Patents

Literature

75results about How to "Achieve synchronous rotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

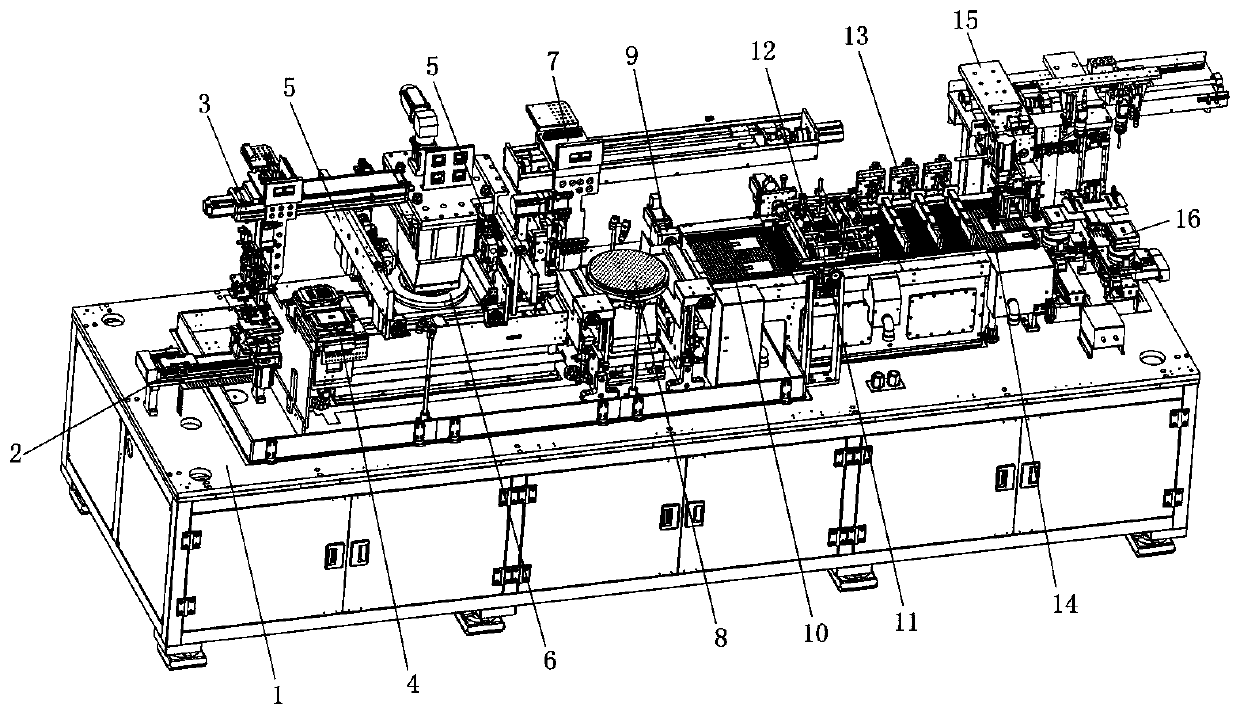

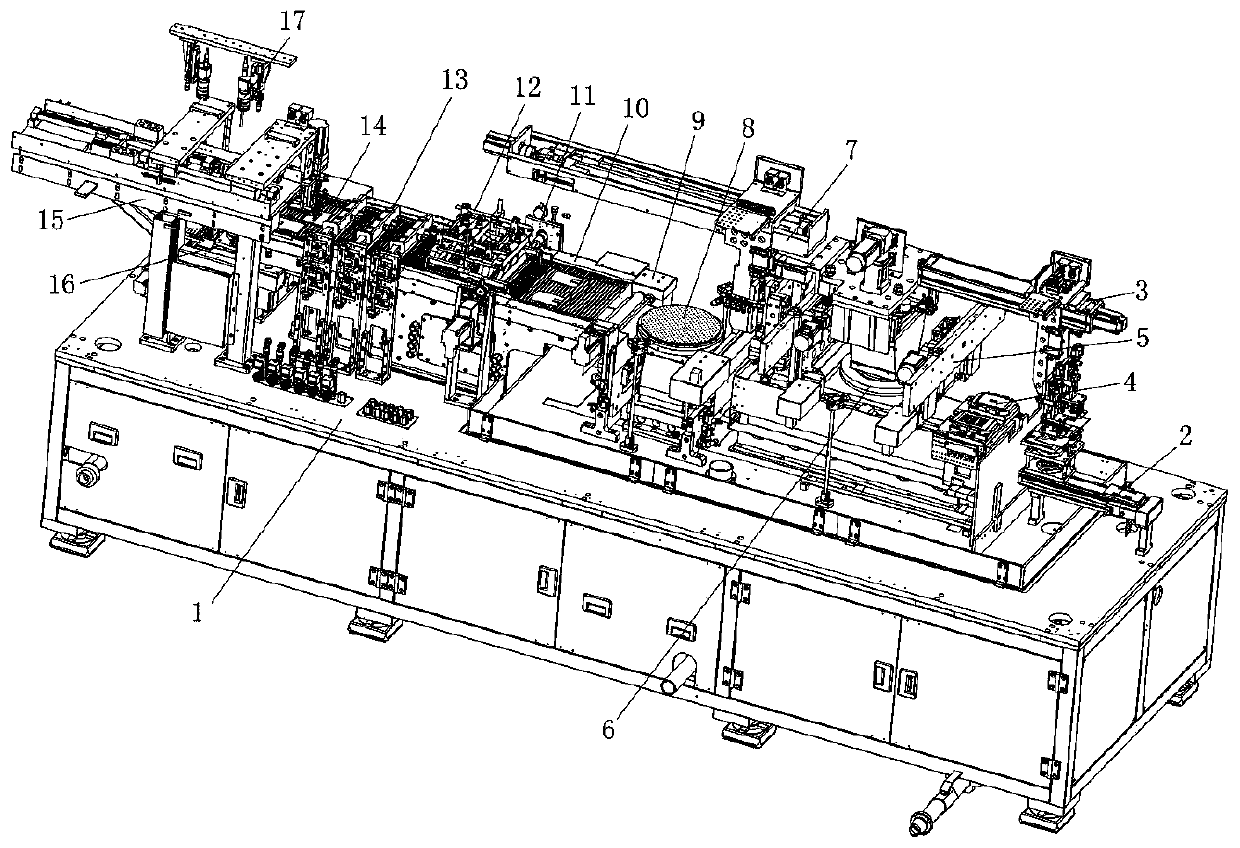

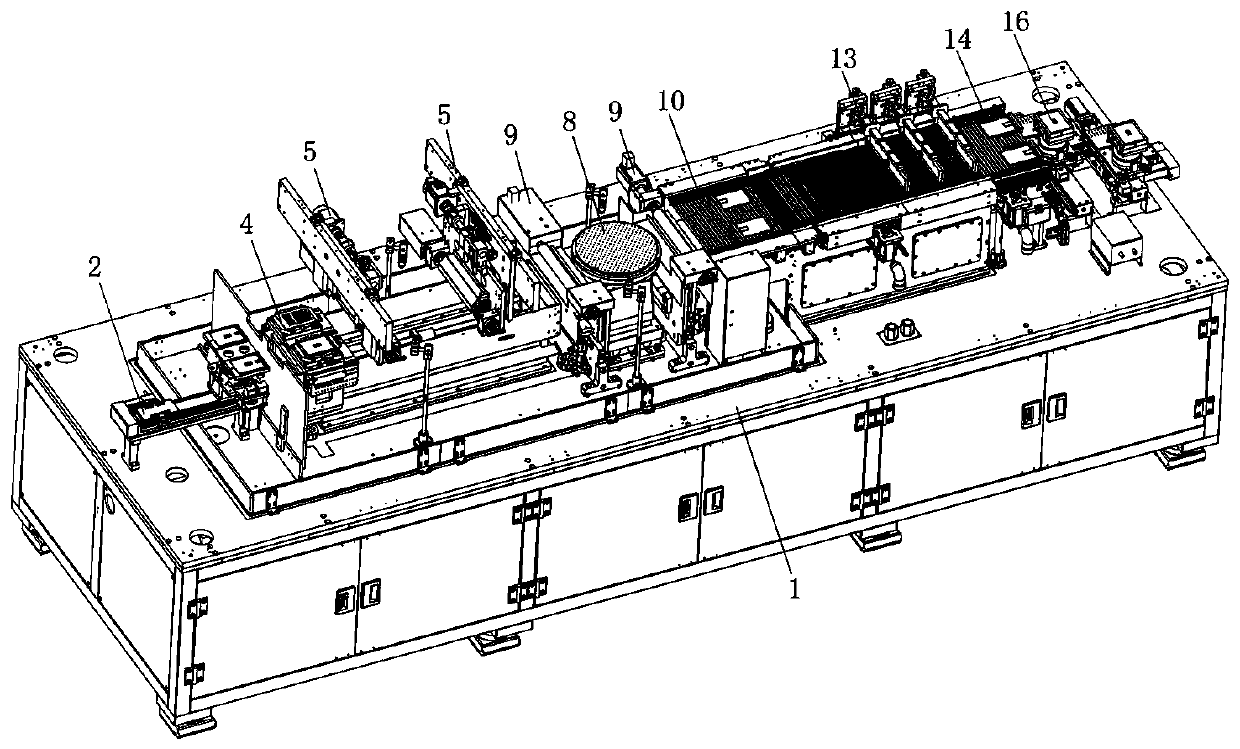

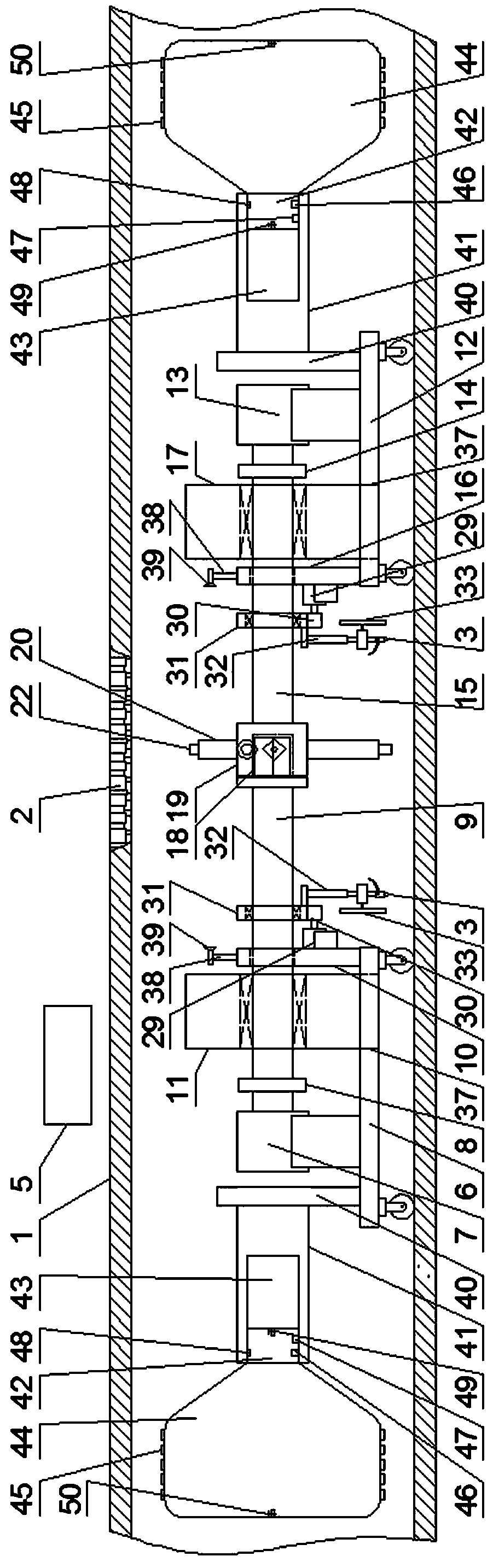

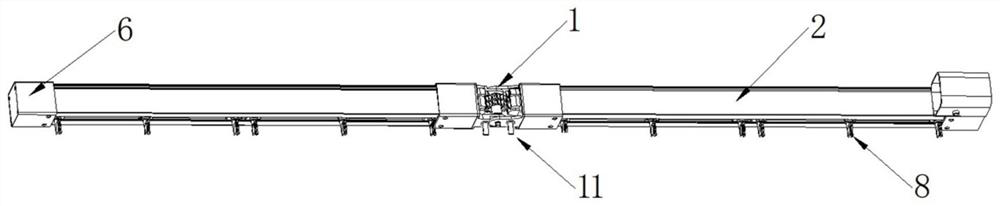

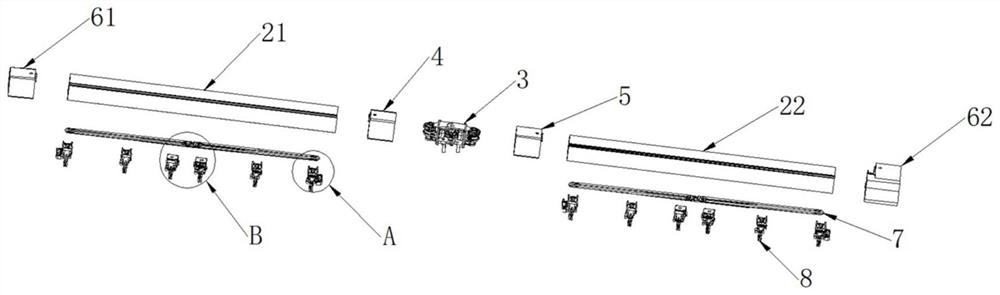

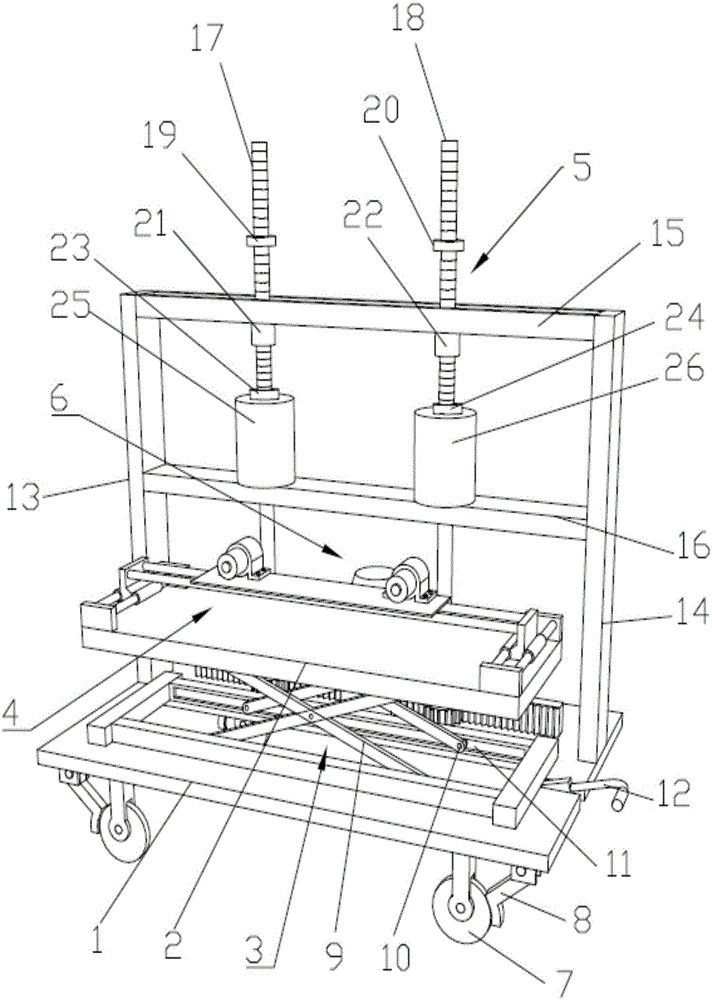

Full-automatic grinding and cleaning machine and grinding and cleaning technology thereof

ActiveCN109955145AAvoid position shiftAvoid positionLapping machinesFlexible article cleaningTransmission channelManipulator

The invention discloses a full-automatic grinding and cleaning machine and a grinding and cleaning technology thereof. The full-automatic grinding and cleaning machine comprises a feeding part, a CF cleaning part, a TFT cleaning part, a two-fluid cleaning and drying part, and a discharging part, wherein the feeding part, the CF cleaning part, the TFT cleaning part, the two-fluid cleaning and drying part and the discharging part are sequentially arranged on a machine table in the flow direction of glass pieces; the to-be-cleaned glass pieces are sequentially transported from the feeding part tothe CF cleaning part, a CF surface is cleaned through the CF cleaning part, the TFR surface is cleaned through the TFT cleaning part, and the CF surface and the TFT surface are cleaned by the two-fluid cleaning and drying part simultaneously and then dried, and the dried glass pieces are discharged and exported through the discharging part. According to the full-automatic grinding and cleaning machine and the grinding and cleaning technology thereof, transmission of the small and micro-sized glass pieces is effectively realized, and the problems of positional displacement and motion interference of the glass pieces in the two-fluid cleaning and drying process are effectively avoided; and rotating, material splitting, and exporting of the glass pieces are realized through cooperation of adouble-glass transmission channel formed by a gap between adjacent conveying rollers in an upward extending mode and a discharging mechanical arm, the height of a brush can be controlled in real time,displacement of the glass pieces is avoided, and the cleaning efficiency of the brush and the real-time cleaning versatility of the brush are effectively improved.

