parameters, adopting the different cutting parameters, and obtaining the maximum cutting force under the optimal cutting parameters through numerical comparison of the cutting force and the machined workpiece surface roughness.

Owner:SHANGHAI AEROSPACE CONTROL TECH INST

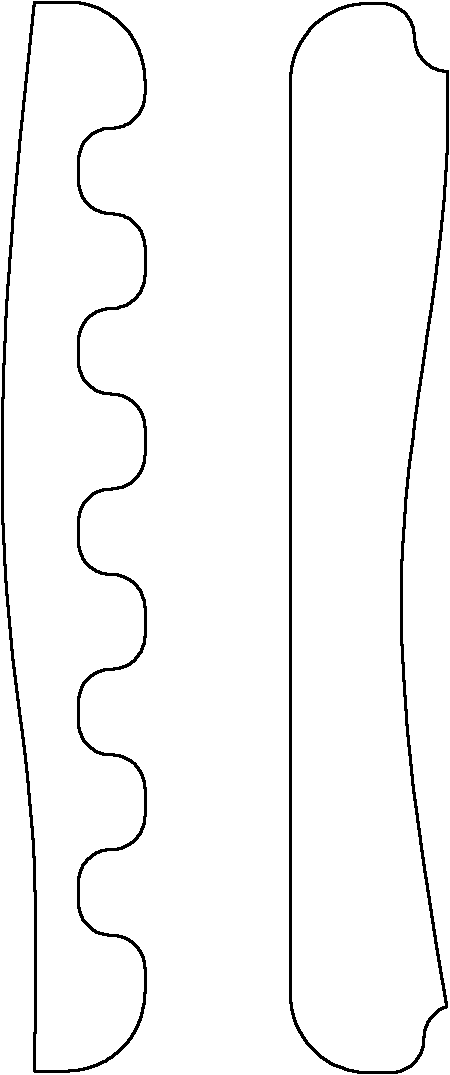

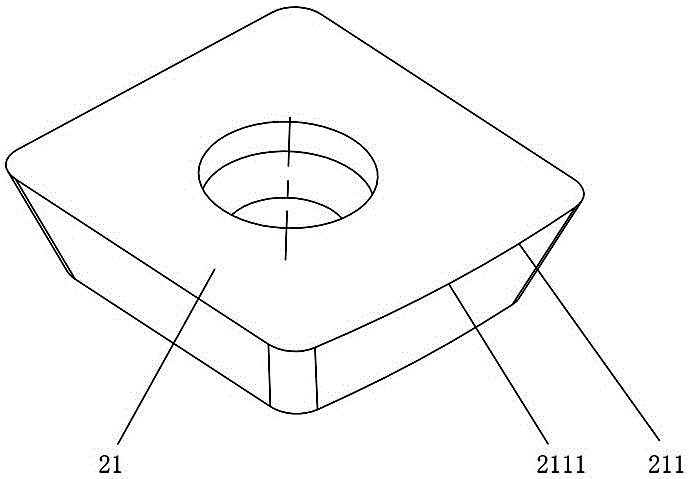

Milling blade, milling cutter and installation method for milling cutter

InactiveCN101837485AIncrease contact areaImproved chip breaking capacityMilling cuttersMilling cutterCutting force

The invention discloses a milling blade. The milling blade comprises a blade body in the shape of a polygonal plate, wherein the blade body is enclosed by an upper surface, a lower surface and a plurality of side faces connecting the upper surface and the lower surface; the centre of the blade body is provided with a blade centre hole for installation and positioning; each side face is provided with a rear gap surface and a rear cutter surface; the rear gap surface is adjacent to the lower surface; the upper surface is provided with a front cutter surface in one-to-one correspondence with each rear cutter surface; the rear cutter surface of at least one side face is a planar rear cutter surface; the front cutter surface corresponding to the planar rear cutter surface is a wavelike surface; and the planer rear cutter surface is crossed with the wavelike planar front cutter surface to form a continuous wavelike blade. The milling blade has the advantages of increasing the contact area of the front cutter surface and a workpiece, reducing the impact when the workpiece is cut, reducing the cutting force, improving the chip breaking and cutting capacity, reducing the wearing and meeting high-efficiency cutting requirement. The invention also discloses a milling cutter provided with the milling blade and an installation method for the milling cutter.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

SiNbCN multi-element gradient cutting tool with composite coating and preparation method thereof

InactiveCN107385401AHigh hardnessImprove toughnessVacuum evaporation coatingSputtering coatingCarbon nitrideNitrogen

The invention belongs to the field of machining cutting tools, and particularly relates to a SiNbCN multi-element gradient cutting tool with a composite coating and a preparation method thereof. The SiNbCN multi-element gradient cutting tool with the composite coating sequentially comprises a cutting tool base body, a Ti transition layer, a SiNbC transition layer and a SiNbCN multi-element gradient composite coating from insider to outside, wherein the nitrogen content gradient of the SiNbCN multi-element gradient composite coating is gradually changed. Firstly, arc plating is adopted to deposit a Ti transition layer, and then an unbalanced magnetron sputtering method is adopted to deposit the SiNbC transition layer and the SiNbCN multi-element gradient composite coating with the gradually-changed nitrogen content gradient. The SiNbCN ultrahard carbon nitride compound coating can obviously improve the cutting machining property of the cutting tool because two kinds of elements of Si, Nb and the like are simultaneously added into the coating and the nitrogen content gradient of the coating structural components is gradually changed. The SiNbCN multi-element gradient cutting tool with with composite coating has very high hardness and roughness, good anti-diffusion wear resistance, a capability of resisting plastic deformation and an excellent character of friction and wear.

Owner:JINING UNIV

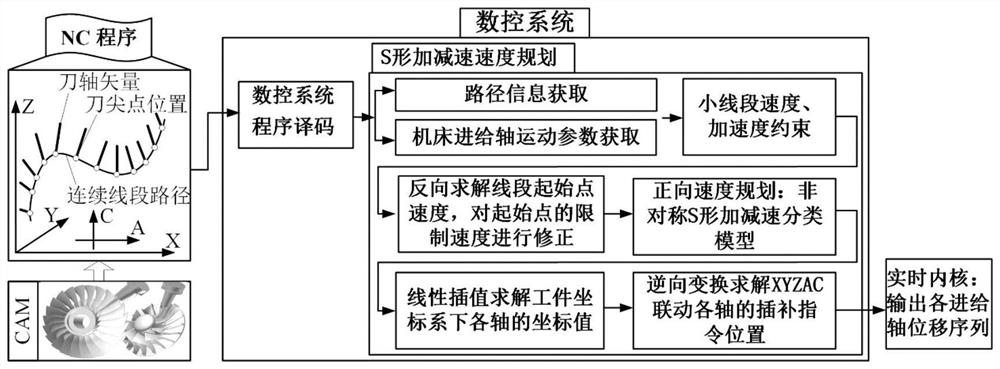

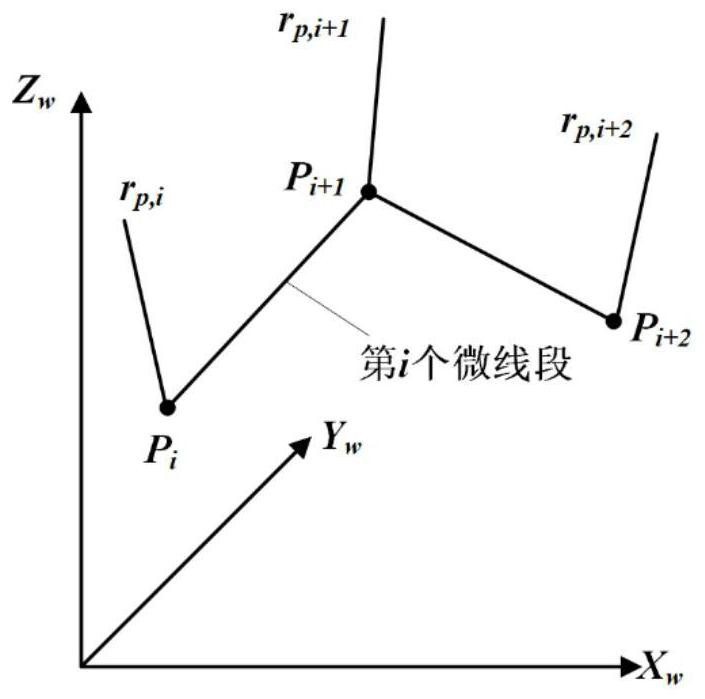

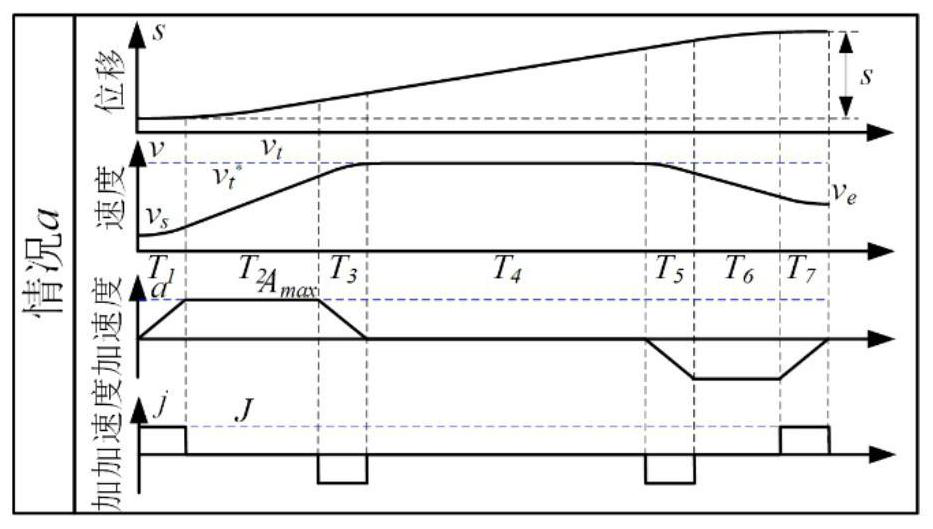

Five-axis machine tool speed planning method based on S-shaped acceleration and deceleration

PendingCN113156893AImprove machine tool processing efficiencyImprove universalityNumerical controlTotal factory controlMachining toolpathLine segment

The invention discloses a five-axis machine tool speed planning method based on S-shaped acceleration and deceleration. The method comprises the steps: obtaining the path information of a continuous machining path, and building a complete S-shaped acceleration and deceleration model; dividing an incomplete acceleration and deceleration process into a plurality of conditions, and establishing a corresponding acceleration and deceleration speed diagram planning method; then correcting the limiting speed of the starting point of the small line segment; determining acceleration and deceleration types which should be adopted by the current small line segments through the S-shaped acceleration and deceleration classification model, calculating displacement, speed and acceleration diagrams of the small line segments, and solving coordinate values of each axis under a workpiece coordinate system through linear interpolation; and finally, converting the coordinate value of each axis in each interpolation period in a workpiece coordinate system into the coordinate value of each axis in each interpolation period in a machine tool coordinate system by adopting reverse coordinate transformation, performing part processing, calculating the velocity diagram of each small line segment forwards segment by segment, and finally obtaining the interpolation instruction position and instruction speed on the whole processing path. High feeding speed can be achieved, and moving stability of moving parts of a machine tool is guaranteed.

Owner:XI AN JIAOTONG UNIV

Combined machining method for threaded hole in high-volume-fraction aluminum-based silicon carbide

ActiveCN112496680AImprove processing qualityQuality improvementThread cutting machinesCarbide siliconUltrasonic vibration

The invention relates to a combined machining method for a threaded hole in high-volume-fraction aluminum-based silicon carbide. According to the combined machining method, the threaded hole with thestandard specification is machined in an aluminum-based silicon carbide material with the volume fraction of higher than 50%, based on a multi-dimensional ultrasonic vibration milling and grinding combined machining method, an advanced machining method for grinding and ultrasonic vibration machining of a difficult-to-machine material is fully combined with a high-precision milling machining methodfor threads, adverse machining influences caused by SiC particle detachment, breakage and other reasons in the machining process in an existing machining technology can be reduced by optimizing the tool design and the technological parameters, and the thread machining quality and efficiency are improved.

Owner:BEIJING SATELLITE MFG FACTORY

Stress-free clamping method for datum plane machining of open thin-walled part

InactiveCN111203738AGuaranteed positioning accuracyAvoid misalignmentPositioning apparatusMetal-working holdersHot meltAlloy

The invention relates to a stress-free clamping method for datum plane machining of an open thin-walled part. According to the method, the open thin-walled part can keep a stress-free clamping state during datum plane machining, thereby meeting machining precision requirements. The method is characterized in that a base serves as a hardware basis, hot melt adhesive and low-melting-point alloy serve as an important element and a main element respectively, the position of the open thin-wall part in the base is limited through the hot melt adhesive, then the low-melting-point alloy subjected to solid-liquid conversion at a certain temperature provides supporting force and rigidity for the open thin-wall part, and finally datum plane milling before finish machining of the open thin-wall part can be achieved.

Owner:CNGC INST NO 206 OF CHINA ARMS IND GRP

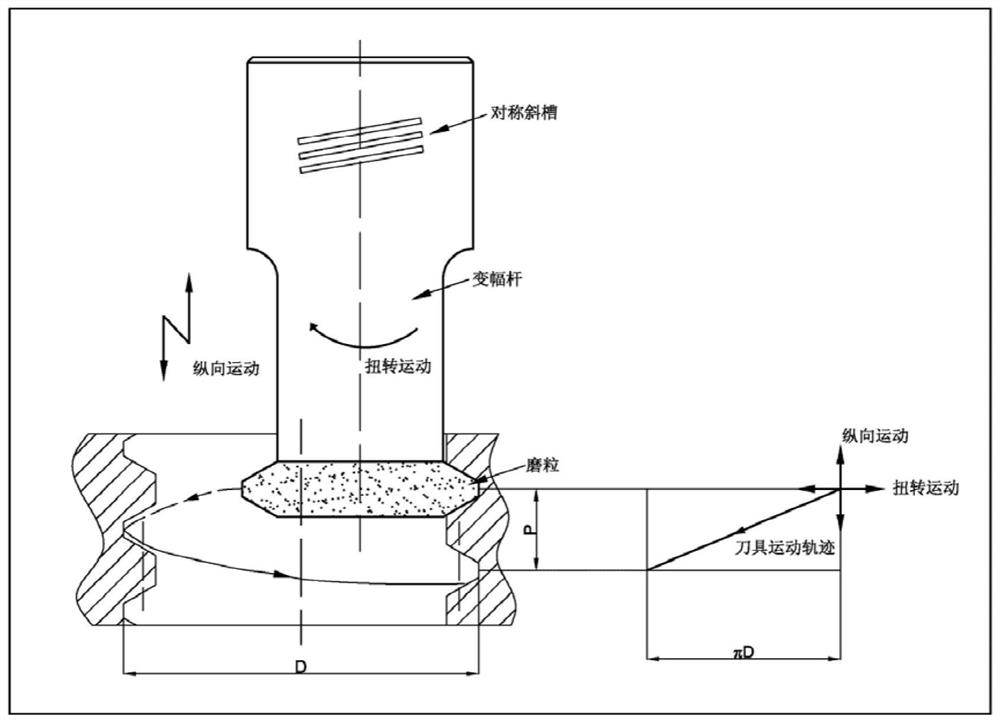

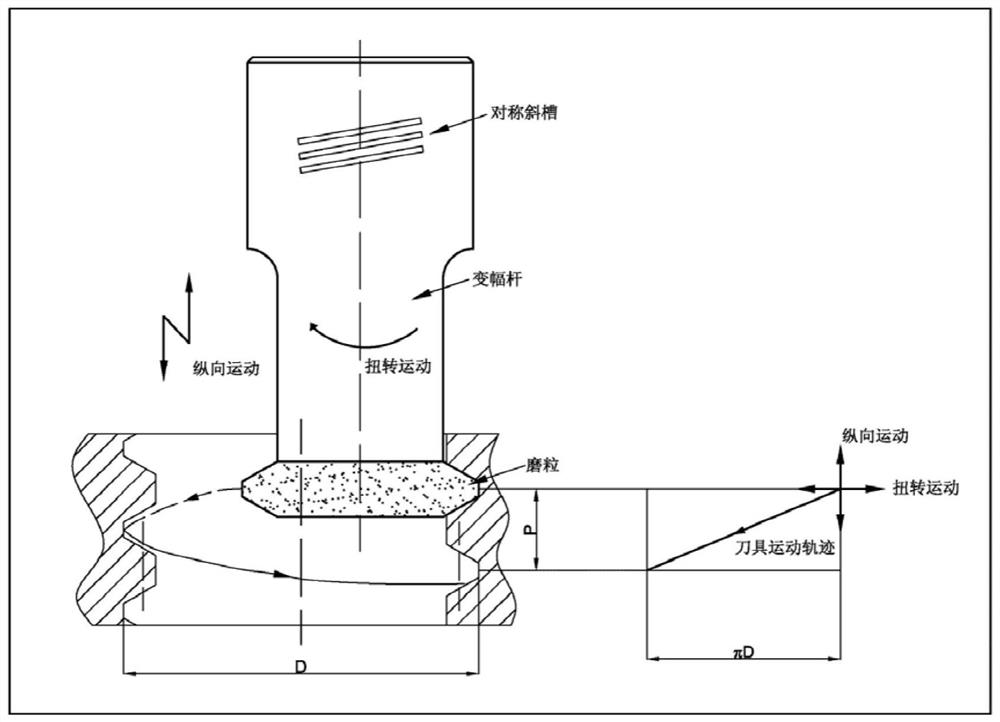

Ultrasonic cutting and polishing machining system

ActiveCN110064764AImprove machined surface qualityReduce the quality of the machined surfaceTurning machinesMetal working apparatusMachined surfaceTransformer

The invention discloses an ultrasonic cutting and polishing machining system. The ultrasonic cutting and polishing machining system comprises an ultrasonic transducer, an amplitude transformer, and awiper blade cutter, wherein the front end of the ultrasonic transducer is tightly and reliably connected with the rear end of the amplitude transformer; the ultrasonic transducer is connected with anultrasonic power supply through a lead; a flange plate is arranged at the vibration displacement node position of the amplitude transformer; the flange plate is connected with a B-axis rotary tool rest through a supporting plate; and the wiper blade cutter is tightly and reliably connected with the front end of the amplitude transformer. According to the ultrasonic cutting and polishing machiningsystem, ultrasonic high-frequency vibration in the feeding direction of the cutter can improve the action length of a wiper blade, reduce the generation of secondary tool marks on the machining surface of the wiper blade, and improve the quality of the machined surface; due to the cleaning effect of the ultrasonic vibration, it is difficult to generate chip accumulation at the wiper edge, and thequality of the machined surface is better guaranteed; the ultrasonic vibration changes the contact state and action mechanism between the cutting edge and the wiper edge and the material to be machined, reduces the cutting force and the cutting temperature, and improves the surface quality after the cutting edge is processed, and thus the quality of the machined surface is further improved due tothe combined action of the polishing edge and the ultrasonic vibration.

