Design method of novel punching die structure

A technology of structural design and design method, applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve problems such as large amount of material used, poor orientation of ZP punching dies, difficult processing of IPT punching dies, etc., to reduce wear , convenient grinding and convenient serial design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] A new die structure design method of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

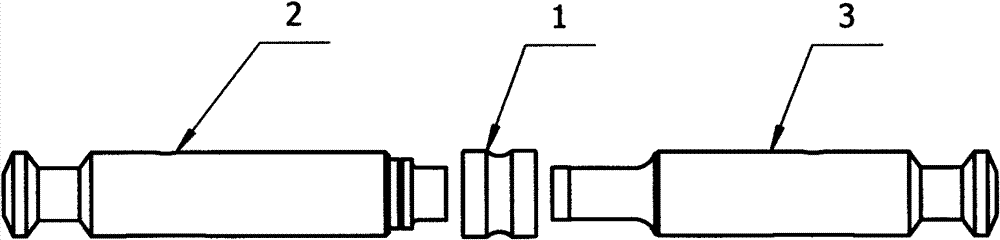

[0013] Such as figure 2 As shown, a new type of punching die structure includes a middle die 1, an upper punch 2, and a lower punch 3, wherein the punch body diameter and the punch tail diameter of the upper punch 2 and the lower punch 3 adopt the same size of Φ22mm, and the punch tail The structure adopts ZP type punching die, the total length of the punch rod is 133.35mm, and the middle die is IPTB type standard die; it can also be made: the punch body diameter and punch tail diameter of the upper punch rod and the lower punch rod adopt the same size of Φ25.35mm, The punch tail structure adopts the IPTB type punching die, the total length of the punch rod is 133.35mm, and the middle die is the IPTB or IPTD type standard die. The structure and size of the remaining parts in the above-mentioned punching die are the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com