Owner:SHENZHEN ETMADE AUTOMATION EQUIP

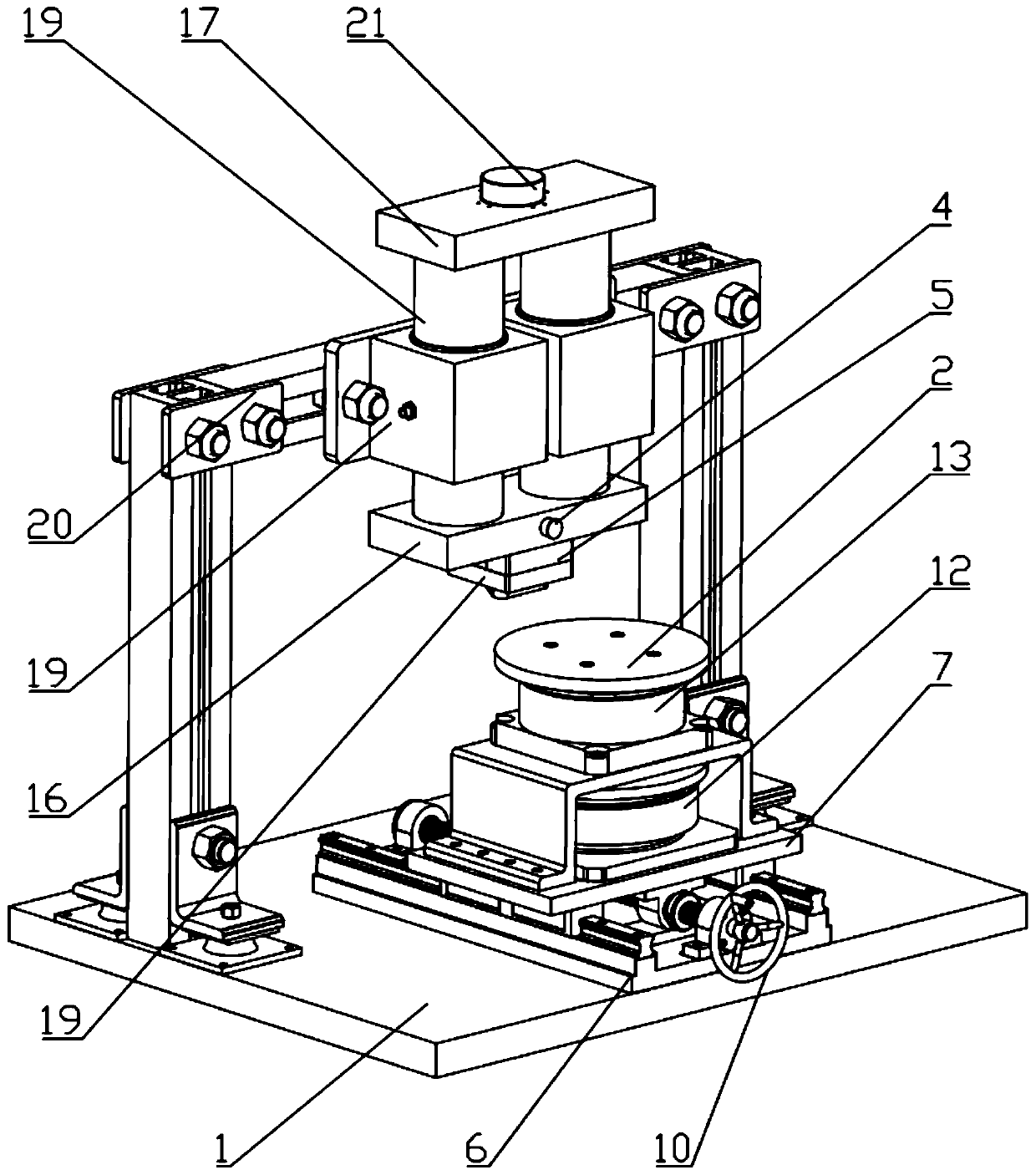

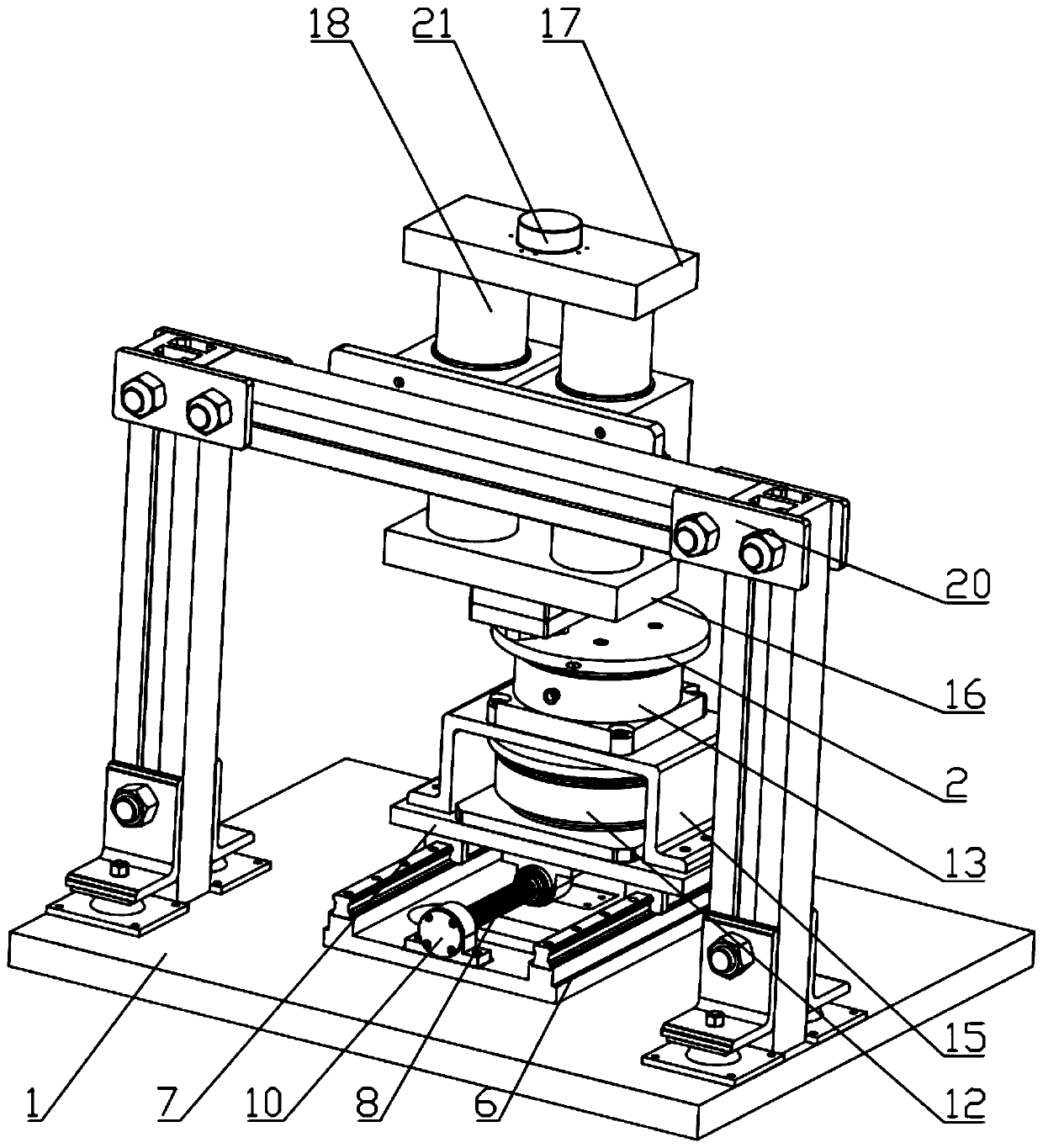

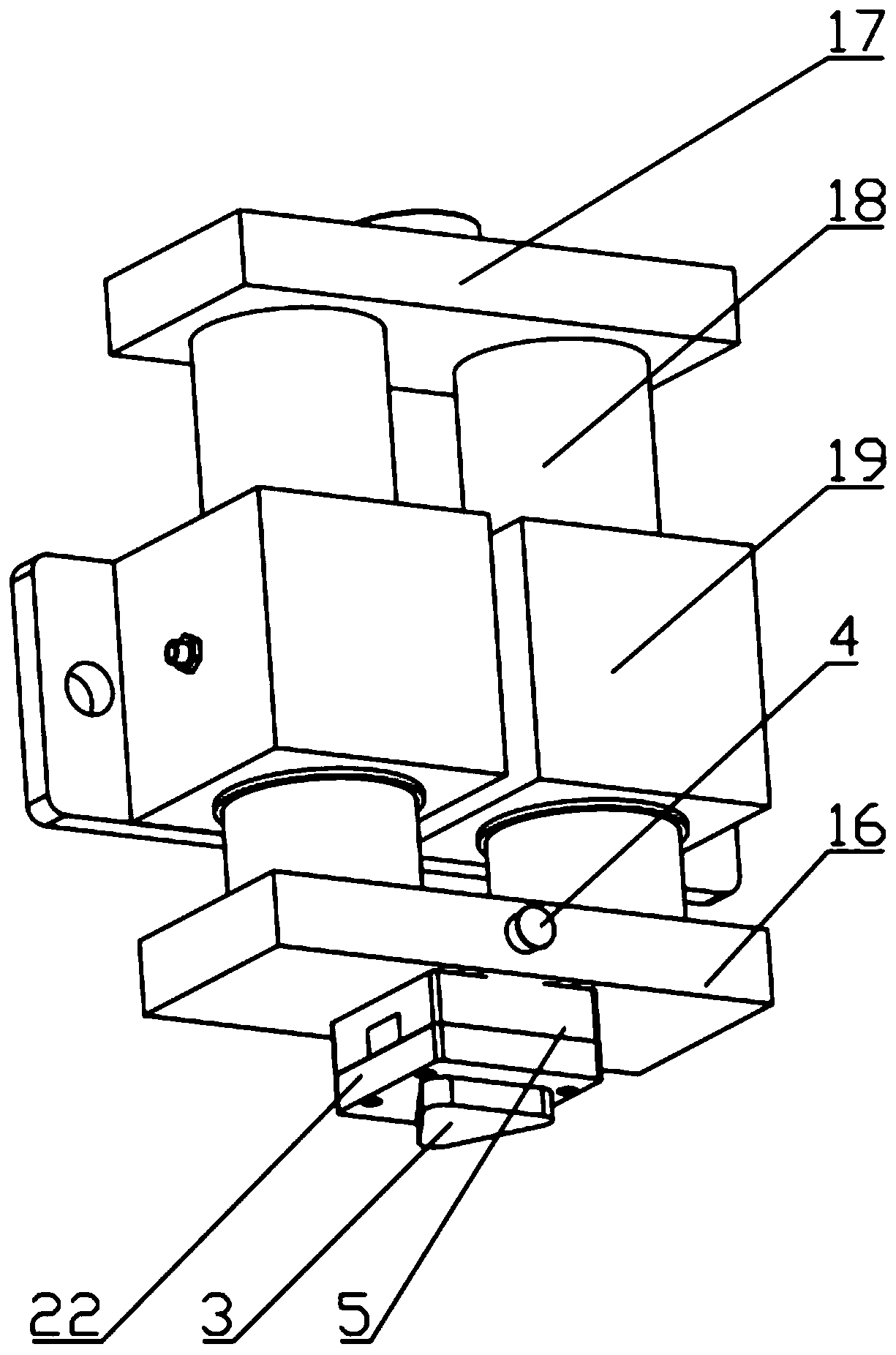

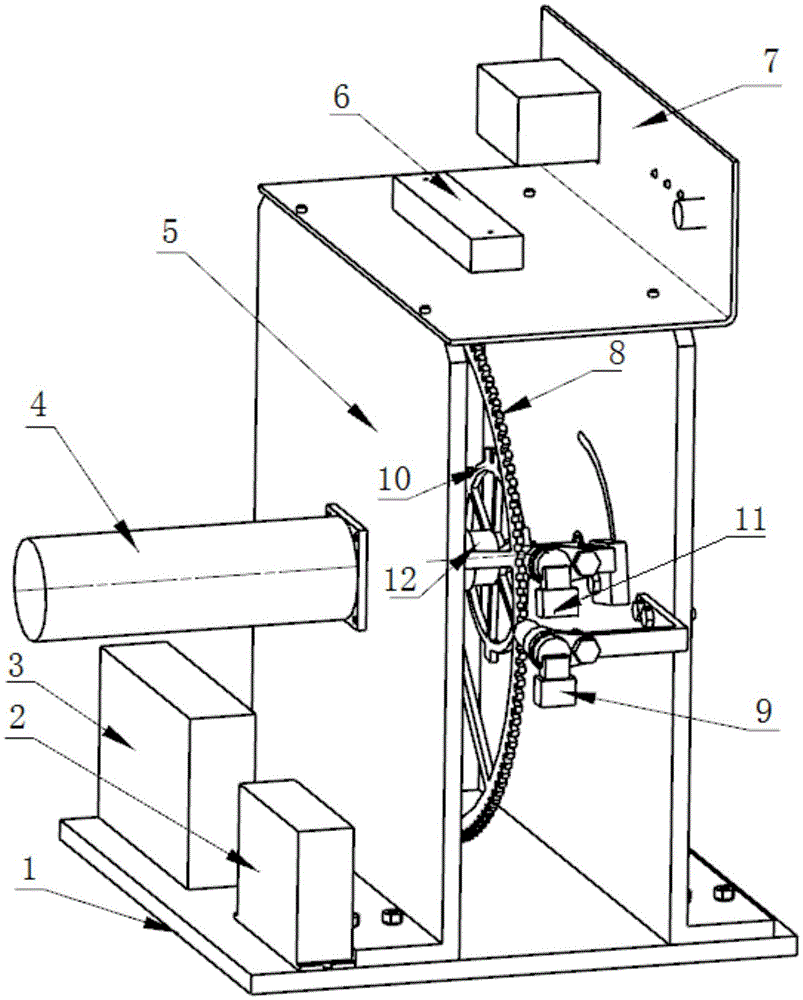

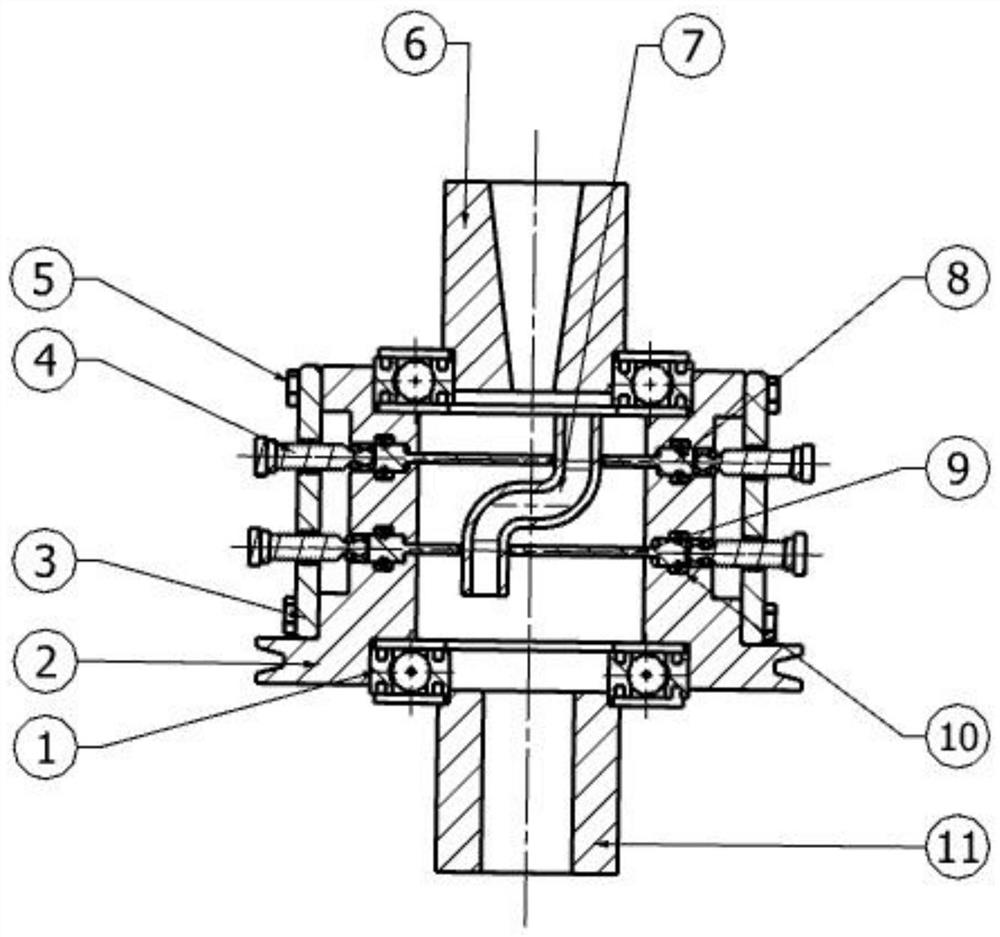

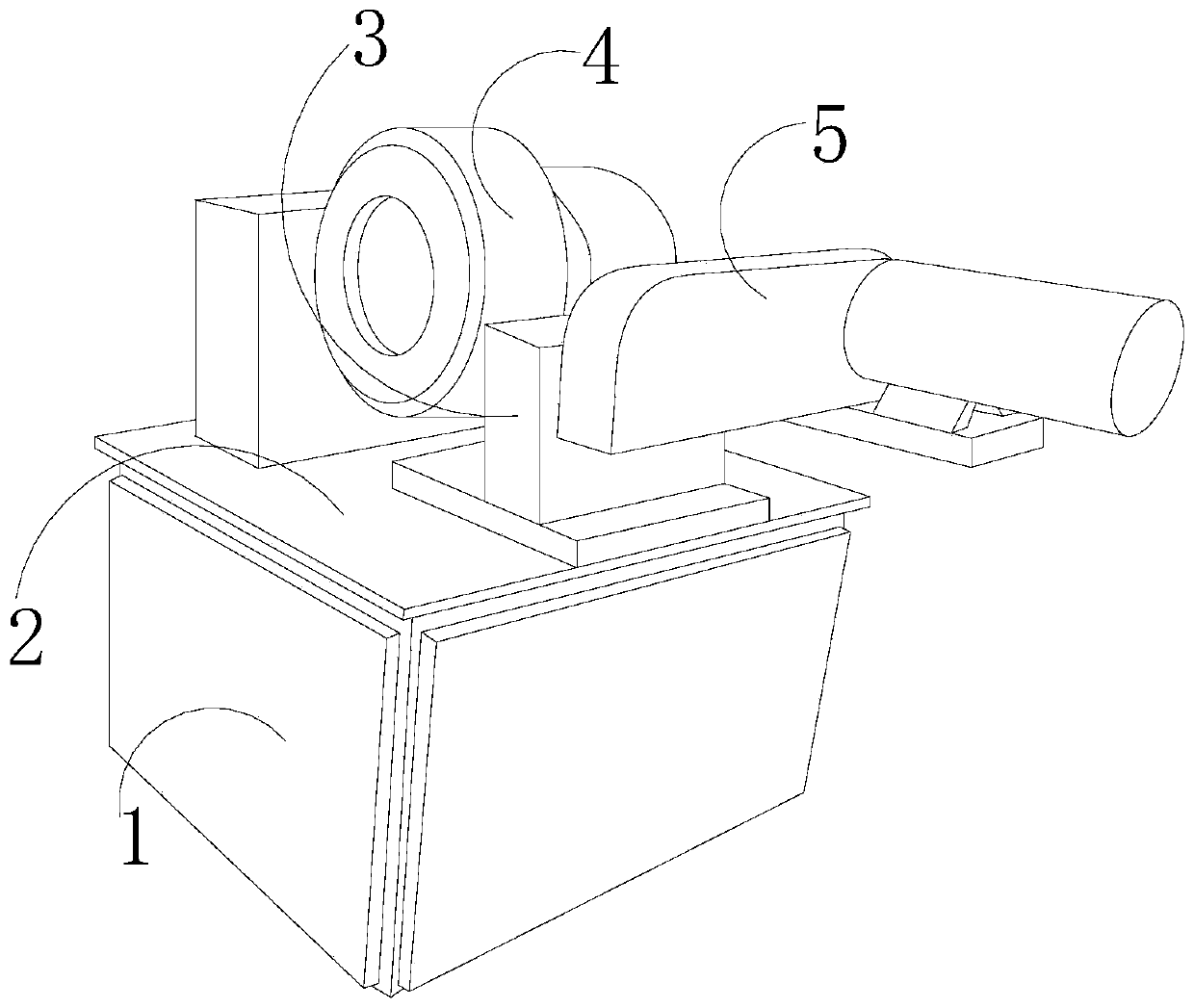

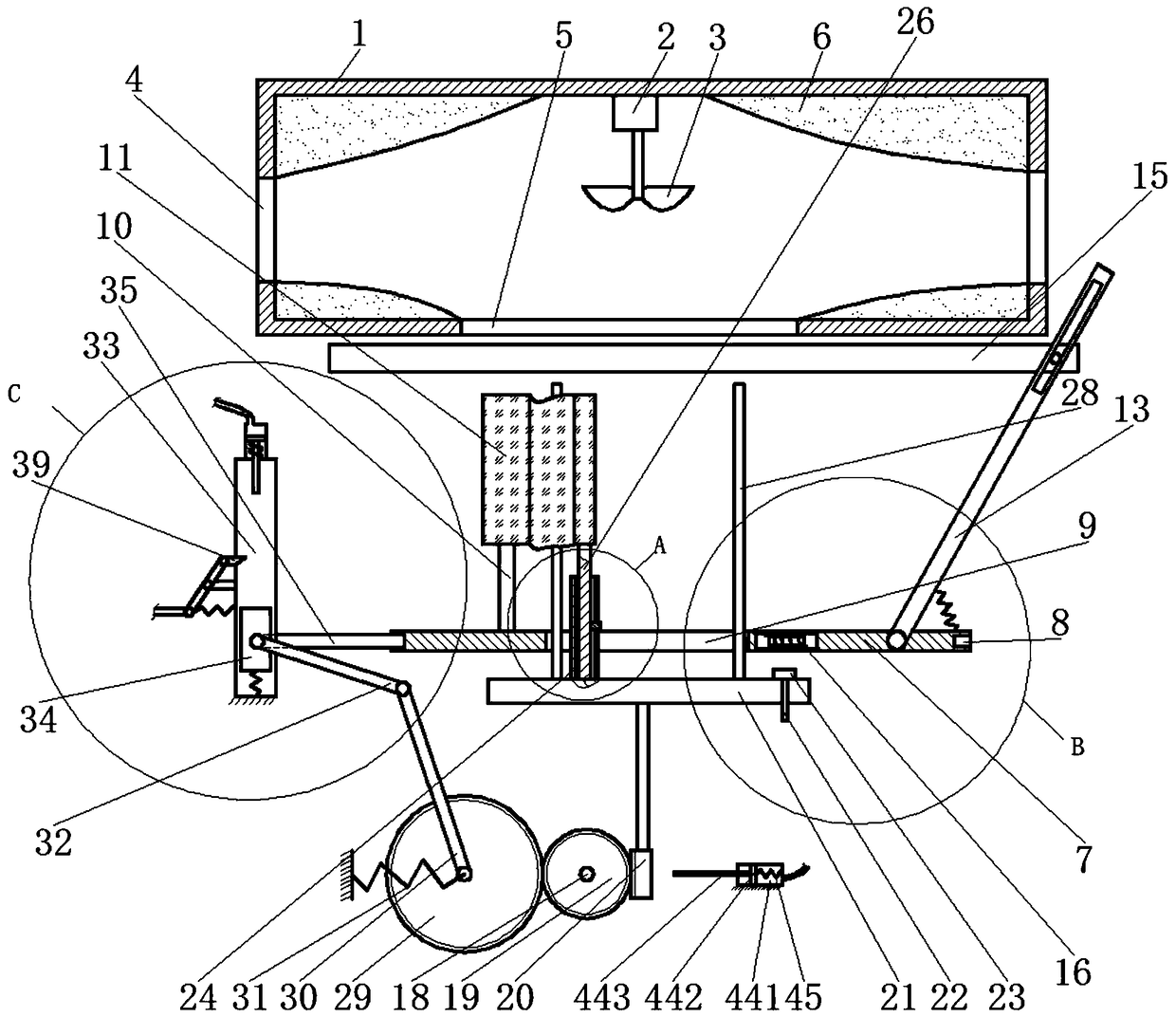

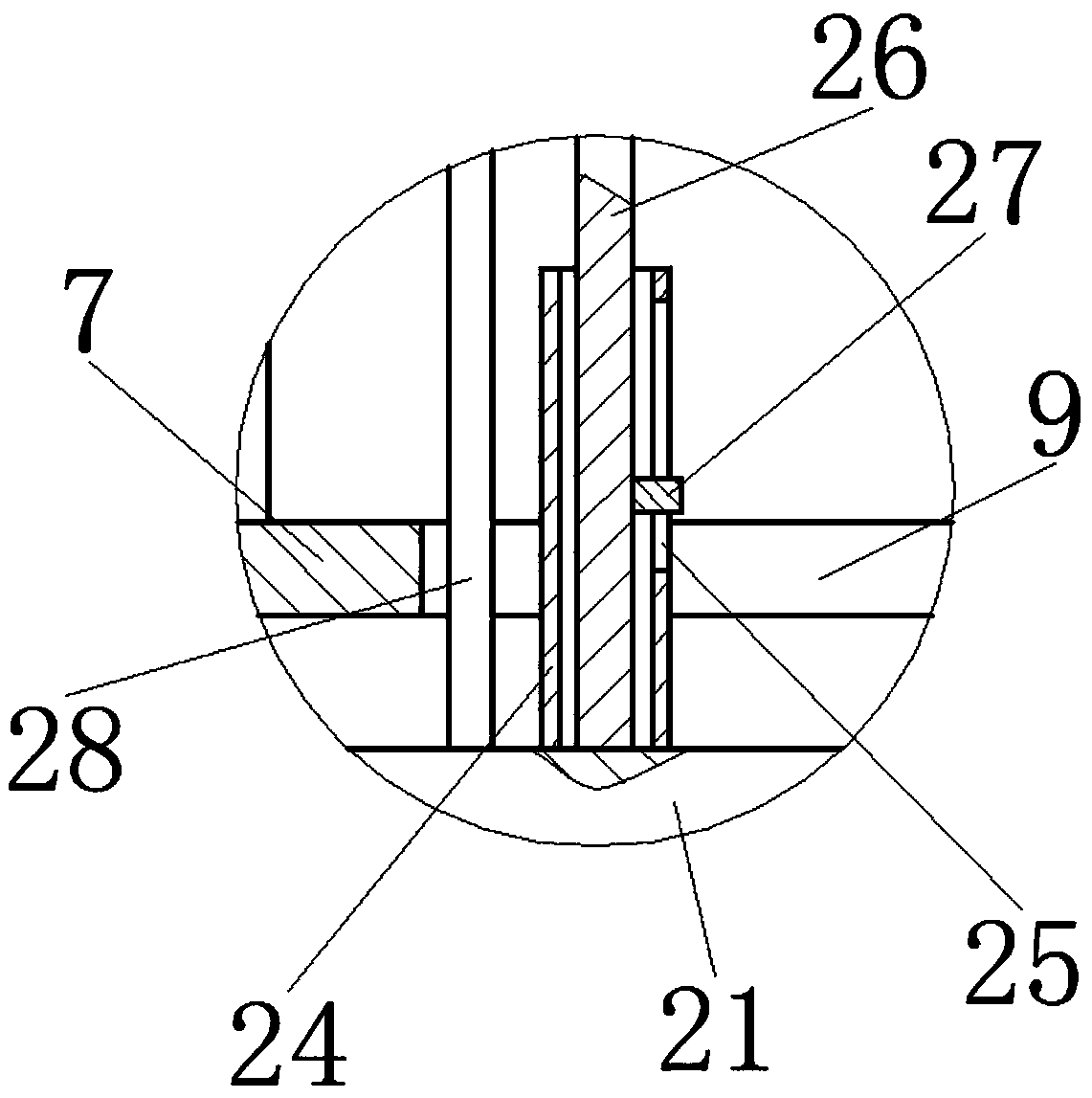

Rotary tribological behavior simulation test bed for realizing vibration decoupling

ActiveCN111307437AShort delayAchieve synchronous rotationMachine part testingSubsonic/sonic/ultrasonic wave measurementAir bearingClassical mechanics

The invention discloses a rotary tribological behavior simulation test bed for realizing vibration decoupling. The test bed comprises a test bed base. A lower friction sample is arranged on the test bed base, an upper friction sample is arranged above the lower friction sample, a rotating system is arranged between the lower friction sample and the test bed base, the upper friction sample is connected with a loading system, and an acceleration sensor and a three-way force sensor are arranged on the loading system. The rotating system is arranged to drive the lower friction sample to rotate; the loading system is arranged to control the friction contact loads required by the upper friction sample and the lower friction sample; on the basis of the non-contact working principle of the air bearing, interference signals caused by structural resonance of a supporting device, vibration of a driving part and the like in a test and interface friction self-excited vibration signals are decoupled, so that influence factors of the interface tribology behavior of the rotary friction pair are researched and analyzed, and an evolution rule and a regulation and control method of the interface tribology behavior of the rotary interface are explored.

Owner:SOUTHWEST JIAOTONG UNIV

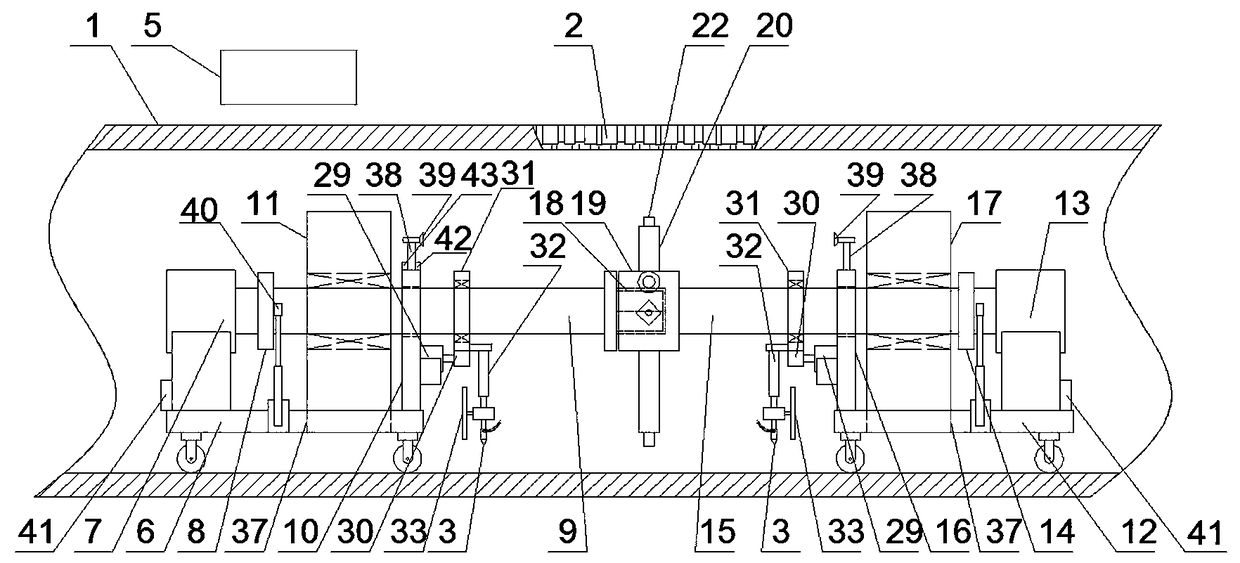

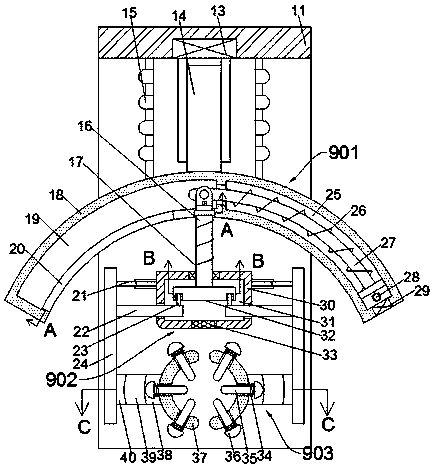

Drainage pipeline non-excavation repairing device

ActiveCN109058646AAvoid deformationAvoid environmental problemsPipe elementsEngineeringEarth surface

The invention discloses a drainage pipeline non-excavation repairing device. The drainage pipeline non-excavation repairing device comprises a first working mechanism which is located on one side of the collapsing deformation position of the interior of a to-be-repaired drainage pipeline, a second working mechanism located on the other side of the collapsing deformation position of the interior ofthe to-be-repaired drainage pipeline, a third working mechanism arranged between the first working mechanism and the second working mechanism, monitoring mechanisms arranged on the first working mechanism and / or the second working mechanism, cutting mechanisms which are arranged on the right side of the first working mechanism and the left side of the second working mechanism correspondingly, first quick-setting cement nozzles arranged on the cutting mechanisms, a second quick-setting cement nozzle arranged on the third working mechanism, and a control mechanism which is located on the groundand used for controlling the whole repairing device to concertedly work. According to the drainage pipeline non-excavation repairing device, only the collapsing deformation position of the drainage pipeline needs to be separated and cut out at first and then is rotated to the side or the bottom, finally, a cut seam, an inserting hole and the collapsing deformation position are subjected to cementfilling repairing through the first quick-setting cement nozzles and the second quick-setting cement nozzles, and repairing is achieved without a new pipeline.

Owner:江西省水利科学研究院 +1

Novel chip-free positioning cutting machine

InactiveCN104439490AIncrease profitAchieve synchronous rotationTube shearing machinesShearing machine accessoriesSteel tubeEnergy consumption

The invention discloses a novel chip-free positioning cutting machine which comprises a machine frame and a chip-free device. A cutter support for fixing a cutter is arranged on the machine frame. A height adjusting device with a support is arranged at one end of the machine frame. The support is provided with a guiding and clamping device for clamping a steel pipe. An air cylinder is arranged at the other end of the machine frame. The chip-free device comprises a base, bearings and a rolling wheel. The base is arranged on the machine frame, and two bearings are arranged on the base. The novel chip-free positioning cutting machine is simple in structure, convenient to operate, capable of quickly and effectively completing cutting work of the steel pipe required to be cut and can play a fixing role on steel pipes different in diameter through simple adjustment operation without fixing device replacement, working efficiency is improved, synchronous rotation of the steel pipe and the cutter is achieved during cutting, produced metal chips are decreased, material utilization rate is improved, and the energy consumption and the cost of the machine are reduced.

Owner:无锡市科洋自动化研究所

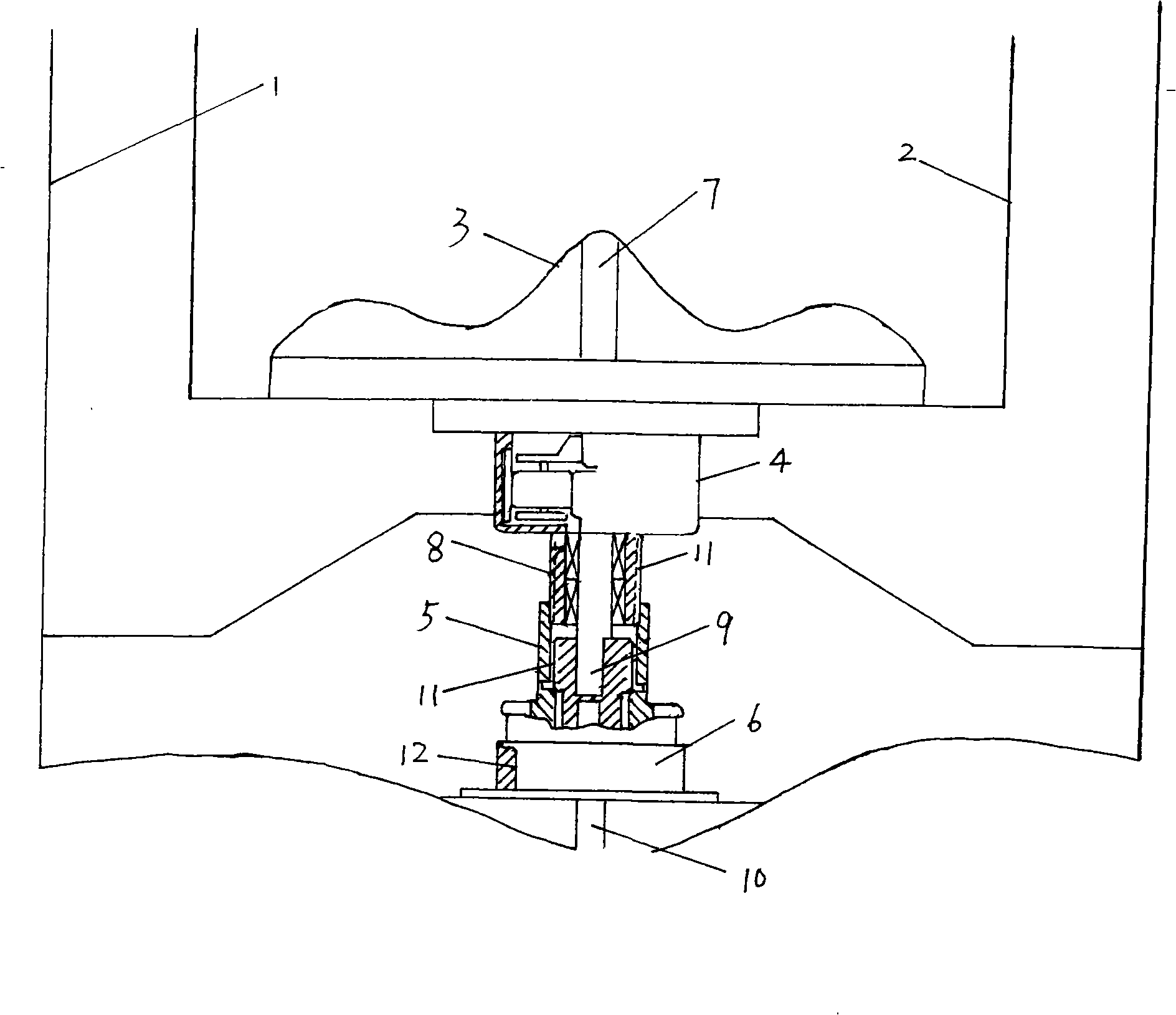

Novel washing machine

ActiveCN101280506ASimple structureThe mechanical connection is validOther washing machinesWashing machine with receptaclesImpellerCoupling

The invention discloses a novel washing machine, which comprises a bucket, a barrel of dehydration, an impeller, a washing machine reduction gear and a motor. The washing machine reduction gear has a transmission shaft, an output shaft and an output shaft bushing, which is characterized in that the output shaft is taken as a driveshaft of the washing machine impeller. The motor shaft is connected to the transmission shaft, and the output shaft bushing of the washing machine reduction gear is directly in rigid connection in a mechanical manner. A clutch is arranged between the transmission shaft and the output shaft bushing, which can be in forward and backward sliding. When the clutch slides up to a certain position, the effective coupling can be achieved with the transmission shaft and the output shaft bushing simultaneously through a mechanical linking method. Thus the separate two-way rotation of the washing impeller can be completed, and the washing function of the washing machine can be achieved. Or the washing impeller and the reduction gear are in synchronous rotation, thus the dehydration function of washing machine is achieved.

Owner:HEFEI MIDEA WASHING MACHINE

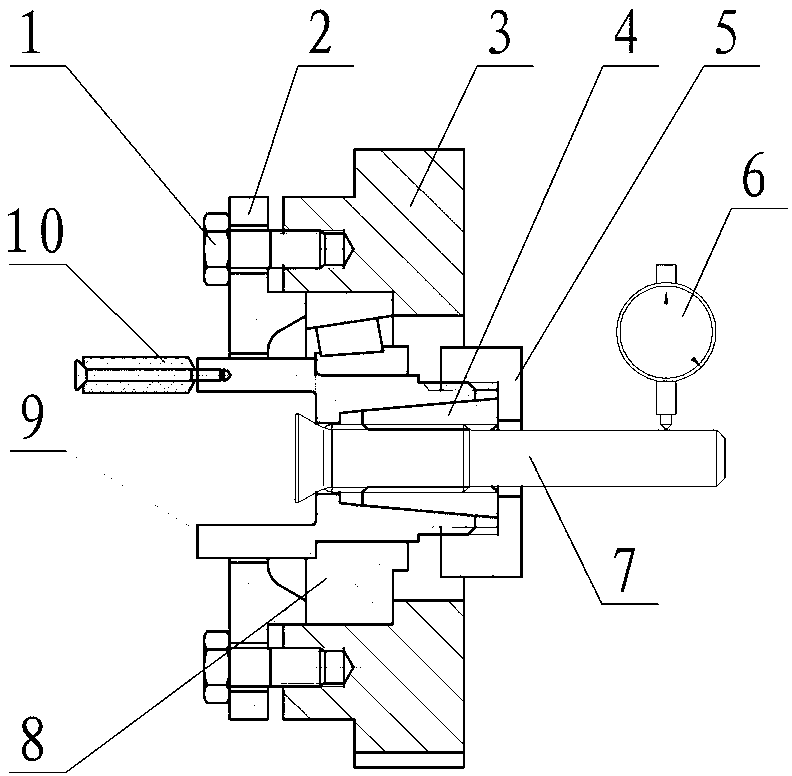

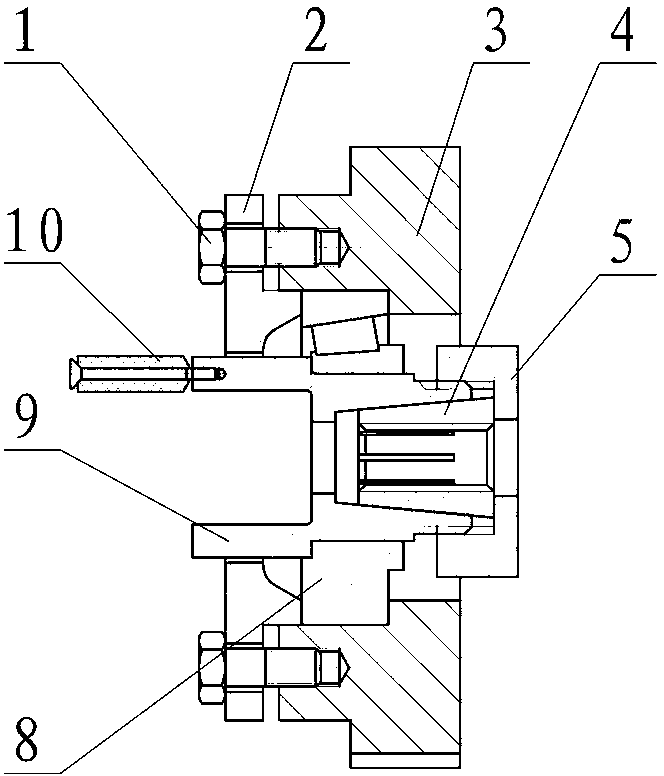

Form and position tolerance detecting instrument for shaft and sleeve

ActiveCN103217086AReduce the impact of errorsAchieve synchronous rotationMechanical measuring arrangementsPosition toleranceEngineering

The invention discloses a form and position tolerance detecting instrument for a part, such as a shaft and a sleeve. The detecting instrument comprises a base and a core shaft which is rotationally arranged in the base through a bearing, wherein a fixing structure used for fixing a reference section of the part to be measured and making the reference section coaxially matched with the core shaft is fixedly arranged on the core shaft; an inner hole of the base is provided with a limit step surface which is leftward and is matched with the bearing in a limit way; the left end of the core shaft extends out of the base, a bearing gland which is matched with the outer ring of the bearing in a compressing way is sleeved on the clearance of the extending part of the core shaft, and adjusting bolts which are peripherally and uniformly distributed along the core shaft are connected between the bearing gland and the base; and an adjusting detection part which is used for detecting the beating degree of the core shaft during a core shaft rotating process through a dial indicator and adjusting the beating degree of the core shaft according to the tightness degree of each adjusting bolt is also arranged on the peripheral surface of the core shaft. While the beating degree of the detected section of the part to be detected in the manner of being relative to the reference section can be detected through the rotation of the core shaft, the influence of the error of the self assembly of the detecting instrument can also be reduced through slight adjustment. The accuracy of detection is improved.

