Patents

Literature

37results about How to "Low circulation resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A health food

Disclosed is a antihypelipidemic and antihyperglycemic health food for preventing diseases including cardiovascular disease, diabetes, adjusting internal secretion, resisting osteoporosis and cancer, and beauty treatment. The raw materials include soybean powder 15-30 parts, pumpkin powder 15-30 parts, soybean isoflavones 0.5-1.5 parts, soybean saponin 2-5 parts, astragalus root 10-20 parts, wolfberry fruit 10-15 parts, kudzuvine root 10-15 parts, Chinese yam 10-15 parts, lotus plumule 6-10 parts, Siberian solomonseal rhizome 6-10 parts, cassia seed 6-10 parts, lily 5-8 parts, mulberry leaf 5-8 parts and ginseng 3-5 parts.

Owner:富天桂

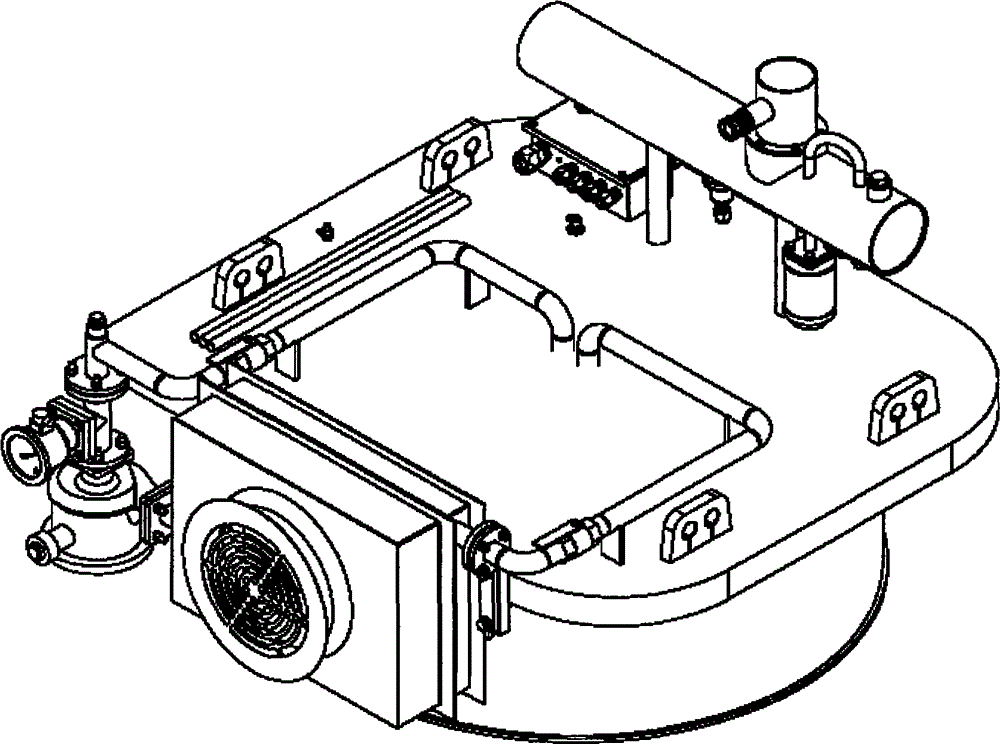

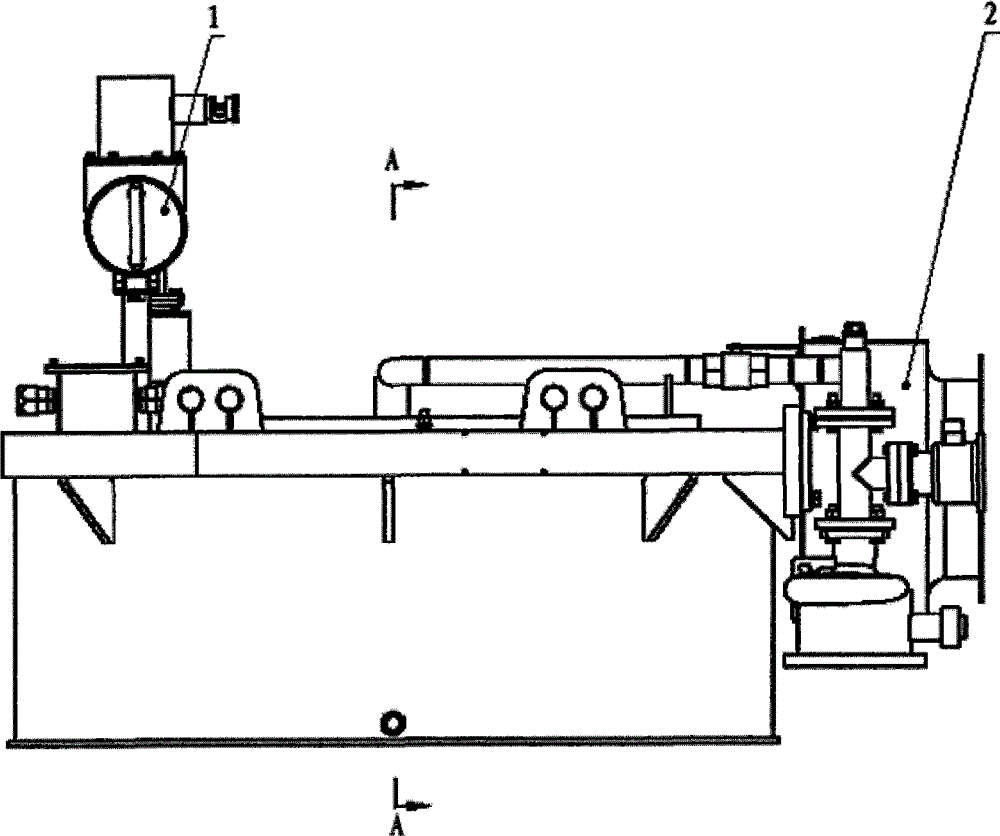

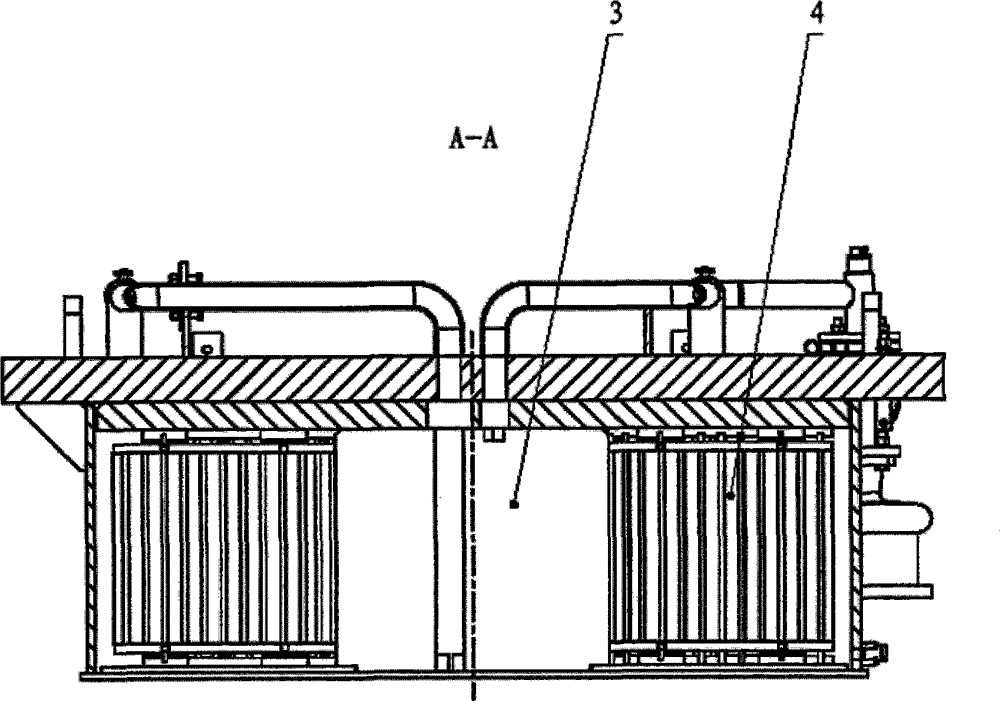

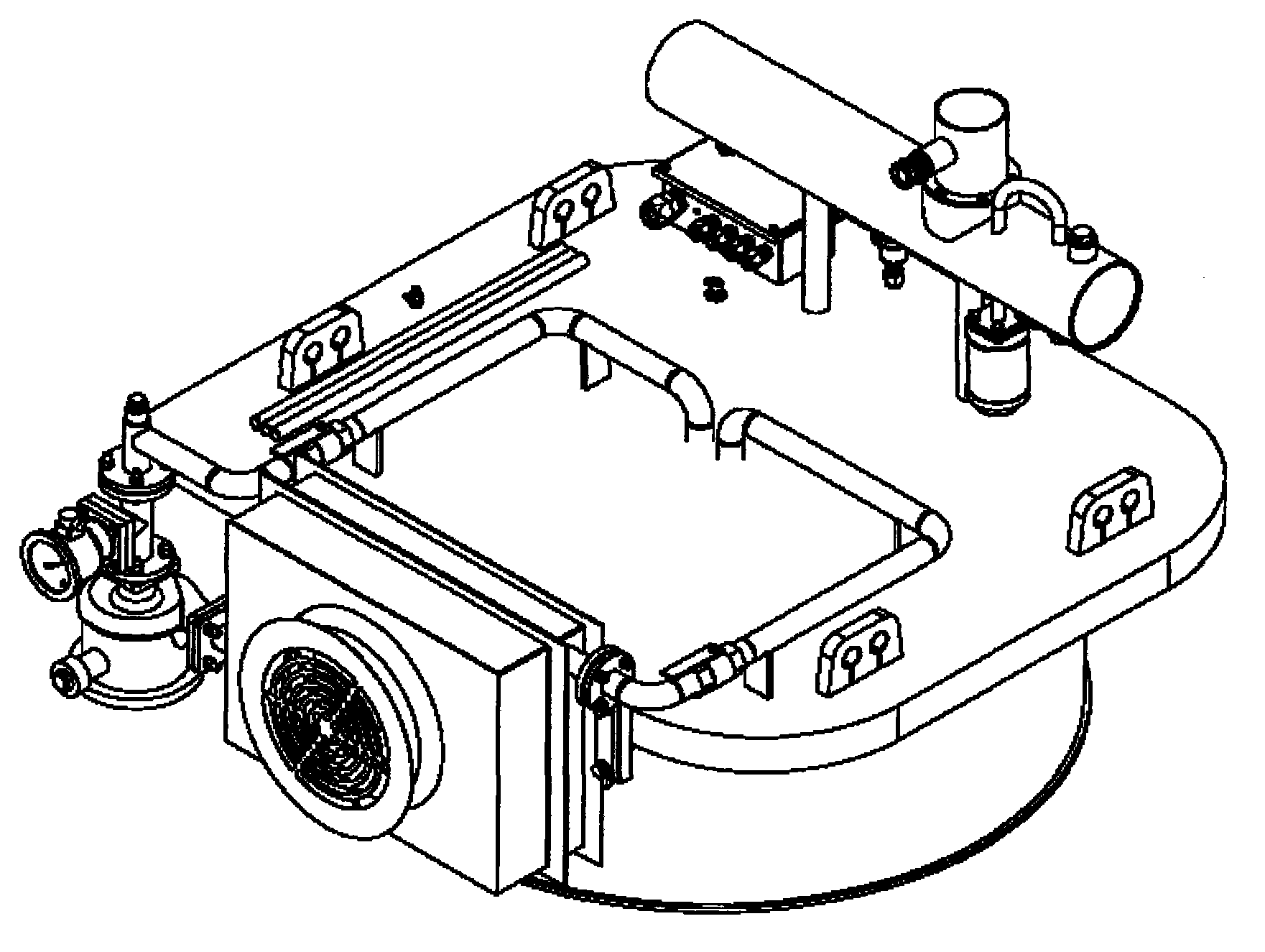

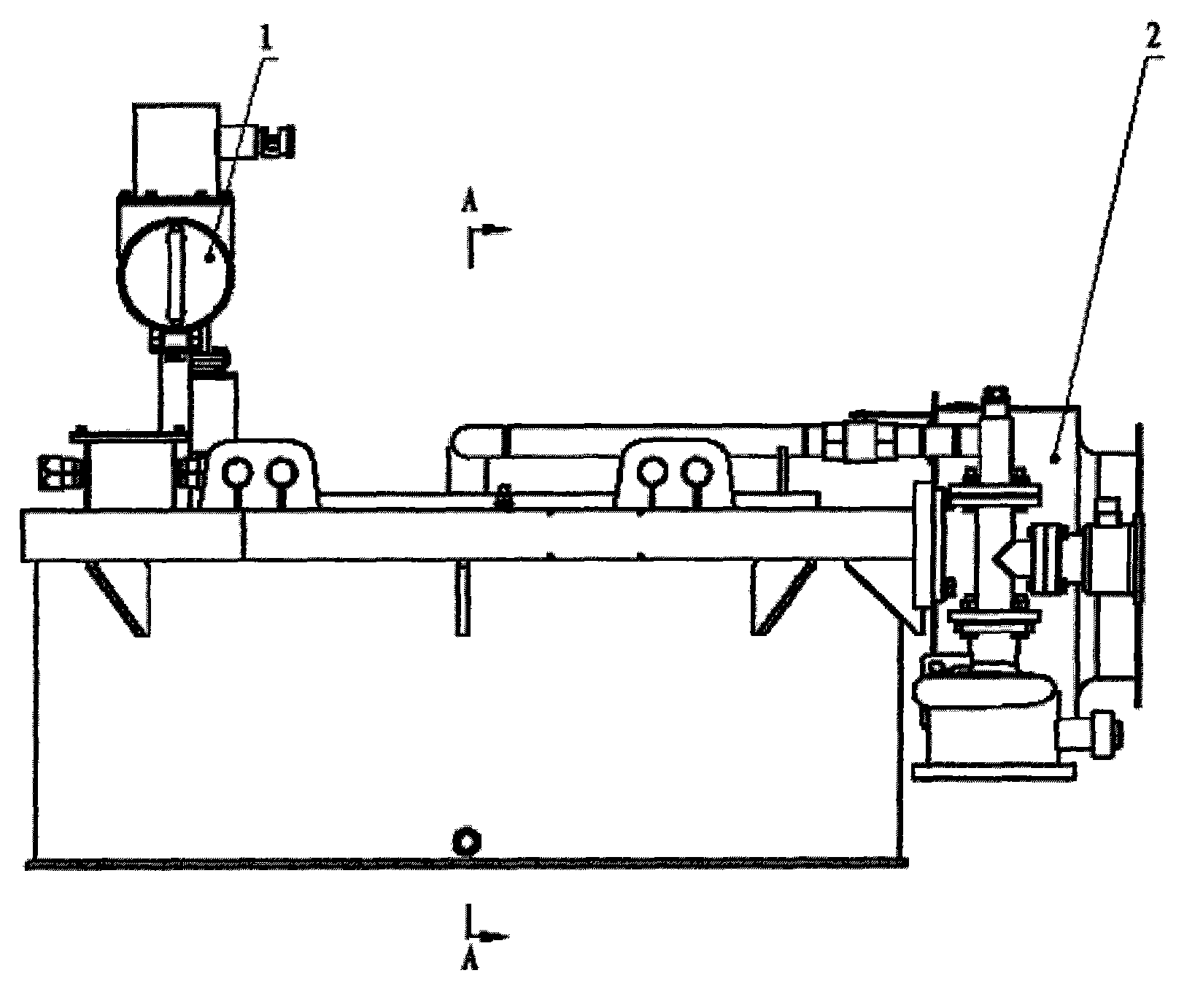

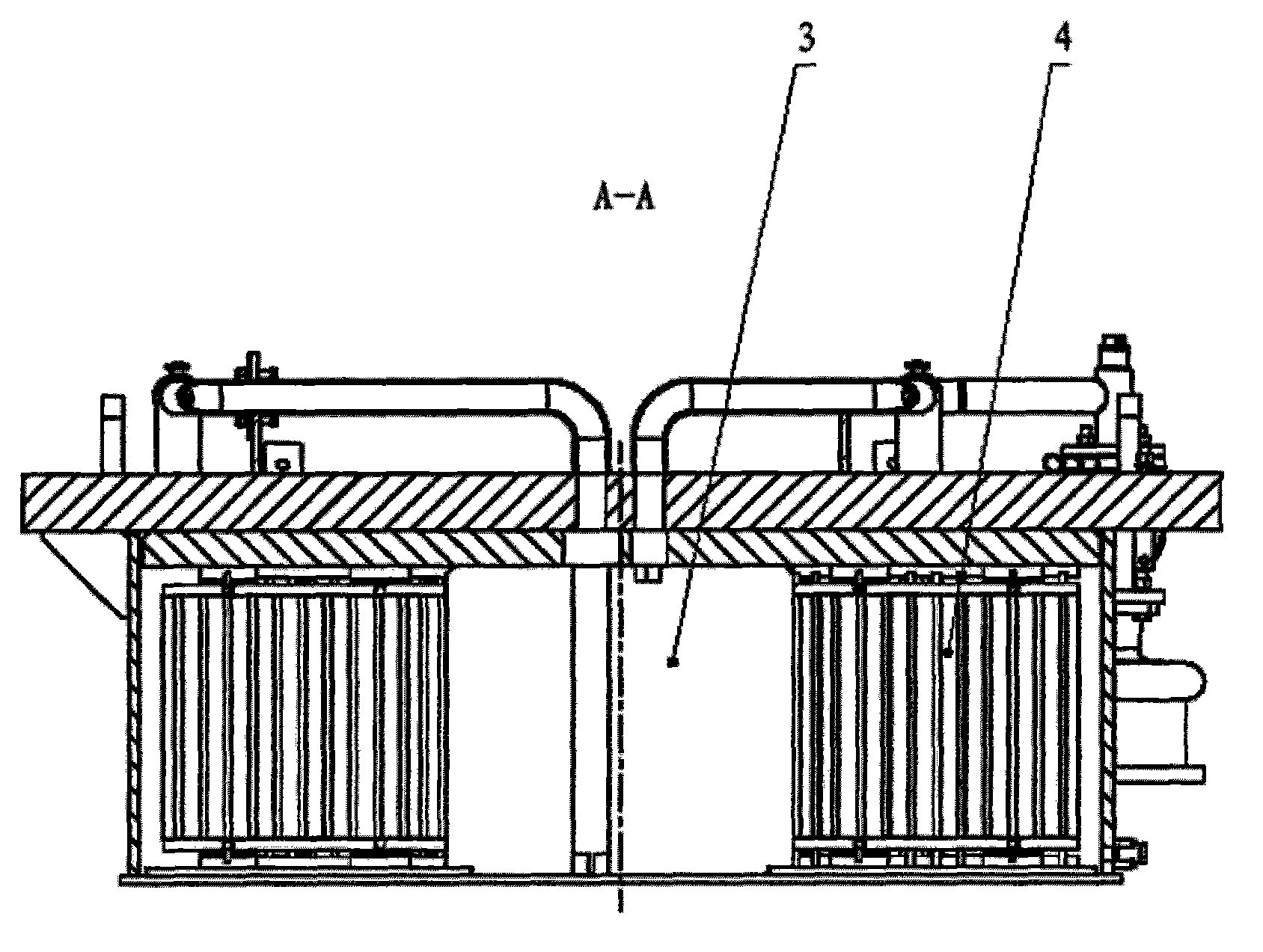

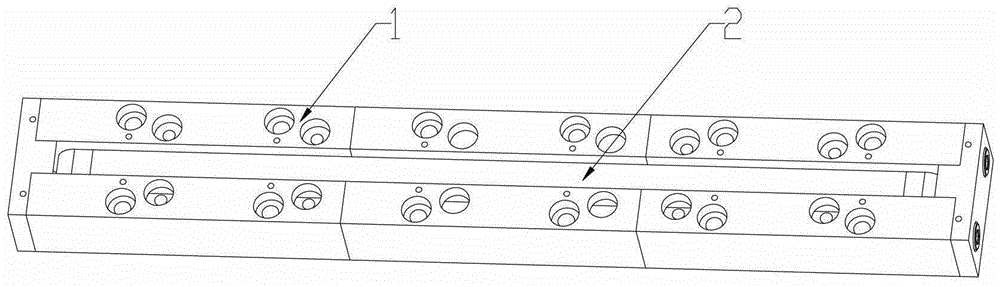

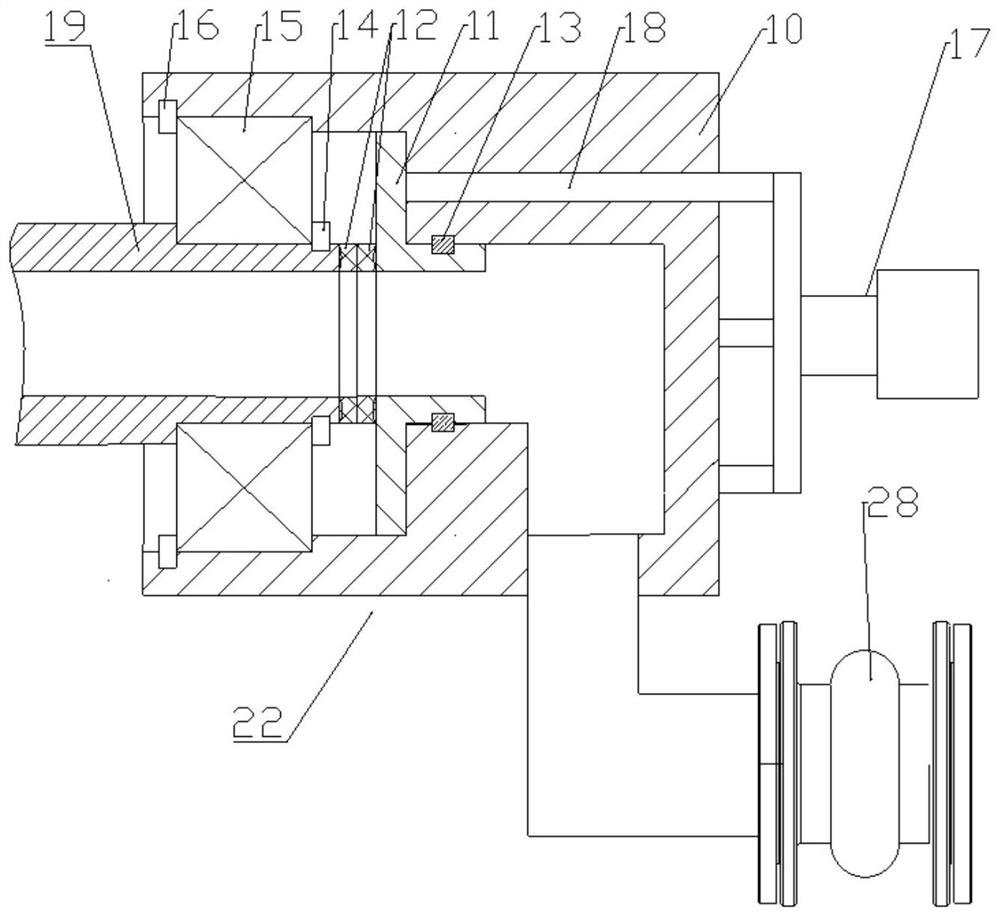

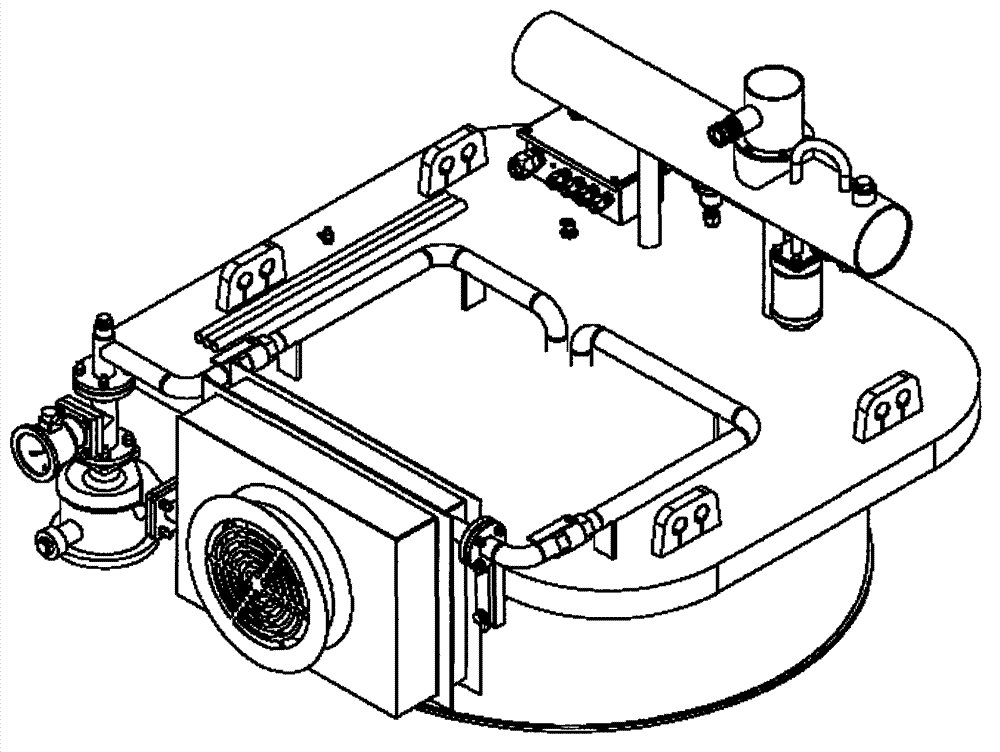

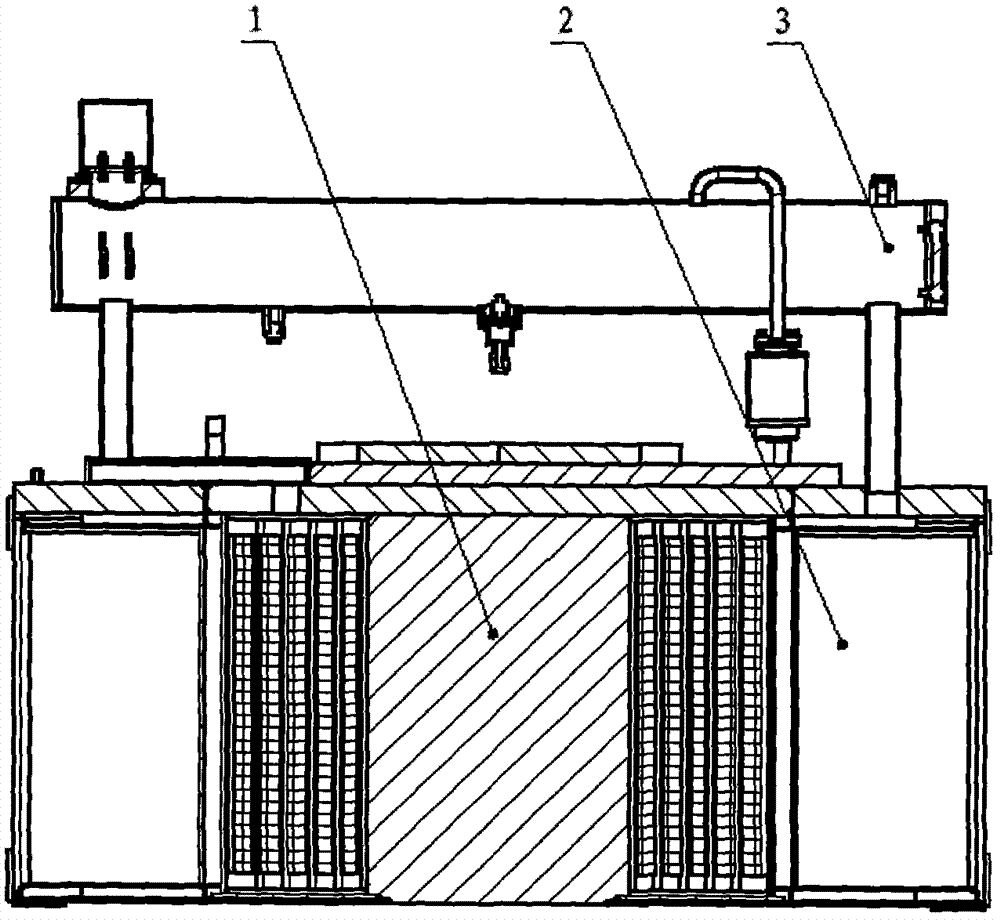

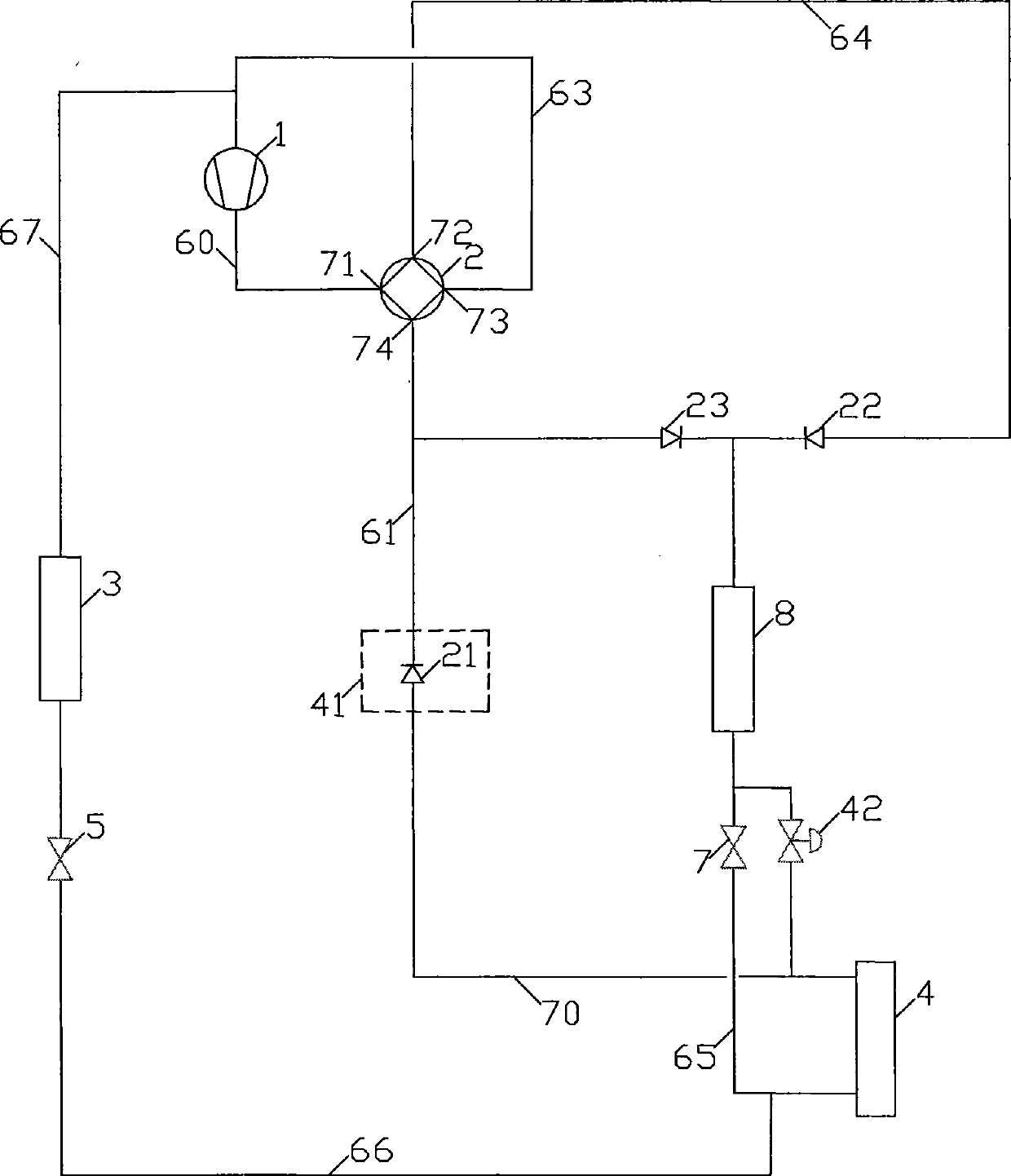

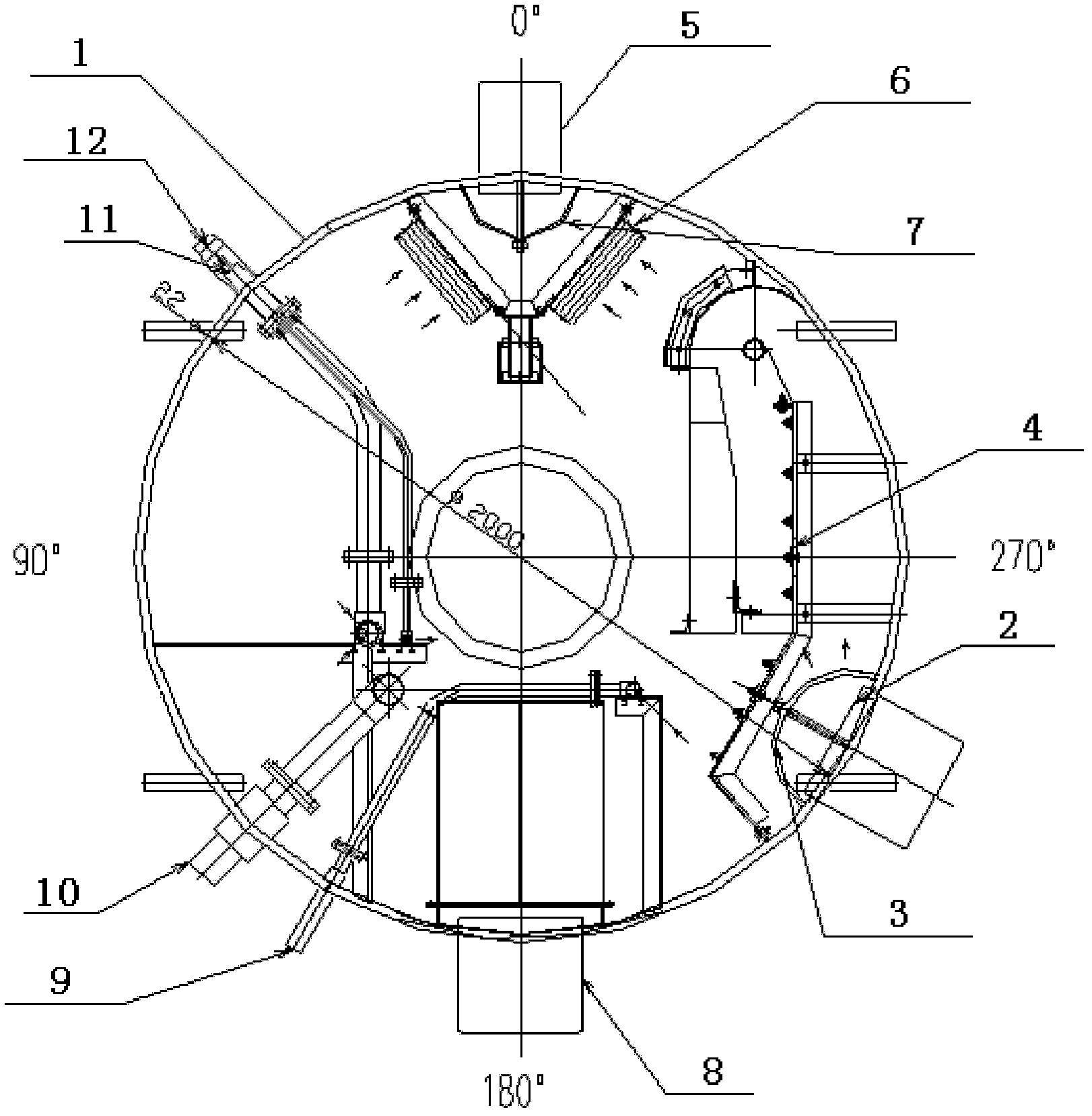

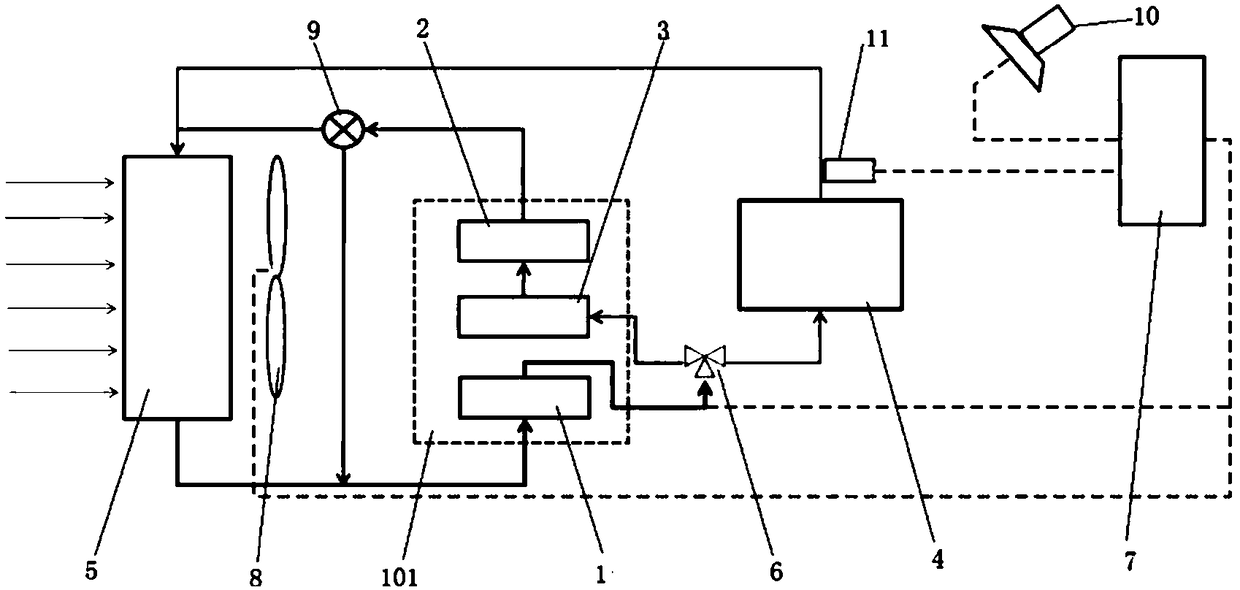

High-gradient internal circulation oil cooling iron remover

ActiveCN103056023ALow circulation resistanceEven and reasonable cycleHigh gradient magnetic separatorsIron absorptionTransformer oil

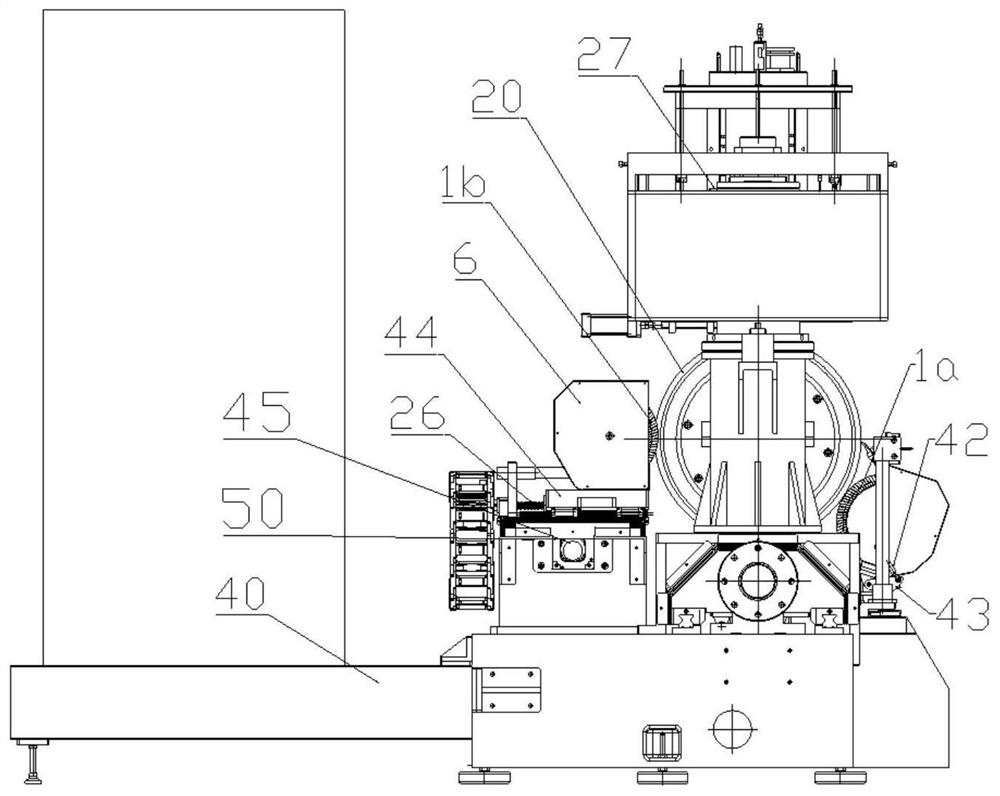

