Patents

Literature

37results about How to "Increase guide length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electronic cigarette

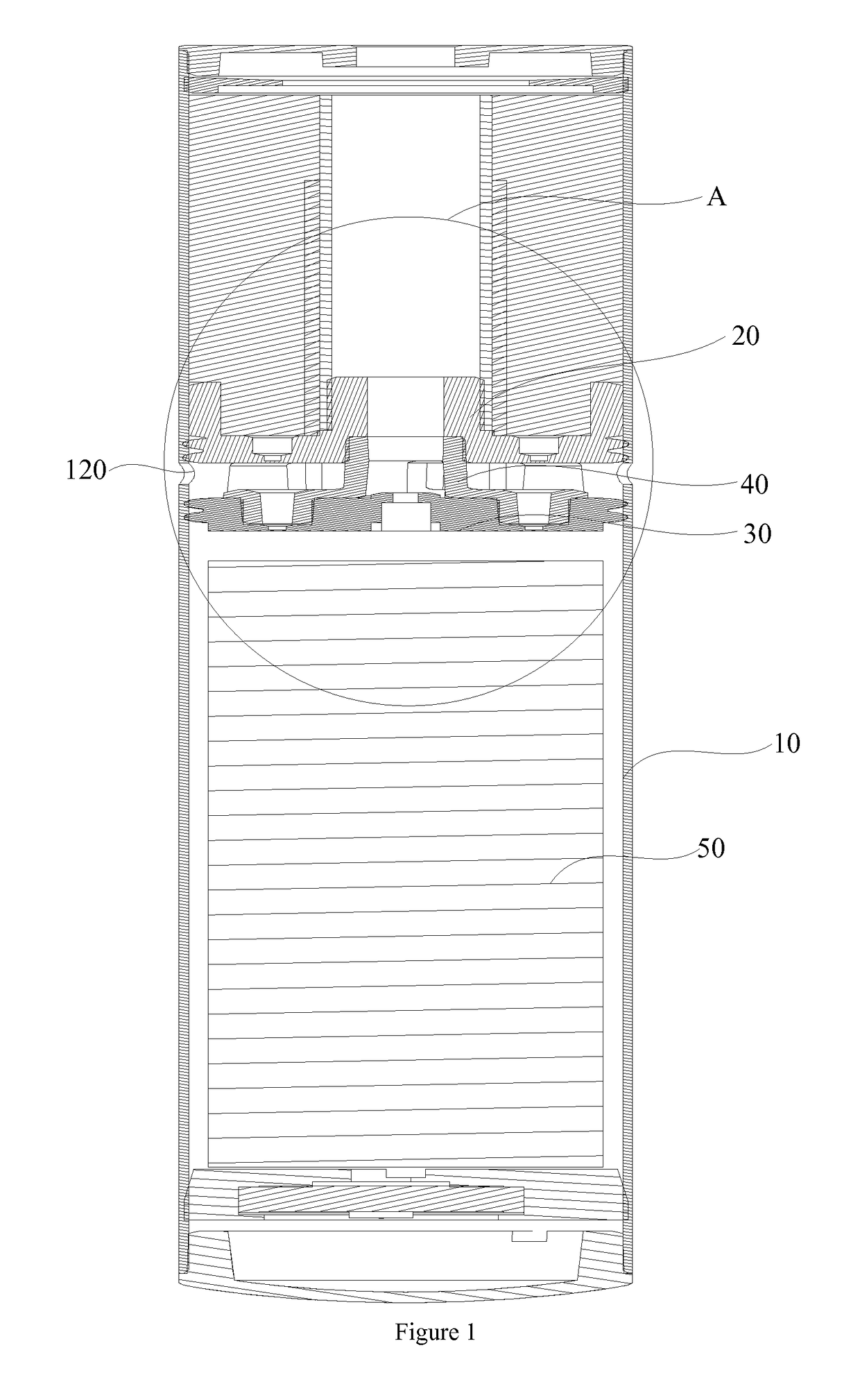

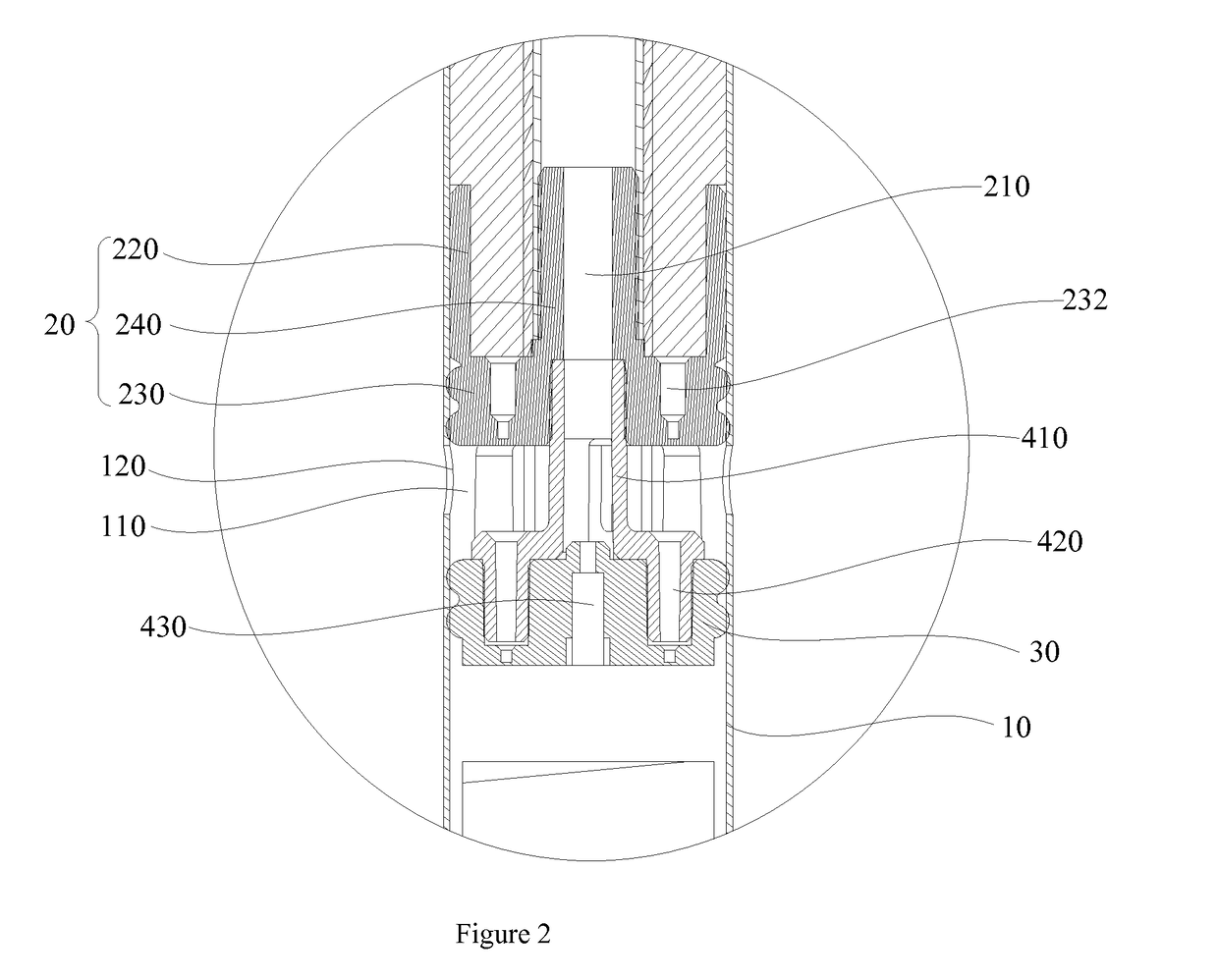

ActiveUS20150020826A1Increase guide lengthImprove leak resistanceTobacco pipesTobacco devicesInterference fitElectronic cigarette

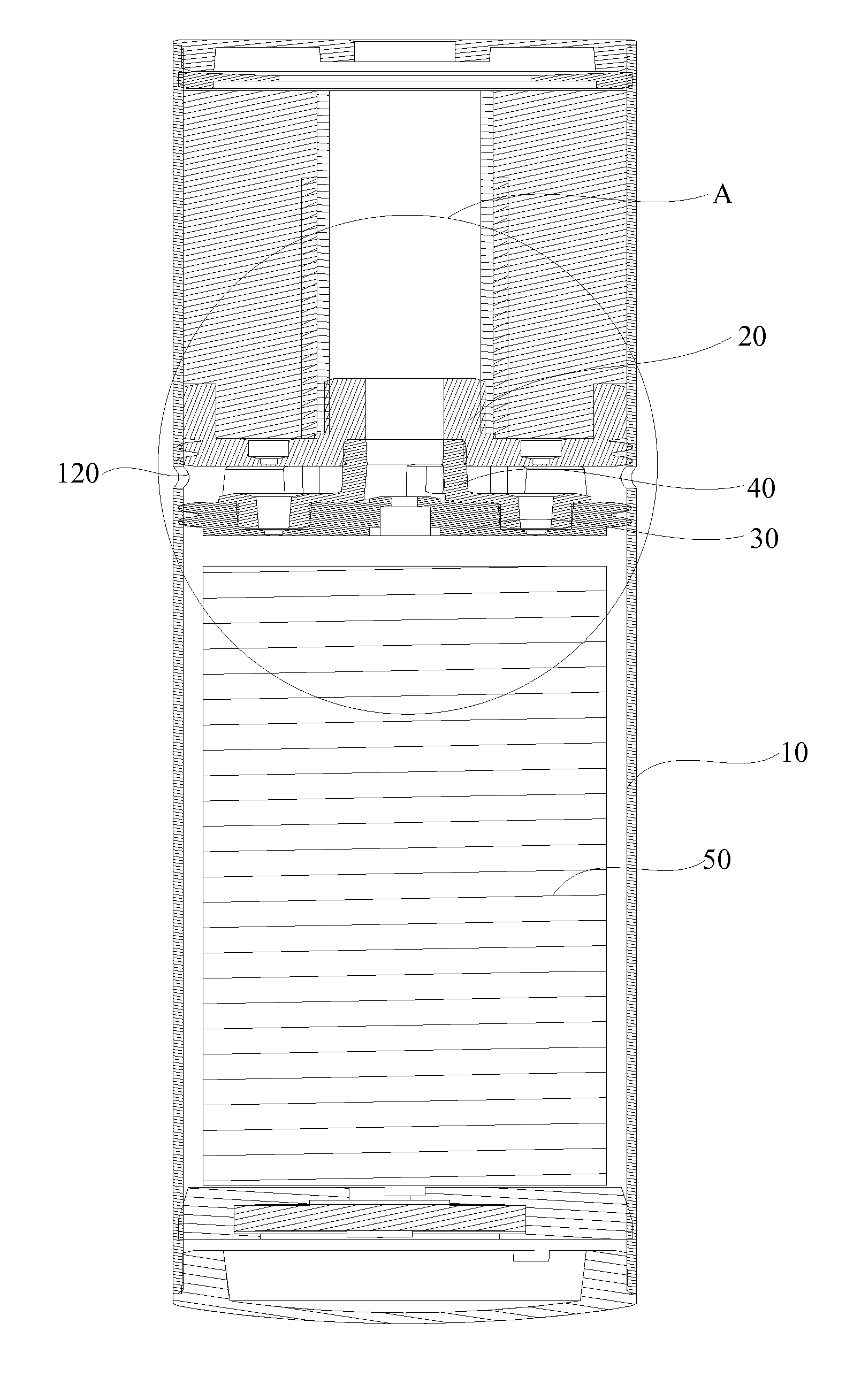

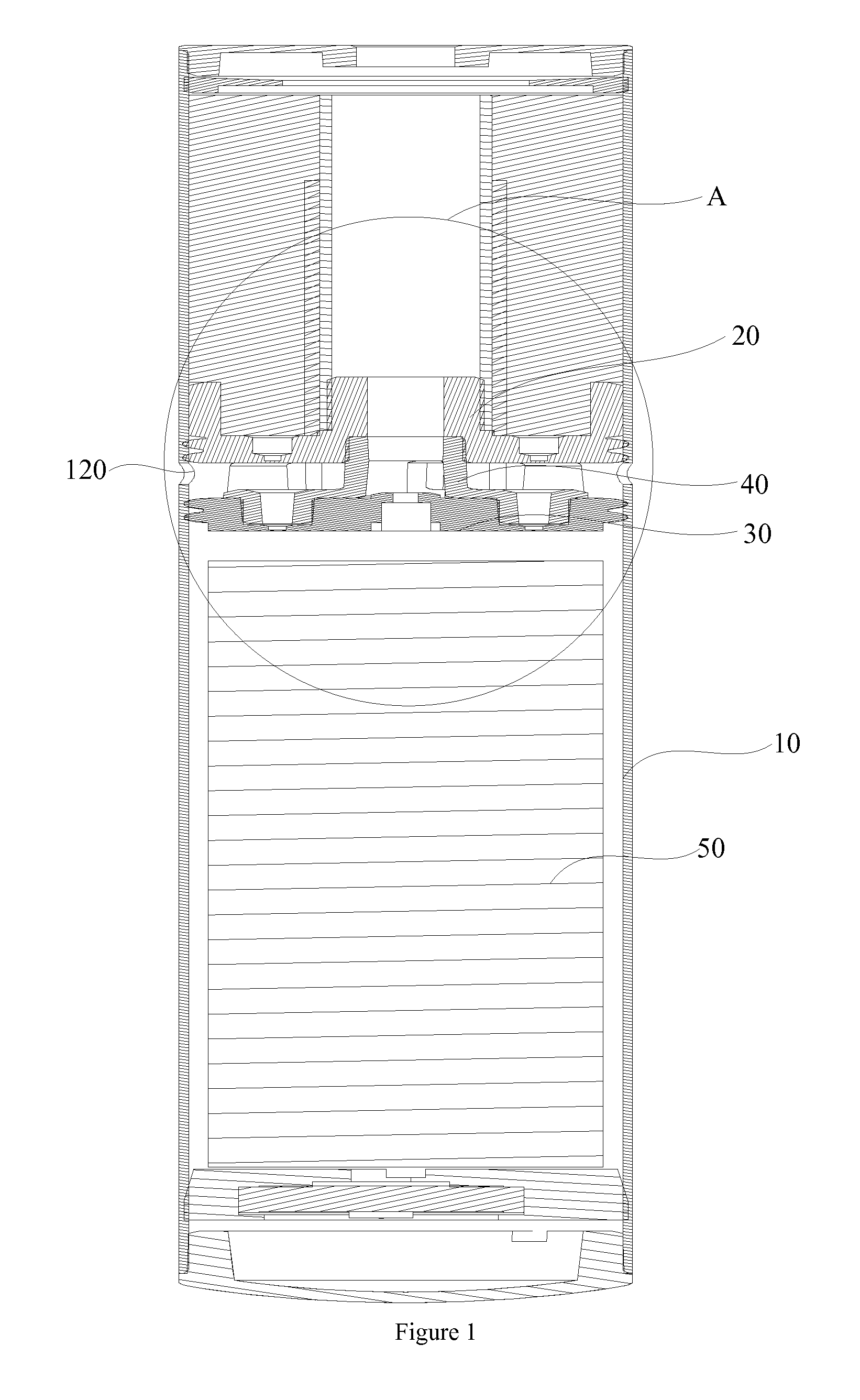

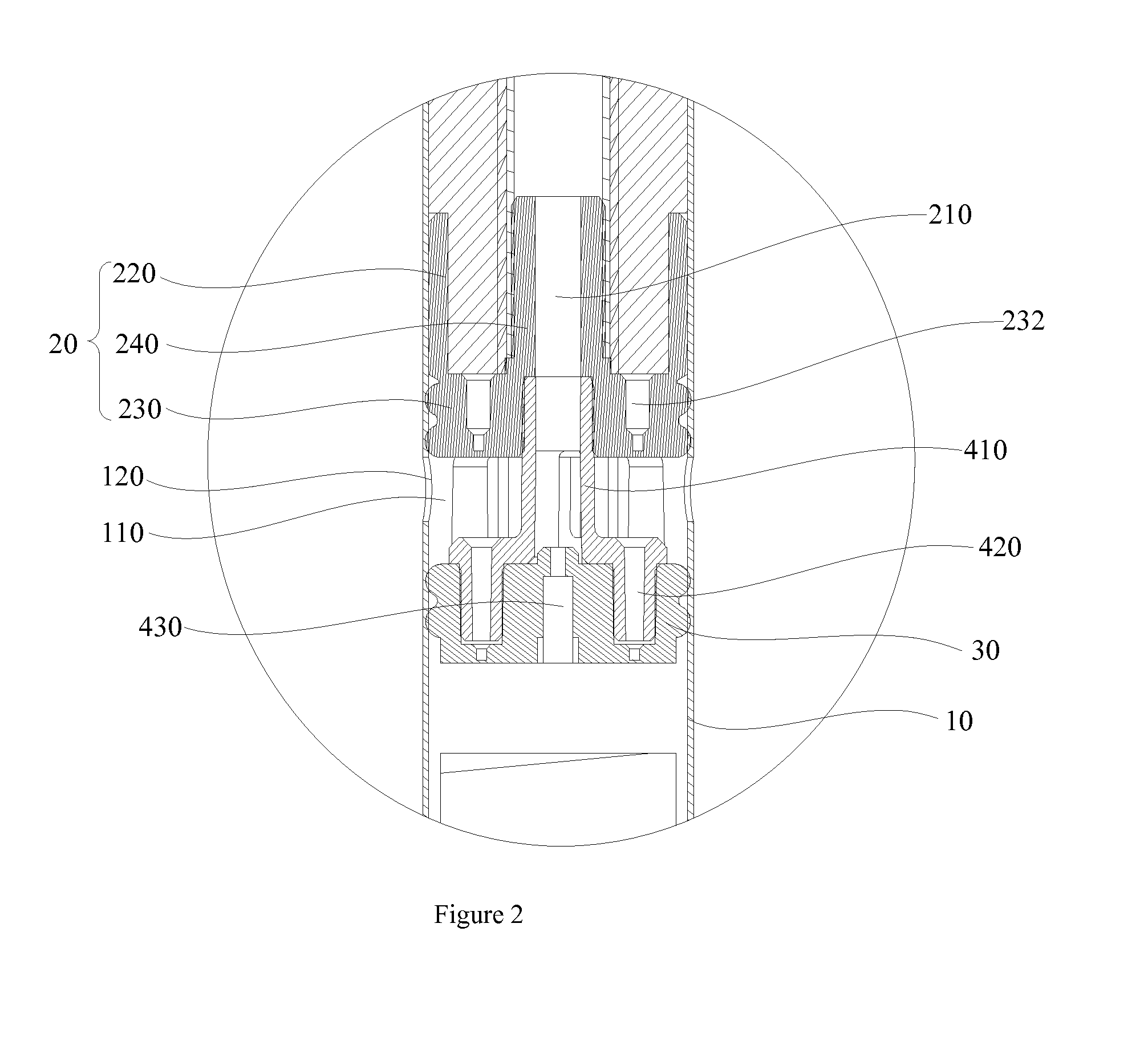

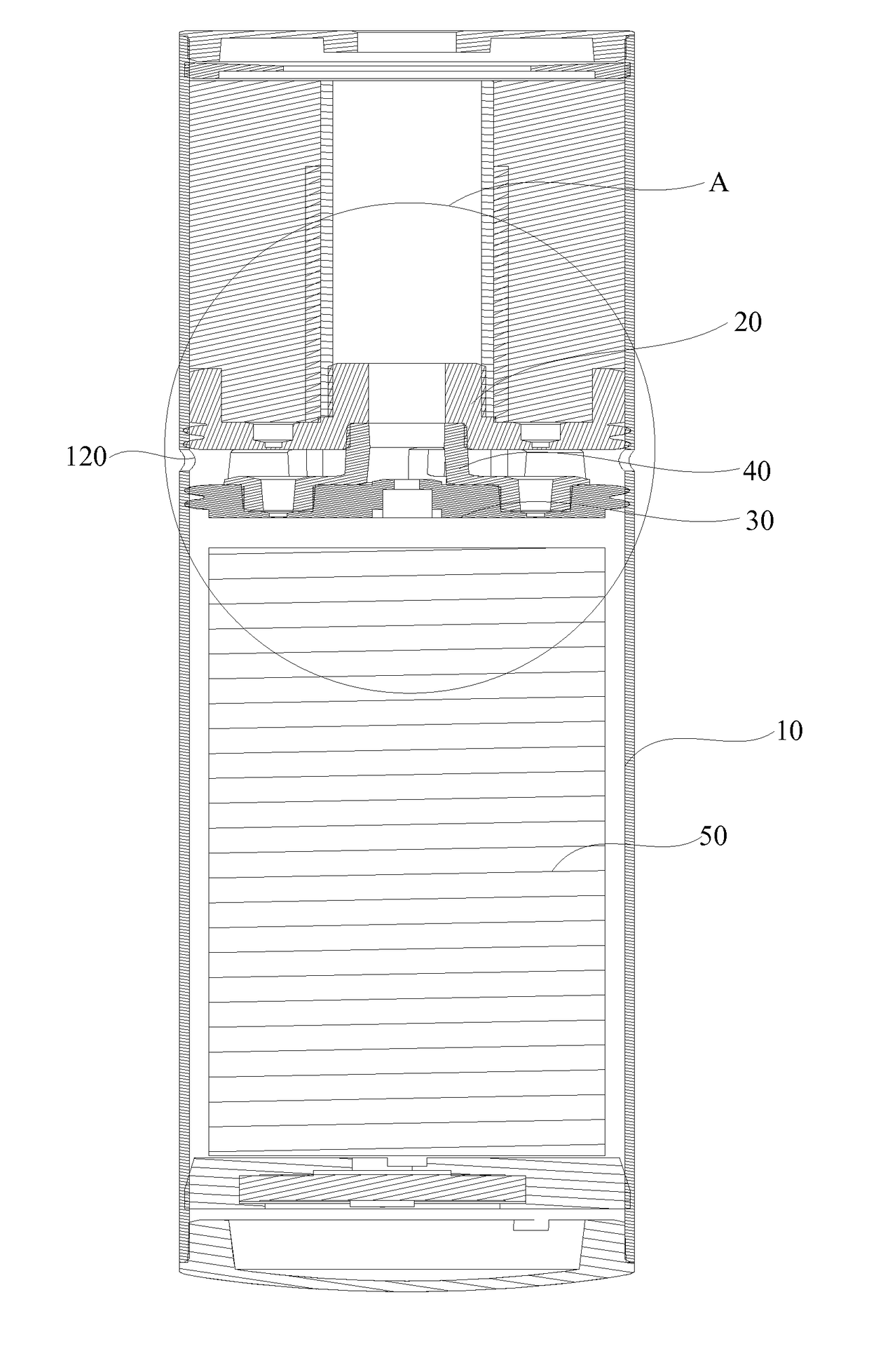

An electronic cigarette is provided, comprising a case, an atomizer seat, and a battery, both the atomizer seat and the battery accommodated in the case, the atomizer seat defining a first through hole; wherein, a bracket and a sealing component corresponding to the bracket are mounted between the atomizer seat and the battery, an extension part corresponding to the first through hole is formed at one side of the bracket facing the atomizer seat, the extension part is inserted in the first through hole to prevent the atomizer seat and the sealing component from leaning, and the sealing component is sleeved in the case and cooperates with an inner surface of the case to form interference fit.

Owner:HUIZHOU KIMREE TECH

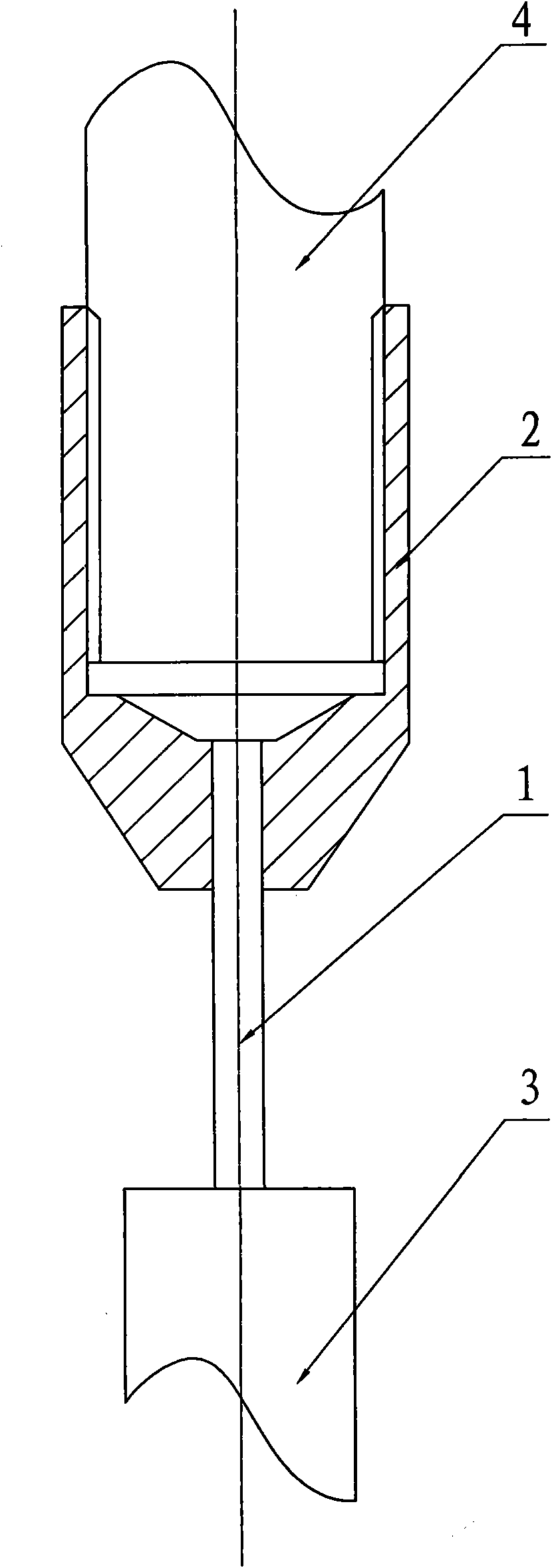

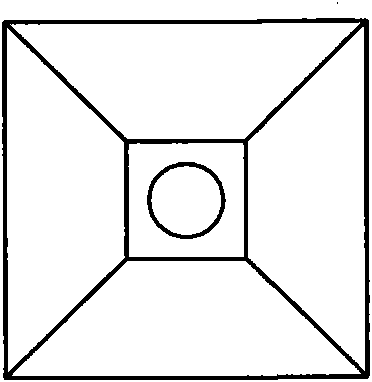

Leakage prevention structure for an electronic cigarette and electronic cigarette

ActiveUS9700075B2Increase guide lengthImprove leak resistanceTobacco devicesEngineeringElectrical and Electronics engineering

An electronic cigarette is provided, comprising a case, an atomizer seat, and a battery, both the atomizer seat and the battery accommodated in the case, the atomizer seat defining a first through hole; wherein, a bracket and a sealing component corresponding to the bracket are mounted between the atomizer seat and the battery, an extension part corresponding to the first through hole is formed at one side of the bracket facing the atomizer seat, the extension part is inserted in the first through hole to prevent the atomizer seat and the sealing component from leaning, and the sealing component is sleeved in the case and cooperates with an inner surface of the case to form interference fit.

