Drainage pipeline non-excavation repairing device

A drainage pipe, non-excavation technology, applied in the direction of pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems affecting the flow of the pipeline and the reduction of the flow area of the pipeline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

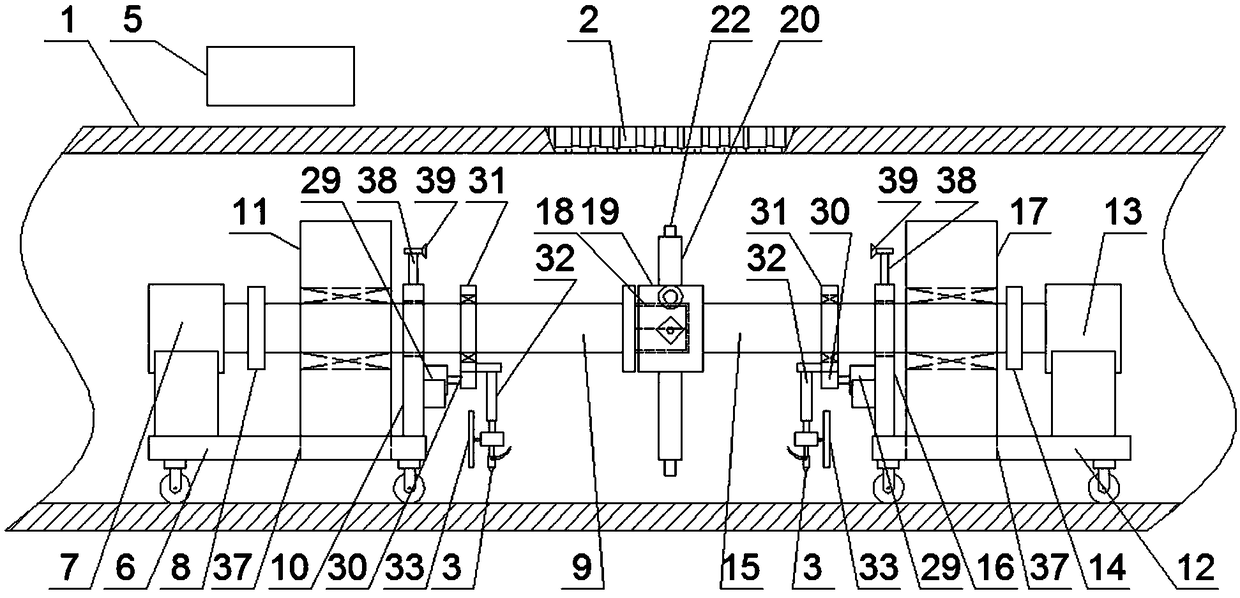

[0044] A non-excavation repairing device for a drainage pipeline, comprising a first working mechanism located on one side of the internal collapse and deformation of the drainage pipeline 1 to be repaired, and a second working mechanism located on the other side of the internal collapse and deformation of the drainage pipeline 1 to be repaired 2 , a third working mechanism arranged between the first working mechanism and the second working mechanism, which is arranged on the first working mechanism and the second working mechanism for guiding and positioning the operation process and monitoring the construction status Mechanisms, which are respectively arranged on the right side of the first working mechanism and the left side of the second working mechanism are used to circularly cut the drainage pipe. The first quick-drying cement nozzle 3 arranged on the cutting mechanism is arranged on the The second quick-drying cement nozzle 4 on the third working mechanism, and the cont...