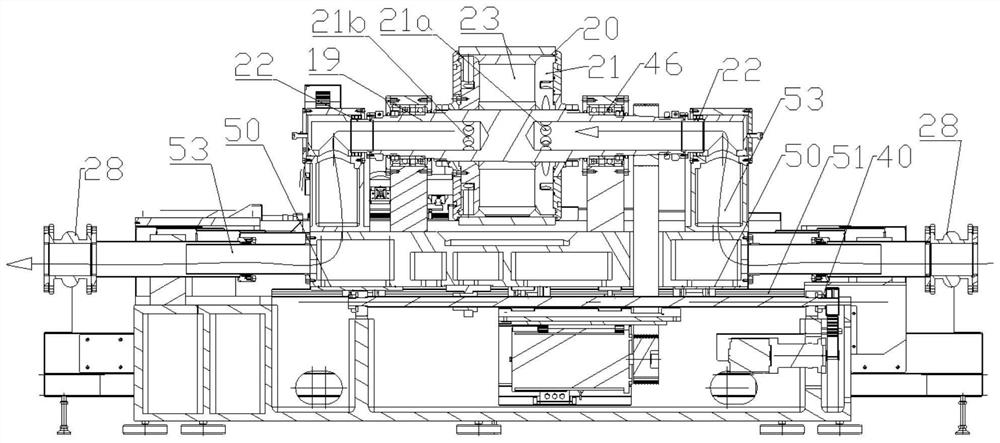

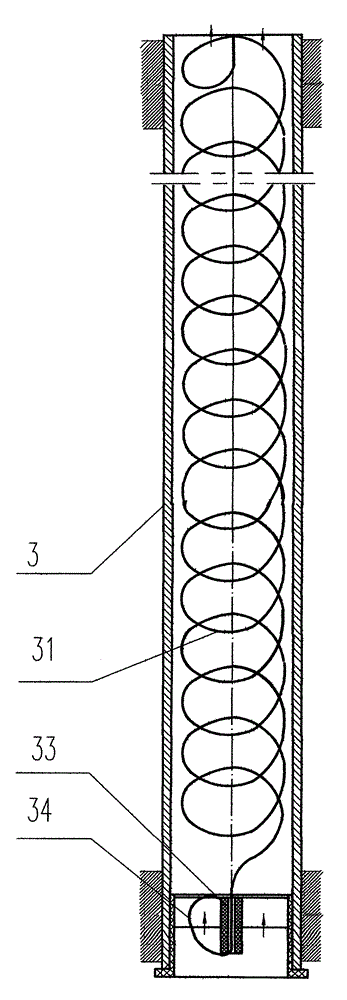

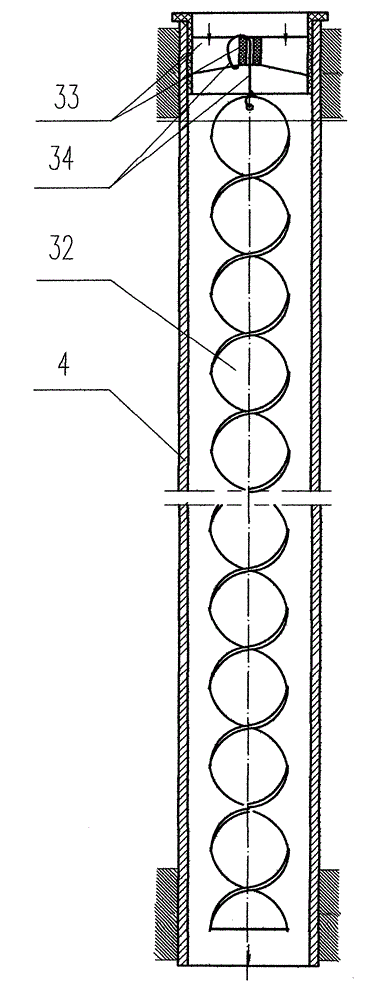

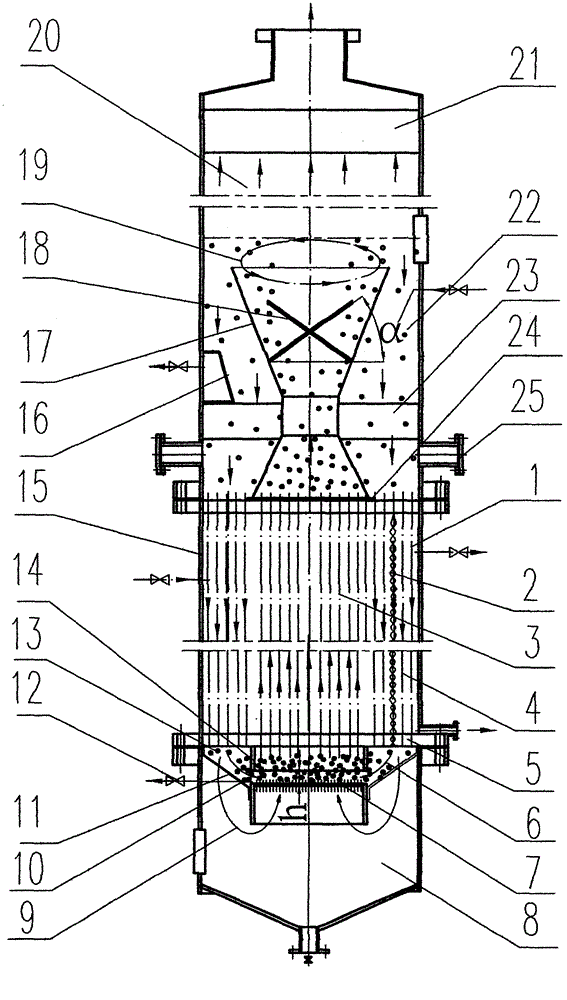

The invention relates to a high-gradient internal circulation oil cooling iron remover, which comprises a magnetic coil (4), an internal circulation oil path system (3), an external cooling system (2) and an oil conservator (1), wherein the magnetic coil (4) is used for generating an excitation magnetic field capable of realizing the iron absorption effect of the iron remover; the magnetic circuit of the magnetic coil (4) is an opened magnetic circuit structure; the internal circulation oil path system (3) is used for distributing, collecting and circulating oil of a transformer; the external cooling system (2) is used for dissipating heat of the oil of the transformer so as to realize internal heat dissipation balance of the high-gradient internal circulation oil cooling iron remover; and the oil conservator (1) is used as a complementary container when oil in the transformer is inflated in the event of operating equipment. By adopting the internal circulation structure, the high-gradient internal circulation oil cooling iron remover disclosed by the invention is capable of simplifying external circulation pipelines, reducing oil path circulation resistance, avoiding the problems of being complex and interferential in oil path arrangement, low in circulation efficiency, leaked in welding spot and the like, ensuring the iron remover to work normally, and increasing the iron removing efficiency.