Owner:HUIZHOU KIMREE TECH

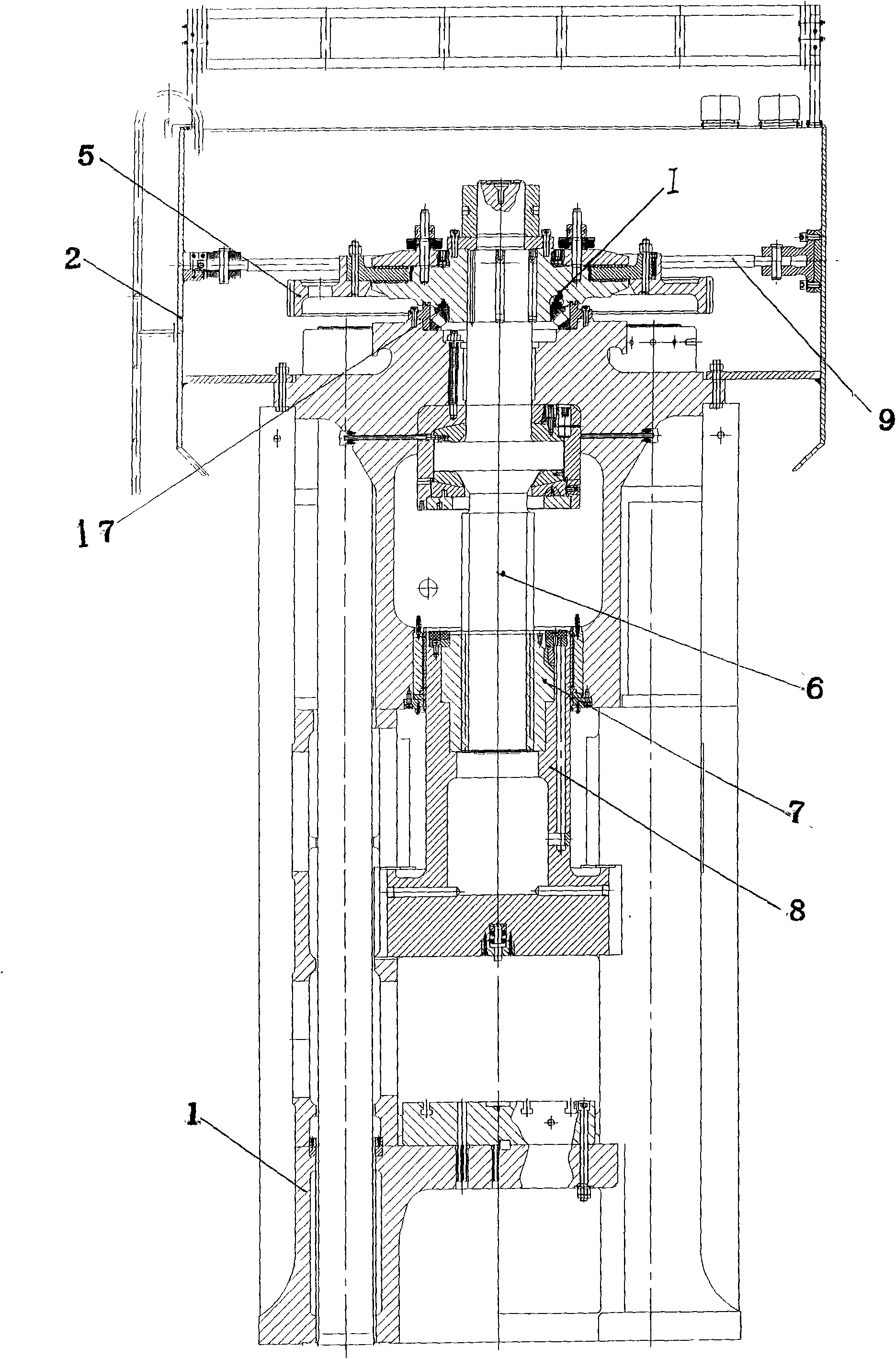

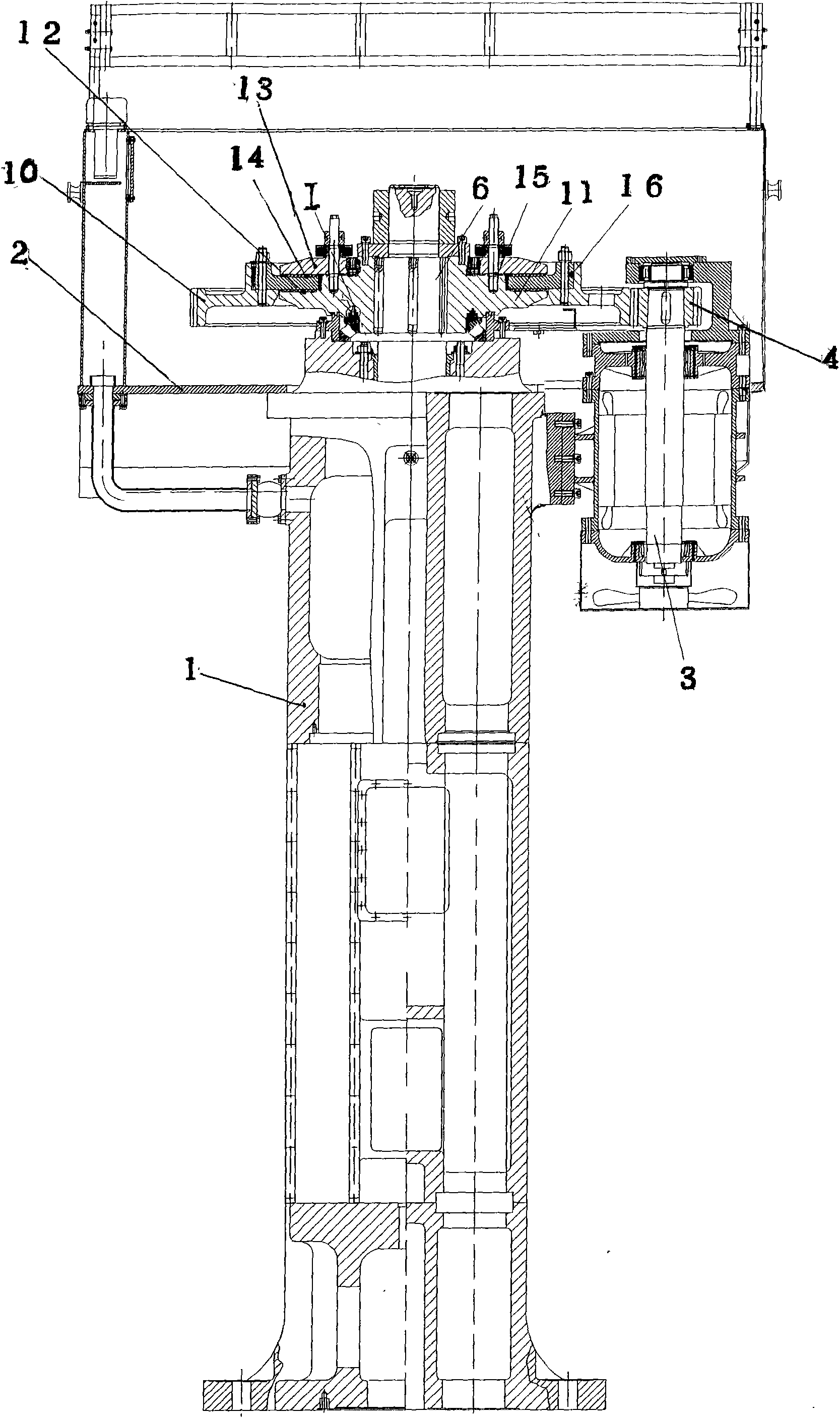

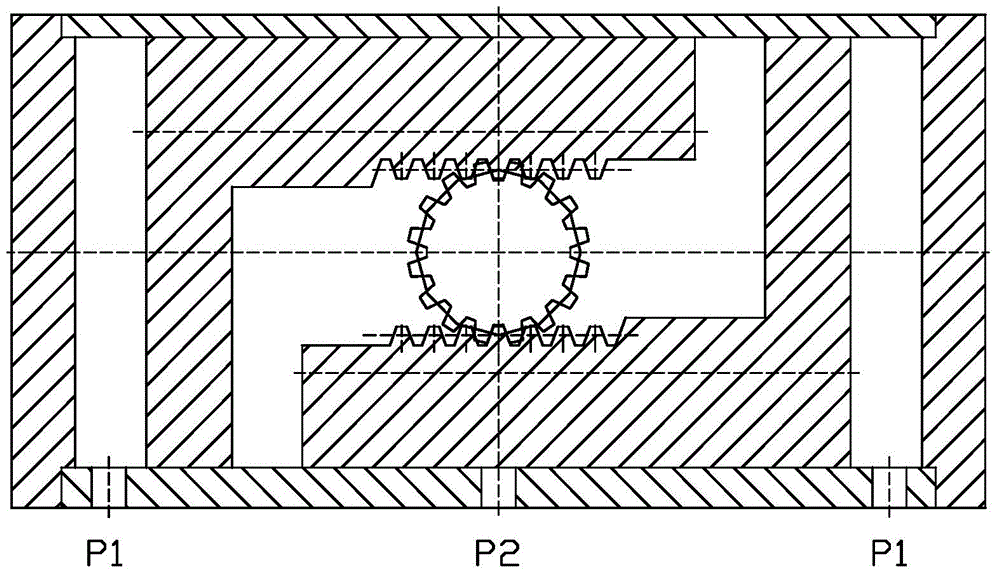

Overload protecting electric screw press

InactiveCN101554640ABig hit energyEliminate energyForging/hammering/pressing machinesForging press drivesLoad resistanceEngineering

An overload protecting electric screw press comprises a body, a platform arranged above the body, a special driving motor vertically disposed and installed at the cross beam of the body, a small driving gear directly mounted on the output shaft of the special driving motor, a friction slipping big flywheel driven by the small driving gear through the joggled transmission, a screw fixed at the flywheel through a pin, a nut driven by the screw, a slide block fixed together with the nut, and an external brake shoe brake installed at the platform for braking the flywheel. The invention has simple structure, a few components, short transmission chain, high mechanical strength, easy manufacturing, convenient maintenance, low cost, simple operation, low loss of components, anti-waving by buffering, good coaxiality, stable running, high beating force and deformation energy, high forming accuracy, strong unbalance loading resistance ability, overload protecting property, safety and reliability, long service life, energy saving and wide application range. The electric screw press can be widely used in forging forming industry.

Owner:青岛宏达锻压机械有限公司

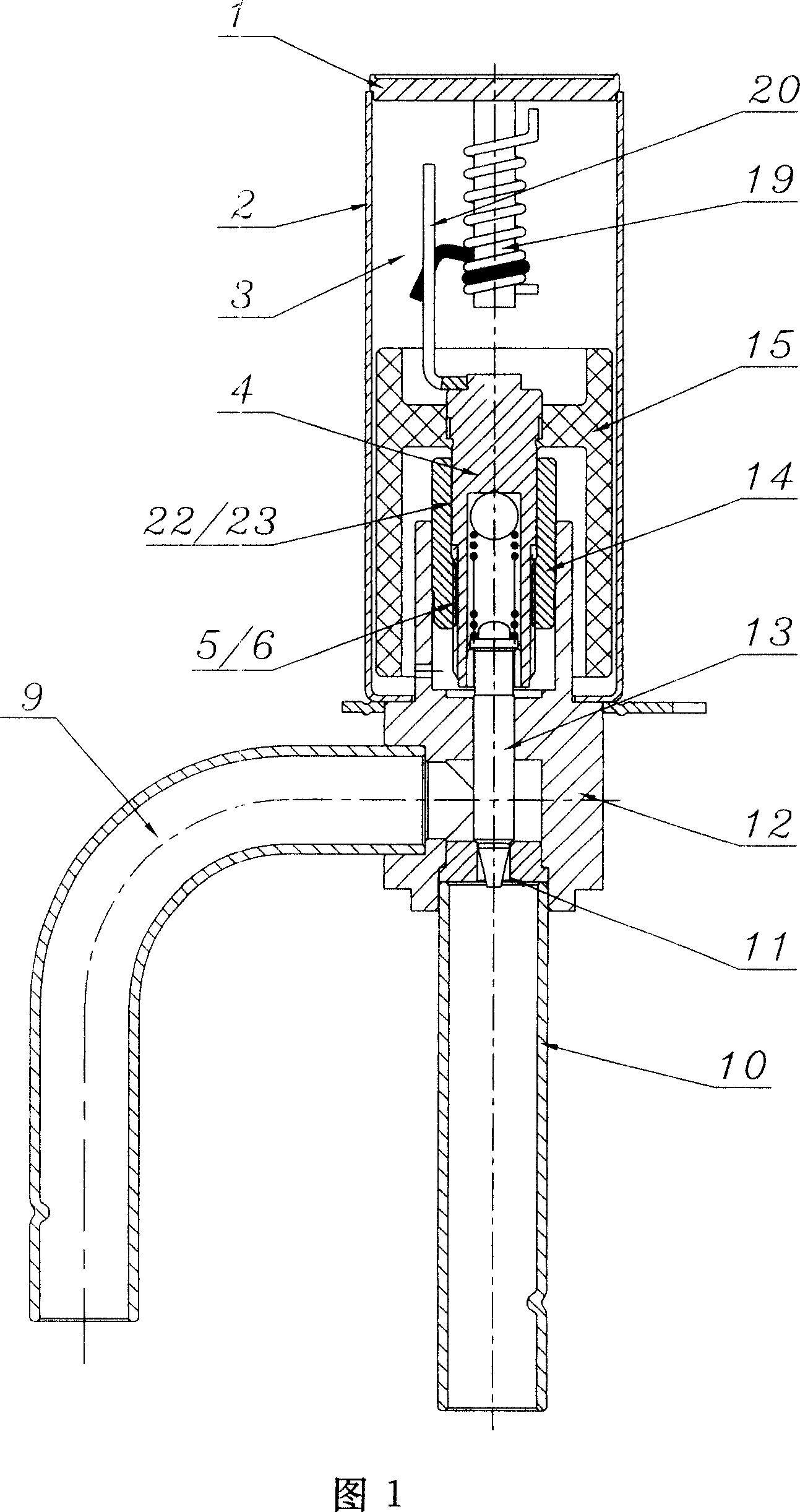

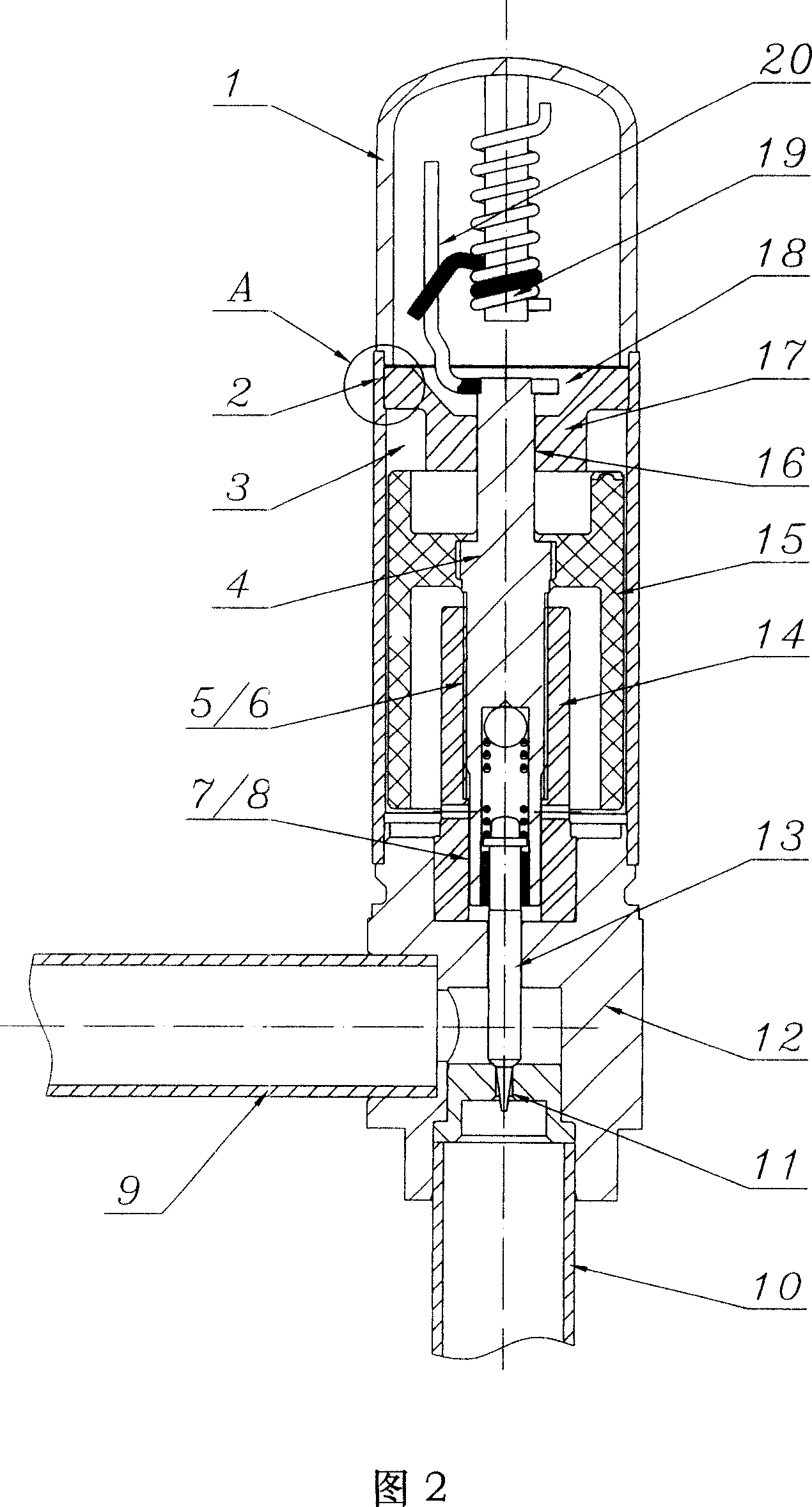

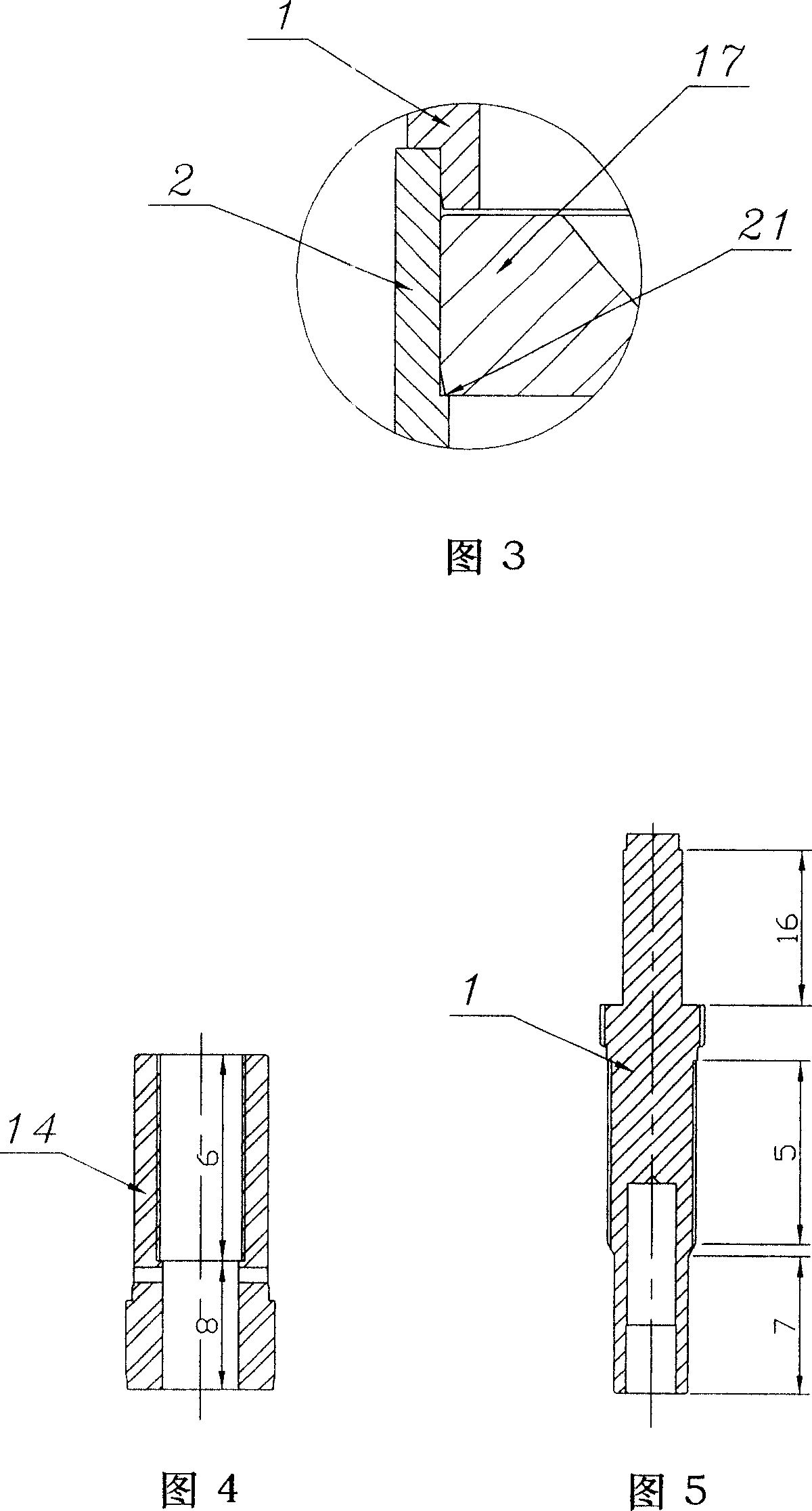

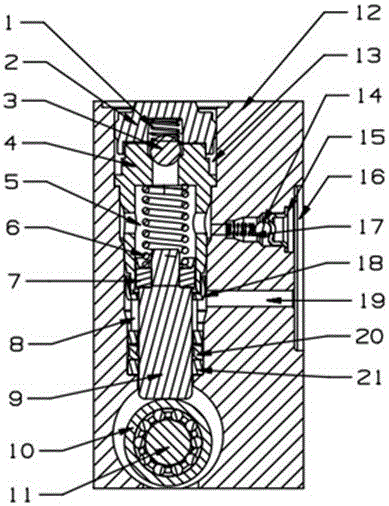

Electric valve

InactiveCN101135386AIncrease guide lengthReduce swingOperating means/releasing devices for valvesEfficient regulation technologiesEngineeringWear resistance

This invention is a motorized valve that is used to adjust refrigerant quantity of refrigerating system. Guiding element and nut are arranged at upper and lower sides of magnet inside of the holding cavity. The said guiding element has guiding hole. The said nut includes internal screw thread section and lower guiding section. The said lead screw includes intermediate external thread section, upper and lower guiding sections that protrude from upper and lower end faces of magnet. The said external and internal thread sections are cooperated. The said upper guiding section is located in the said guiding hole of guiding element. The said lower guiding section is located in the lower guiding section of the said nut. This invention extends the guiding length of lead screw. It can reduce the swing range of lead screw. This invention decreases magnet vibration and increases the abrasion resistant capability of thread section.