Owner:DALIAN JIAOTONG UNIVERSITY

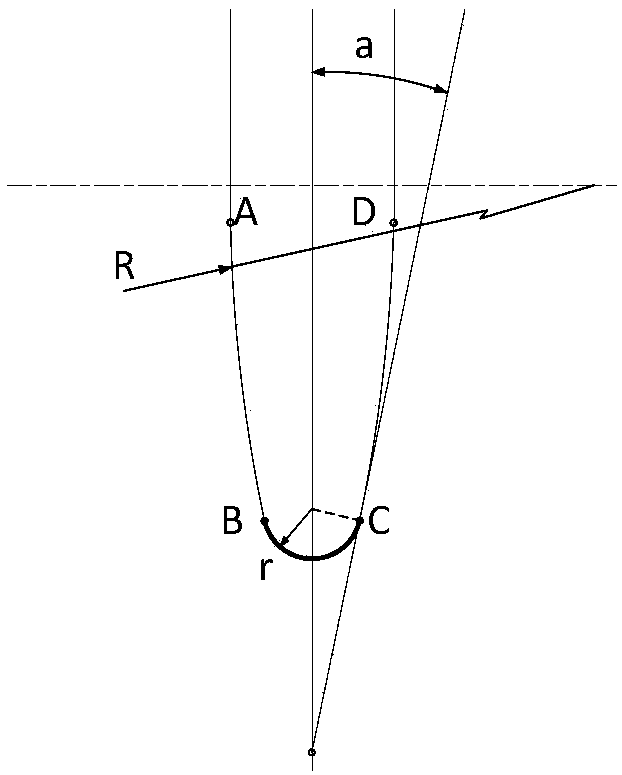

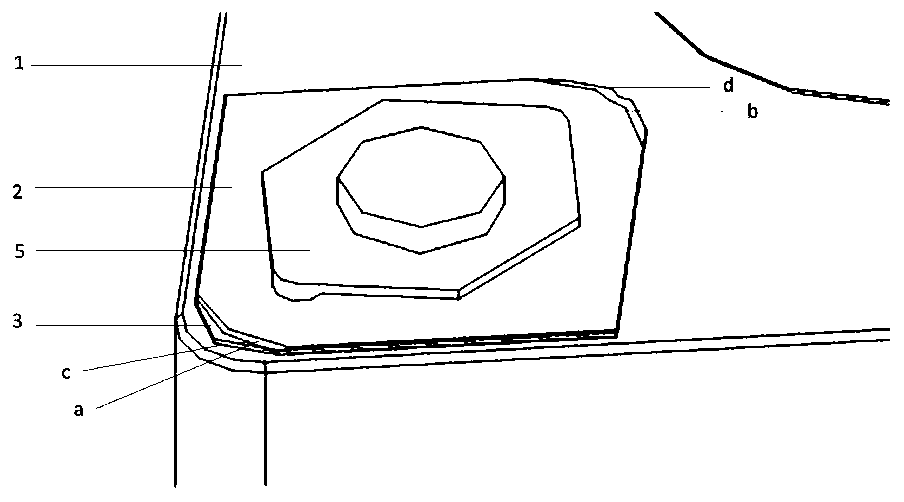

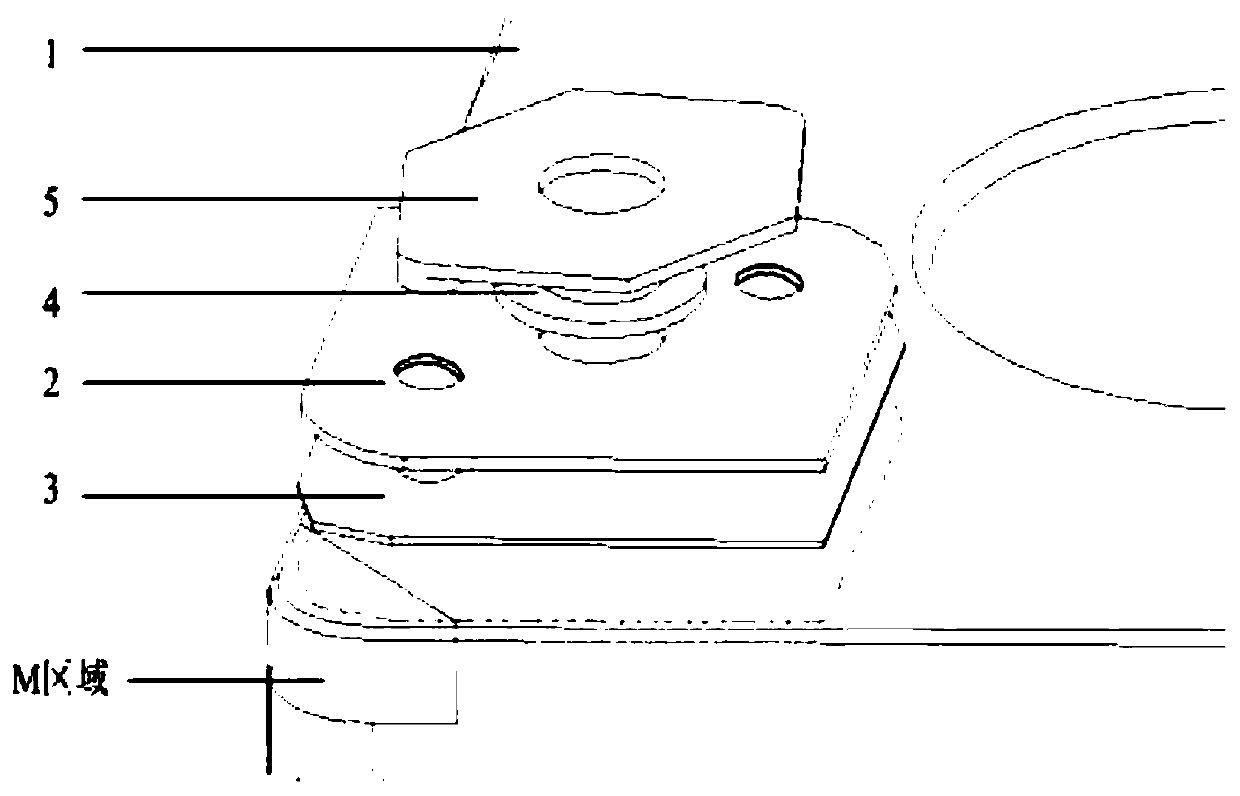

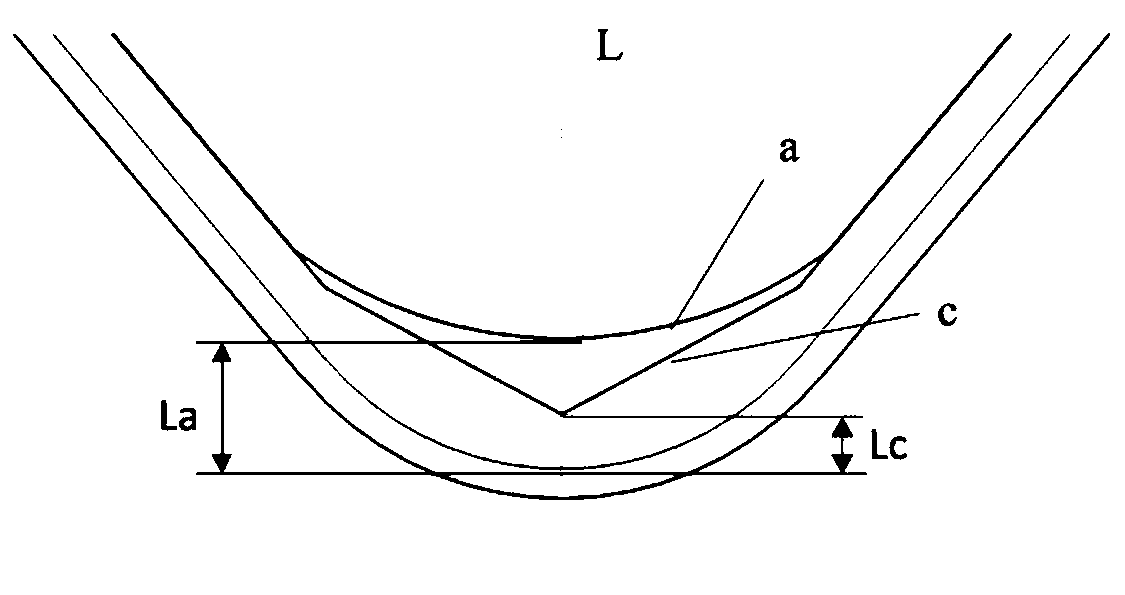

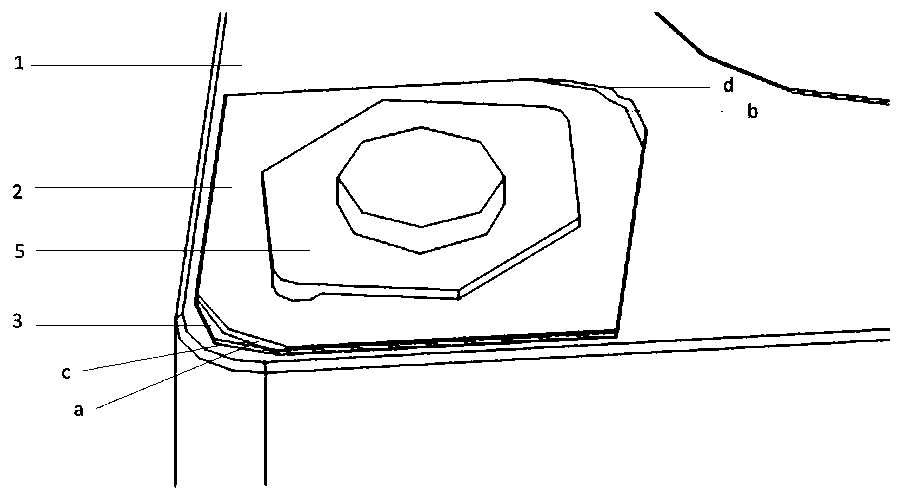

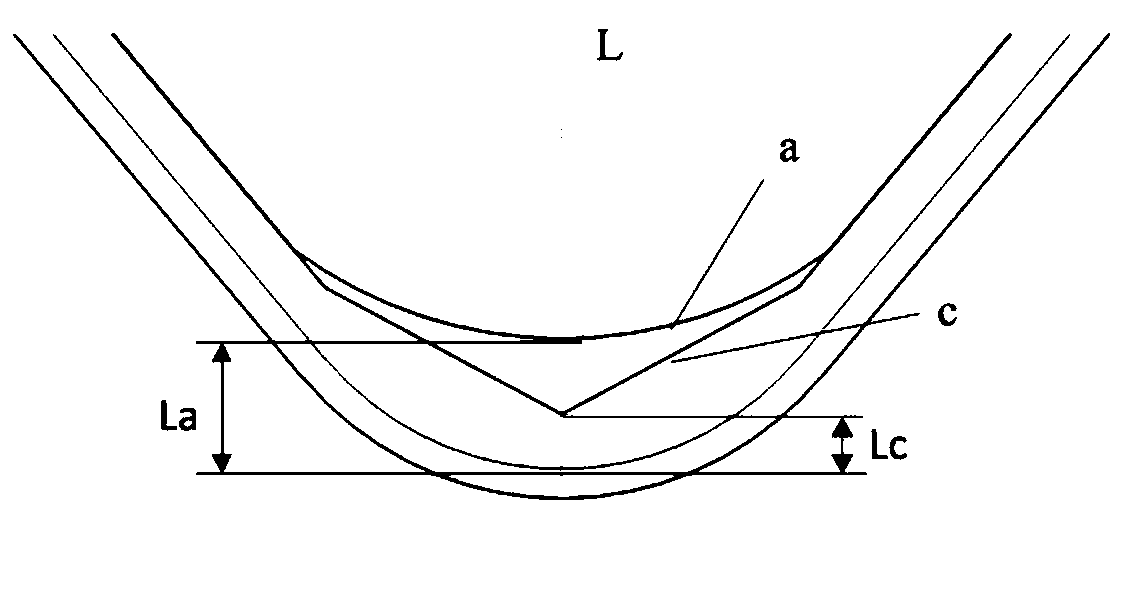

Customizing method of drum-taper-shaped ball-end milling cutter

ActiveCN108176887AGuarantee the quality of the machined surfaceImprove processing efficiencyGeometric CADMilling cuttersNumerical controlGeometric relations

The invention provides a customizing method of a drum-taper-shaped ball-end milling cutter, and belongs to the technical field of numerical control milling machining. The customizing method comprisesthe steps that relevant geometrical relationships of the drum-taper-shaped ball-end milling cutter are designed, and cutting parameters of the machining efficiency are taken into consideration, so that relevant geometrical drawings are obtained; then mathematical models are established according to the limitation and restriction relationship of the relevant geometrical relationships; when parameterized customization is conducted, known parameters are brought in the relevant mathematical models, and the barrel-shaped side blade radius range and the cutter bar neck diameter range are calculated;parameters within the barrel-shaped side blade radius range and the cutter bar neck diameter range are manually given, and integers are selected as the parameters; and the rest of parameter values are obtained, and a three-dimensional model of the drum-taper-shaped ball-end milling cutter is established in three-dimensional software UG. The customizing method of the drum-taper-shaped ball-end milling cutter has the advantages that the machining efficiency is improved threefold or severalfold on the basis that the quality of the machined surface is guaranteed, the phenomenon that due to cutterreplacement, cutter connecting marks and cutter replacement errors exist is avoided, systematized and parameterized customization conducted by engineering personnel is facilitated, and the customizing method is quite simple and convenient to use.