Owner:LONGI MAGNET CO LTD

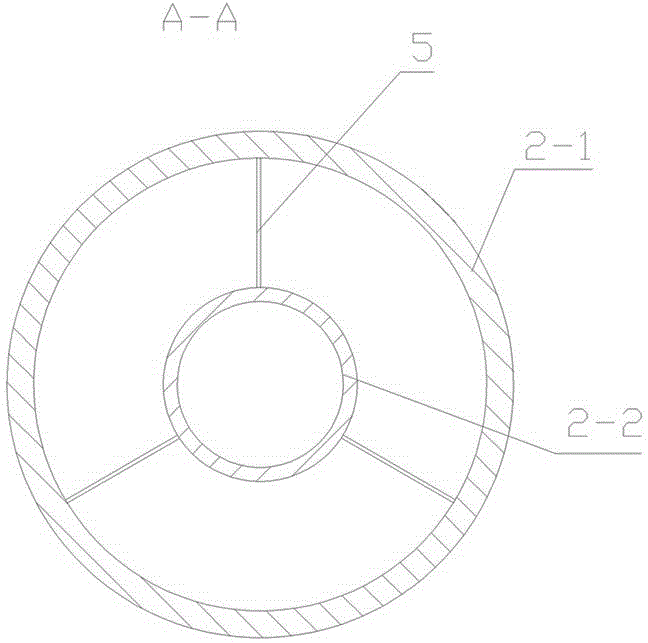

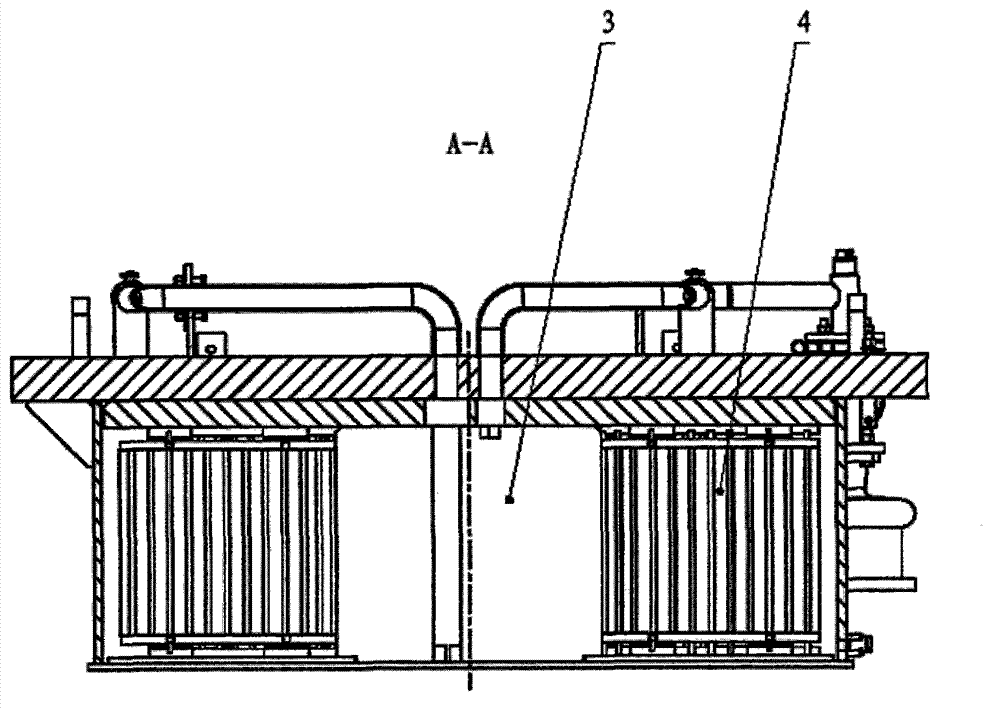

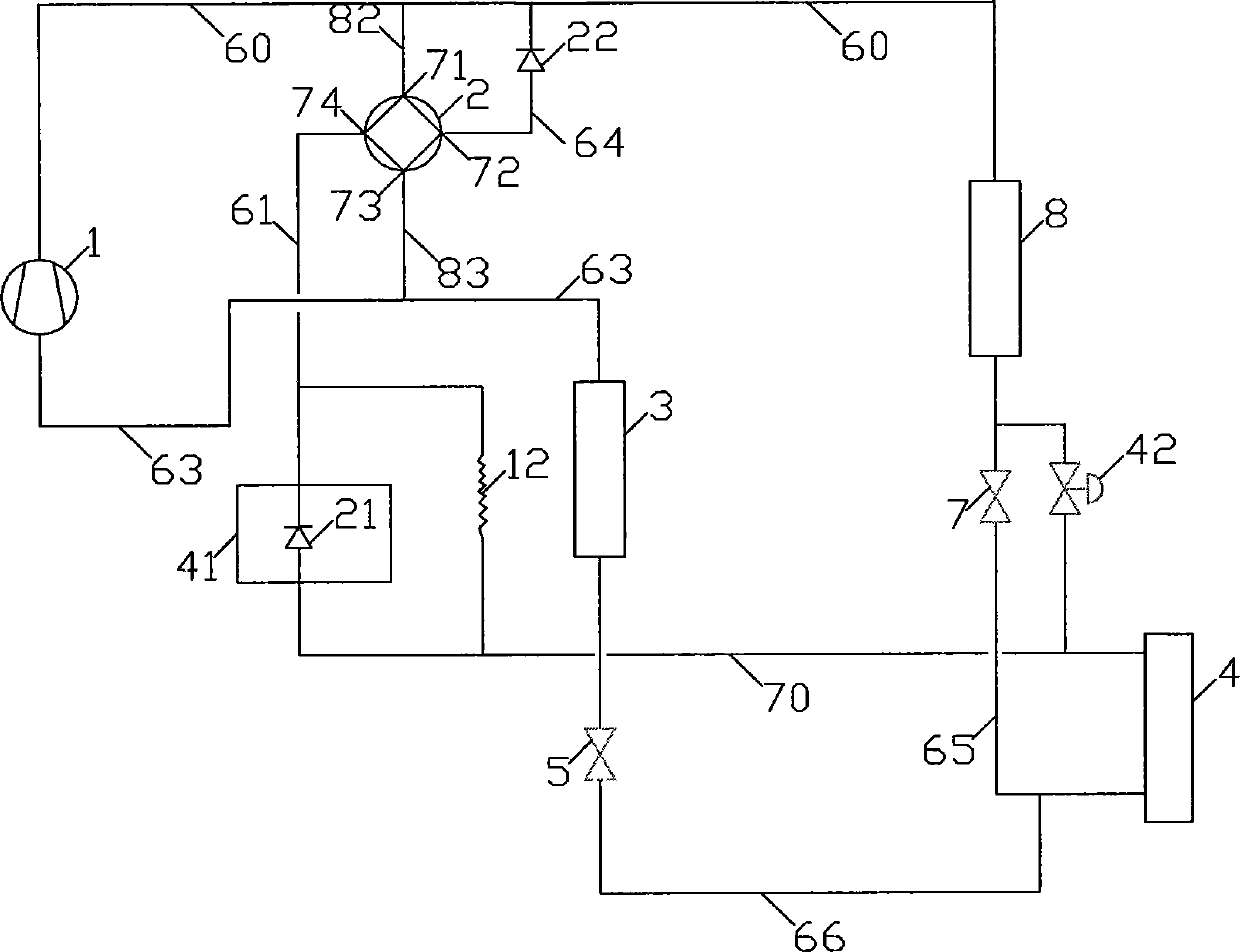

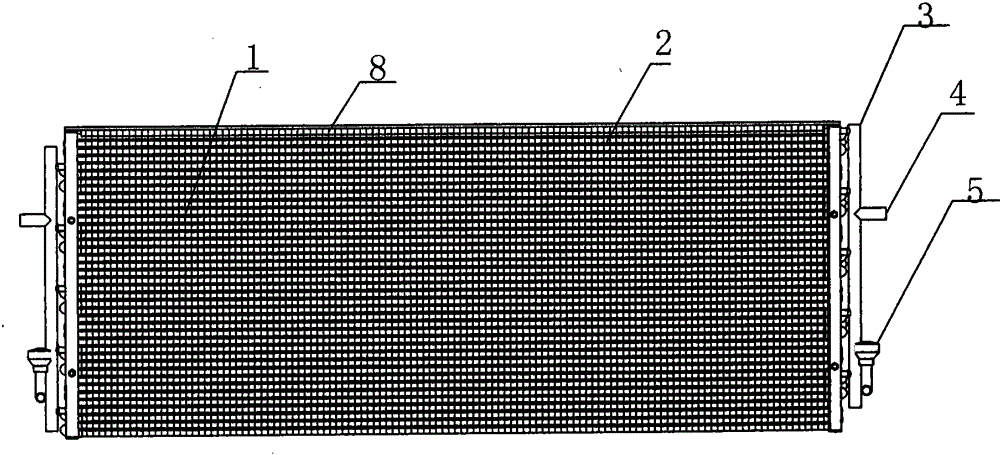

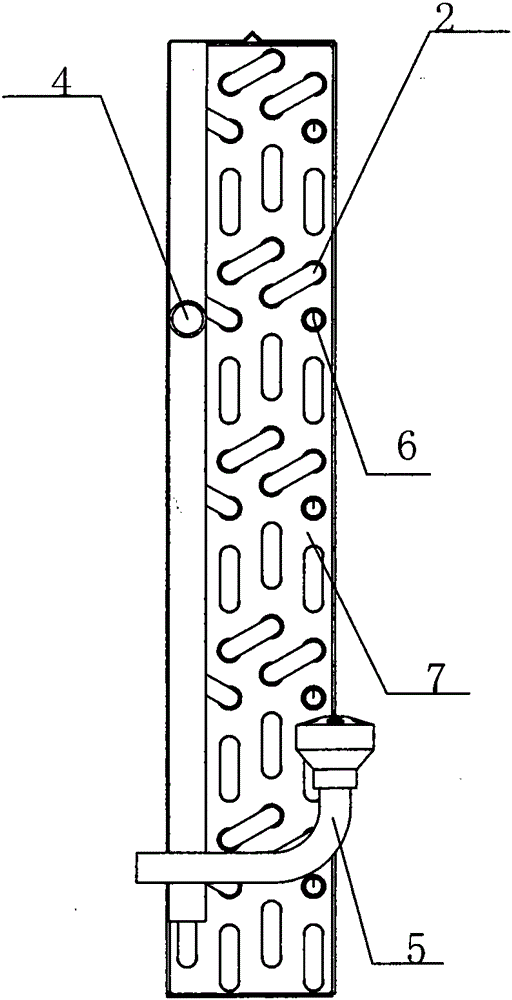

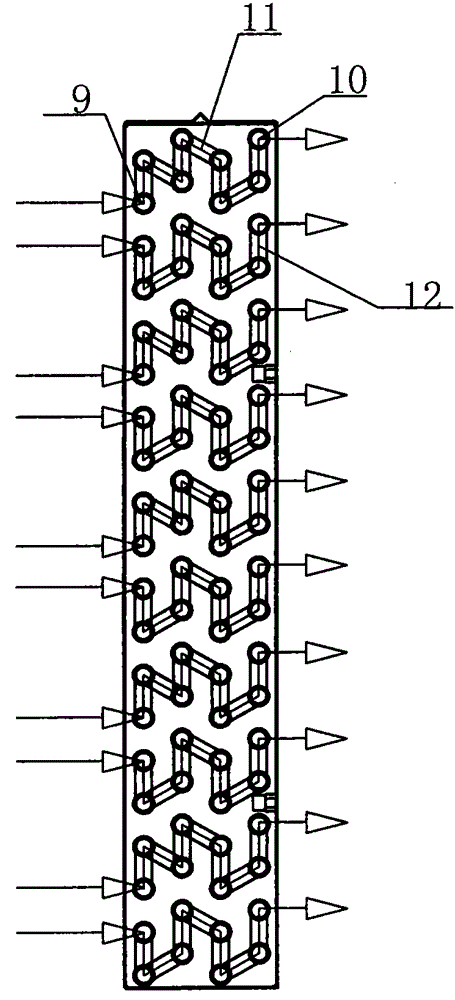

High-gradient internal circulation oil cooling iron remover

ActiveCN103008100ALow circulation resistanceEven and reasonable cycleHigh gradient magnetic separationTransformers/inductances coolingExpansion tankTransformer oil

The invention discloses a high-gradient internal circulation oil cooling iron remover which comprises a magnetic system coil (4), an internal circulation oil path system (3), an external cooling system (2) and an expansion tank (1), wherein the magnetic system coil (4) is used for generating an excitation magnetic field which realizes the iron sucking function of the iron remover; the magnetic path of the magnetic system coil (4) is in an opened magnetic path structure; the internal circulation oil path system (3) is used for distributing, collecting and circulating transformer oil; the external cooling system (2) is used for radiating the heat of the transformer oil so as to realize the heat radiation balance in the high-gradient internal circulation oil cooling iron remover; and the expansion tank (1) is used as a compensation container for the transformer oil expansion when equipment operates. By adopting the internal circulation structure, the external circulation pipeline is simplified, the oil path circulation resistance is reduced, problems that an oil path is complexly arranged with interference, the circulation efficiency is low, a welding spot has leakage and the like are avoided, the normal operation of the iron remover is ensured, and the iron removing efficiency is improved.