Owner:ZHEJIANG SANHUA CLIMATE & APPLIANCE CONTROLS GRP CO LTD

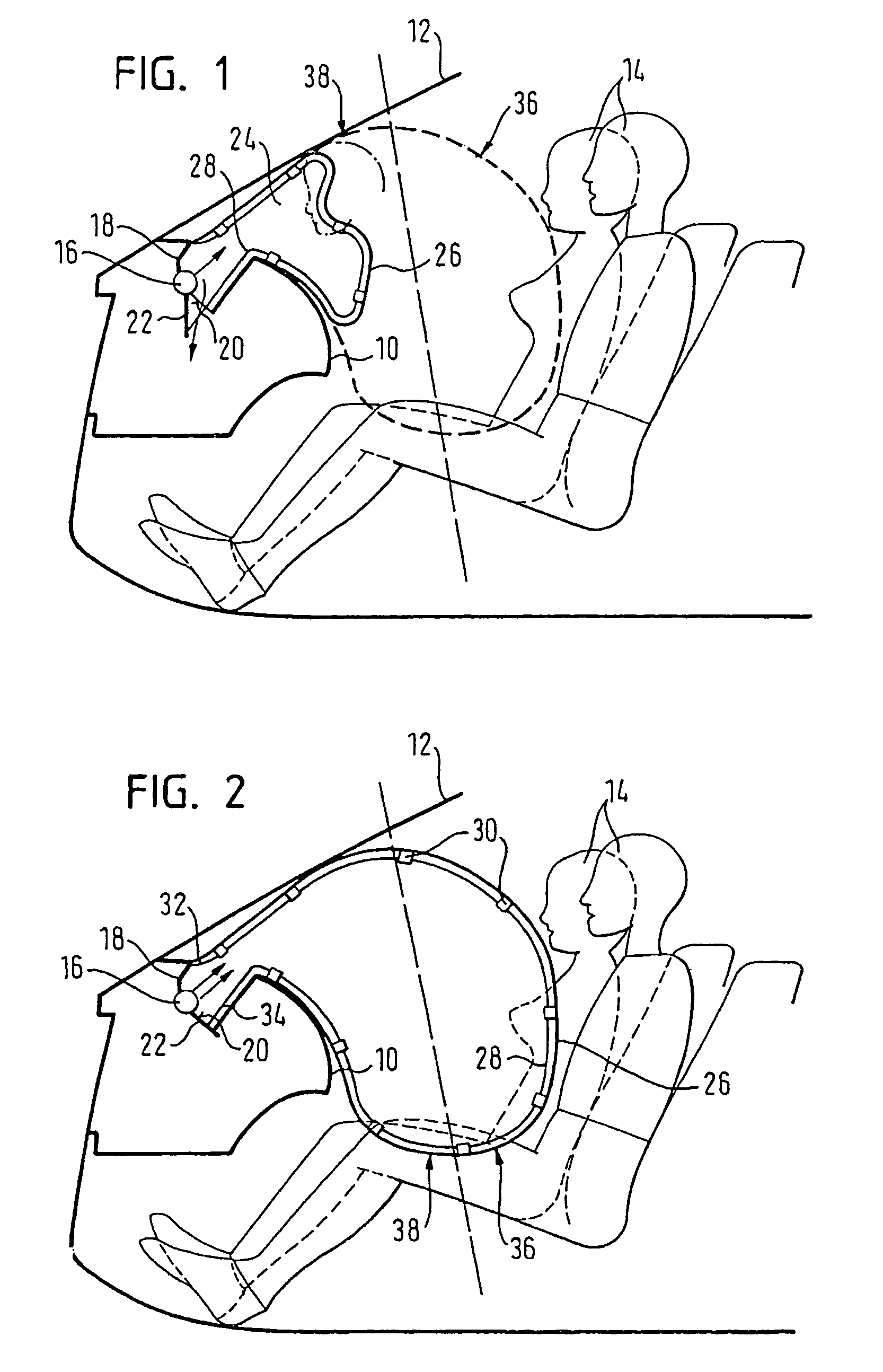

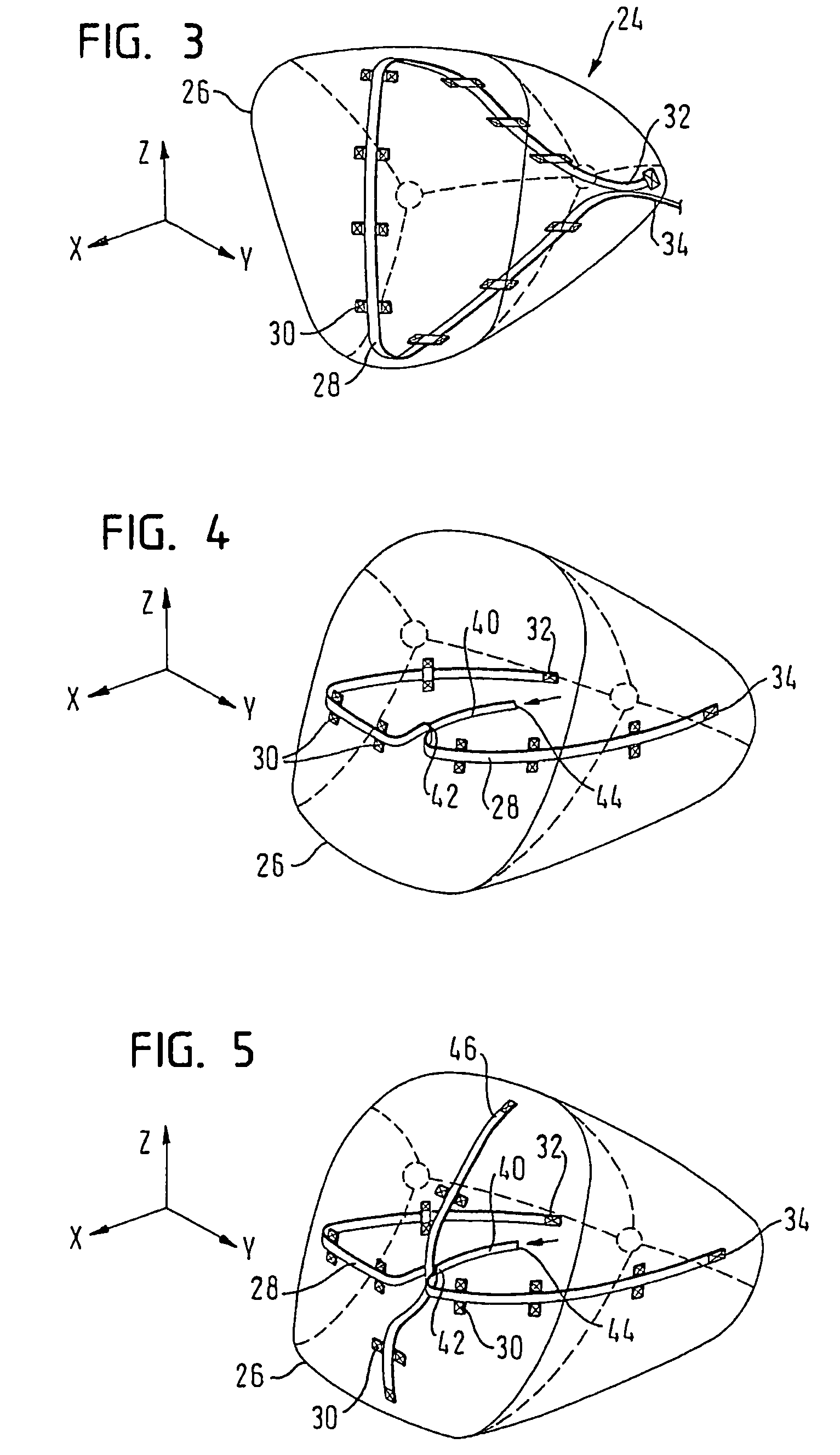

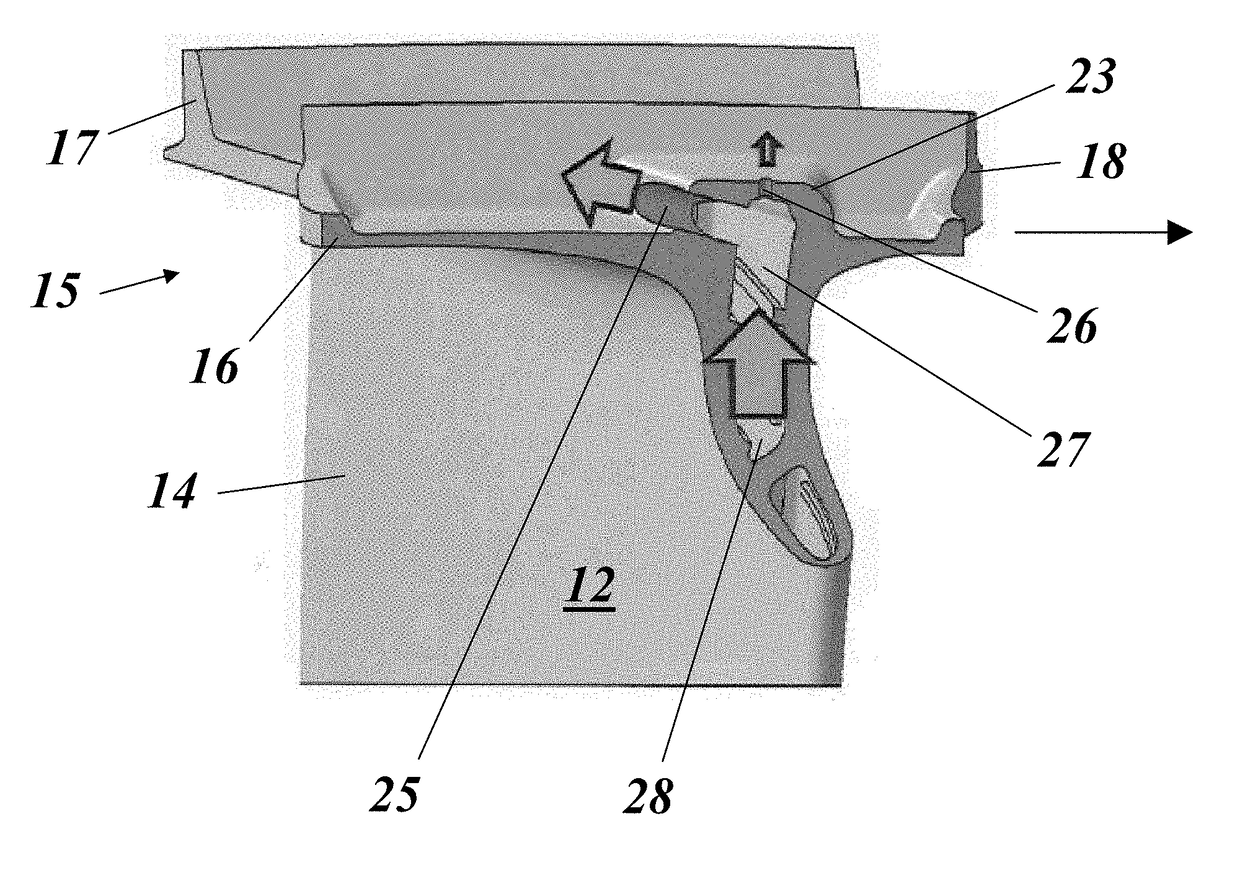

Gas bag module

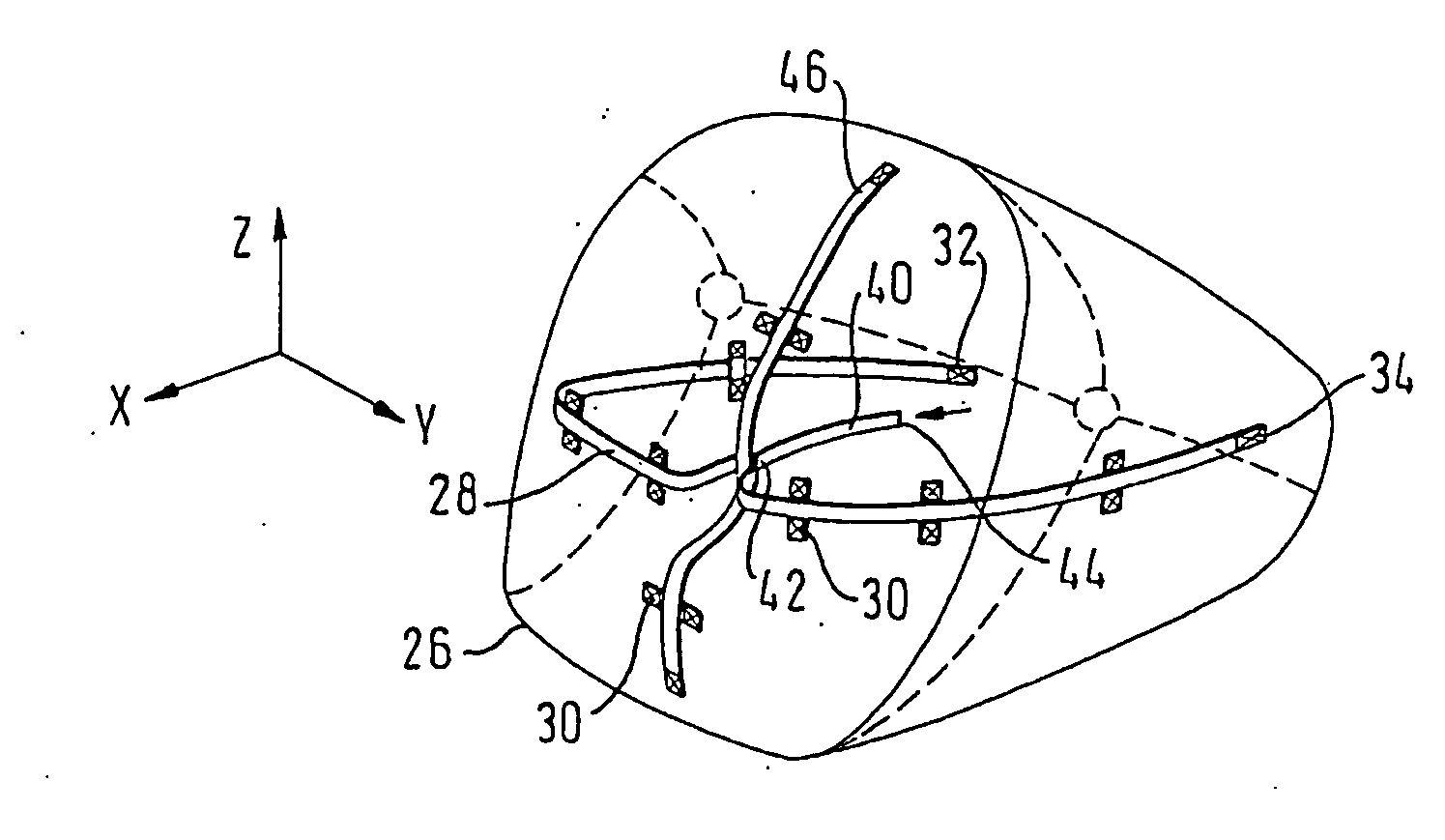

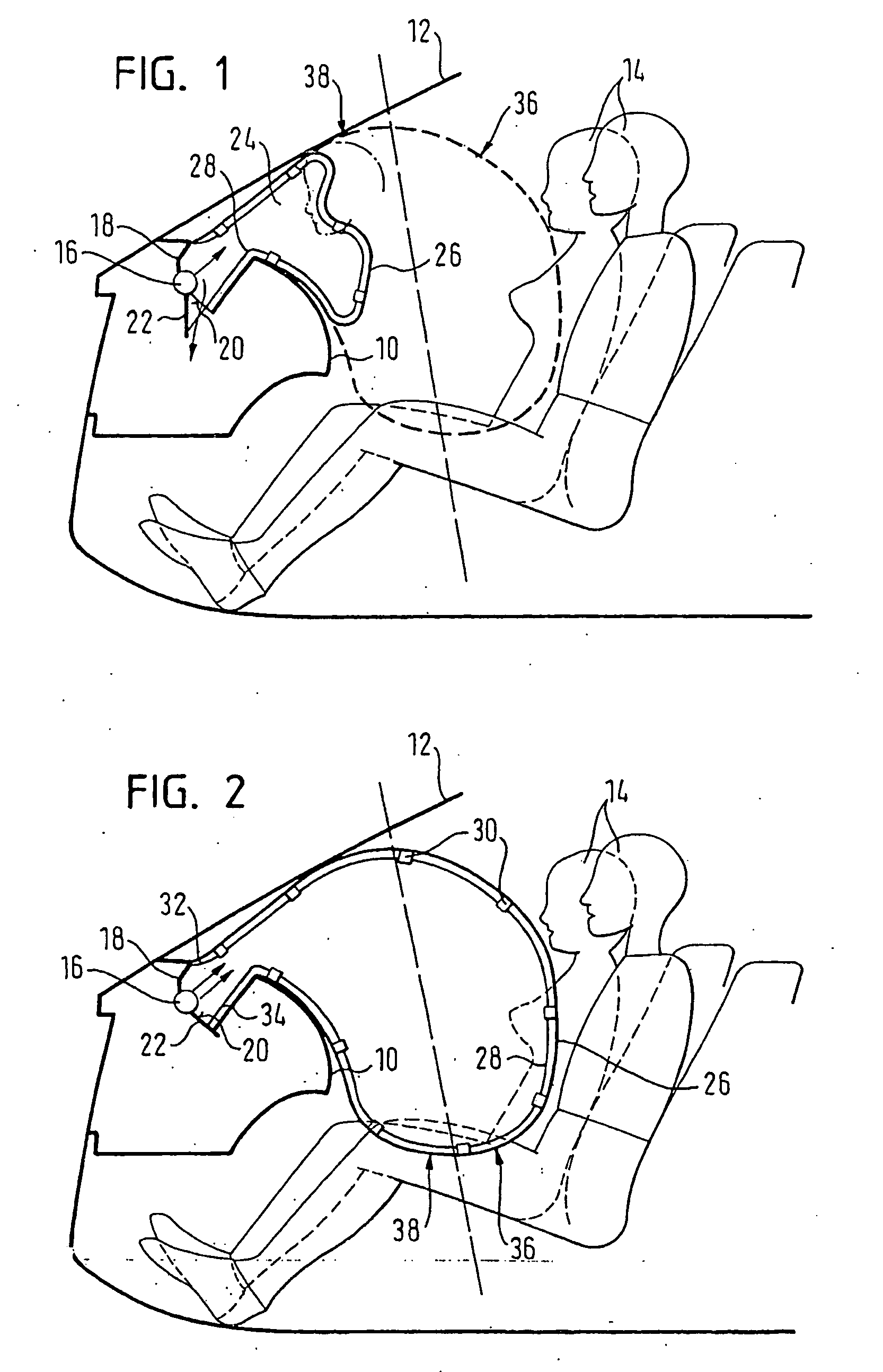

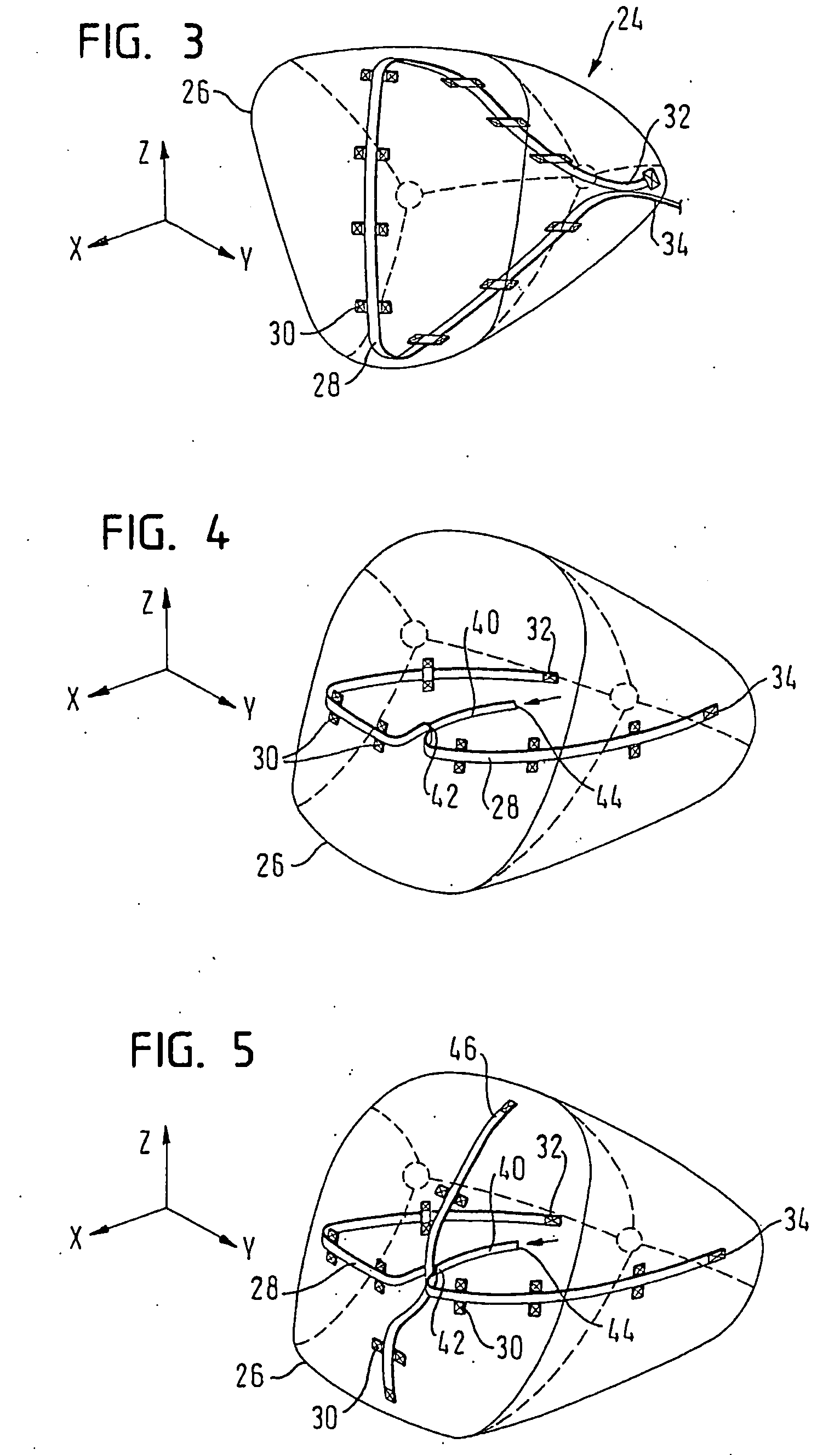

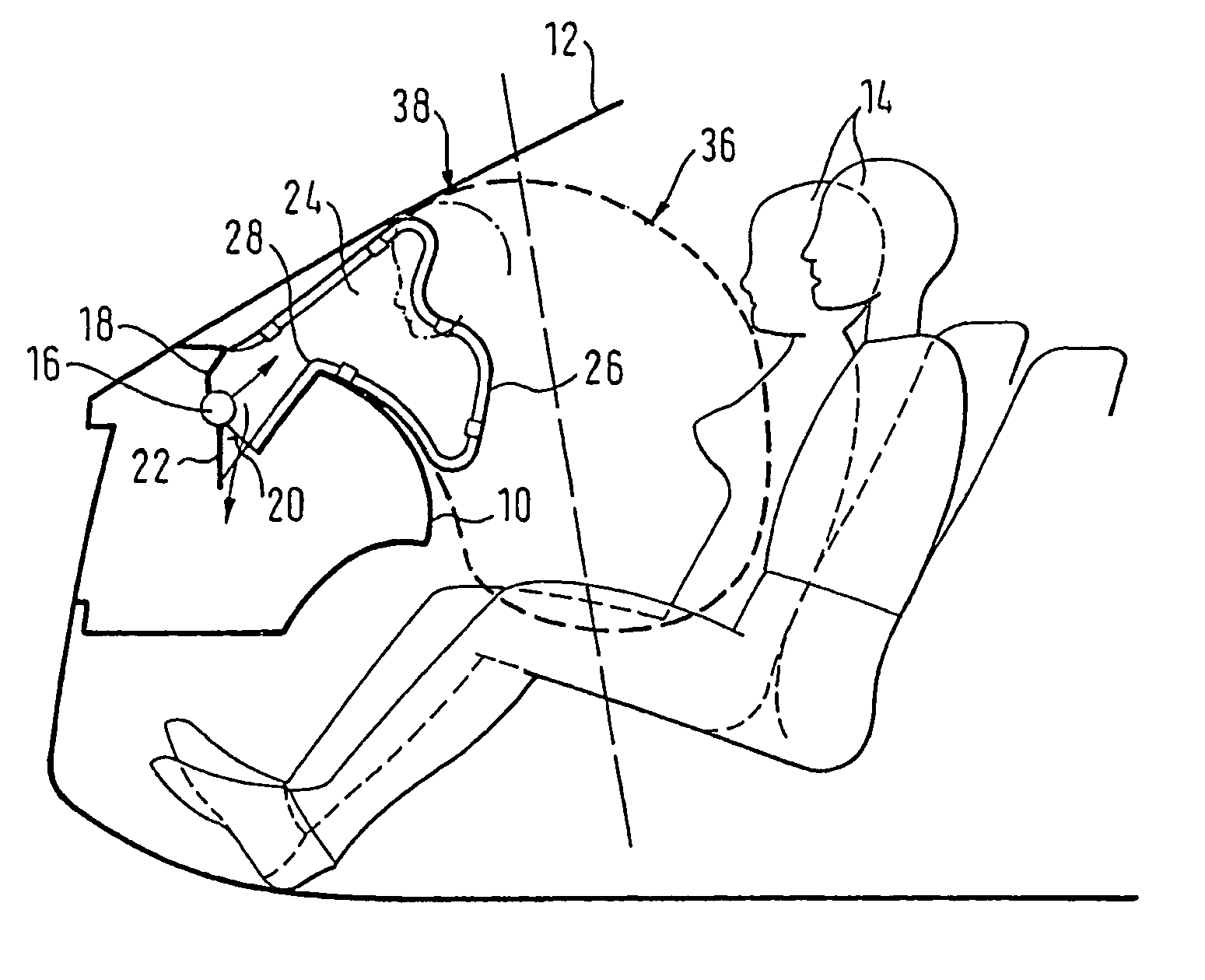

ActiveUS20070080530A1Possible influenceEasy transferPedestrian/occupant safety arrangementEngineeringMechanical engineering

A gas bag module includes a module housing (18), a gas bag (24) having a gas bag wall (26), a discharge opening (20) which can be closed by a closure device (22), and a limiting strap (28), the limiting strap (28) being coupled with the gas bag wall (26) and the closure device (22). The limiting strap (28) is tensioned in case of an unimpeded unfolding of the gas bag (24) such that the closure device (22) closes the discharge opening (20), and the limiting strap (28) is guided along the gas bag wall (26).

Owner:TRW AUTOMOTIVE GMBH

Gas bag module

ActiveUS7789421B2Easy to installEasy to movePedestrian/occupant safety arrangementEngineeringMechanical engineering

A gas bag module includes a module housing (18), a gas bag (24) having a gas bag wall (26), a discharge opening (20) which can be closed by a closure device (22), and a limiting strap (28), the limiting strap (28) being coupled with the gas bag wall (26) and the closure device (22). The limiting strap (28) is tensioned in case of an unimpeded unfolding of the gas bag (24) such that the closure device (22) closes the discharge opening (20), and the limiting strap (28) is guided along the gas bag wall (26).