Owner:DALIAN UNIV OF TECH

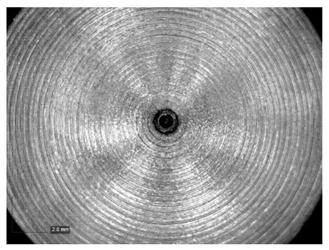

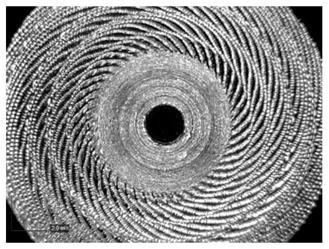

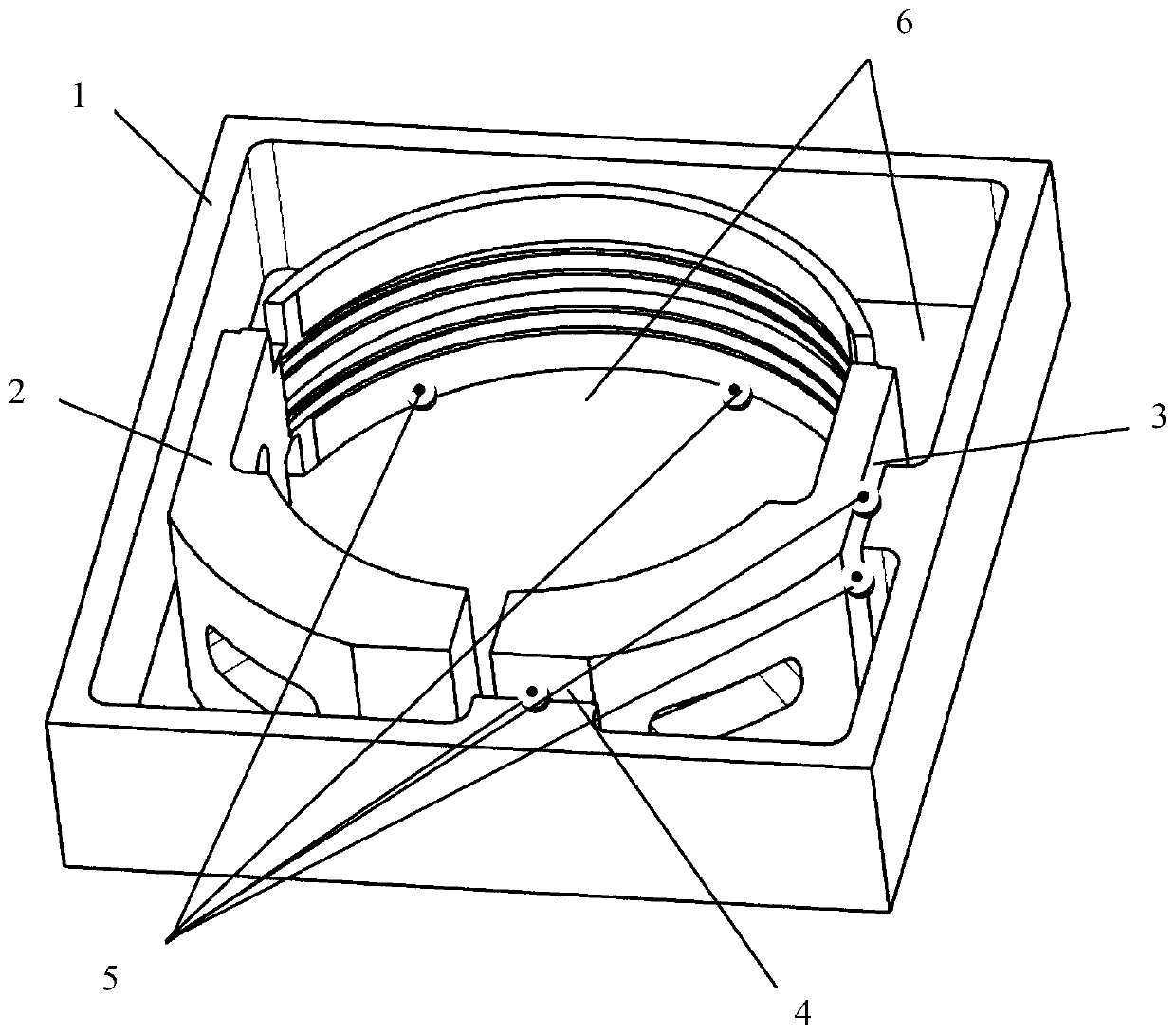

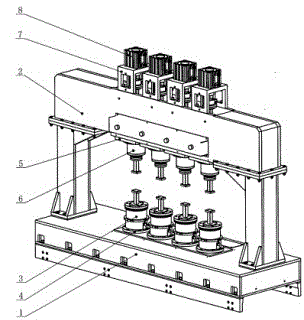

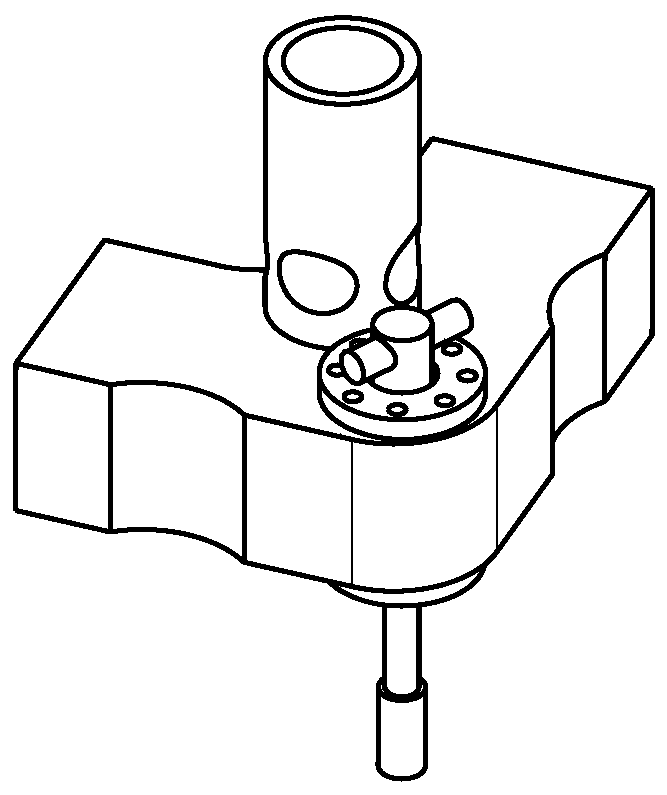

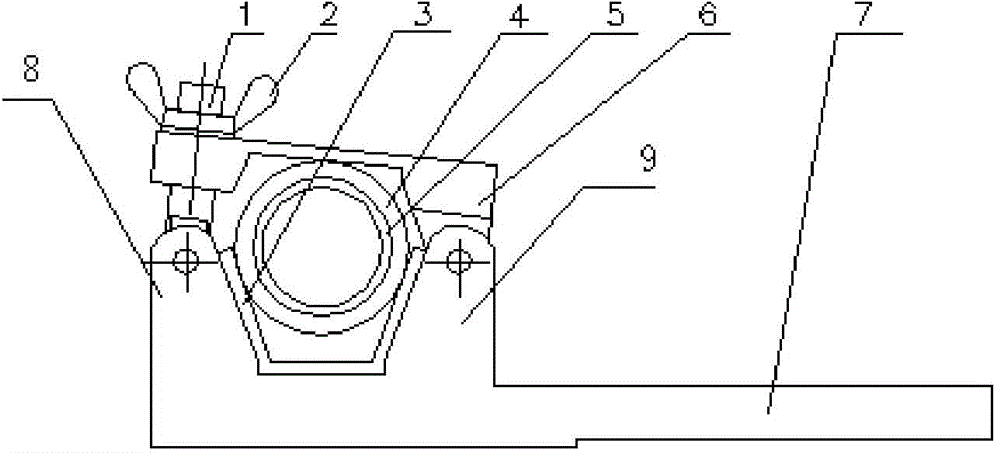

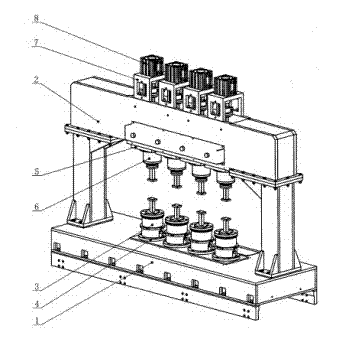

A rotary press table for processing small and medium-sized polarizing laminates

ActiveCN102862154BAchieve compactionAchieve synchronous rotationWork benchesThrust bearingEngineering

The invention discloses a rotary press table for machining laminated polarizers in middle and small size. The rotary press stable solves the problems of complicated structure, low positioning precision and inconvenience in operation of the existing equipment and comprises a framework, an upper rotary table and a lower rotary table. The upper rotary table is fixedly arranged on a horizontal cross beam on the upper portion of the framework. A direct-drive motor rotary table which is hollow is arranged on the upper portion of an upper rotary table fixed plate, a spline shaft of a ball spline pair penetrates through a center hole of the direct-drive motor rotary table and the center of a spacer sleeve, the upper end of the spline shaft is connected with a push rod of an air cylinder through a spline connecting flange, two thrust bearings, a transfer shaft and a floating joint, and the lower end of the spline shaft is connected with an upper press head through an upper press head connecting flange. The lower rotary table is fixedly arranged on a bottom frame of the framework through a lower rotary table fixed plate, and the other direct-drive motor rotary table is fixedly arranged on the lower rotary table fixed plate. By the rotary press table, a stack of laminated polarizers can be pressed, positioned accurately and rotate synchronously.