Owner:河南航天精工制造有限公司

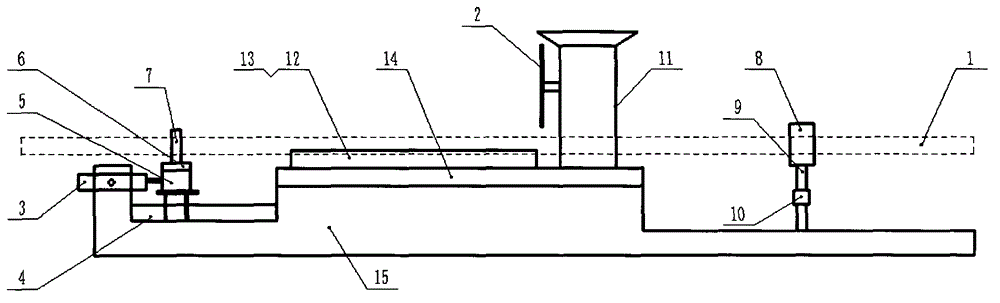

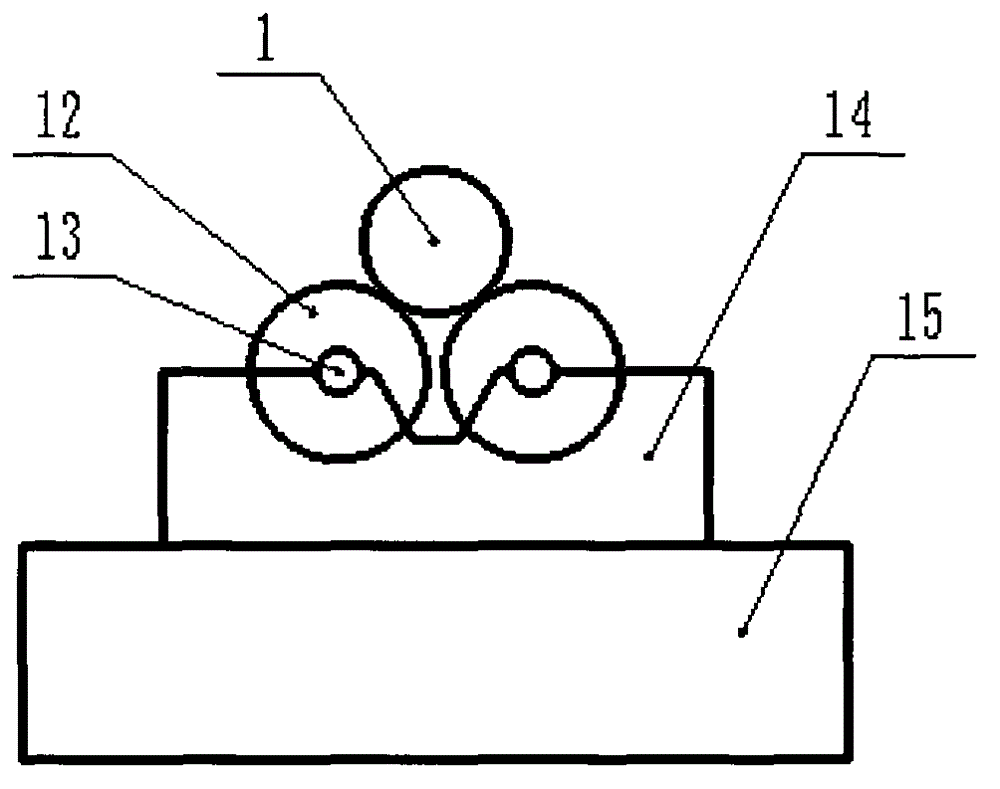

Chipless cutting machine

InactiveCN103317180AAchieve synchronous rotationReduce generationTube shearing machinesPositioning apparatusEngineeringMechanical engineering

The invention relates to a chipless cutting machine which comprises a saw and a rack. A circular blade is movably arranged on the saw, and the radius of the circular blade is larger than the radius of a steel tube to be cut. A base is arranged on the rack, two rollers are movably arranged on the base, and a gap between the two rollers is smaller than the diameter of the steel tube to be cut. The chipless cutting machine is applicable to the steel tube cutting field.

Owner:JIANGSU FENGLI PRECISION TUBE MFG

Multifunctional high-frequency incision knife

ActiveCN103750901AReduce blood lossReduce the number of repeated instrument changesSurgical instruments for heatingEngineeringHigh Frequency Waves

Owner:徐美东

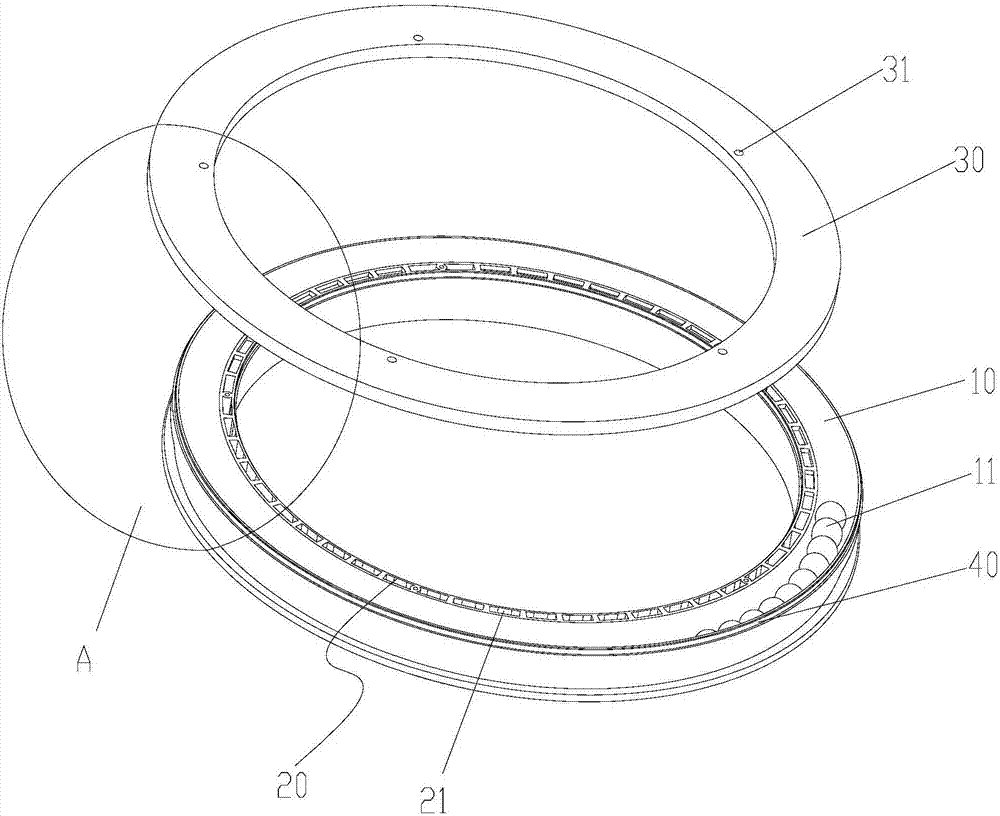

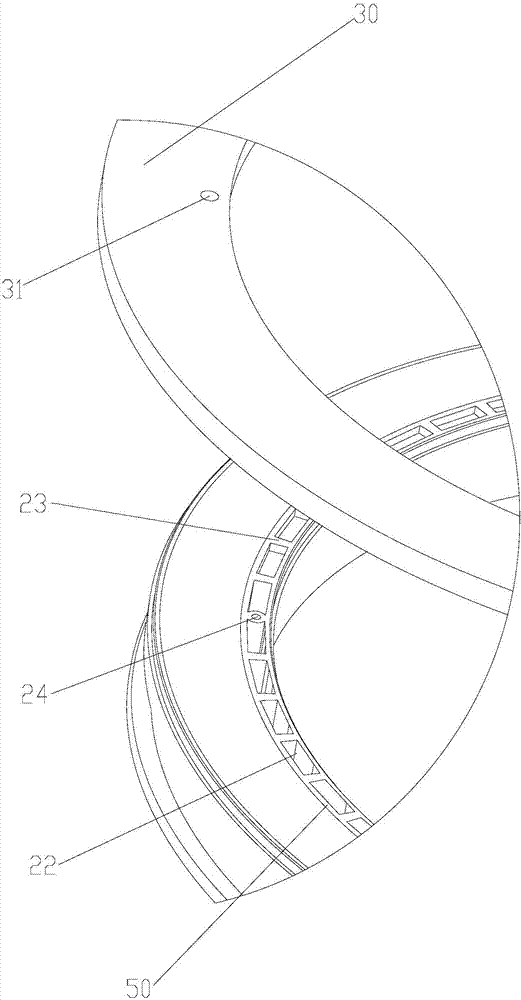

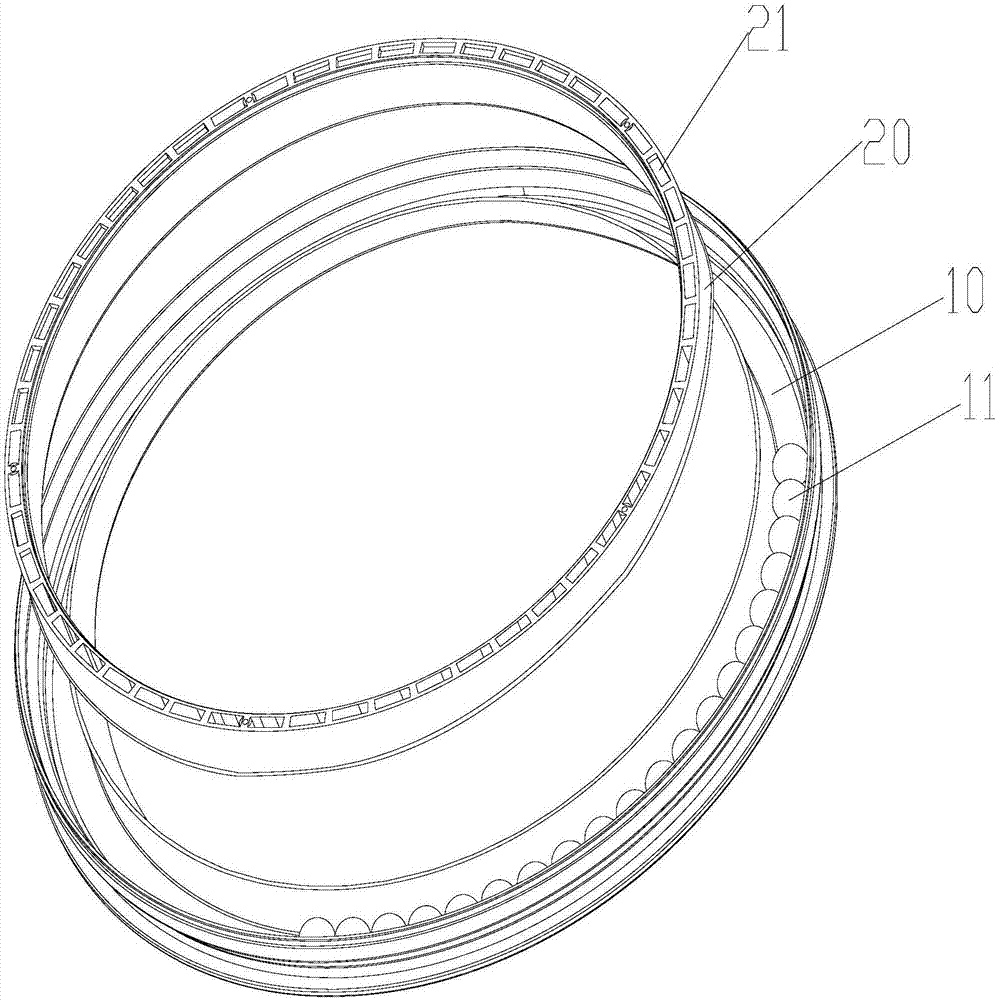

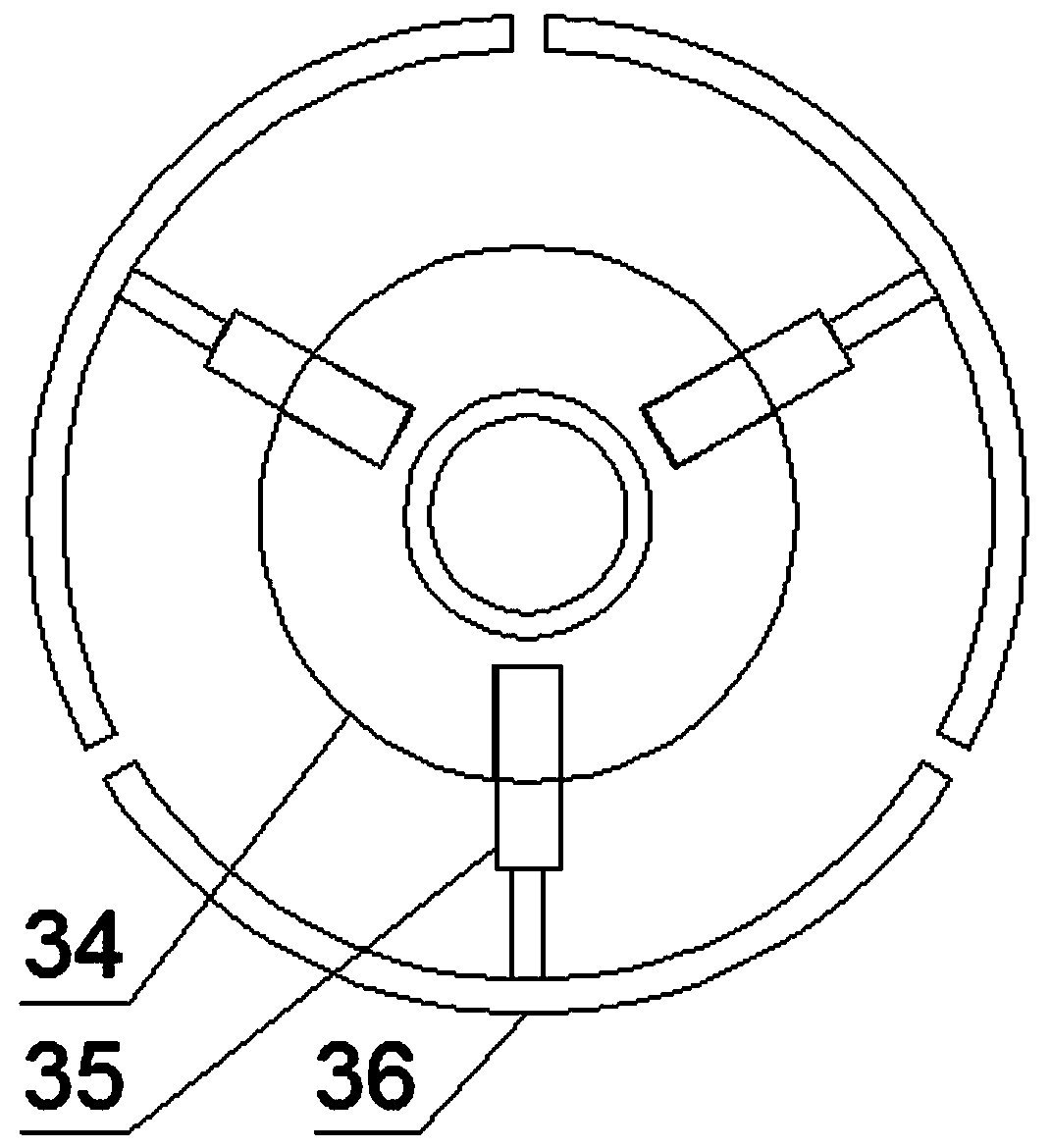

Balance ring, control method used for balance ring and washing machine

ActiveCN107034622AAchieve synchronous rotationGuaranteed stabilityOther washing machinesControl devices for washing apparatusEddy currentEngineering

The invention discloses a balance ring. The balance ring comprises an annular body; the body comprises a first annular cavity and a second annular cavity, a plurality of spheres made from non-magnetic materials are placed in the first annular cavity, and a plurality of magnetic blocks are placed in the second annular cavity. Magnetic induction lines of the magnetic blocks are cut when the spheres roll and generate magnetic eddy-current damping. According to the balance ring, the magnetic blocks are used for generating a magnetic field, the magnetic eddy-current damping generated by cutting the magnetic induction lines with the spheres is used for ensuring that the rotating speed of each sphere is close to that of a roller at the starting moment, the use of liquid is avoided, and the problem that liquid leakage occurs in the use process of the balance ring is thus avoided.

Owner:QINGDAO HAIER SMART TECH R & D CO LTD +1

Underground drainage pipeline repair system and repair method

The invention discloses an underground drainage pipeline repair system and repair method. The underground drainage pipeline repair system includes a first working mechanism on one side of an internalcollapse deformation of a drainage pipe to be repaired, a second working mechanism located on the other side, a third working body disposed between the first working body and the second working body,a monitoring mechanism and an auxiliary stabilizing mechanism arranged on the first working mechanism and the second working mechanism, a cutting mechanism respectively arranged on the right side of the first working mechanism and the left side of the second working mechanism, a quick-drying cement nozzle arranged on the cutting mechanism and the third working mechanism, and control mechanisms, the invention only needs to separate and cut the collapse deformation part of the drainage pipe, Then it is rotated to the side or bottom, and finally, the first dry cement nozzle and the second quick-drying cement nozzle are used for cement filling and repairing the cutting seam, the socket hole and the collapse deformation part, so that no new pipeline is needed for repairing, and the collapse part can be smoothly accessed in the complicated sewage pipe at the same time.

