Water and electricity separation energy-saving water dispenser

A technology for separation of water and electricity and water dispenser, applied in the fields of electric water dispenser and electric water heater, can solve the problems of increasing process difficulty, easy to produce scale, and high power consumption, and achieve the effects of scientific and reasonable water flow system, small circulation resistance, and improved thermal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

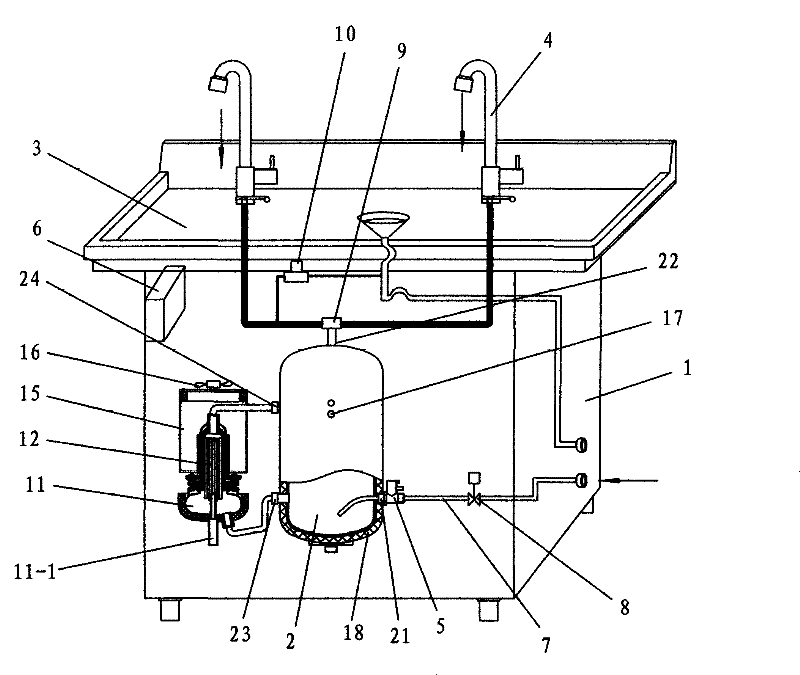

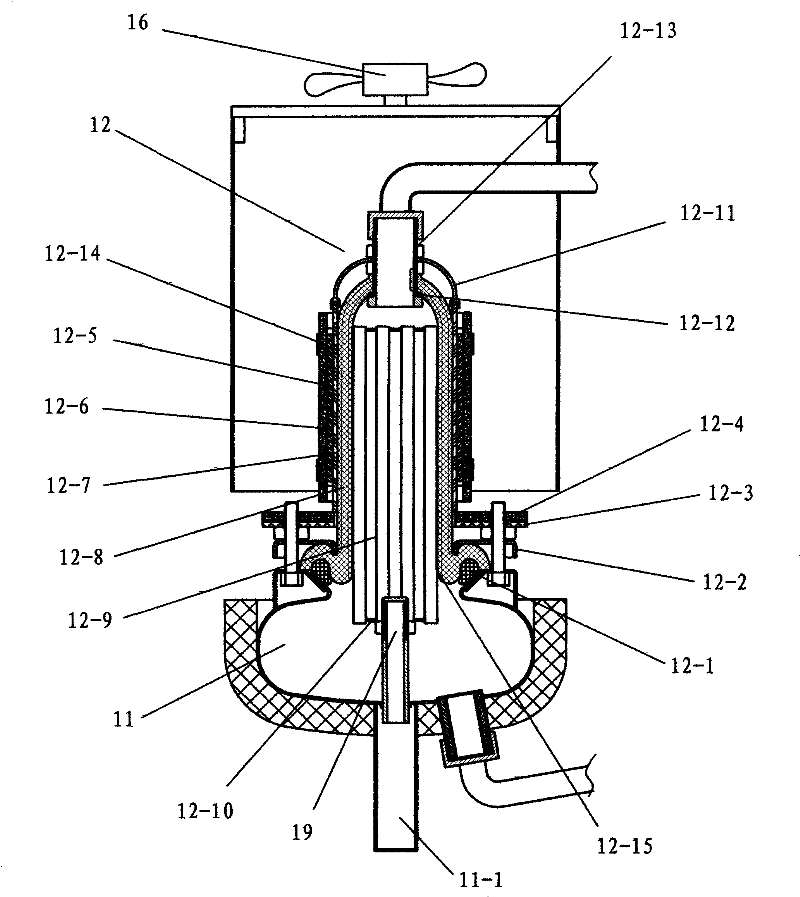

[0025] Embodiment one: if figure 1As shown, a water and electricity separation energy-saving water dispenser includes a water dispenser cabinet 1, on which a water storage tank 2, a water receiving basin 3, a water outlet connector 9, a water faucet 4, a safety valve 5 and an electric control device 6 are installed. , the lower part of the water tank 2 has a water inlet 21, and its upper part has a water outlet 22, the water inlet 21 is connected to the water inlet pipeline 7, the safety valve 5 and the water inlet solenoid valve 8 are installed on the water inlet pipeline 7, and the water outlet 22 is connected There is a water outlet joint 9, and the water opening faucet 4 and the drainer 10 are respectively connected to the water outlet joint 