Burner fire cover, burner and gas stove

A burner and fire cover technology, which is applied to burners, gas fuel burners, combustion methods, etc., can solve the problems of uneven mixing of gas and air, poor flame shape, and large burner volume, and is easy to disassemble and assemble. The effect of cleaning, good shape and uniform flame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

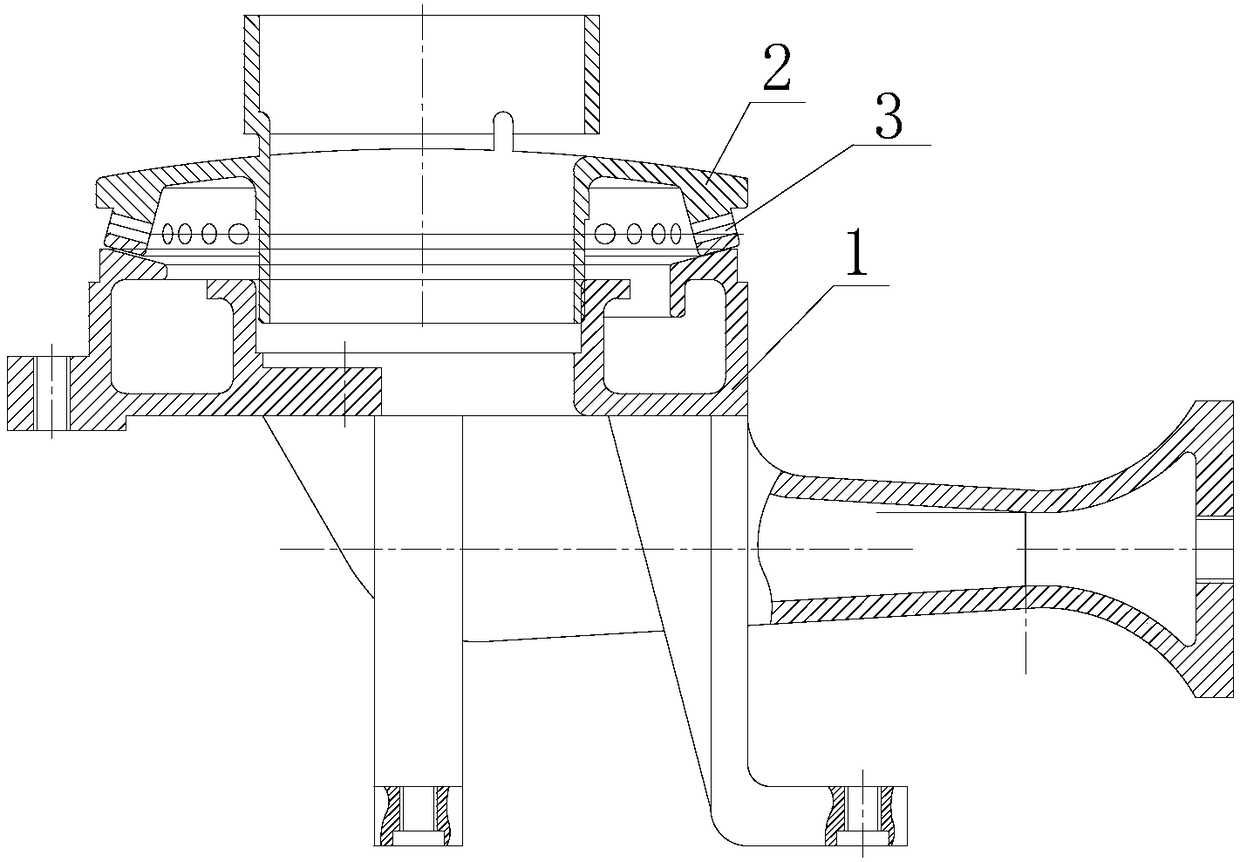

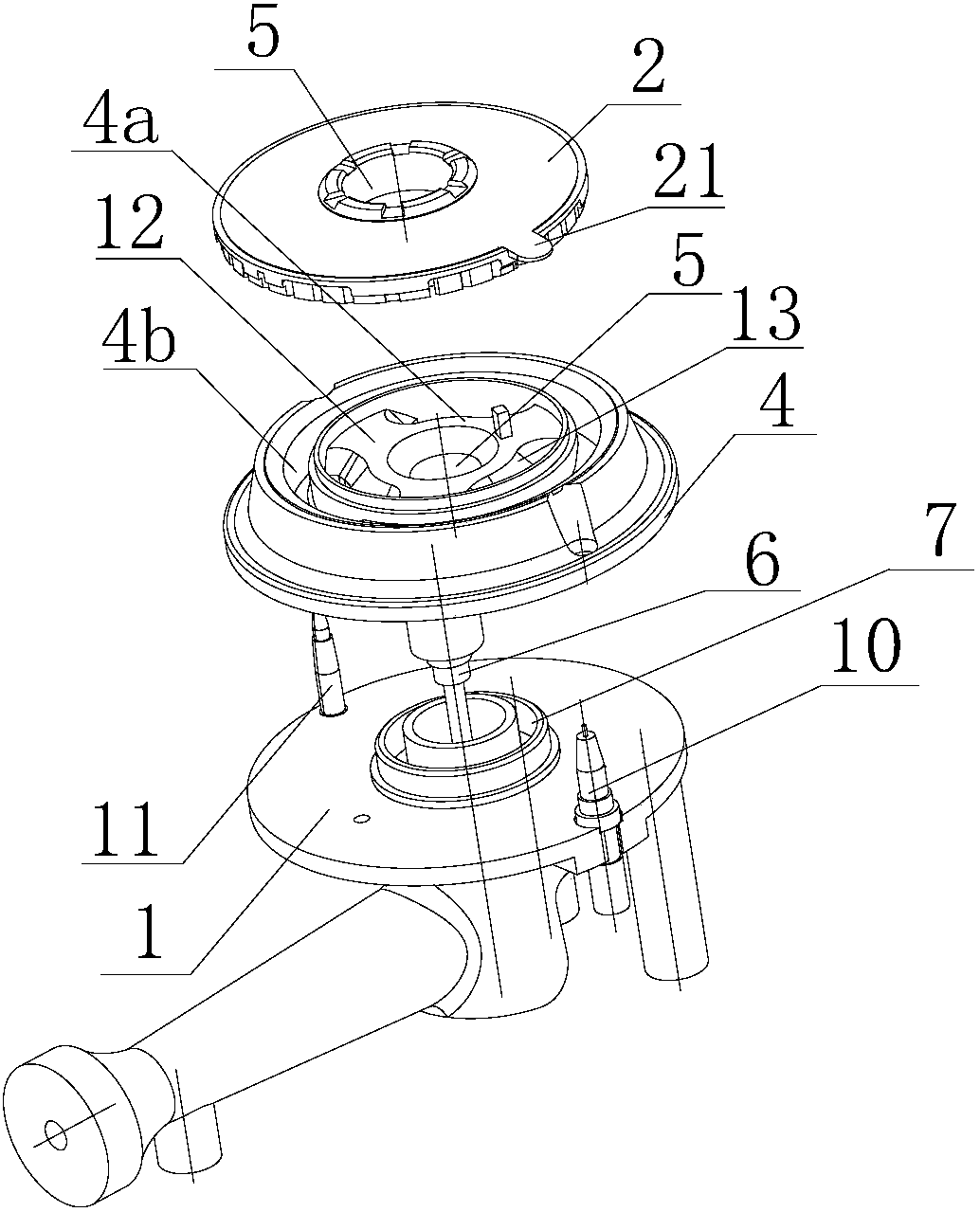