Owner:TRW AUTOMOTIVE GMBH

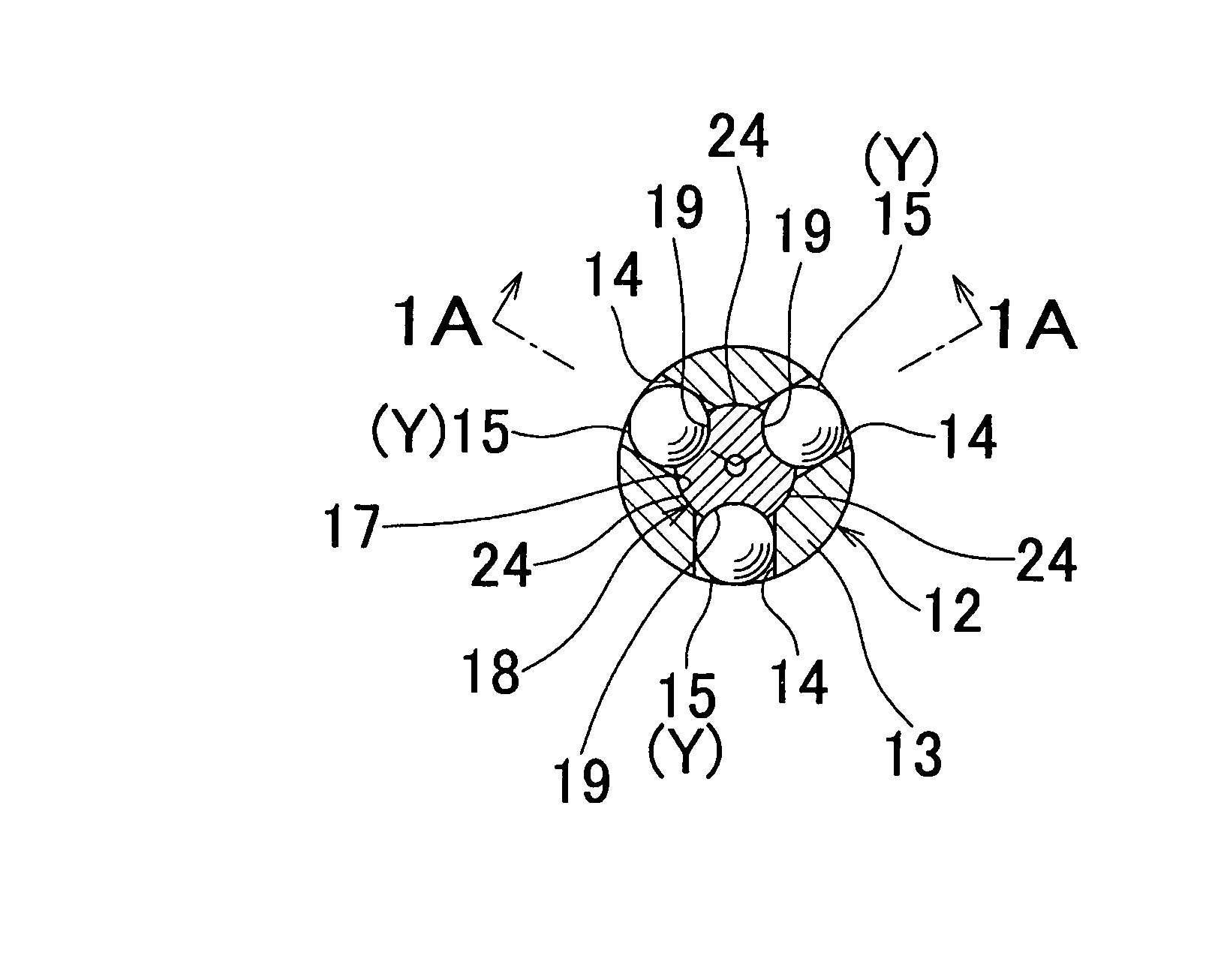

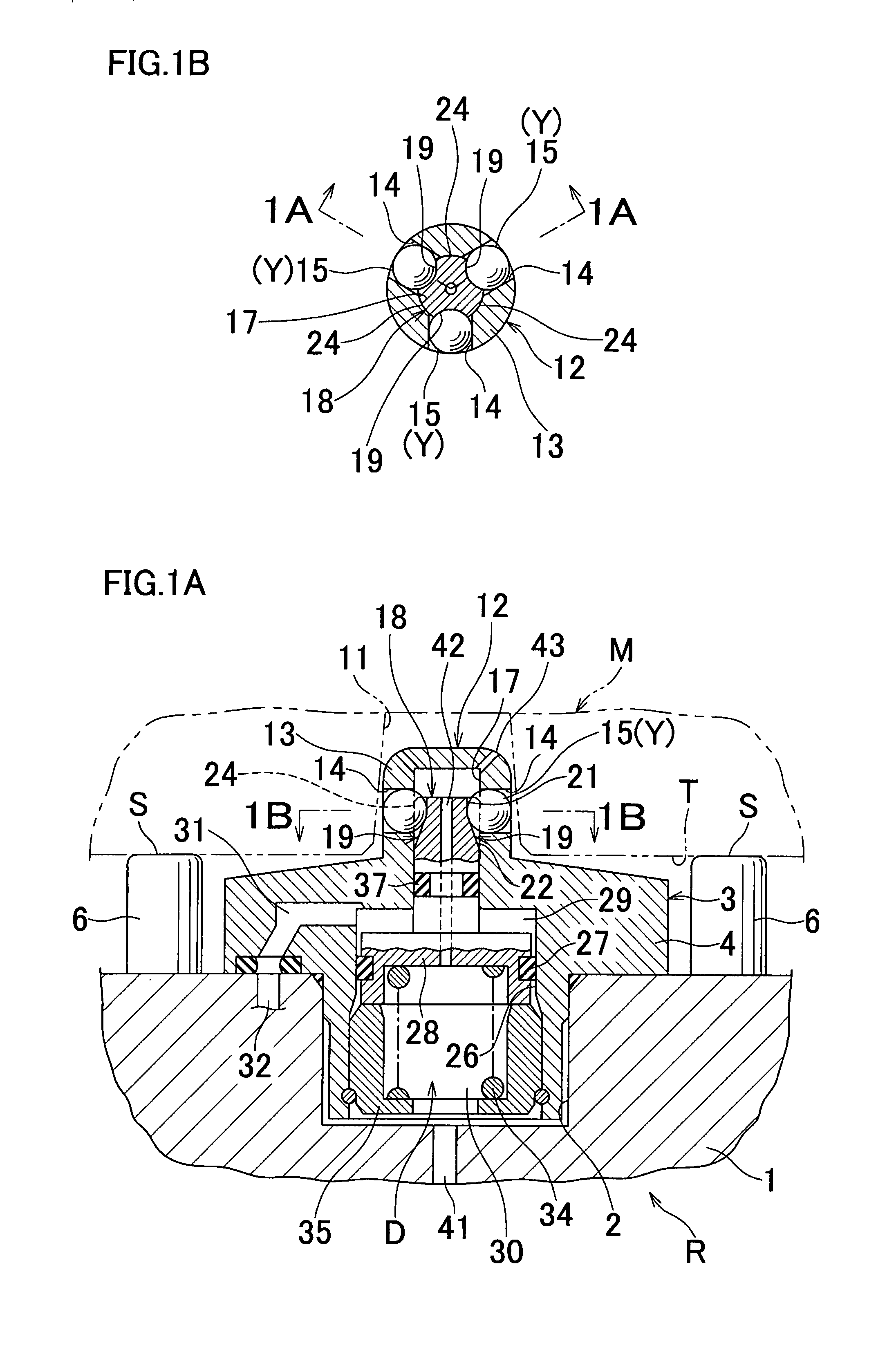

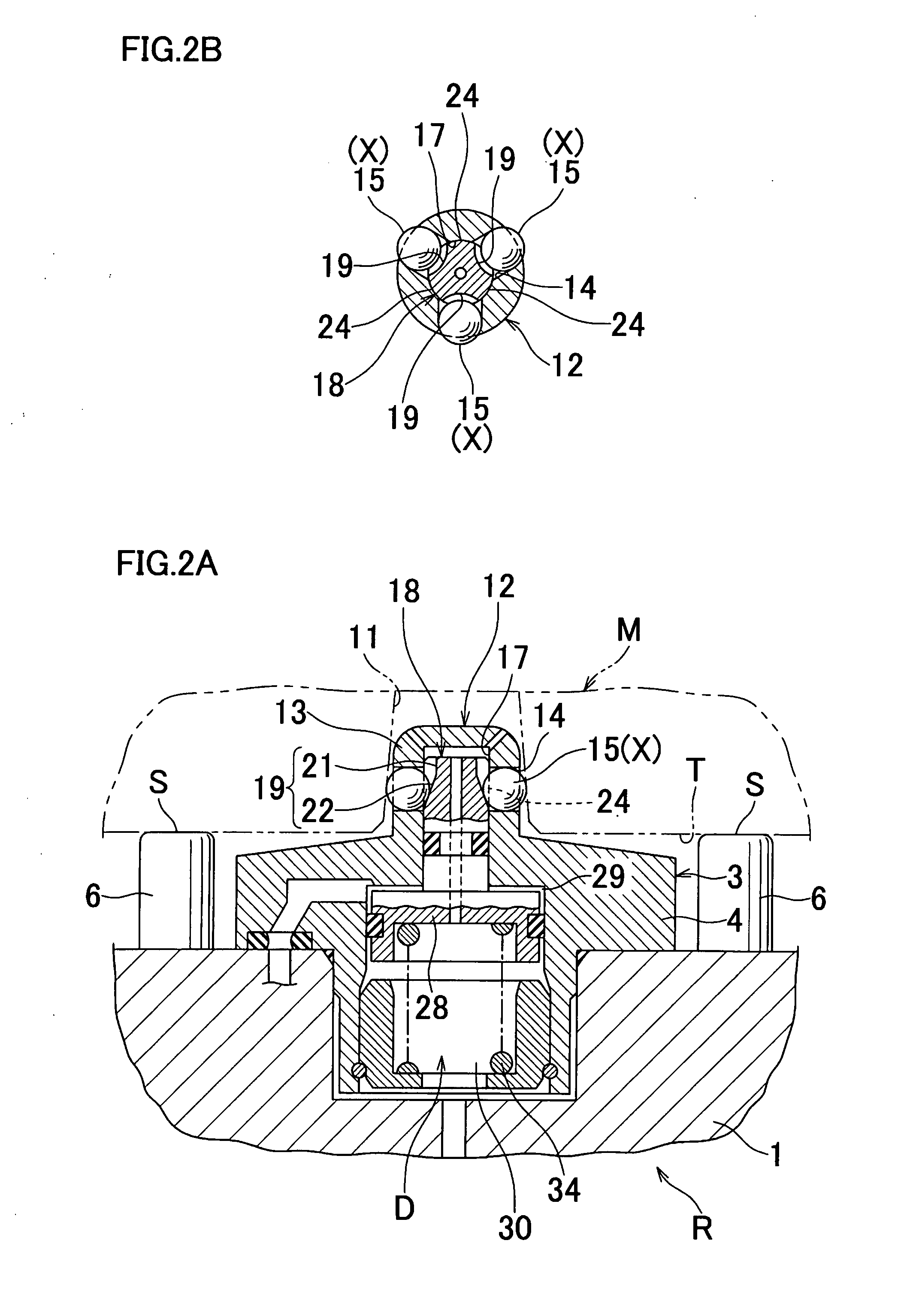

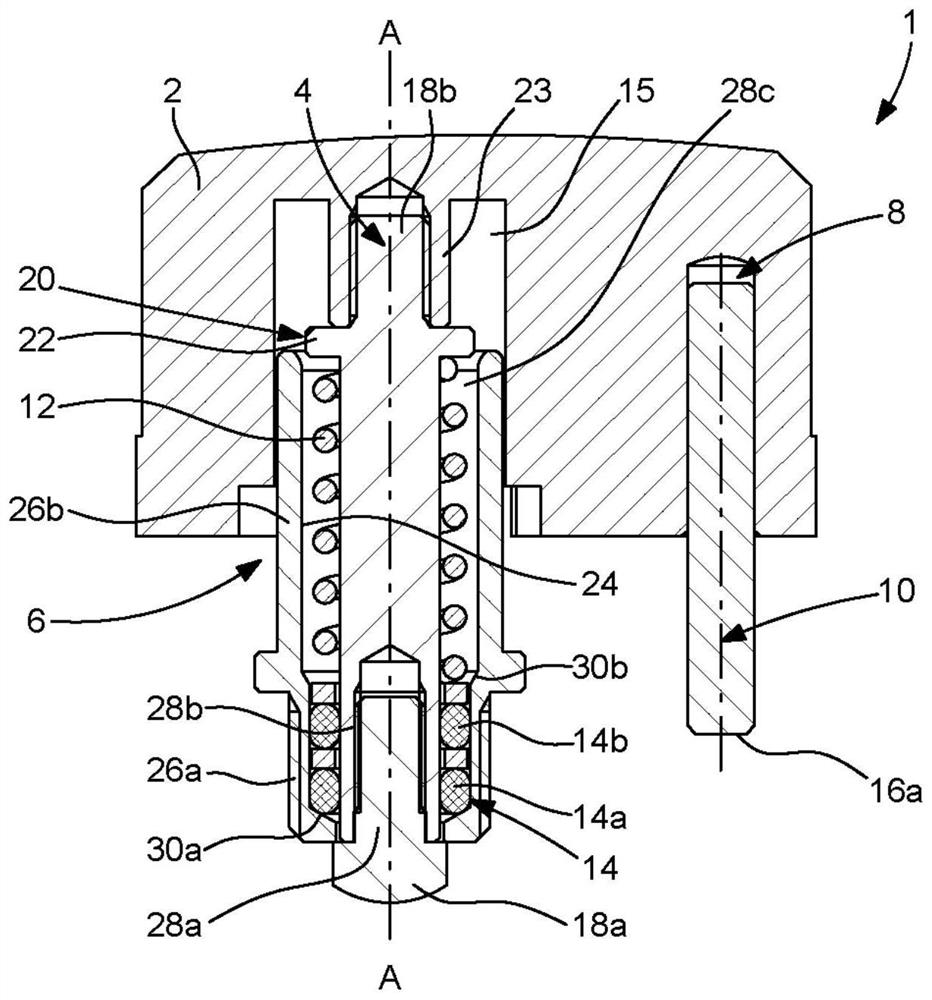

Positioning Apparatus and Positioning System Having the Same

InactiveUS20070262508A1Simple and compactMove preciselyLarge fixed membersPositioning apparatusMechanical engineeringPositioning system

An annular plug (12) to be inserted into a cast hole (11) of a work (M) is projected upward from a housing (3). In a peripheral wall (13) of the annular plug (12), through holes (14) extending radially are formed at intervals circumferentially. A ball (15) is inserted into each of the through holes (14). An operating rod (18) is inserted into a cylindrical hole (17) of the annular plug (12). In an outer peripheral surface of an upper end portion of the operating rod (18), accommodating grooves (19) extending vertically are formed at intervals circumferentially corresponding to the balls (15). Guide surfaces (24, 24, 24) are formed between the adjacent accommodating grooves (19, 19). These guide surfaces (24) are fitted into the cylindrical hole (17) so as to be prevented from moving radially and allowed to move axially.

Owner:KOSMEK LTD (JP)

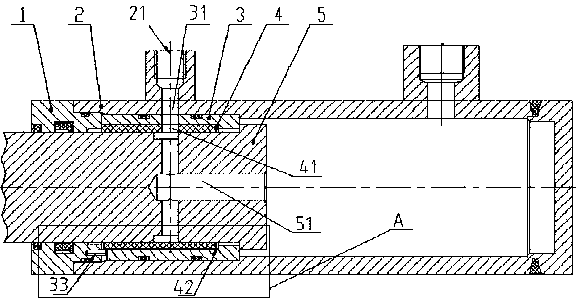

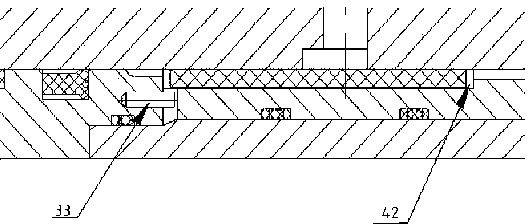

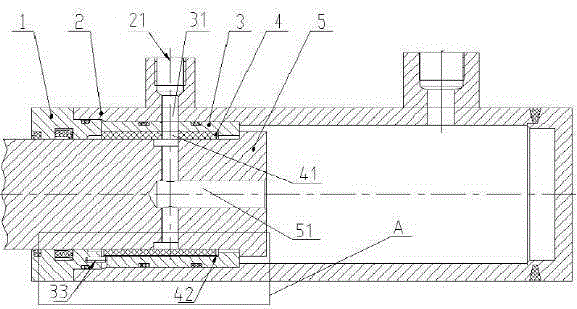

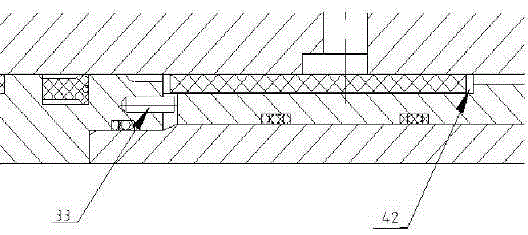

Clearance seal plunger type cylinder

ActiveCN104006023ARealize logic controlEasily damagedPiston ringsFluid-pressure actuatorsHydraulic cylinderOil free

The invention discloses a clearance seal plunger type cylinder and belongs to the technical field of hydraulic cylinders. The clearance seal plunger type cylinder comprises a cylinder barrel, a piston rod and a gland; a guide sleeve is fixed on the inner cylindrical surface of the cylinder barrel; a copper-base anti-abrasion oil-free bushing is mounted between the piston rod and the guide sleeve; an oil passage for communicating the outer side of the cylinder barrel with the high-pressure cavity of the cylinder barrel when the piston rod finishes traveling is opened in the plunger type cylinder, when the piston rod of the plunger type cylinder finishes traveling, the oil passage can output pressure oil and send a pressure signal to realize the logic control for a hydraulic system; a very small clearance is formed between the relatively moving surfaces of the copper-base anti-abrasion oil-free bushing and the piston rod to form clearance seal.

Owner:XCMG HYDRAULICS CO LTD

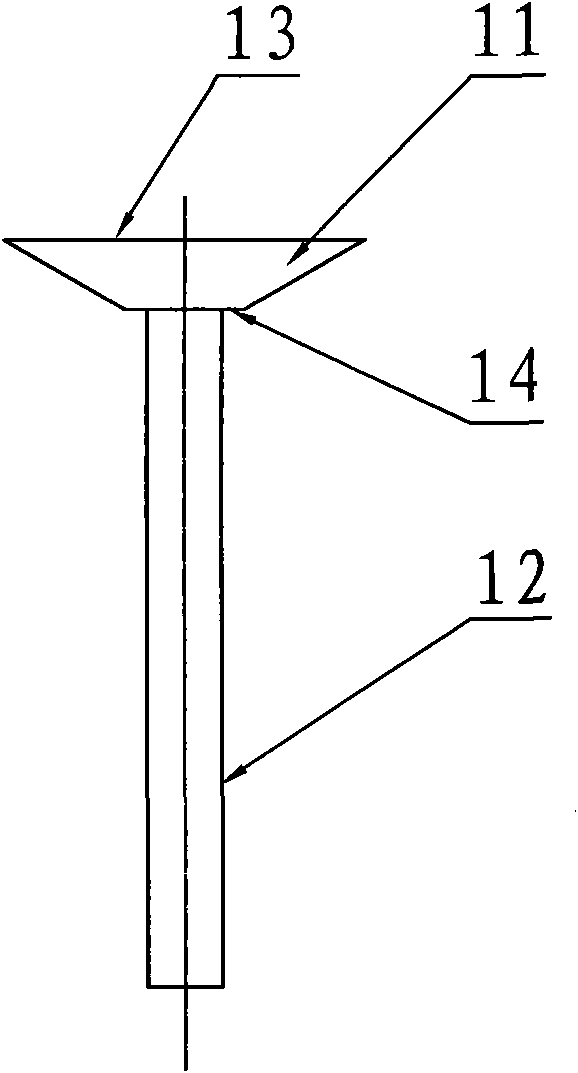

Crystal clamp part for broaching silicon rod

InactiveCN101781792AIncrease guide lengthEliminate breakage factorsBy pulling from meltEngineeringTorque transmission

The invention relates to a crystal clamp part for broaching a silicon rod, which is provided with a polygon terrace hole. A crystal is provided with a connecting polygon terrace and a lifting rod, wherein the upper terrace face of the connecting polygon terrace is greater than the lower terrace face; the lifting rod is arranged on the lower end face of the lower terrace face; the clamp is provided with a polygon terrace hole; a connecting polygon terrace for the crystal is sheathed in the polygon terrace hole; torque transmission and axial tension between the crystal and the clamp can be realized through the matched connecting structure of a shaft and the hole of the polygon terrace without grinding nicks on crystal or using a fixing pin for connection. The section area of the lifting rod on the crystal cannot be reduced so that the breaking factor of the crystal in the broaching process is eliminated in structure. The invention not only can solve the breaking problem of the crystal, but also can realize synchronous rotation of the crystal and the crystal clamp.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

