Parallel gripper

A technology of parallel grippers and grippers, applied in the direction of collets, chucks, manipulators, etc., can solve problems such as deformation and shell distortion, and achieve the effect of a compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

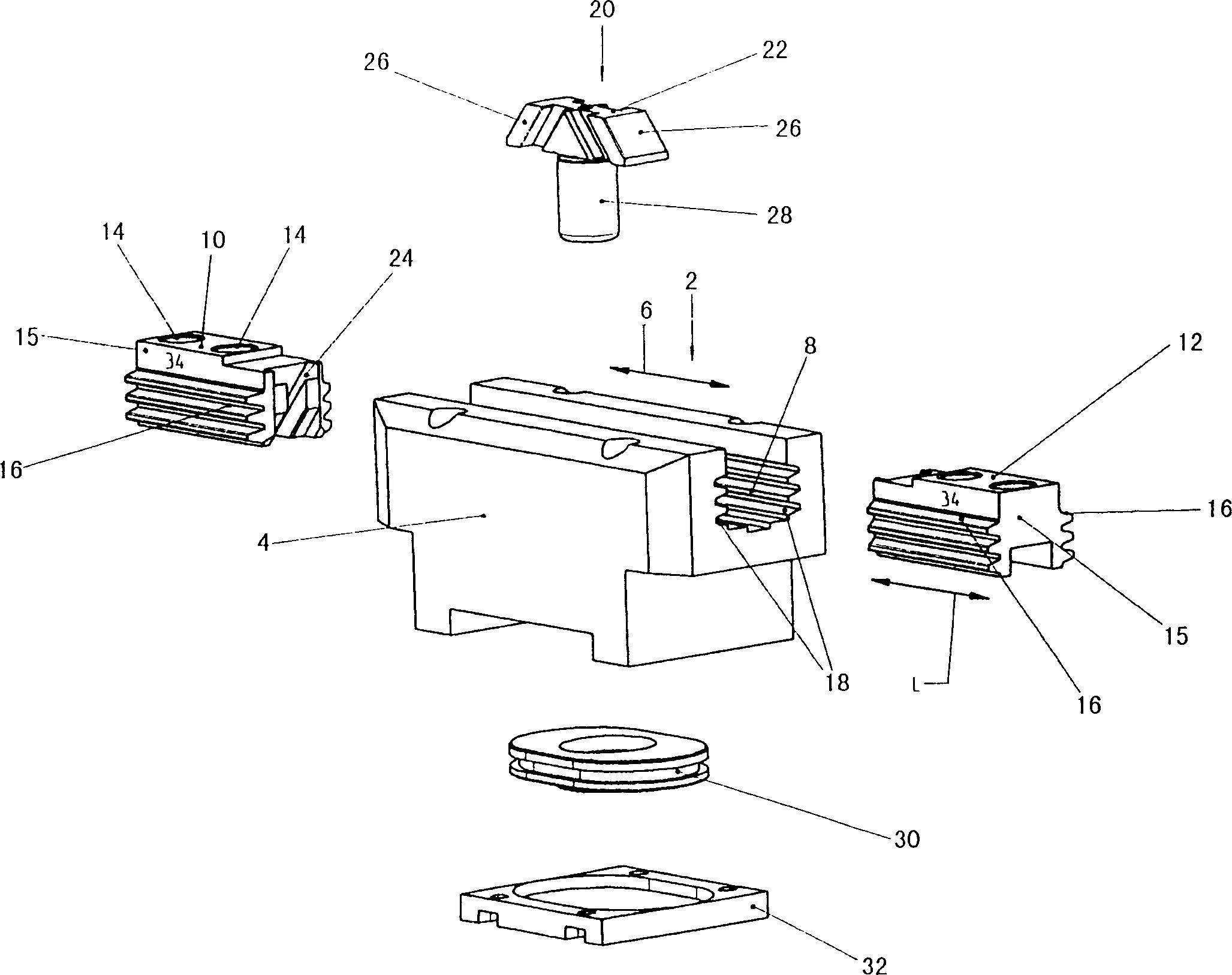

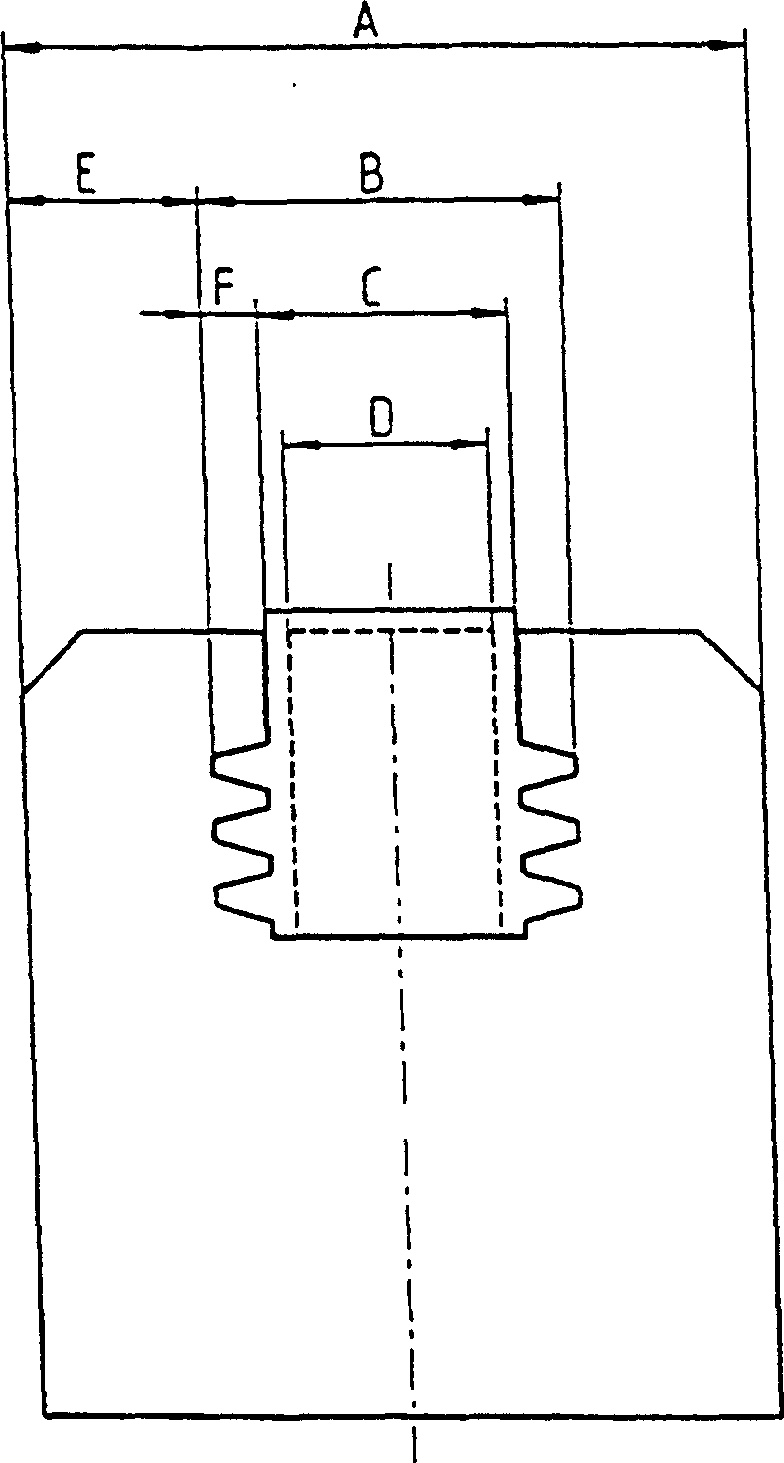

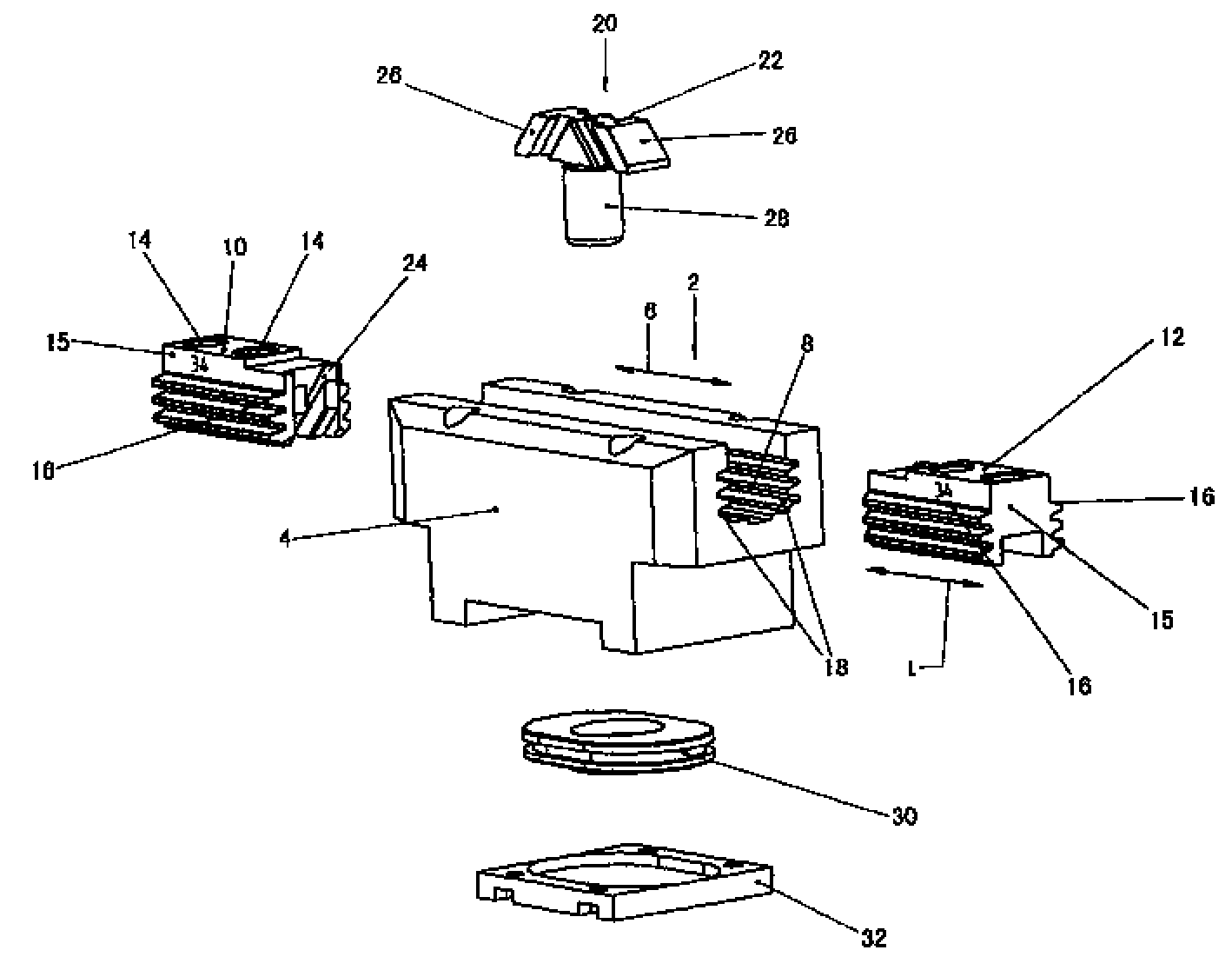

[0022] figure 1 A parallel gripper, generally designated by reference numeral 2, is shown. The gripper comprises a gripper housing 4 with gripper guide recesses 8 extending in the longitudinal direction 6 for the basic grippers 10 and 12, which are shown outside the housing and can be It is inserted in the longitudinal direction 6 into the guide recess 8 of the clamping block and can be moved therein. On one surface of the basic clamping blocks 10, 12 are provided mounting holes 14 for detachably attaching jaw elements, which will not be further described here.

[0023] The basic clamping blocks 10 , 12 each have guide strips 16 extending in the longitudinal direction 6 and thus in the direction of movement on both sides, which are wedge-shaped or trapezoidal in shape with flattened ends. On both sides of each basic clamping block 10 , 12 three guide strips 16 arranged one above the other protruding from its base body 15 and extending over the entire length L of the basic cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com