Heavy-load roller guide shoe mechanism

A technology of roller guide shoes and rollers, which is applied in the field of elevator safety protection, can solve problems such as limited guide length of a single roller, large installation space, failure of guide and limit, etc., to solve large load or large partial load force, improve Load capacity, effect of increasing guide length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

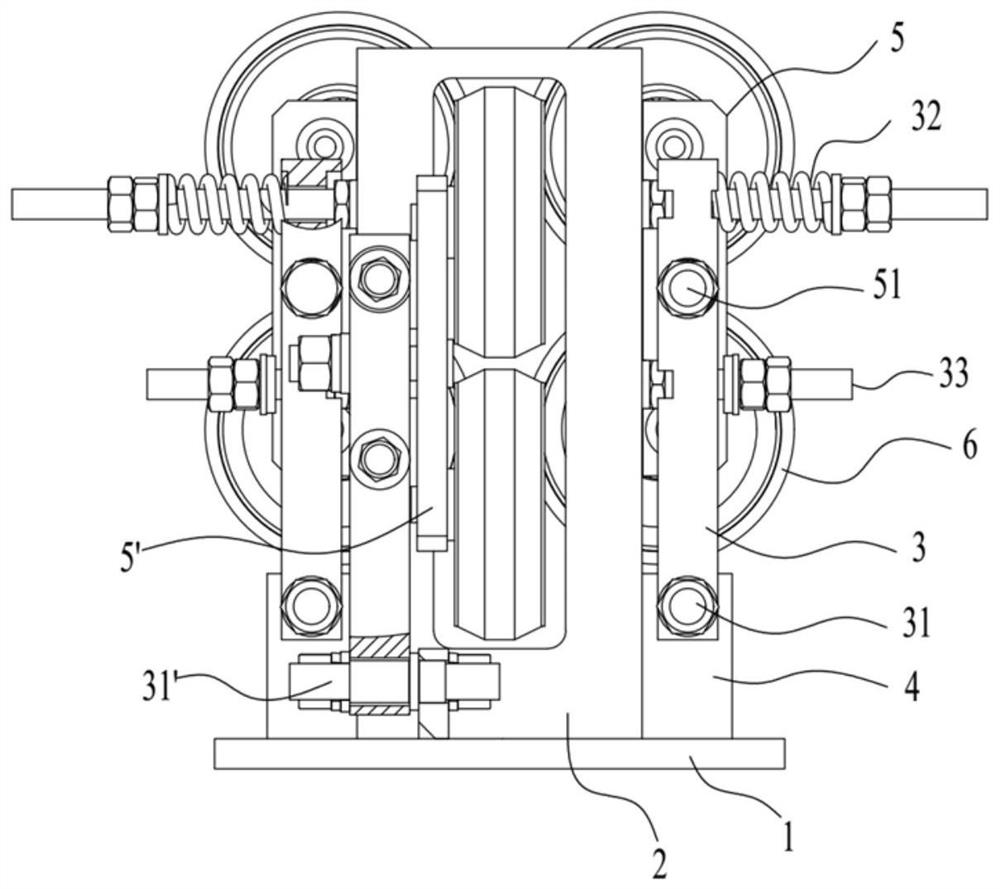

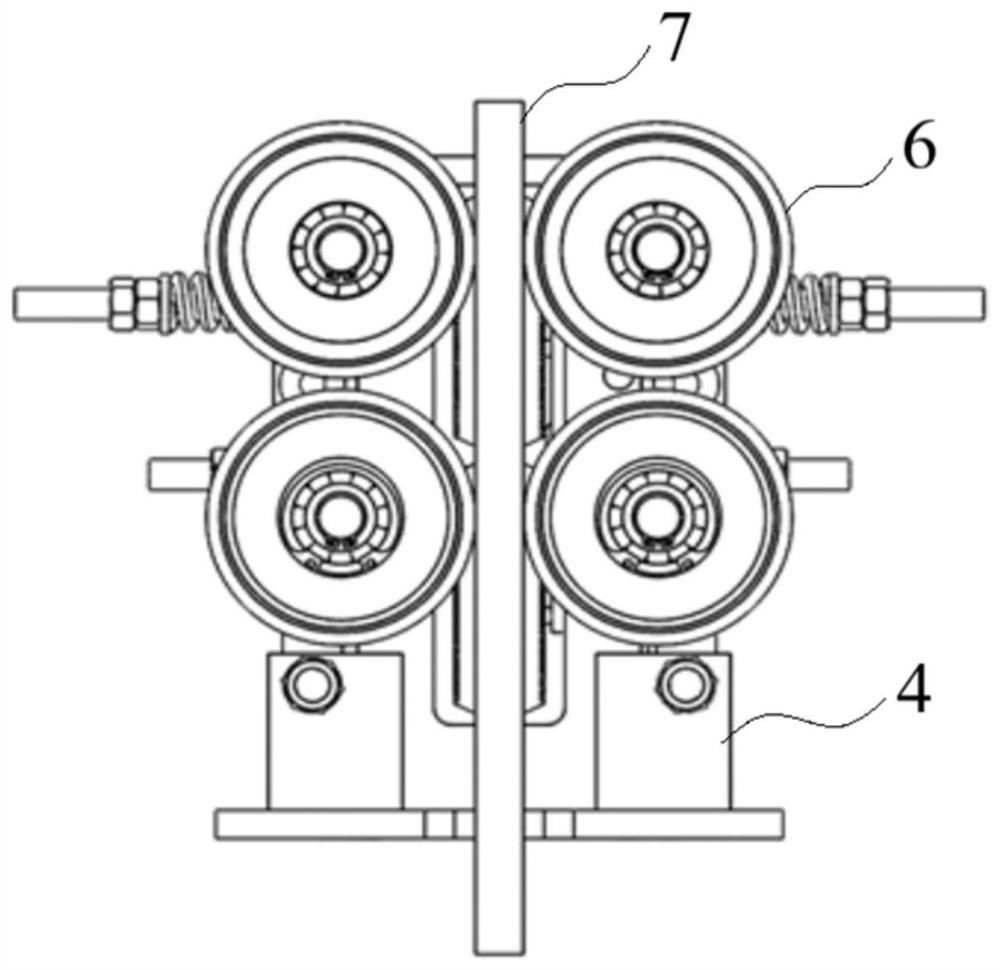

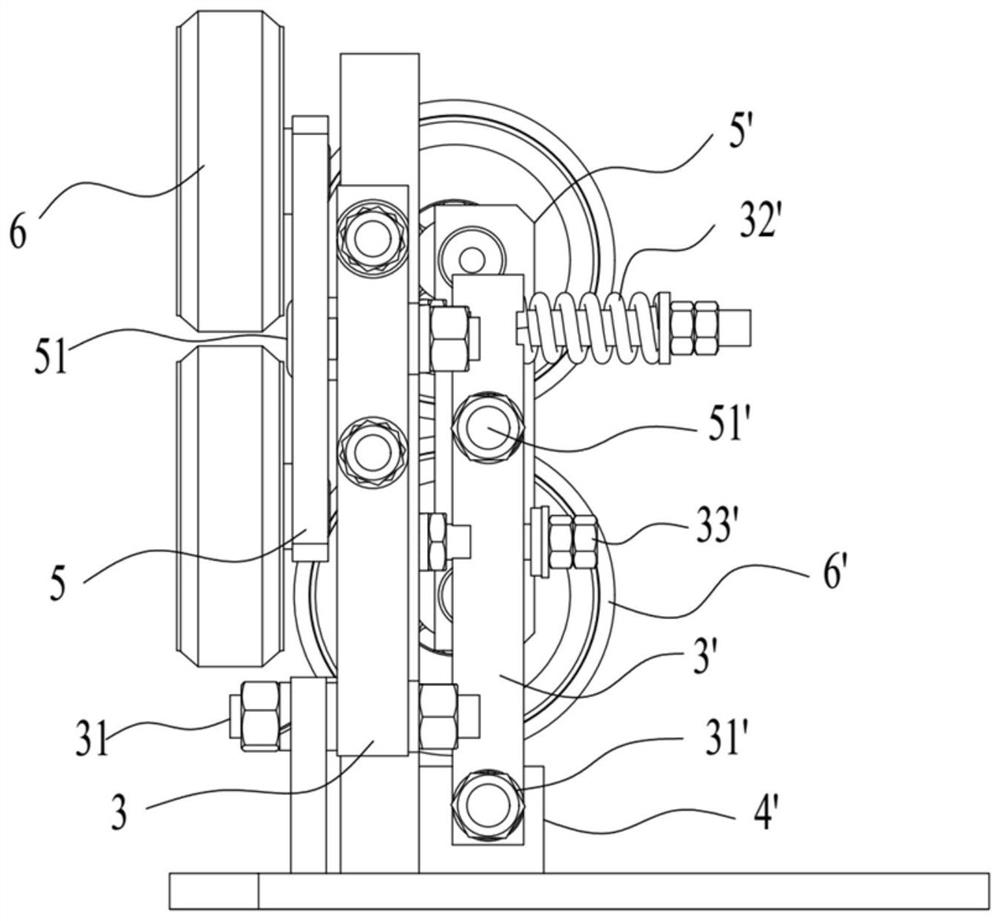

[0022] This embodiment provides a large-load roller guide shoe mechanism, which is used to improve the bearing capacity of the elevator guide, and solve the problems of excessive guide shoe size and limited guide length of a single roller caused by the need to use large-diameter rollers under heavy load.

[0023] Specifically, as Figure 1-4 As shown, the large-load roller guide shoe mechanism includes a base plate 1 and a bracket 2 fixed above the base plate 1. Swing components are provided on the left and right sides of the bracket. The swing components include a swing arm 3, a swing rod 5 and a support 4, and the support 4 is fixed on the top of the base plate 1, the bottom of the swing arm 3 is installed on the support 4 through the swing shaft 31, and the swing arm 3 can swing around the swing shaft 31; Bar 5 can swing around rotating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com