Owner:TAIYUAN FENGHUA INFORMATION EQUIP

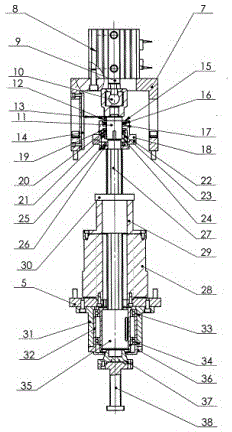

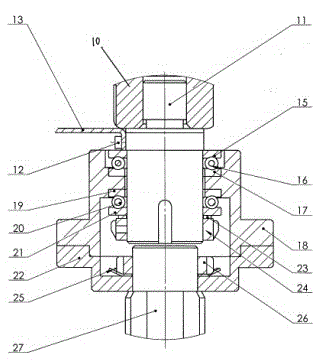

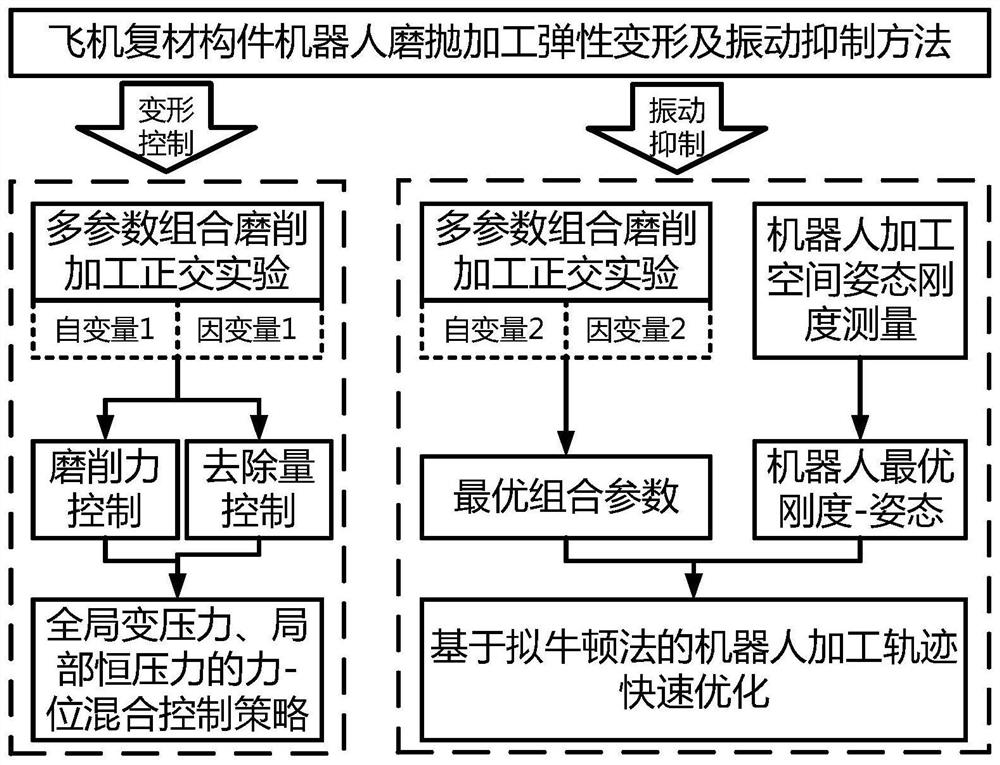

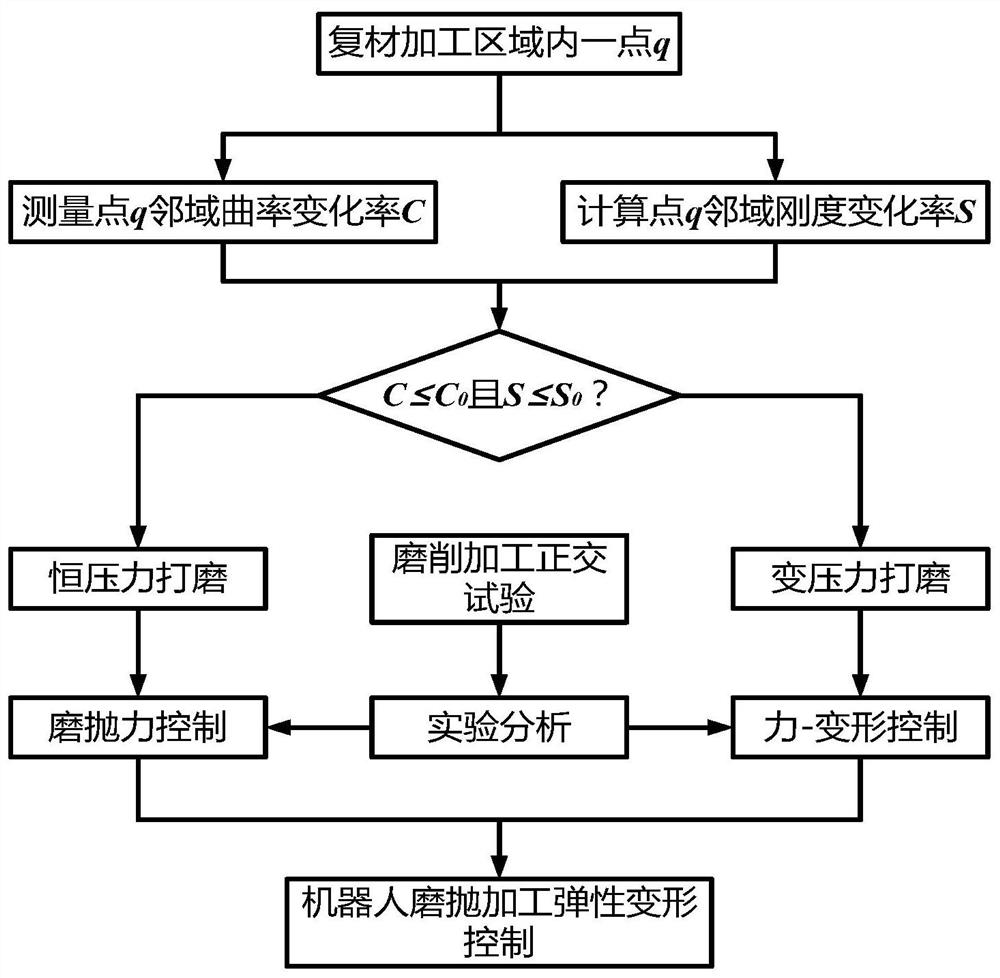

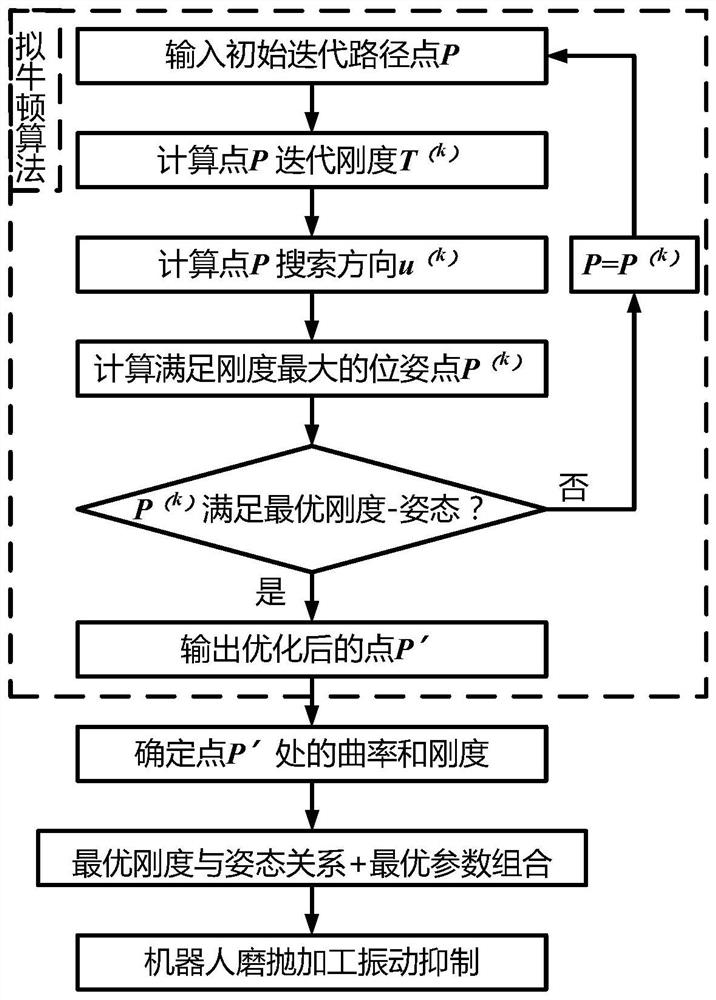

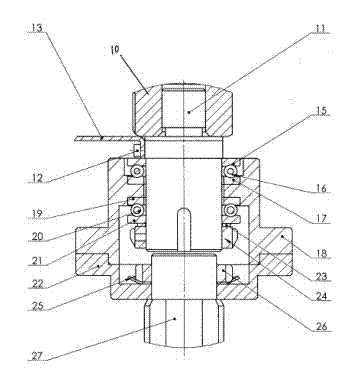

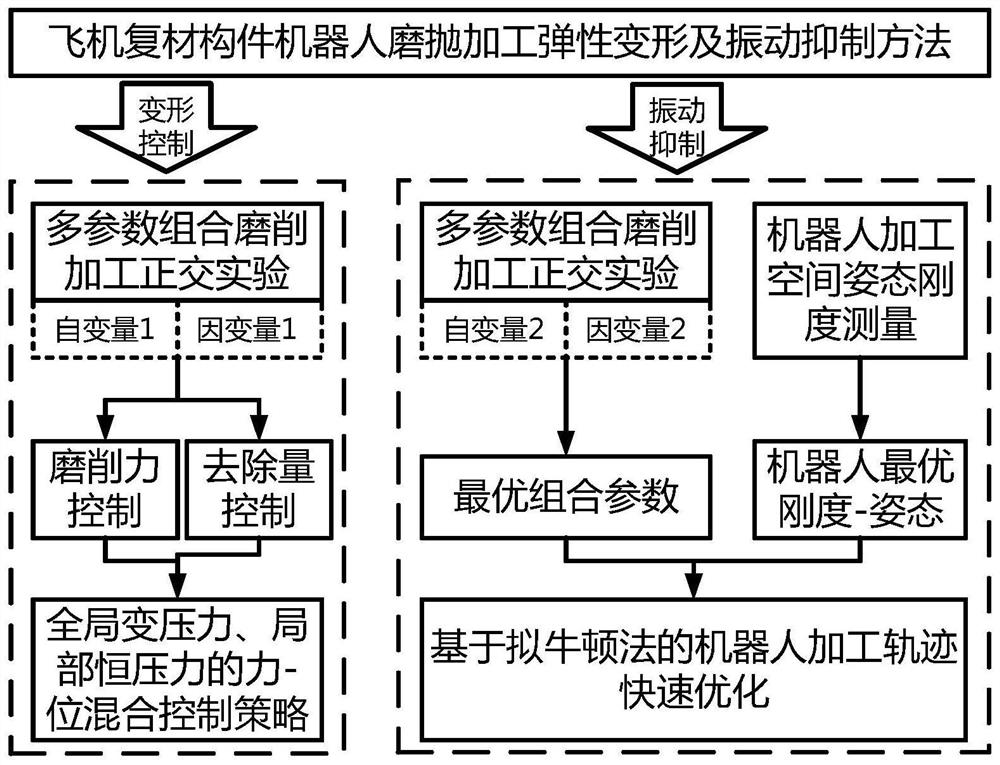

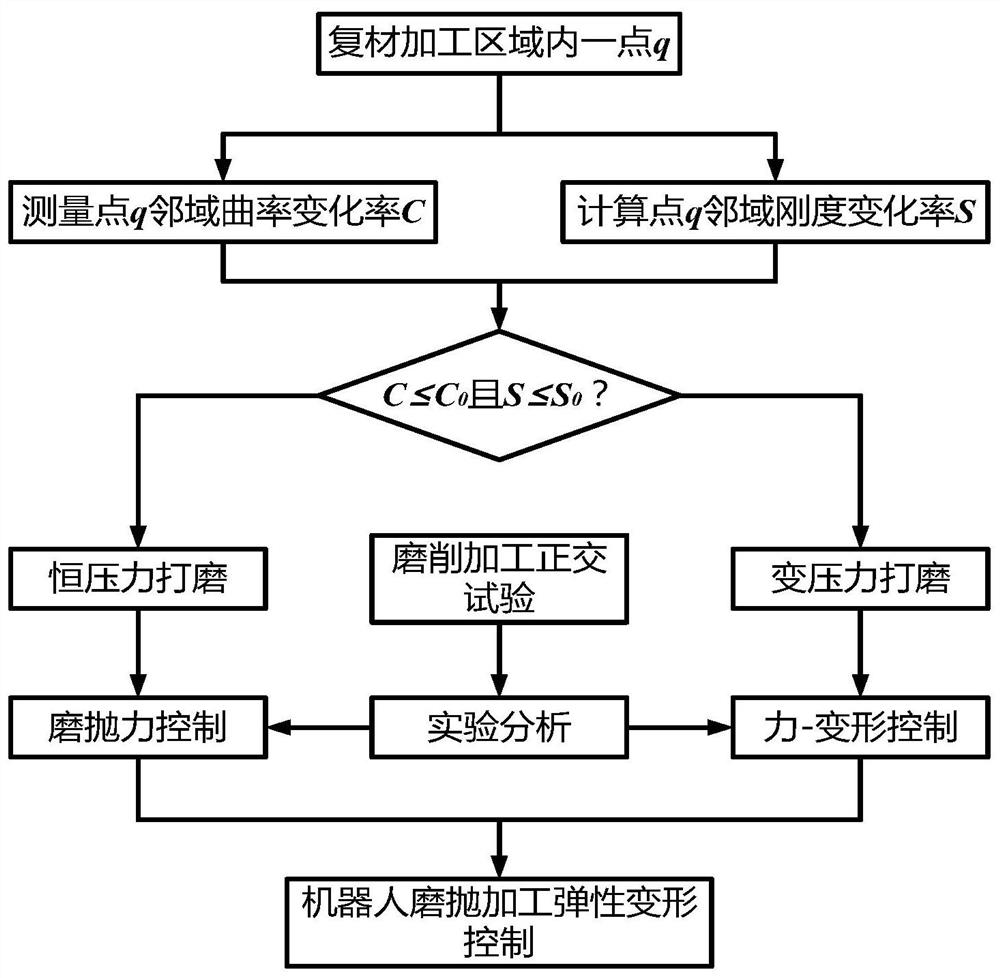

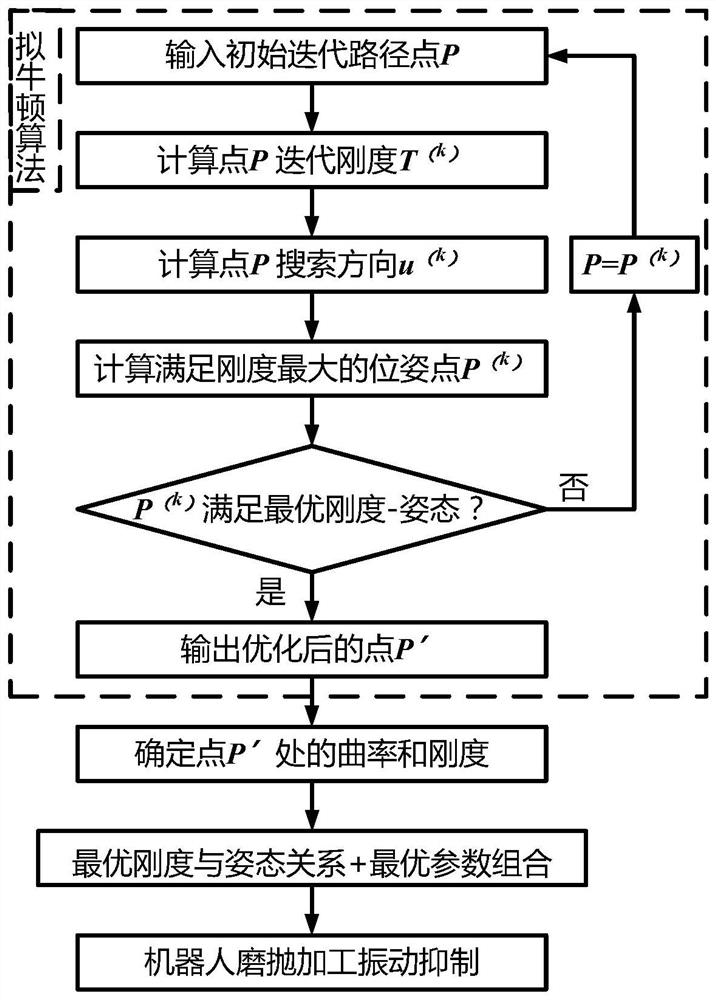

Elastic deformation and vibration inhibition method for grinding and polishing machining of airplane composite material component by robot

ActiveCN111673611AReduce vibrationMeet sizeProgramme controlProgramme-controlled manipulatorMachining vibrationsMaterial removal

The invention belongs to the field of grinding and polishing machining of a composite material component by a robot, and particularly discloses an elastic deformation and vibration inhibition method for grinding and polishing machining of the airplane composite material component by the robot. The method comprises the following steps that a first independent variable group and a first dependent variable group are designed; a multi-parameter combined grinding machining orthogonal test is carried out on the first independent variable group and the first dependent variable group to obtain a nonlinear relationship between the grinding force and the material removal amount; a force-position hybrid control strategy of global variable pressure and local constant pressure is adopted to control elastic deformation in the grinding machining process by the robot; and an optimal rigidity and posture relation in the machining space of the robot is constructed, a machining track of the robot is optimized according to optimal combination and grinding and polishing machining process parameters after elastic deformation control to determine grinding and polishing machining process parameters of a machining area. According to the elastic deformation and vibration inhibition method for grinding and polishing machining of the airplane composite material component by the robot, effective control ofthe elastic deformation and vibration suppression in the grinding and polishing machining process of the airplane composite material component by the robot can be achieved, grinding and polishing machining vibration lines are eliminated, and the machined surface quality is guaranteed.

Owner:HUAZHONG UNIV OF SCI & TECH +1

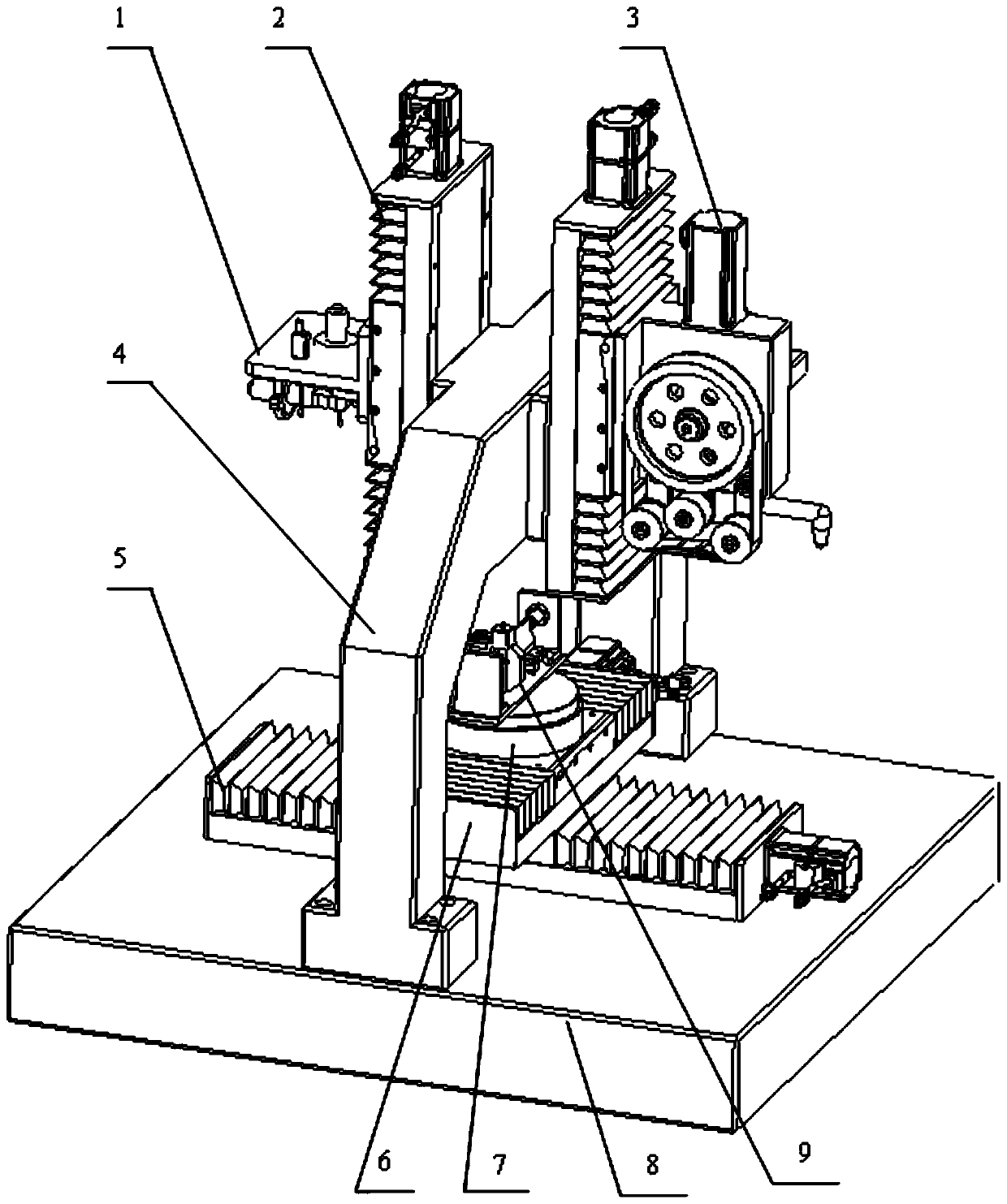

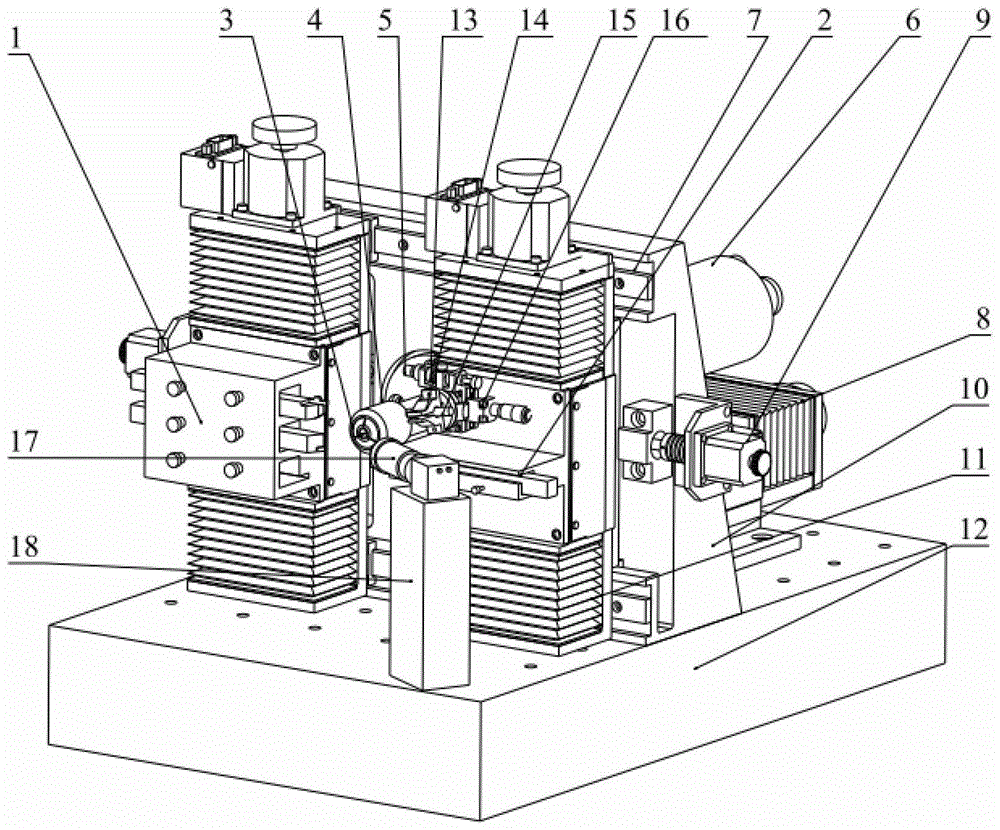

Complicated curved face milling, grinding and measuring integrated machining machine tool and forming method

ActiveCN110076577AImprove surface roughnessReduce cutting forceOther manufacturing equipments/toolsUltrasonic machiningMachining process

The invention relates to a complicated curved face milling, grinding and measuring integrated machining machine tool and a forming method and belongs to the technical field of mechanical manufacturing. A gantry is fixedly connected to a base, and an X-direction slide table is fixedly connected to the base; a Y-direction guide rail is fixedly connected to a slide table of an X-direction guide rail;a rotating workbench is fixedly connected to a slide table of the Y-direction guide rail; the upper portion of the rotating workbench is used for being fixedly connected with a clamp and a workpiece;two Z-direction slide tables are arranged, and fixedly connected to the left and right sides of the middle of the gantry correspondingly; an ultrasonic machining system is fixedly connected to a sliding table body of the Z-direction slide table on the left side; and a grinding and polishing assembly is fixedly connected to a slide table body of the Z-direction slide table on the right side. The complicated curved face milling, grinding and measuring integrated machining machine tool and the forming method have the beneficial effects that correcting is achieved many times in the machining process, and the machining precision is improved; machining manners are diverse and comprises milling polishing, grinding polishing and milling and grinding polishing, operation from starting to ending iscompleted in one time of clamping, the clamping frequency is reduced, and the machining precision and the machining efficiency are improved.