Owner:张桂华

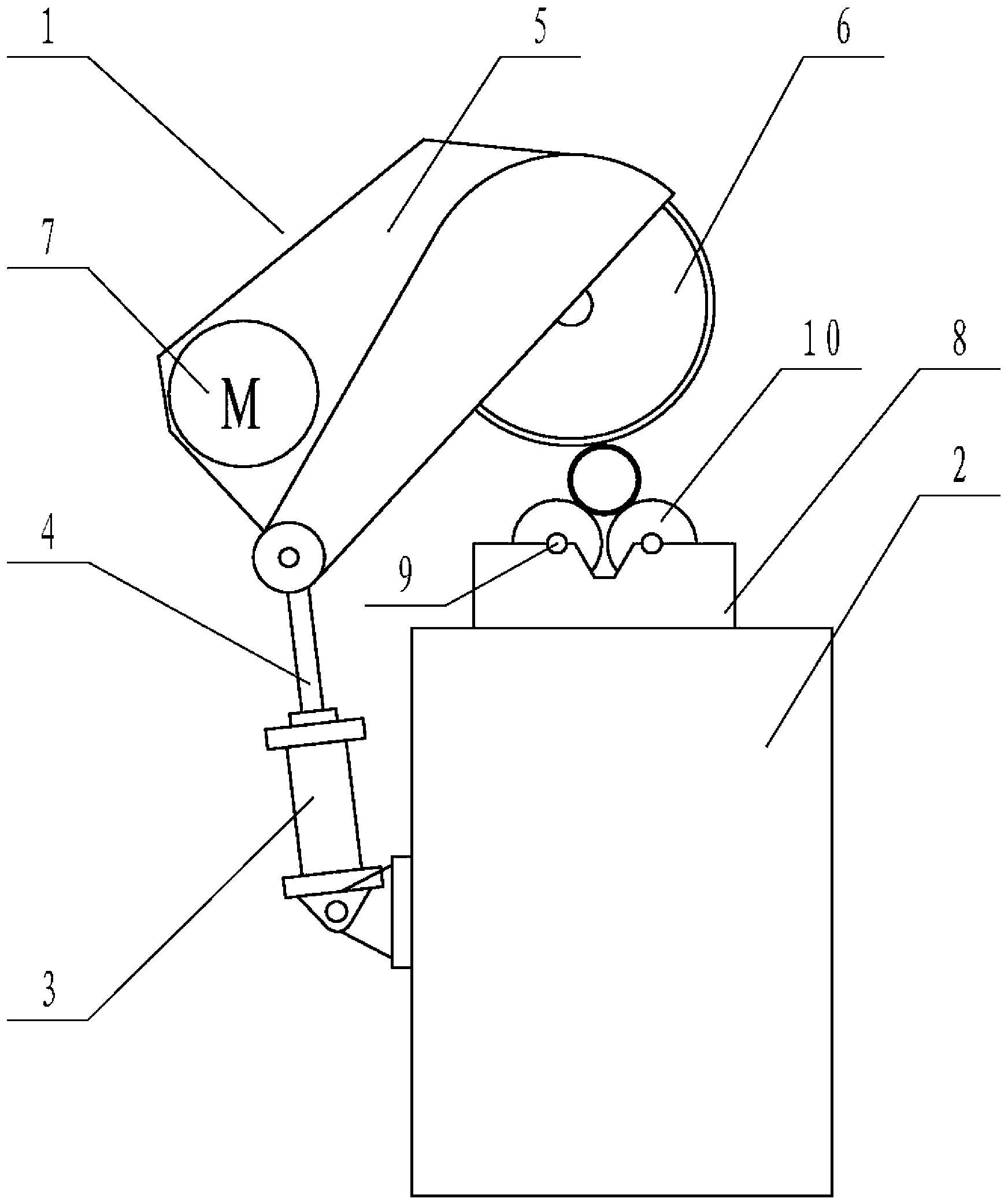

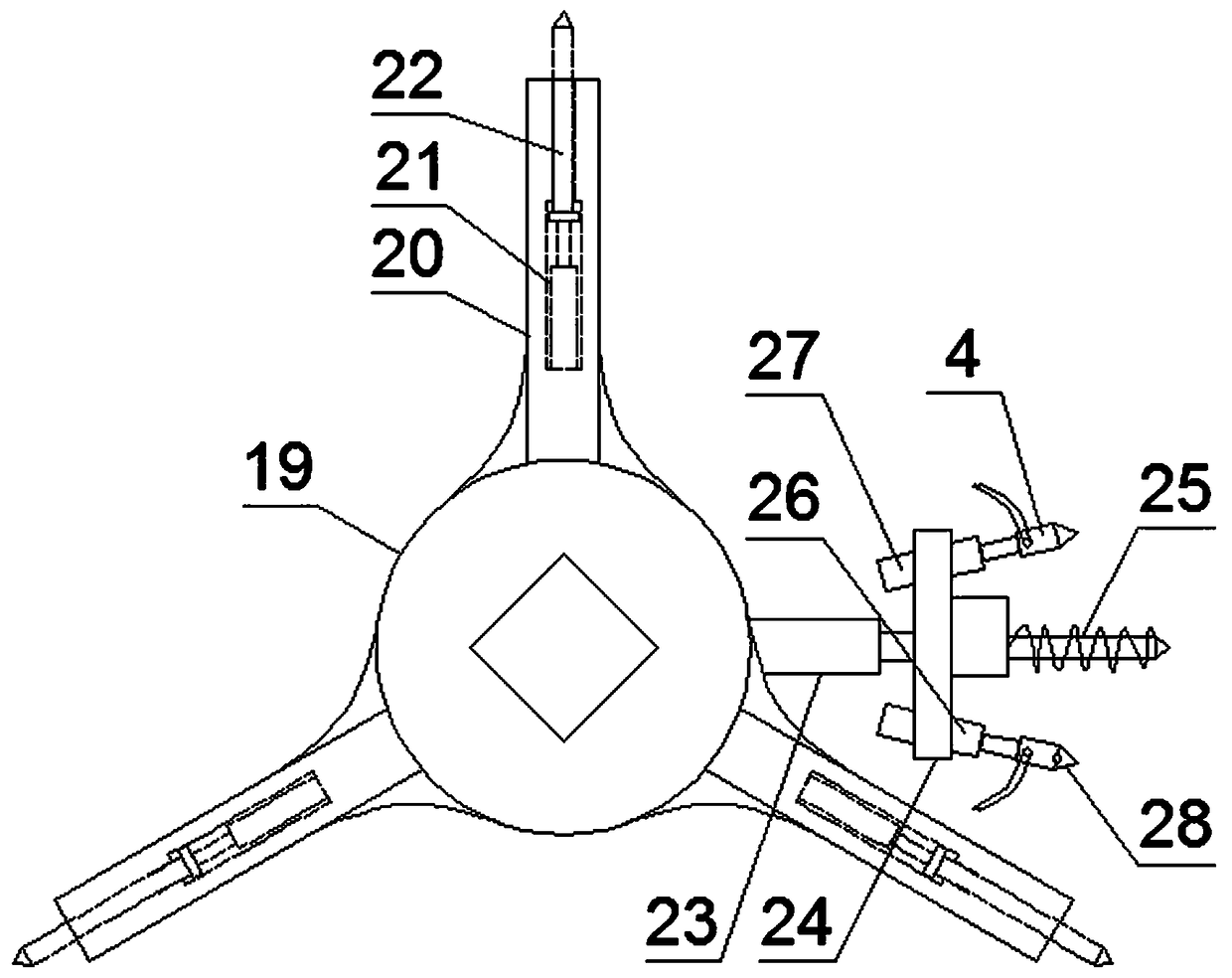

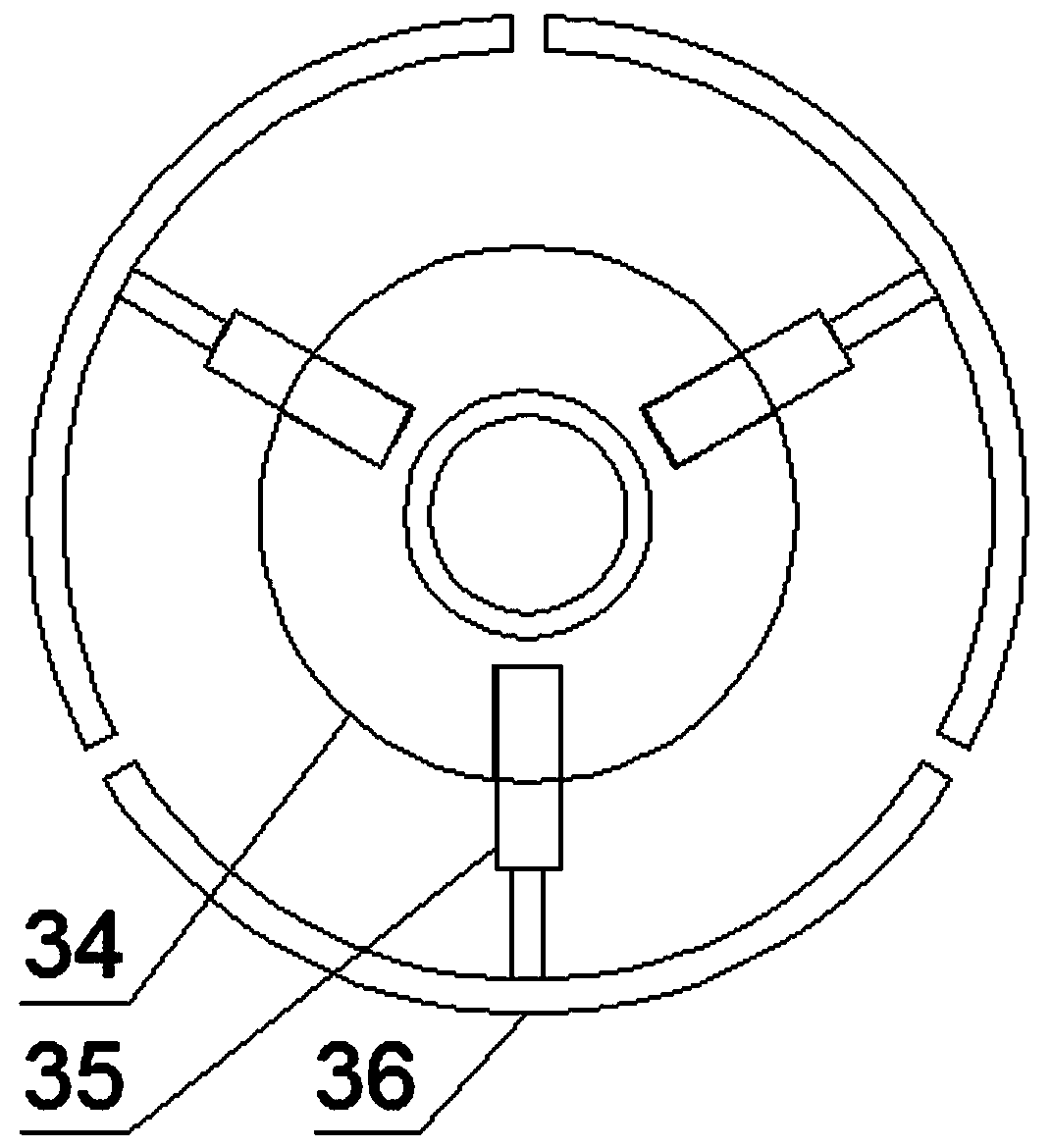

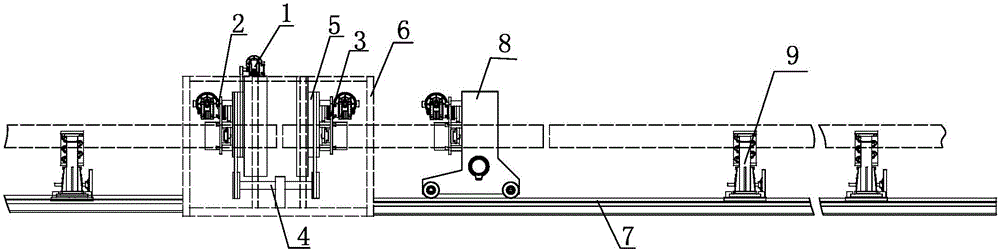

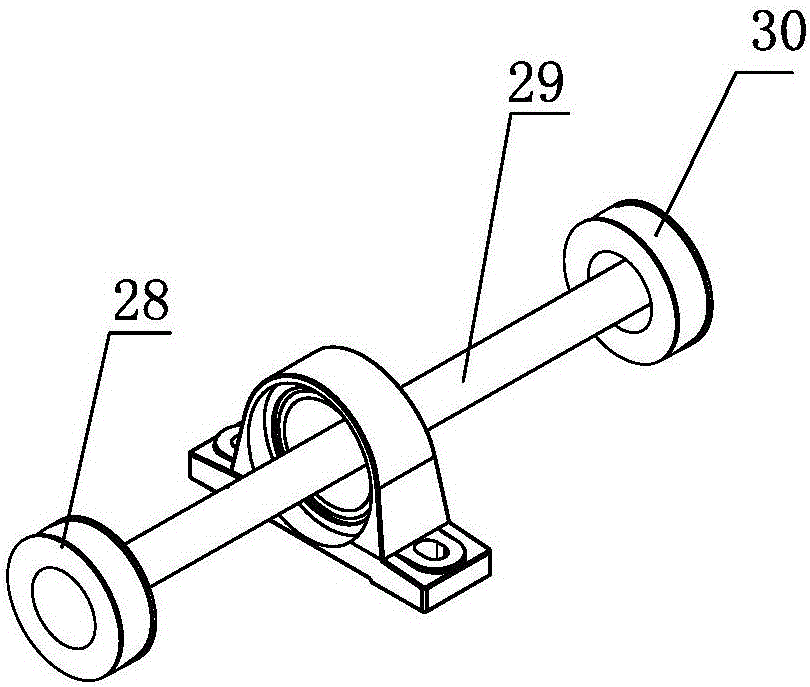

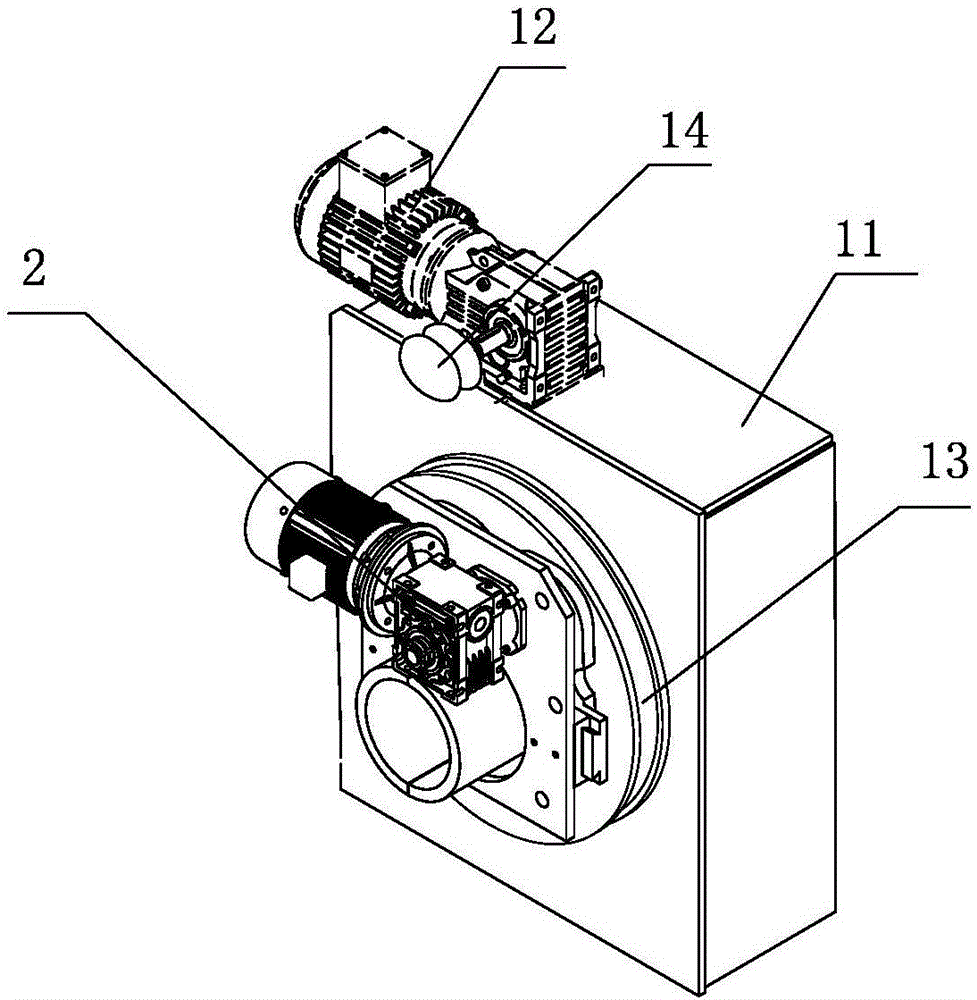

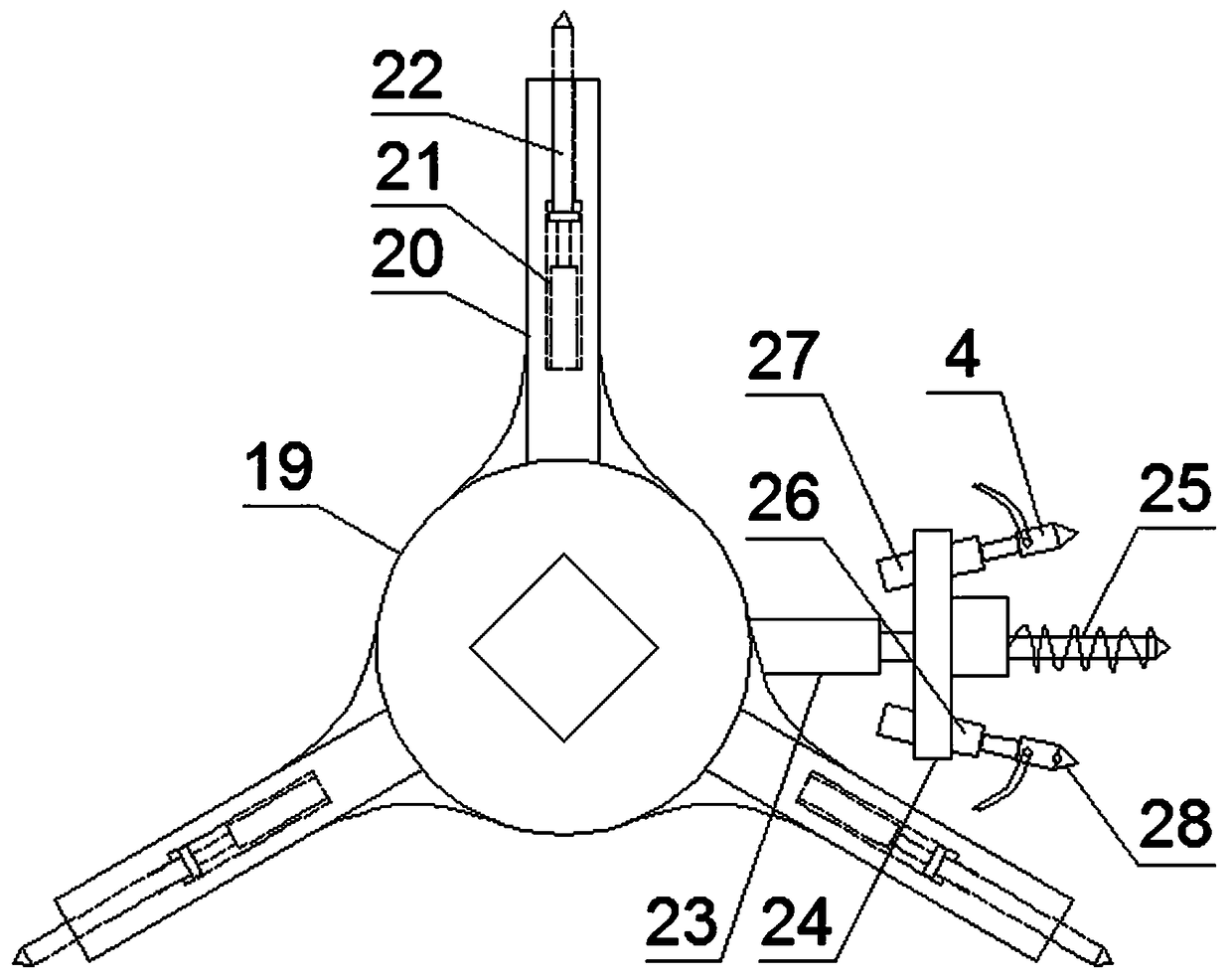

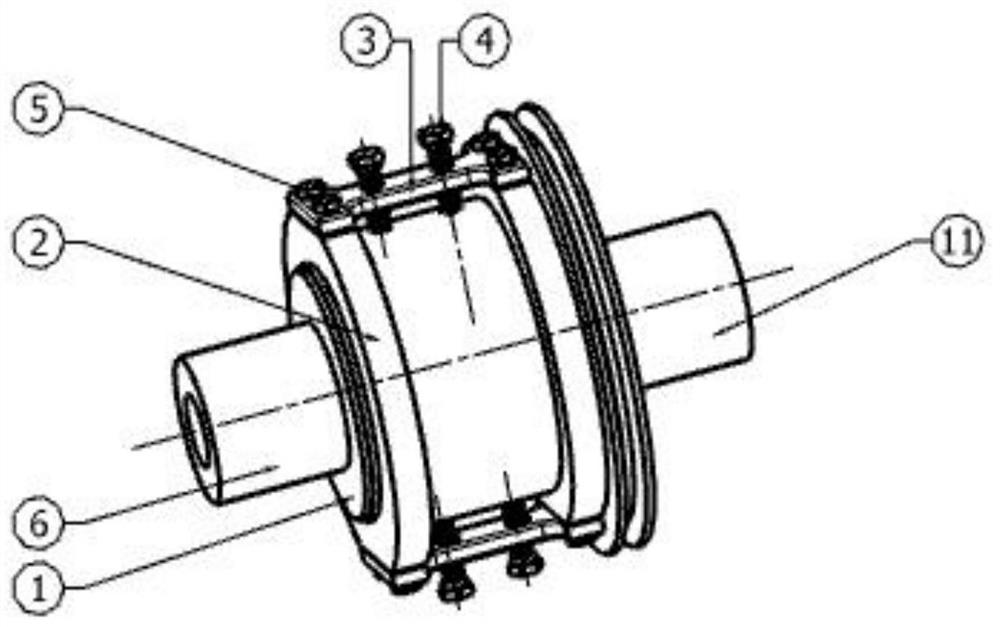

Fixed-distance conveying, rotating and clamping device for electric tower pipe

ActiveCN106392444AAchieve synchronous rotationEasy to moveWelding/cutting auxillary devicesAuxillary welding devicesTowerMechanical engineering

The invention aims at providing a fixed-distance conveying, rotating and clamping device for an electric tower pipe to achieve the technical purpose that multiple sections of tower pipe are conveyed successively in the welding process of the electric tower pipe, and the front section of tower pipe and the rear section of tower pipe are clamped and driven to be rotated and welded. The fixed-distance conveying and rotary clamping device comprises a rotating and clamping device, a fixed-distance moving device, lifting devices and a rail. The rotating and clamping device comprises a rotating power mechanism, clamping mechanisms, a synchronous rotating transmission mechanism, a rear clamping and rotating installation mechanism and a rotating fixing frame. The fixed-distance conveying, rotating and clamping device has the beneficial effects that the two sections of tower pipe needing to be welded are clamped through the clamping mechanisms, in the welding process of the tower pipe, synchronous rotating of the front section of tower pipe and the rear section of tower pipe can be achieved through the rotating power mechanism, the synchronous rotating transmission mechanism and the rear clamping and rotating installation mechanism.

Owner:JINAN CITY CHANGQING DISTRICT POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +1

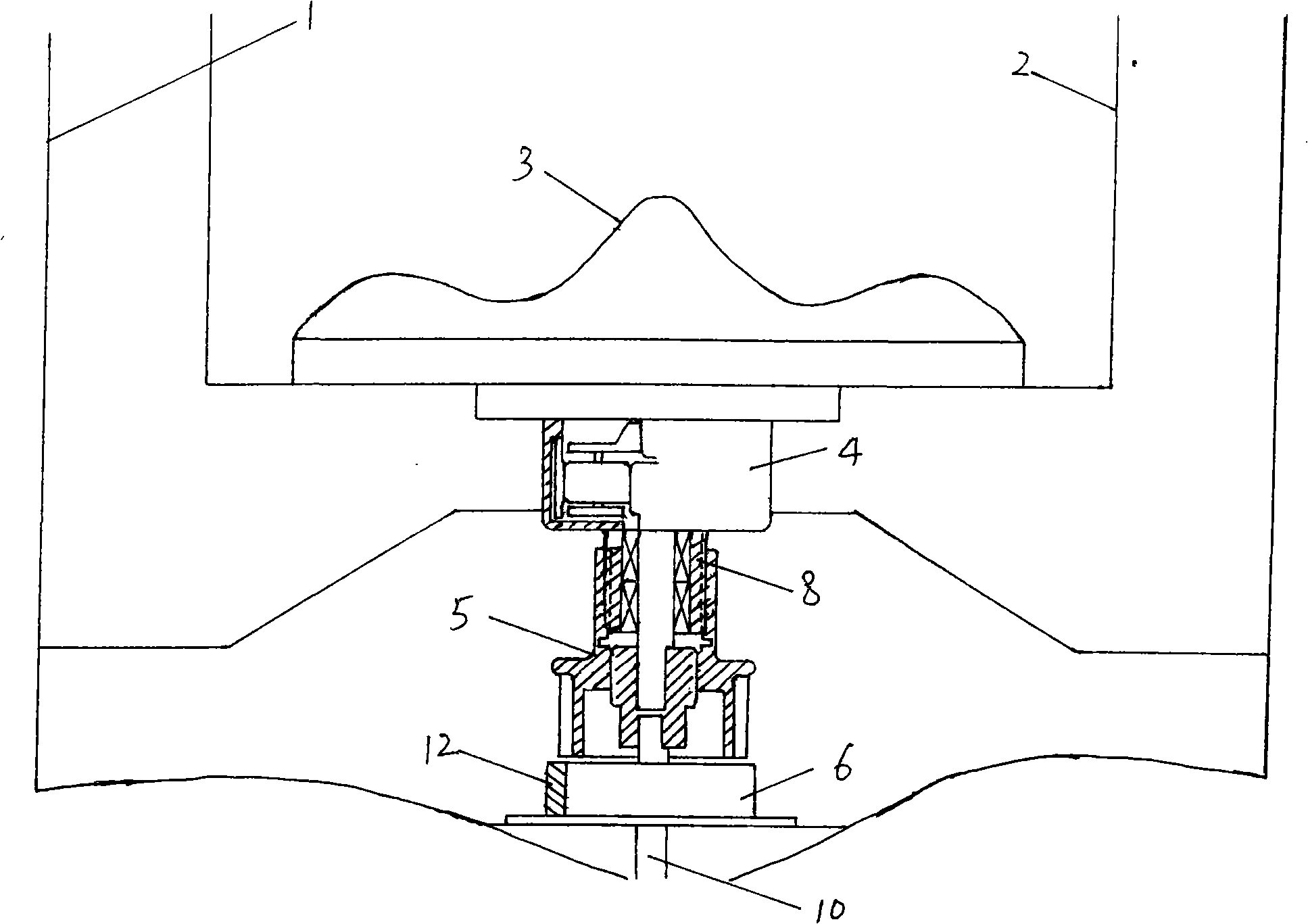

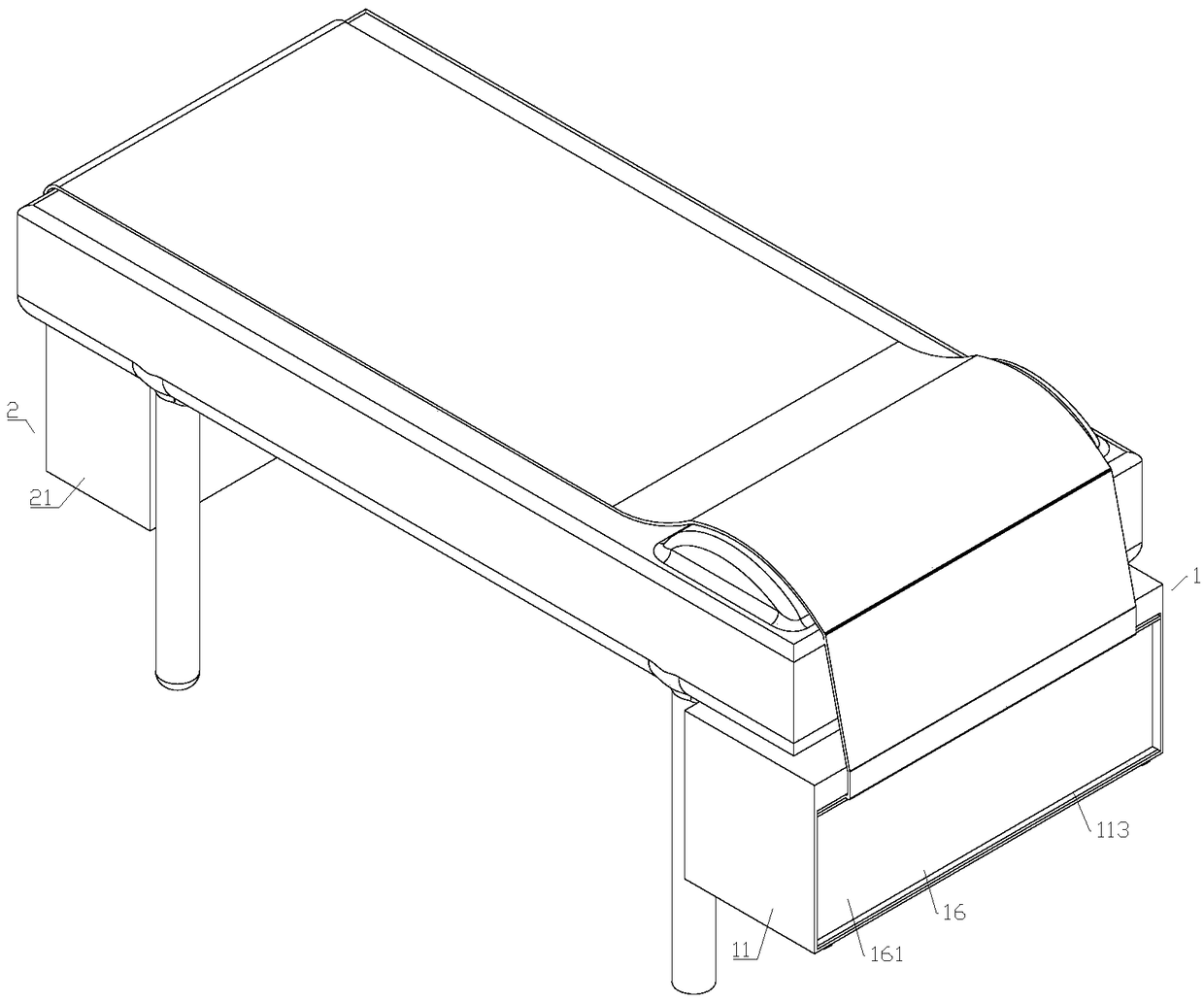

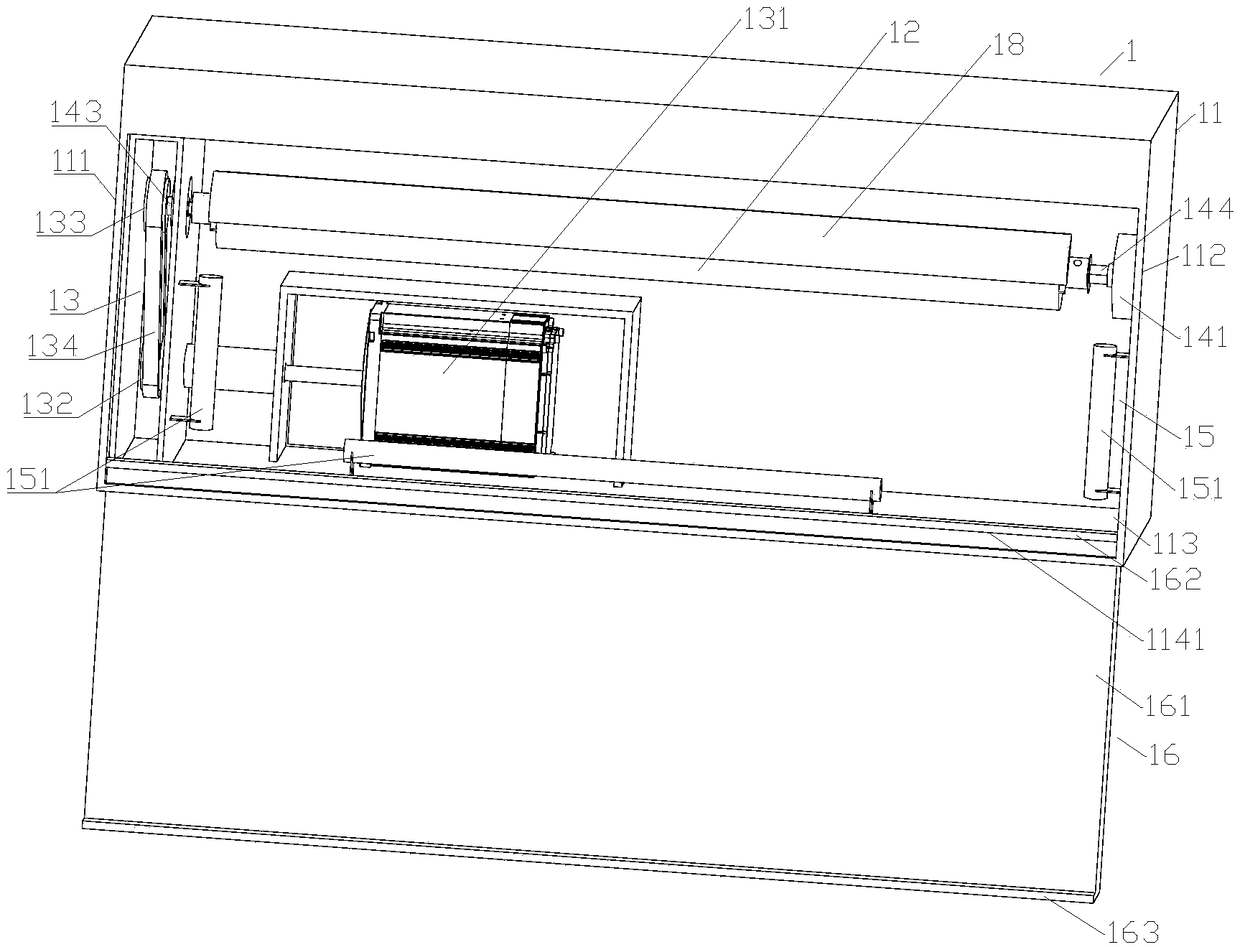

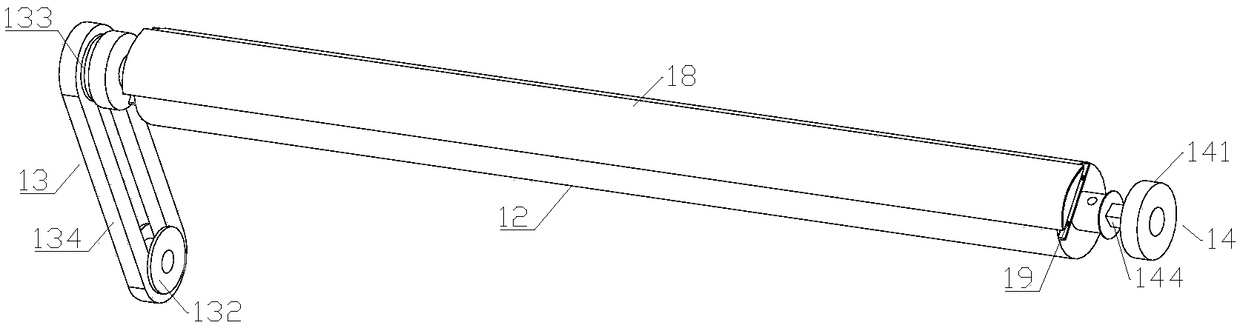

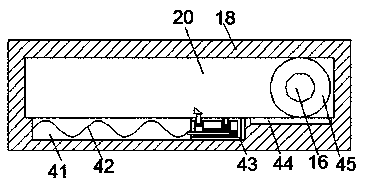

Bed sheet tidying robot for medical bed

ActiveCN109350403AEasy to operateEasy to install and replaceNursing bedsRadiationBed sheetsEngineering

The invention relates to a bed sheet tidying robot for a medical bed. The bed sheet tidying robot for the medical bed comprises a winding mechanism and an unwinding mechanism; the winding mechanism comprises a first box body and a first roll shaft which is positioned in the first box body; the unwinding mechanism comprises a second box body and a second roll shaft which is positioned in the secondbox body; and the first box body and the second box body are respectively fixed to the two ends of the medical bed. The bed sheet tidying robot for the medical bed has the beneficial effects that when the bed sheet tidying robot for the medical bed is used, a bed sheet can be wound on the first roll shaft or the second roll shaft directly, and then the bed sheet on the medical bed is replaced byrotating the first roll shaft or the second roll shaft; and the bed sheet tidying robot for the medical bed is easy and quick to operate.

Owner:鄂州市中心医院

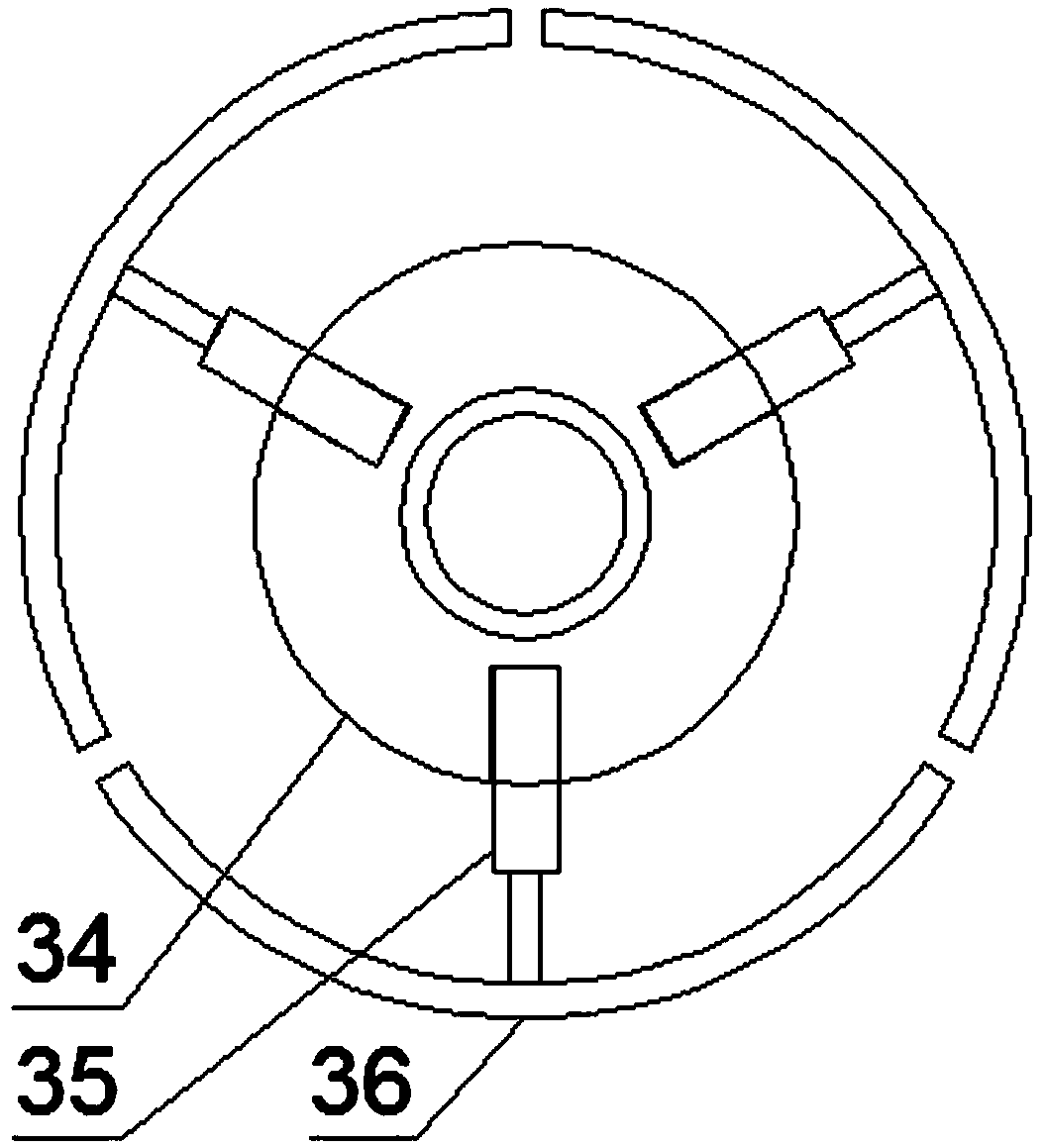

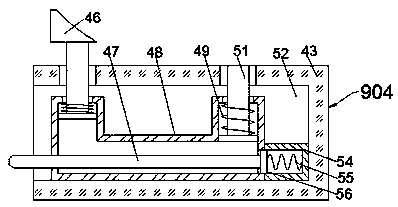

Fastening device for assisting in tightening three-jaw chuck on lathe

ActiveCN110802243AAchieve synchronous rotationRealize disconnect driveAuxillary equipmentMetal working apparatusStructural engineeringAnnular array

The invention discloses a fastening device for assisting in tightening a three-jaw chuck on a lathe. The fastening device comprises a right-angle hanging plate with a bolt hole, wherein an air cylinder is embedded in the horizontal end surface of the right-angle hanging plate; the lower end of the air cylinder is in power connection with a lifting rod; an arc-shaped track is arranged at the lowerend of the lifting rod; and a swinging assembly is arranged in the arc-shaped track. According to the fastening device disclosed by the invention, a plurality of groups of limiting rods which are clamped on double surfaces and are arrayed along the three-jaw chuck in an annular manner are utilized, and the limiting rods can be movably separated from abutting against an extension rod of the three-jaw chuck, so that synchronous rotation or disconnection transmission of the three-jaw chuck is controlled; the position change of oil liquid difference in a sealed pipeline is changed, so that the limiting capacity of rotation of a double-surface clamping structure part is realized, and the ordered working steps of the clamping structure part clamping-sliding out-releasing-sliding back along a circular rail are realized; and the whole process can be controlled by a program, and manual intervention is not needed, so that the problem that a workpiece is not completely fixed due to insufficient force is avoided, and the probability that workers are accidentally injured by a cutter is reduced.

Owner:江苏鑫品工业装备有限公司

Small-diameter underground pipeline non-excavation type repair equipment

InactiveCN109469096AAvoid environmental problemsImprove repair effectArtificial islandsFoundation repairRestoration deviceSpray nozzle

The invention discloses small-diameter underground pipeline non-excavation type repair equipment. The small-diameter underground pipeline non-excavation type repair equipment comprises a first workingmechanism and a second working mechanism which are separately positioned at the two sides of a collapsed and deformed part inside a to-be-repaired underground pipeline, a third working mechanism positioned between the two working mechanisms, a monitoring mechanism arranged on the first working mechanism and / or the second working mechanism, cutting mechanisms which are separately arranged at the right side of the first working mechanism and the left side of the second working mechanism, a first quick-drying cement spray nozzle arranged on the cutting mechanisms, a second quick-drying cement spray nozzle arranged on the third working mechanism, water retaining mechanisms which are separately arranged at the left side of the first working mechanism and the right side of the second working mechanism, and a control mechanism. One section, which is collapsed and deformed, of an underground pipeline only needs to separate and cut out, the collapsed and deformed part is rotated to the side surface or the bottom, and the first quick-drying cement spray nozzle and the second quick-drying cement spray nozzle are finally utilized to perform cement filling repair on a cutting seam, a jack andthe collapsed and deformed part, so that a novel pipeline is not required.

Owner:张桂华

Electric curtain rail with rail butt joint device

PendingCN114515096AImprove practicalityAchieve synchronous rotationCurtain suspension devicesCurtainsButt jointGear wheel

The invention discloses an electric curtain track with a track butt joint device, which comprises the track butt joint device, two ends of the track butt joint device are connected with curtain tracks, the track butt joint device comprises a track rotating device and a track connecting piece, one end of the track connecting piece is connected with the track rotating device, and the other end of the track connecting piece is connected with the curtain tracks. The curtain rails are rotatably connected through the rail butt joint devices. And by arranging the rail butt joint device, the curtain rails can rotate at any angle according to actual requirements. The stroke is adjusted through the clutch type gear, and synchronous rotation of the left curtain track and the right curtain track is achieved. The fixing buckles are arranged at the two ends of the sliding rail, the pulleys at the two ends of the curtain rail are fixed through the fixing buckles, and the problem of curtain light leakage caused by the fact that the pulleys move to drive the curtain to move is solved. By arranging the magnetic attraction pulleys, the magnetic attraction pulleys are attracted together through the magnetic attraction blocks after getting close to each other in the sliding rails, the situation that the magnetic attraction pulleys are bounced off due to collision is avoided, and it is guaranteed that the curtain is closed without light leakage.

Owner:佛山市启沃智能窗饰有限公司

3D track stereoscopic display type exhibition display screen

ActiveCN114087488AAchieve synchronous rotationEasy to watchStands/trestlesIdentification meansComputer graphics (images)Display device

The invention discloses a 3D track stereoscopic display type exhibition display screen which comprises a base and a top cover, a first profile steel frame and a second profile steel frame are welded to the positions of the corresponding edge side edges of the base and the top cover correspondingly, and the first profile steel frame and the second profile steel frame are fixed through two arc-shaped profile steel frames. An up-down driving rotating mechanism is arranged at the top of the base. According to the 3D track stereoscopic display type exhibition display screen, the display mechanism is arranged, and the display mechanism comprises a driving motor, a driving shaft, a threaded sleeve, a second triangular claw disc, a connecting shaft, a second connecting rod, a sliding groove, a first connecting rod, a T-shaped metal plate steel plate, a shaft avoiding groove, a square clamping groove, a pin shaft and a linkage block; synchronous rotation of the three displays can be achieved, viewers at all angles can conveniently watch displayed content, the distance between the displays and the viewers can be increased through the stretching mode in the mechanism, and the watching effect is improved.

