Plunger type cylinder system for adjustment of motion platform of full-automatic platen gold stamping die-cutting machine

A motion platform, flattening and flattening technology, applied in the direction of fluid pressure actuators, etc., can solve problems such as difficulty in ensuring the height consistency of wedge-shaped iron units, adverse effects on product processing quality, and unbalanced die-cutting pressure of workpieces, etc., to achieve reliable Locking, simple structure and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

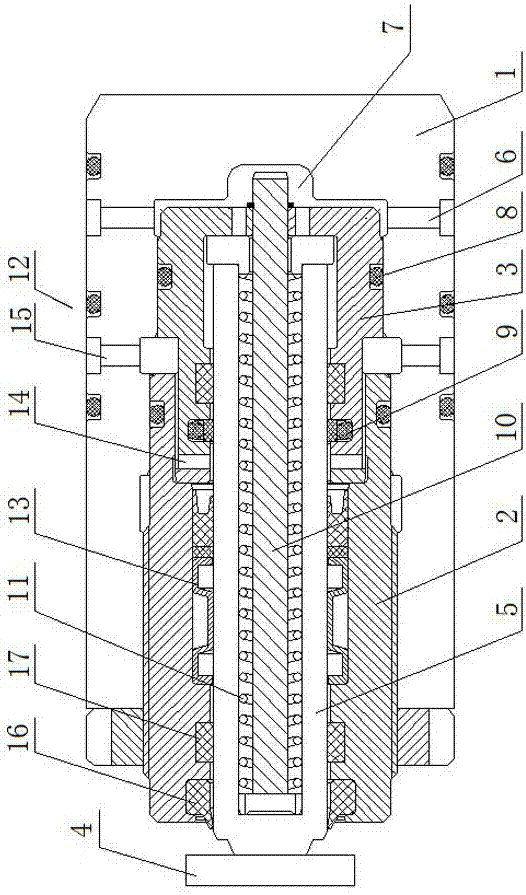

[0017] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail;

[0018] Such as figure 1 As shown in the figure, a plunger cylinder system for adjusting the motion platform of a fully automatic flat stamping die-cutting machine includes a cylinder composed of a main cylinder 1, a front cylinder 2 and a rear cylinder 3 arranged in the main cylinder 1 Body assembly, the front cylinder body 2 and the rear cylinder body 3 are provided with a retractable plunger 5 acting on the workpiece 4, and there is a device on the main cylinder body 1 that can supply oil to the plunger 5 and push it The oil inlet hole 6 through which the plunger 5 moves is provided with an oil supply channel 7 for delivering pressure oil acting on the plunger 5 in the main cylinder 1 , and the oil supply channel 7 communicates with the oil inlet hole 6 . Between the main cylinder block 1 and the rear cylinder block 3 and between the rear cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com