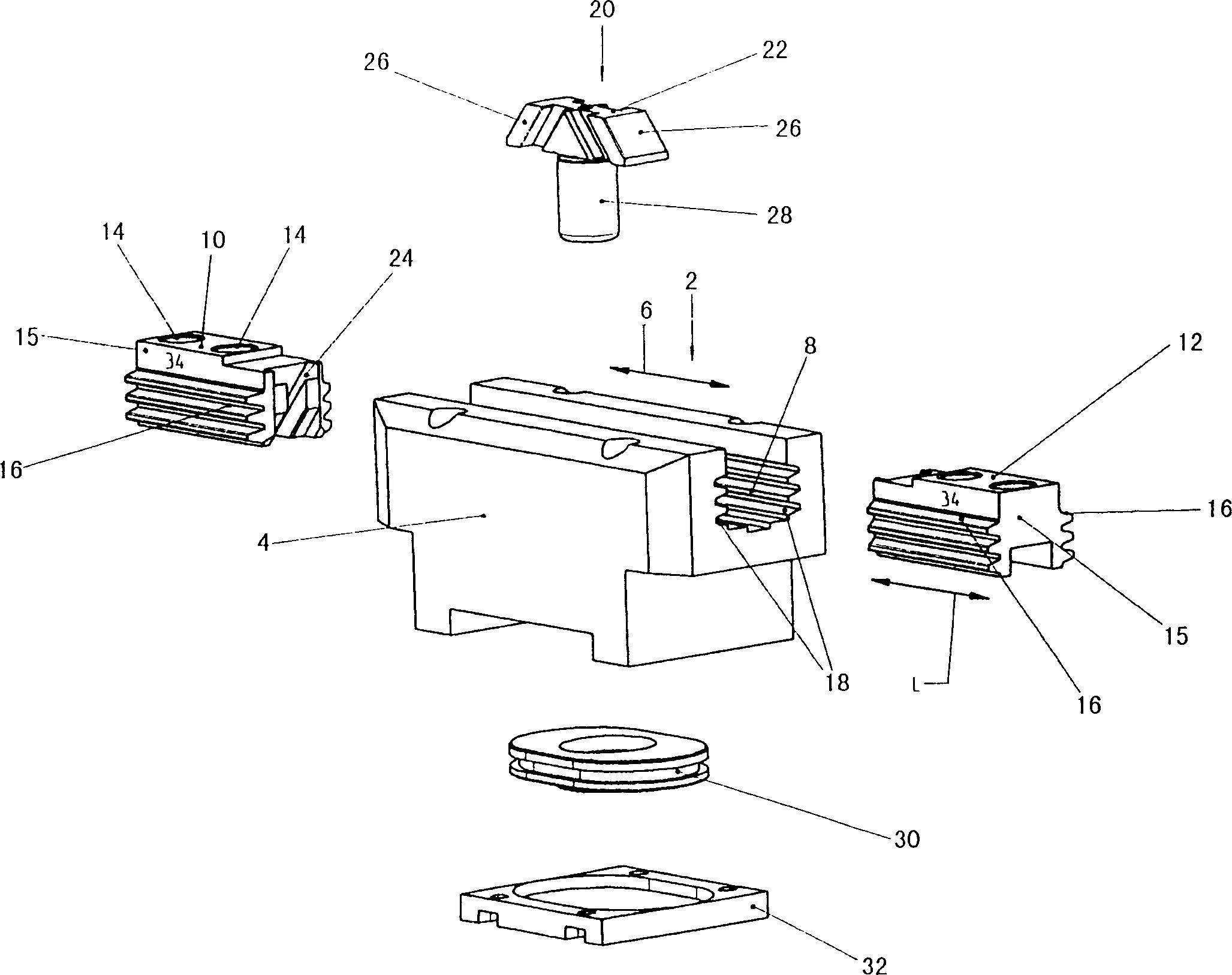

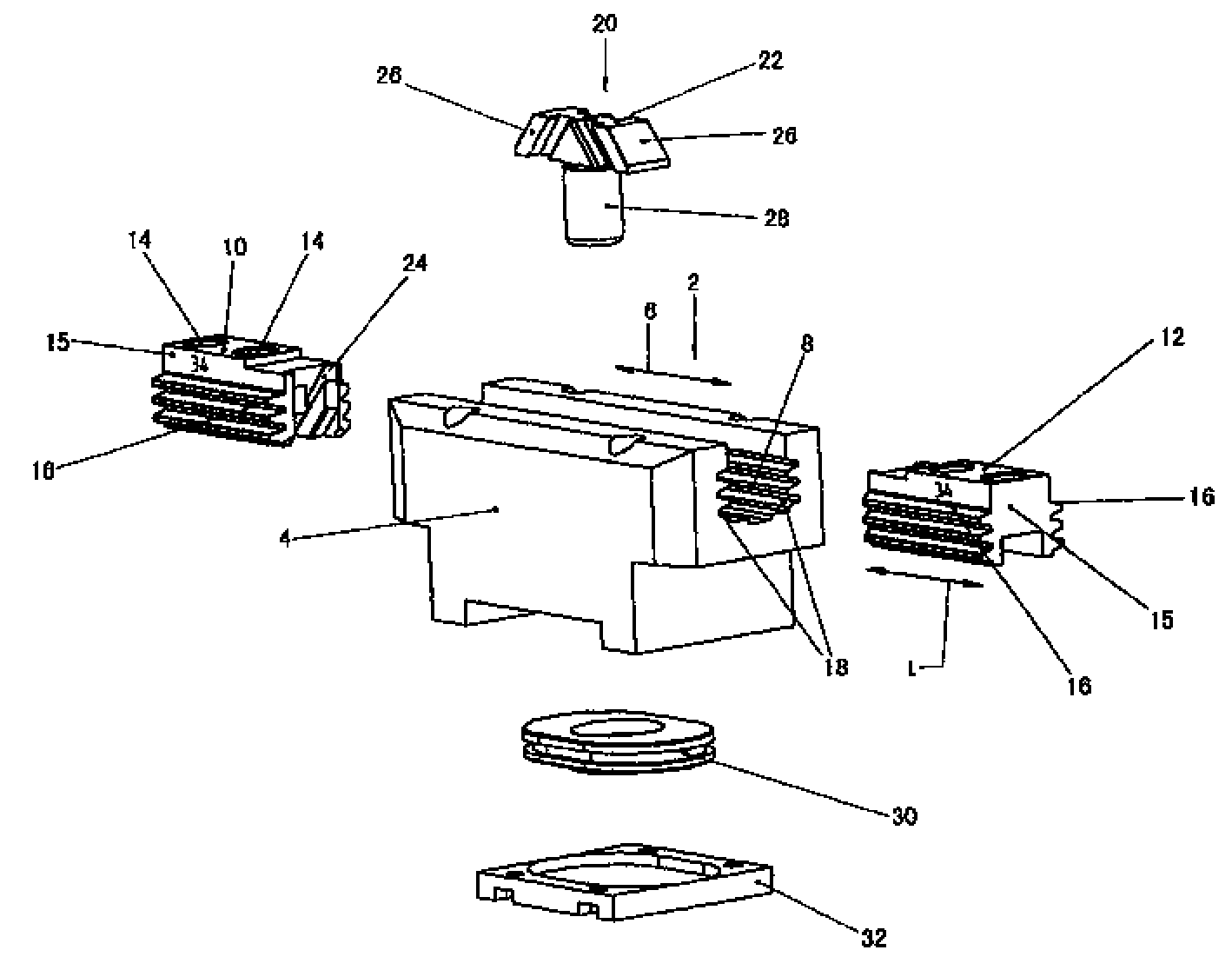

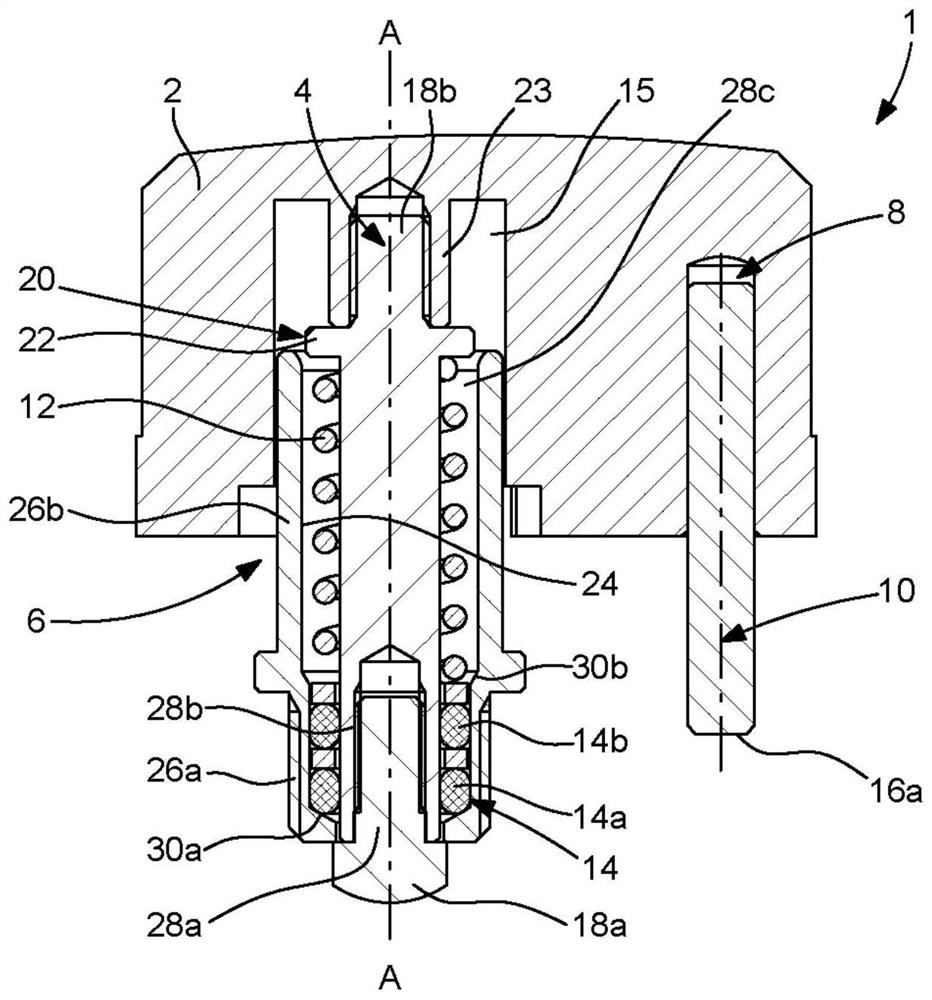

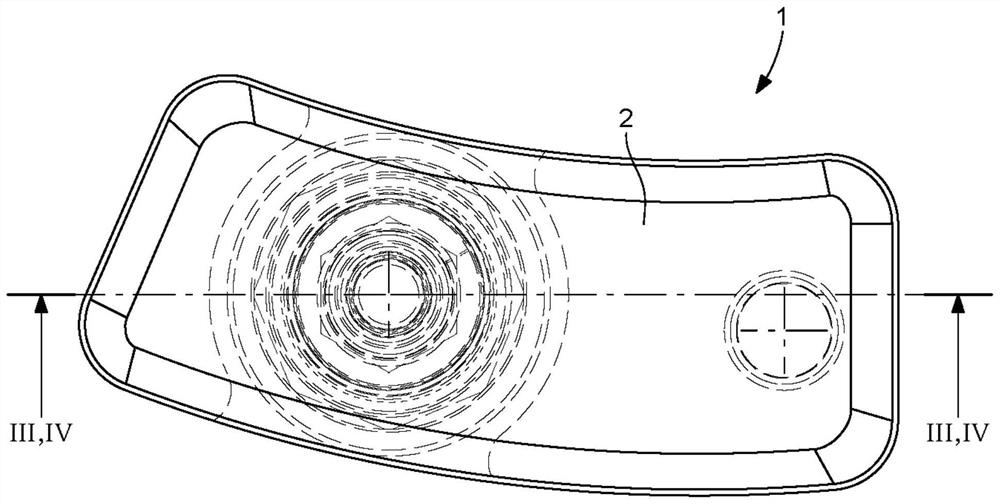

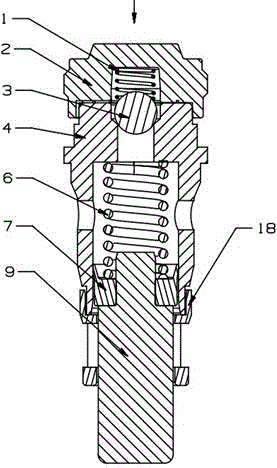

Parallel gripper

InactiveCN1261284CCompact structureEasy to adjustSleeve/socket jointsGripping headsPistonWedge shape

The invention relates to a parallel gripper comprising a housing (4) and two adjustable gripper base jaws (10, 12) which are guided in the housing (4) in a jaw guiding recess (8) in a displaceable manner. The base jaws (10, 12) can be moved towards or away from one another by means of a wedge hook gearing (20) that can be adjusted by means of a piston (30) that is guided in said housing. The aim of the invention is to provide a compact parallel gripper for transmitting and receiving great gripper forces or overturning moments. According to the invention, the parallel gripper is configured in such a way that the piston (30) is provided with an oval or essentially rectangular form having rounded edges and that the base jaws (10, 12) are provided with at least two guiding webs (16) on both sides respectively. Said webs are rectangular, wedge-shaped or trapezoidal in the cross-section thereof and extend in the direction of displacement (6). The jaw guiding recess (8) is provided with guiding grooves (18) which are configured complementary thereto. The ratio of the wall thickness (E) of the housing (4) measured between the base of the guiding grooves (18) and the outside of the housing in relation to the width (A) of the housing measured vertically in relation to the direction of displacement(6) of the base jaws (10, 12) amounts to at least 0.2. The ratio of the width of inclined traction of the wedge hook gearing (D) (20) in relation to the outside width (B) of the base jaws (10, 12) amounts to at least 0.4.

