Tilting type horizontal rack vertical die splitting multi-way die forging press

A vertical die splitting and multi-directional die forging technology, applied in the field of hydraulic presses, can solve problems such as difficulty in realizing large-tonnage, high-precision multi-directional die forging, difficult operation of molds and workpieces, and limited tonnage of horizontal cylinders, etc., to achieve volume occupation Small space, easy assembly, and improved machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

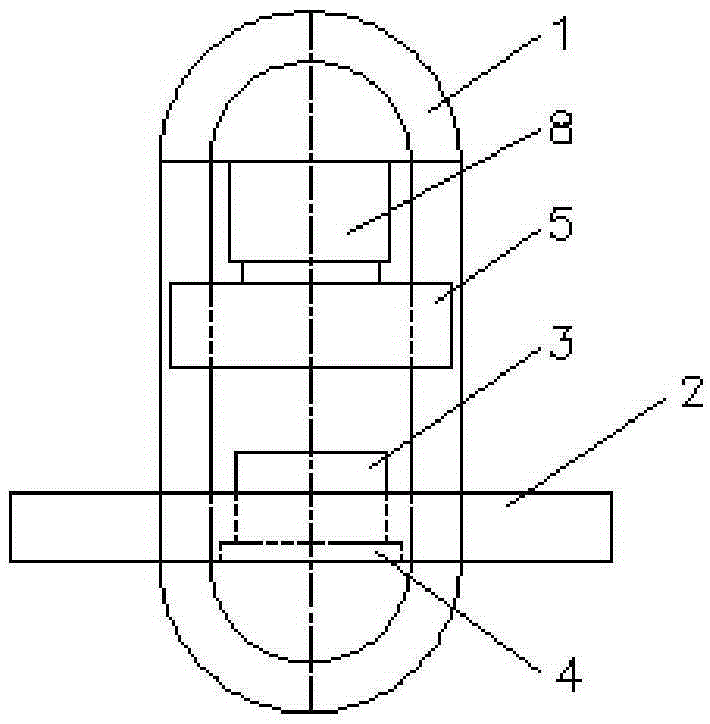

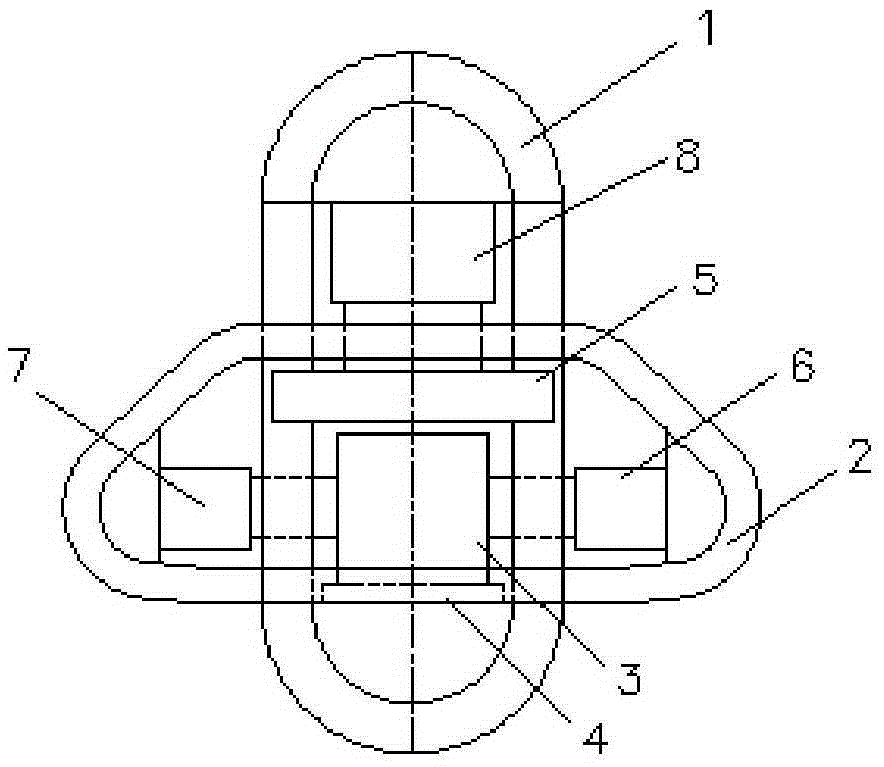

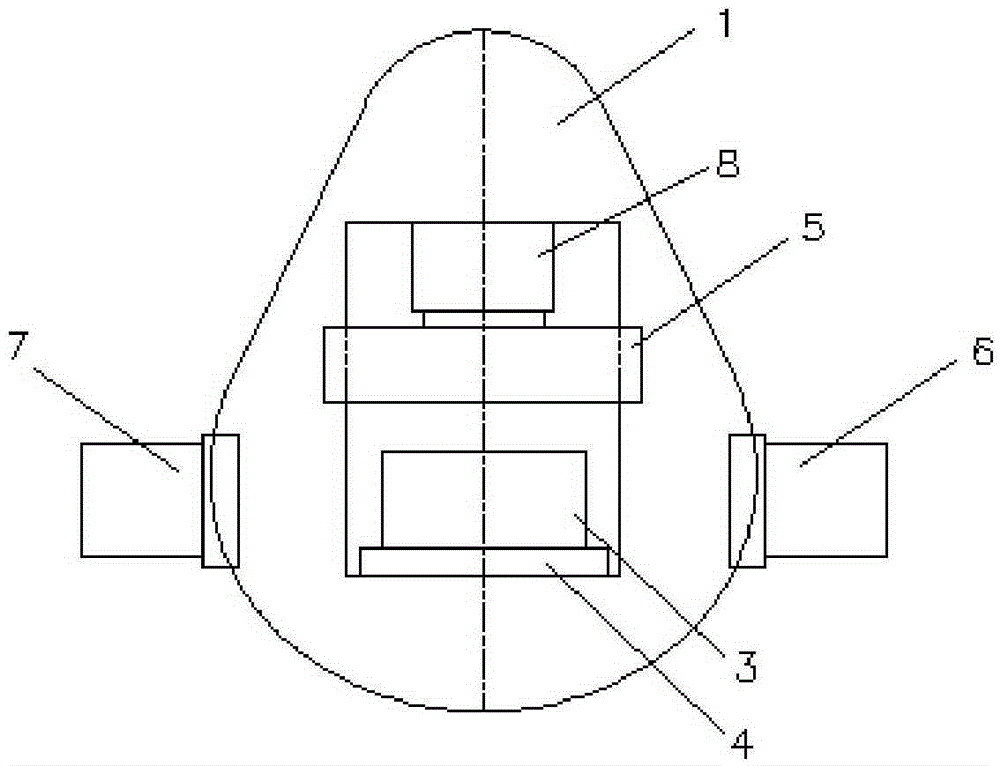

[0026] Embodiment: a tilting horizontal frame 2 vertical split multi-directional die forging hydraulic press, including a vertical frame 1 in the vertical direction, a workbench 4, a mold 3, a moving beam 5 and a vertical oil cylinder 8, the workbench 4 is positioned on the frame, the mold 3 is fixedly installed on the workbench 4, the moving beam 5 can move longitudinally and is installed on the vertical frame 1, the vertical oil cylinder 8 drives the moving beam 5 to move, and the horizontal frame 2 and the first 2. Two horizontal oil cylinders 6, 7, the horizontal frame 2 is sleeved on the outside of the vertical frame 1, the horizontal frame 2 forms an angle of inclination greater than zero with the horizontal plane, and the height of the horizontal frame 2 towards the side of the operating direction is not Higher than the height of the 4 sides of the workbench, the cylinder blocks of the first and second horizontal oil cylinders 6 and 7 are fixedly installed on the inner s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com