Cooling cavity transmission system in LPCVD (Low-Pressure Chemical Vapor Deposition) process

A transmission system and cooling cavity technology, applied in metal material coating processes, conveyors, manufacturing tools, etc., can solve problems such as increased glass substrate breakage, increased glass substrate breakage probability, glass breakage, etc., to improve stability, eliminate Local temperature changes are too drastic, eliminating the effect of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

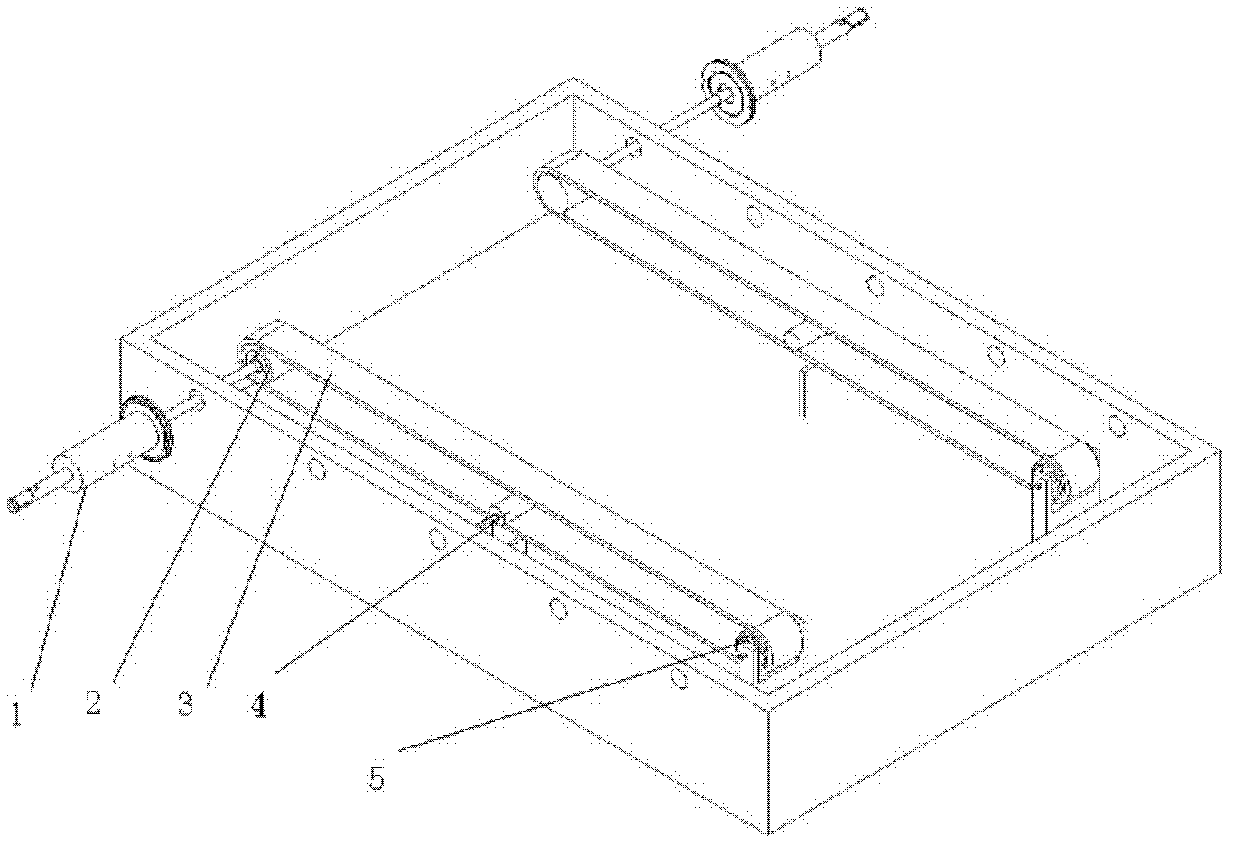

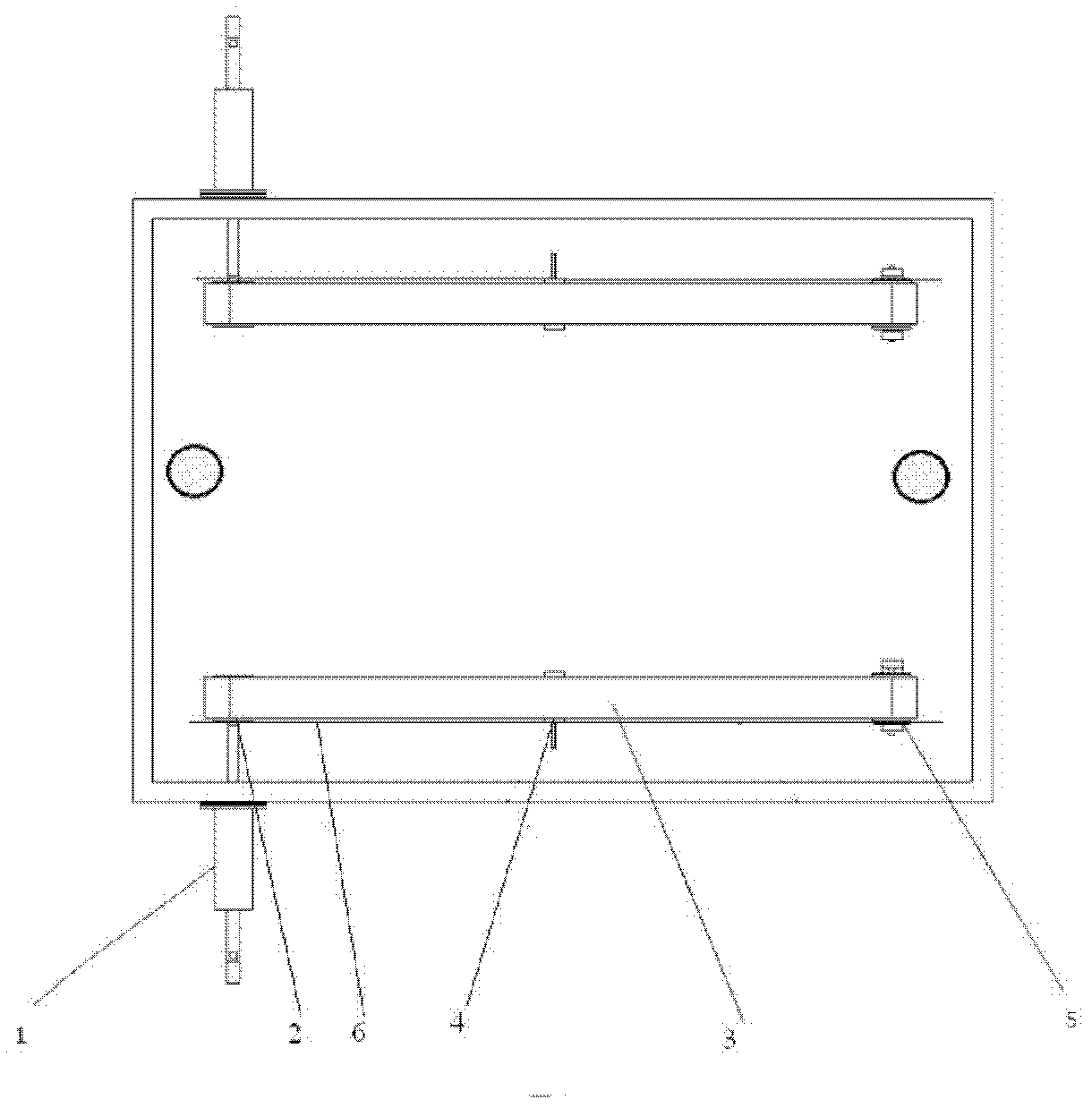

[0019] A cooling chamber delivery system in an LPCVD process, such as figure 2 , 3 Shown, comprise a group of transmission rollers 2, also comprise driven roller 5 and the transmission belt 3 driven by transmission roller 2, transmission roller 2 and driven roller 5 are respectively positioned at the two ends of transmission direction of transmission belt 3; Transmission belt 3 is One on each side, respectively erected on the driving roller 2 and the driven roller 5 on both sides of the cooling chamber, to ensure that the conveyor belt 3 can run at a constant speed, and then drive the glass to be transported at a uniform speed.

[0020] The conveying belt 3 is a belt resistant to a high temperature of 200°C, which can ensure that the contact between the edge of the glass and the belt will not reduce the service life of the belt. Simultaneously, because the conveyer belt 3 itself is a poor conductor of heat, it will not cause drastic changes in the local temperature of the gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com