Owner:JILIN UNIV

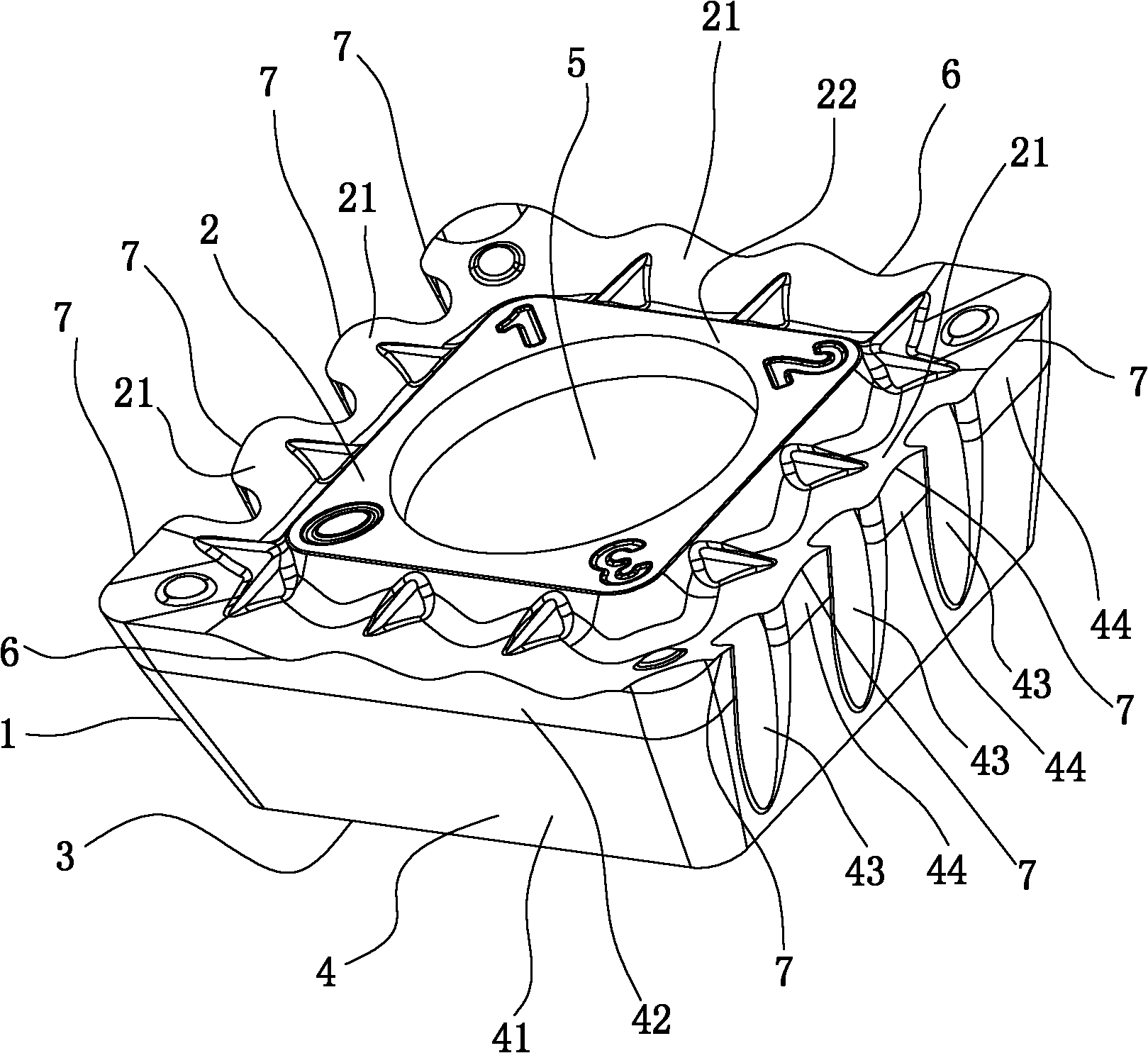

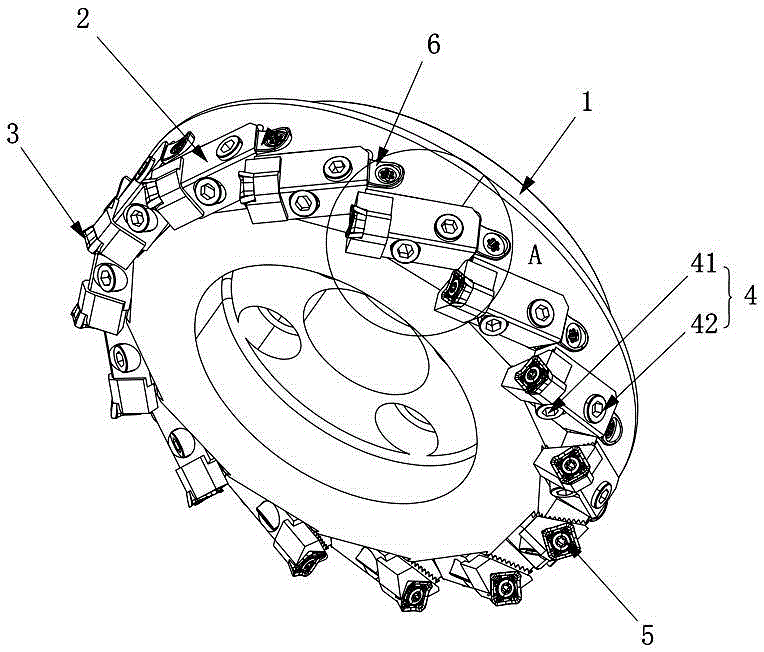

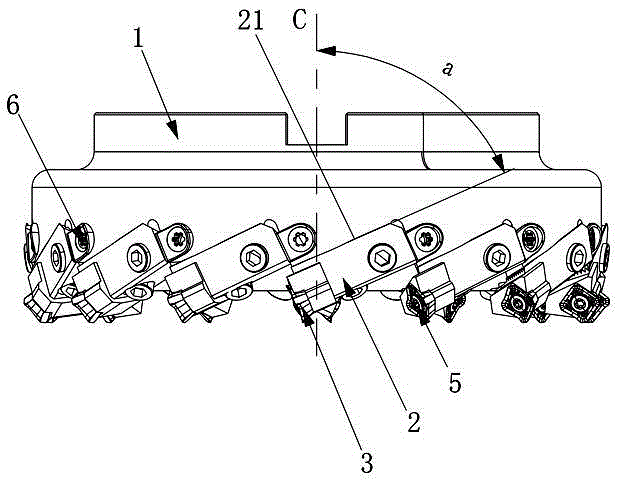

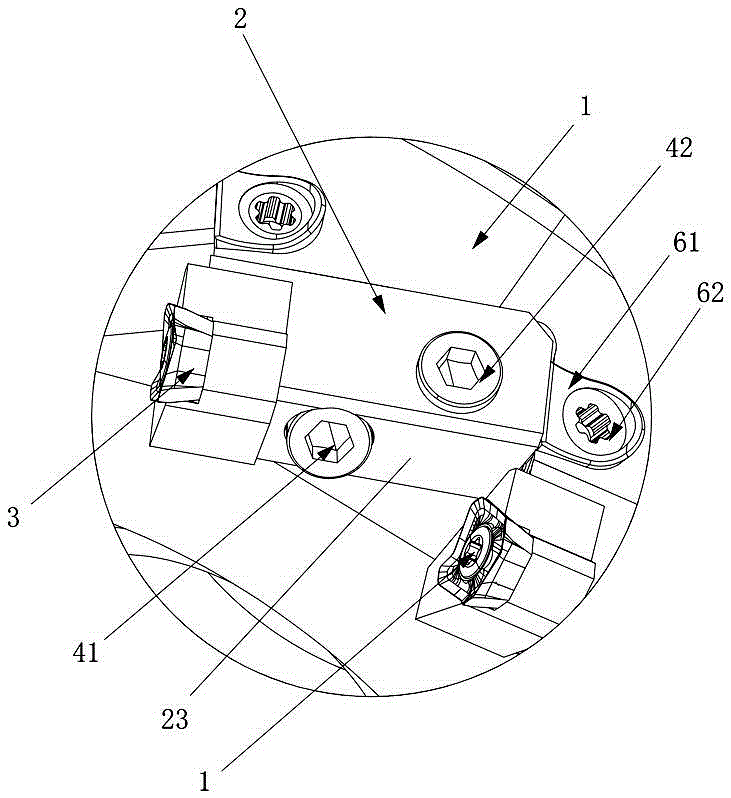

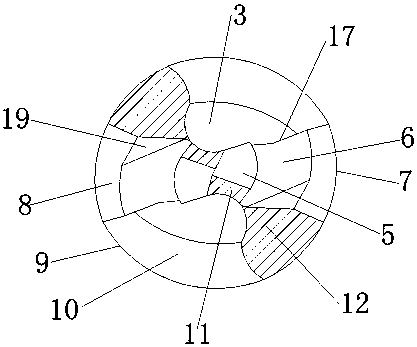

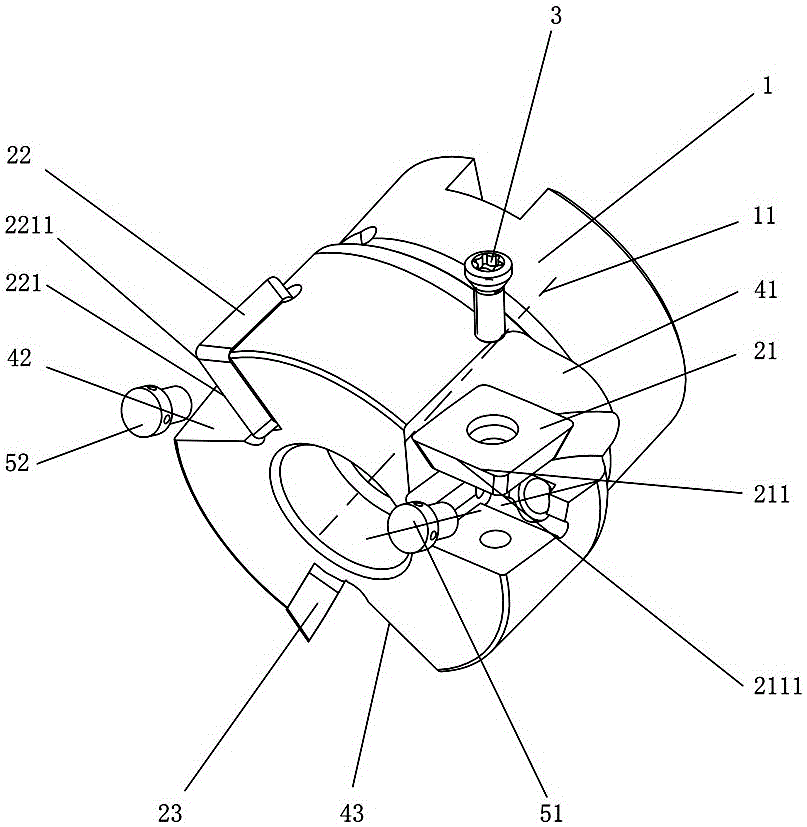

Rotary machining cutter

ActiveCN105328224AGuarantee the quality of the machined surfaceExtended service lifeCutting insertsTurning toolsMachiningFastener

The invention discloses a rotary machining cutter which comprises a rotary cutter body, wherein cutter slots are formed in the outer edge at the front end of the rotary cutter body; cutter holders are mounted in the cutter slots through cutter holder fastening components; cutting blades are mounted at the head parts of the cutter holders through cutting blade fasteners; adjusting structures are also mounted in the cutter slots; the adjusting structures are located between the tail part surfaces of the cutter holders and the tail part positioning surfaces of the cutter slots; all the surfaces, located between the tail part surfaces and the end surfaces of the cutter holders, of the cutter holders are circumferential surfaces of the cutter holders; each cutter holder fastening component comprises at least two cutter holder fasteners; and the cutter holders are locked by the cutter holder fasteners in different directions of the circumferential surfaces of the cutter holders. The rotary machining cutter provided by the invention has the advantages of positioning stability, strong vibration resistance, long service life, high machining precision and the like.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