Embodiment 2

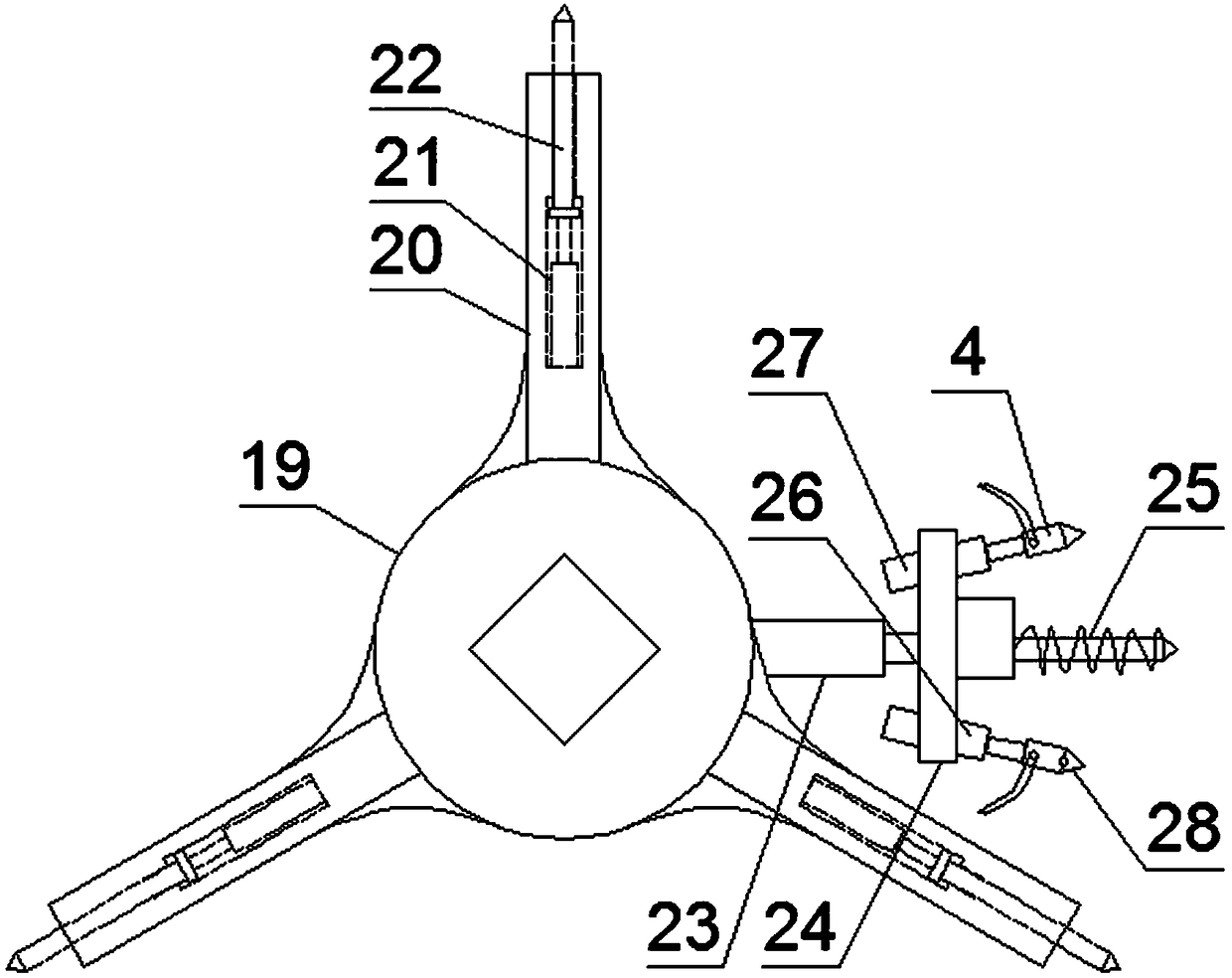

[0058] The difference from Embodiment 1 is that the third working mechanism includes three cylinders 20 with constricted openings arranged radially on the outer surface of the inner polygonal sleeve 19, and all the cylinders 20 are uniform in circumference. Distributed on the outer surface of the inner polygonal sleeve 19, a first automatic telescopic rod 21 is arranged in the axial direction in the cylinder body 20, and an insertion rod 22 is arranged at the end of the first automatic telescopic rod 21, and the insertion rod 22 The end portion protrudes from the constriction opening of the cylinder body 20 .

[0059]The third working mechanism also includes a second automatic telescopic rod 23 arranged radially on the outer surface of the inner polygonal sleeve 19, the end of the second automatic telescopic rod 23 is provided with a bearing plate 24, and the bearing plate 24, a drill bit 25, a third automatic telescopic rod 26 and a sixth automatic telescopic rod 27 are arran...