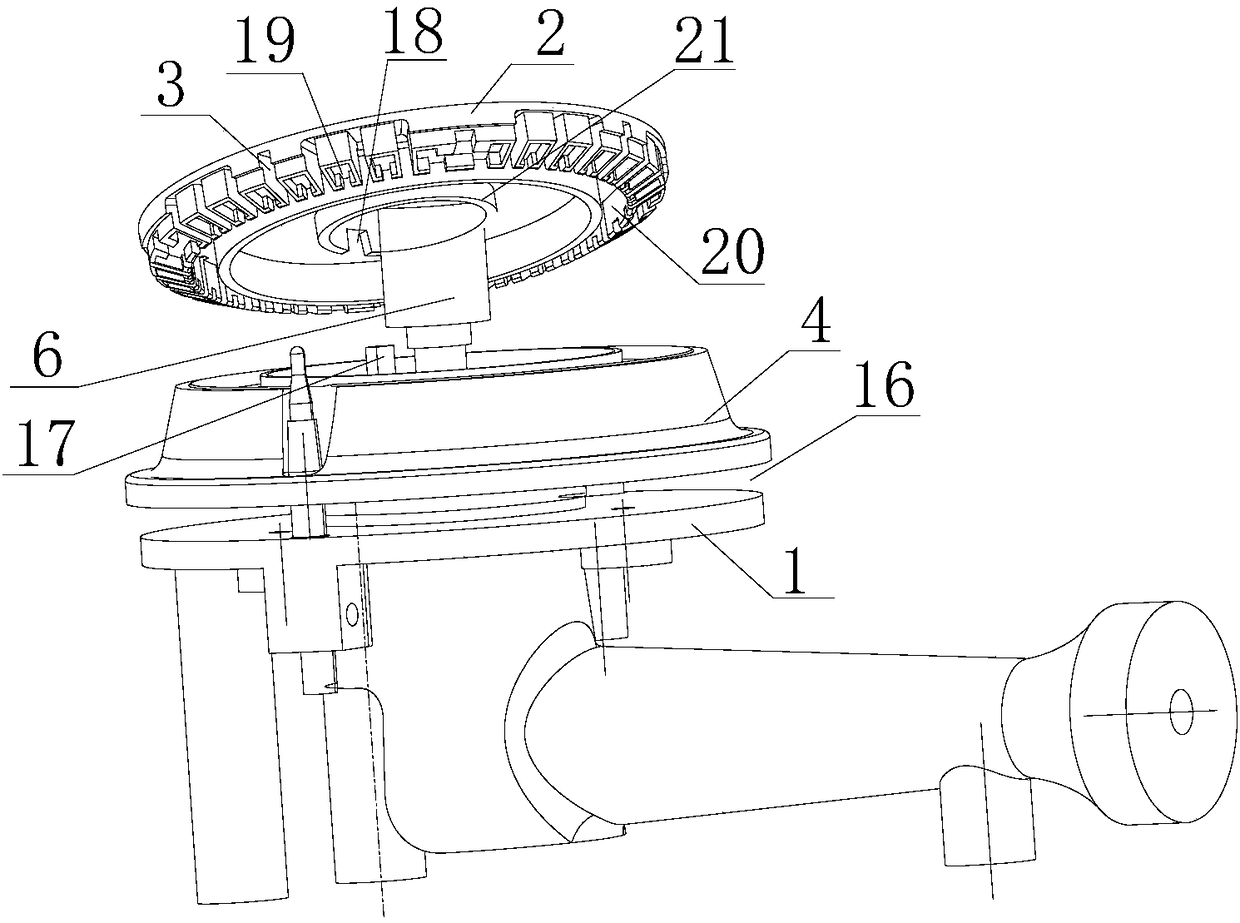

[0035] Such as Figure 2 to Figure 4 As shown, a burner provided by the present invention is a single-ring burner, including a burner head 1, a fire cover 2 and a fire cover seat 4, the fire cover seat 4 is plugged and installed on the burner head 1, and the fire cover 2 is plugged Installed on the fire cover seat 4, a circle of fire outlet grooves 3 is set on the side wall outside the fire cover 2, and the combustion gas is burned after being sprayed out by several fire outlet grooves 3. There is a through hole 5 in the center of the fire cover 2 , the fire cover seat 4 and the burner 1 , and the anti-dry burning sensor 6 is fixed through the through hole 5 . The bottom of the anti-dry sensor 6 is fixedly installed on the burner 1 through a fixed structure such as a bracket, and can also be fixedly installed on the bottom shell of the gas rang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com