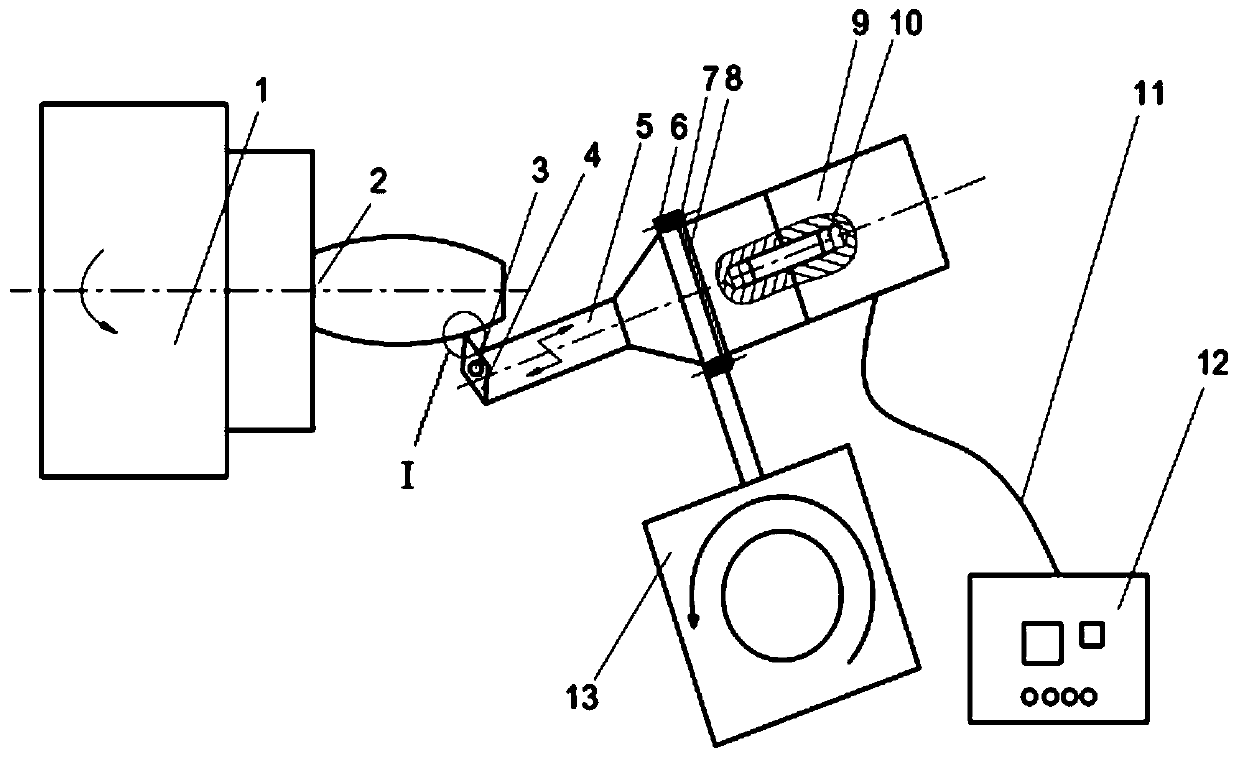

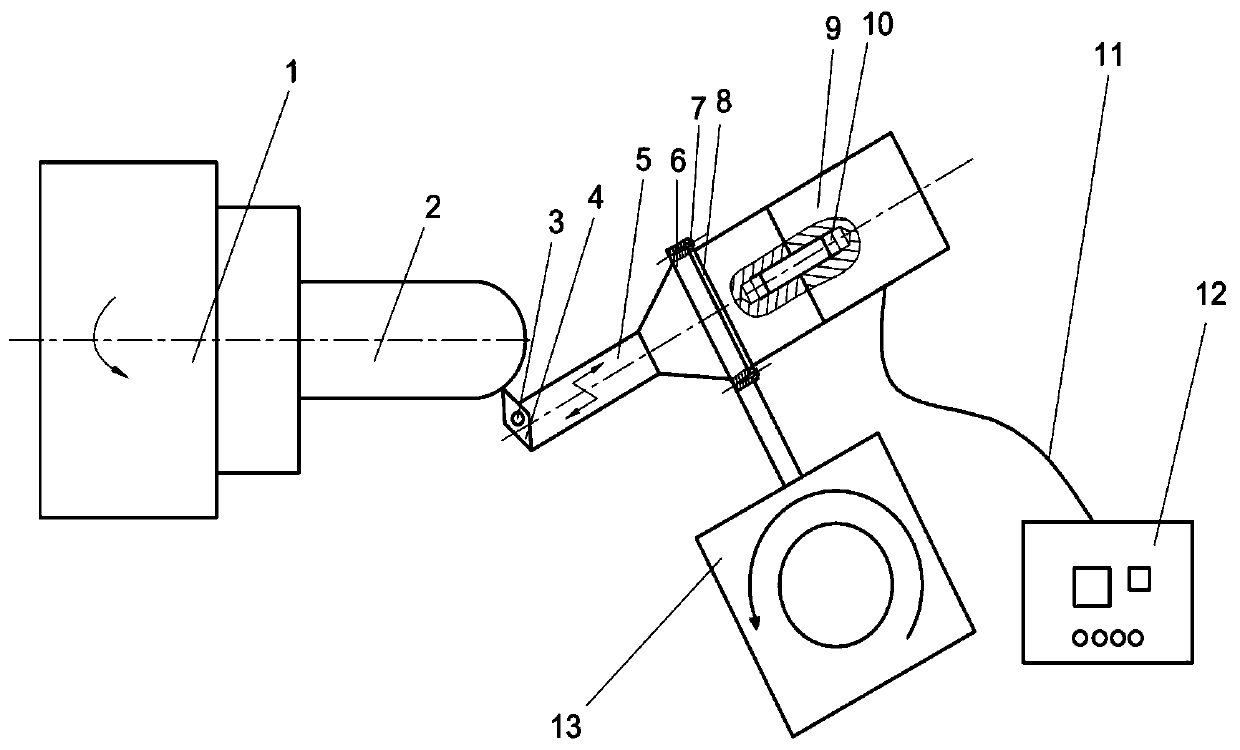

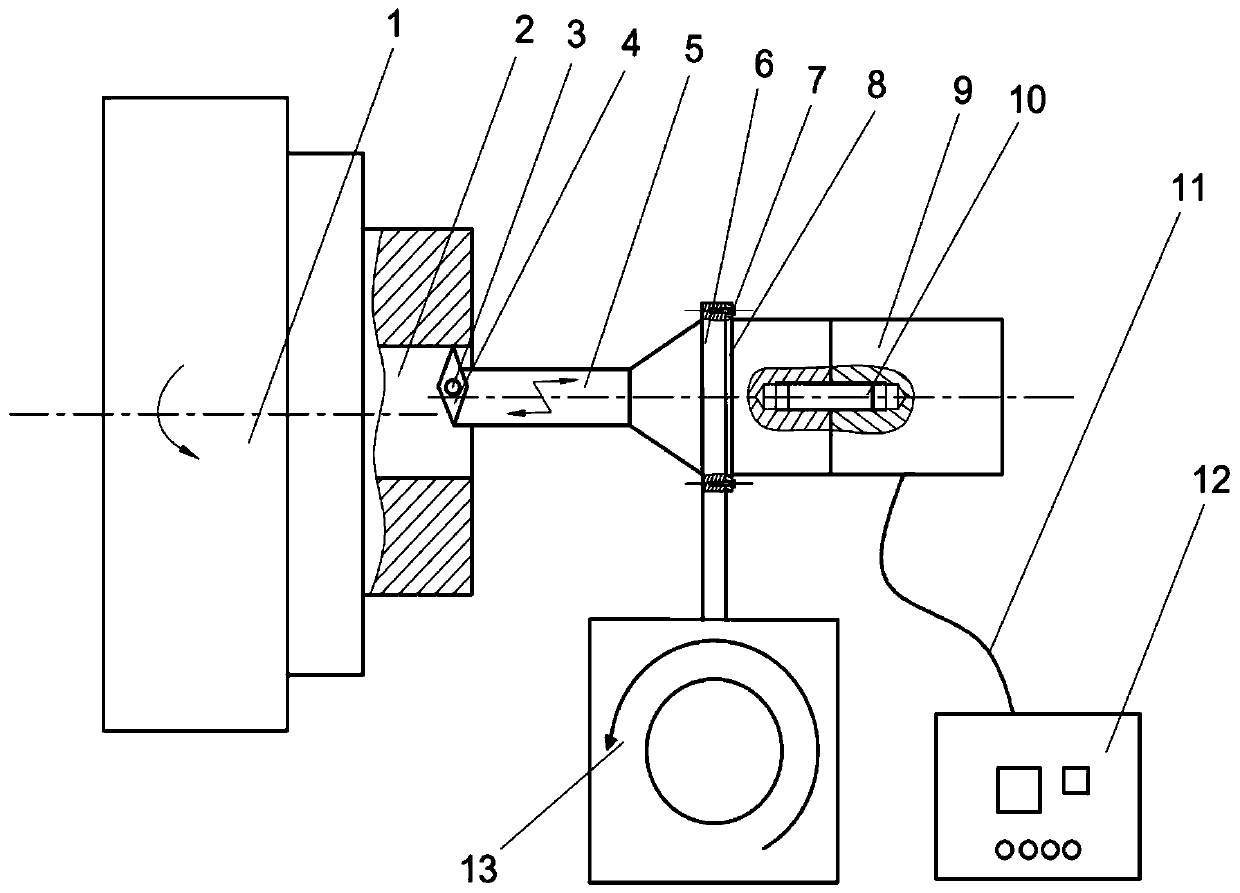

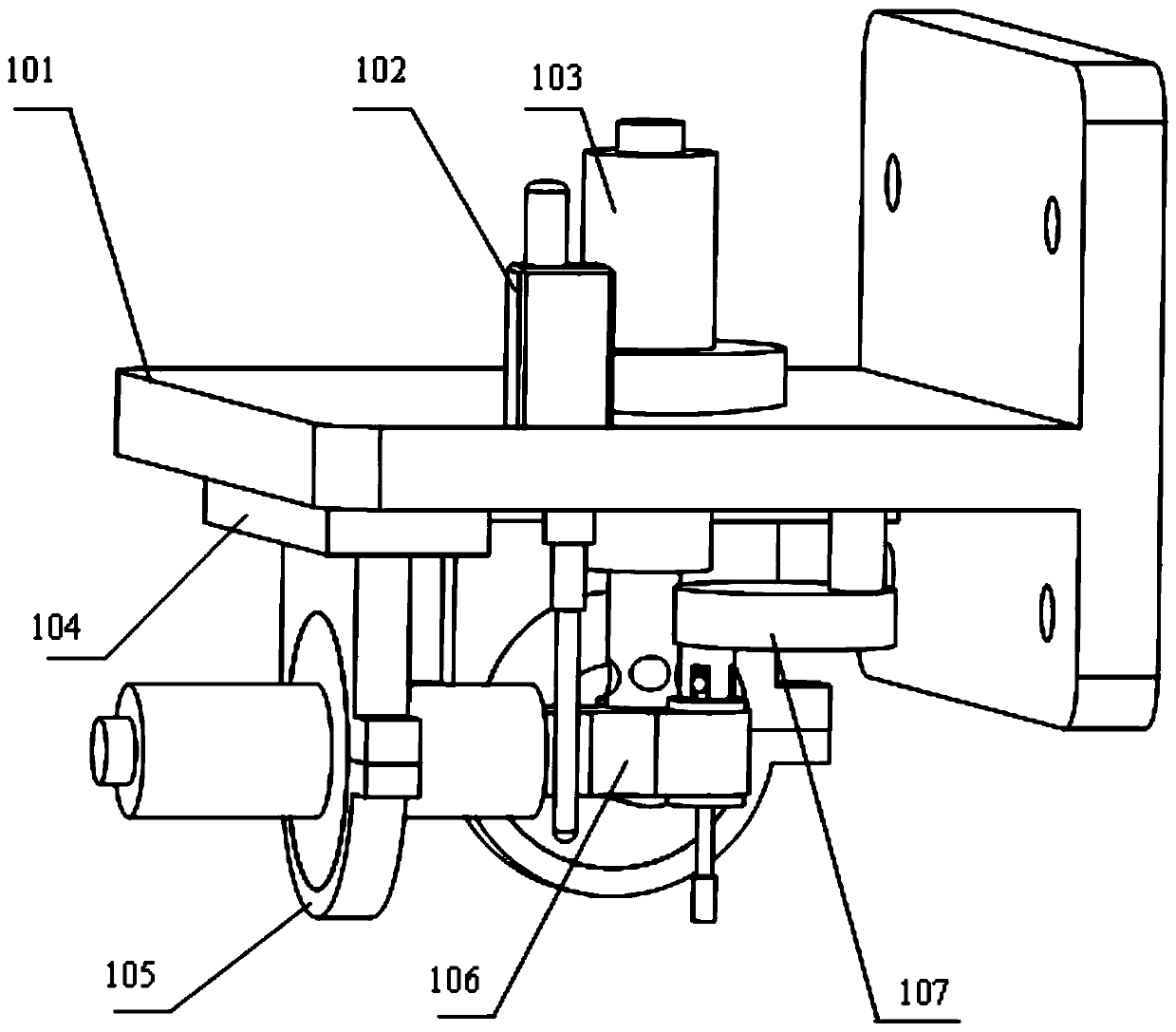

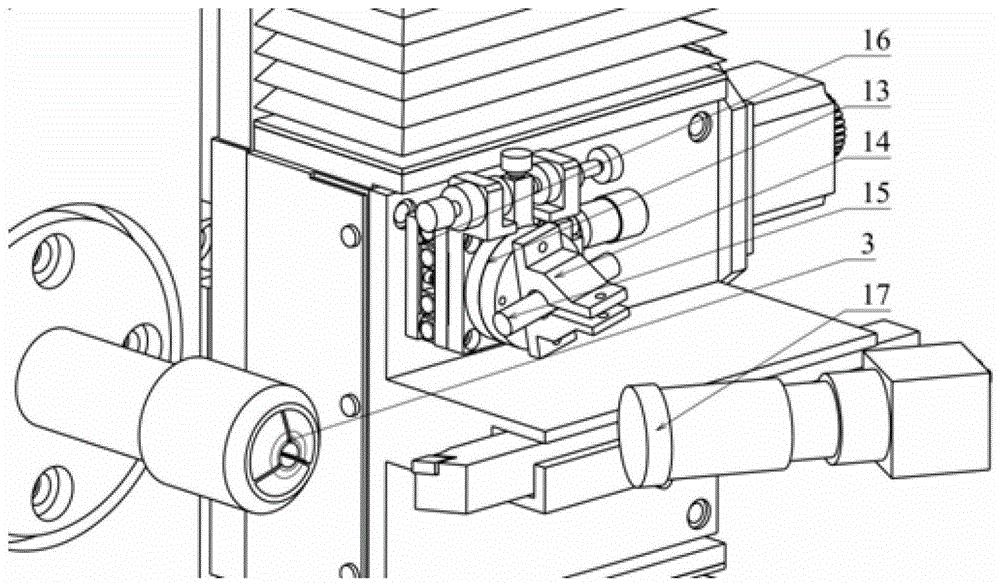

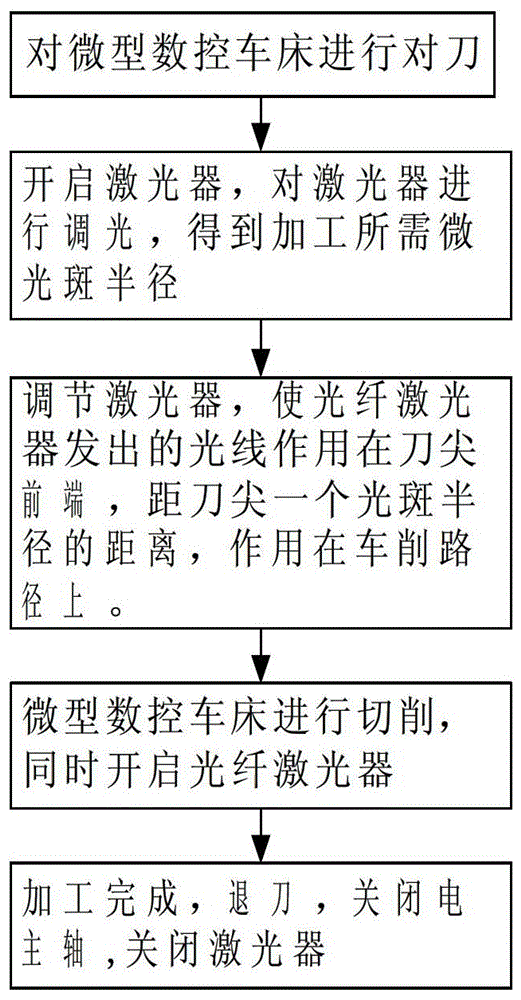

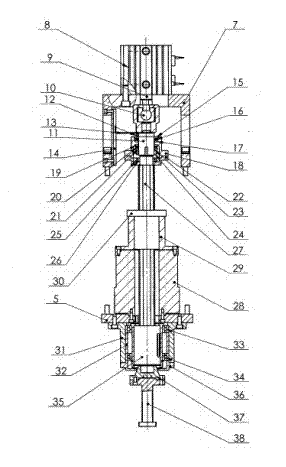

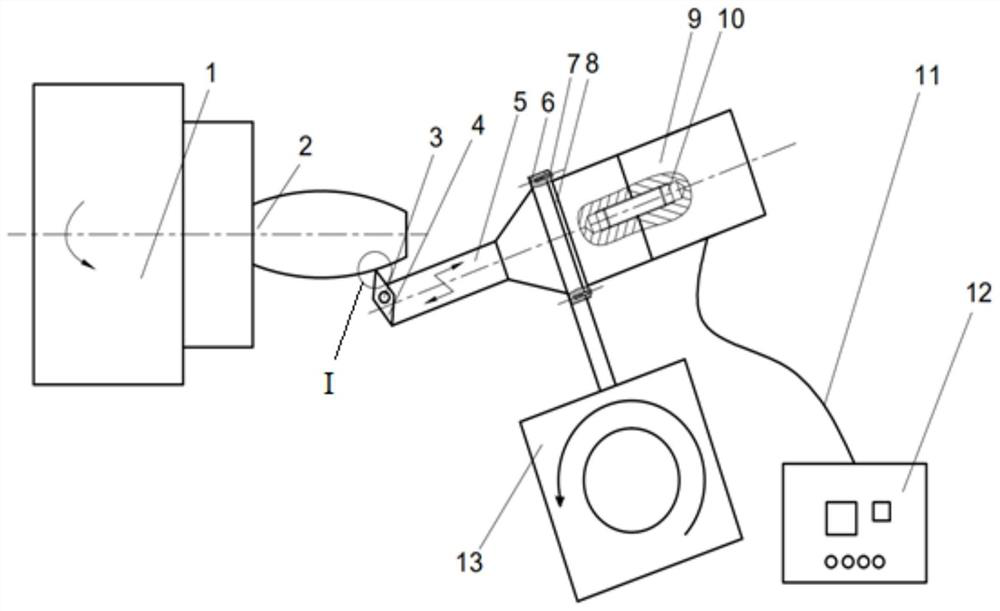

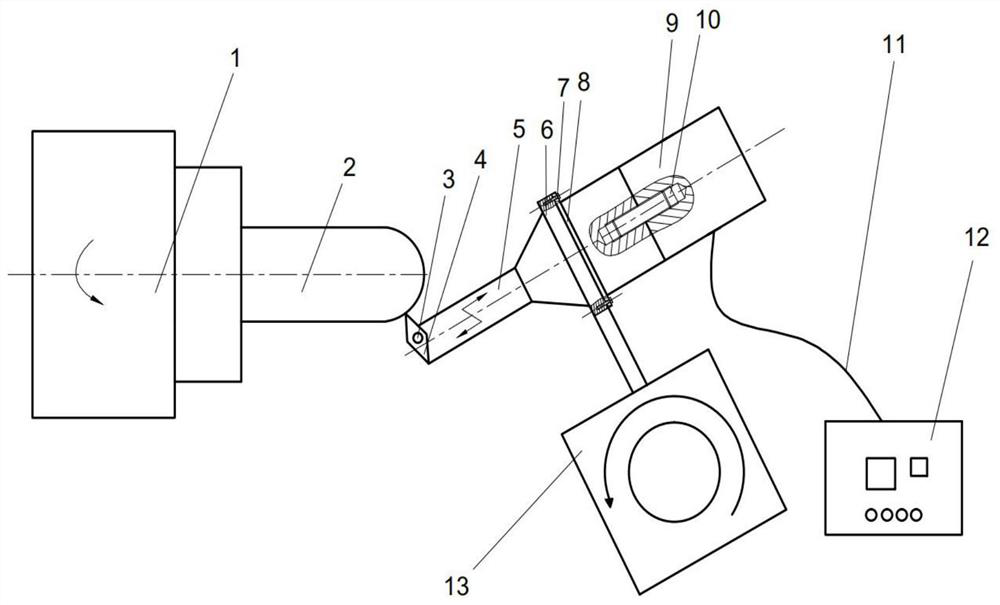

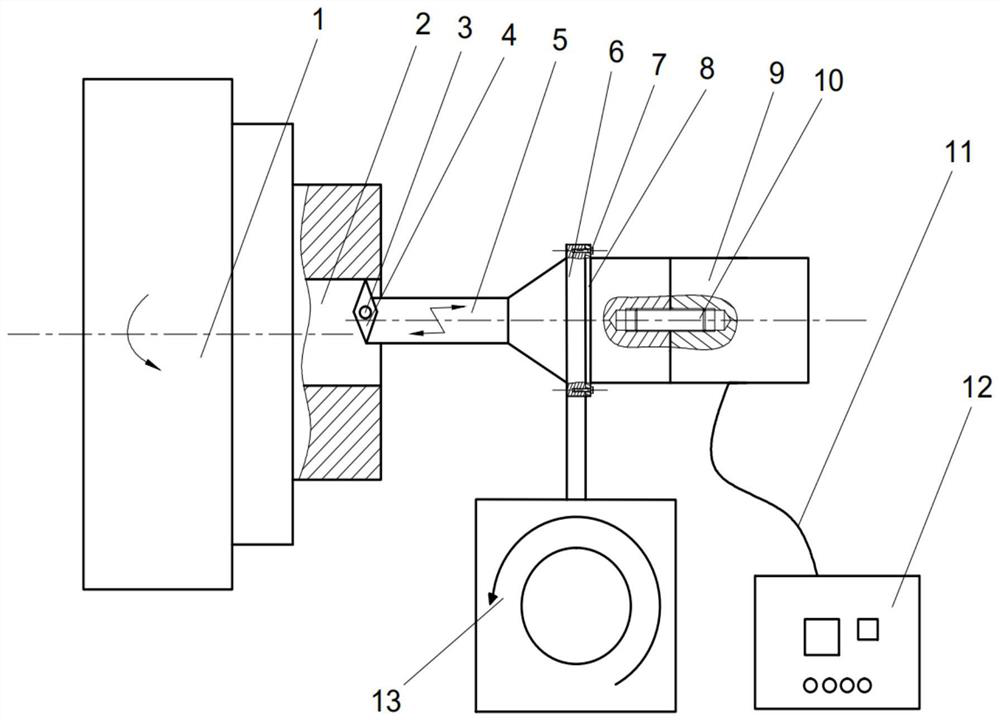

Laser Heating Assisted Micro-turning Device

ActiveCN103567464BWarm up high speedWarm up fastAuxillary equipmentTurning machinesCutting forceLaser heating

The invention relates to a laser heating auxiliary micro-turning fixture and a laser heating auxiliary micro-turning method and belongs to the field of auxiliary processing of machine tools, and the device and the method are used for solving the problems of poor processed surface quality, tool abrasion and tool breakage existing in the prior art. The device comprises a rotary sliding table, a translation sliding table, a laser and a clamp, wherein the translation sliding table is fixedly arranged on a Y-directional sliding table; the rotary sliding table is fixedly arranged on the translation sliding table; the laser is fixedly arranged on the rotary sliding table by virtue of the clamp; the axis of a gun head of the laser and a vertical surface in which the tool tip of a tool of a machine tool is located are coplanar. According to the method, rays of the laser are applied to the front end of a micro tool tip, and local preheating for a to-be-processed workpiece by virtue of lasers is realized. The laser and the micro-turning device are combined for preheating the to-be-processed workpiece, so that the micro-turning for a difficult-to-process material is realized, the quality and size precision of a processed surface are ensured, the cutting force is reduced, and phenomena of serious tool abrasion and tool breakage substantial results are improved; a camera is used for monitoring in real time, so that the precise and reliable micro diameter of a laser spot can be ensured.

Owner:CHANGCHUN UNIV OF SCI & TECH

Quick change chip removing drill bit

The invention provides a quick change chip removing drill bit. The quick change chip removing drill bit comprises a drill handle and a cutter body coaxial with the drill handle. A spiral groove is formed in the cutter body, a drill point is arranged at the top end of the cutter body, and two rear cutter faces in central symmetry are arranged on the drill point. Each rear cutter face comprises a stepped first cutter face, a stepped second cutter face, and a third cutter face formed by coping towards the second cutter face along a back ridge of a drill bit, a spiral chip guide cambered face is arranged in the spiral groove along a tail ridge of the drill bit, rear ditch ridges of the first cutter face, the second cutter face and the third cutter face and the tail ridge of the top of the cutter body are simultaneously coped in the chisel edge direction, a first coping face and a second coping face are formed on the front face of the cutter body, an annular groove is formed in the drill handle along the outer peripheral face, and multiple hemispherical blind holes are formed in the drill handle.

Owner:JIANGSU TIANGONG PRECISION TOOLS CO LTD

A kind of composite machining method of high-volume aluminum-based silicon carbide threaded hole

ActiveCN112496680BImprove processing qualityQuality improvementThread cutting machinesCarbide siliconMetallurgy

Owner:BEIJING SATELLITE MFG FACTORY

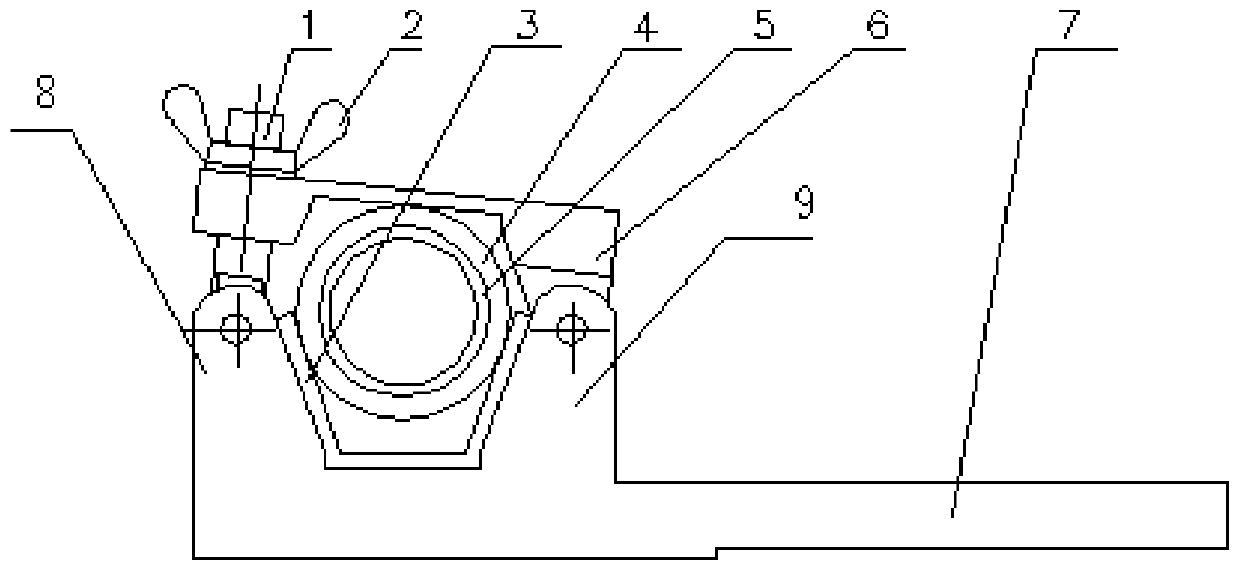

Non-waterline cutting method and non-waterline cutting device

ActiveCN104551281AAvoid cutting tension that cannot be kept constantImprove machining accuracyElectrical-based auxillary apparatusDatum referenceEngineering

The invention belongs to the technical field of spaceflight servo systems, and particularly relates to a non-waterline cutting method and a non-waterline cutting device. By the non-waterline cutting method and the non-waterline cutting device, requirements on linear cutting machining precision and cutting speed of an end surface of a filter element are met, and the cutting quality is high under the condition that the filter element is not polluted when cut off. The non-waterline cutting method comprises the following steps of (1) preparing a setting process; (2) erecting up a core tube 5 of which the length is smaller than that of the filter element in the filter element 4, and placing the core tube 5 and a dovetail groove supporting seat 3 of which the boundary dimension is matched with that of the filter element 4 in a base 7 together; (3) covering the base 7 by using an upper cover plate 6 and fixing the filter element 4 by manually fastening a butterfly nut 2; and (4) changing the dovetail groove supporting seat when filter elements with different specifications are machined and remaining rest positioning datum reference pieces in the device. The dovetail supporting seat is a V-shaped support, and the filter element can be automatically aligned after being placed in the dovetail supporting seat.