Owner:LONGI MAGNET CO LTD

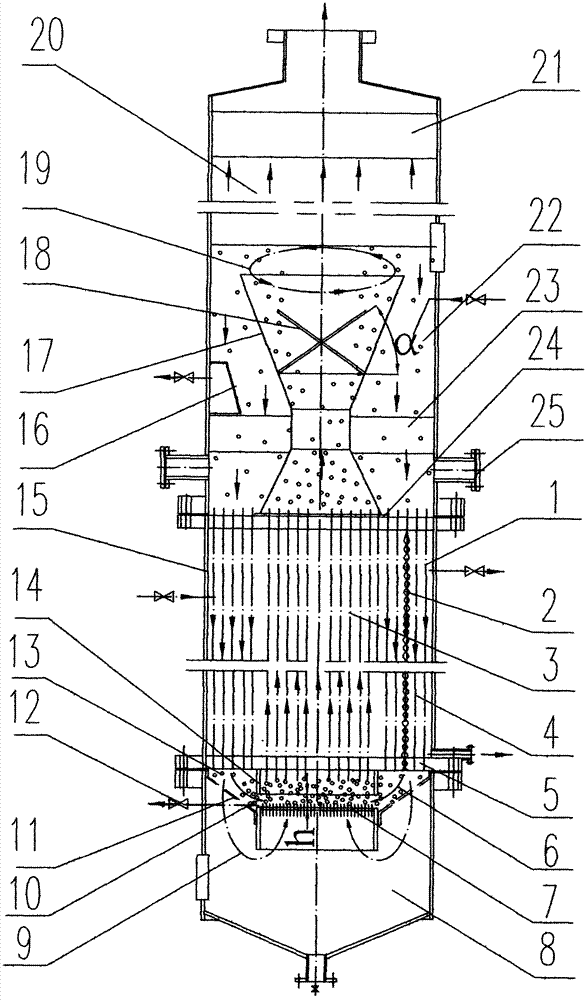

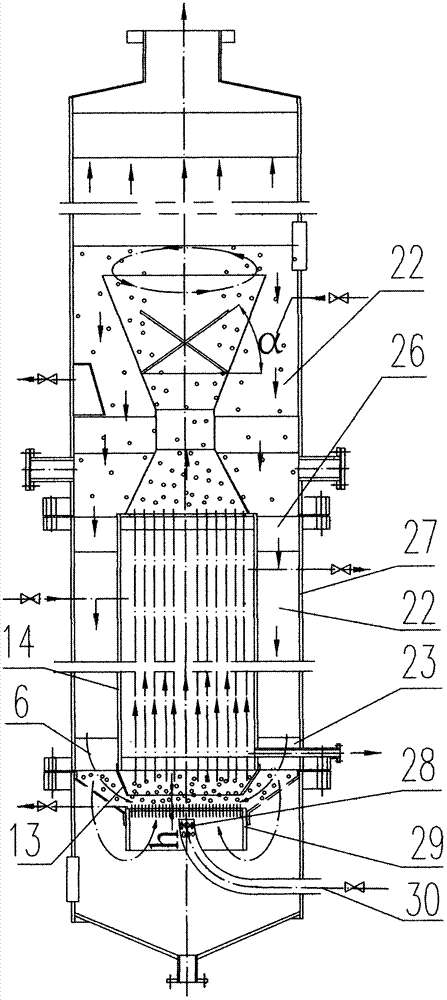

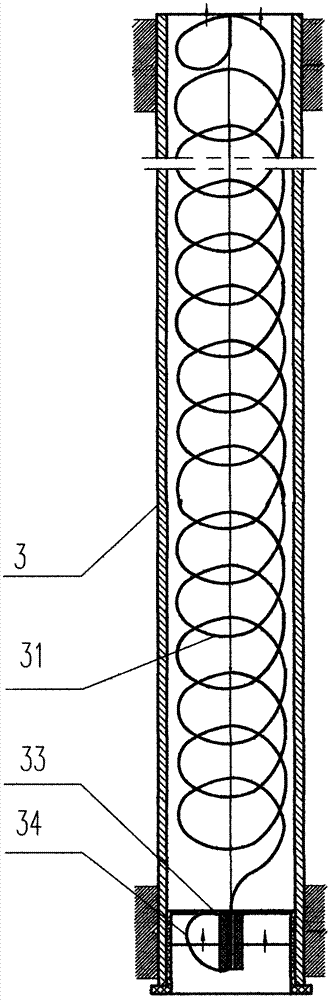

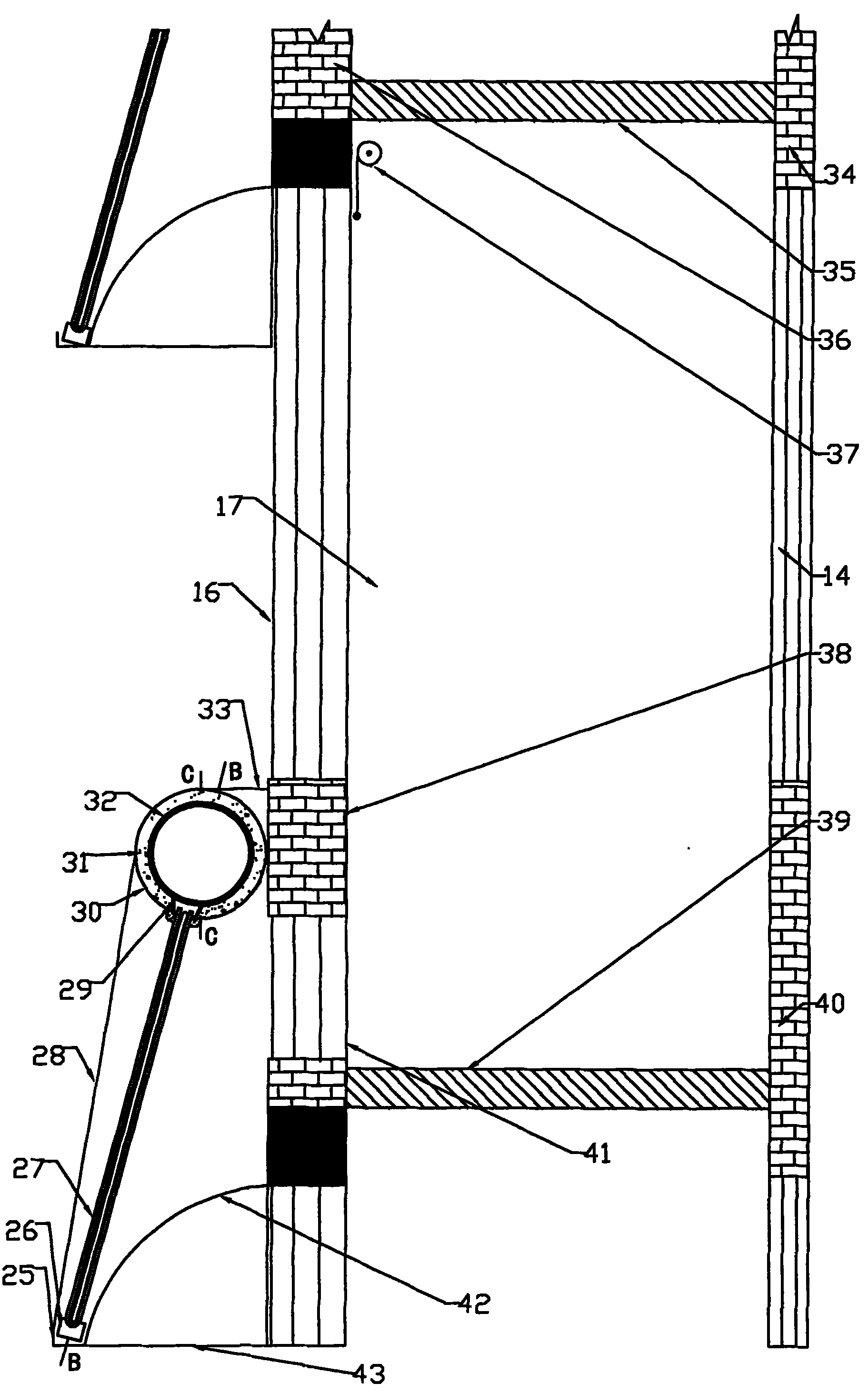

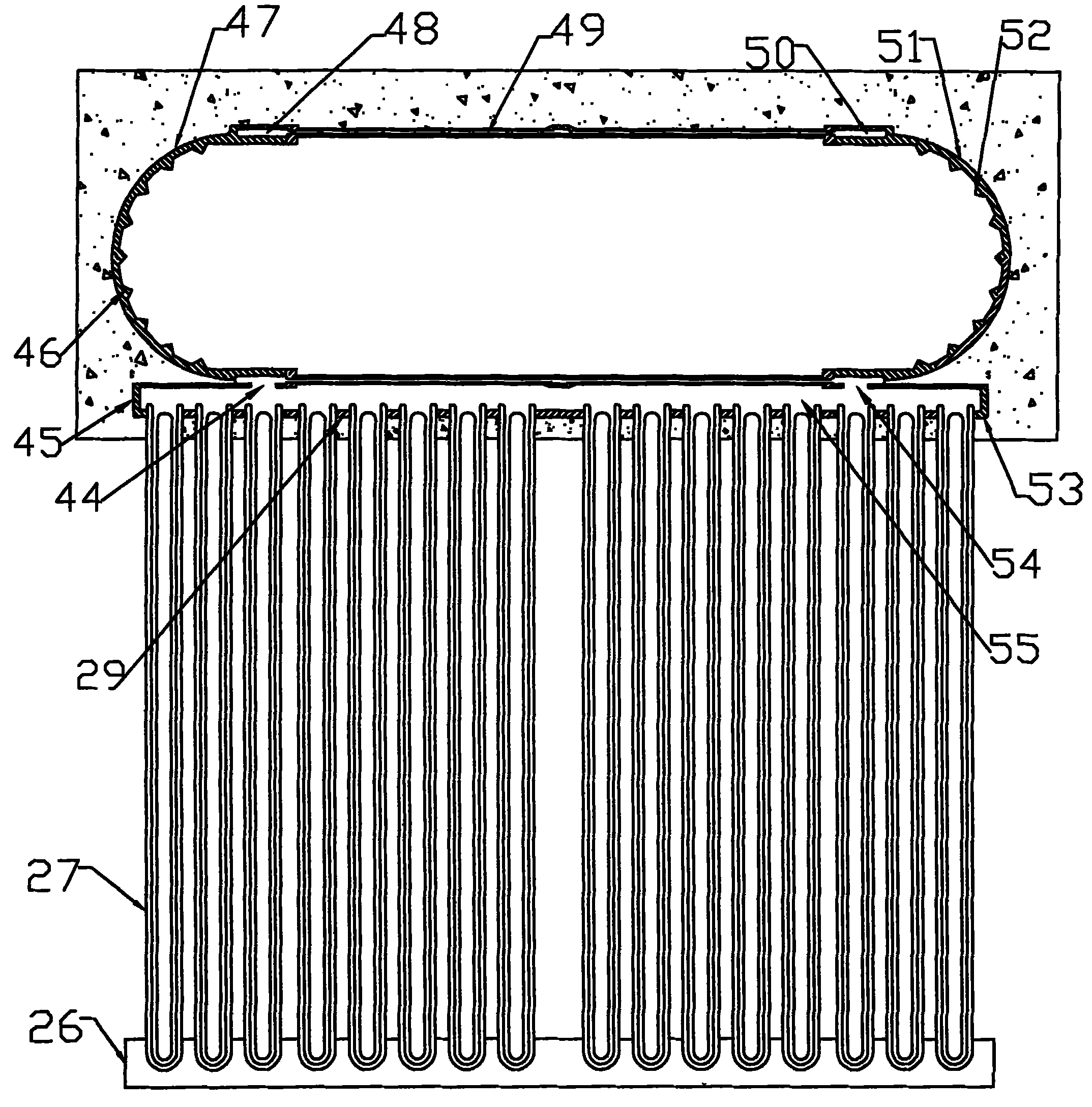

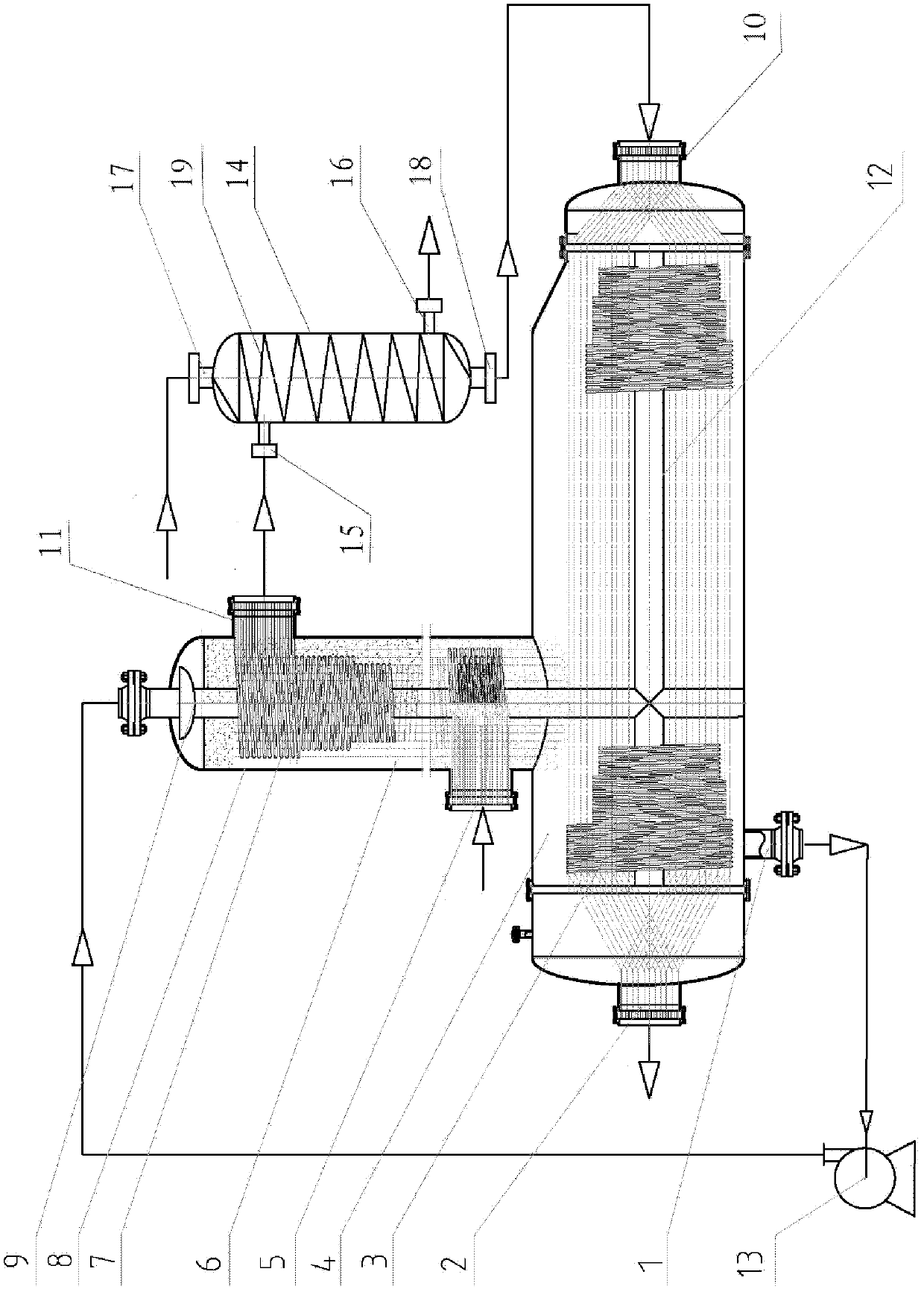

Natural-circulation self-cleaning evaporation device

ActiveCN102949856AEfficient spiral fluidized automatic cleaningSimple structureEvaporators with vertical tubesThermodynamicsEngineering

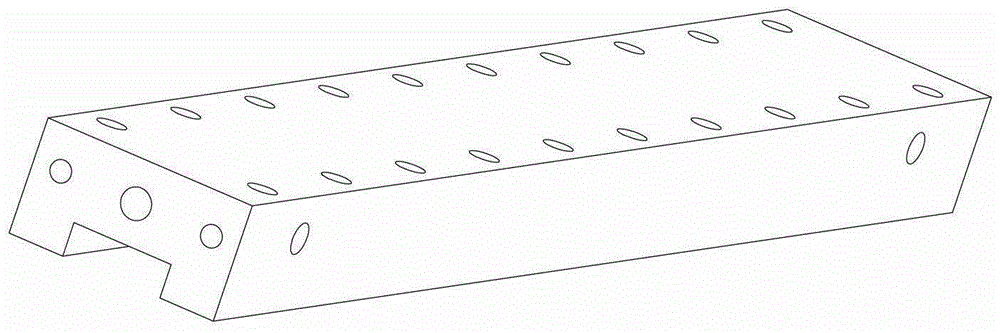

A natural-circulation self-cleaning evaporation device is disclosed. A steel wire screw is mounted in an uplink heating pipe; a twisted strip screw is mounted in a downlink heating pipe. Fluidization balls are added into a circulation solution to realize high-efficient cleaning by the fluidization balls with a low concentration of 0.1%-3.0% in a spiral fluidization state. A boiling pipe is disposed above a heating chamber, is trumpet-shaped, prevents fluidization ball obstruction by adopting a converged section and a gradually-expanded section, and reduces the circulation resistance and the outlet kinetic energy loss. A shunting skirt is designed at the lower end of a lower pipe plate of the heating chamber. The circulation solution flowing downwards is shunted into a circulation main flow and a circulation auxiliary flow before the shunting skirt; the circulation auxiliary flow flows into and stirs the fluidization balls to form a fluidization state when passing through sieve pores on a sieve plate, which allows the fluidization balls to flow into the uplink heating pipe uniformly and smoothly, so as to realize natural circulation flow of the fluidization balls. The spiral-fluidization self-cleaning evaporation device can not only realize natural circulation, but also realize high-efficient automatic cleaning, is reliable in operation, simple in maintenance, and thus can realize both great yield increase and energy saving.

Owner:浙江建装工程技术研究有限公司

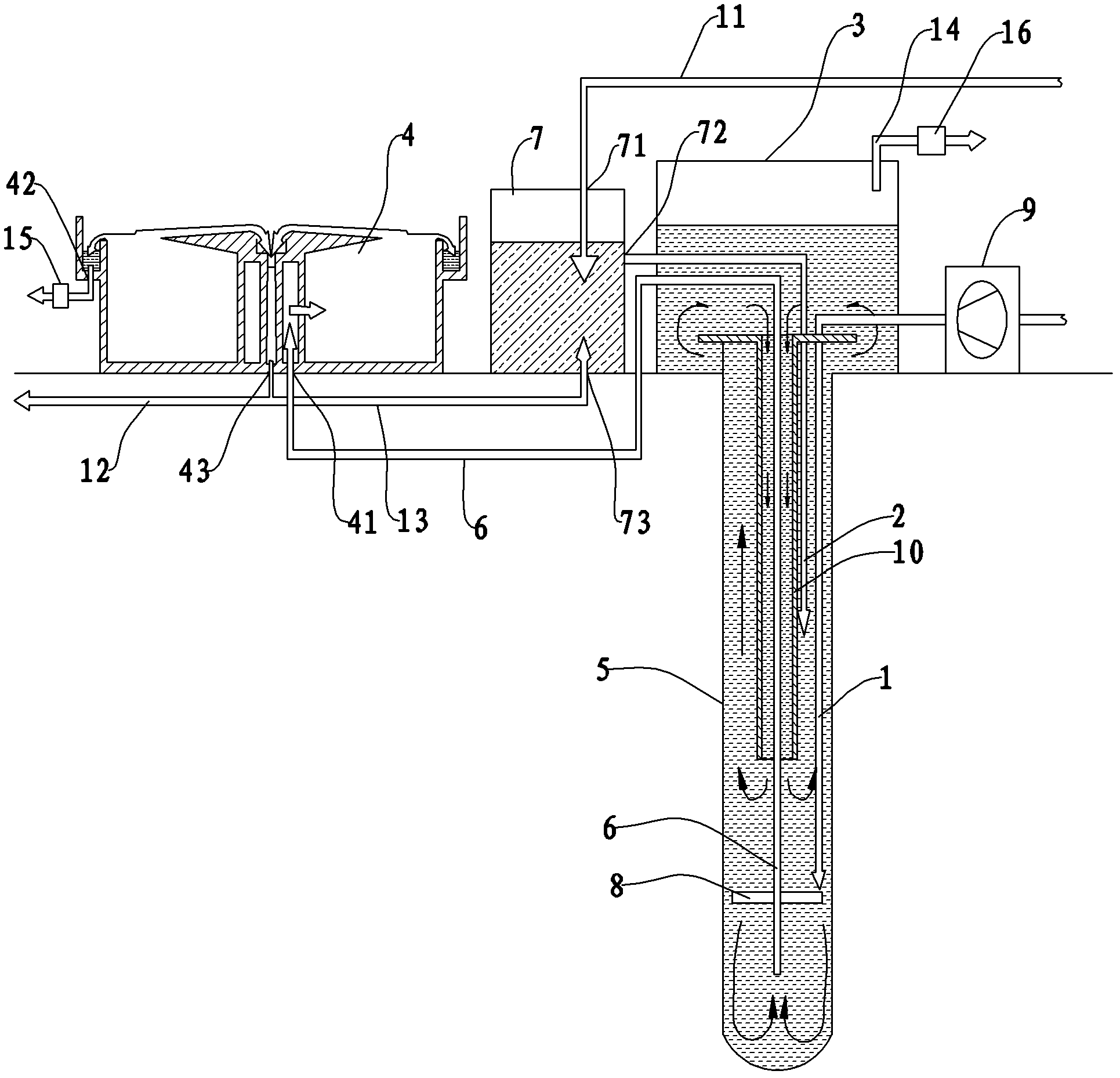

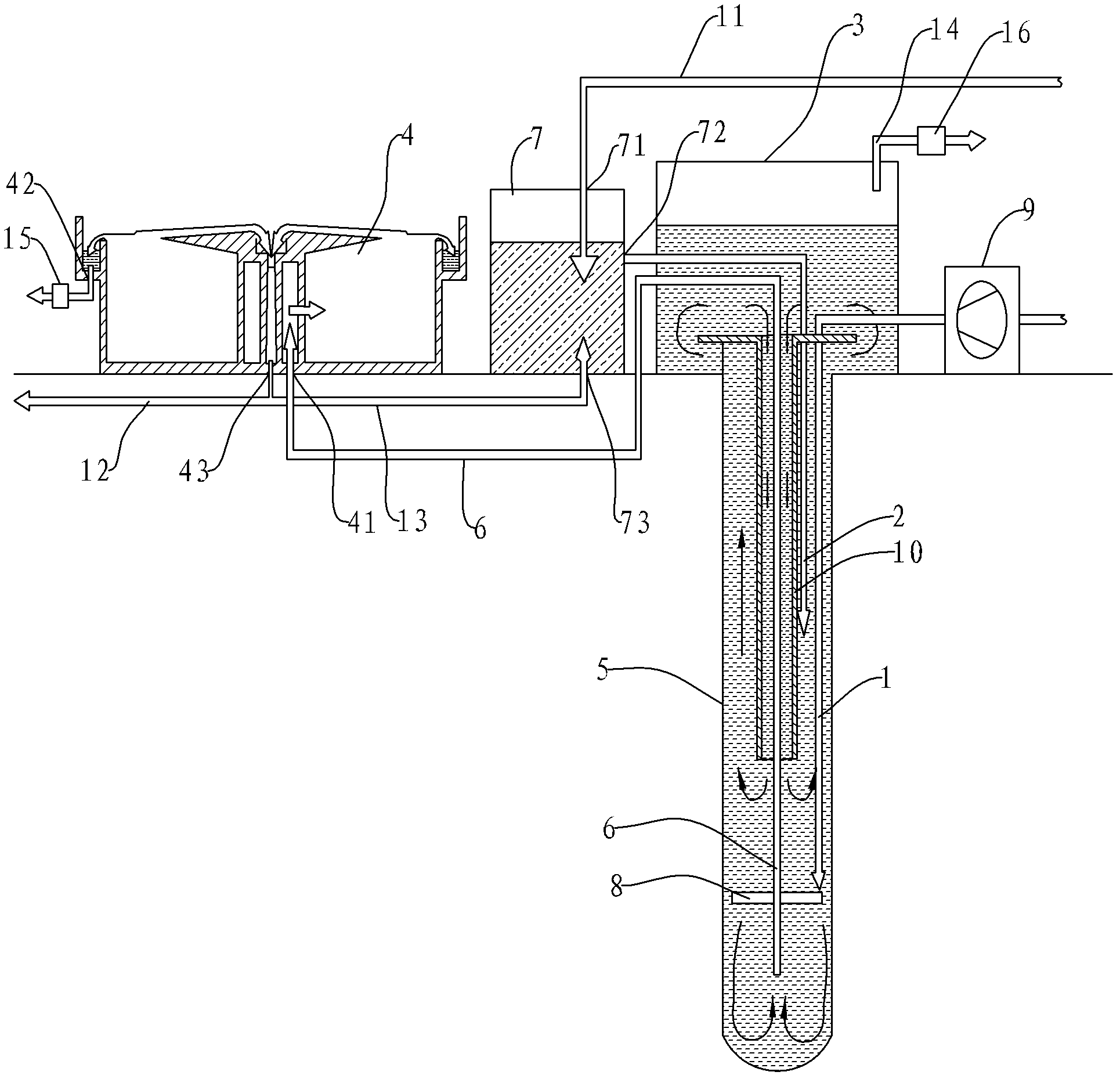

High-load vertical ultradeep bioreactor

ActiveCN102515344AWell mixedPrevent short flow of waterTreatment using aerobic processesSustainable biological treatmentHydrogenWastewater

A high-load vertical ultradeep bioreactor comprises a reactor body and a head box. An aerating device, a water inlet pipe, an air supply pipe and a water outlet pipe are disposed in the reactor body, and an air inlet of the air supply pipe is connected with an air compressor. The high-load vertical ultradeep bioreactor is characterized in that a water outlet of the water inlet pipe is positioned in the axial middle of the reactor body, an air outlet of the air supply pipe is lower than the water outlet of the water inlet pipe, and a water inlet of the water outlet pipe is positioned at the inner bottom of the reactor body and below the aerating device. An inner tube is further arranged in the reactor body, an upper port of the inner tube is higher than the top end of the reactor body and positioned in the head box, and a bottom port of the inner tube is lower than the water outlet of the water supply pipe and higher than the air outlet of the air supply pipe. Water power short circuit is avoided during operation of the high-load vertical ultradeep bioreactor, and circulation of a whole system can be realized with less air flow. In addition, the high-load vertical ultradeep bioreactor has the advantages of simple structure, low cost, small occupied are, higher hydrogen utilizing rate, low operation and maintenance cost, less foam and the like, and is applicable to treatment of industrial wastewater and urban sewage.

Owner:山东汇盛天泽环境工程有限公司

Bioactive glass gel and production process of same

The invention discloses bioactive glass gel. The protective gel includes: bioactive glass, sodium hyaluronate, Vaseline and glycerin according to weight ratio of 24.5:0.05:75:0.75, wherein the bioactive glass comprises, by weight, 4-5% of SiO2, 24% of CaO, 25% of NaO and 6% of P2O5. The bioactive glass gel can inhibit growth of bacteria, reduce inflammatory exudation, reduce circulation resistance, promote angiogenesis, adsorb proliferated cells, accelerate healing of a wound, modify arrangement of collagen and reduce scar formation. The bioactive glass gel is easy to prepare.

Owner:张河

Three-dimensional dynamic water cooling system of spray belt device

PendingCN113587541AImprove product qualityIncrease productivityLighting and heating apparatusCooling fluid circulationCooling effectMechanical engineering

The invention discloses a three-dimensional dynamic water cooling system of a spray belt device. The three-dimensional dynamic water cooling system comprises a cooling inner cavity arranged in a copper roller, dynamic seal connecting devices and hollow shafts which communicate and are connected between the cooling inner cavity of the copper roller and the corresponding dynamic seal connecting devices and fixedly connected with the copper roller; the dynamic seal connecting devices are arranged on a sliding frame, and the hollow shafts are arranged on the sliding frame through corresponding bearing devices; and the sliding frame is arranged on a rack slidably. The three-dimensional dynamic water cooling system of the spray belt device is simple and reasonable in structure, excellent in overall structural performance and good in cooling effect.

Owner:宜春市龙腾机械电气有限公司

High-efficiency heat exchange fire grate of heat-conducting oil furnace

ActiveCN102748859AGuaranteed flow rateLow circulation resistanceStorage heatersHollow bar grateHeat conductingPetroleum engineering

The invention discloses a high-efficiency heat exchange fire grate of a heat-conducting oil furnace, comprising a heat exchange tube in a structure, wherein the heat exchange is connected in parallel between a lower communicated horizontal tube and an upper communicated horizontal tube, and is formed like a fire grate; an oil inlet and an oil outlet are respectively arranged on the lower communicated horizontal tube and the upper communicated horizontal tube; the heat exchange tube is a compound sleeve tube structure; an internal sleeve tube is a blind tube which has a closed end and which is located on an inner wall of an external sleeve tube by means of an end bracket. The fire grate provided by the invention also ensures flow speed of heat-conducting oils in the tube under the condition that rigidity of the heat exchange tube is ensured so as to reach provisions of related state standards.

