Cascade mould-regulating mould-locking hydraulic cylinder

A clamping oil cylinder and oil cylinder technology, applied in the field of hydraulic cylinders, can solve the problems of large floor space, steel consumption, poor system rigidity, short service life, etc., achieve weight reduction, ideal sliding foot guiding state, and reduce fastening bolts Quantity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

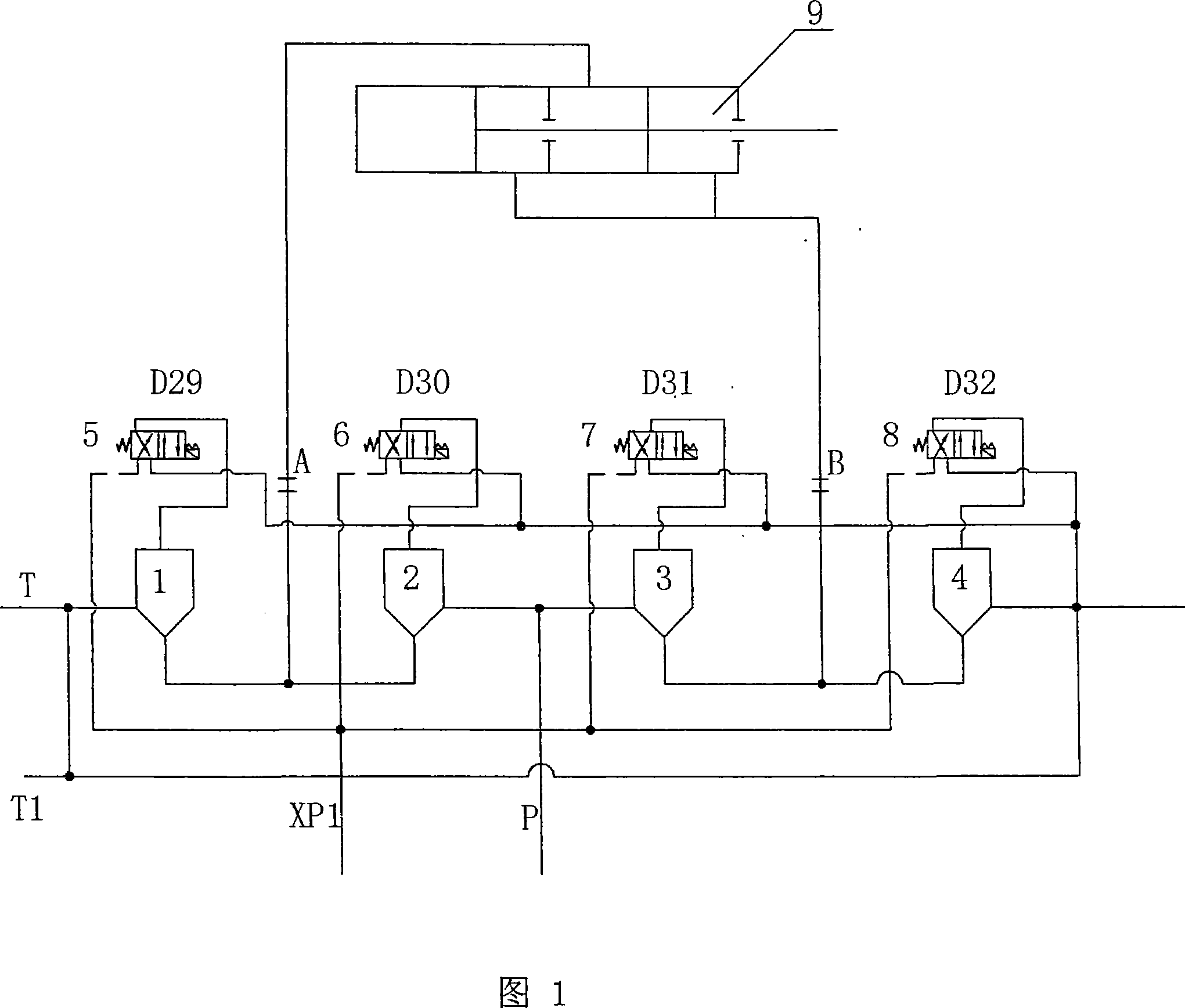

Method used

Image

Examples

specific Embodiment approach

[0010] First put the front cover 3 into the movable template 2, then put the front cylinder 4 into it, then the front cover 3 can be stuck, put the Gelin pillar, that is, the piston rod 5, and then install the front piston 6 on the Gelin Then install the middle cover 8 and the rear oil cylinder piston 10 in sequence, and finally screw on the nut 11 to lock the parts loaded in the front, and finally install the rear oil cylinder body 9 and the rear cover 12 with the pull rod 13 And the nut is fixed on the moving template.

[0011] During operation, one pressure oil enters the front chamber of the front cylinder through the oil port of the middle cover 8, and one road of hydraulic oil enters the front chamber of the rear cylinder through the other oil port of the middle cover 8, and the pressure oil passes through the piston 10, piston rod 5, The oil passage (1) of the front piston 6 reaches the front chamber of the front oil cylinder.

[0012] There are two functions of series...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com