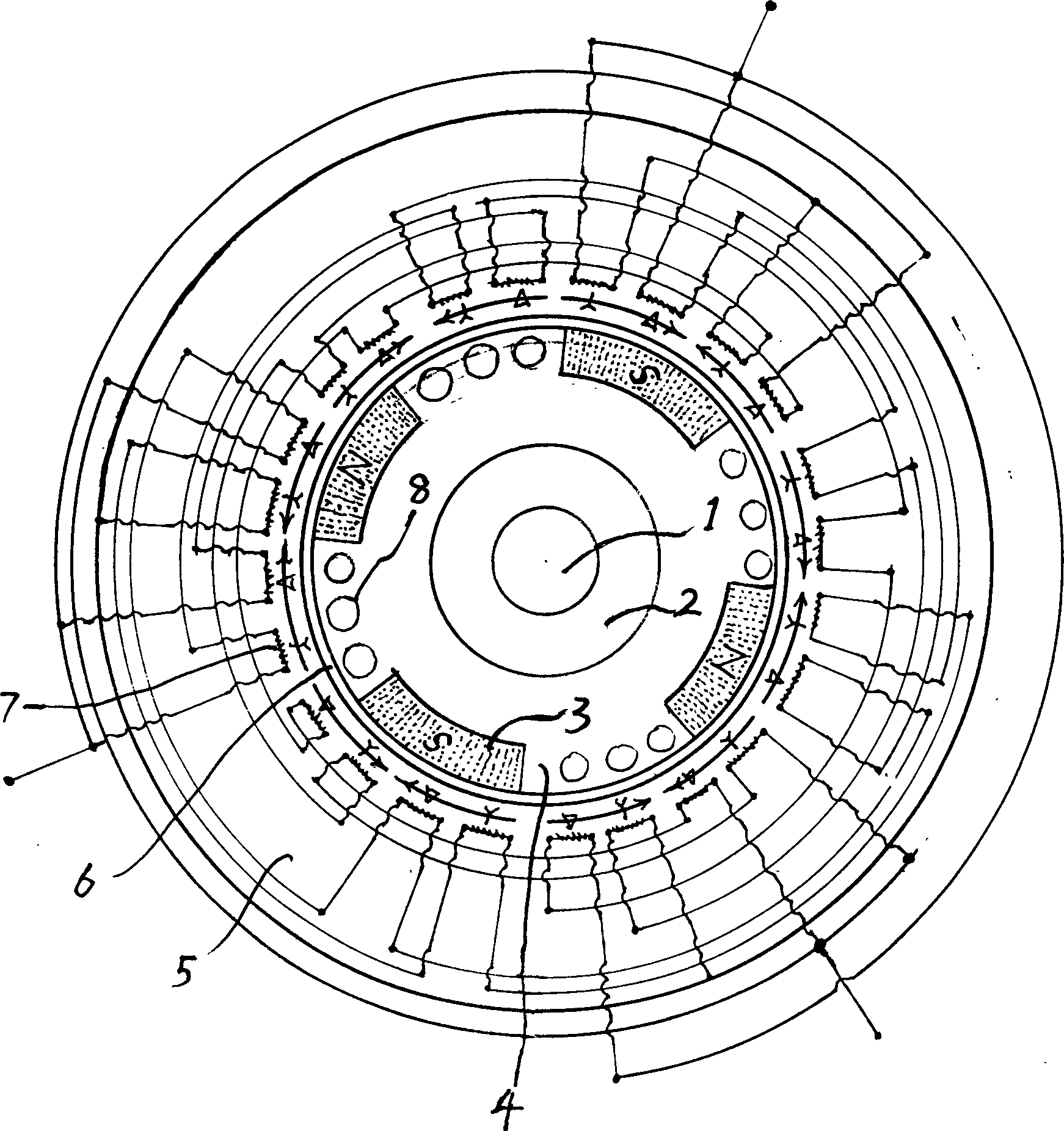

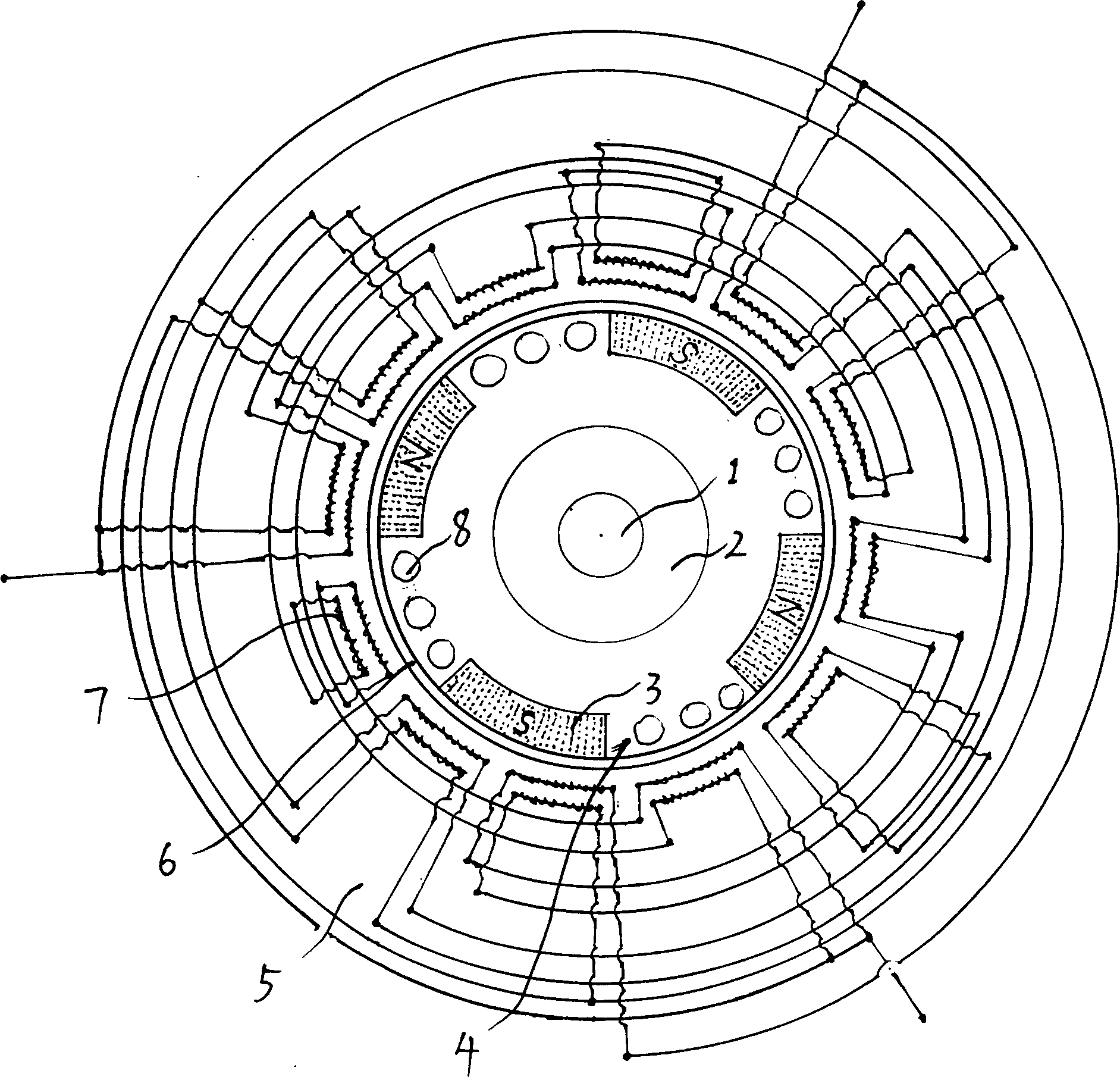

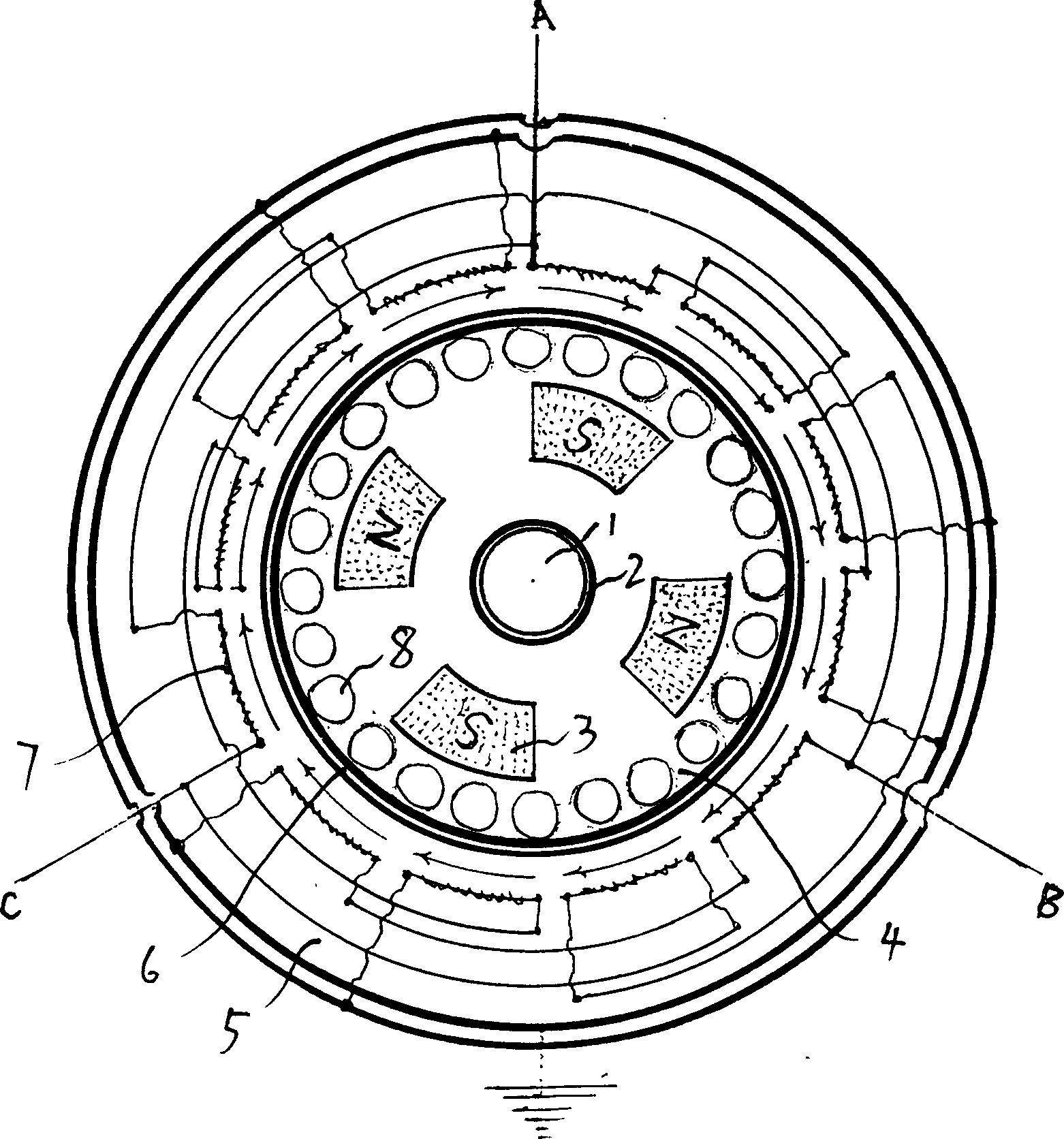

Three phase AC permanent magnet synchronous motor

InactiveCN1458734AImprove startupAchieve synchronous rotationMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsPhysicsMagnetic flux

This invention discloses an improved three-phase AC permasyn motor, the stator winding of which can be extended-delta or star-delta connection mode, the wiring pattern can be single-double lap winding or single-double layer lap concentric winding mode. The said winding of the extened-delta lags behind the star winding by 30 deg. space electric angle when arrayed in the stator slot; and the star winding of stan-delta lags behind the delta winding by 30 deg. when arrayed in the stator slot. Tilt of the stator lamination slot is 1:1.25-1.45, magnetic flux density generated by the permament magnet in the rotor should be 3 times that of stator electromagnetic iron, the total sectional area of the conductive metal strips is designed as 7 times that of the machine rated current conductive, and metal strip numbers are 0.83-0.92 that of the stator core slots.

Owner:刘硕成 +1

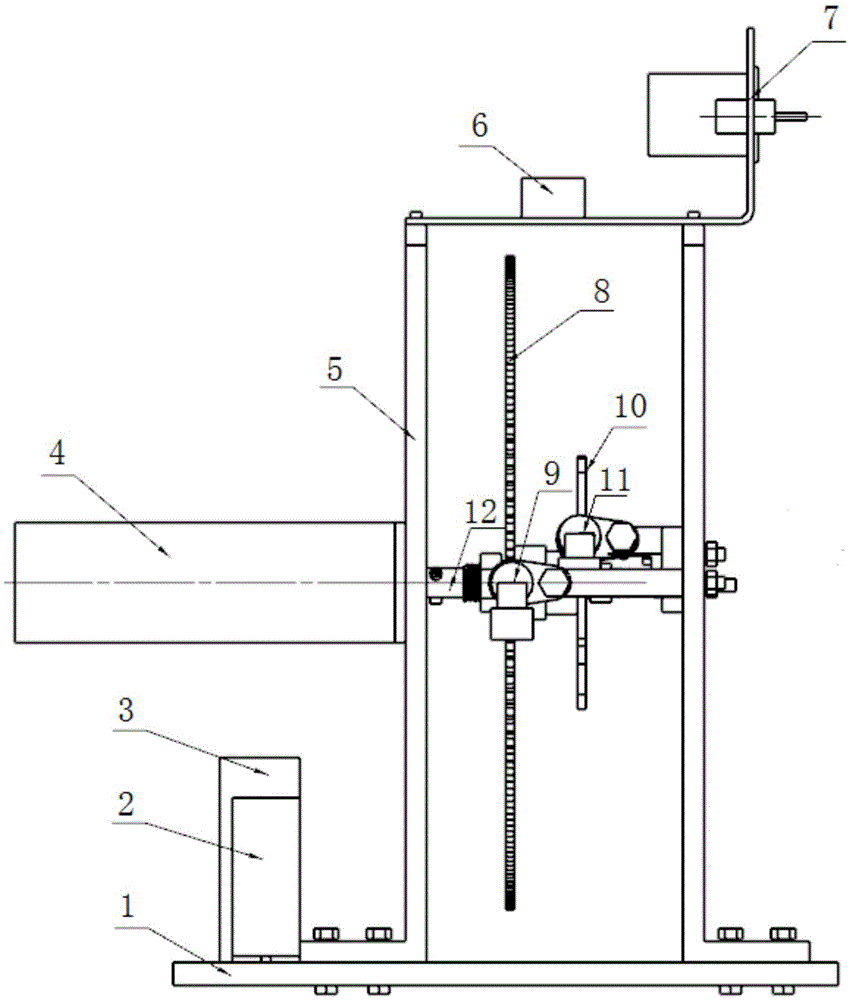

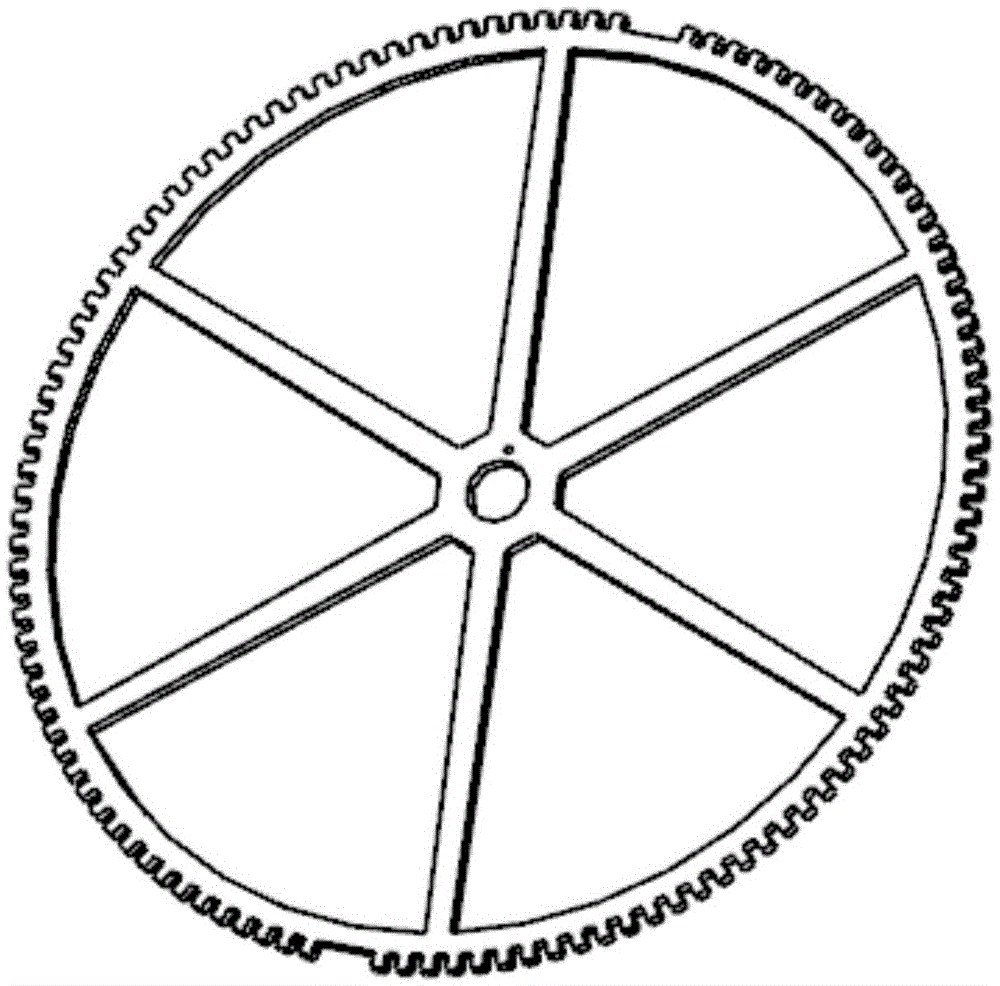

Shaft transmission-based engine rotation speed signal simulation system

ActiveCN105573146AAchieve synchronous rotationHigh precisionSimulator controlDrive shaftControl theory

The invention relates to a shaft transmission-based engine rotation speed signal simulation system, which comprises a mounting seat, and a driving mechanism, a crankshaft signal disk, a camshaft signal disk, a crankshaft rotation speed sensor and a camshaft rotation speed sensor arranged on the mounting seat, wherein the crankshaft rotation speed sensor and the camshaft rotation speed sensor are arranged on side surfaces of the camshaft signal disk and the crankshaft signal disk correspondingly. The system also comprises a transmission shaft. The driving mechanism is connected with the transmission shaft; both the crankshaft signal disk and the camshaft signal disk sleeve the transmission shaft and are fixedly connected with the transmission shaft respectively; the driving mechanism drives the transmission shaft to rotate to further drive the crankshaft signal disk and the camshaft signal disk to rotate synchronously; and the crankshaft rotation speed sensor and the camshaft rotation speed sensor detect rotation speed signals of the crankshaft signal disk and the camshaft signal disk respectively. Compared with the prior art, the shaft transmission-based engine rotation speed signal simulation system has the advantages that the structure is simple; the precision is high; the simulation result is closer to an actual condition and the like.

Owner:SHANGHAI UNIV OF ENG SCI

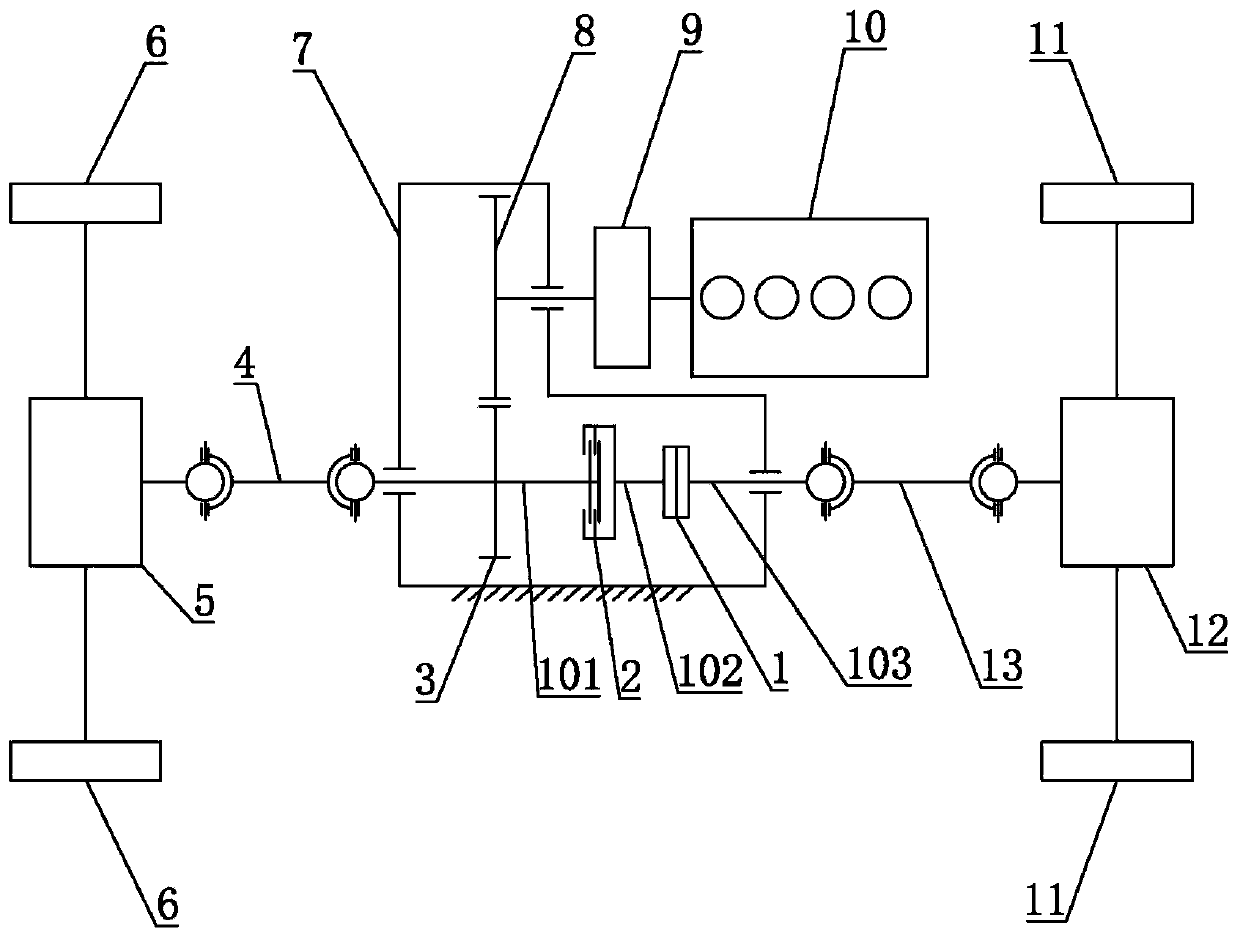

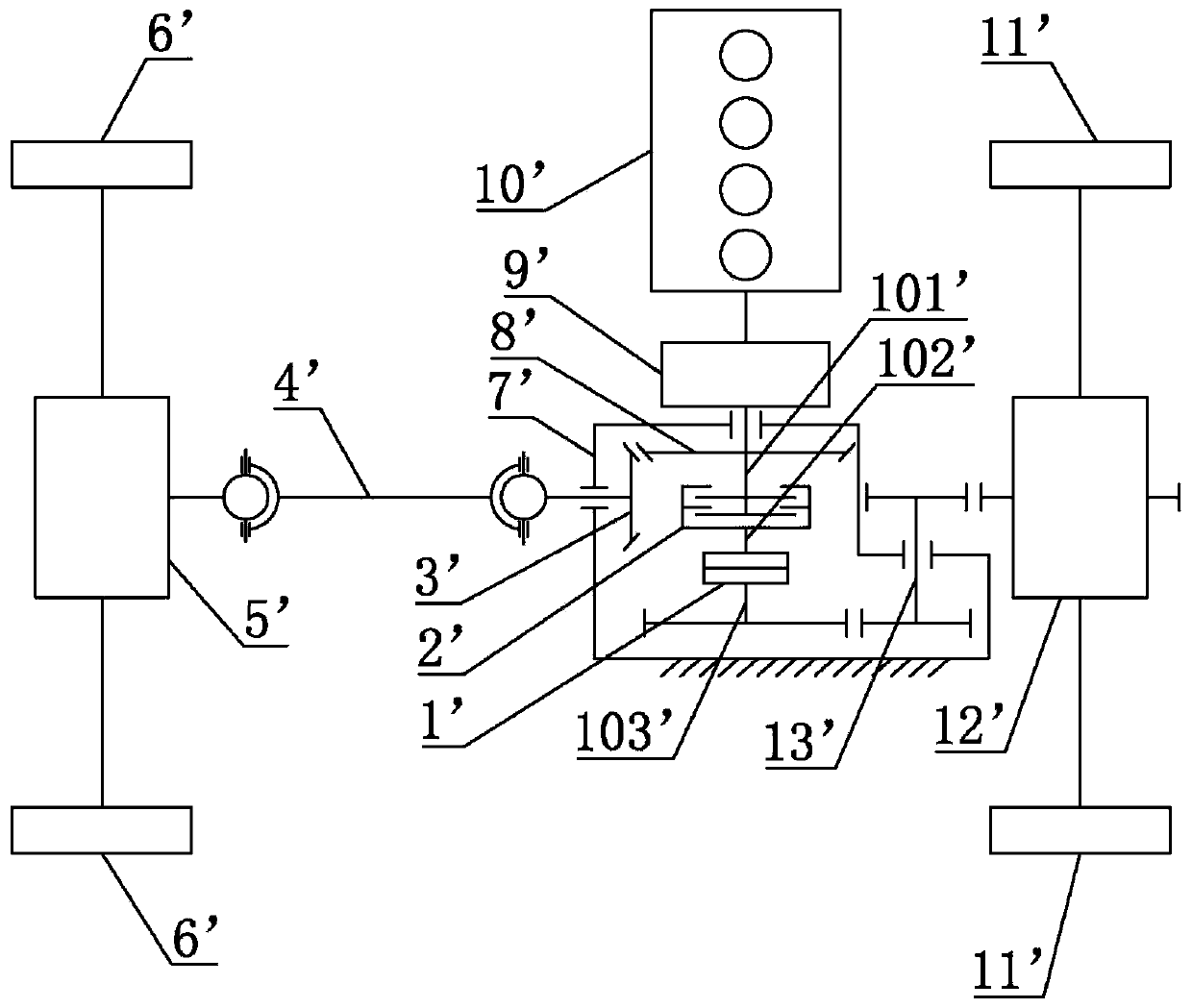

Central slip-limiting differential device, driving system comprising same, and application

ActiveCN110053476AMeet the needs of rotating at different speedsRealize the need for rotationControl devicesTwo-wheel drivePower output

The invention discloses a central slip-limiting differential device, which comprises a power input shaft, a clutch, an intermediate transmission device, a ratchet assembly and a power output shaft. The clutch comprises a driving part and a driven part capable of being detached and engaged, and the power input shaft is provided with the driving part to be connected with a power mechanism and drivethe driving part to rotate; the ratchet assembly comprises a part A and a part B which are matched with each other, and the driven part of the clutch is connected with the part A of the ratchet assembly through the intermediate transmission device; the part B of the ratchet assembly is mounted on the power output shaft, and the rotating speed of the part B is not smaller than the rotating speed ofthe part A; and a ratchet or a pawl is adopted as the part A, and a pawl or a ratchet matched with the part A is adopted as the part B. Through cooperation of the clutch and the ratchet assembly, thepart A and the part B can rotate synchronously or asynchronously, different using occasions are met, and thus a four-wheel automobile can be switched to adopt a two-wheel drive mode or a four-wheel drive mode.