Owner:北京实验工厂有限责任公司 +1

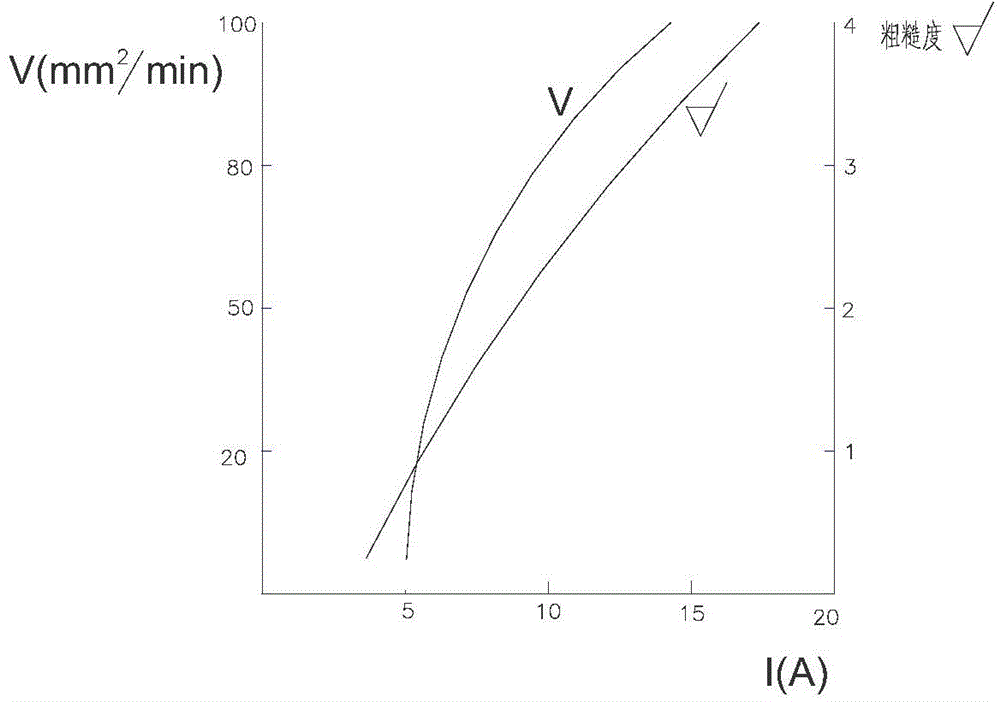

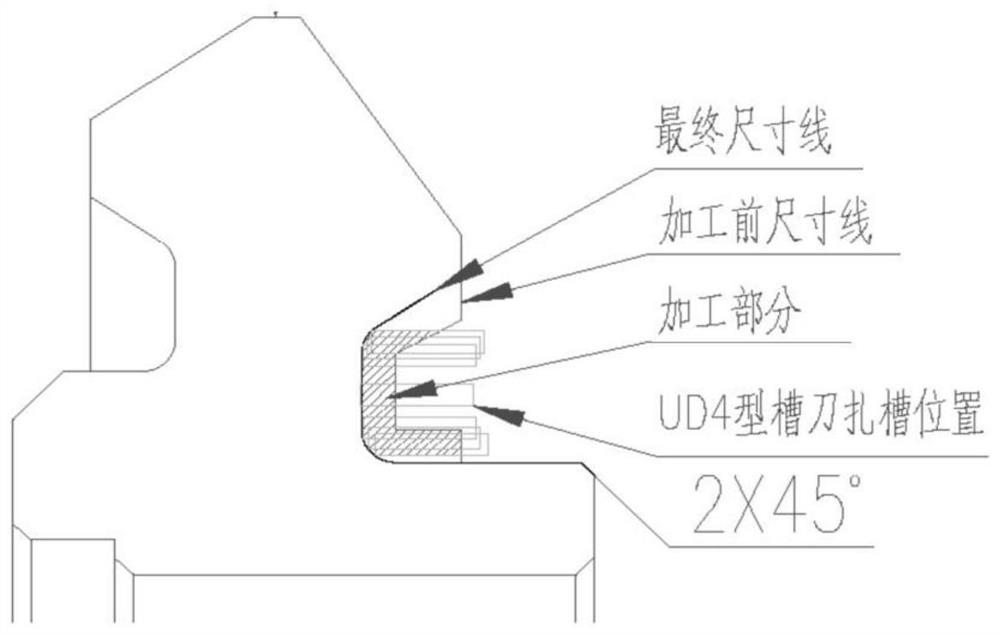

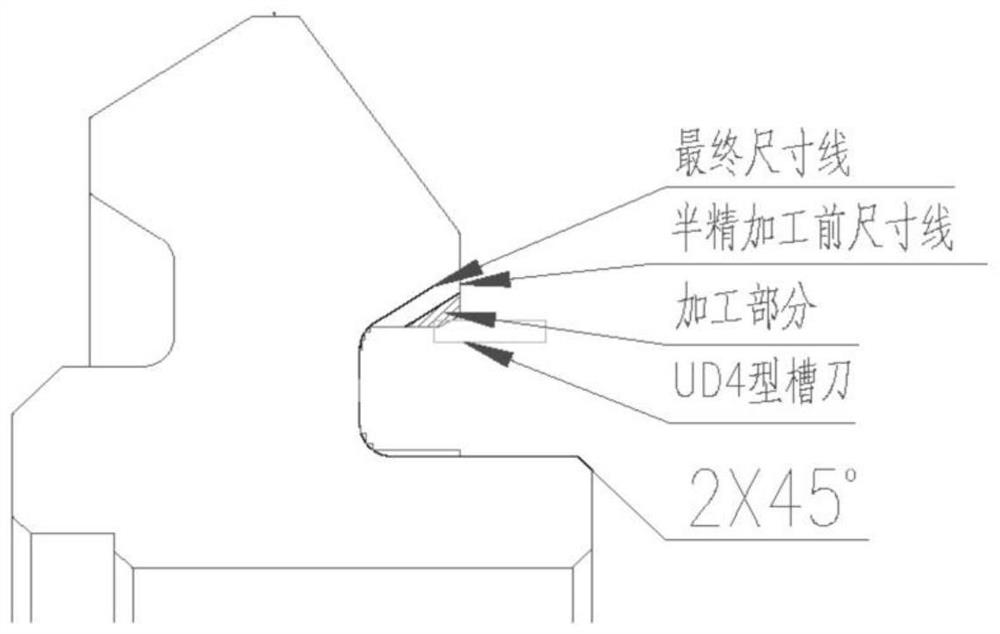

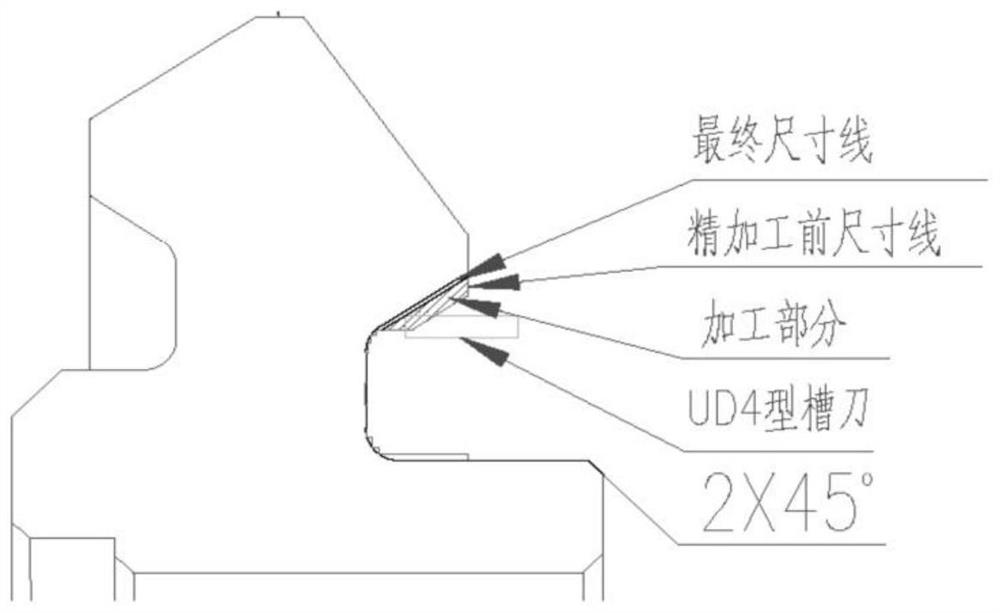

A method for machining inner circular grooves of spiral bevel gears

ActiveCN112620662BImproved chip breakingReduce lintTurning machinesMachined surfaceStructural engineering

The present invention proposes a method for machining inner circular grooves of spiral bevel gears. Compared with the traditional processing method based on the original circular groove type direct circular cutting, this method changes the processing path. The straight line arc of the inner circular groove and the angle connecting arc are selected to form several steps, and the processing of the inner circular groove is simplified into a three-step process according to the shape of the inner circular groove. Semi-finishing circular arc groove shape, finishing circular arc groove shape, designing an effective groove path to cut off the horizontal curl of iron chips can improve the chip breaking situation and reduce the occurrence of chip entanglement. The method of the invention is simple and easy to implement, can ensure the quality of the processed surface, and further improve the efficiency of processing and clamping and changing production.

Owner:BEIJING NORTH VEHICLE GROUP CORP

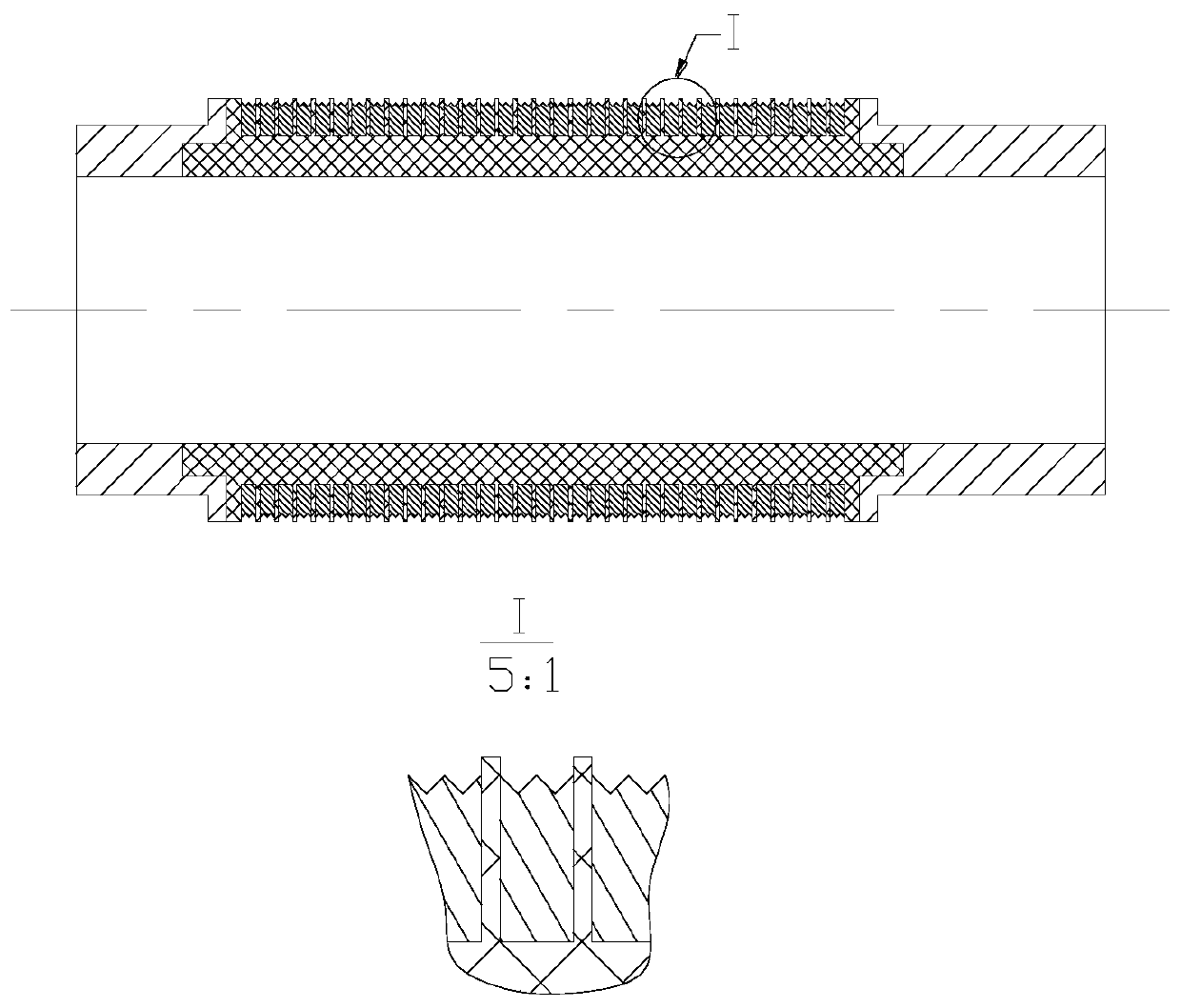

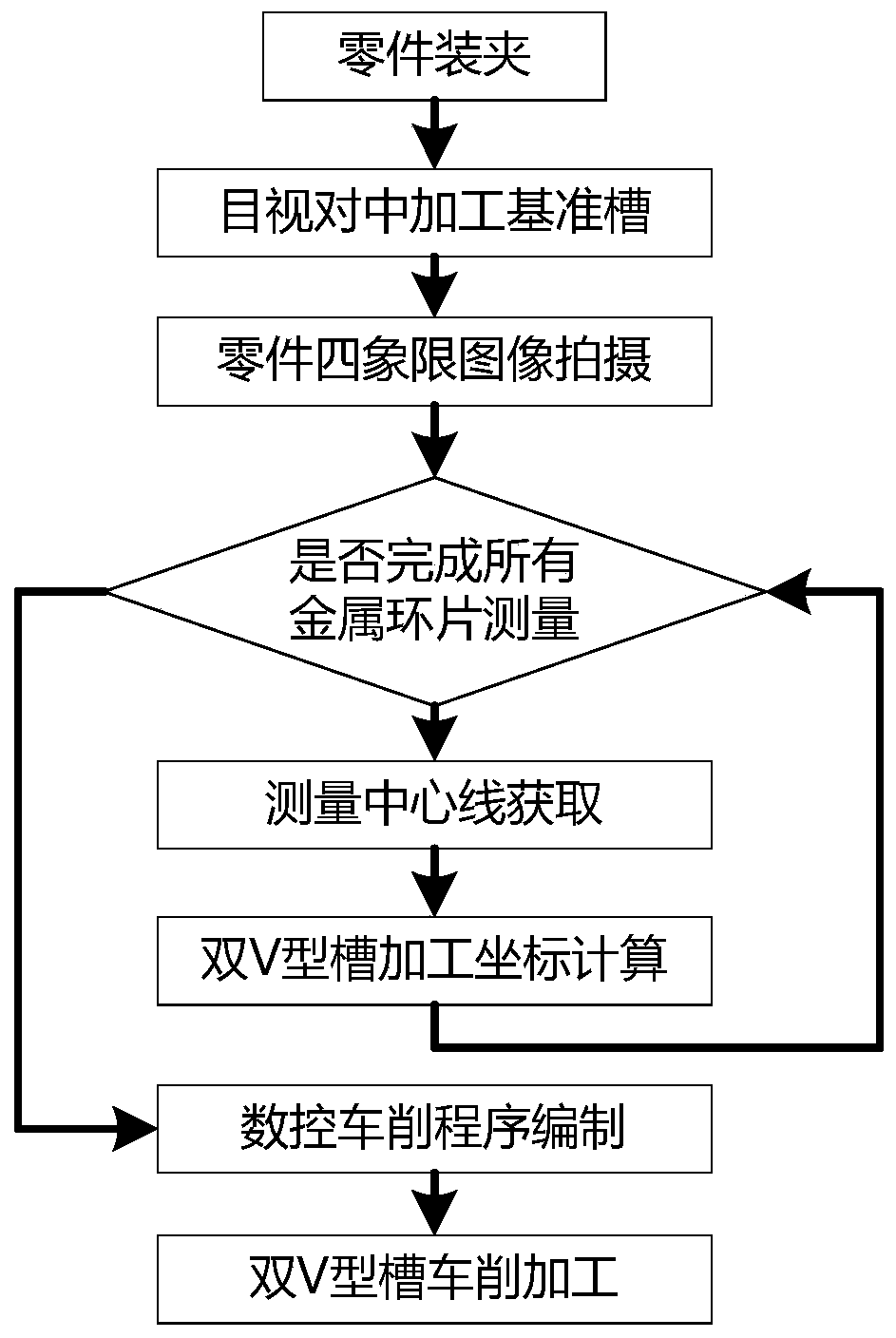

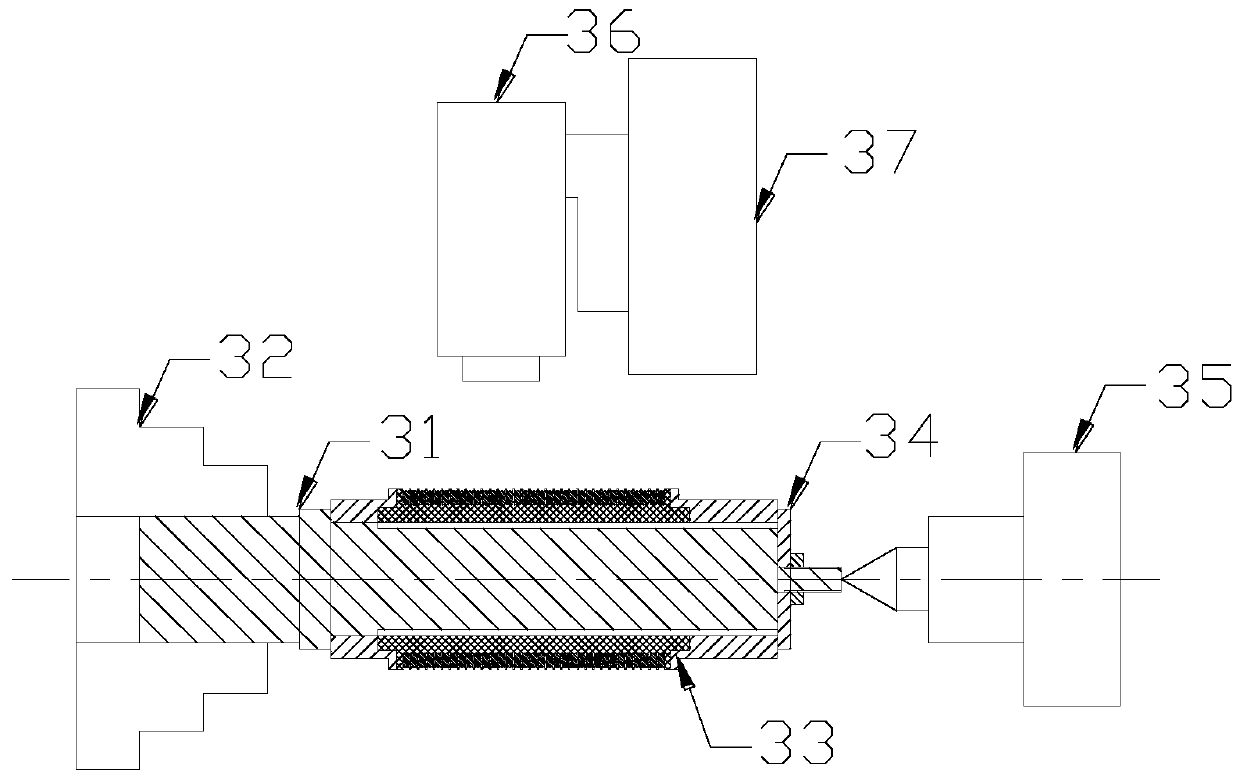

Conductive slip ring dissimilar material pressure poured piece numerical control turning method