Owner:HEBEI GOLD BANGZI BOILER

Heat exchanger of oil tank heated by heat pump

InactiveCN105423552ALow circulation resistanceIncrease cycle frequencyStorage heatersEngineeringRecuperator

The invention discloses a heat exchanger of an oil tank heated by a heat pump and relates to an oil tank. The heat exchanger is provided with at least two heat radiating pipes, wherein an outlet of the first heat radiating pipe is provided with an elbow joint; an inlet of the last heat radiating pipe is provided with an elbow joint; each of an inlet of the first heat radiating pipe and an outlet of the last heat radiating pipe as well as inlets and outlets of other heat radiating pipes is provided with a tee joint; inlets of the adjacent heat radiating pipes are connected through the tee joints; outlets of the adjacent heat radiating pipes are connected through the tee joints; an inlet of a heating medium of the first heat radiating pipe is connected with an outlet of a refrigerant of the heat pump; an outlet of a heating medium of the last heat radiating pipe is connected with an inlet of a backflow heating medium of the heat pump; and when being used, the heat exchanger of the oil tank heated by the heat pump is arranged at the bottom inside a tank body of the oil tank. Due to the adoption of same-stroke rectangle principle design, the circulating resistance of the heating medium is greatly reduced, meanwhile the circulating frequency is increased, and therefore, the heating efficiency is increased under the same condition.

Owner:XIAMEN HAOBENG ELECTROMECHANICAL EQUIP CO LTD

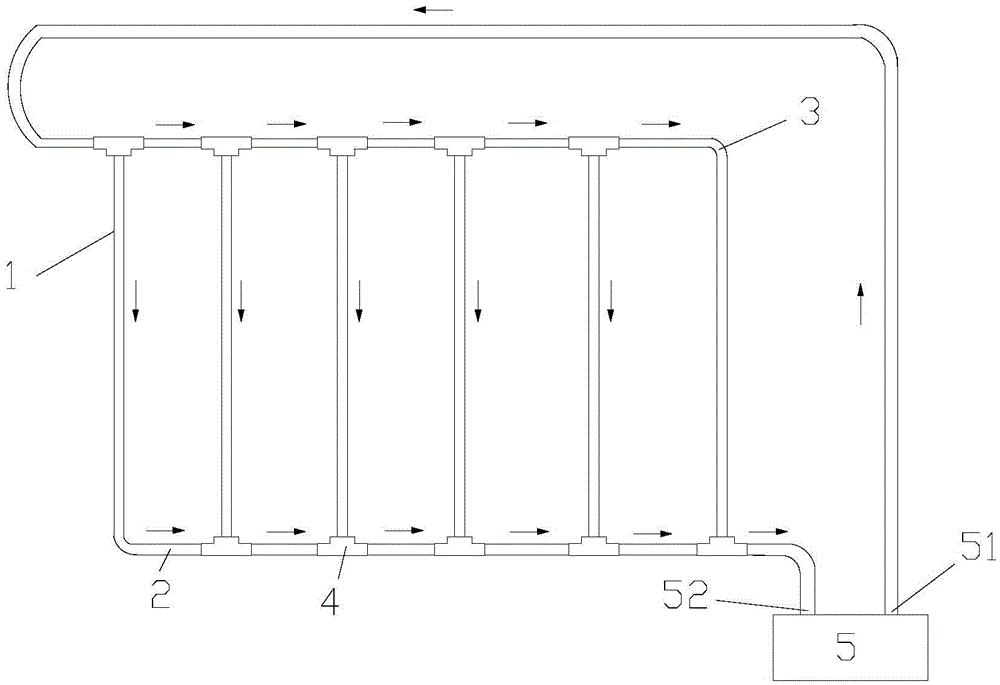

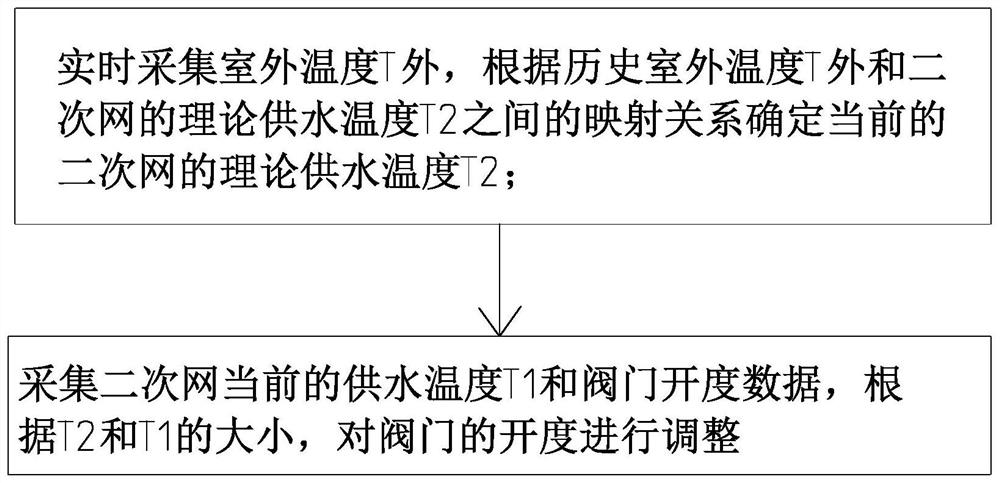

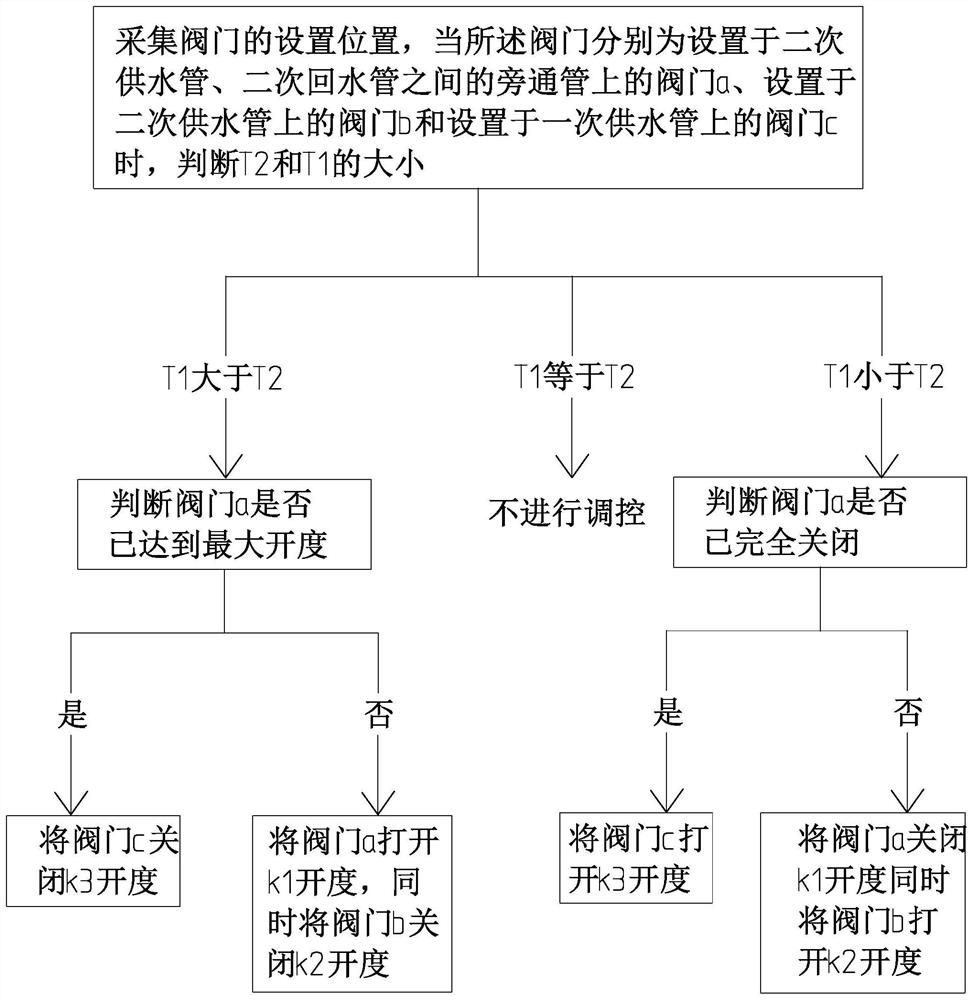

Intelligent pipe network control method and system

ActiveCN111765506AReduce workloadReduce the problem of temperature imbalance and insufficient heating at the endLighting and heating apparatusEfficient regulation technologiesThermodynamicsControl engineering

The invention provides an intelligent pipe network control method. The intelligent pipe network control method comprises the following steps of acquiring an outdoor temperature T < outside > in real time, and determining a current theoretical water supply temperature T2 of a secondary network according to a mapping relation between the historical outdoor temperature T < outside > and the theoretical water supply temperature T2 of the secondary network; and collecting the current water supply temperature T1 and valve opening data of the secondary network, and adjusting the opening of a valve according to the T2 and the T1. The intelligent pipe network control method has the beneficial effects that 1, an initial workload of heating is reduced; 2, the workload of field technicians is reduced;3, front-end oversupply is reduced, and energy is saved; 4, oversupply in the heating season is reduced, and the energy is saved; 5, the problems of unbalanced temperature of the front and rear endsof a building and insufficient heat supply of the tail end are relieved; and 6, electric power is saved, and control is smooth and stable.

Owner:戢森

Drilling bit of ice drill for drilling warm ice layer

InactiveCN107630664AReduce widthReduce cutting heatDrill bitsConstructionsMicro nanoPetroleum engineering

The invention discloses a drilling bit of an ice drill for drilling warm ice layer. The drilling bit comprises a drilling bit body, special-shaped cutting tools and pad shoes, wherein the bottom of the drilling bit body is provided with a plurality of water troughs, a channel is formed between the inner cavity and the outer wall of the drilling bit body due to the water troughs, the plurality of special-shaped cutting tools and the pad shoes are fixed on the bottom lip surface of the drilling bit body parallelly, and the bottom of the pad shoes is provided with a plurality of micro-nano bulgesor pits. The drilling bit has the beneficial effect of reducing friction heat of the bottom of the drilling bit. The drilling bit of the ice drill can lower cutting heat, is good for coolinga drilling liquid and carrying flake ice, can effectively prevent a large quantity of flake ice from bonding and gathering, and can drill warm ice layer of the glacier safely and rapidly.

Owner:JILIN UNIV

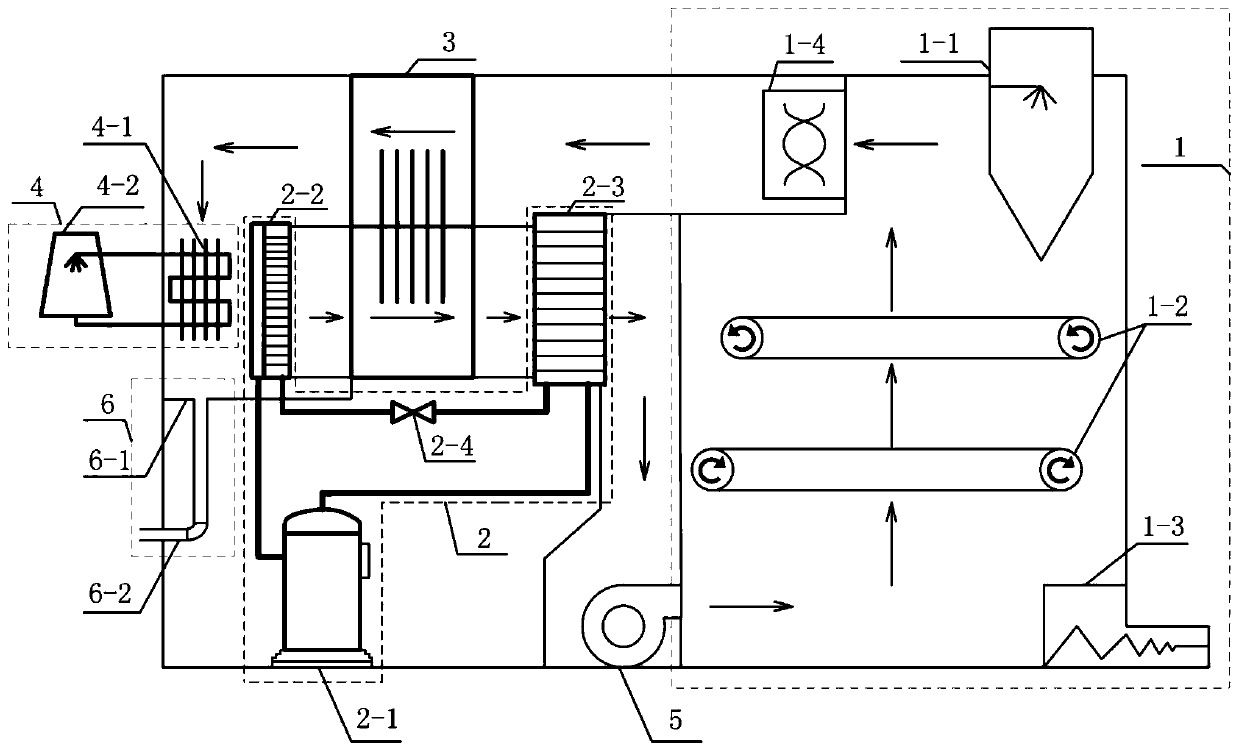

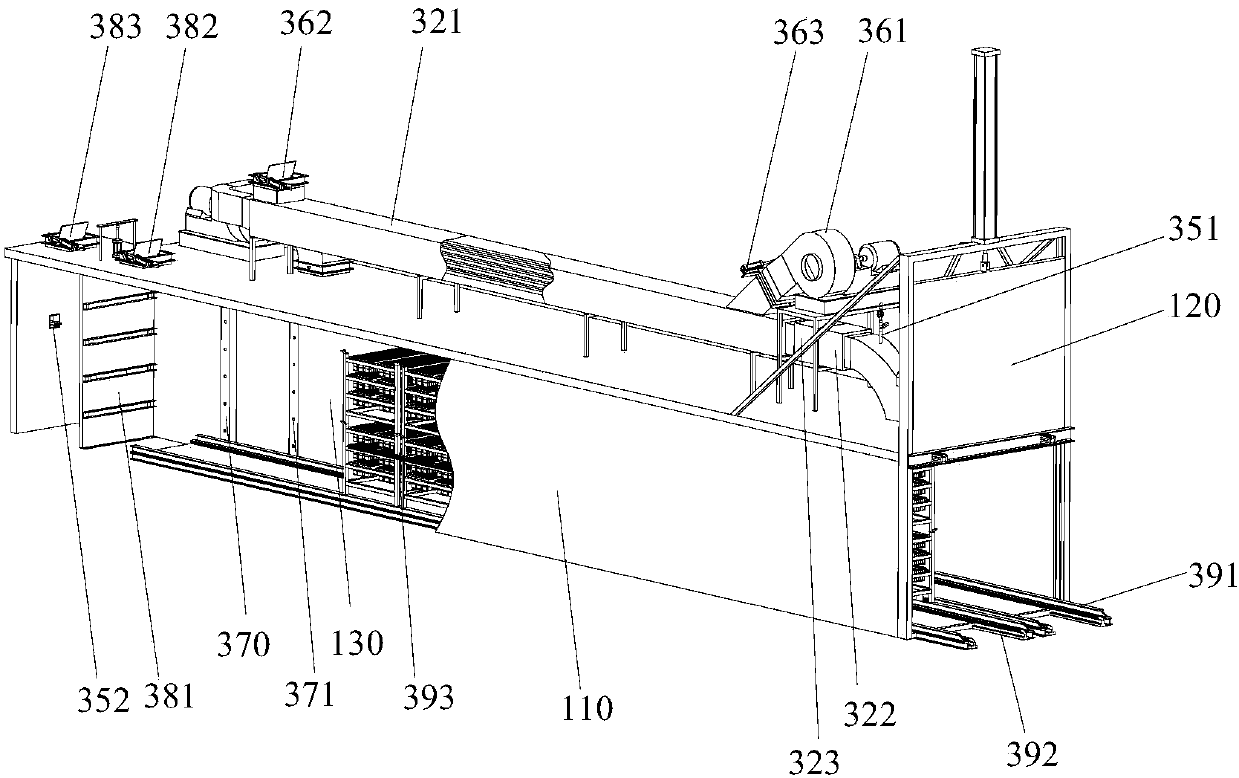

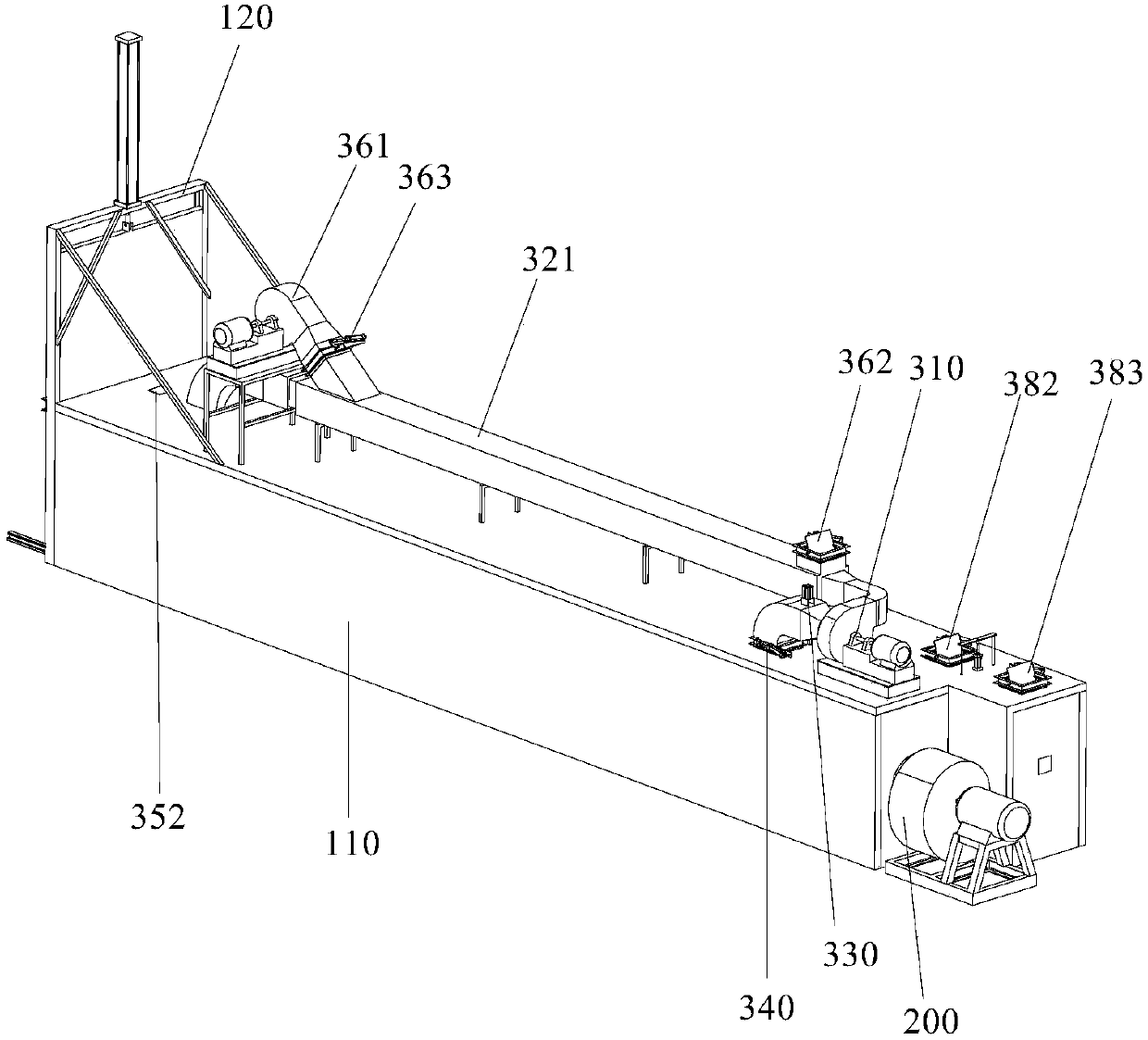

A heat pump sludge dryer with evaporator precooling

A Hot pump sludge dryer for pre-cooling an evaporator relates to sludge drying equipment. The problems that inner circulating air of a system cannot be pre-cooled and cooled by utilizing outdoor air in the existing hot pump sludge drying technology so as not to reduce operation energy consumption of the hot pump and improve the dehumidification rate are solved. The dryer comprises a drying chamber, a hot pump system, a heat returner, cooling equipment, an air feeding machine and a condensed water collection and drainage device, wherein an evaporator and a condenser in the hot pump system are positioned in an air circulating pipeline enclosed by the dryer; hot end inlet air of the heat returner is delivered by a filter in the drying chamber; a hot end outlet air of the heat returner is fed to the cooling equipment; cold end inlet air of the heat returner is delivered by the evaporator, and cold end outlet air of the heat returner is fed to the condenser; the cooling equipment is positioned at the front end of the hot pump evaporator; the air feeding machine is positioned behind the condenser and the circulating air is pressurized and fed to the drying chamber; and the condensed water collection and drainage device is positioned below the heat returner, the cooling equipment and the evaporator. The dryer is used for drying the sludge.

Owner:HARBIN INST OF TECH

Special antiscaling agent for nitrate section of salt nitrate cogeneration system and preparation method thereof

ActiveCN105314742BGuaranteed uptimeEasy to save energyTreatment using complexing/solubilising chemicalsSucroseQuality level

The invention provides a dedicated anti-scale agent for a sulfate section of a salt and sulfate co-production system. The dedicated anti-scale agent is prepared by mixing sucrose phosphate, sodium gluconate, a tartaric acid-malic acid-sodium hypophosphite telomer and purified water according to a certain proportion. Being added into a sulfate section mother liquid of the salt and sulfate co-production system, the anti-scale agent can effectively prevent Ca<2+> and Mg<2+> from generating non-soluble salt crystals, so as to avoid scaling, causing reduction of heat-transfer property and evaporation efficiency, of Ca<2+> and Mg<2+> in sulfate producing equipment, reduce cleaning frequency, remarkably prolong the operation cycle of the sulfate producing equipment, improve sulfate producing efficiency, and improve the quality level of a sulfate product. Moreover, the anti-scale agent can form a corrosion-resistant protecting film on the metal surface of the equipment, so as to reduce corrosion of the mother liquid to the sulfate producing equipment. Adoption in sulfate producing equipment in five salt and sulfate co-production enterprises in China shows that the effects of energy conservation, scaling prevention, stable yield and quality improvement are excellent.