Owner:青岛鲜佰客食品科技有限公司

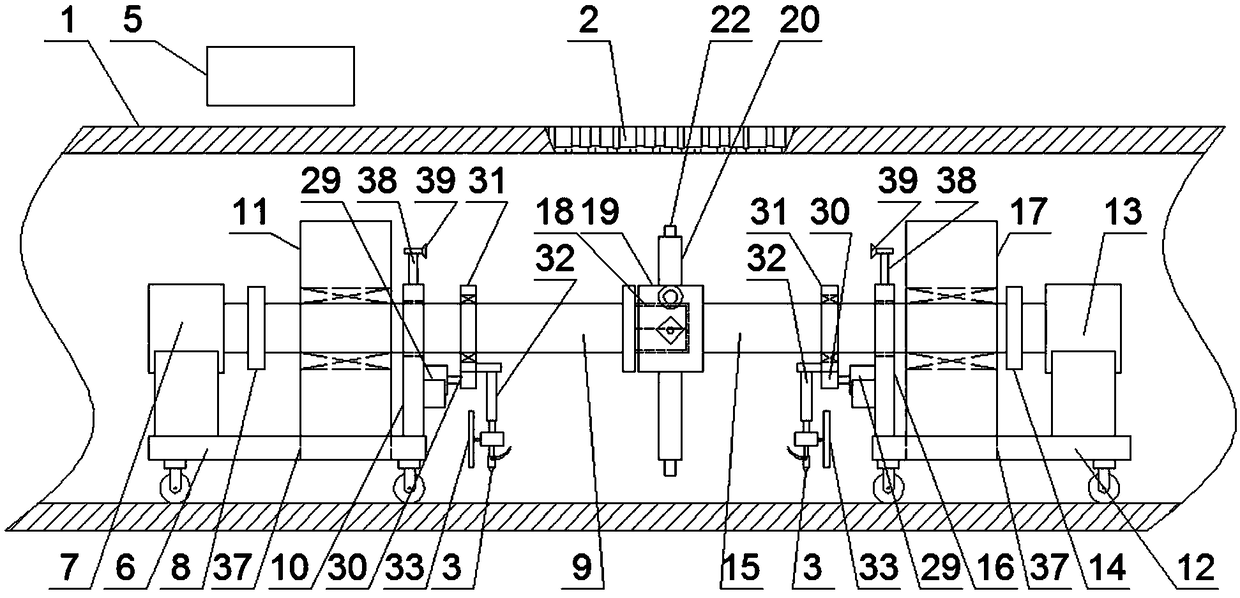

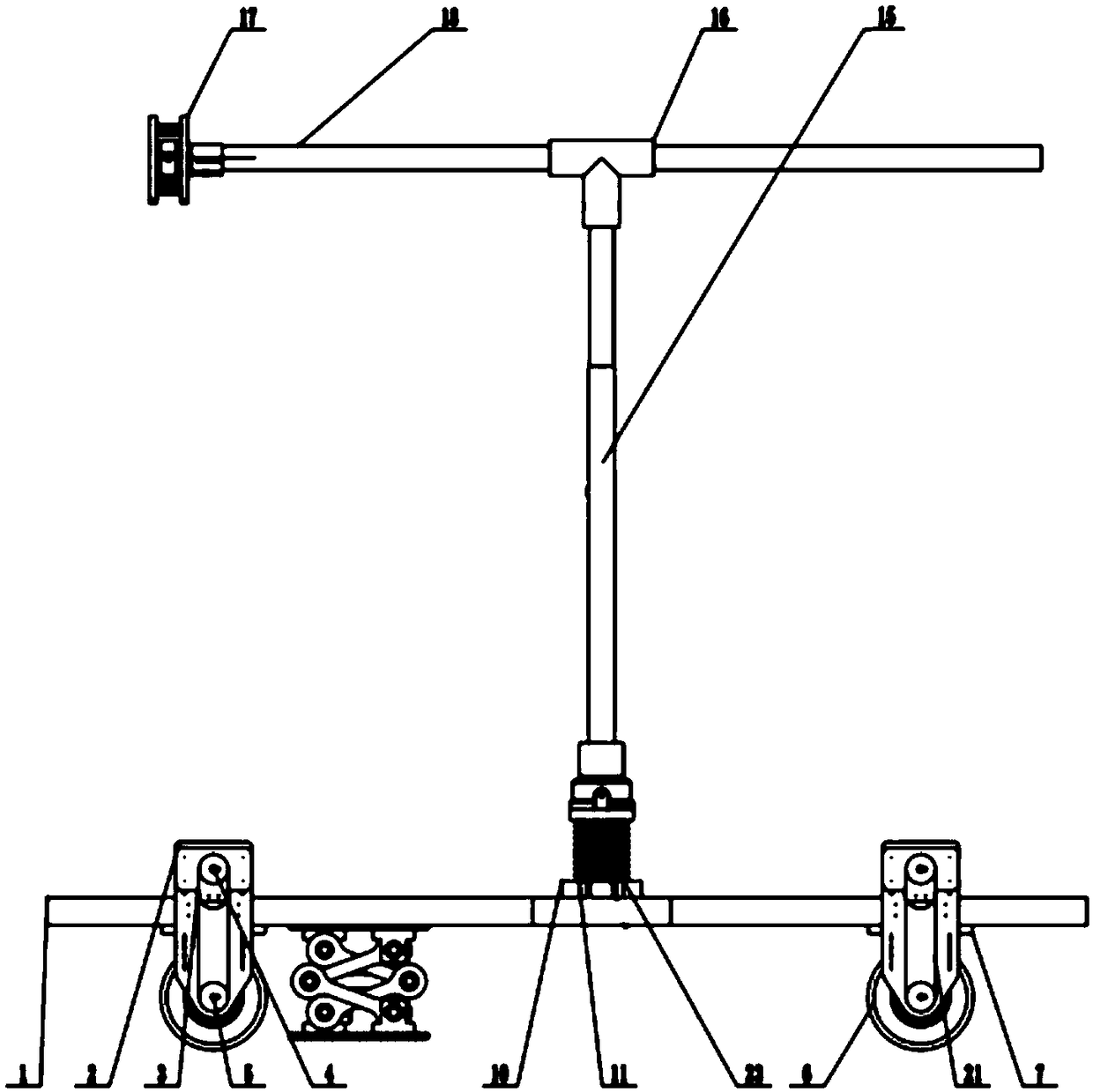

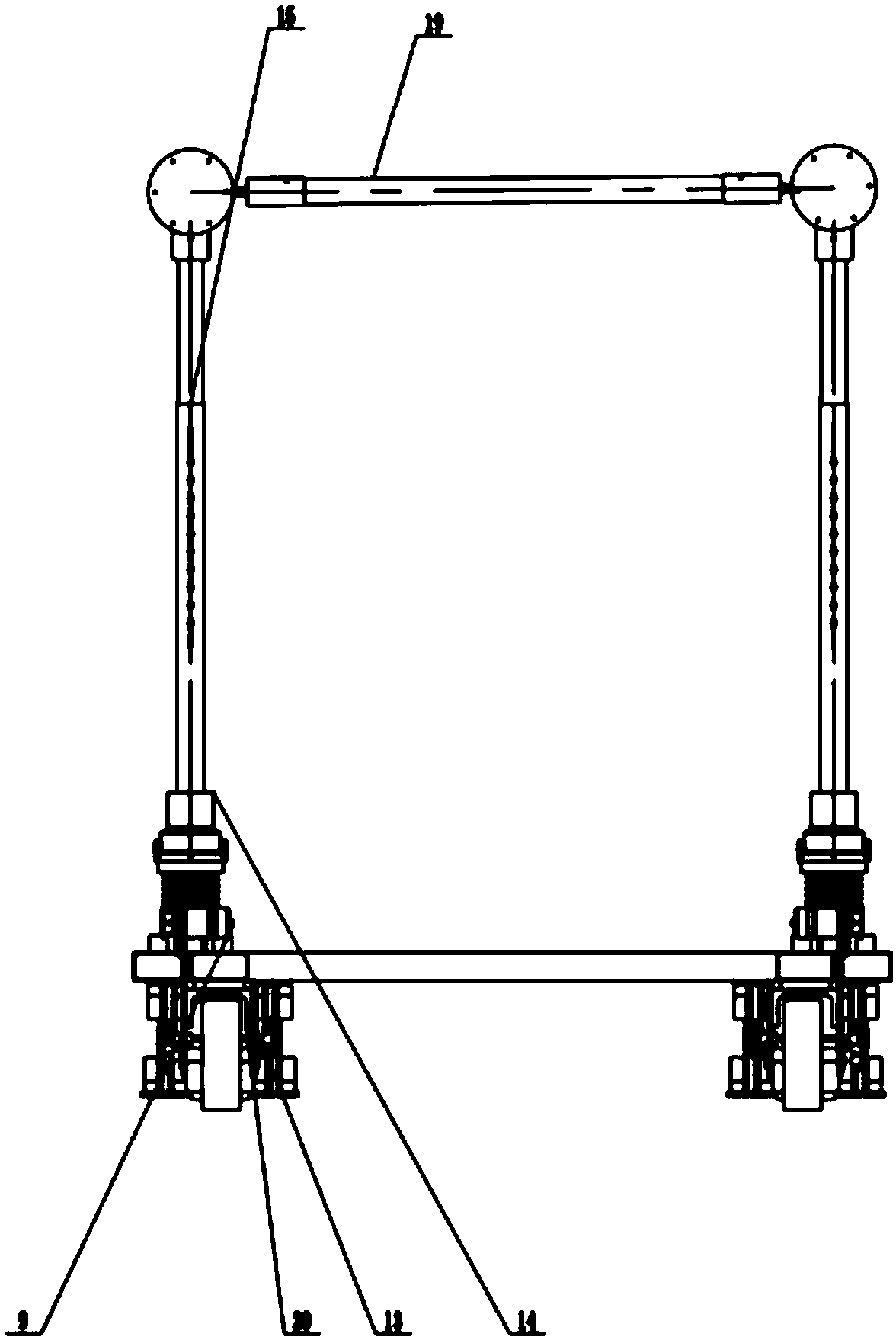

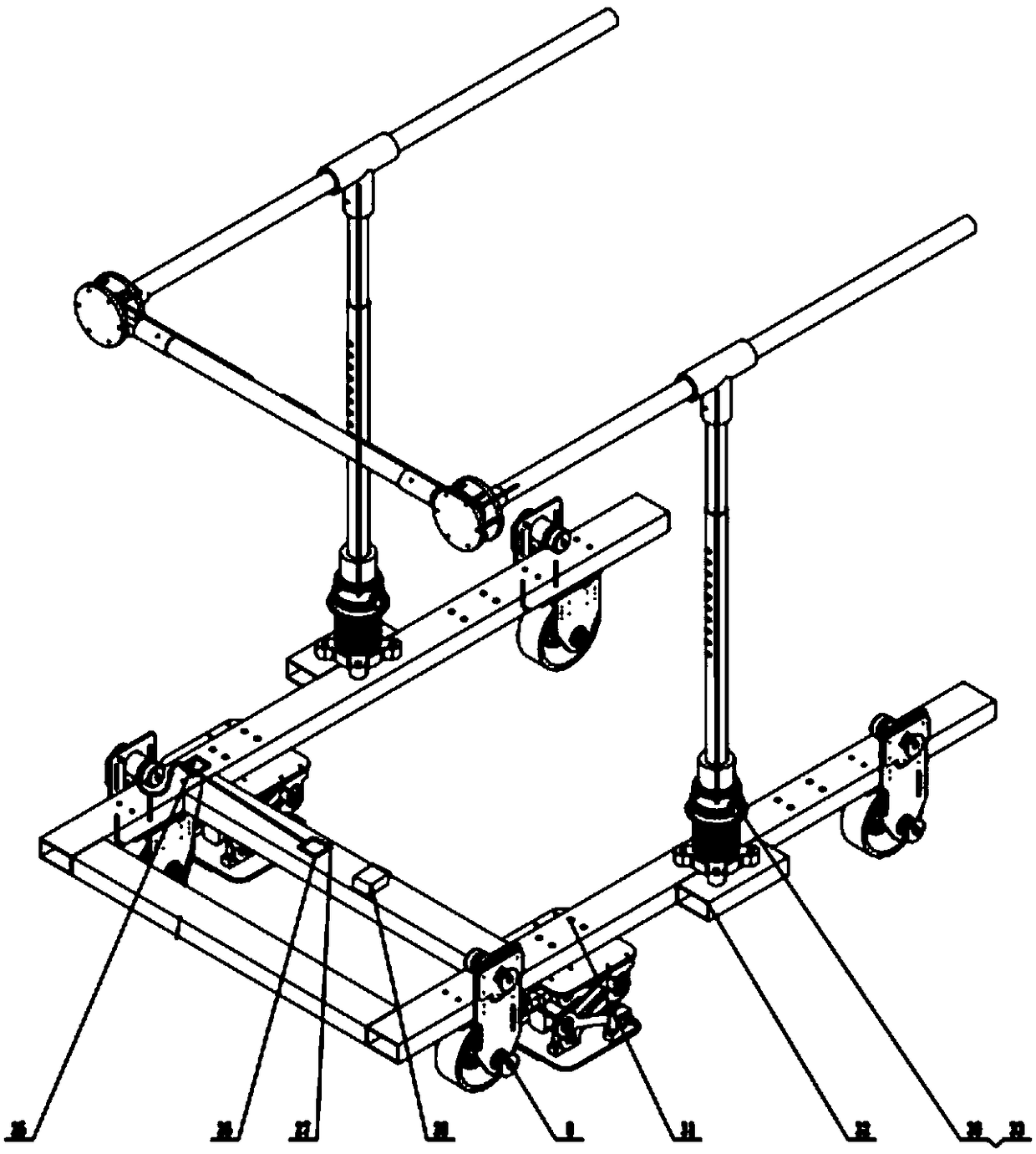

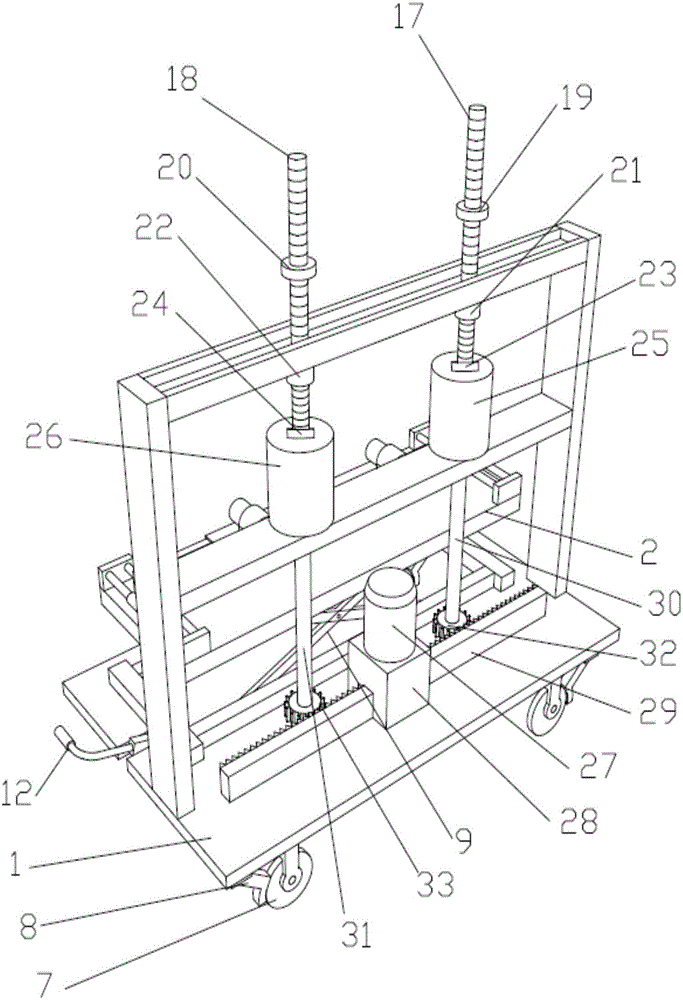

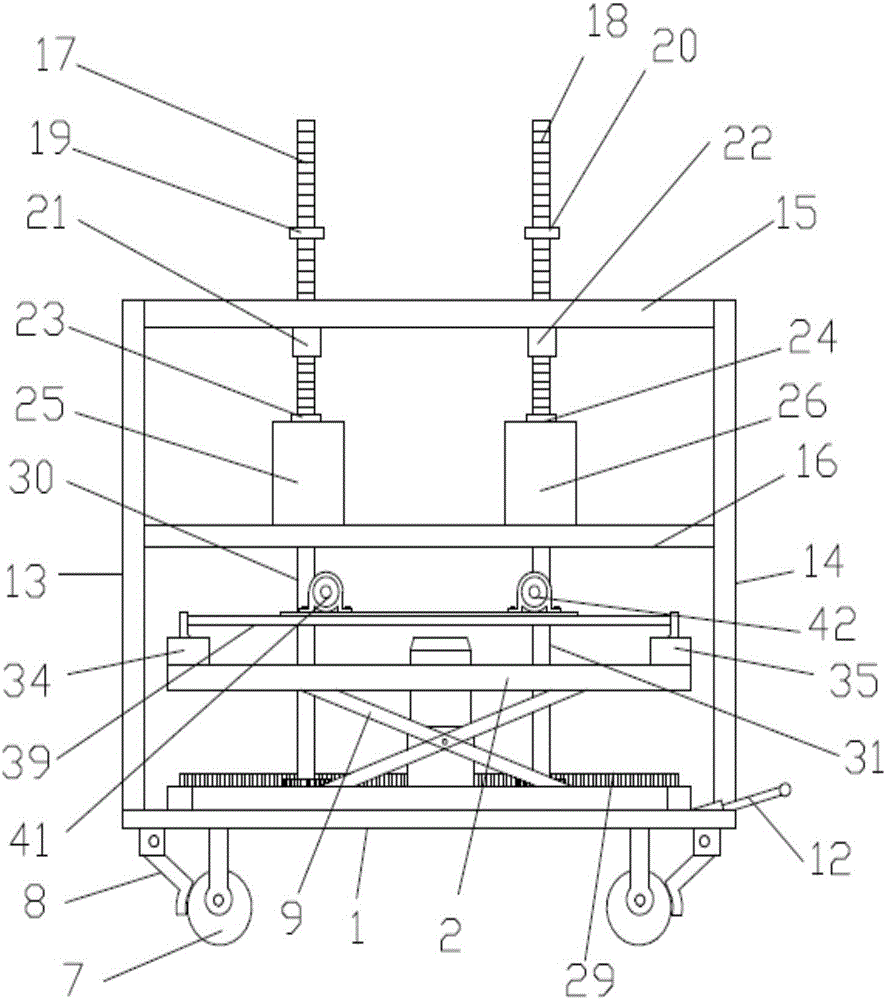

Anti-tumble all-directional walking ability rehabilitation device and working method thereof

The invention belongs to the field of rehabilitation equipment and particularly relates to an anti-tumble all-directional walking ability rehabilitation device and a working method thereof. Accordingto the technical scheme, the anti-tumble all-directional walking ability rehabilitation device comprises an all-directional chassis, all-directional wheel sets, a frame supporting mechanism, damping swing mechanisms, driving motors, a battery and a control system. The all-directional chassis is of a three-face semi-surrounding structure, the four all-directional wheel sets are arranged below the lower face of the all-directional chassis, and the frame supporting mechanism is installed on the upper surface of the all-directional chassis through the two damping swing mechanisms; the four drivingmotors are used for driving the four all-directional wheel sets to move, the battery provides energy for the device, and the control system is used for operating and controlling the device. Accordingto the anti-tumble all-directional walking ability rehabilitation device and the working method thereof, the walking ability with the controllable speed during all-directional movement can be trained, the training distance and effect are monitored in real time, the stopping function under the abnormal state is guaranteed, and continuous, controllable and safe training is achieved.

Owner:NORTHEASTERN UNIV

Carving machine applied to woodwork processing

PendingCN107521272ASolving Engraving ProblemsSimple structureOther artistic work equipmentsModel makingEconomic benefitsWorkbench

The invention discloses a carving machine applied to woodwork processing. The carving machine comprises a base, a workbench and a supporting frame. The workbench is located on the front side of the base, the supporting frame is located on the rear side of the base, an air cylinder lifting device is arranged between the base and the workbench, a carving device is arranged on the workbench and comprises a slide bar assembly and a transmission assembly, the transmission assembly comprises transmission motors and a transmission plate, the transmission motors include the first transmission motor and the second transmission motor, the first transmission motor is mounted on the left side of the transmission plate, the second transmission motor is mounted on the right side of the transmission plate, a positioning tool is arranged on the first transmission motor, a cutting tool is arranged on the second transmission motor, a rotating device is arranged on the lower portion of the supporting frame, and a fixing and adjusting device is arranged on the supporting frame. The machine is simple in structure, scientific, convenient, high in pertinence, high in automation degree, high in practicability, low in manufacturing cost and remarkable in economic benefit, and carving applied to woodwork processing is well achieved.

Owner:HANGZHOU DIANZI UNIV

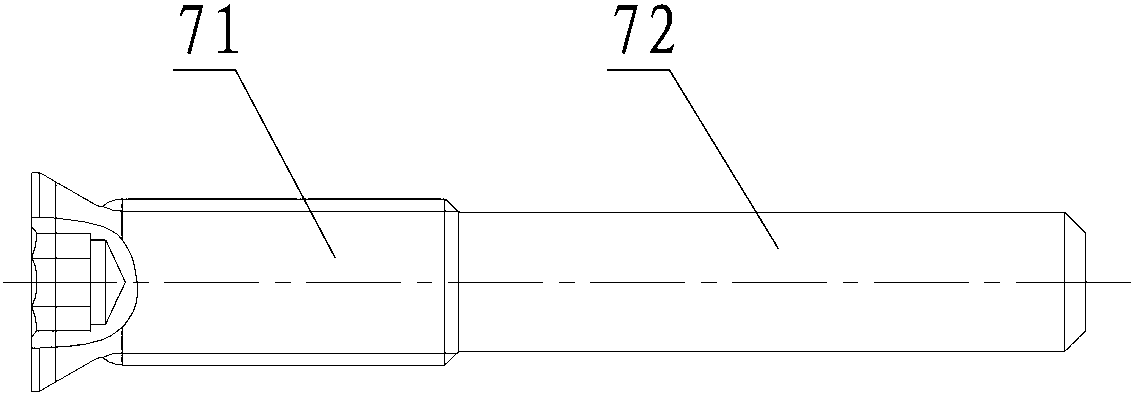

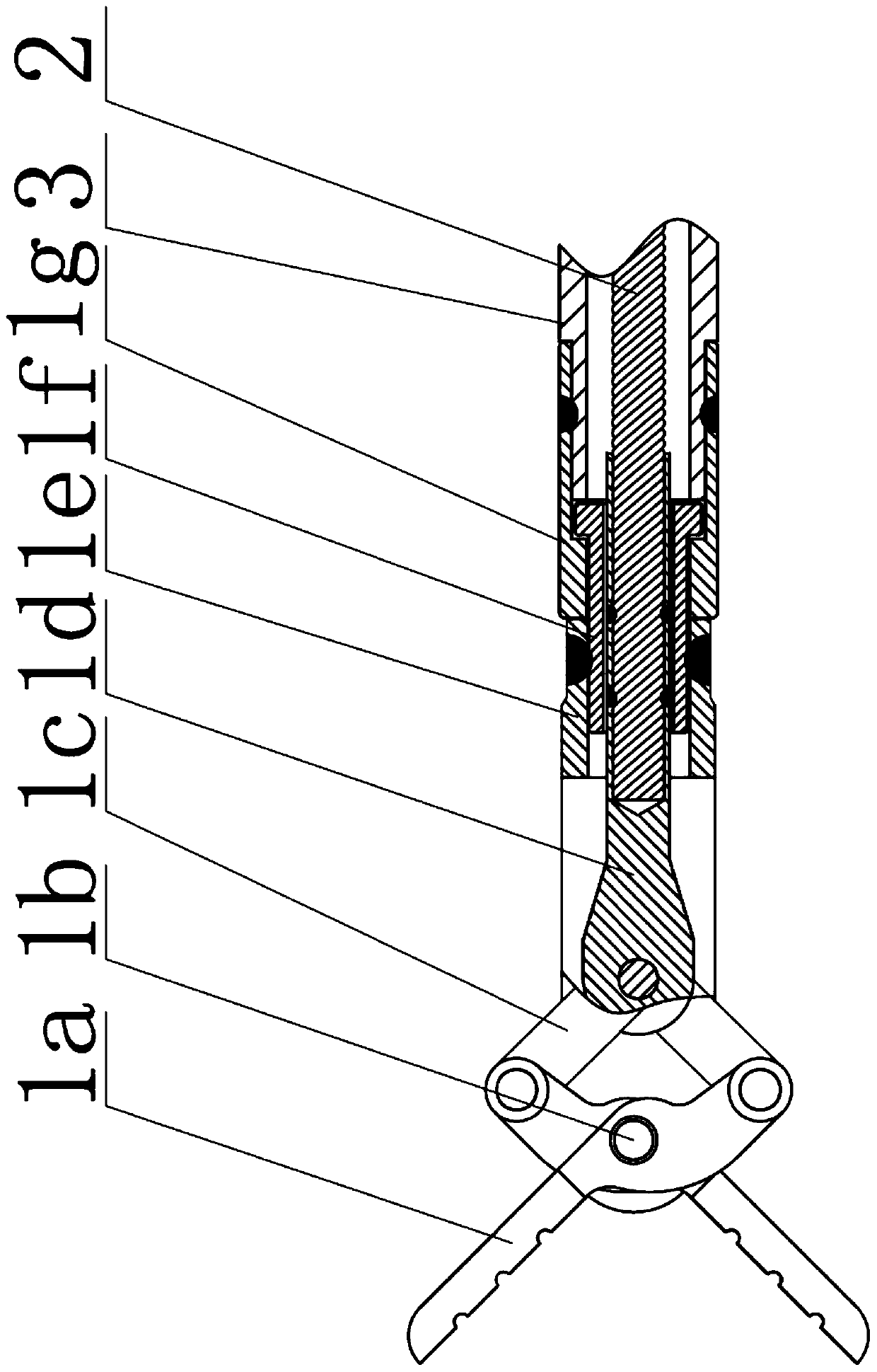

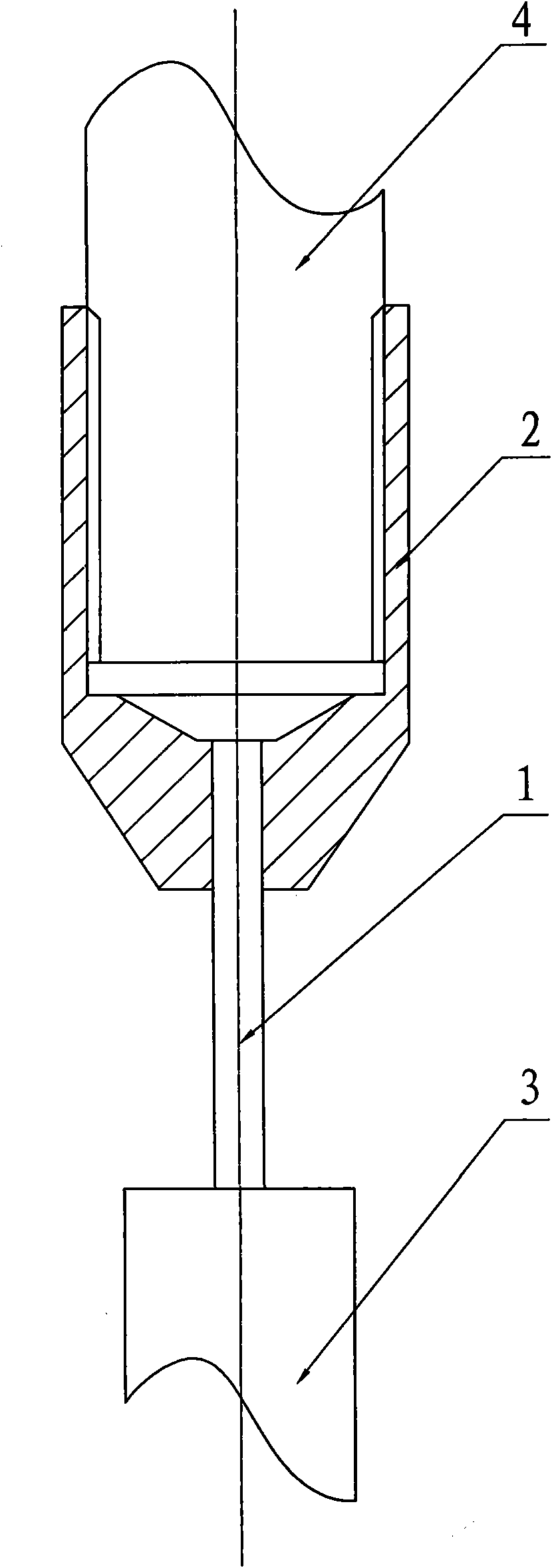

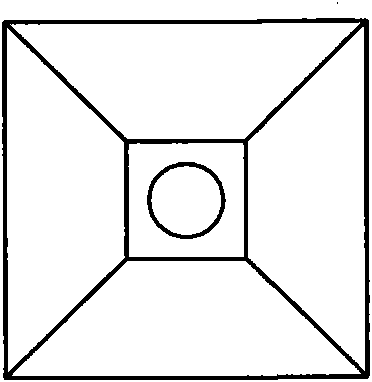

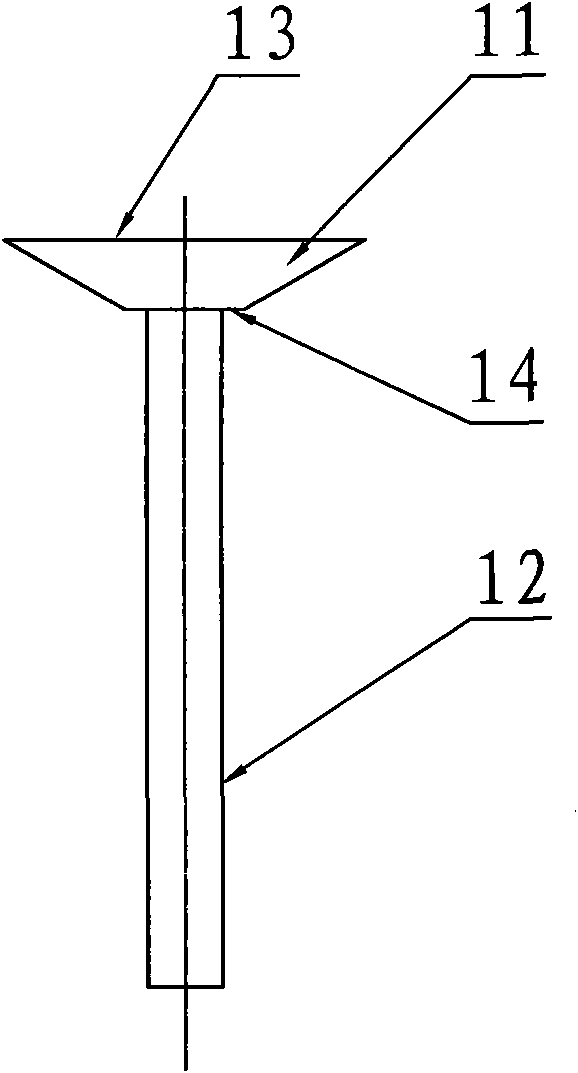

Crystal clamp part for broaching silicon rod

InactiveCN101781792AIncrease guide lengthEliminate breakage factorsBy pulling from meltEngineeringTorque transmission

The invention relates to a crystal clamp part for broaching a silicon rod, which is provided with a polygon terrace hole. A crystal is provided with a connecting polygon terrace and a lifting rod, wherein the upper terrace face of the connecting polygon terrace is greater than the lower terrace face; the lifting rod is arranged on the lower end face of the lower terrace face; the clamp is provided with a polygon terrace hole; a connecting polygon terrace for the crystal is sheathed in the polygon terrace hole; torque transmission and axial tension between the crystal and the clamp can be realized through the matched connecting structure of a shaft and the hole of the polygon terrace without grinding nicks on crystal or using a fixing pin for connection. The section area of the lifting rod on the crystal cannot be reduced so that the breaking factor of the crystal in the broaching process is eliminated in structure. The invention not only can solve the breaking problem of the crystal, but also can realize synchronous rotation of the crystal and the crystal clamp.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

