A rotary press table for processing small and medium-sized polarizing laminates

A technology of polarizing lamination and rotary pressing, which can be applied to workbenches, manufacturing tools, etc., and can solve the problems of large pressing mechanism, low positioning accuracy, and inconvenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

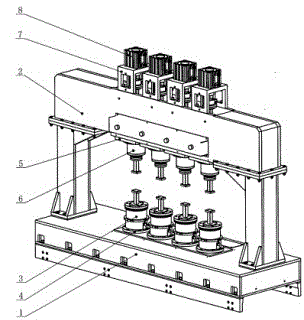

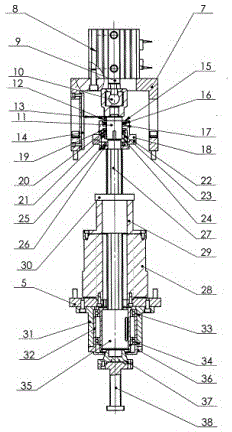

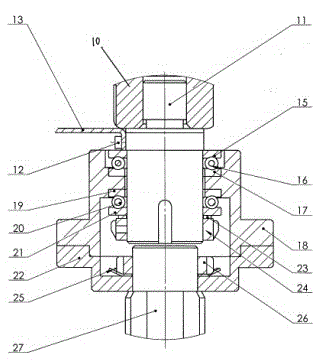

[0012] A rotary press table for processing small and medium-sized polarized laminates, including a base frame 1, a gantry frame 2 is fixedly arranged on the base frame 1, and a lower turntable 3 is fixedly arranged on the table surface of the bottom frame 1 through a lower turntable fixing seat 4 On the bottom surface of the crossbeam of the gantry 2 directly above the lower turntable 3, an upper turntable fixing seat 5 is arranged, and an upper turntable 6 is arranged on the upper turntable fixing seat 5, and the top of the crossbeam of the gantry 2 directly above the upper turntable 6 A door-shaped cylinder mounting seat 7 is arranged on the surface, and a cylinder 8 whose output shaft protrudes downward is arranged on the door-shaped cylinder mounting seat 7. The shaft end of the cylinder output shaft 9 of the cylinder 8 is connected with one end of the floating joint 10, and the floating The other end of the joint 10 is screwed together with the upper cylinder of the steppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com