Owner:顺科两合公司夹具和抓取工具厂

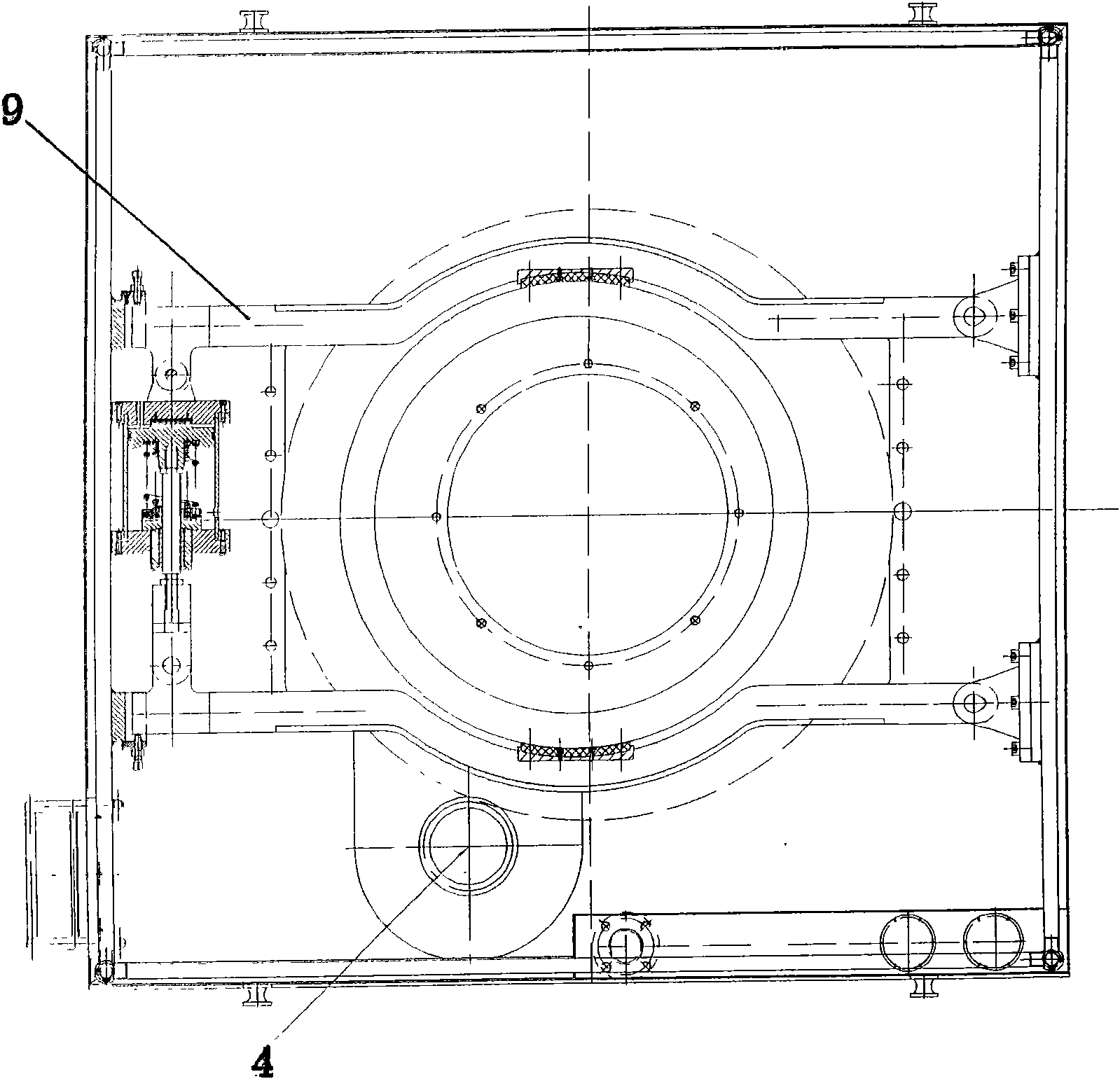

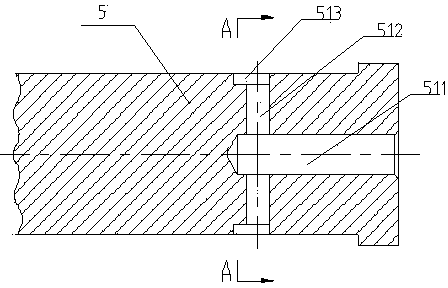

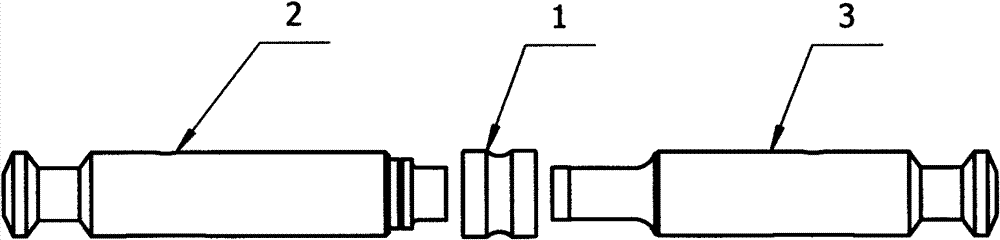

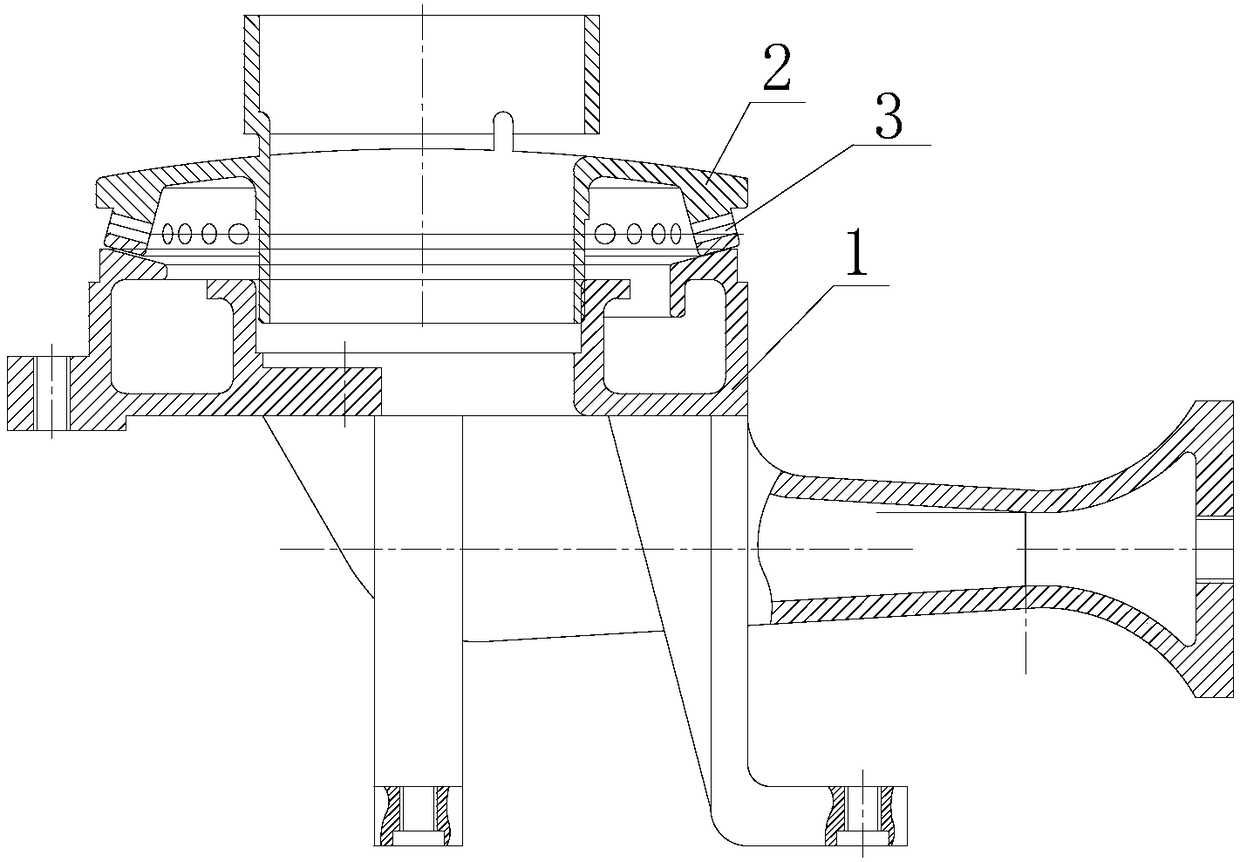

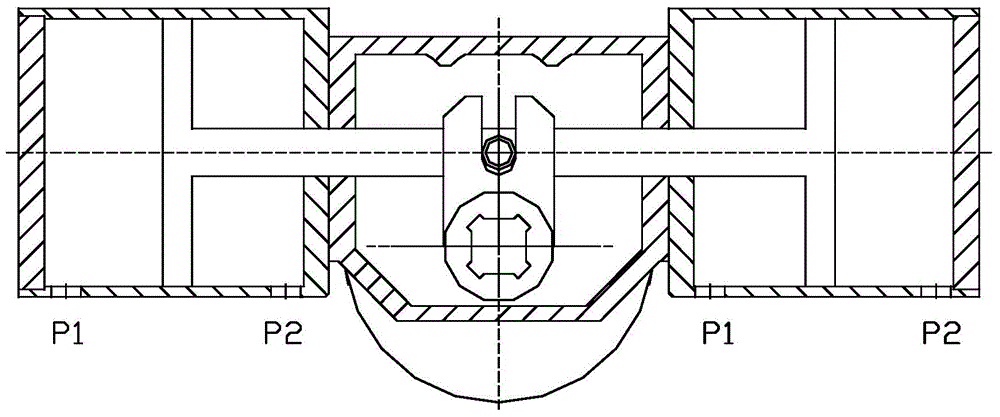

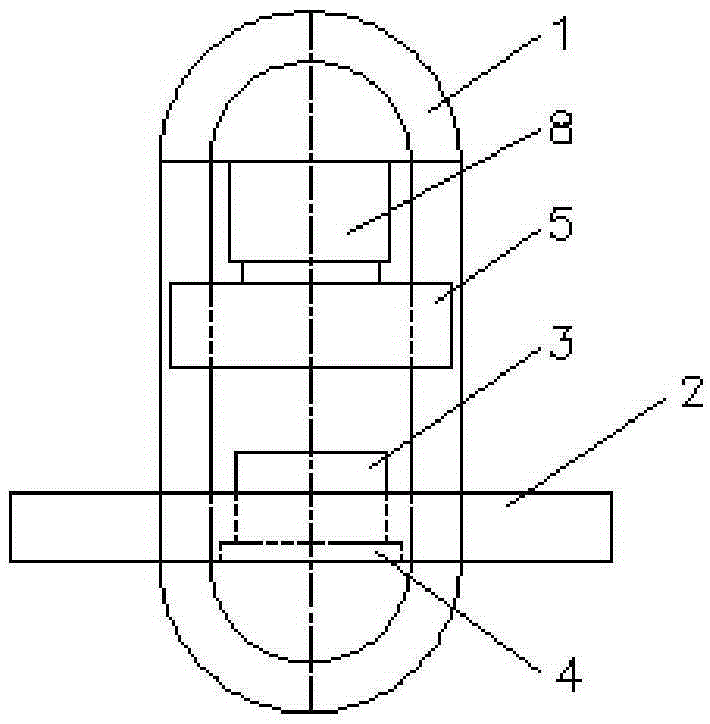

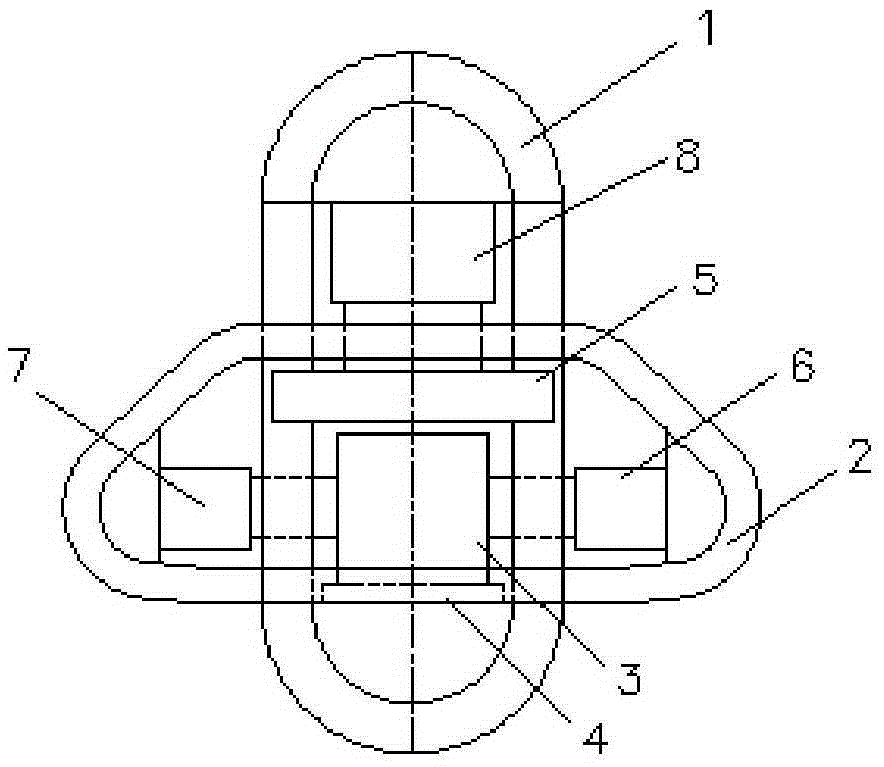

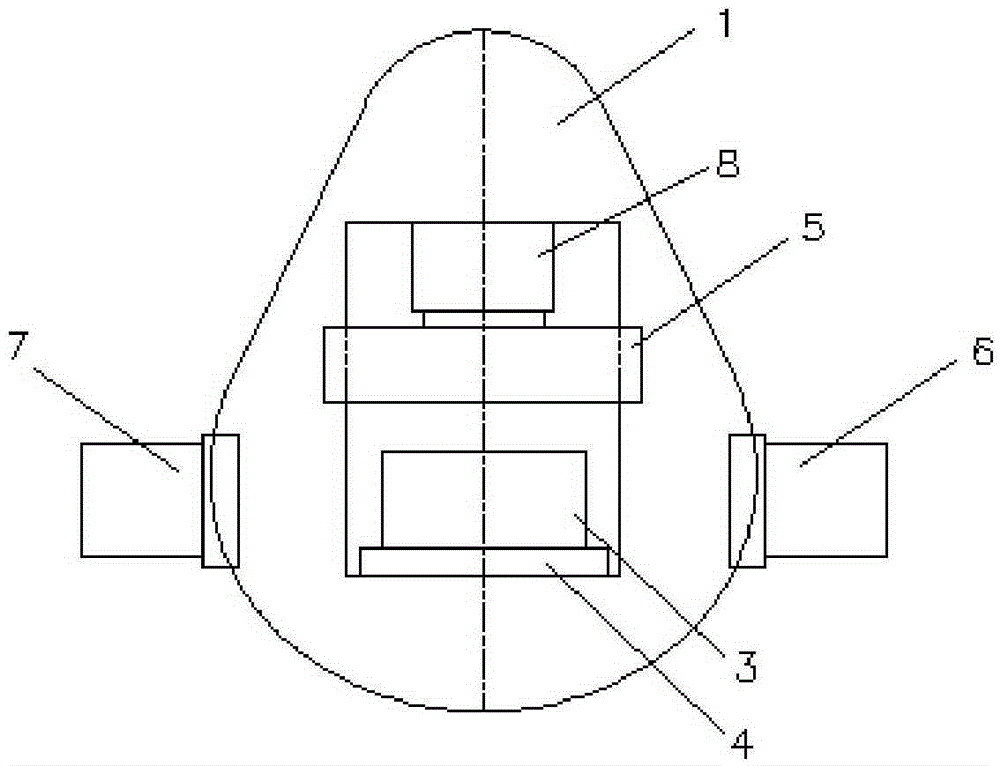

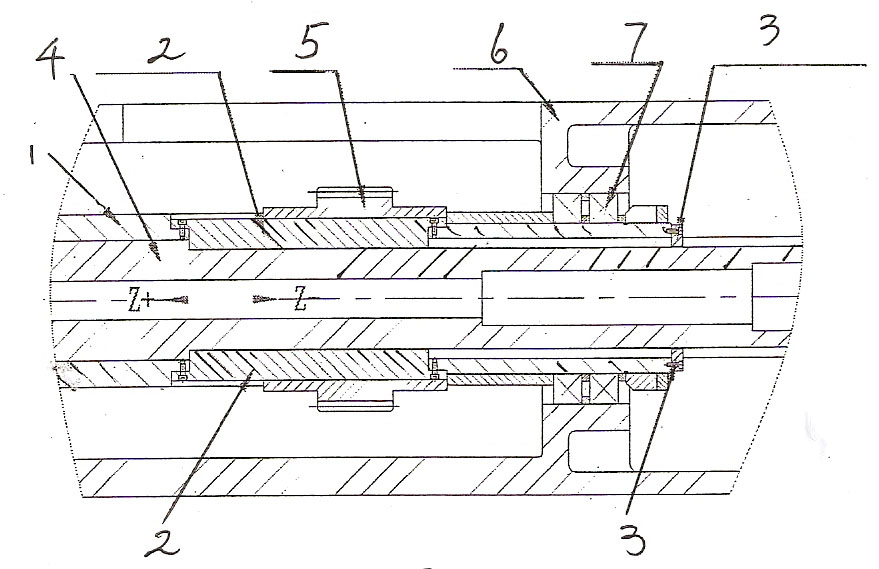

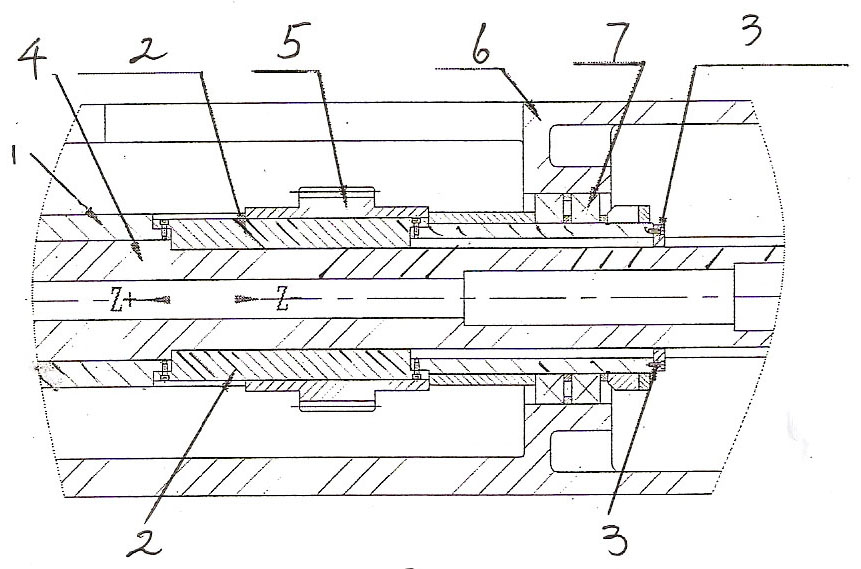

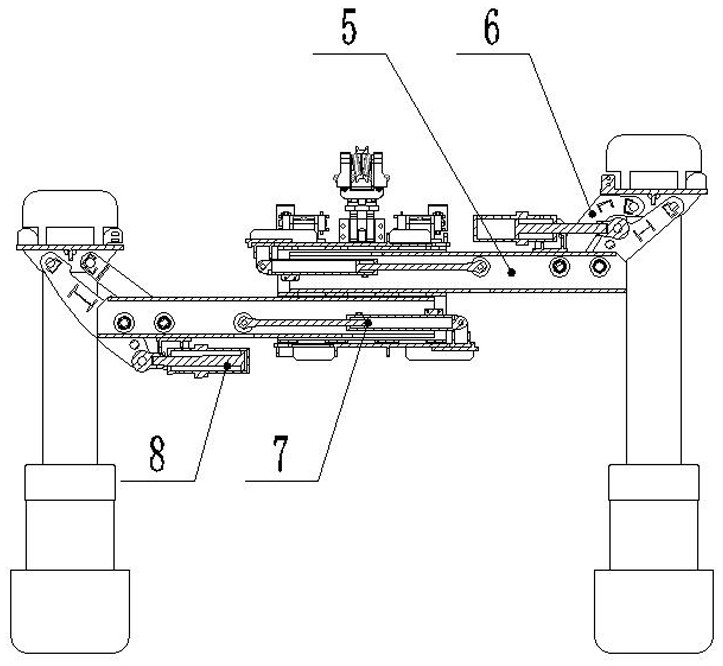

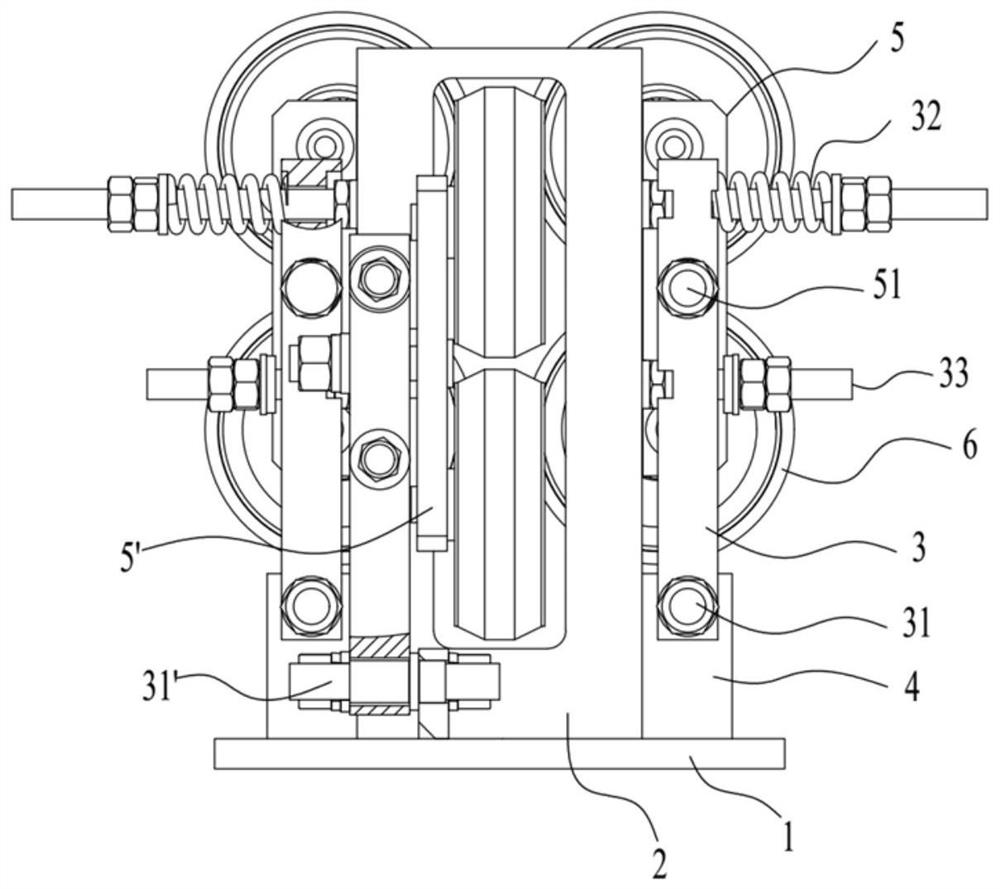

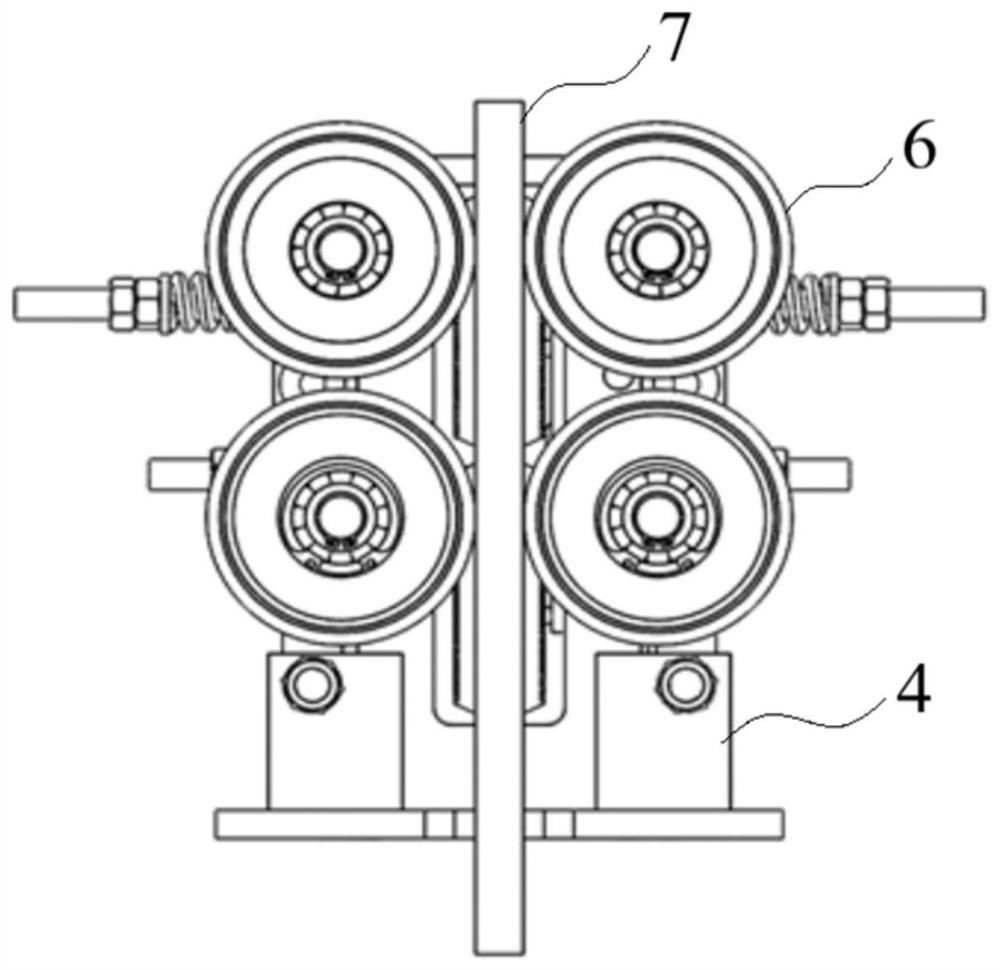

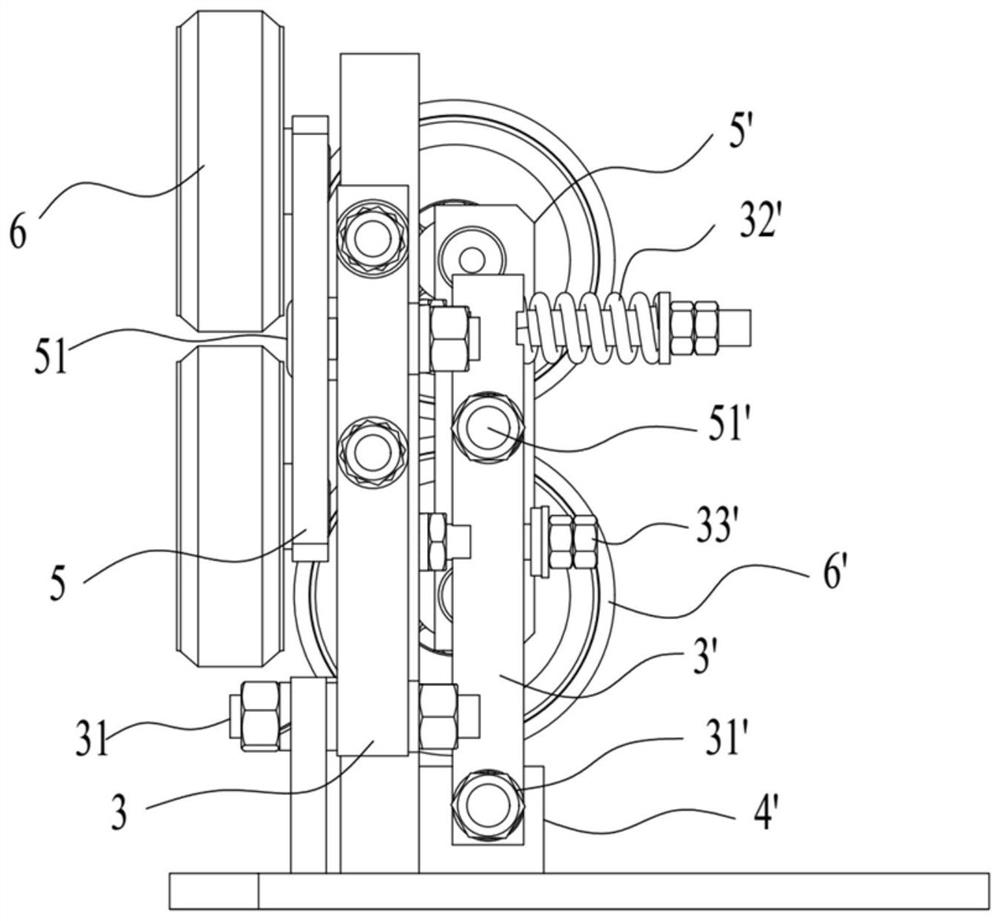

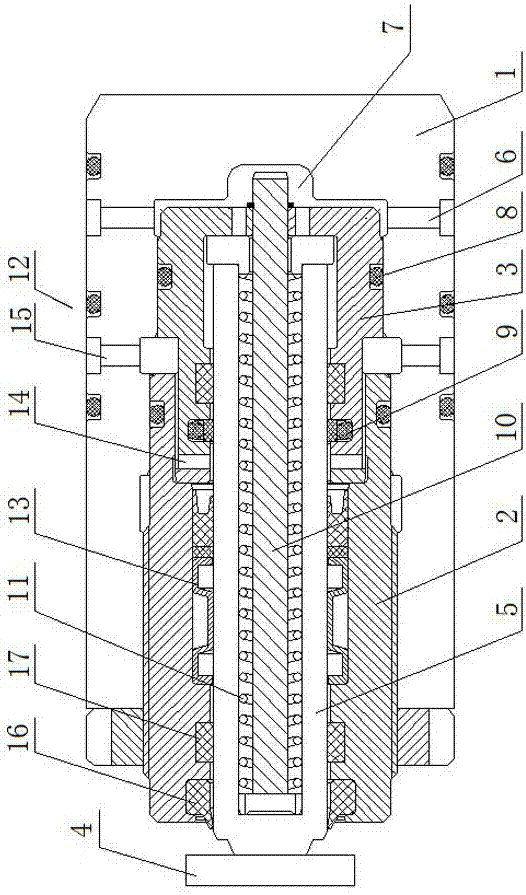

Lengthening device for tie bar guide hole of movable template of die casting machine

The invention relates to a lengthening device for a tie bar guide hole of a movable template of a die casting machine. The lengthening device is characterized in that a left guide copper sleeve is mounted in a left end hole of the movable template; the excircle surface of the left guide copper sleeve is in transition fit with the inner hole surface of the movable template; a right guide seat is mounted in a right end hole of the movable template; a right guide copper sleeve is mounted in a hole of the right guide seat; the excircle surface of the right guide seat is in transition fit with the inner hole surface of the movable template; the inner hole surface of the right guide seat is in transition fit with the excircle surface of the right guide copper sleeve; a tie bar is matched with the inner hole surface of the left guide copper sleeve and the inner hole surface of the right guide copper sleeve; a first lubricating oil channel is formed in the movable template; the first lubricating oil channel communicates with an oil storage tank on the left guide copper sleeve; a second lubricating oil channel is formed in the right guide seat; and the second lubricating oil channel communicates with an oil storage tank on the right guide copper sleeve. According to the lengthening device, the guide seat is mounted at one end of the tie bar guide hole of the movable template, the guide length is lengthened, stability and repeated accuracy of locked mold opening are improved, oil is injected into the lubricating oil channels, and the tie bar and the guide copper sleeves are well lubricated.

Owner:SUZHOU SANJI FOUNDRY EQUIP

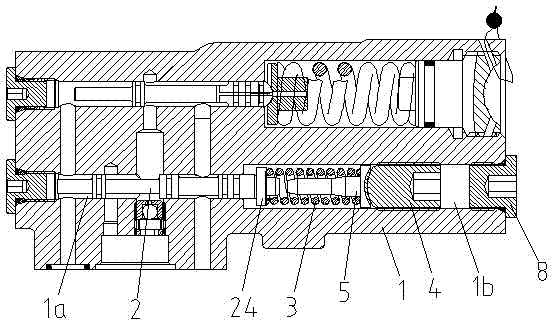

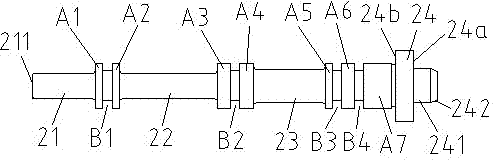

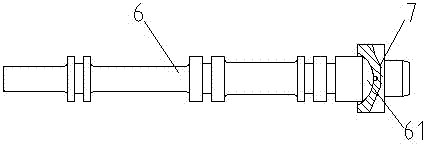

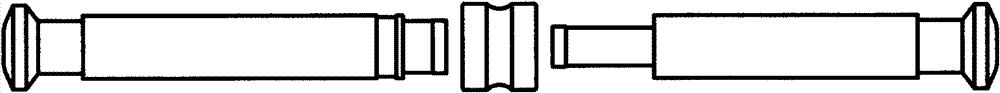

Novel valve core with spring seat

InactiveCN103032400AIncrease guide lengthReduce assembly requirementsServomotor componentsTorsion springMachining

The invention discloses a novel valve core with a spring seat. The novel valve core comprises a valve core rod body which is slidably assembled in a lower valve cavity of a valve body, wherein seven annular sealing bosses are arranged on the valve core rod body; the circumferential surface of each annular sealing boss is slidably matched with the inner peripheral wall of the lower valve cavity through liquid sealing; the tail part of the valve core rod body is integrally provided with the spring seat connected to a back face of the seventh annular sealing boss to form a novel spring seat valve core structure with the spring seat; a spring guide rod is arranged in the center of the spring seat; a compression spring is sleeved on the spring guide rod; the front end of the compression spring is abutted against and matched with a positioning annular face of the spring seat; the valve core rod body is abutted against and assembled in the lower valve cavity of the valve body through the compression spring; and a pressure adjusting spiral plug is spirally pressed at the rear end of the compression spring. The novel valve core has the advantages of simple structure, convenience in machining, low assembly requirement and capabilities of greatly improving the mounting success rate of a PVECVP valve and reducing the production and manufacturing cost, and has the characteristics of high mounting speed and stable performance.

Owner:SAIKESI HYDRAULIC TECH CO LTD

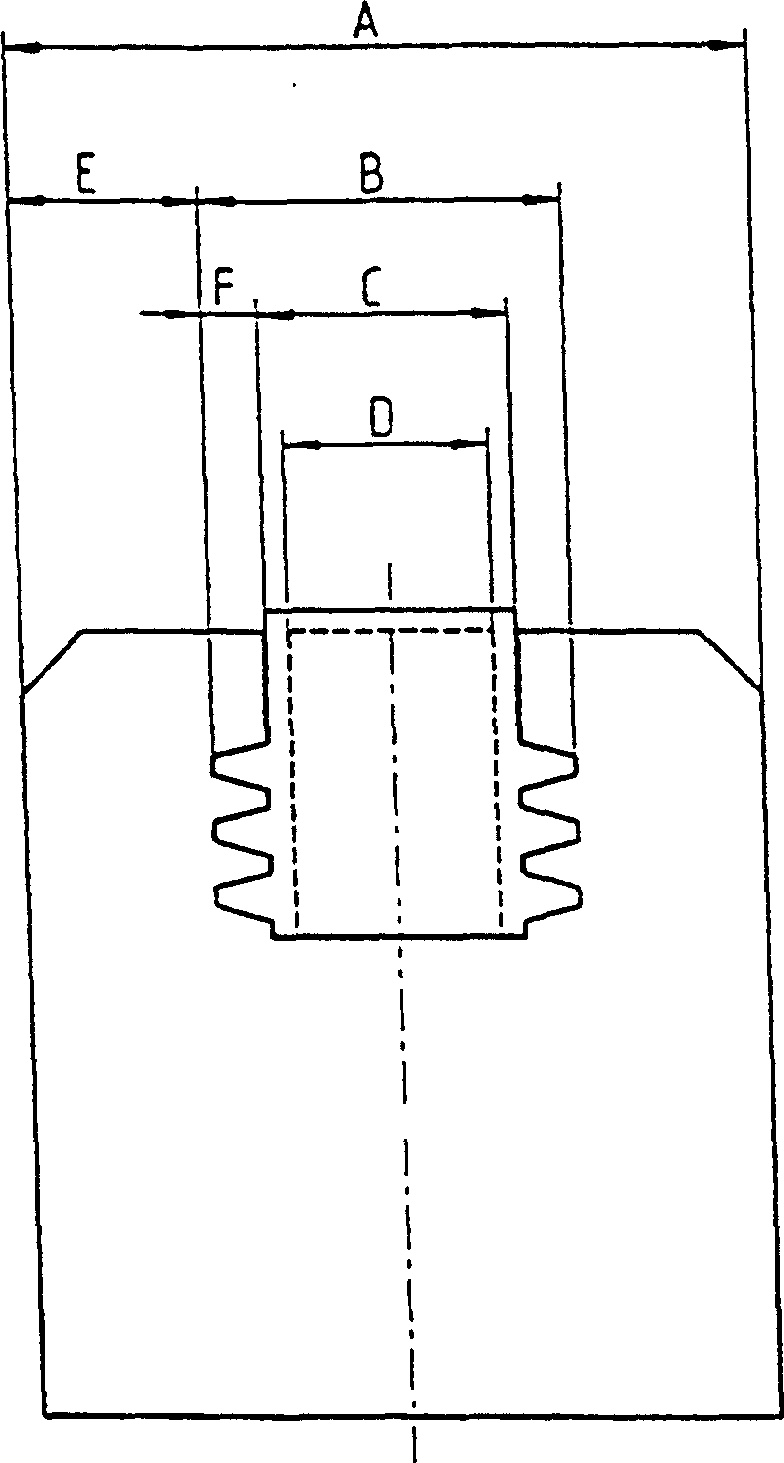

Design method of novel punching die structure

InactiveCN102950800AReduce manufacturing costHigh degree of versatilityShaping pressPunchingMaterial consumption

The invention discloses a design method of a novel punching die structure and aims to overcome the defects that ZP punching dies are poor in guidance, IPT punching dies are difficult to machine and high in material consumption and the like. The design method includes structural and size design of a punching die. The punching die structurally comprises a middle die, an upper punching rod and a lower punching rod and is characterized in that the diameters of the bodies of the upper punching rod and the lower punching rod and the diameter of a punching tail are all phi 22mm or phi 25.25mm, the overall length of the punching rods is 133.35mm, the punching tail is of the structure of the ZP type punching die or the IPTB type punching die, the middle die is the IPTB or IPTD type standard middle die. The novel punching die structure mainly applies to rotary type tablet machines.

Owner:上海天和制药机械有限公司

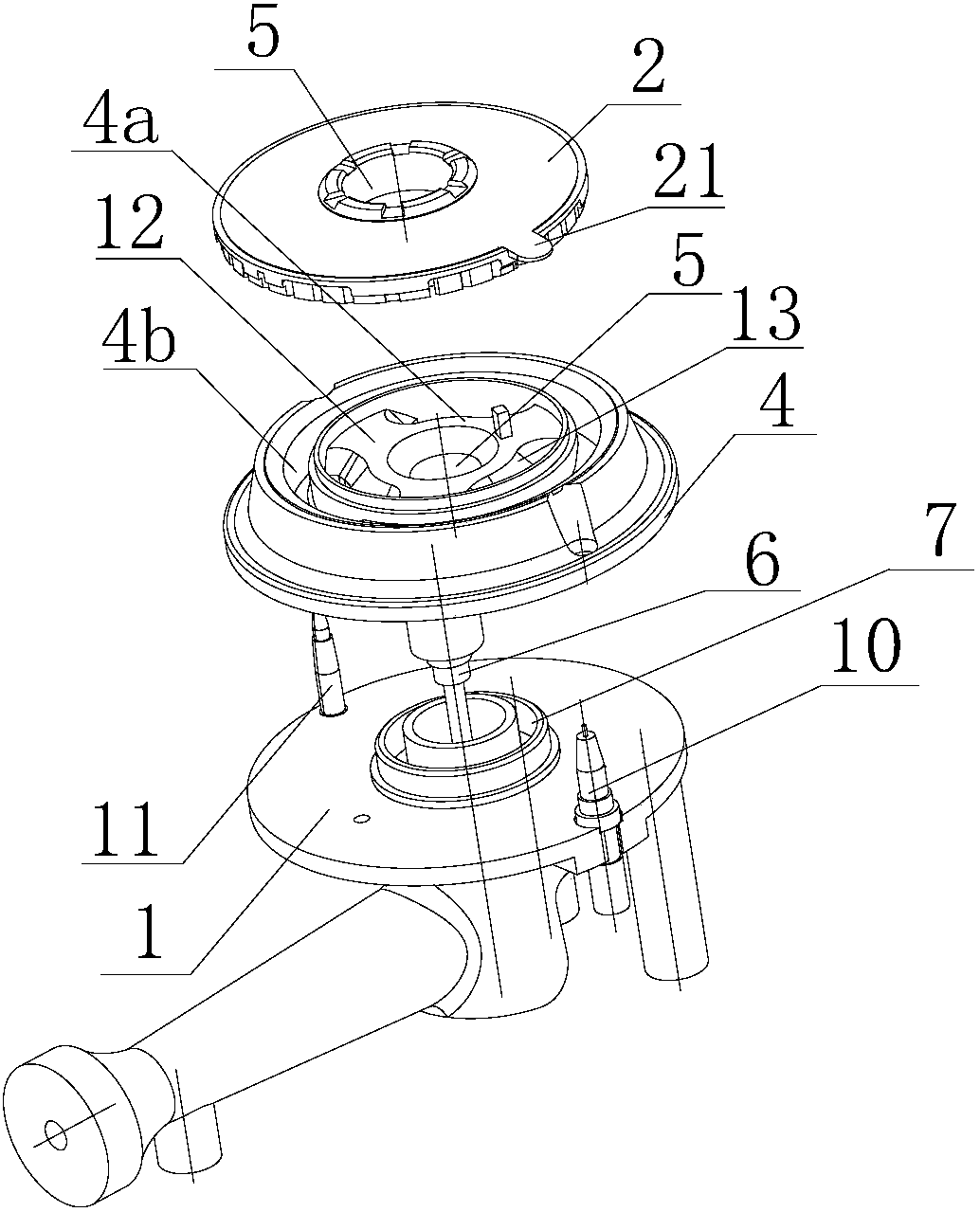

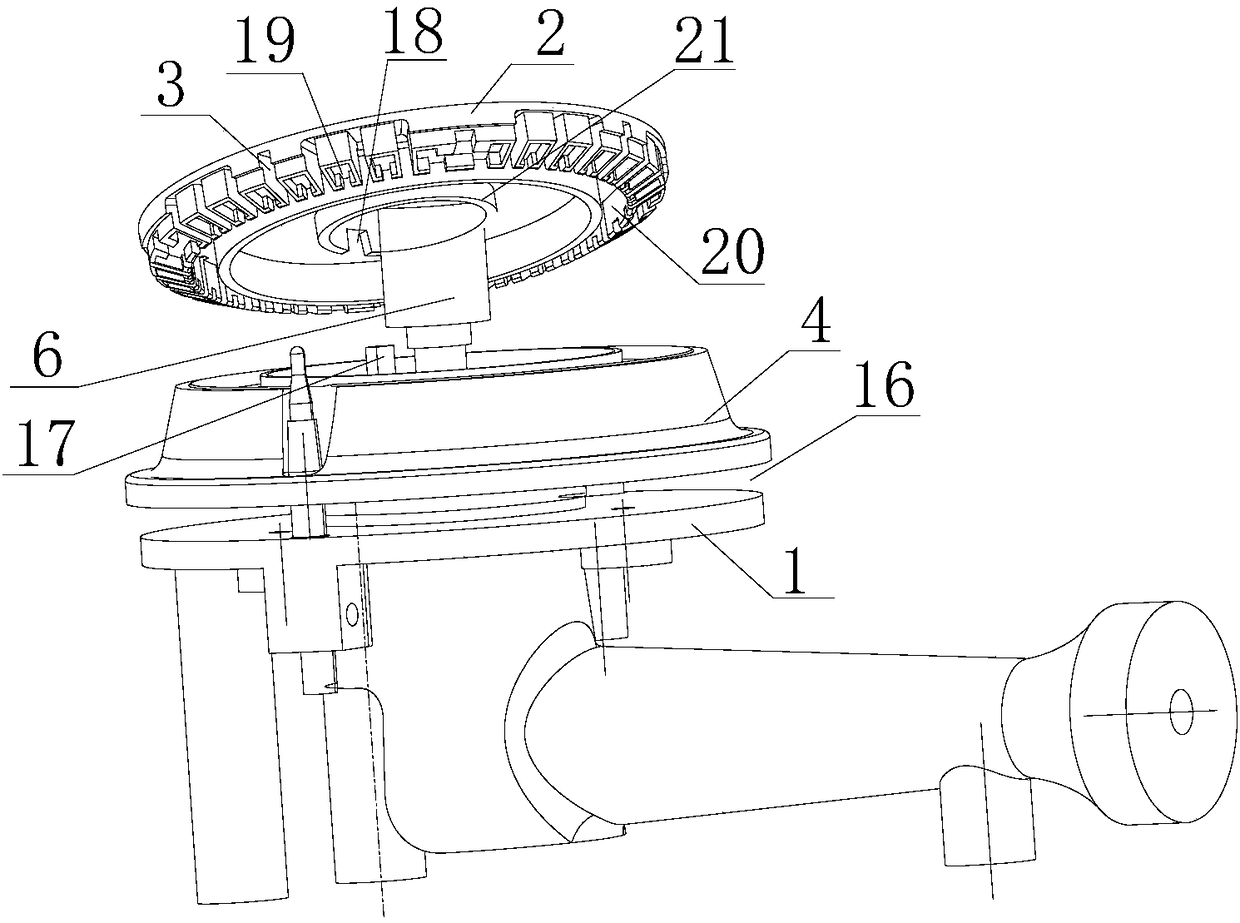

Burner fire cover, burner and gas stove

PendingCN108730979ARealize anti-dry functionSimple structureGaseous fuel burnerHome appliance efficiency improvementEngineeringGas stoves

The invention relates to a burner fire cover, a burner and a gas stove. A fire cover base is arranged on a furnace end, the fire cover is arranged on the fire cover base, a fire outlet groove is formed in the fire cover, a penetrating through hole is formed in the centers of the fire cover, the fire cover base and the furnace end, a dry-burning-prevention sensor is arranged in the through hole, aninner ring cavity and an outer ring cavity are formed in the fire cover base, the inner ring cavity is annularly arranged around the through hole, a gas outlet of the furnace end communicates with the inner ring cavity, the fire outlet groove communicates with the outer ring cavity, the inner ring cavity and the outer ring cavity communicate through a connection channel, and the longitudinal section of the fire outlet groove is square. The whole structure is simple, dismounting, mounting and cleaning are easy, gas sufficient mixing is facilitated, flames are more uniform, combustion is more sufficient, and the combustion effect is better.