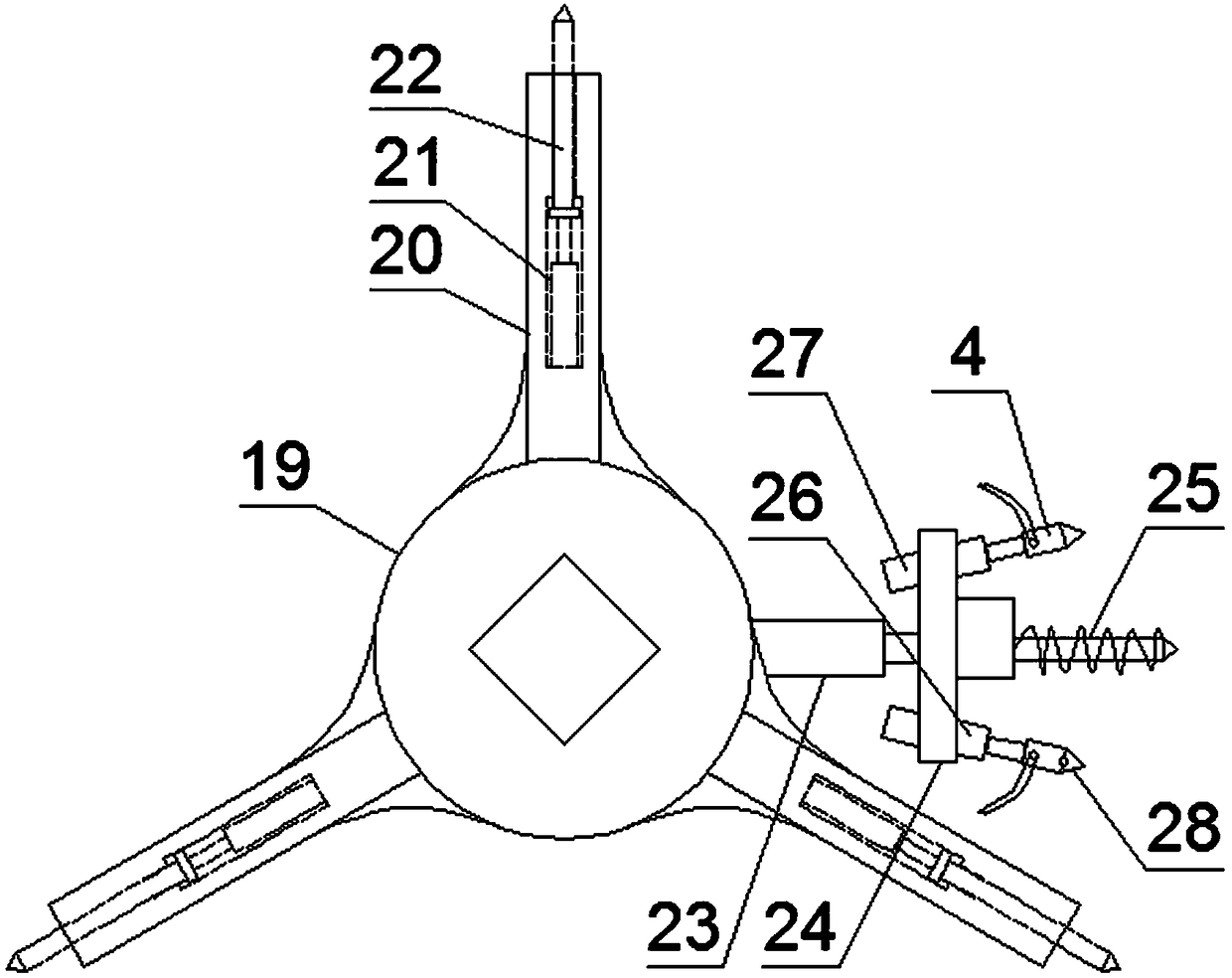

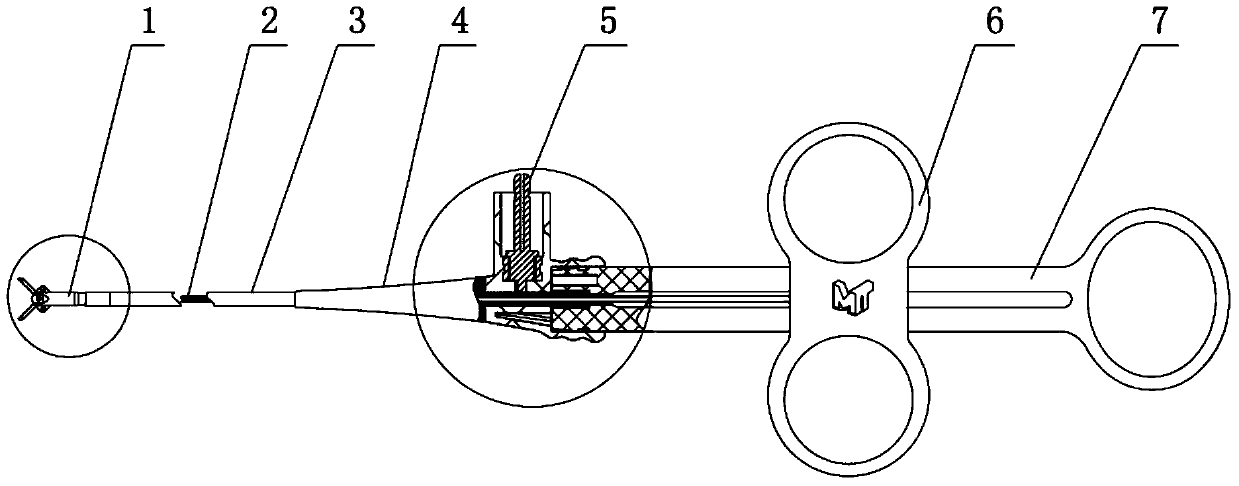

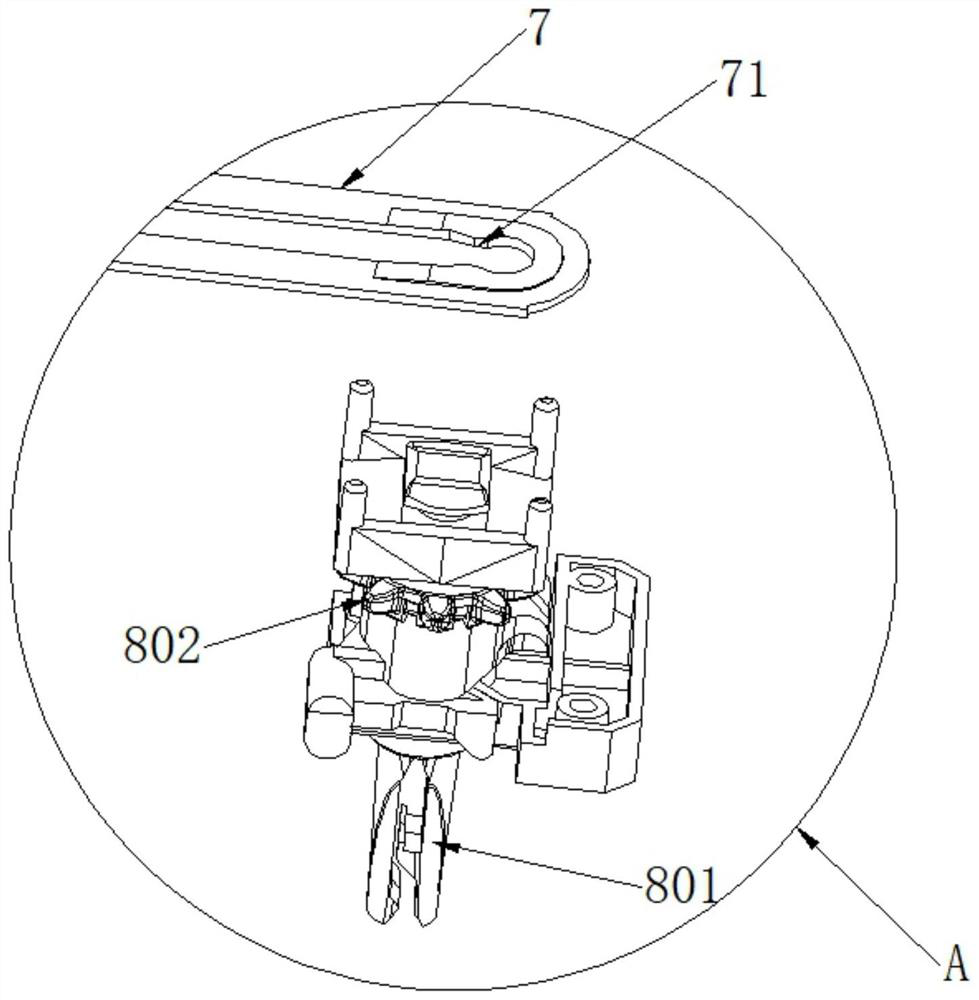

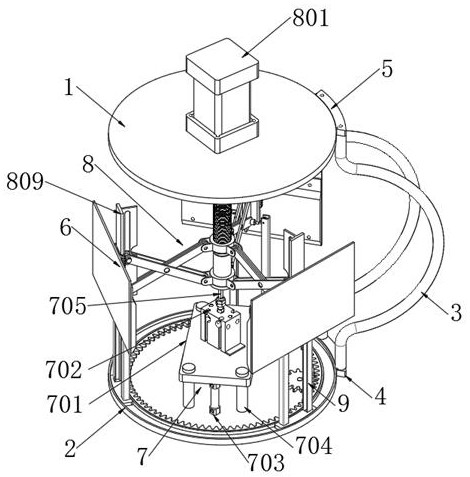

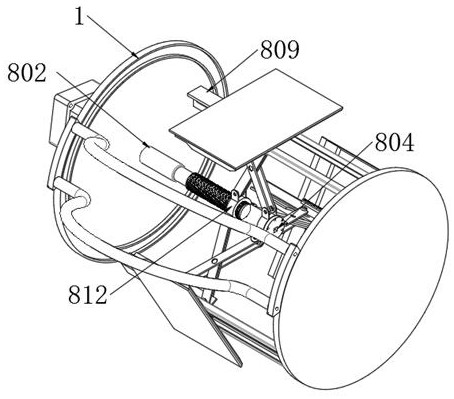

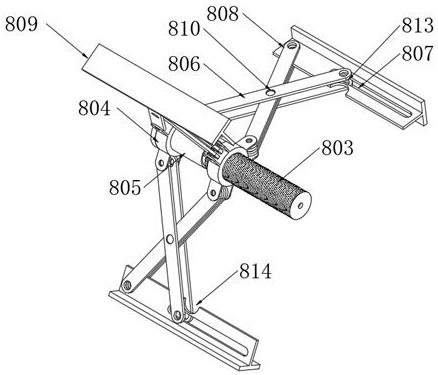

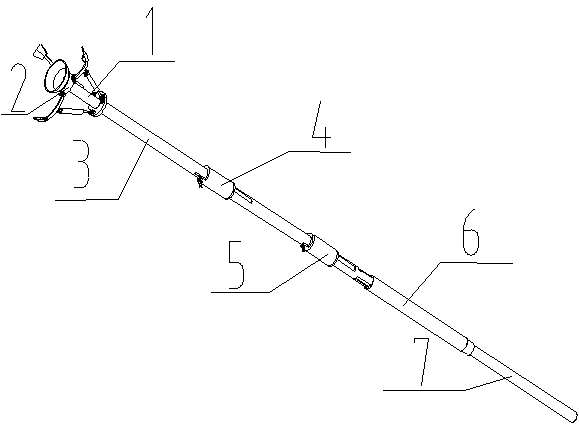

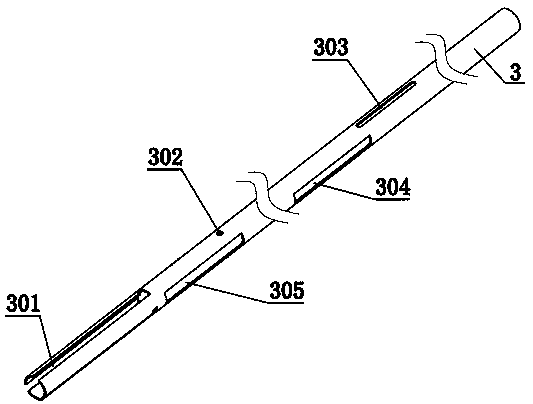

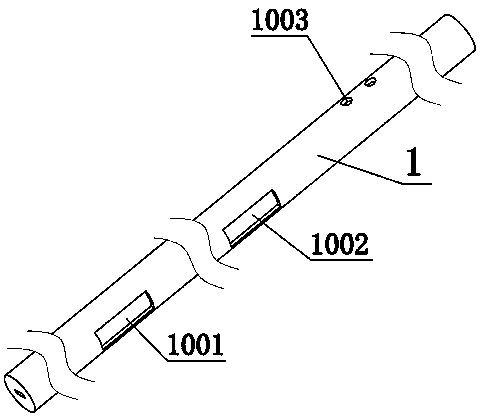

Spherical fruit picking device

ActiveCN109089545AAchieve synchronous rotationImplement rotary pickingPicking devicesEngineeringFixed position

The application discloses a spherical fruit picking device, which comprises an inner rod and a multi-slot sleeve rod. The inner rod and the multi-slot sleeve rod are in slide fit along a front-to-backdirection; a sleeve support is fixedly arranged at the front end of the inner rod and is in slide fit with a sphere along a front-to-back direction, the sphere is fixed to a slider sleeve rod capableof being adjusted front to back at a fixed position of the inner rod and the sleeve support is hinged with clamp fingers; a nylon sleeve is fixed on the multi-slot sleeve rod, and two ends of each elastic telescopic rod are hinged to the nylon sleeve and the middle of each clamping finger respectively; an external fixing sleeve is in rotational connection with an internal fixing sleeve, the internal fixing sleeve is fixedly connected with the inner rod through a fixing block, is in slide connection with the multi-slot sleeve rod in a front-to-back direction, and is provided with a fixing device connected with the multi-slot sleeve rod; the multi-slot sleeve rod is connected with a front-to-back pulling device and a rotation driving device is arranged at the back end of the inner rod; front-back position of the sphere can be adjusted by adjusting the fixing position of the slider sleeve rod at the inner rod, and thus, the device can be used for picking spherical fruit in different size.

Owner:ANYANG INST OF TECH

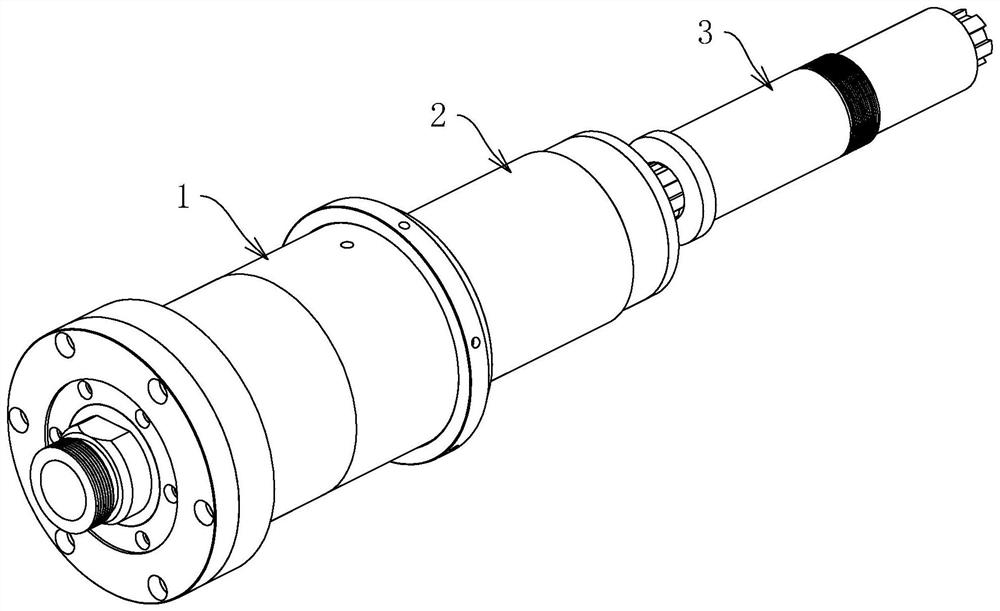

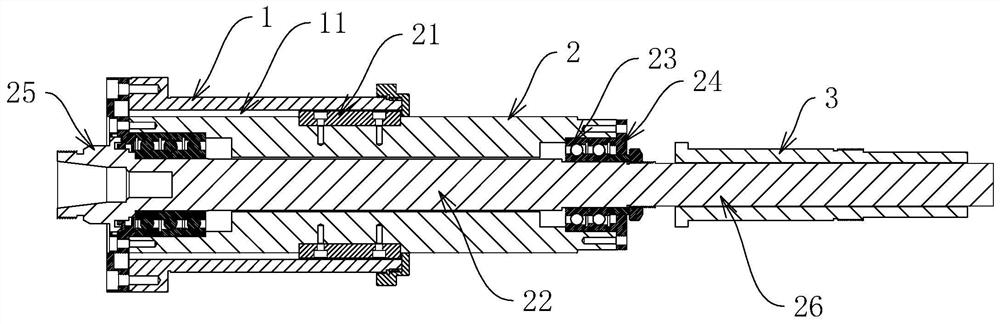

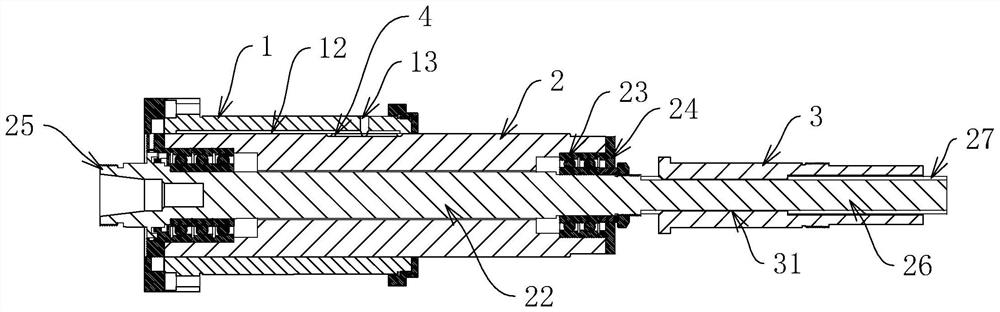

Main shaft of numerical control machine tool and main shaft box thereof

InactiveCN111957992AImprove ease of useRealize free feed controlLarge fixed membersNumerical controlDrive shaft

The invention discloses a main shaft of a numerical control machine tool, and relates to the field of numerical control machine tools. The main shaft comprises a shaft sleeve, wherein a mounting shaftis horizontally and slidably connected in the shaft sleeve; a mandrel is horizontally and rotatably connected in the mounting shaft; end covers are arranged between the mandrel and the two ends of the mounting shaft; a tool apron used for fixing a tool is arranged at the end, positioned outside the mounting shaft, of the mandrel; a sliding shaft is arranged at the other end, positioned outside the mounting shaft, of the mandrel in an extending mode; a driving shaft is arranged on the outer wall of the sliding shaft; the sliding shaft is horizontally and slidably connected to the driving shaft; a spline is arranged on the outer wall of the sliding shaft; and a key groove allowing the spline to slide is formed in the inner wall of the driving shaft. The main shaft has the following advantages and effects that the mandrel and the sliding shaft which slide and rotate independently are arranged, the whole main shaft does not need to be driven to move synchronously for feeding, free feedingcontrol during rotation of the tool apron and the tool can be realized, and the use convenience of the main shaft is improved.