9. The water opening faucet 4 is a water and electricity linkage faucet. The program is opened and closed synchronously, so that the water storage tank 2 maintains a normal pressure state, and an independent boiling water tank 11 is al...

Embodiment 2

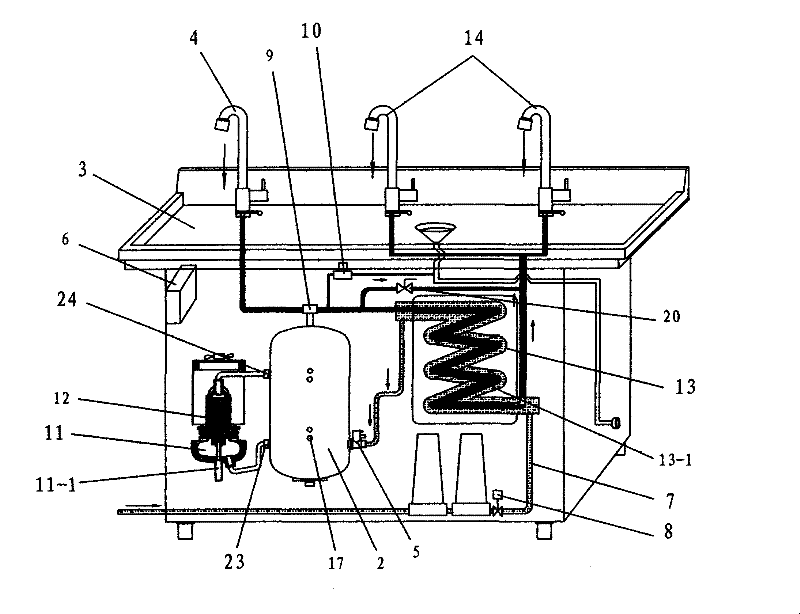

[0031] Embodiment two: if image 3 As shown, this embodiment is similar to Example 1, the only difference is that a heat exchanger 13 is also installed on the water inlet pipeline 7 of the water tank, and one end of the inner tube 13-1 of the heat exchanger 13 is connected to the water outlet connector. 9 is connected, and the other end is connected with warm water faucet 14, and warm water faucet 14 is hydropower linkage valve, so that it cooperates with electric control device 6, makes water storage tank 2 maintain normal pressure state, and the inner pipe 13-1 of heat exchanger 13 two The end is also connected with a temperature regulating valve 20; by adding a heat exchanger 13 on the water dispenser, utilizing the principle of the inner tube 13-1 of the heat exchanger for hot water and the outer tube for cold water (tap water), the hot water dissipates heat and the cold water absorbs heat. , can not only provide people with warm water for instant drinking, but also improv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com