InactiveCN109787063ARemove the effects of space warpsAvoid deformationSlip-rings manufactureFour quadrantsEngineering

The invention provides a conductive slip ring dissimilar material pressure poured piece numerical control turning method. The method comprises the steps that first, a benchmark slot is machined in a part fixture and a numerical control lathe chuck through an annular slot turning tool; second, a camera-shooting measuring system is used to perform shooting on four quadrants of a part; third, in thecamera-shooting measuring system, an image, obtained in the second step, of the four quadrants of the part is processed; fourth, a mid-value of a positive extreme value and a negative extreme value isused as a measuring center line of a first metal ring sheet; fifth, a benchmark slot center line on the first metal ring sheet is read, and the distance between the benchmark slot center line and a measuring center line is calculated; sixth, as to other metal ring sheets of the part, the fourth step is repeated to acquire the measuring center line of each metal ring sheet, and then the fifth stepis repeated to calculate the distance between the benchmark slot center line and the measuring center line of each metal ring sheet; and seventh, a numerical control turning program is made accordingto obtained Z-axis coordinates of a numerical control system during turning of a double-V-shaped slot of each metal ring sheet, and a forming turning tool of the double-V-shaped slots is adopted to perform turning.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

Waterless cutting method

ActiveCN104551281BAvoid cutting tension that cannot be kept constantImprove machining accuracyElectrical-based auxillary apparatusDatum referenceWire cutting

The invention belongs to the technical field of spaceflight servo systems, and particularly relates to a non-waterline cutting method and a non-waterline cutting device. By the non-waterline cutting method and the non-waterline cutting device, requirements on linear cutting machining precision and cutting speed of an end surface of a filter element are met, and the cutting quality is high under the condition that the filter element is not polluted when cut off. The non-waterline cutting method comprises the following steps of (1) preparing a setting process; (2) erecting up a core tube 5 of which the length is smaller than that of the filter element in the filter element 4, and placing the core tube 5 and a dovetail groove supporting seat 3 of which the boundary dimension is matched with that of the filter element 4 in a base 7 together; (3) covering the base 7 by using an upper cover plate 6 and fixing the filter element 4 by manually fastening a butterfly nut 2; and (4) changing the dovetail groove supporting seat when filter elements with different specifications are machined and remaining rest positioning datum reference pieces in the device. The dovetail supporting seat is a V-shaped support, and the filter element can be automatically aligned after being placed in the dovetail supporting seat.

Owner:北京实验工厂有限责任公司 +1

Rotary press table for machining laminated polarizers in middle and small size

ActiveCN102862154AAchieve compactionAchieve synchronous rotationWork benchesThrust bearingDrive motor

The invention discloses a rotary press table for machining laminated polarizers in middle and small size. The rotary press stable solves the problems of complicated structure, low positioning precision and inconvenience in operation of the existing equipment and comprises a framework, an upper rotary table and a lower rotary table. The upper rotary table is fixedly arranged on a horizontal cross beam on the upper portion of the framework. A direct-drive motor rotary table which is hollow is arranged on the upper portion of an upper rotary table fixed plate, a spline shaft of a ball spline pair penetrates through a center hole of the direct-drive motor rotary table and the center of a spacer sleeve, the upper end of the spline shaft is connected with a push rod of an air cylinder through a spline connecting flange, two thrust bearings, a transfer shaft and a floating joint, and the lower end of the spline shaft is connected with an upper press head through an upper press head connecting flange. The lower rotary table is fixedly arranged on a bottom frame of the framework through a lower rotary table fixed plate, and the other direct-drive motor rotary table is fixedly arranged on the lower rotary table fixed plate. By the rotary press table, a stack of laminated polarizers can be pressed, positioned accurately and rotate synchronously.

Owner:TAIYUAN FENGHUA INFORMATION EQUIP

Elastic deformation and vibration suppression method for robot grinding and polishing of aircraft composite components

ActiveCN111673611BReduce vibrationSolve the problem of inconsistent grinding and polishing effectsProgramme controlProgramme-controlled manipulatorMaterial removalMachined surface

The invention belongs to the field of robotic grinding and polishing of composite components, and specifically discloses a method for suppressing elastic deformation and vibration of aircraft composite components during robotic grinding and polishing. The method includes: designing a first independent variable group and a first dependent variable group; carrying out a multi-parameter combined grinding process orthogonal test on the first independent variable group and the first dependent variable group to obtain the grinding force and the material removal amount Non-linear relationship; use the force-position hybrid control strategy of global variable pressure and local constant pressure to control the elastic deformation in the robot grinding process; construct the optimal stiffness and attitude relationship in the robot processing space, according to the optimal combination and elastic deformation control The final grinding and polishing process parameters are used to optimize the robot's machining trajectory and determine the grinding and polishing process parameters of the processing area. The invention can realize the effective control of elastic deformation and vibration suppression in robot grinding and polishing of aircraft composite components, eliminate grinding and polishing vibration marks, and ensure the quality of the processed surface.

Owner:HUAZHONG UNIV OF SCI & TECH +1

PCBN blade with combined cuttings-guiding structure

The invention discloses a PCBN blade with a combined cuttings-guiding structure. On the basis of an original blade, two rotatable cuttings-guiding sheet bodies are additionally arranged on a cutter body and are the upper cuttings-guiding sheet body and the lower cuttings-guiding sheet correspondingly, and the two cuttings-guiding sheet bodies are each provided with two types of cuttings-guiding cutter-edge shapes such as the circular arc shape, the broken line shape, the triangle and the linear circular arc shape; compressing washers are arranged at the centers of upper parts of the two cuttings-guiding sheet bodies, and fixing chunk devices are mounted on the two sides of a rotating center. According to the PCBN blade with the combined cuttings-guiding structure, in order to meet the cuttings-guiding needs of hard cutting machining, lower the production cost of cutters and realize quick replacing, the same blade can be used in various machining conditions, and the using efficiency isimproved; and the PCBN blade provides a new cutter design thought for coordinating cutting flow and improving the surface machining quality.

Owner:HARBIN UNIV OF SCI & TECH

sizrcn gradient composite coating tool and preparation method thereof

ActiveCN107177828BHigh hardnessImprove thermal stabilityVacuum evaporation coatingSputtering coatingSputteringHeat stability

The invention belongs to the field of mechanical manufacture cutting cutters, and in particular relates to a SiZrCN gradient composite coating cutter and preparation method thereof. The coating is the SiZrCN gradient composite coating prepared by adopting a composite coating method of unbalanced magnetron sputtering and electric arc plating; the surface of the coating cutter is SiZrCN gradient composite coating with gradually-changed gradient of nitrogen content, a Ti transition layer and a SiZrC transition layer are sequentially arranged between a cutter base body and the coating. By adopting the SiZrCN ultra-hard carbon-nitrogen compound coating, because two metals including Si and Zr are added in the coating at the same time, the nitrogen content of the coating structure component is gradually changed in a gradient manner, so that the cutting machining performance of the cutter can be improved. The coating has high hardness and heat stability, and also has good diffusion prevention and wear prevention performances, good plastic deformation resistance ability and excellent friction and wear resistance property. In the cutting process, the cutter can effectively prevent the occurrence of cracking of cutting edges and hot cracks, guarantee the machining surface quality of the workpieces, and prolong the service life of the cutter by more than 70%.

Owner:JINING UNIV

An Ultrasonic Cutting Finishing System

ActiveCN110064764BImprove machined surface qualityReduce the quality of the machined surfaceMetal working apparatusTurning machinesMachined surfaceEngineering

The invention discloses an ultrasonic cutting and polishing machining system. The ultrasonic cutting and polishing machining system comprises an ultrasonic transducer, an amplitude transformer, and awiper blade cutter, wherein the front end of the ultrasonic transducer is tightly and reliably connected with the rear end of the amplitude transformer; the ultrasonic transducer is connected with anultrasonic power supply through a lead; a flange plate is arranged at the vibration displacement node position of the amplitude transformer; the flange plate is connected with a B-axis rotary tool rest through a supporting plate; and the wiper blade cutter is tightly and reliably connected with the front end of the amplitude transformer. According to the ultrasonic cutting and polishing machiningsystem, ultrasonic high-frequency vibration in the feeding direction of the cutter can improve the action length of a wiper blade, reduce the generation of secondary tool marks on the machining surface of the wiper blade, and improve the quality of the machined surface; due to the cleaning effect of the ultrasonic vibration, it is difficult to generate chip accumulation at the wiper edge, and thequality of the machined surface is better guaranteed; the ultrasonic vibration changes the contact state and action mechanism between the cutting edge and the wiper edge and the material to be machined, reduces the cutting force and the cutting temperature, and improves the surface quality after the cutting edge is processed, and thus the quality of the machined surface is further improved due tothe combined action of the polishing edge and the ultrasonic vibration.

Owner:DALIAN JIAOTONG UNIVERSITY

A pcbn blade with combined chip guide structure

ActiveCN109877349BSimple structureEasy to installTurning toolsAgricultural engineeringCentre of rotation

Owner:HARBIN UNIV OF SCI & TECH

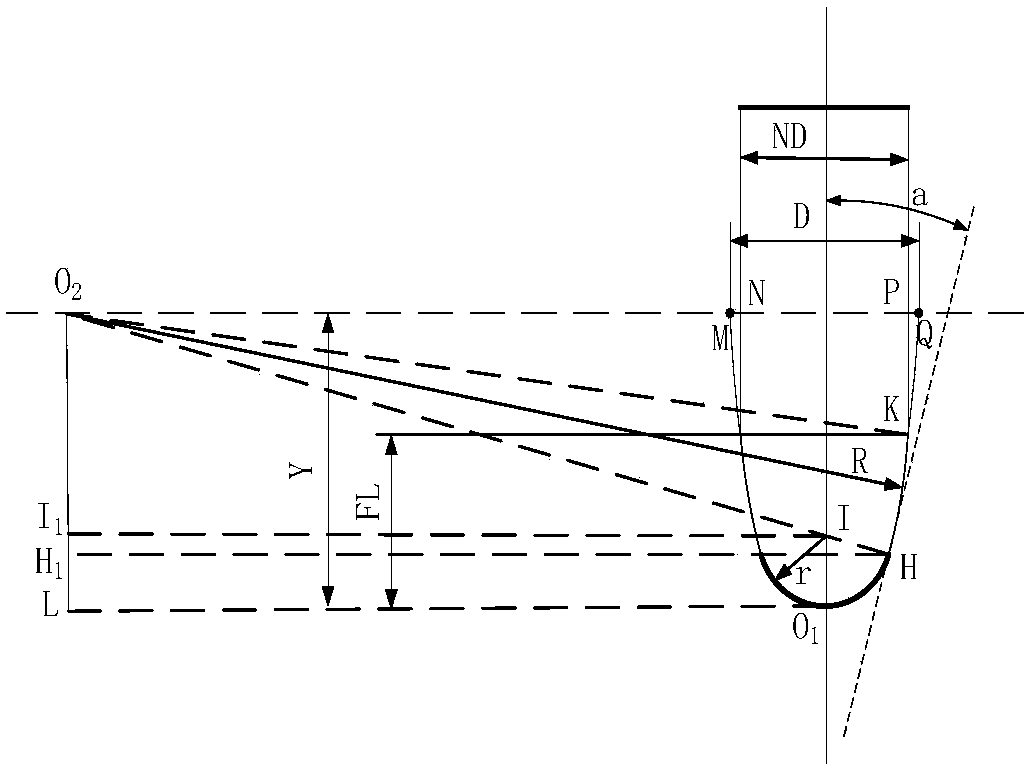

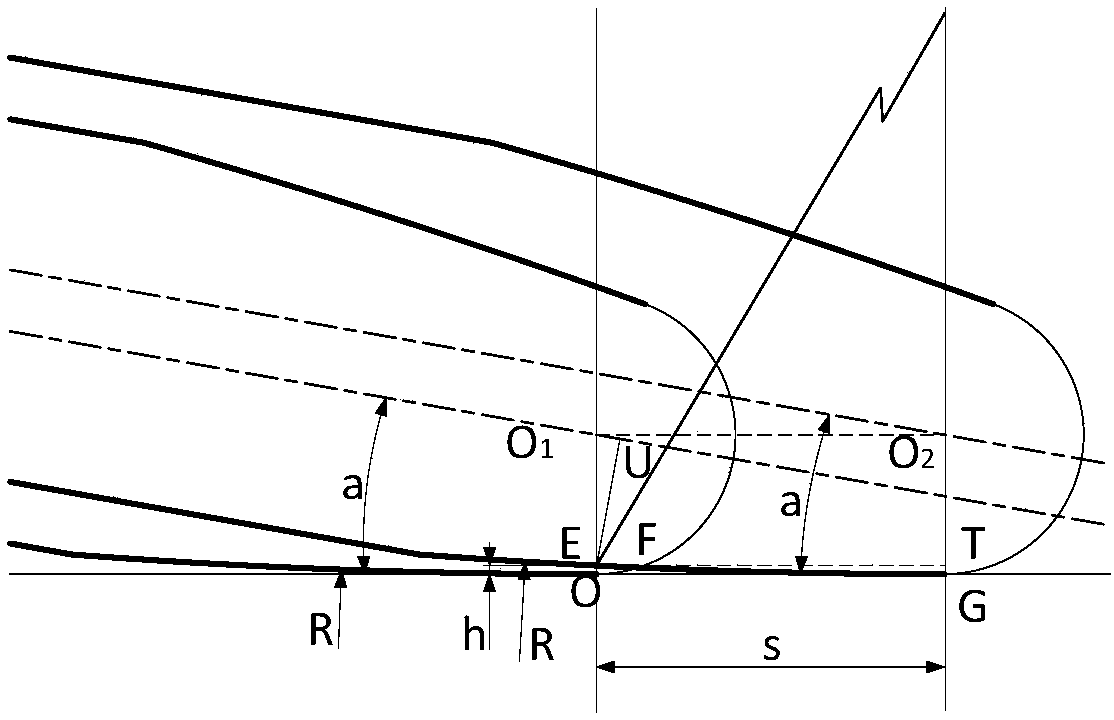

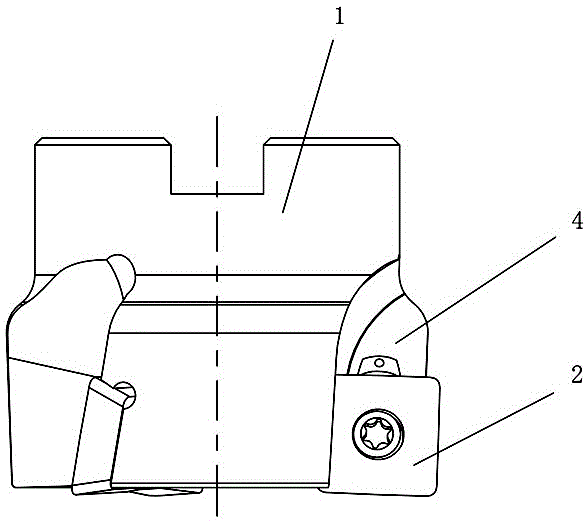

A finishing milling tool

The invention discloses a finishing milling cutter, which comprises a cutter body, a cutting cutter group and a cutter group fastener, the cutter body is provided with a slit, and the cutting cutter group is installed through the cutter group fastener In the sipe, the cutting tool set includes a first fine cutting blade and a second fine cutting blade, the first fine cutting blade is provided with a first arcuate cutting edge, and the second fine cutting blade is provided with There is a second arched cutting edge corresponding to the first arched cutting edge, the radius of curvature of the middle high convex point of the first arched cutting edge is R, and the second arched cutting edge is far away from the The radius of curvature at the endpoint of one end of the central axis of rotation of the cutter body is r, and r

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com