Owner:QINGDAO HAIER DISHWASHER

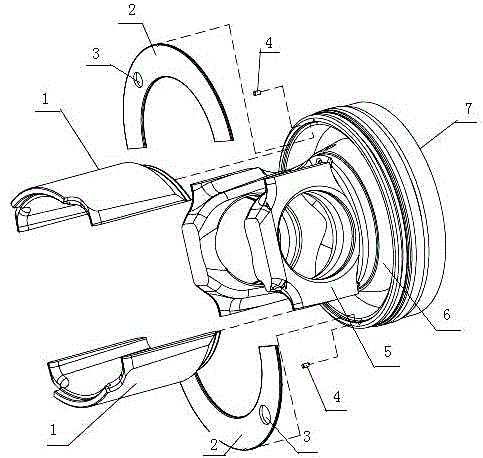

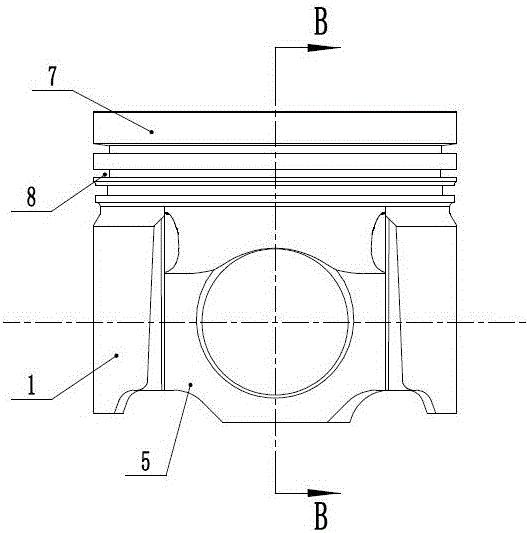

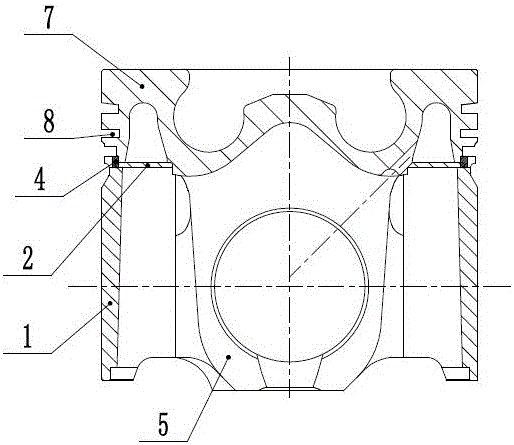

Steel piston for diesel engine and production process thereof

The invention discloses a steel piston for a diesel engine and a production process thereof. The steel piston comprises a piston seat, two semi-annular oil duct baffle plates which are same and a pair of piston skirts which are symmetrically arranged along the axis of the piston seat, wherein a combustion room is arranged at the head of the piston seat, a cooling liquid groove is formed in the back surface of the piston seat, a pair of symmetrically arranged supporting seats is further integrally forged on the back surface of the piston seat and through holes are formed in the supporting seats, the piston skirts compress the oil duct baffle plates above the cooling liquid groove and the two side edges of the piston skirts are connected to the side edges of the supporting seats to form piston guide seats, oil inlets are formed in the oil duct baffle plates and pin holes are formed in the edge positions, and aligning pins matched with the pin holes are arranged on the piston seat. The steel piston disclosed by the invention is simple in structure, the acting force on a weld joint is small in a piston moving process, the guiding precision of the piston can be controlled well, the service life of the piston is prolonged, and the strength and the anti-impact capacity of the piston are improved; the adopted production process is concise and reasonable in process, convenient to produce and suitable for scaled production.

Owner:江苏华星机电制造有限公司

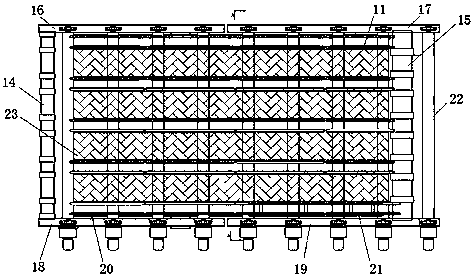

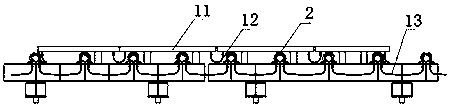

Casting blank built-in before-cutting roller bed

The invention relates to a casting blank built-in before-cutting roller bed, and belongs to the technical field of continuous casting equipment in the metallurgical industry. According to the technical scheme, integral through rollers (3) are of a hollow structure, and the two ends of each integral through roller (3) are arranged on bearing seats correspondingly; metal hoses which are cooled afterwater injection are arranged between the bearing seats; protective covers (5) are arranged on the bearing seats; motors (9) are in driving connection with the integral through rollers (3) through speed reducers (7); the two ends of each integral through roller (3) are provided with a water feeding rotation connector (1) and a water discharging rotation connector (8) which communicate with the interior of the integral through roller (3) correspondingly; the positions, corresponding to the two sides of each current of a continuous casting machine, of a plurality of before-cutting rollers arranged in parallel are provided with water cooling plates (11) correspondingly; and the water cooling plates (11) are long-strip-shaped guide plates and provided with water troughs. The casting blank built-in before-cutting roller bed has the beneficial effects that the self weight is decreased, the rigidity of the before-cutting rollers is improved, and the situation that creep deformation and down-warping are conducted on the steel structures of the before-cutting rollers at the high temperature can be avoided.

Owner:宣化钢铁集团有限责任公司

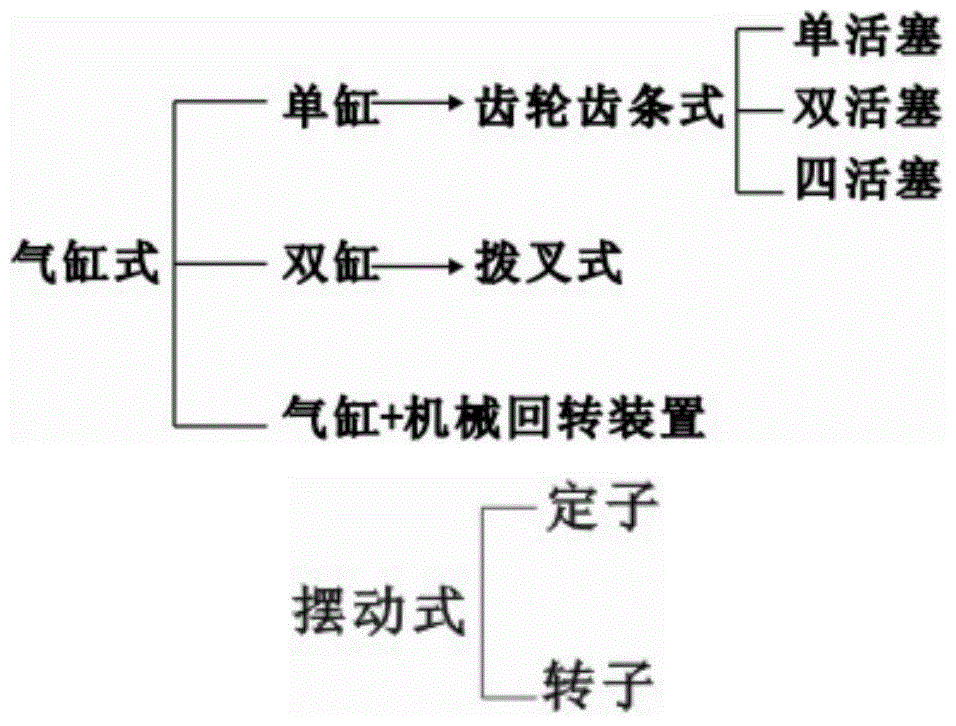

Dual-rotating-wedge speed-adjusting variable-pitch pneumatic valve actuator

ActiveCN104455667AImprove output efficiencyMeet the "slow-fast-slow" operation requirementsOperating means/releasing devices for valvesEnd stagesPneumatic valve

The invention discloses a dual-rotating-wedge speed-adjusting variable-pitch pneumatic valve actuator which comprises a housing as well as a main shaft and a piston which are arranged in the housing, wherein the main shaft is positioned in the middle of the housing; the piston is mounted at the periphery of the main shaft and can axially move up and down in the housing through air source pressure; two outer rotating wedge grooves passing through a central line are formed in the outer wall of the piston; two inner rotating wedge grooves passing through the central line are formed in the inner wall of the piston; the rotating directions of the outer rotating wedge grooves and the inner rotating wedge grooves are opposite; the outer rotating wedge grooves are matched with an outer pin fixed to the housing and an outer pin sleeve to form primary transmission; the piston rotates clockwise or anticlockwise while moving up and down; the inner rotating wedge grooves are matched with an inner pin fixed to the main shaft and an inner pin sleeve to form secondary transmission; the main shaft rotates clockwise or anticlockwise relative to the piston; the output angle of the main shaft is equal to the sum of two-stage transmission angles. According to the pneumatic valve actuator, the utilization rate of the output power of the pneumatic valve actuator can be greatly increased; the buffering operation can be automatically carried out at the starting and ending stages and the buffering speed is adjustable; the pneumatic valve actuator is simple and compact in structure and long in service life, and has few faults.

Owner:HUBEI HIGH & HIGH PRESSURE VALVE CO LTD

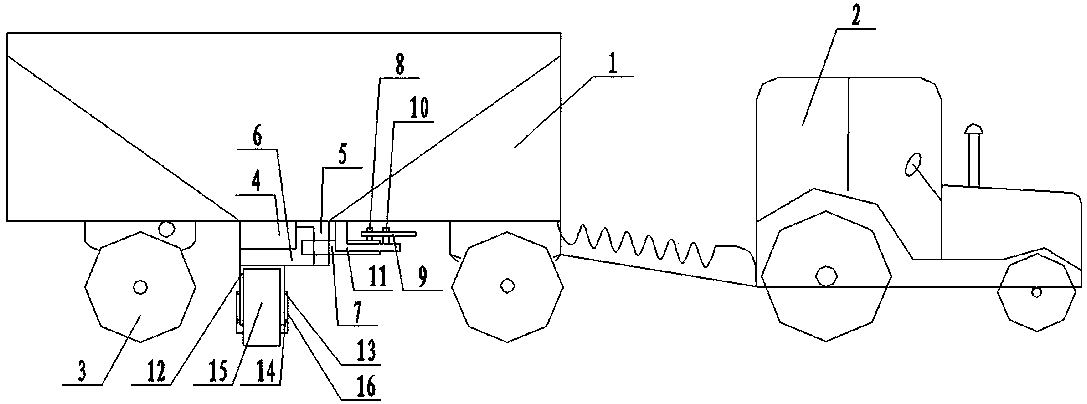

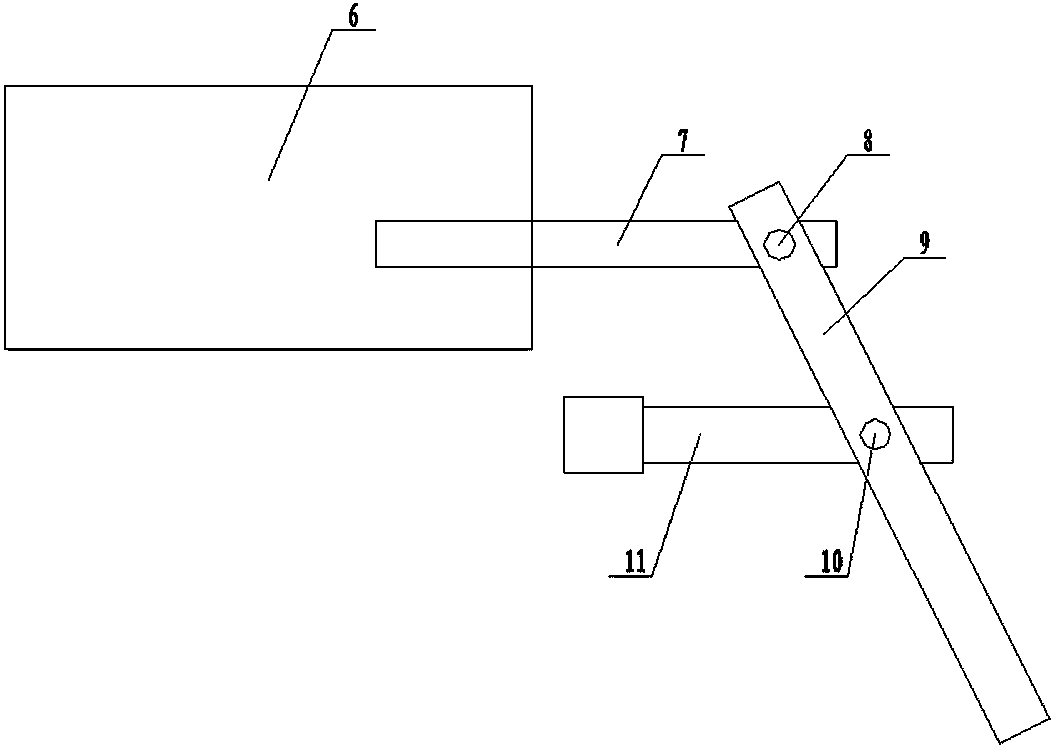

Tilting type horizontal rack vertical die splitting multi-way die forging press

ActiveCN105215249AExtend your lifeConvenient lifeForging press detailsForging press drivesWorking lifePiston rod

The invention discloses a tilting type horizontal rack vertical die splitting multi-way die forging press which comprises a vertical rack in the vertical direction, a workbench, a die, a moving beam and a vertical oil cylinder, wherein the workbench is positioned on the rack, the die is fixedly mounted on the workbench, the moving beam can move longitudinally and is mounted on the vertical rack, the vertical oil cylinder drives the moving beam to move, a horizontal rack, a first horizontal oil cylinder and a second horizontal oil cylinder are further arranged on the workbench, the horizontal rack is further arranged on the outer side of the vertical rack in a sleeving manner, the horizontal rack forms a tilt included angle, larger than 0 degrees, with the horizontal plane, the height of one side, facing to an operating direction, of the horizontal rack is not larger than that of the workbench, the cylinder bodies of the first horizontal oil cylinder and the second horizontal oil cylinder are respectively fixed on the inner sides of the left end and the right end of the horizontal rack, the piston rods of the first horizontal oil cylinder and the second horizontal oil cylinder are respectively and fixedly connected with the left side and the right side of the die, the multi-way die forging press provided by the invention can be used as a large-tonnage horizontal die sinking workpiece, the machining precision is high, and the working life of the press is long.

Owner:KUNSHAN YONGNIAN ADVANCED MFG TECH

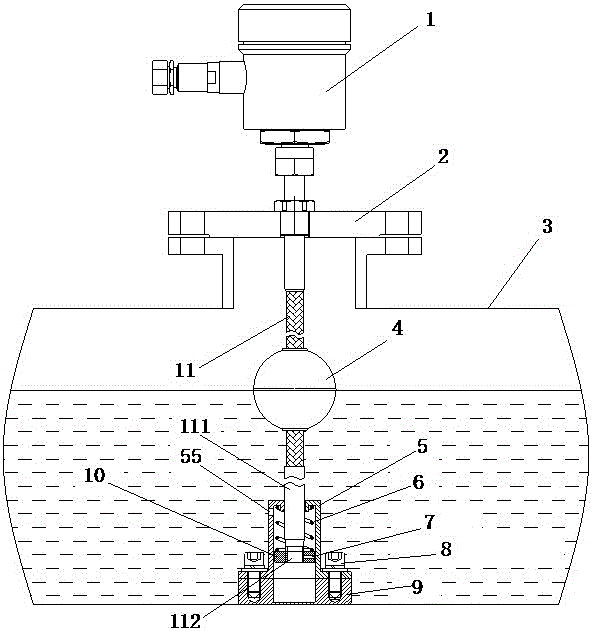

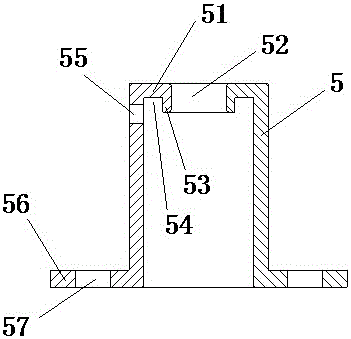

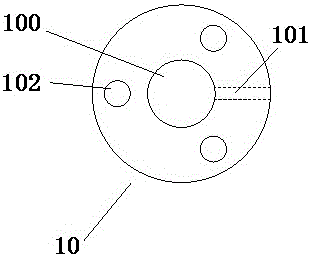

Magnetostrictive liquid level sensor and fixing device thereof

PendingCN106679767APrevent slipping outGuaranteed free telescopic distanceLevel indicators by floatsEngineeringLiquid level sensor

The invention provides a fixing device of a magnetostrictive liquid level sensor. The magnetostrictive liquid level sensor comprises a measuring rod, wherein the end of the measuring rod is provided with a rigid section and a threaded section, the fixing device comprises a guiding structure and a limiting block, the end of the measuring rod is arranged in the guiding structure and can vertically move under the guiding effect of the guiding structure, the limiting block is arranged in the guiding structure and is provided with a threaded hole, the limiting block is installed at the threaded section in a screwed mode, and the fixing device can be fixed to the bottom of a liquid storage container. The fixing device can keep the bottom of the magnetostrictive liquid level sensor including the measuring rod straight and non-swinging, the application range of the magnetostrictive liquid level sensor can be greatly widened, and the service life of the measuring rod can be prolonged. The invention further provides the magnetostrictive liquid level sensor. The sensor includes the fixing device and is wide in application range and long in service life.

Owner:北京航天金泰星测技术有限公司

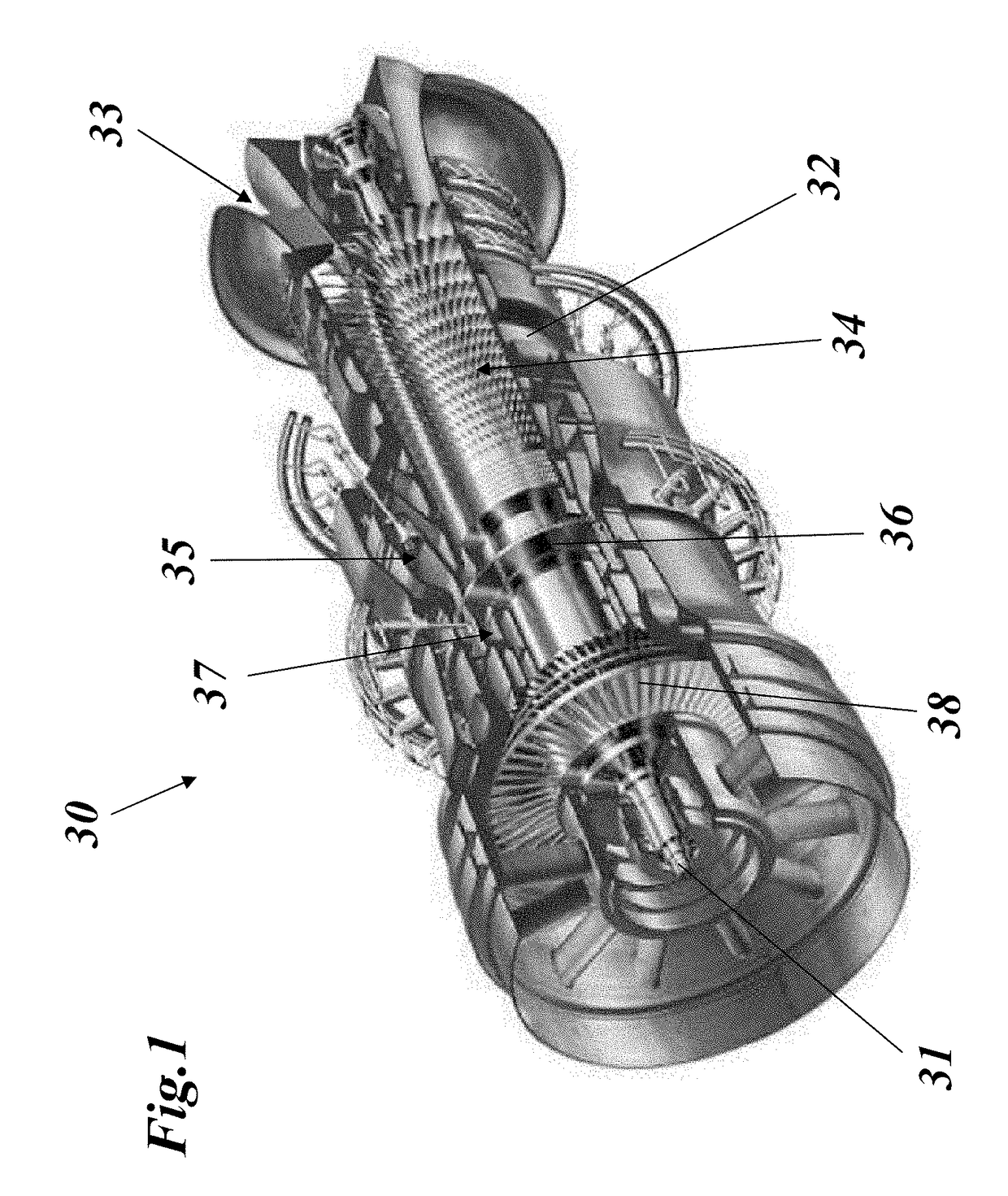

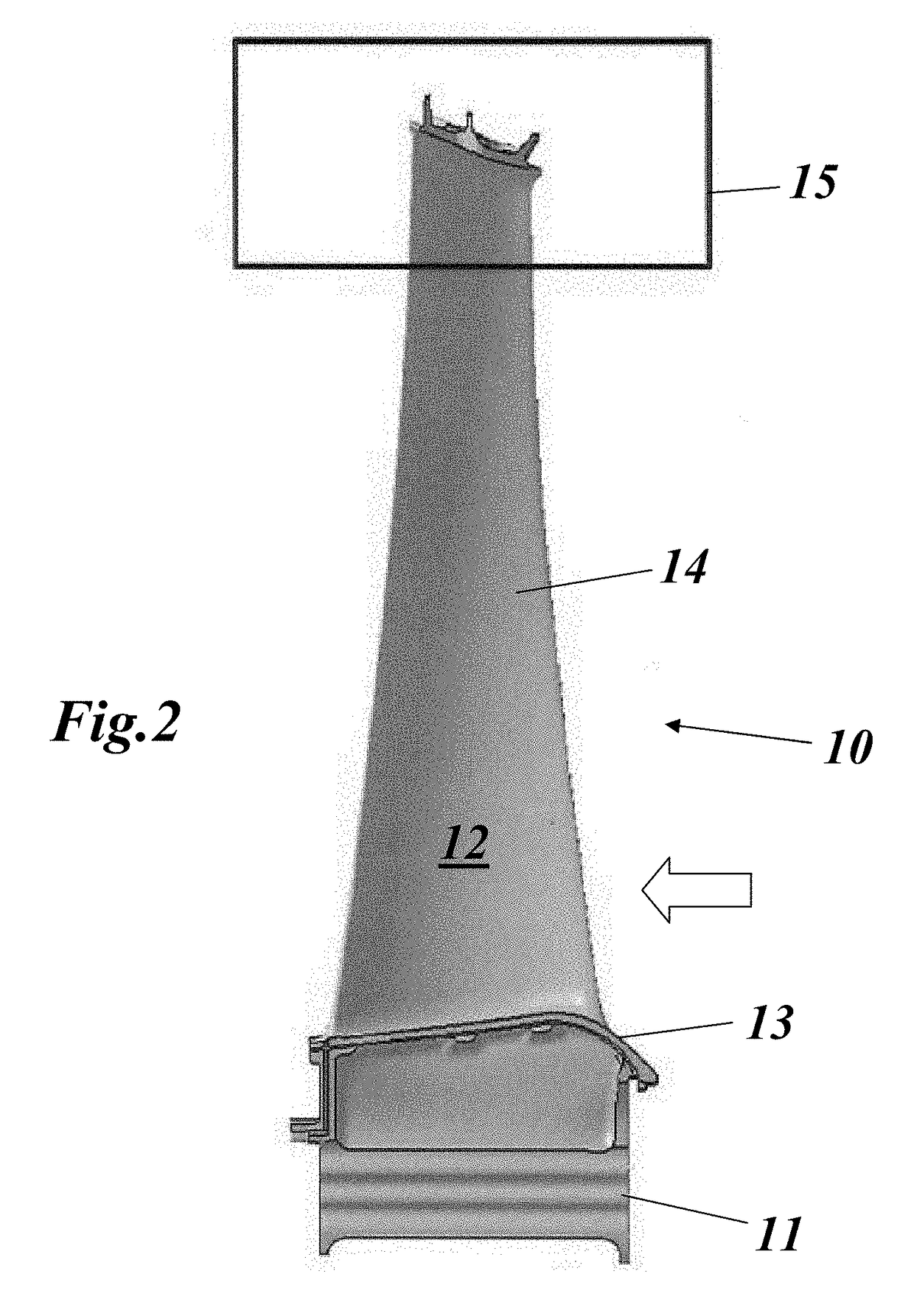

Rotating gas turbine blade and gas turbine with such a blade

A rotating gas turbine blade is disclosed which includes an airfoil with a suction side and a pressure side, the airfoil extending in a radial direction from a blade root to a blade tip. The blade tip includes a tip shroud, the airfoil having internal cooling passages for a cooling medium, which extend through the tip shroud. Outlet ports are provided above a selected internal airfoil cooling passage for the cooling medium to be ejected above the tip shroud in a direction of the blade's pressure side. Dust accumulation is avoided at the tip end of the selected internal cooling passage.

