Lengthening device for tie bar guide hole of movable template of die casting machine

A technology of moving templates and guide holes, which is applied in the field of extended device for die-casting mobile templates and guide holes. It can solve the problems affecting the pass rate and output, lengthening of the moving template structure, and low repeatability, so as to improve stability and repeatability. , Improve productivity and capacity, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

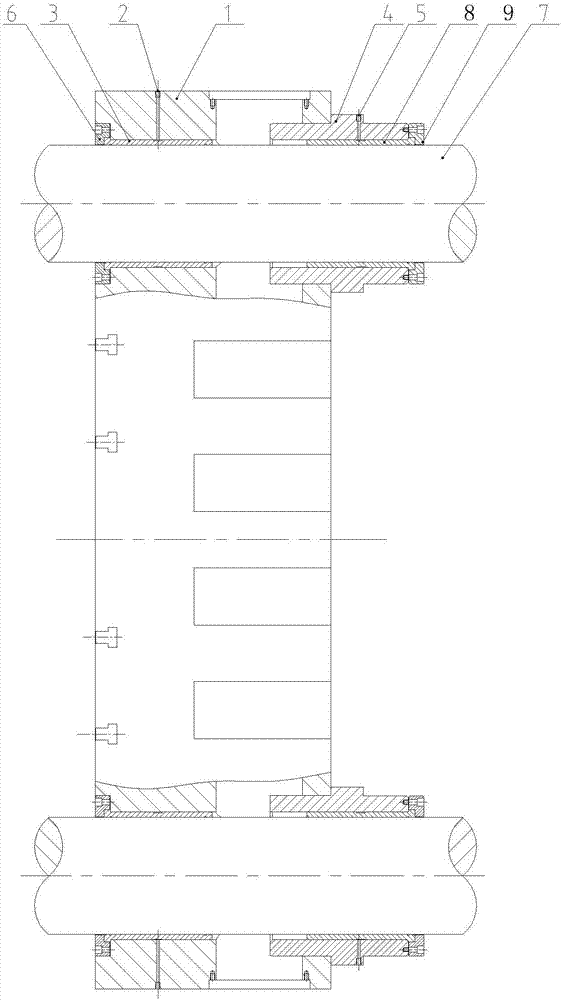

[0018] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, specific implementations will now be described in detail with reference to the accompanying drawings.

[0019] Such as figure 1 As shown in the die-casting motorized formwork Corinthian guide hole extension device, the left end hole of the movable template 1 is equipped with a left guide copper sleeve 3, and the outer circular surface of the left guide copper sleeve 3 is transitionally fitted with the inner hole surface of the movable template 1, and the movable template The right end hole of 1 is equipped with a right guide seat 4, and the right guide seat 4 protrudes from the end face of the movable template, and the right guide copper sleeve 8 is installed in the hole of the right guide seat 4, and the outer circular surface of the right guide seat 4 and the movable template 1 The transition fit of the inner hole surface, the inner hole surface of the ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com