Owner:甘肃格瑞科技实业有限公司

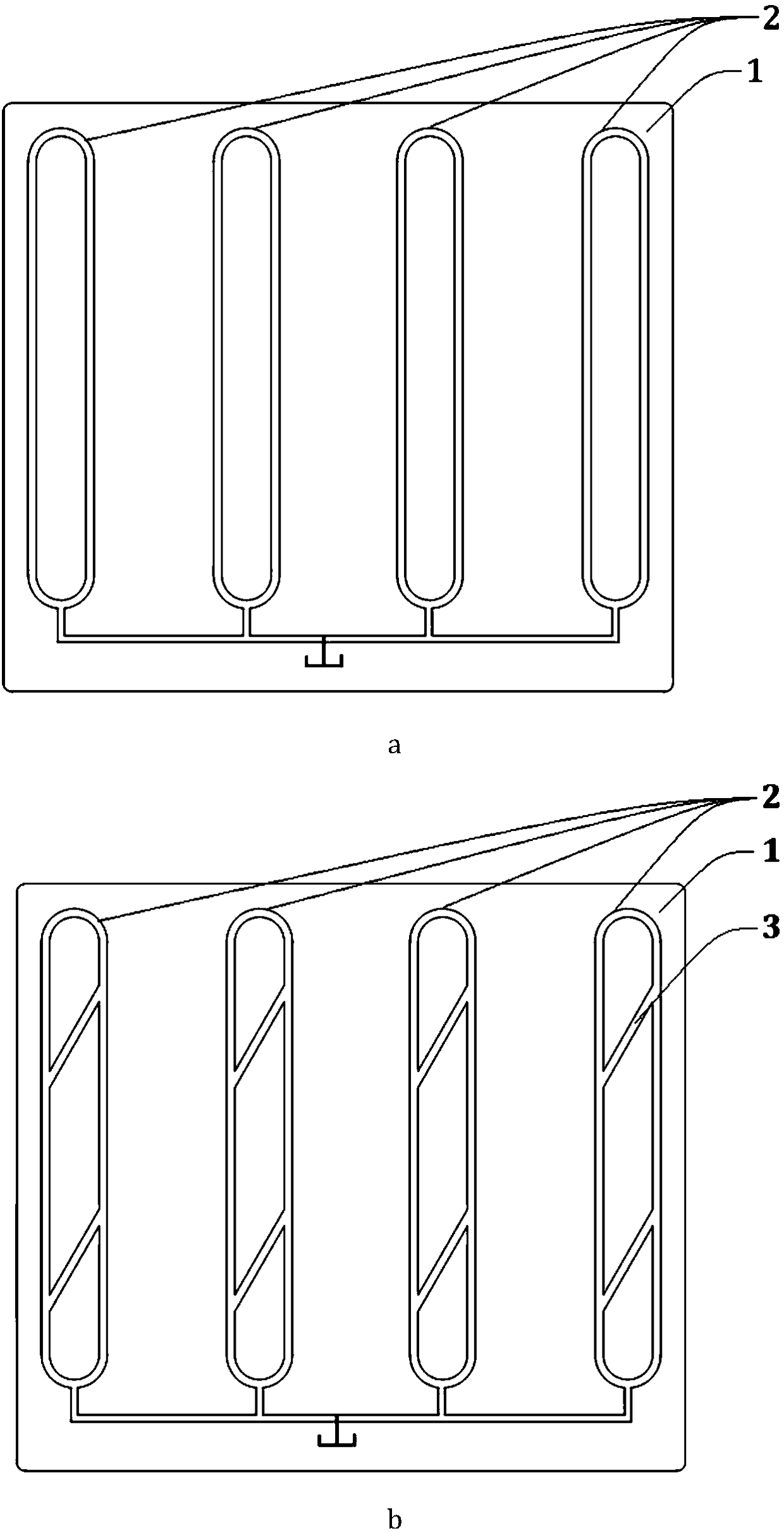

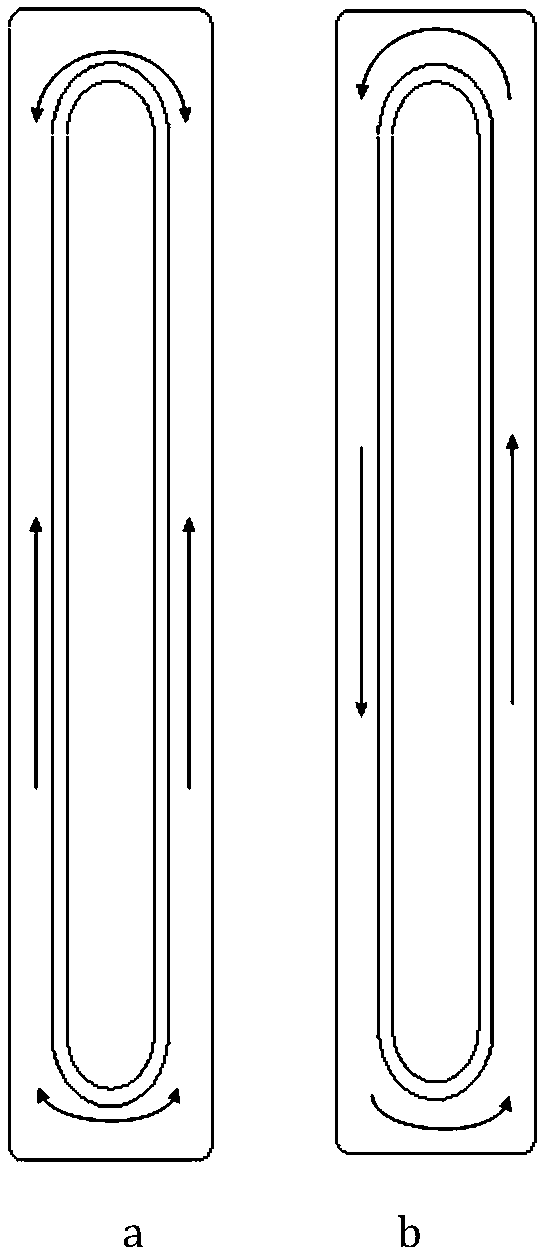

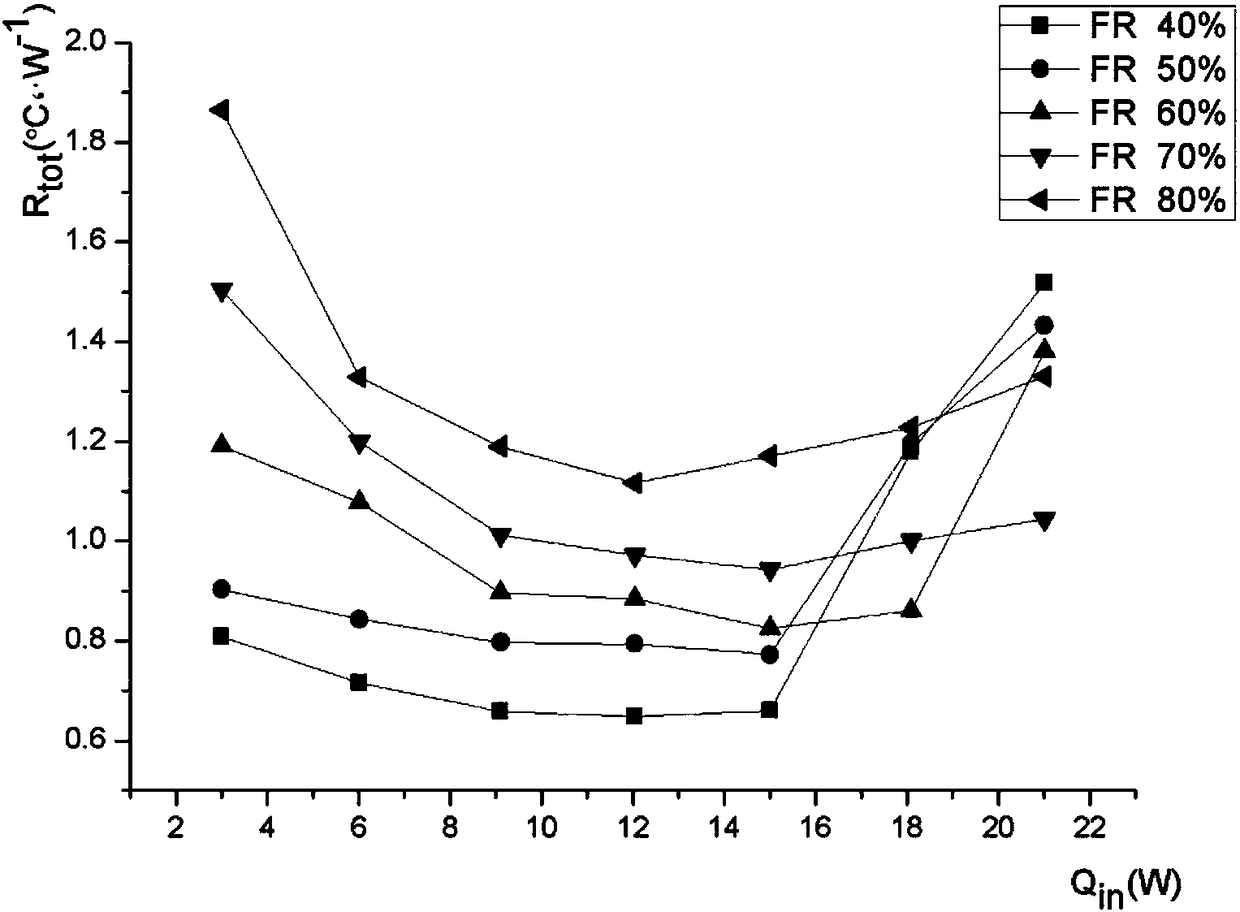

Plate loop thermosiphon equal temperature plate

ActiveCN106455431BHeightened stress imbalanceEnhance heat and mass transferCooling/ventilation/heating modificationsMain channelMiniaturization

The invention discloses a board type loop thermosyphon uniform-temperature board, and belongs to the heat dissipation technical field of an electronic device. The board type loop thermosyphon uniform-temperature board comprises annular grooves formed in a flat board body, wherein the annular grooves comprise left and right main channels and upper and lower bending channels connected with the left and main channels; and connecting channels arranged in a tilted manner are connected between the left and right main channels. By adoption of the board type loop thermosyphon uniform-temperature board, the dimension of a heat pipe can be reduced to be matched with an electronic device; the miniaturization is realized while the contact thermal resistance is lowered, and the two-phase flowing in the heat pipe is reinforced, so that the heat exchange efficiency of the electronic device is improved consequently.

Owner:SHANGHAI JIAO TONG UNIV

Natural-circulation self-cleaning evaporation device

ActiveCN102949856BLow circulation resistanceSatisfy the flow rateEvaporators with vertical tubesEvaporationEngineering

Owner:浙江建装工程技术研究有限公司

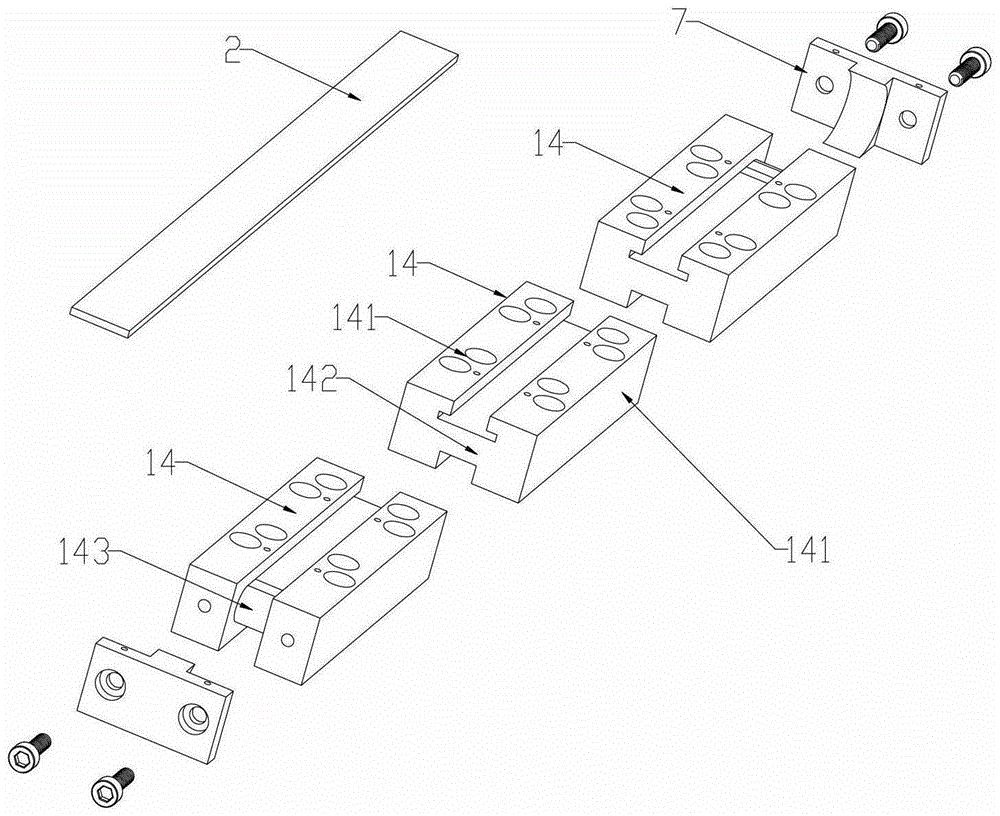

An upper bearing component and a guide rail system

Owner:广东鑫泰科技集团有限公司

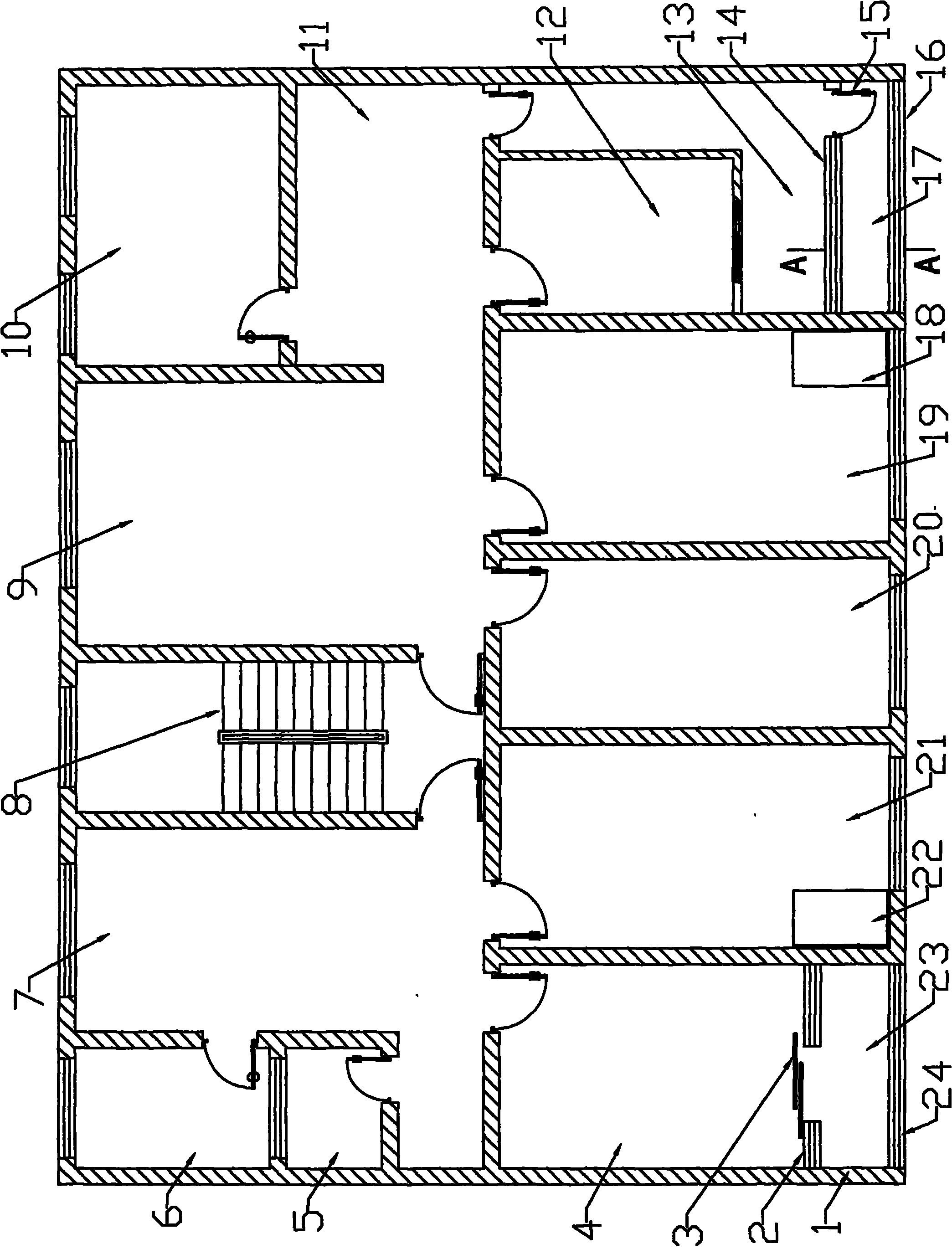

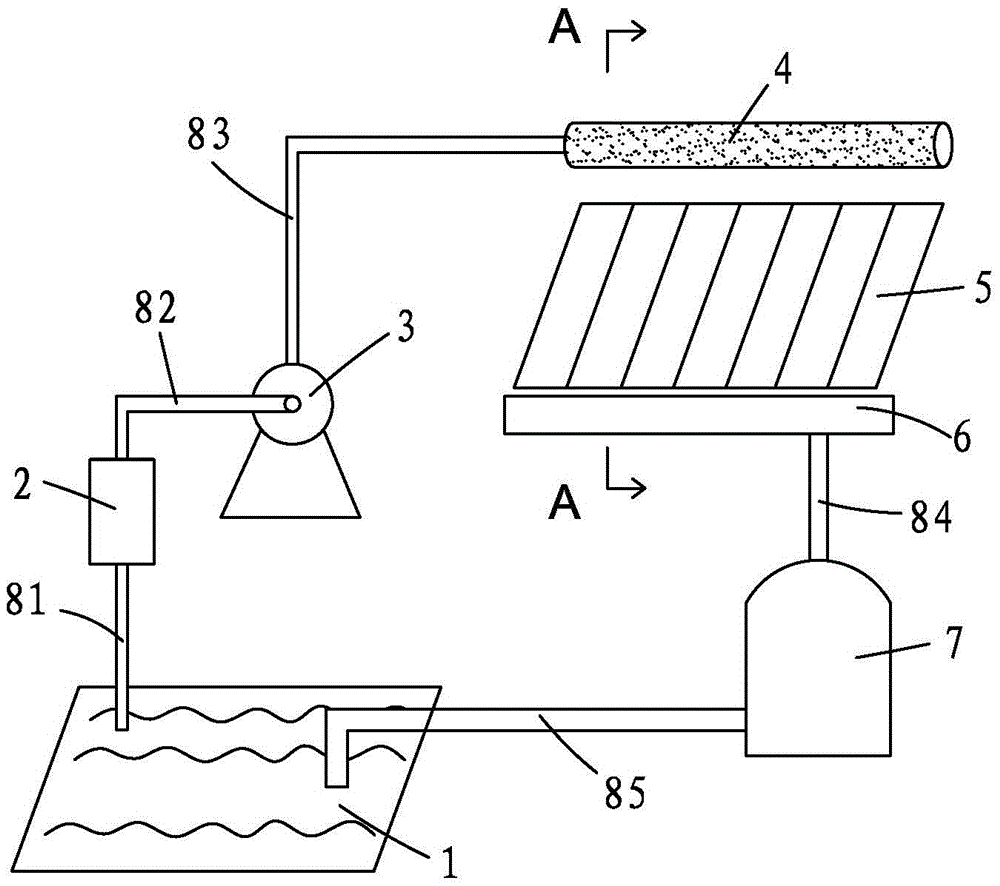

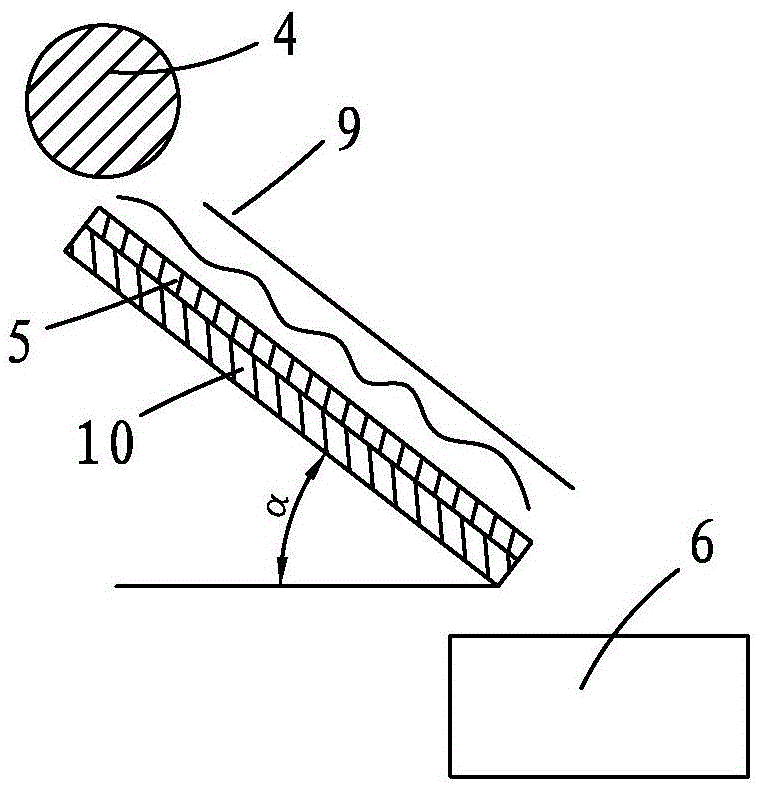

Straight-insertion type pressure-bearing dual-circulation solar balcony bathroom

InactiveCN101988344ALow circulation resistanceLow cycle heat lossSolar heating energySolar heat devicesSolar waterEngineering

The invention relates to a straight-insertion type pressure-bearing dual-circulation solar balcony bathroom which comprises a passive solar house, a pressure-bearing dual-circulation solar water heater and a connecting tube thereof. A wall, a window, a door, a roof and a bottom surface of a balcony are enclosed into the passive solar house; and a water tank, a hole in the wall of the water tank, an end cover and an annular hole together form a heat exchanger. The heat exchanger is in a full-plastic structure and never scales, which can ensure that the heat exchanger keeps higher heat exchange efficiency for a long time. The pressure-bearing dual-circulation solar water heater and the passive solar house are integrally designed, which can provide a large quantity of life hot water and provide a showing space with a room temperature of reaching 25-45 DEG C, thus even in a winter night with roaring north wind, hot water in the water tank can be used to ensure that the bathroom rapidly increases the temperature and keeps constant. The balcony has all functions of the balcony and can be used as the bathroom and a toilet as well as can also be used as a ventilation channel of an adjacent room.