Embodiment 3

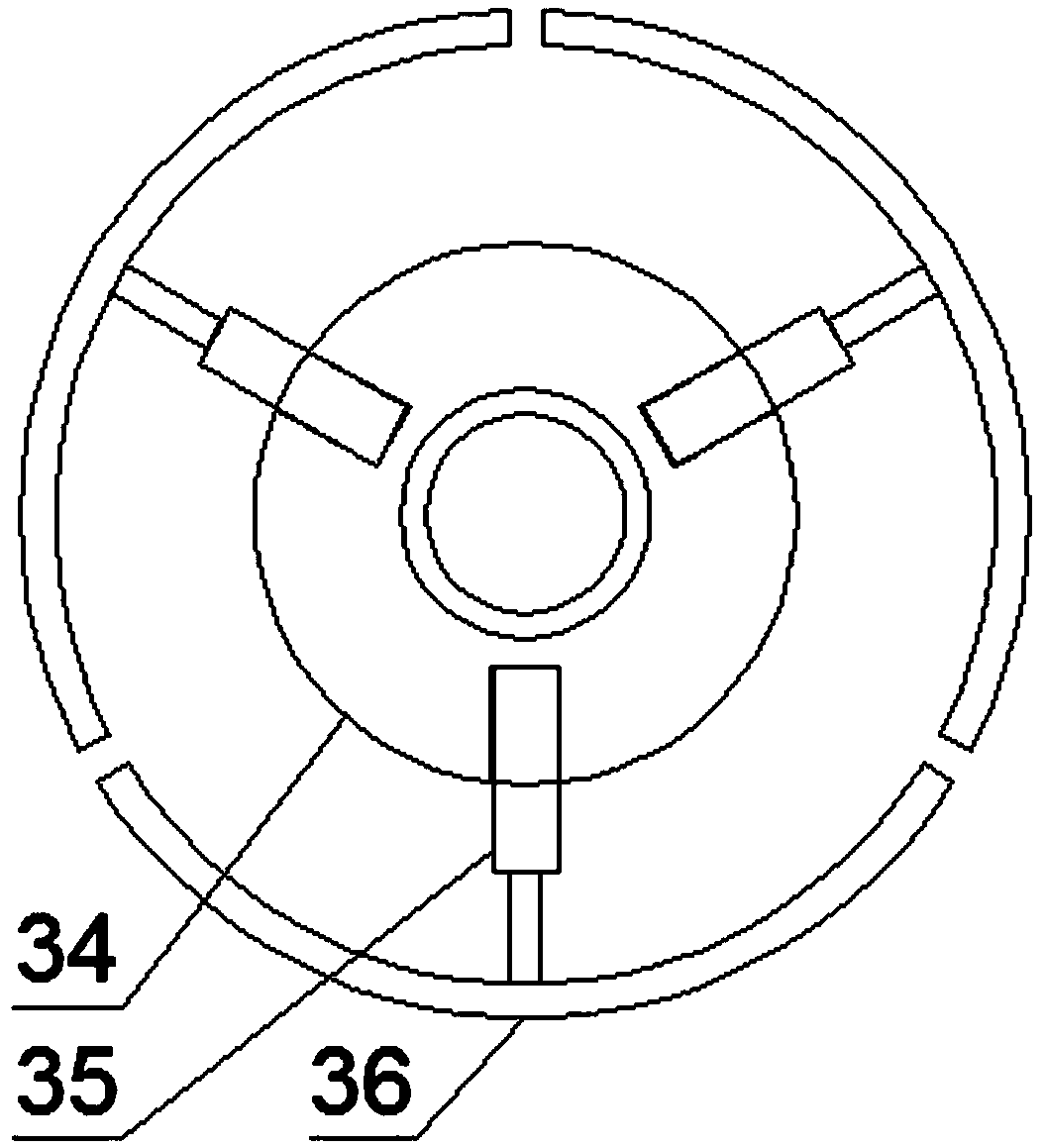

[0063] The difference between it and the second embodiment is that the cutting mechanism includes a low-speed motor 29 arranged on the side of the corresponding shaft seat, a driving gear 30 arranged on the output shaft of the low-speed motor 29, and a drive gear 30 arranged on the corresponding rotating shaft through a bearing sleeve and The driven gear 31 matched with the driving gear 30, the fourth automatic telescopic rod 32 arranged on the end face of the driven gear 31, and the end of the fourth automatic telescopic rod 32 are used to divide the parts to be repaired. The concrete cutting machine 33 of drainage pipeline 1, described first quick-drying cement nozzle 3 is arranged on the shell bottom of described concrete cutting machine 33; The structure of the cutting mechanism is the same, the difference is that: the low-speed motor on the first working mechanism is set on the right side of the first shaft seat, and its driven gear is sleeved on the first rotating shaft t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com