Owner:ANSALDO ENERGIA SWITZERLAND AG

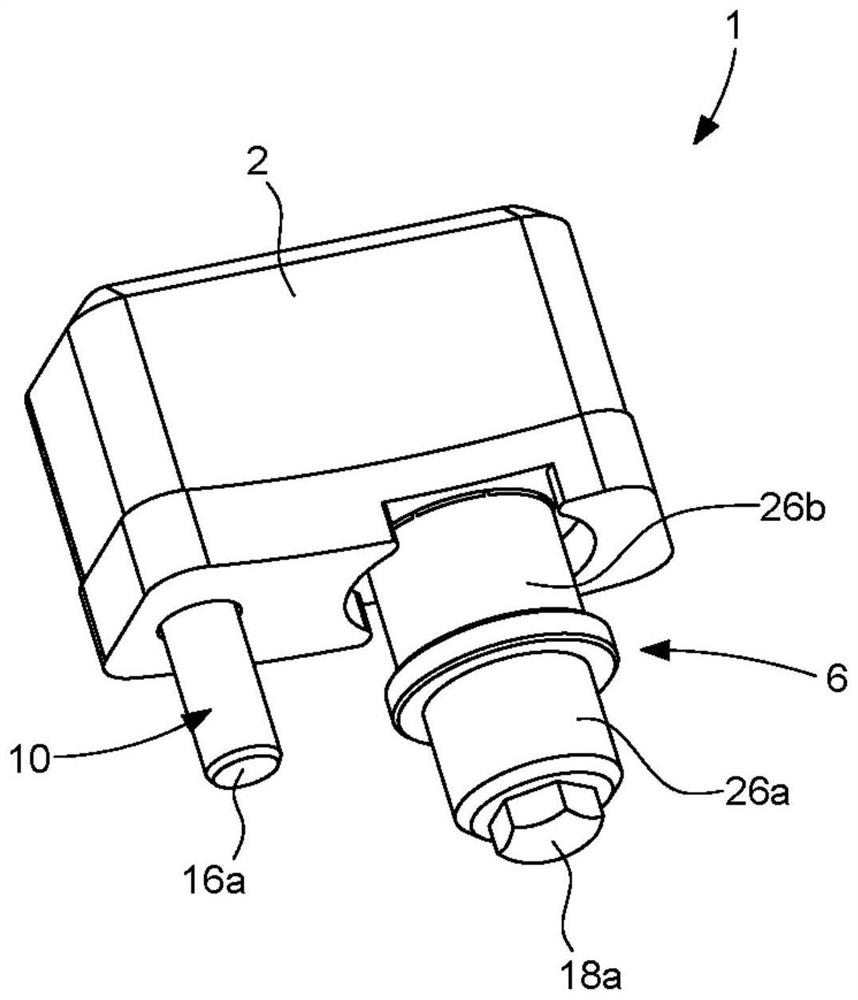

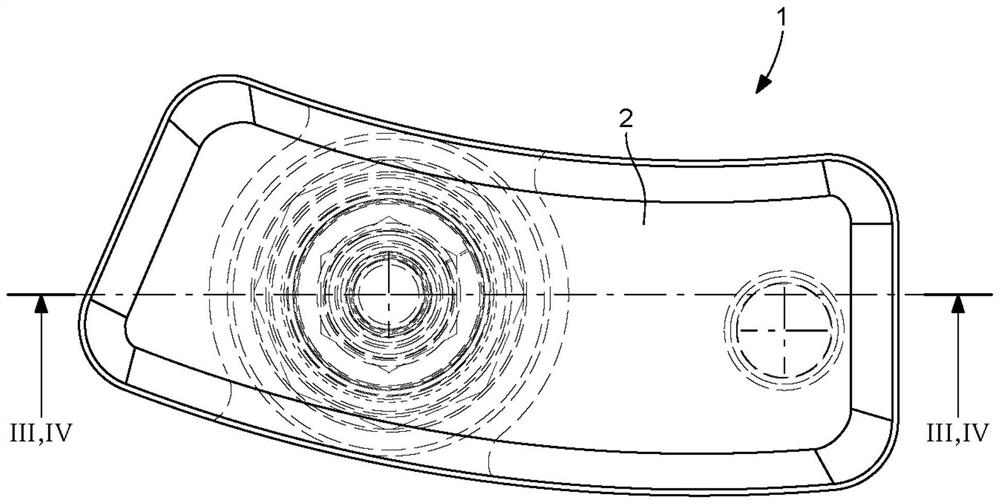

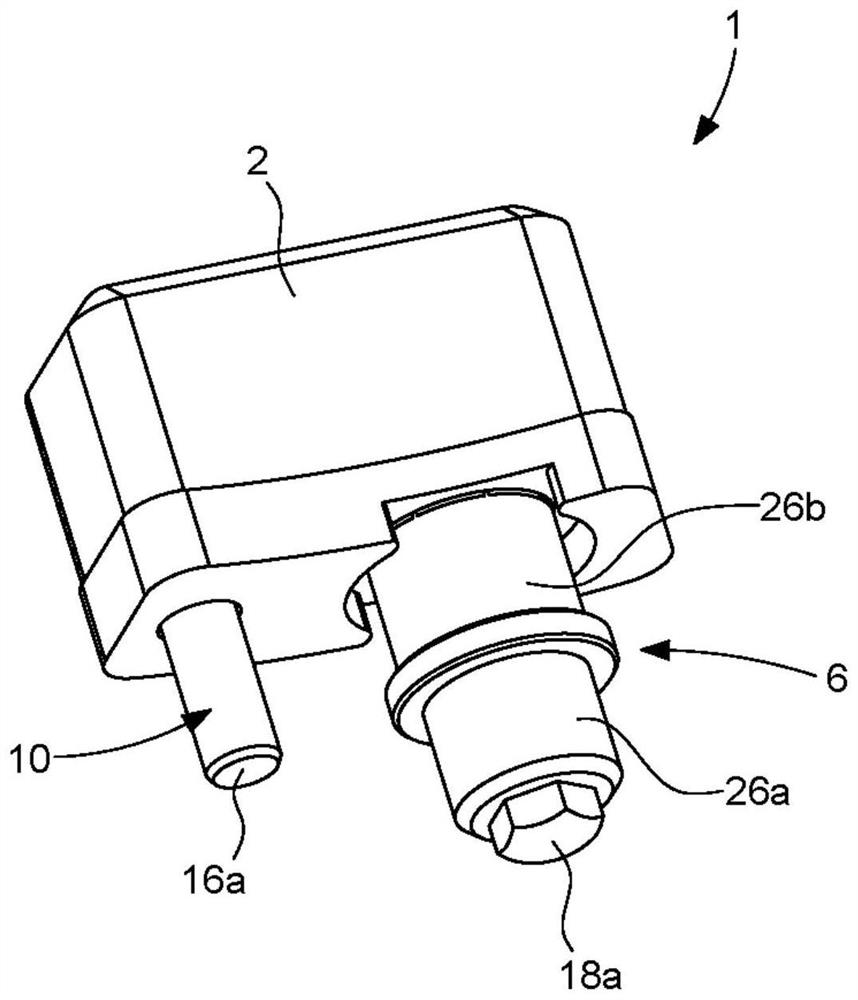

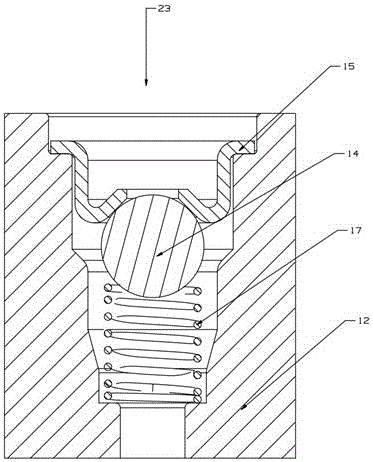

Push button system, and timepiece comprising same

ActiveCN111983910AIncrease guide lengthNot super staticMechanical unknown time interval measurementElectromechanical unknown time interval measurementStructural engineeringActuator

The invention relates to a push button system for activating an actuation member, the system including a button head, a pusher actuator integral with the button head, a first hollow guide member, thepusher actuator being mounted to slide inside the first hollow guide member, the first hollow guide member being intended to be secured to a fixed element relative to the button head and to the pusheractuator, a second hollow guide member arranged in the button head, and a pin mounted to slide inside the second hollow member, and intended to be secured to the fixed element. The pusher actuator has an upper portion provided on the periphery thereof with a collar intended to cooperate with an internal face of the first hollow guide member to guide the pusher inside the member.

Owner:MECO SA

Boring bar guide device

InactiveCN102179537AReasonable structureIncrease guide lengthBoring barsEngineeringMechanical engineering

Owner:NANTONG MACHINE TOOLS GROUP

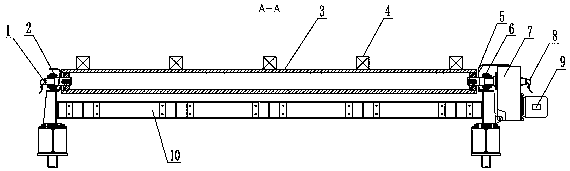

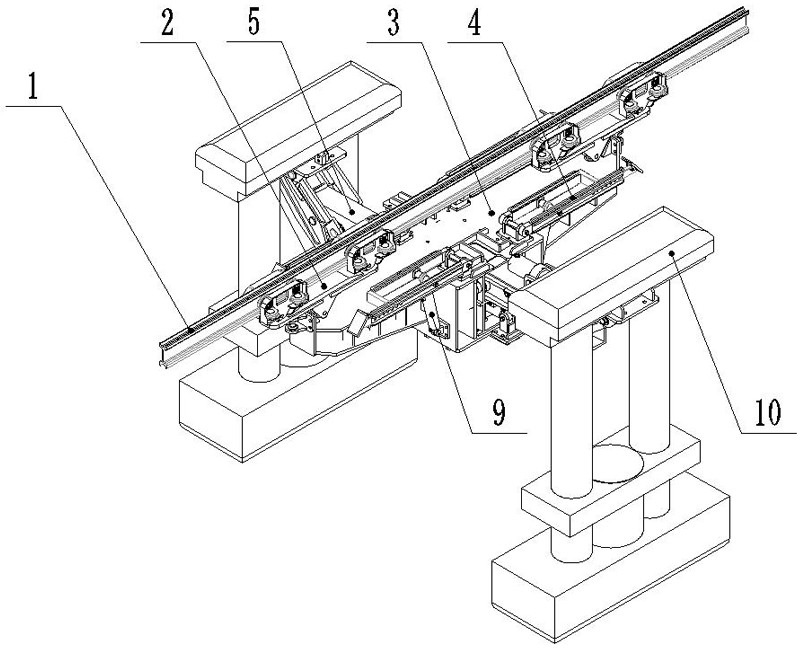

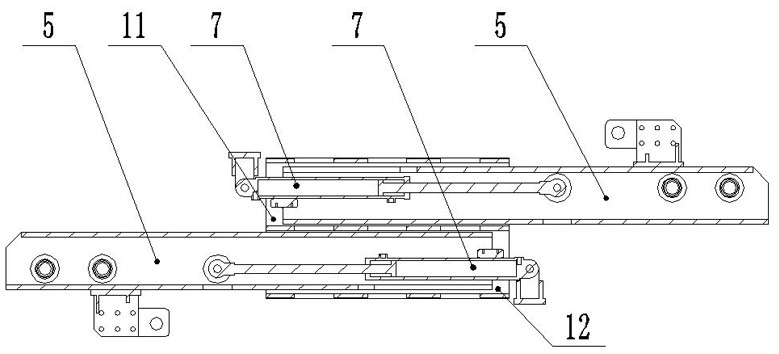

A telescopic lifting beam used for monorail locomotive in coal mine

ActiveCN114348868BIncrease guide lengthStable and safe situationTravelling gearTrolleysMining engineeringWorking environment

A telescopic lifting beam used for a coal mine monorail locomotive belongs to the technical field of coal mine machinery and solves the technical problems of transporting and placing stacked supports. The device includes a load-bearing beam, a load-carrying trolley and a telescopic arm. The direction of the upper chute and the lower chute are set respectively, and the upper chute and the lower chute are set as one-sided openings. The opening ends of the upper chute and the lower chute are in opposite directions. The end of the free end of the telescopic arm is provided with an overturn cylinder along the horizontal direction, and the overturn cylinder drives the overturn mechanism to rotate around the hinge position; Retract; the top support cylinder drives the top support mechanism to rotate around the root. The present invention adopts a unique hoisting method inside the frame of the stacked bracket, fully utilizes the stretching stroke of the stacked bracket itself, and can adapt to the harsh working environment under the mine.

Owner:TAIYUAN KUANGJI ELECTRIC

Push button system and timepiece including the push button system

ActiveCN111983910BIncrease guide lengthNot super staticMechanical unknown time interval measurementElectromechanical unknown time interval measurementPhysicsPush-button

The invention relates to a button system for activating an actuating member, the system comprising a button head, a pusher integral with the button head, a first hollow guide member, the pusher mounted to slide inside the first hollow guide member, The first hollow guide member is for fixing to the fixing element relative to the button head and the pusher, the second hollow guiding member is arranged in the button head, and the pin is mounted to slide inside the second hollow member and for fixing to the fixing element superior. According to the invention, the pusher has an upper part provided on its periphery with a flange intended to cooperate with the inner surface of the first hollow guide member to guide the pusher within said member.

Owner:MECO SA

Piston pump for automobile brake system

ActiveCN103661336BImprove oil absorption efficiencyEasy to inhalePositive displacement pump componentsPumpsBrake fluidMotor shaft

The invention discloses a plunger pump for an automobile braking system. The plunger pump for the automobile braking system comprises a motor eccentric bearing, a motor shaft, a valve block, a pump oil outlet cavity, a backpressure cavity, an active pressurization oil passing channel, a star-shaped sealing ring, a pump guide sleeve, a pump oil inlet assembly and a pump plunger assembly. The plunger pump is composed of the independent pump oil inlet assembly, the pump plunger assembly, the star-shaped sealing ring, the pump guide sleeve and the valve block, the active pressurization oil passing channel is formed between a low-pressure cavity and the backpressure cavity of the plunger pump, when brake fluid of the low-pressure cavity is compressed by pushback movement of a plunger rod assembly, the brake fluid provides active pressurization for oil absorption of the plunger pump through the active pressurization oil passing channel, and therefore the efficiency of the pump is improved.

Owner:WANXIANG QIANCHAO SHANGHAI AUTOMOTIVE SYST +1

Heavy-load roller guide shoe mechanism

PendingCN112978539AImprove carrying capacityGood orientationElevatorsStructural engineeringMechanical engineering

The invention discloses a heavy-load roller guide shoe mechanism. The heavy-load roller guide shoe mechanism comprises a bottom plate and a support fixedly arranged on the bottom plate, wherein swing assemblies are arranged on the left side and the right side of the support, each swing assembly comprises a swing arm, a swing rod and a support base, the support bases are fixedly arranged on the bottom plate, and the bottoms of the swing arms are mounted on the support bases through swing shafts; and the middles of the swing rods are mounted on the swing arms through rotating shafts, the tops and the bottoms of the swing rods are provided with rollers, and the upper rollers and the lower rollers are symmetrically arranged with the rotating shafts as the centers and are linked through the swing rods to act on a guide rail simultaneously. According to the mechanism, single rollers are improved into the upper rollers and the lower rollers to be linked through the swing rods and act on the guide rail simultaneously, the swing rods swing around fulcrums to enable the upper rollers and the lower rollers to be automatically attached to the guide rail, the bearing capacity of a guide shoe is improved, the problem of large load or large unbalance loading force is solved, meanwhile, the guide length is increased, and a guide effect of the roller guide shoe is improved.

Owner:HANGZHOU HUNING ELEVATOR PARTS CO LTD

Plunger type cylinder system for adjustment of motion platform of full-automatic platen gold stamping die-cutting machine

ActiveCN107120334AEliminate gapsSimple structureFluid-pressure actuatorsMechanical engineeringPlunger

The invention discloses a plunger type cylinder system for adjustment of a motion platform of a full-automatic platen gold stamping die-cutting machine. The plunger type cylinder system comprises a main cylinder body and a cylinder body assembly which is arranged in the main cylinder body and formed by a front cylinder body and a rear cylinder body, wherein a plunger capable of acting on a workpiece telescopically is arranged in the front cylinder body and the rear cylinder body, an oil inlet hole capable of supplying oil to the plunger and pushing the plunger to move is formed in the main cylinder body, seal rings are arranged between the main cylinder body and the rear cylinder body as well as between the rear cylinder body and the plunger, a return pull rod fixedly connected with the main cylinder body is arranged in the plunger in the axial direction of the plunger, a spring for driving the plunger to return is arranged between the plunger and the return pull rod, and a self-locking system capable of locking the plunger when the plunger reaches a work position is arranged in the cylinder body assembly. Adjustment consistency is guaranteed to the greatest extent, and the problems of troublesome operation and unevenness in adjustment of manual adjustment in the prior art are solved completely.

Owner:青岛黎马敦包装有限公司

A plunger cylinder utilizing gap sealing

ActiveCN104006023BRealize logic controlEasily damagedPiston ringsFluid-pressure actuatorsHydraulic cylinderEngineering

The invention discloses a clearance seal plunger type cylinder and belongs to the technical field of hydraulic cylinders. The clearance seal plunger type cylinder comprises a cylinder barrel, a piston rod and a gland; a guide sleeve is fixed on the inner cylindrical surface of the cylinder barrel; a copper-base anti-abrasion oil-free bushing is mounted between the piston rod and the guide sleeve; an oil passage for communicating the outer side of the cylinder barrel with the high-pressure cavity of the cylinder barrel when the piston rod finishes traveling is opened in the plunger type cylinder, when the piston rod of the plunger type cylinder finishes traveling, the oil passage can output pressure oil and send a pressure signal to realize the logic control for a hydraulic system; a very small clearance is formed between the relatively moving surfaces of the copper-base anti-abrasion oil-free bushing and the piston rod to form clearance seal.

Owner:XCMG HYDRAULICS CO LTD

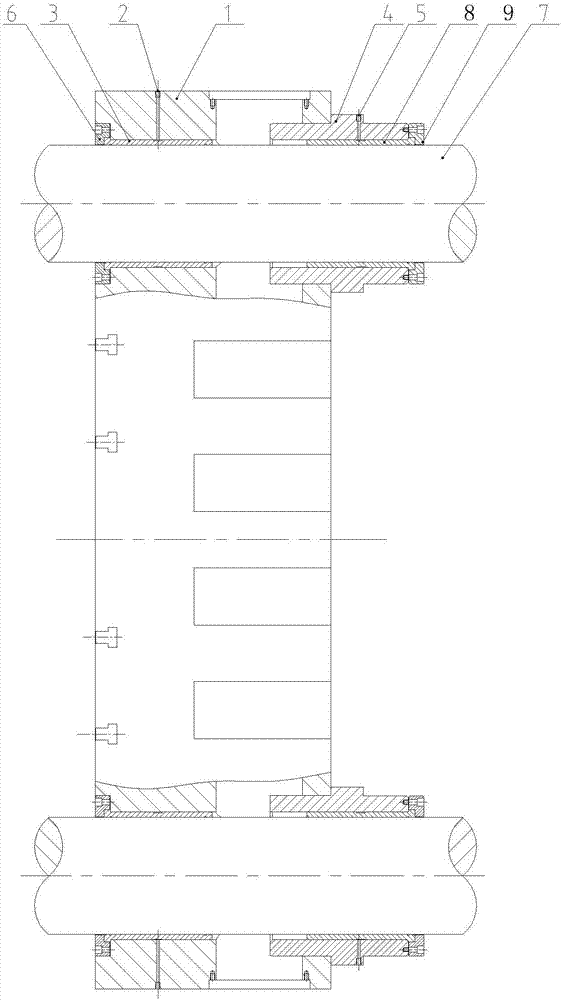

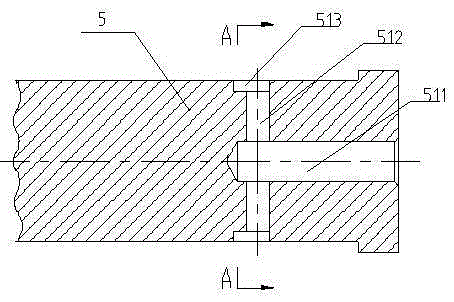

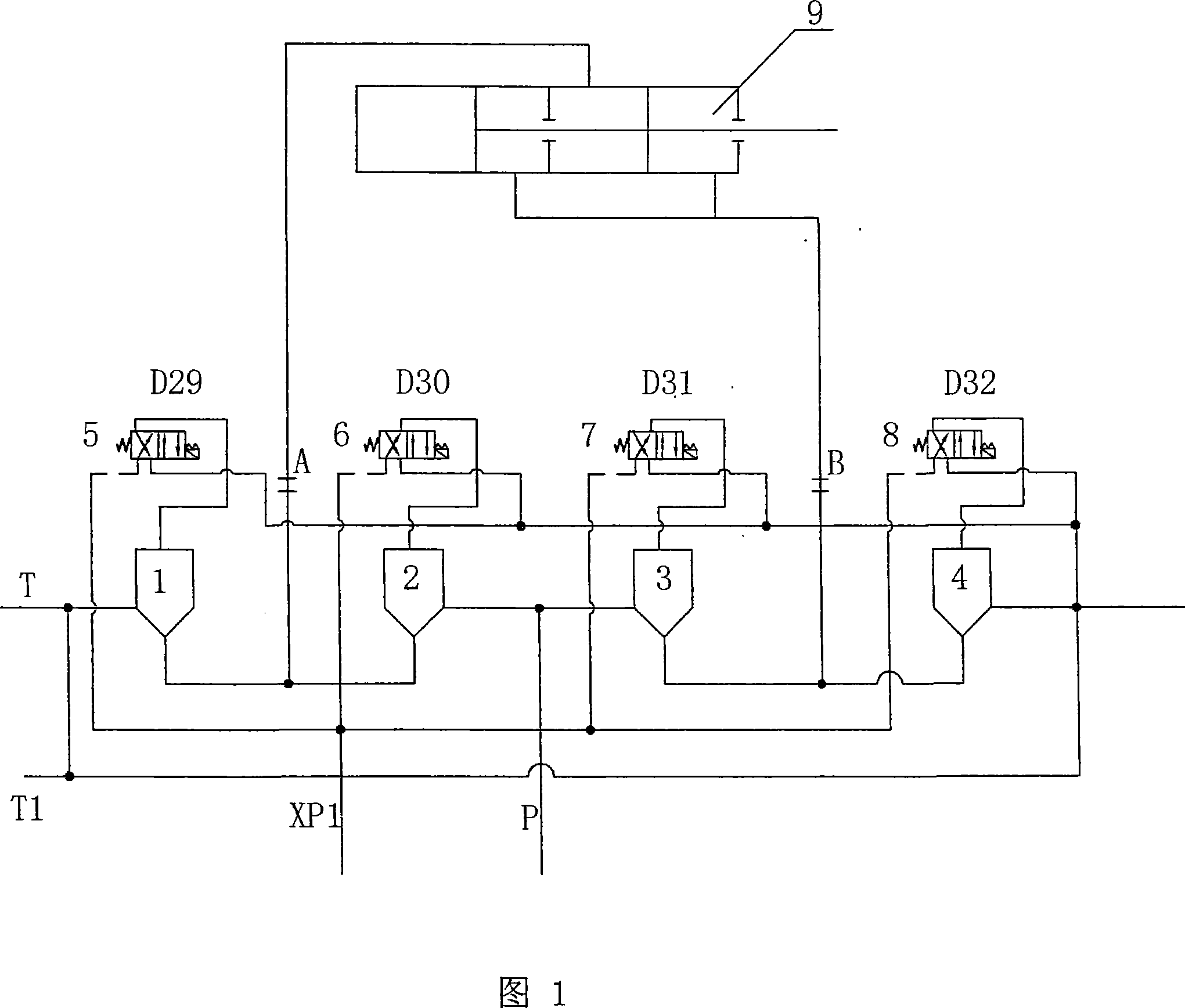

Cascade mould-regulating mould-locking hydraulic cylinder

The invention discloses a serial adjusting film and locking film oil cylinder, which pertains to a hydraulic oil cylinder device and solves steel waste, large size of seals and high price caused by huge volume and large occupied area of the oil cylinders with relatively large pressure as well as the problem of inconvenient maintenance. The invention comprises a movable template (2), a prepositive oil cylinder and a postposing oil cylinder, wherein, a cylinder body (4) of the prepositive oil cylinder is fixedly arranged inside the movable template (2) and a piston bar (5) thereof extends out of the oil cylinder through a front cover (3) of the prepositive oil cylinder; however, the postposing oil cylinder is connected with the prepositive oil cylinder through a middle cover (8) in series; meanwhile, a piston bar of the postposing oil cylinder enters a rear cavity of the prepositive oil cylinder through the middle cover (8) and the head part thereof is fixedly connected with a piston (6) of the prepositive oil cylinder, an oil line (1) is arranged on the piston bar of the postposing oil cylinder, and a front cavity of the prepositive oil cylinder is communicated with a rear cavity of the postposing oil cylinder through the oil line. The invention is especially applicable for locking film mechanisms of large and super large injecting machines.

Owner:SHANXI FENXI HEAVY IND

Efficient grain conveying vehicle

InactiveCN103770687ASimple resultReduce spillageLoading/unloading vehicle arrangmentTransportation itemsAgricultural engineering

The invention discloses an efficient grain conveying vehicle convenient for unloading, comprising a main compartment body, a vehicle head and wheels arranged at the bottom of the main compartment body; a discharging port and a fixing baffle are arranged at the lower end of the main compartment body; a brake plate in slide match with the fixing baffle is arranged at the lower end of the discharging port; the brake plate is fixedly connected with one end of a connection rod of which the other end is connected with a handle by a first rotary shaft; the middle of the handle is connected with a fixed support by a second rotary shaft; the fixed support is fixed on the main compartment body; an unloading hopper matched with the discharging port is arranged at the bottom of the man compartment body; an upper fixing button and a lower fixing button are respectively arranged at two sides of the unloading hopper; a telescopic material hopper is arranged in the unloading hopper; limiting chains mutually matched with the upper fixing button and the lower fixing button are respectively arranged at two sides of the lower end of the telescopic material hopper.

Owner:SHANGHAI HAIFENG RICE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com