Owner:侯国山

Self-adaptive automatic balance circulating cooling system

The invention discloses a self-adaptive automatic balance circulating cooling system. The self-adaptive automatic balance circulating cooling system comprises a dynamic sealing connecting device, the dynamic sealing connecting device comprises a connecting sleeve and a static ring arranged in an inner cavity of the connecting sleeve, the self-adaptive automatic balance circulating cooling system is characterized by further comprising a piston device, the static ring is connected with the inner wall of the connecting sleeve through a sealing piece, the connecting sleeve is connected to a hollow shaft through a bearing device, and the hollow shaft and the static ring mutually form end face friction sealing connection. The self-adaptive automatic balance circulating cooling system is simple and reasonable in structural composition, excellent in overall structural performance and good in cooling effect.

Owner:宜春市龙腾机械电气有限公司

High-gradient internal circulation oil cooling iron remover

ActiveCN103056023BLow circulation resistanceEven and reasonable cycleHigh gradient magnetic separatorsTransformer oilIron absorption

The invention relates to a high-gradient internal circulation oil cooling iron remover, which comprises a magnetic coil (4), an internal circulation oil path system (3), an external cooling system (2) and an oil conservator (1), wherein the magnetic coil (4) is used for generating an excitation magnetic field capable of realizing the iron absorption effect of the iron remover; the magnetic circuit of the magnetic coil (4) is an opened magnetic circuit structure; the internal circulation oil path system (3) is used for distributing, collecting and circulating oil of a transformer; the external cooling system (2) is used for dissipating heat of the oil of the transformer so as to realize internal heat dissipation balance of the high-gradient internal circulation oil cooling iron remover; and the oil conservator (1) is used as a complementary container when oil in the transformer is inflated in the event of operating equipment. By adopting the internal circulation structure, the high-gradient internal circulation oil cooling iron remover disclosed by the invention is capable of simplifying external circulation pipelines, reducing oil path circulation resistance, avoiding the problems of being complex and interferential in oil path arrangement, low in circulation efficiency, leaked in welding spot and the like, ensuring the iron remover to work normally, and increasing the iron removing efficiency.