Owner:台州松普数控科技有限公司

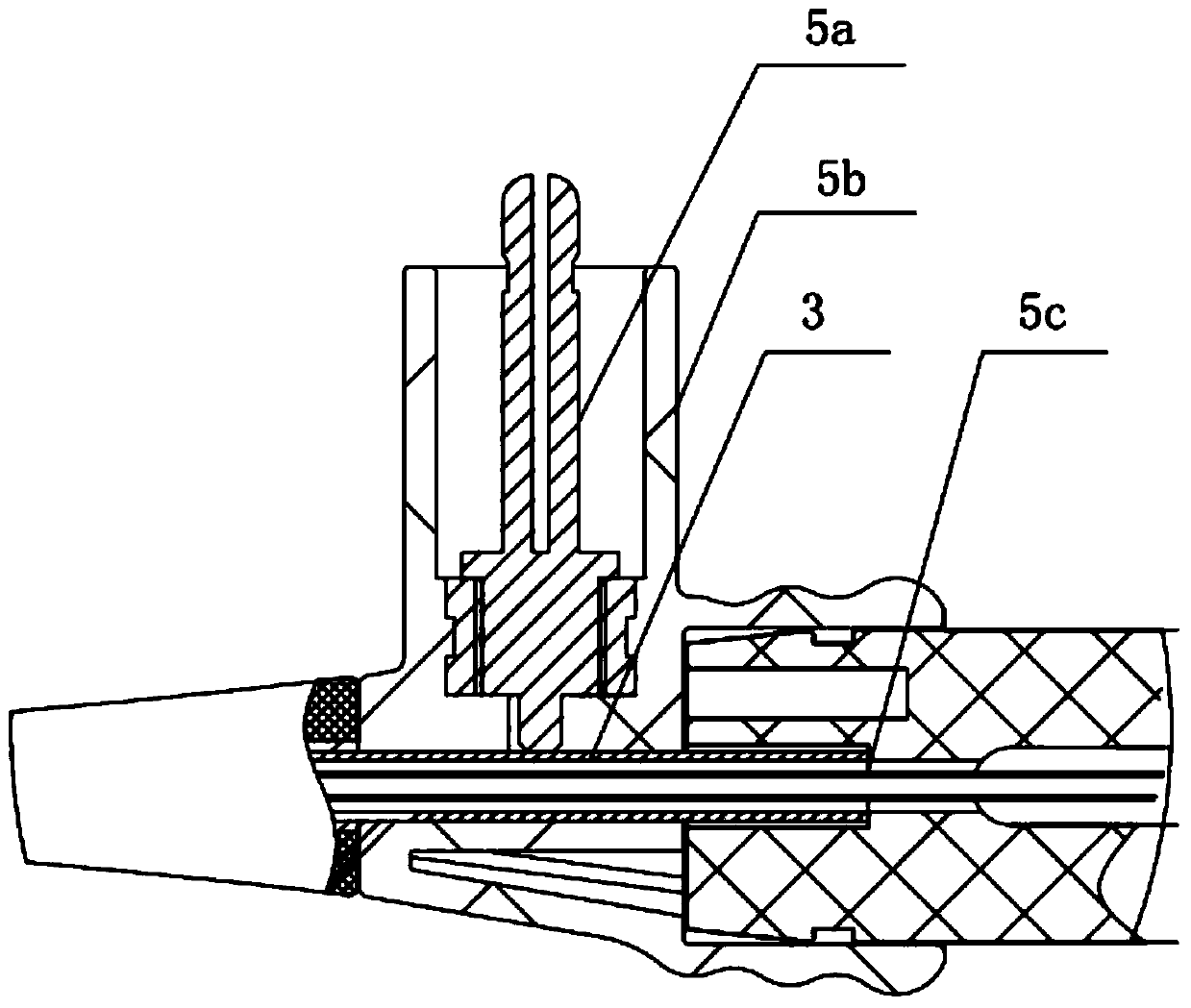

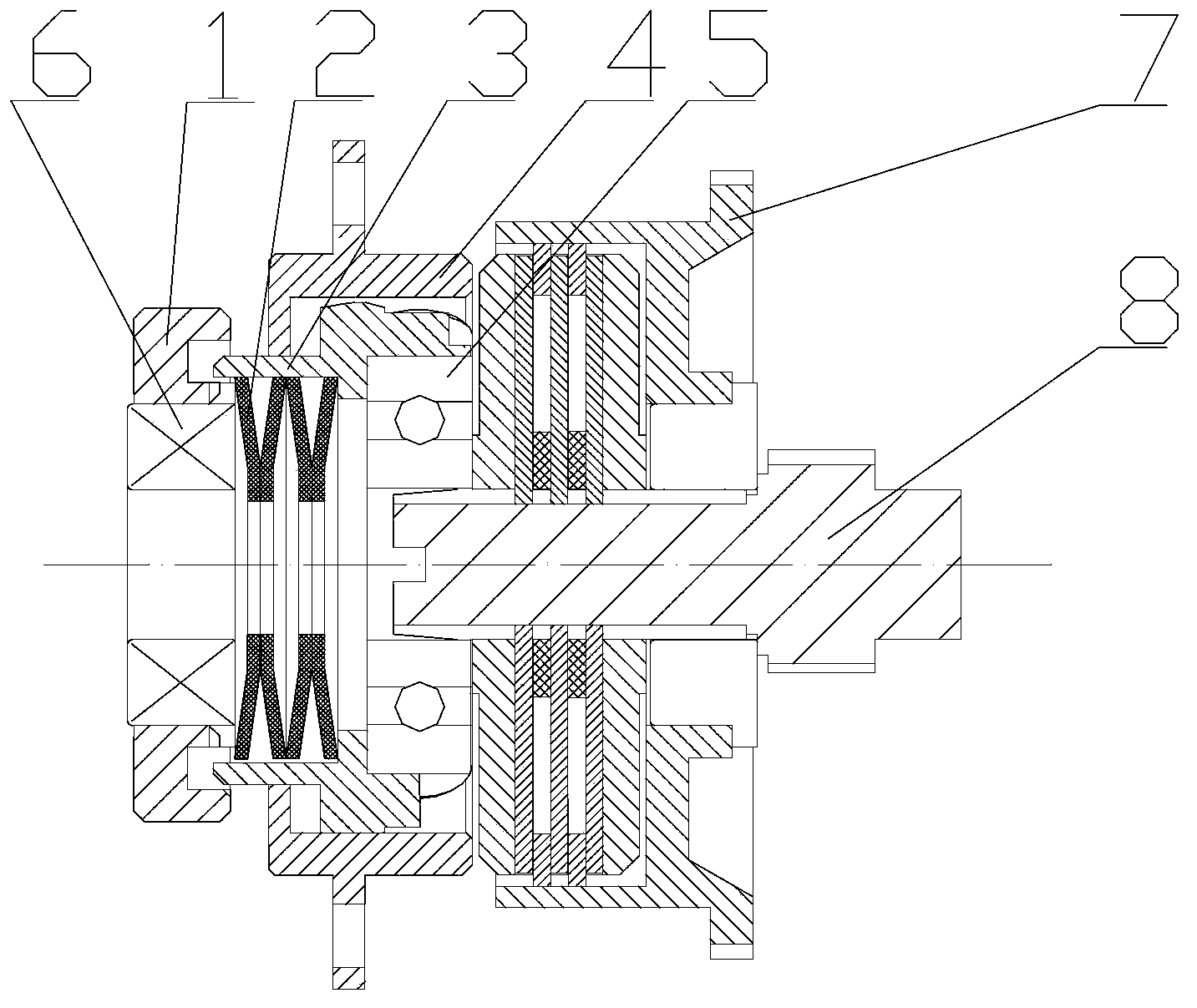

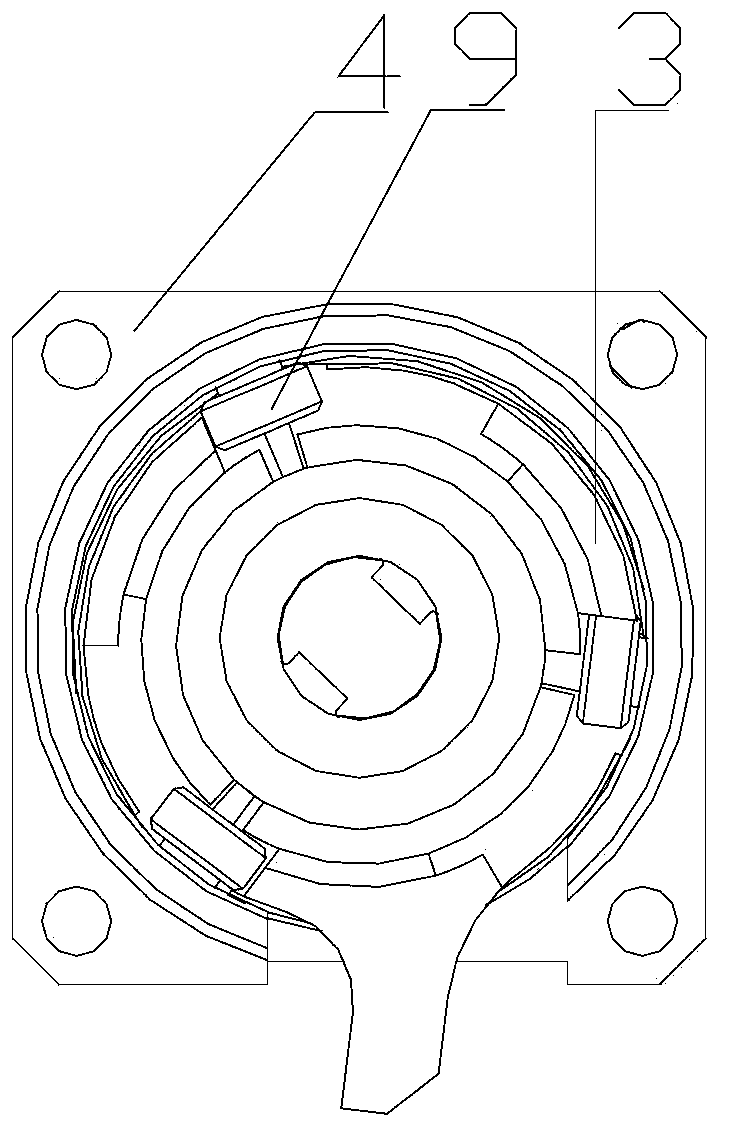

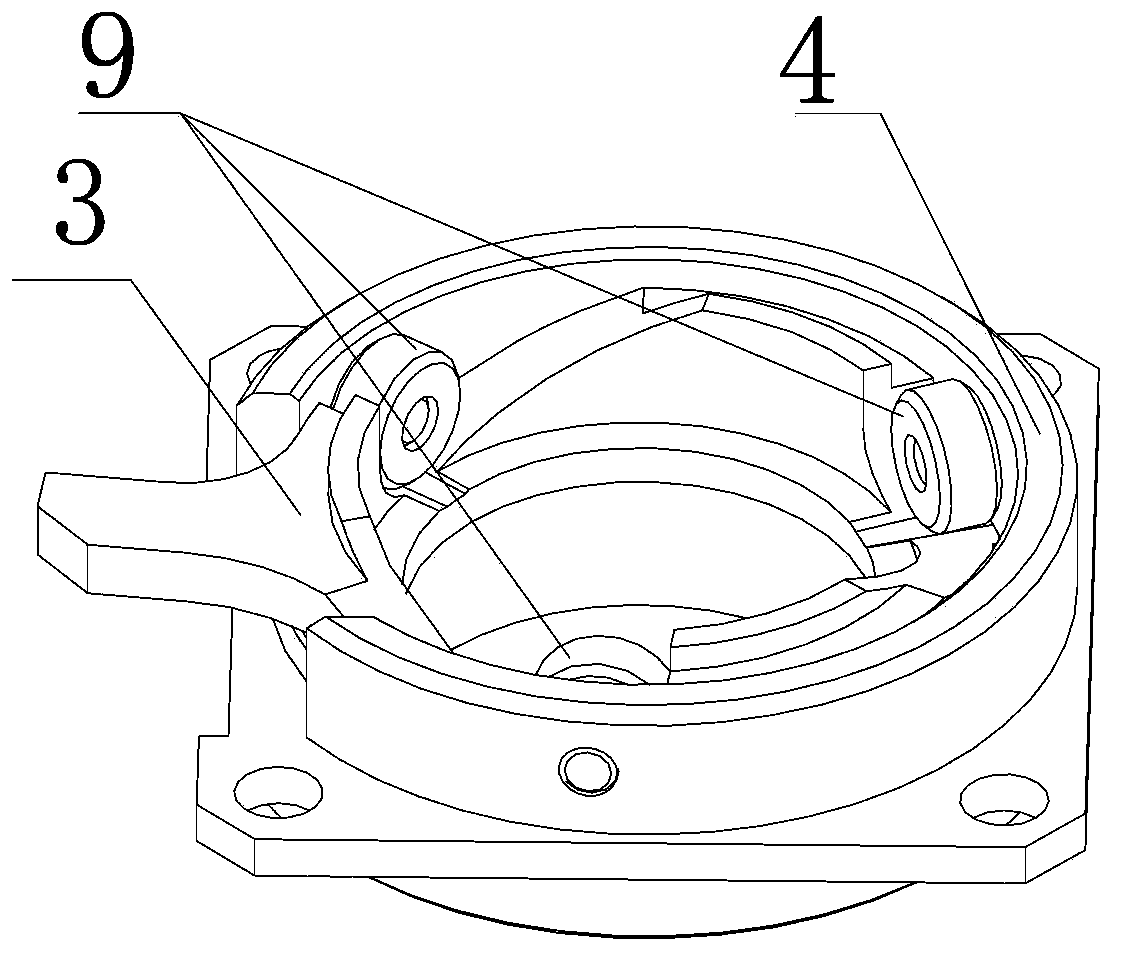

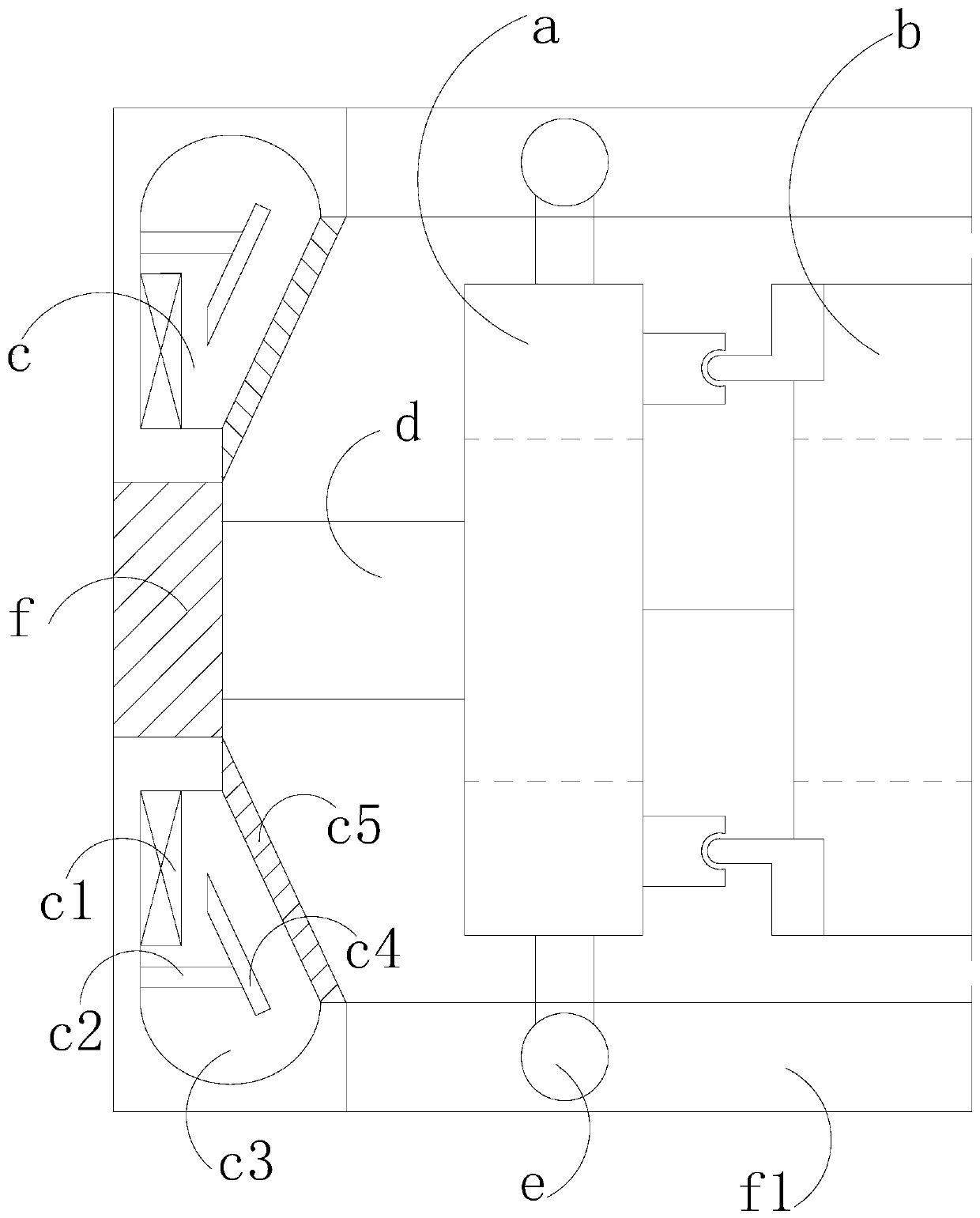

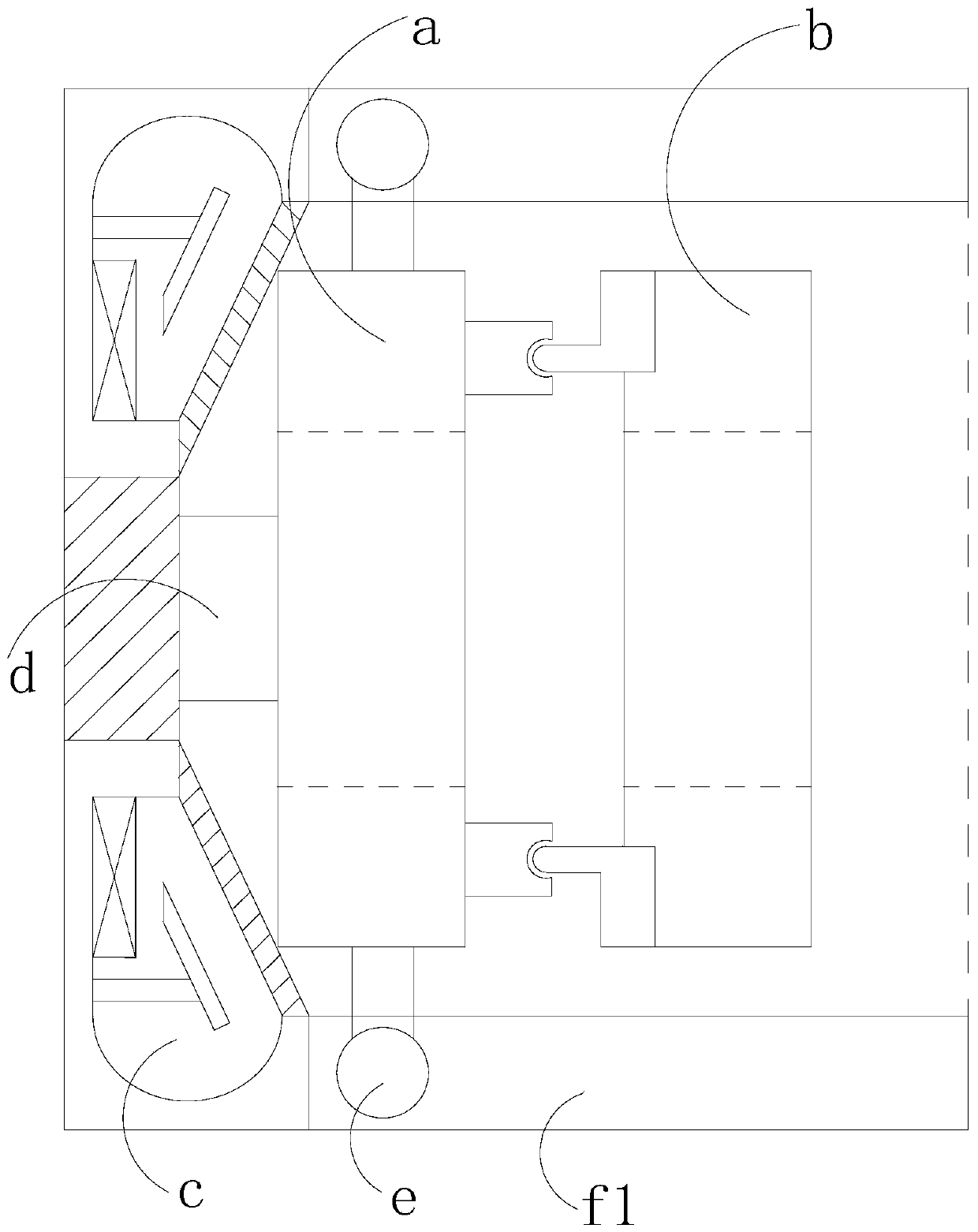

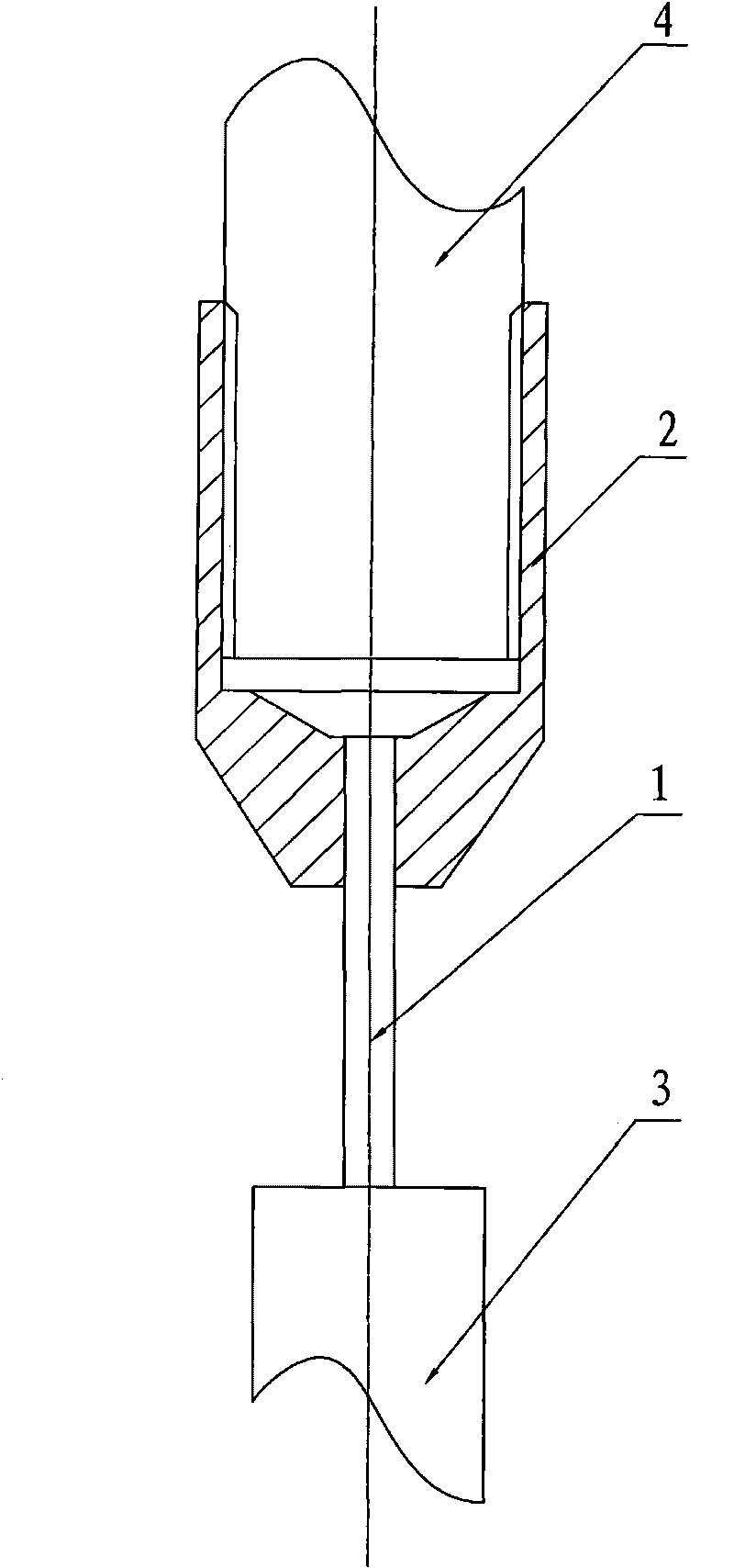

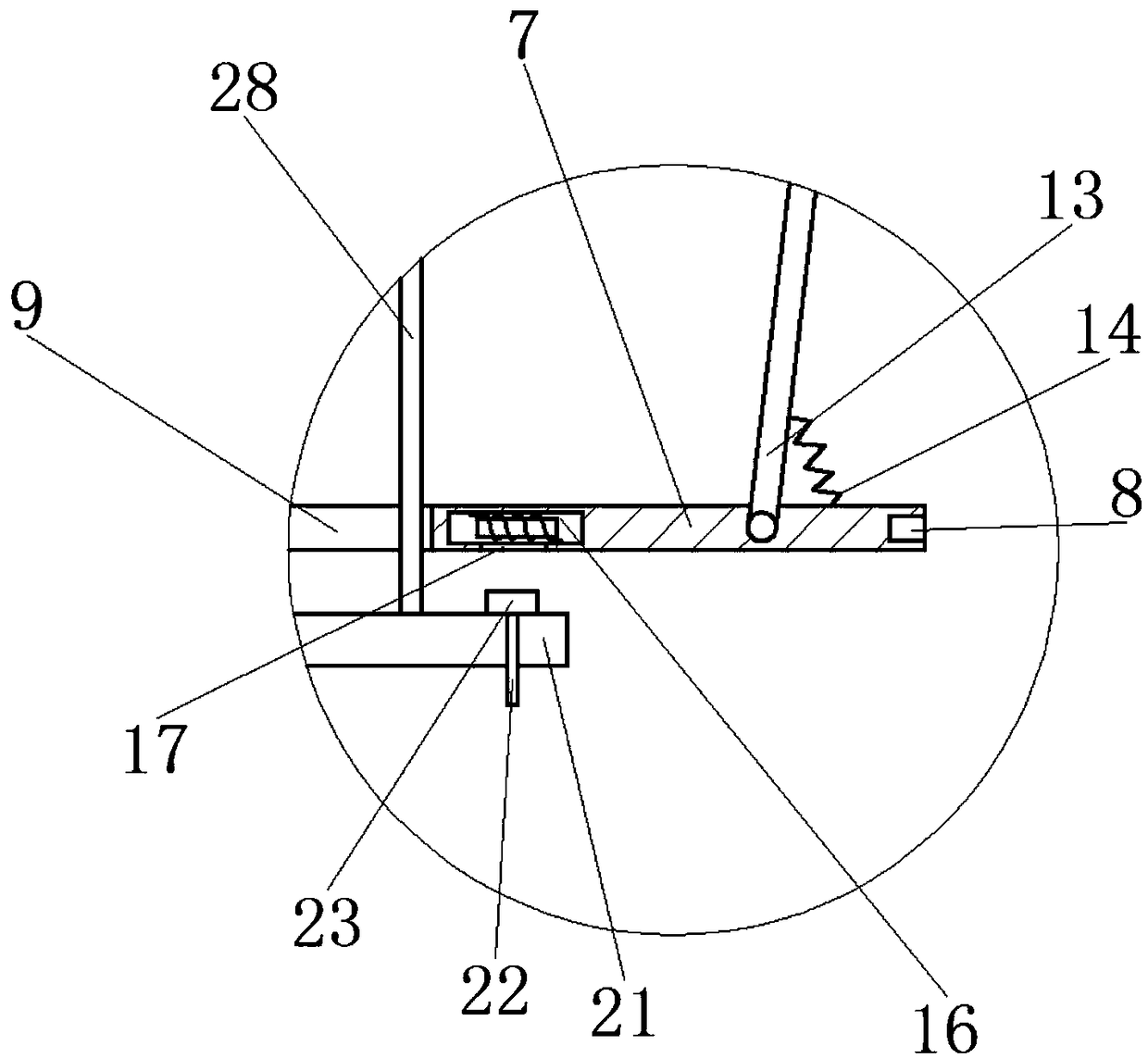

Automatic and manual integrated clutch

The invention relates to an automatic and manual integrated clutch. A bearing base 1 and a shell 4 of the automatic and manual integrated clutch are fixed on an electric mechanism; a shifting fork 3 is positioned inside the clutch shell 4; a spring piece set bearing 6 is arranged between a butterfly spring piece set 2 and the bearing base 1; a roller 9 is fixedly installed inside the clutch shell 4; the roller 9 contacts a bevel on the shifting fork 3; a friction piece set comprises a plurality of friction pieces 16; a friction ring 17 and a disc spring 14 are arranged between every two friction pieces 16; friction plates 13 are arranged on the two sides of each friction piece 16; the friction plates 13 contact a friction piece set bearing 5 and a transmission gear 7 respectively. Through the arrangement of the shifting fork, automatic and manual operations are integrated, an aero seat is regulated to adapt to various environments, and the safety of an aircraft and a pilot is ensured; the automatic and manual integrated clutch is reliable to work and significant in effect.

Owner:HARBIN DONGAN ENGINE GRP

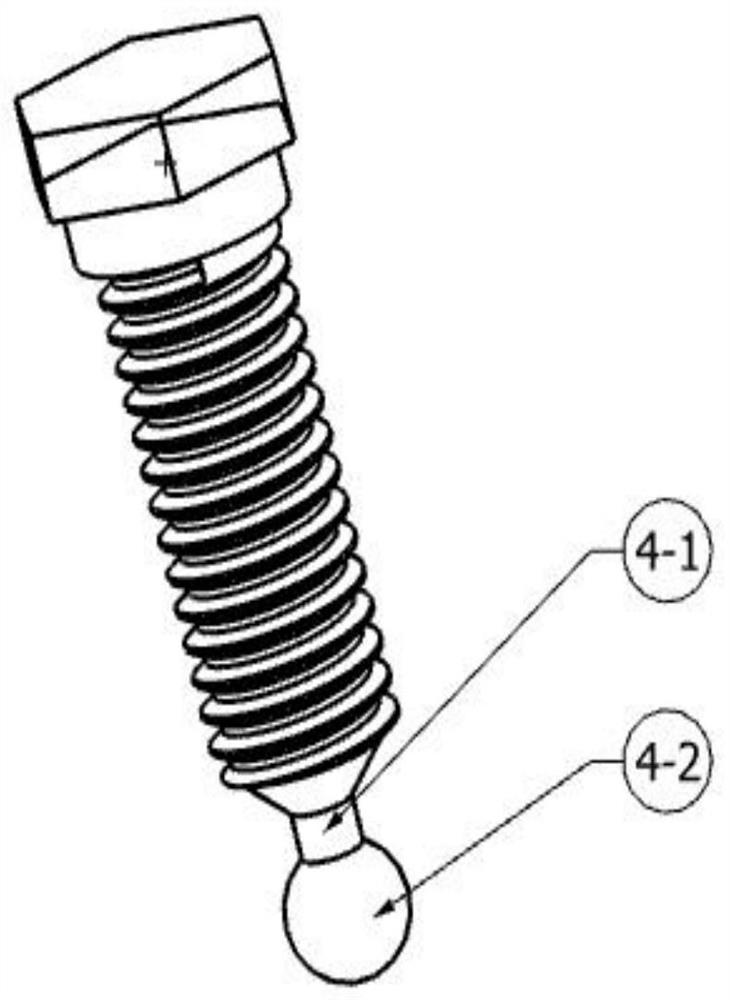

Abrasive flow polishing machining device for small-diameter elbow

PendingCN111604800ASolving Polishing ProblemsAchieve synchronous rotationEdge grinding machinesPolishing machinesEngineeringMechanical engineering

The invention provides an abrasive flow polishing machining device for a small-diameter elbow. The device is composed of two parts including a clamp clamping part and a transmission part, an I-shapedplate is installed on an abrasive cylinder through a bolt, a connecting bolt and a V-shaped limiting guide column are connected through a spherical protrusion, a threaded hole in the I-shaped plate ismatched with the connecting bolt, and the clamping degree of the V-shaped limiting guide column to the small-diameter elbow can be adjusted through rotating the connecting bolt. The transmission function of the transmission part is achieved through a V-belt wheel groove in the abrasive cylinder, a motor rotating shaft and the abrasive cylinder are connected through a V belt, synchronous rotationof the abrasive cylinder and the small-diameter elbow can be achieved through adjusting the rotating speed of the motor rotating shaft, grinding materials are introduced into a grinding material inlet, and polishing treatment of the inner wall and the outer wall of the small-diameter elbow is further achieved. The abrasive flow polishing machining device is convenient to install, easy and reliableto use and capable of polishing bent pipelines of different sizes.

Owner:CHANGCHUN UNIV OF SCI & TECH

Bridge construction machine

ActiveCN111229744AAchieve synchronous rotationAchieve recyclingLiquid surface applicatorsHollow article cleaningArchitectural engineeringWorkbench

The invention discloses a bridge construction machine. The bridge construction machine structurally comprises a fixing base, a workbench, a connecting base, a rust removal device and a connecting block. The workbench is arranged on the fixing base and fixedly connected with the fixing base. The connecting base is arranged on the workbench and mechanically connected with the connecting block. The rust removal device is installed on the workbench. The bridge construction machine has the advantages that synchronous rotation between a rust removal head and an anti-rust head is achieved through cooperation of a spiral ball and a spiral groove, so that after rust removal of a steel pipe, when the steel pipe passes through a painting wheel, a cotton layer is tightly attached to the surface of thesteel pipe, when the painting wheel rolls through the surface of the steel pipe, the surface of the steel pipe is painted, and the steel pipe is prevented from being oxidized again; and a draught fanis reversely installed, so that an inlet has adsorption force, falling rust chips are sucked in, and rust chip recycling is further achieved.

Owner:苏清彬

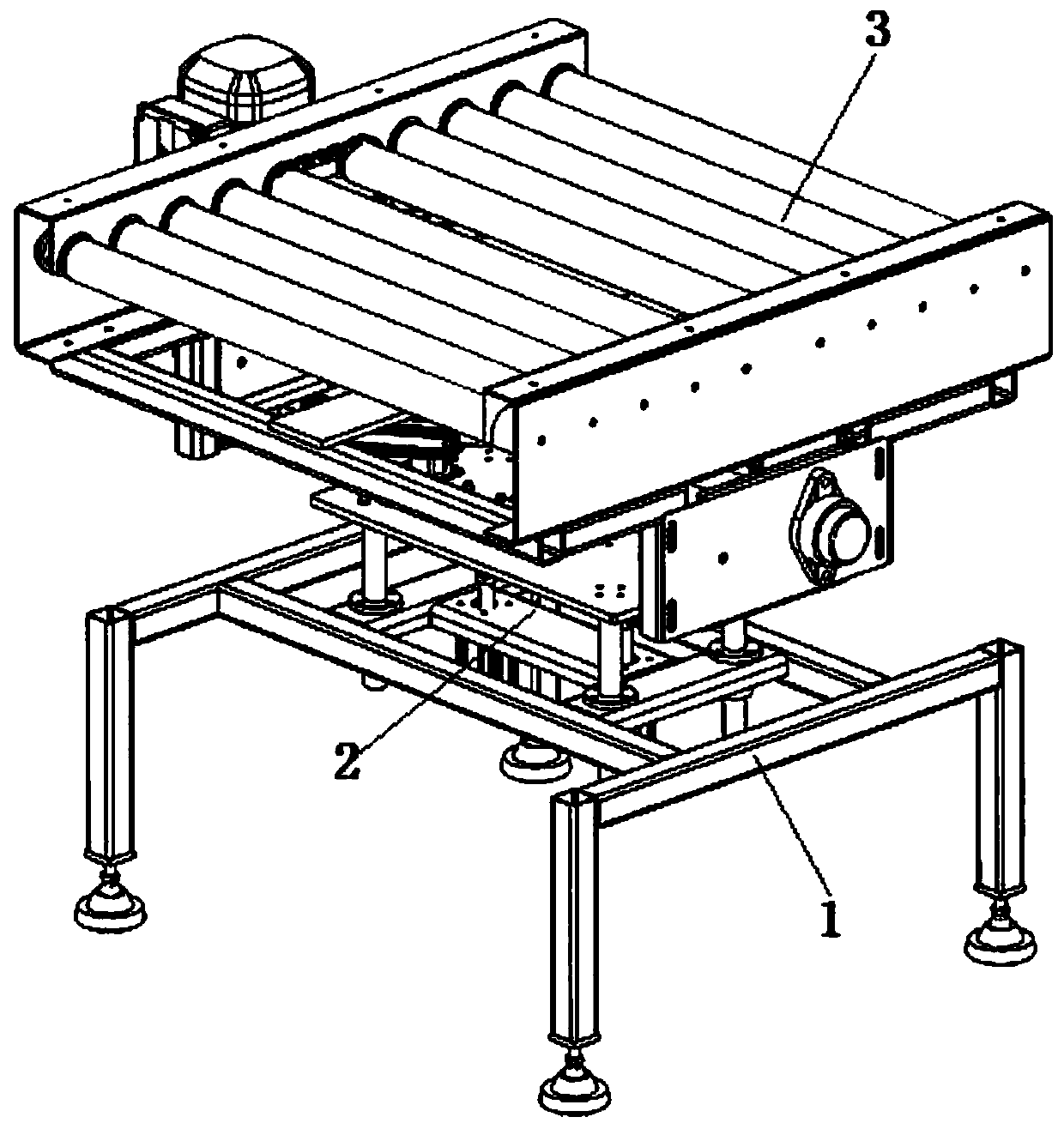

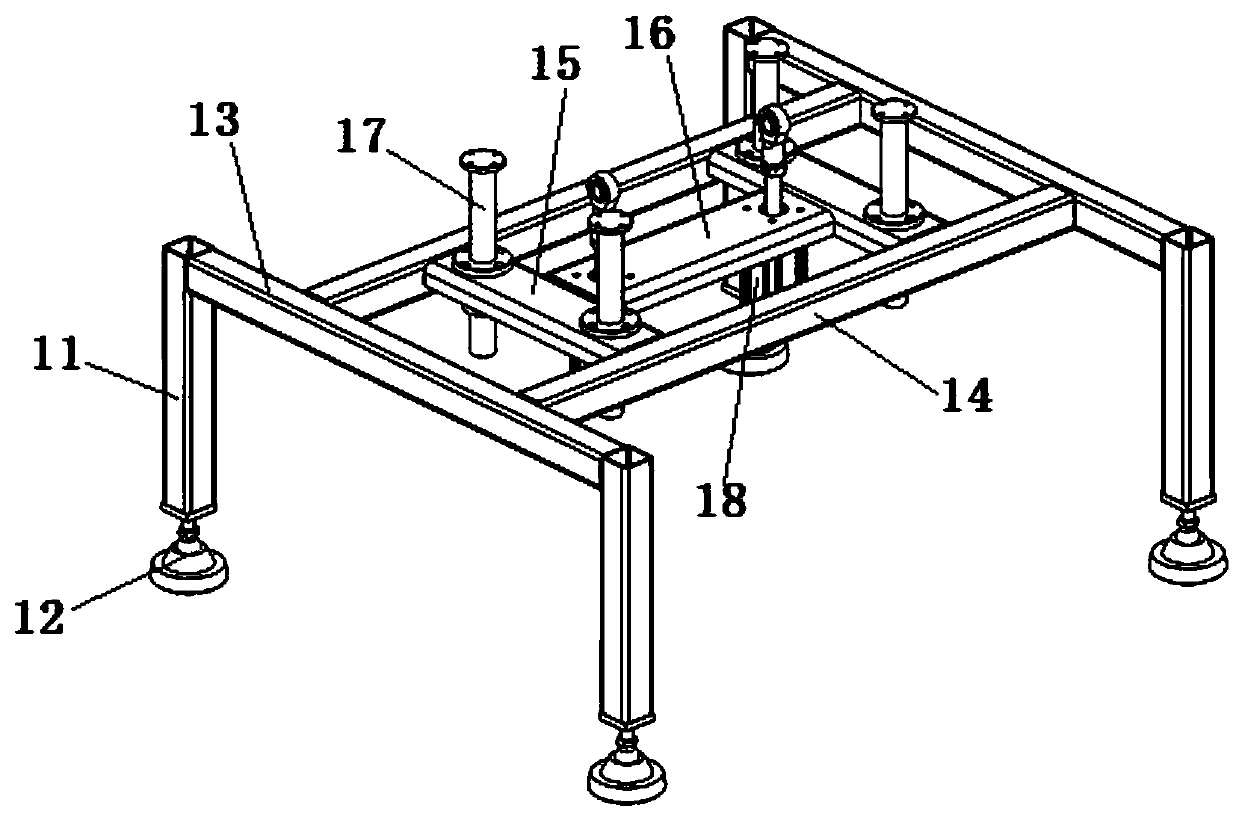

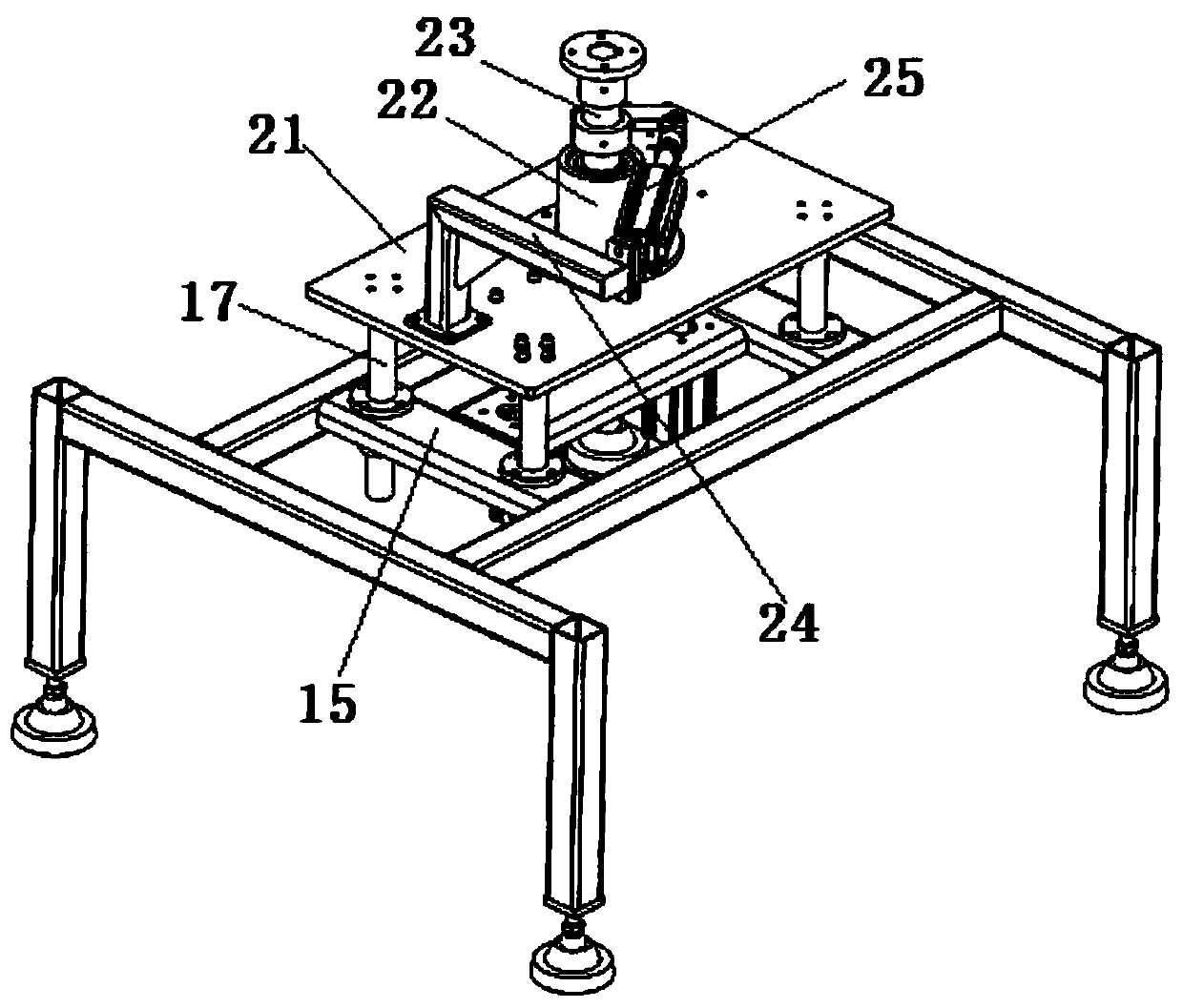

Conveying device for pipe machining

The present invention discloses a conveying device for pipe machining. The device comprises a base, an adjusting device and a conveying device. The adjusting device is installed between the base and the conveying device, the adjusting device comprises a bearing plate, the top end of a second supporting column and the top end of the piston section of a first cylinder are both fixed at the lower surface of the bearing plate, an L-shaped fixing frame is further fixed to the surface of the bearing plate, and a direction adjusting structure is fixed to the other end of the L-shaped fixing frame andcan enable a third supporting rod to rotate to adjust the direction of the conveying device; a bearing frame is fixed to the upper surface of a third supporting beam of the conveying device, and a plurality of rollers arranged in parallel are installed on the bearing frame; a linkage mechanism is further arranged on the bearing frame and can drive all the rollers to rotate. According to the conveying device, orderly conveying of the pipes can be achieved, and through the arrangement of the adjusting device, the height and the direction of the conveying device can be conveniently and rapidly adjusted, and therefore, the applicability and high efficiency of the conveying device are improved.

Owner:FOSHAN LONGXIN LASER TECH CO LTD

Matted crystal for pulling silicon rod

The invention relates to a matted crystal for pulling a silicon rod, which is provided with a connecting polygon stand and a lifting pole, wherein the upper stand surface of the connecting polygon stand is larger than the lower stand surface; the lifting pole is arranged on the lower end surface of the lower stand surface; a polygon stand hole is arranged on a clamping head; and the connecting polygon stand of the matted crystal is nested in the polygon stand hole of the clamping head. Torque transfer and axial tension bearing between the matted crystal and the clamping head are realized through the shaft-hole fit connecting structure of the polygon stand, thus a gap ground on the matted crystal wall is not needed, and a fixing pin is not needed for connection; the cross sectional area of the lifting pole on the matted crystal can not be reduced, thereby eliminating the factors of rupture of the matted crystal in the pulling process on structure; and the invention solves the problem of rupture of the matted crystal and can realize synchronous rotation of the matted crystal and the clamping head of the matted crystal.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

Air blocking structure of electric fan

ActiveCN109441880AAchieve synchronous rotationWind flow area is not occupiedPump componentsPump controlBlock structureElectrical and Electronics engineering

The invention relates to the technical field of electric fans, and discloses an air blocking structure of an electric fan. The air blocking structure comprises a rack and an air bellow, the air bellowis internally provided with a first motor and fan blades, air outlets are formed in the side walls of the air bellow, a first opening is formed in the bottom of the air bellow, a limiting plate is arranged in the rack, a through hole is formed in the center of the limiting plate, a first supporting column is vertically fixed to the surface of the limiting plate, and the upper end of the first supporting column is rotationally connected with a coil stock used blocking air. A second motor is arranged below the limiting plate, the output end of the second motor is fixedly connected with a firstgear, the side wall of the first gear is engaged with a worm and a second gear, the worm is coaxially connected with a rotating disc, and the upper surface of the rotating disc is fixedly connected with a telescopic assembly and limiting bars; the second gear is coaxially connected with a second connecting rod and a third connecting rod; and the rack is internally provided with a limiting mechanism used for controlling the limiting plate to move up and down. By controlling the covering degree of the coil stock between the first supporting rod and the telescopic assembly to the air outlets, theair blocking area is changed.

Owner:宁波市弘露电子商务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com