Matted crystal for pulling silicon rod

A silicon rod drawing and sub-crystal technology, which is applied in the field of parts and components, can solve problems such as sub-crystals are easy to break, and achieve the effect of solving fracture, eliminating fracture factors, and synchronous rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation of the present invention will be described in detail below by taking the structure of the clamp part of the tetragonal subcrystal as an example.

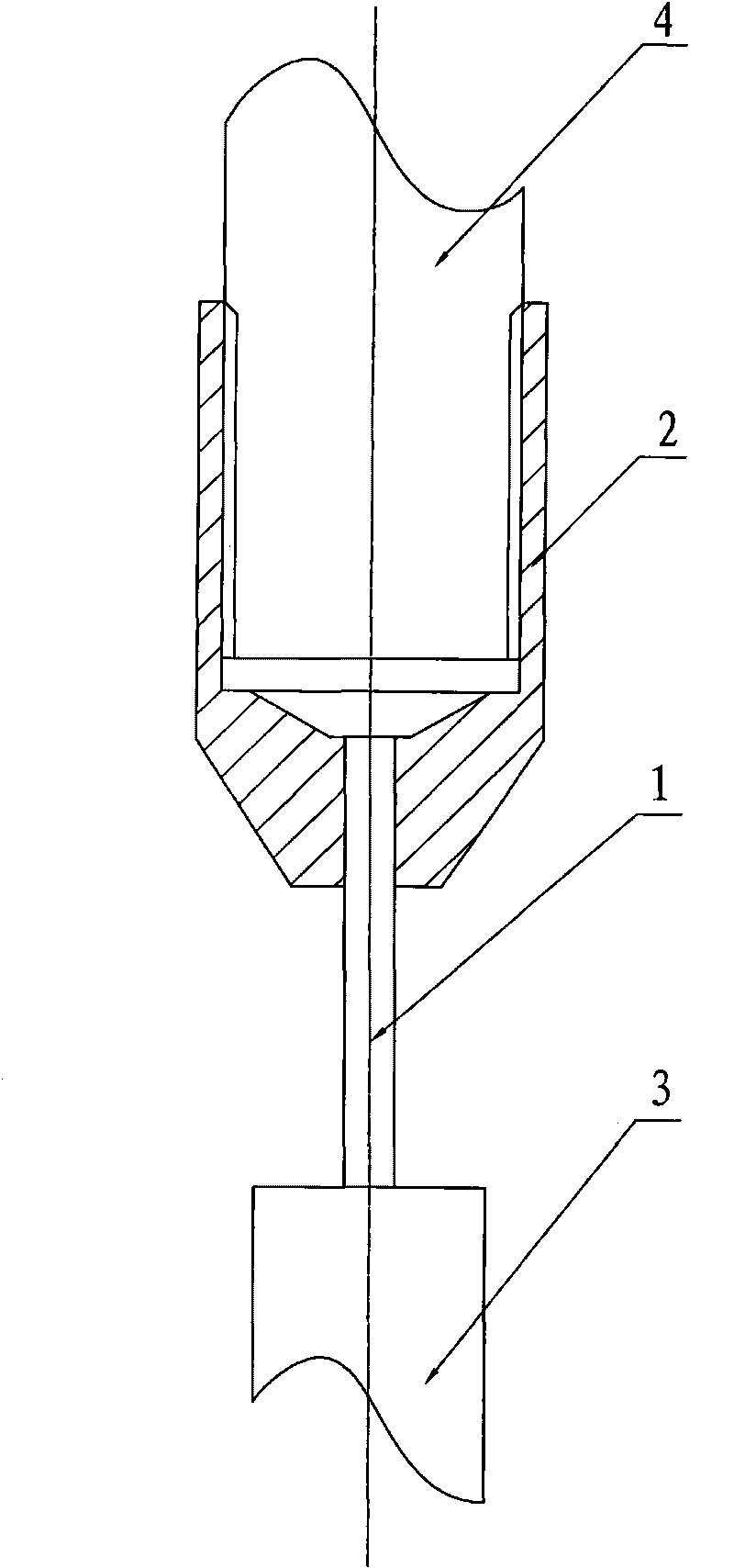

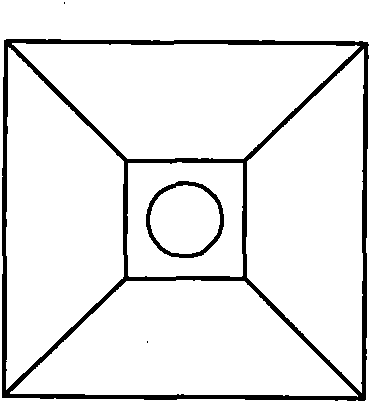

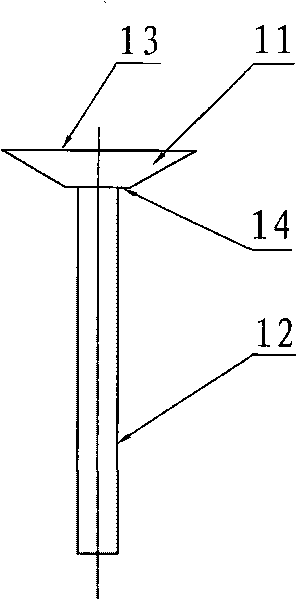

[0016] as attached Figure 1 to Figure 4 Shown is the silicon rod drawing sub-crystal chuck part, which is composed of the present invention and the chuck 2. The present invention includes a connecting polygonal platform 11 and a lifting rod 12 whose cross-sectional shape is a square, and connects the upper table surface of the polygonal platform 11. 13 is larger than the lower table surface 14, and the lifting rod 12 is arranged on the lower end surface of the lower table surface 14. The chuck 2 includes a threaded hole 21, a polygonal platform hole 22 and a guide hole 23. The three are coaxial hole systems, and the polygonal platform hole 22 The cross-sectional shape of the truss is a quadrangular truss, and the taper angle of the truncated polygonal hole 22 is 120°; the shape and the taper angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com