Pre-water cycle heat exchange solar water heating engineering system

A technology for solar hot water and water circulation, which is applied in the field of front water circulation heat exchange solar hot water engineering systems, can solve the problems of increased operating costs, long hot water pipelines, and high engineering costs, and achieves reduction of convective heat loss, low water circulation resistance, The effect of low circulation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

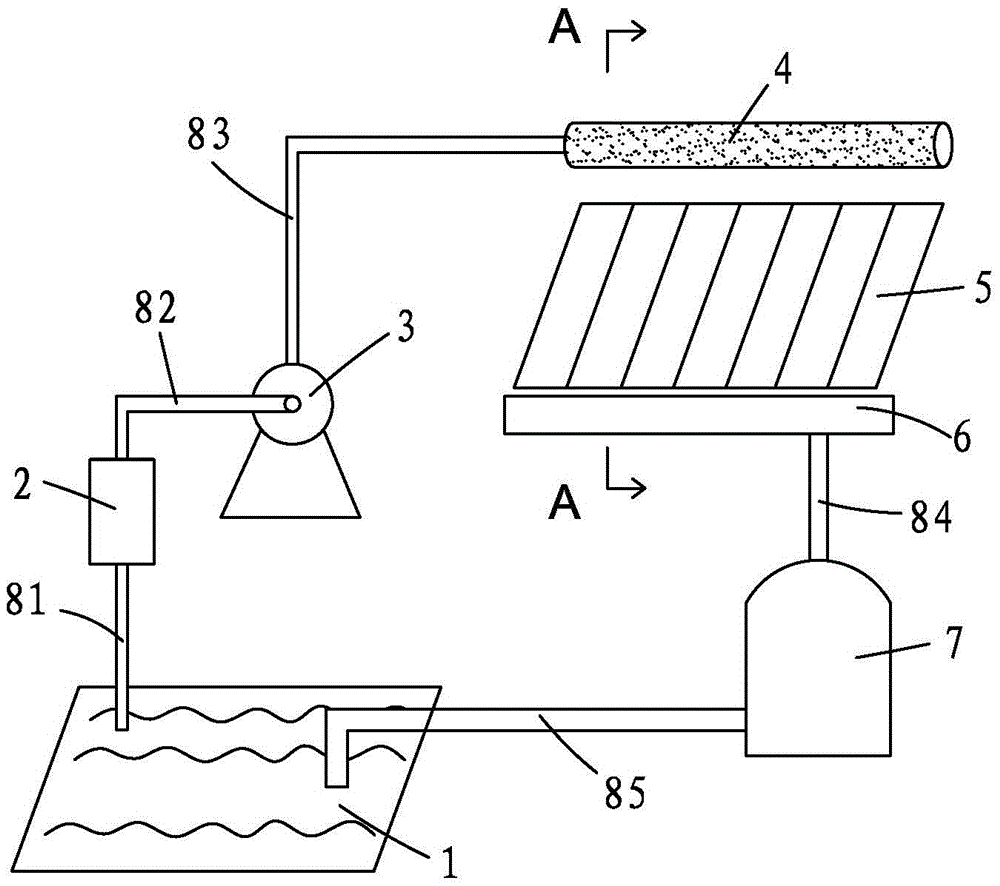

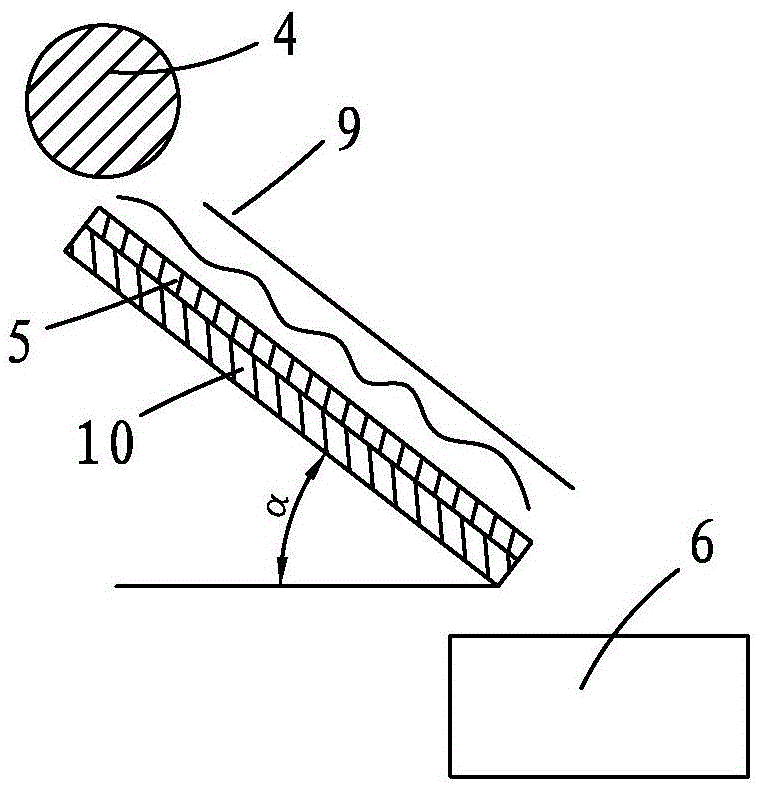

[0015] Please refer to Figure 1 to Figure 2 As shown, the front water circulation heat exchange solar hot water engineering system of the present invention includes a water tank 1, a coarse filter net 2, a circulating pump 3, a water distributor 4, a heat absorbing plate 5, a water collection tank 6, a fine filter 7, a permeable Light plastic thermal insulation film 9 and foam thermal insulation backboard 10, described water pool 1 is connected with described rough filter net 2 (for carrying out initial filtration to water) through first pipeline 81, and this coarse filter net 2 passes second pipeline 82 again Connect the circulation pump 3, the circulation pump 3 is used to lift the water in the water pool 1 into the water distributor 4; the circulation pump 3 is connected with the water distributor 4 through the third pipeline 83 , and the water distributor 4 is located above the high-end water inlet of the heat-absorbing plate 5; The flat panel, or the roof panel coated w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com