Owner:LONGI MAGNET CO LTD

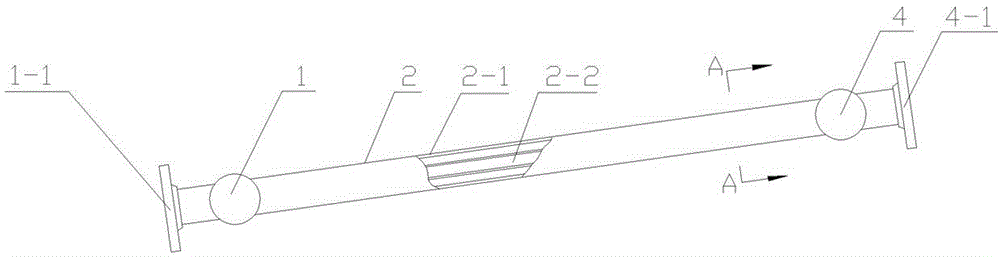

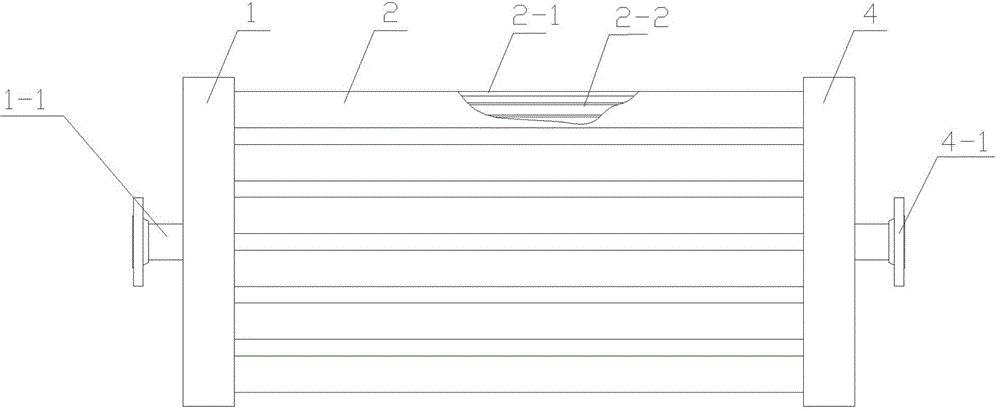

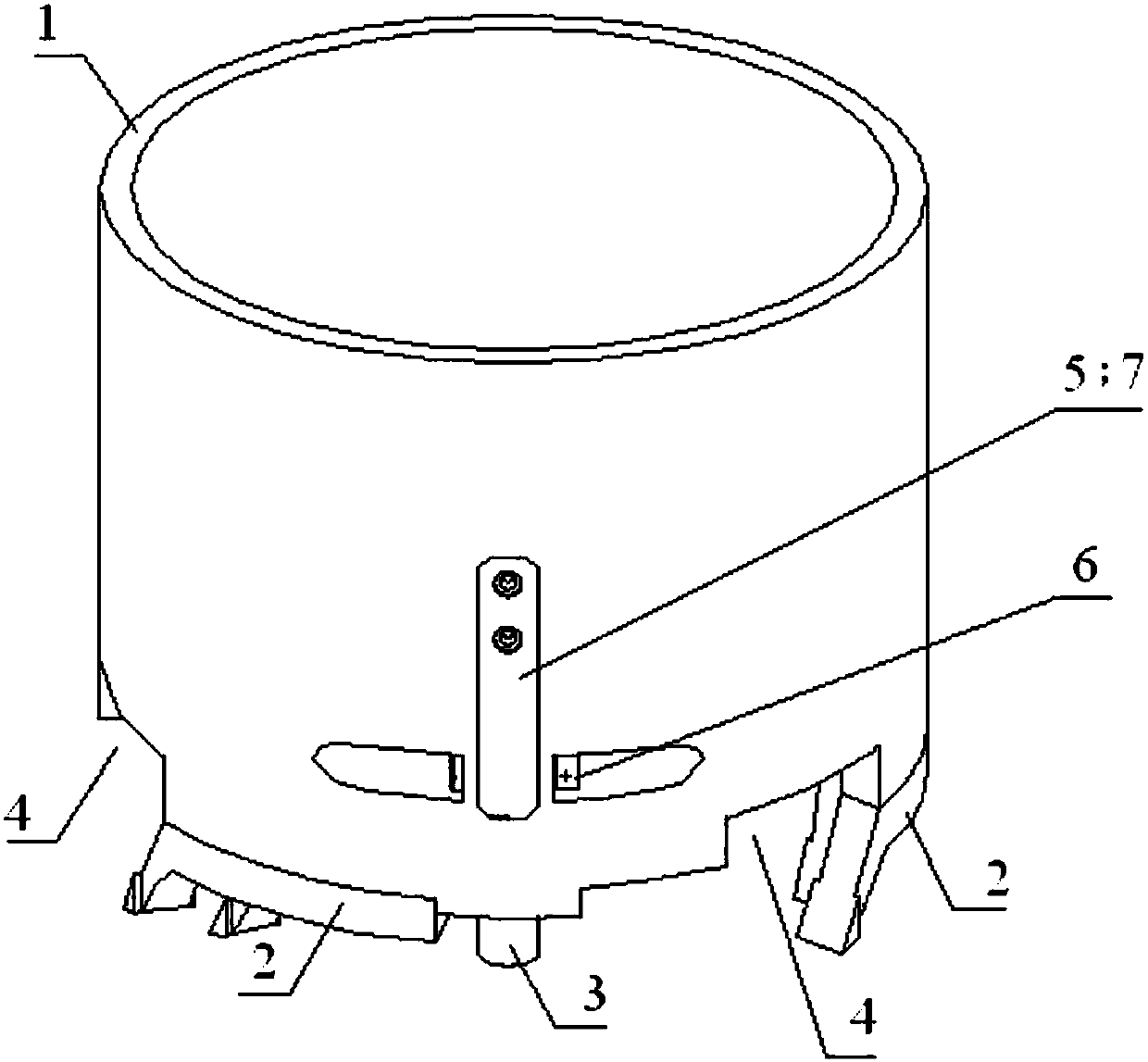

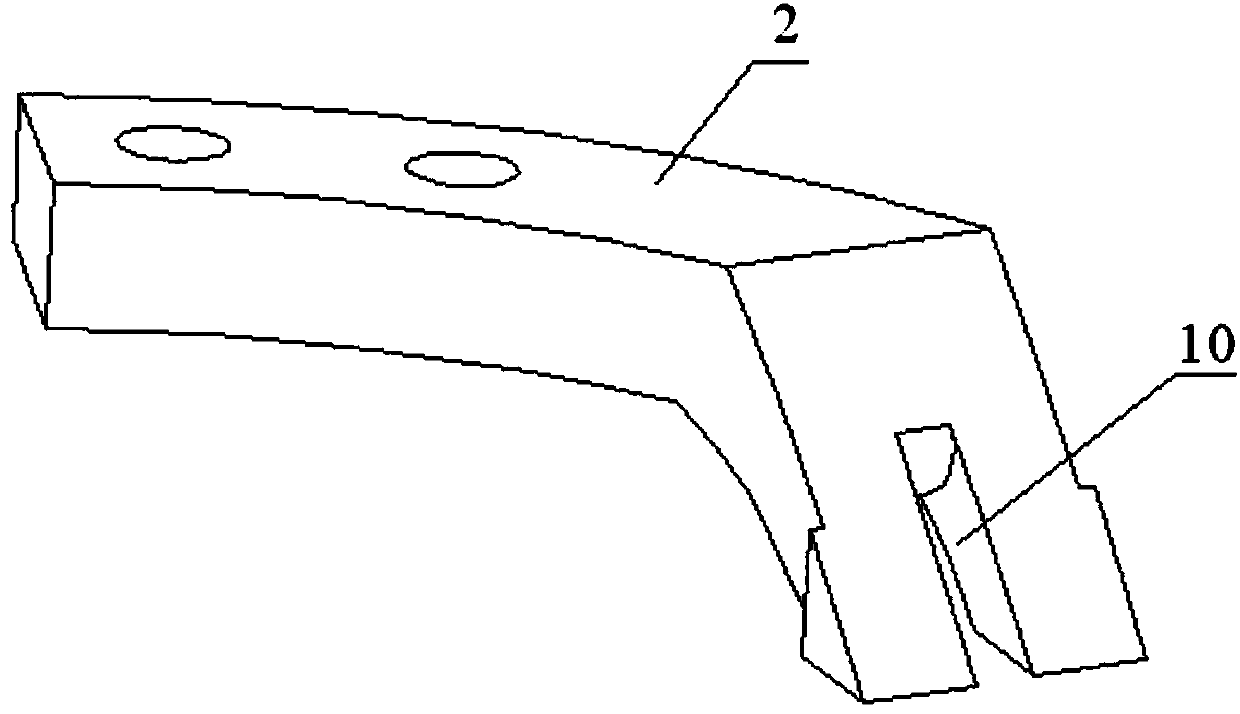

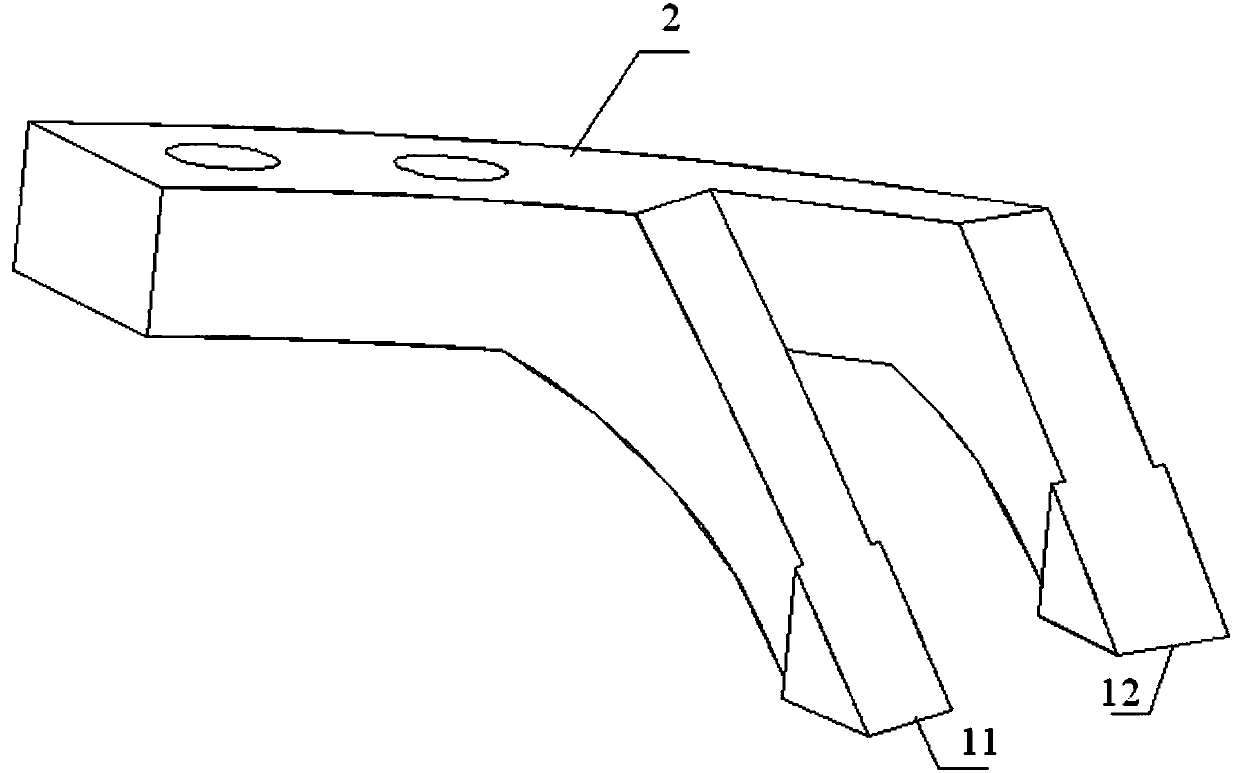

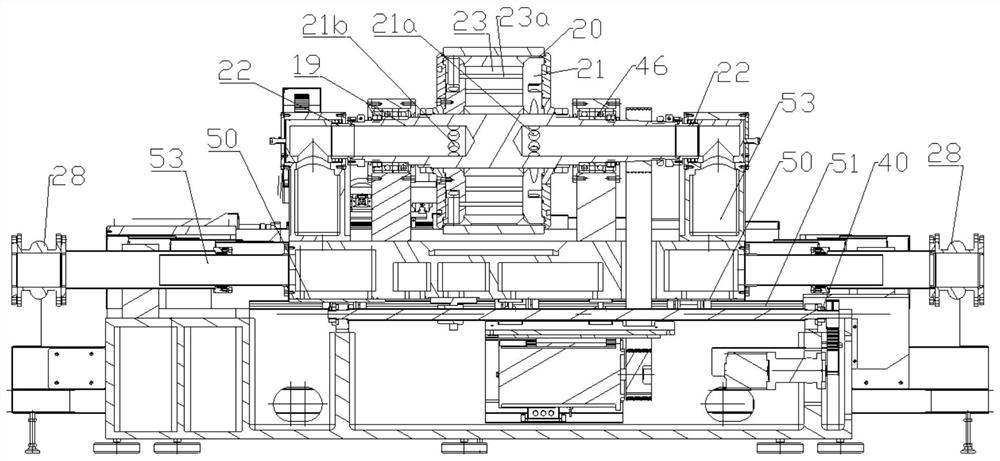

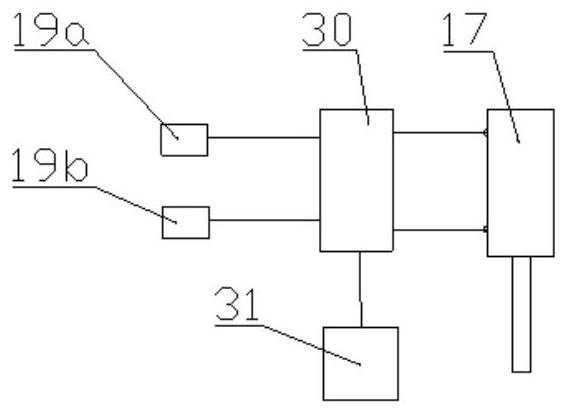

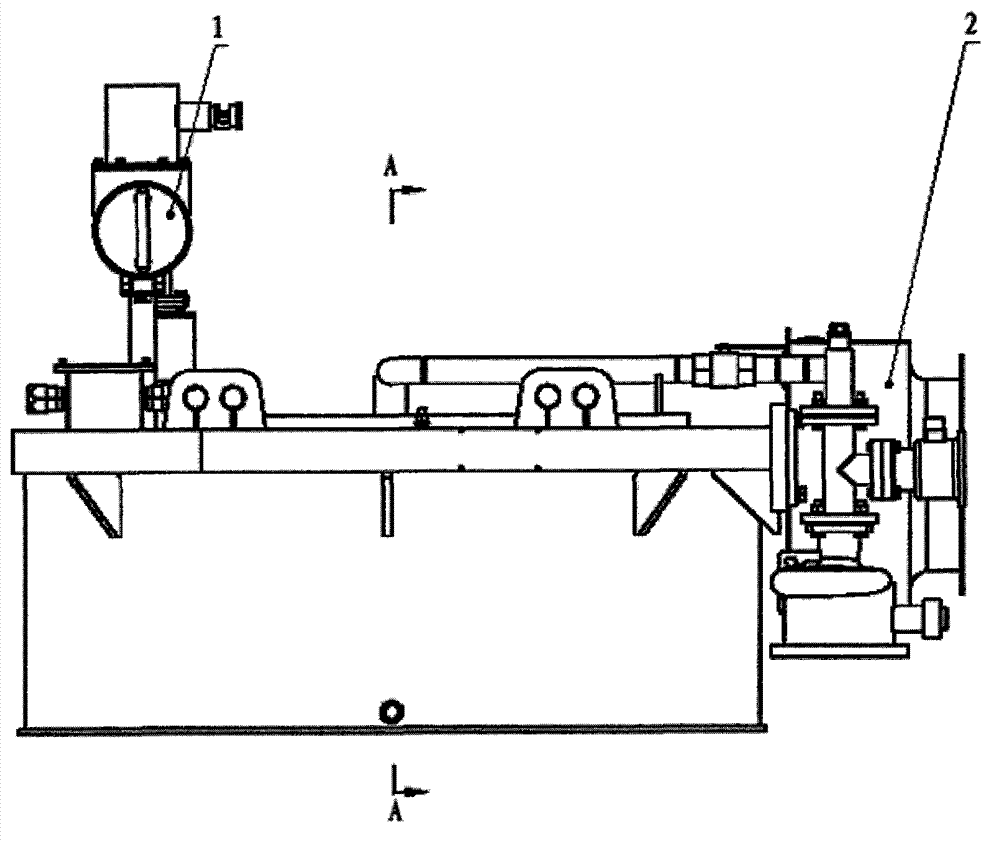

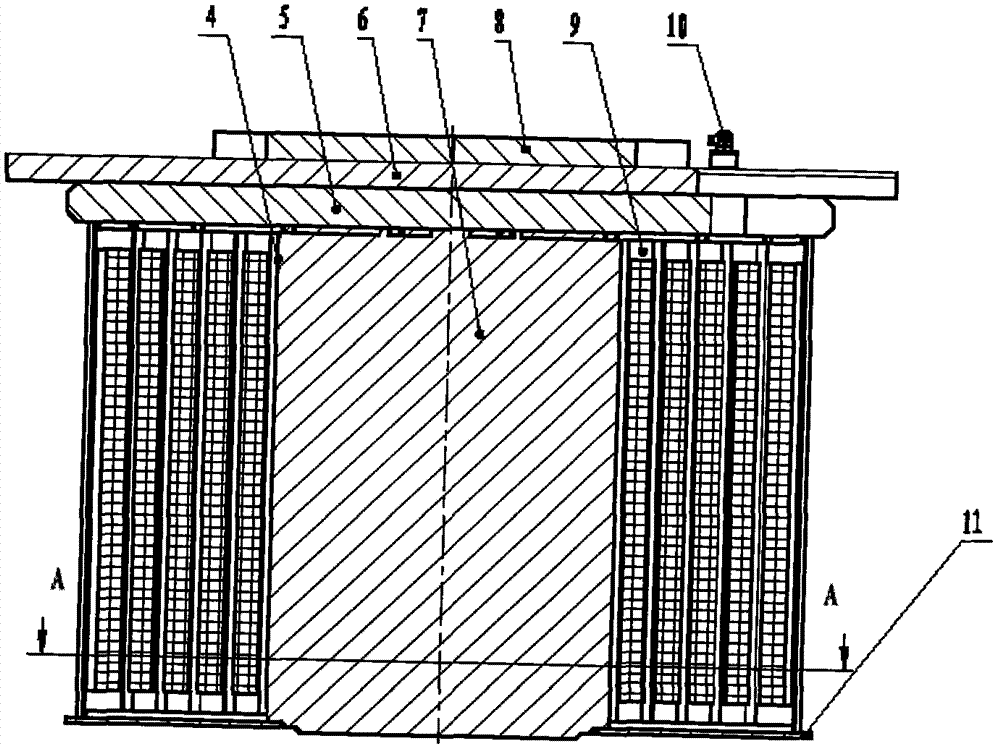

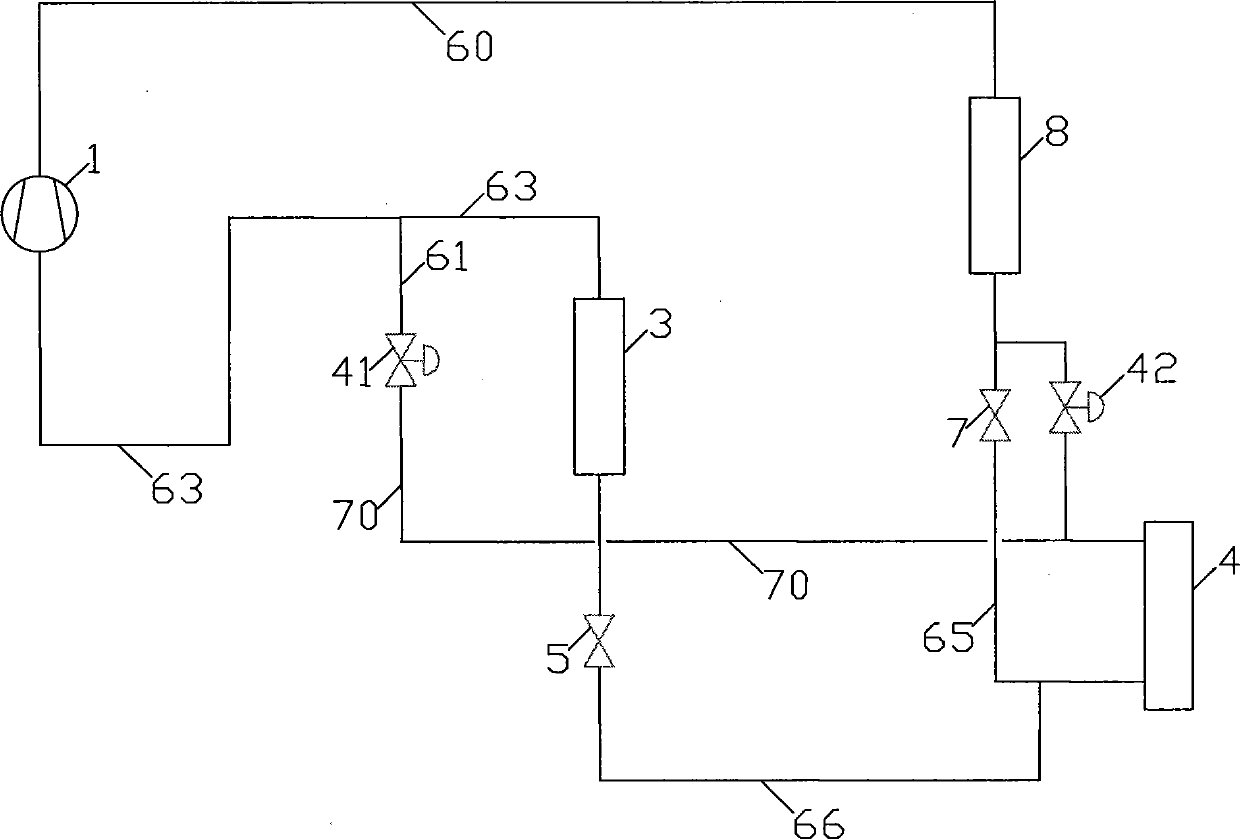

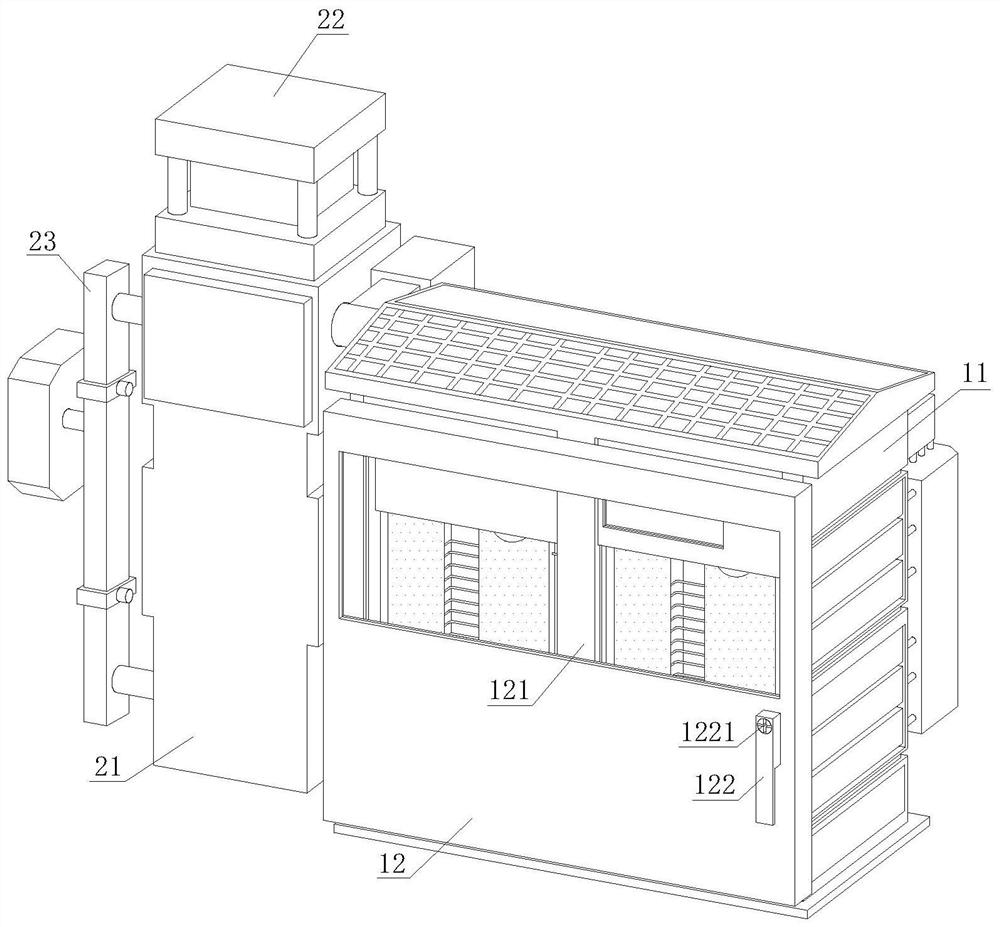

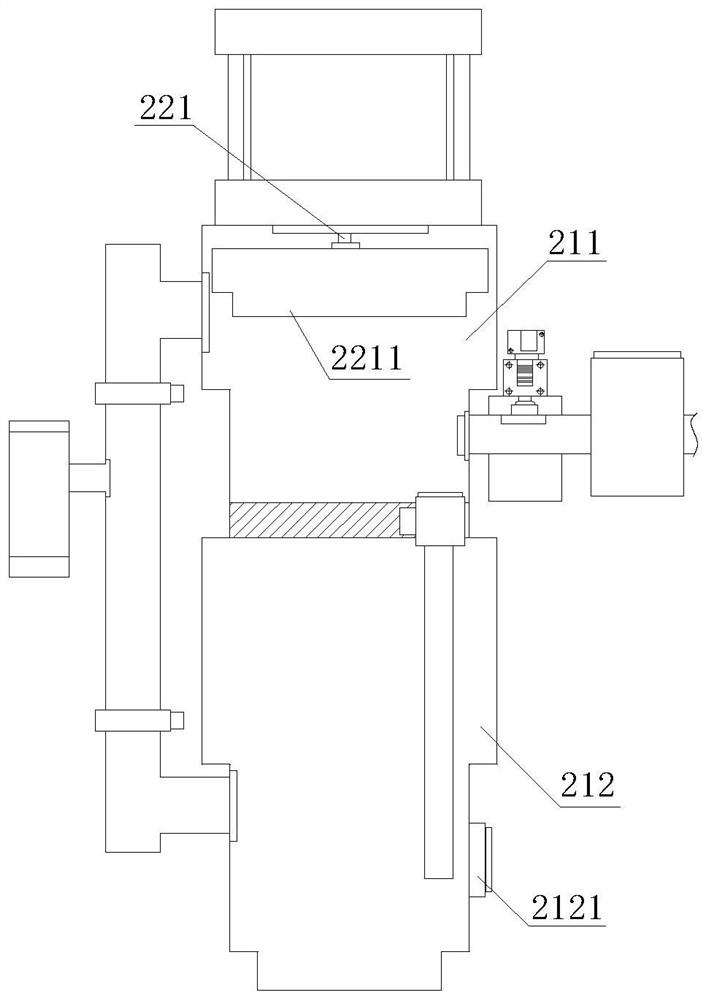

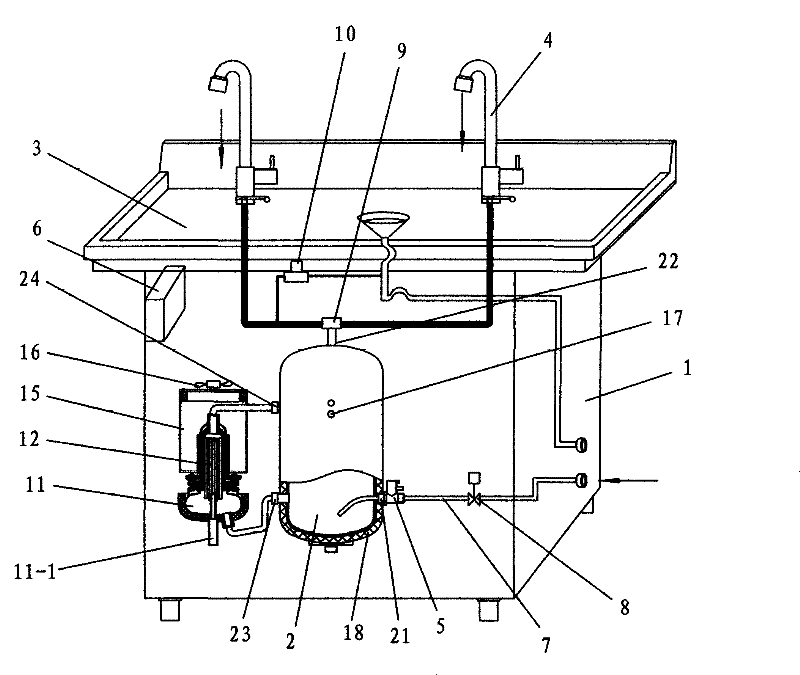

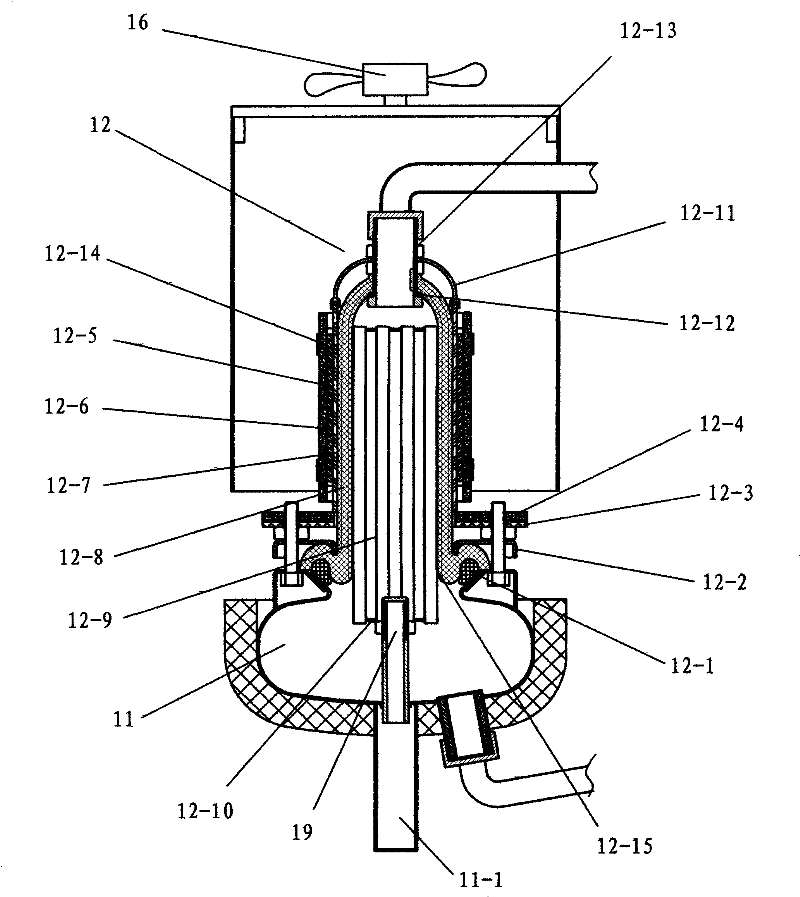

Low power self-circulating oil-cooled iron remover

ActiveCN103433129BLow circulation resistanceGuaranteed to workMagnetic separationExpansion tankFuel tank

The invention discloses a low-power self-circulation oil cooling de-ironing separator which comprises a magnetic system assembly (1), an oil tank assembly (2) and an expansion tank (3), wherein the magnetic system assembly (1) is a core part of the de-ironing separator, and is used for generating an excitation magnetic field capable of realizing an iron attracting function of the de-ironing separator, a magnetic circuit of the magnetic system assembly (1) is in an opened magnetic circuit structure, the oil tank assembly (2) is used for circulating and heat-radiating transformer oil so as to realize heat radiation balance inside the low-power self-circulation oil cooling de-ironing separator; and the expansion tank (3) is a supplementation container for expansion of the transformer oil when a device runs. According to the low-power self-circulation oil cooling de-ironing separator, by adopting a natural oil cooling circulation structure, an external circulation pipeline is eliminated, oil pipeline circulation resistance is reduced, the problems of complicated and interfered oil pipeline arrangement, low circulation efficiency, welding spot leakage and the like are avoided, the de-ironing separator is enabled to normally work, and the de-ironing efficiency is increased.

Owner:LONGI MAGNET CO LTD

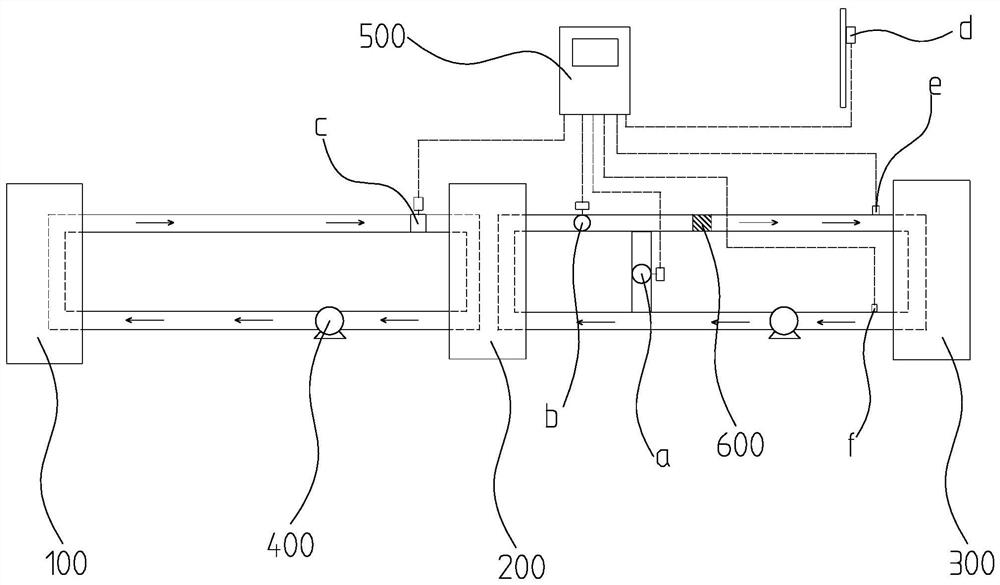

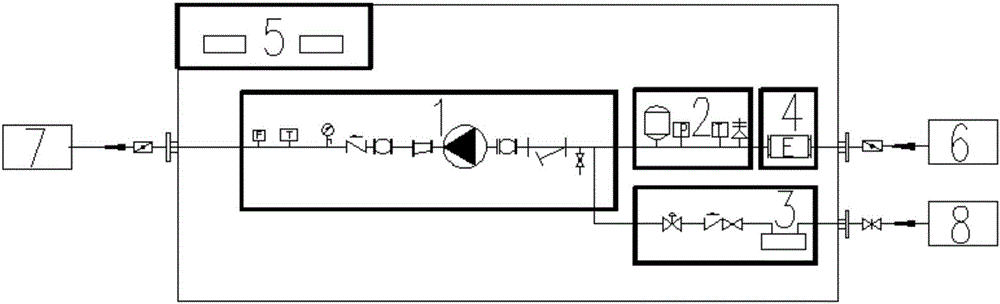

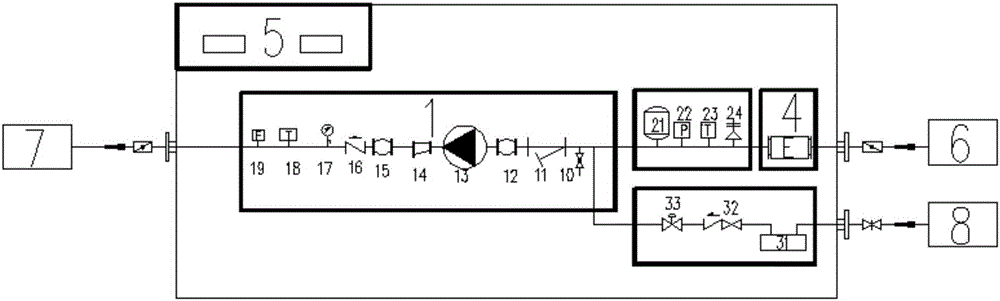

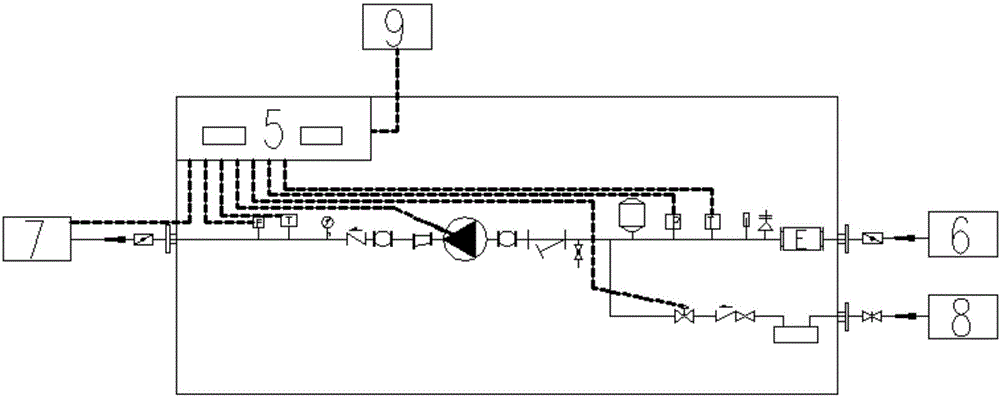

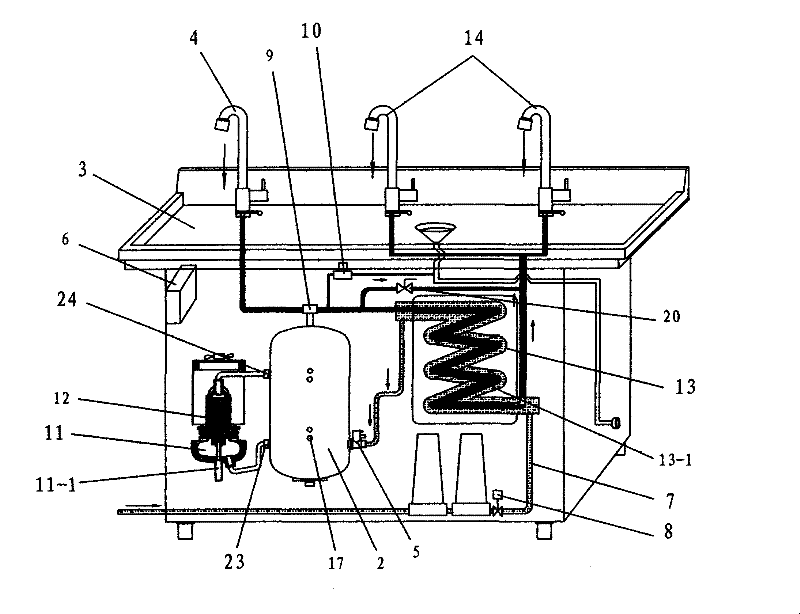

Integration hydrodynamic force transportation and distribution system

InactiveCN105910350ASmall footprintEnergy efficient operationMechanical apparatusSpace heating and ventilation detailsCyclic processDistribution control

The invention relates to an integration hydrodynamic force transportation and distribution system and belongs to the field of related technologies and equipment of new energy resources. The integration hydrodynamic force transportation and distribution system comprises a circulating power module which communicates with a constant pressure module and a water processing and moisturizing module, and the constant pressure module communicates with a scale removing and decontaminating module; the circulating power module comprises a water escape valve, a filter, a circulating water pump, a circulating water temperature sensor and a water flow switch which are sequentially connected; tap water enters the circulating power module to become fluid after being processed by the water processing and moisturizing module, and the circulating water pump pumps the fluid to circulate between a user side and a cold and heat source side; cold and heat fluid is continuously purified by the scale removing and decontaminating module in the circulating process; and the pressure of the cold and heat fluid is maintained to be stable through the constant pressure module. According to the integration hydrodynamic force transportation and distribution system, correlating control over the transportation and distribution system and the cold and heat source is achieved through the novel structure, and the operation situation of high flow, small temperature difference and high energy consumption is avoided; and energy-saving operation of the transportation and distribution system and data teletransmission are achieved through a power distribution control and communication module, and remote expert management of the system is facilitated.

Owner:山东中瑞新能源科技有限公司

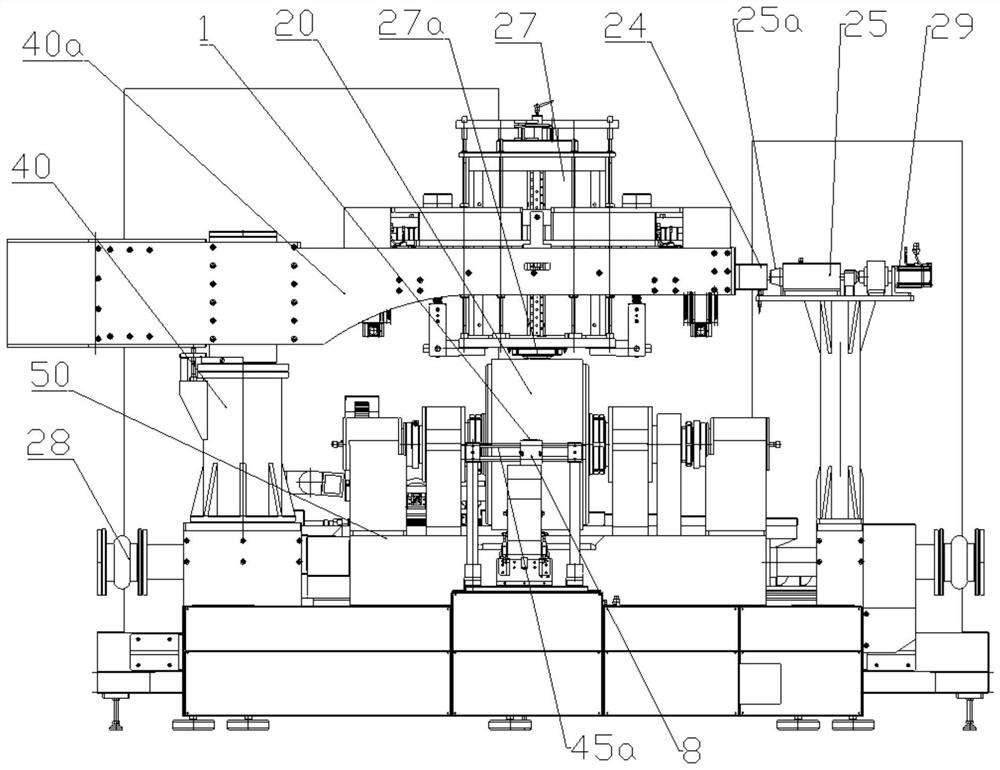

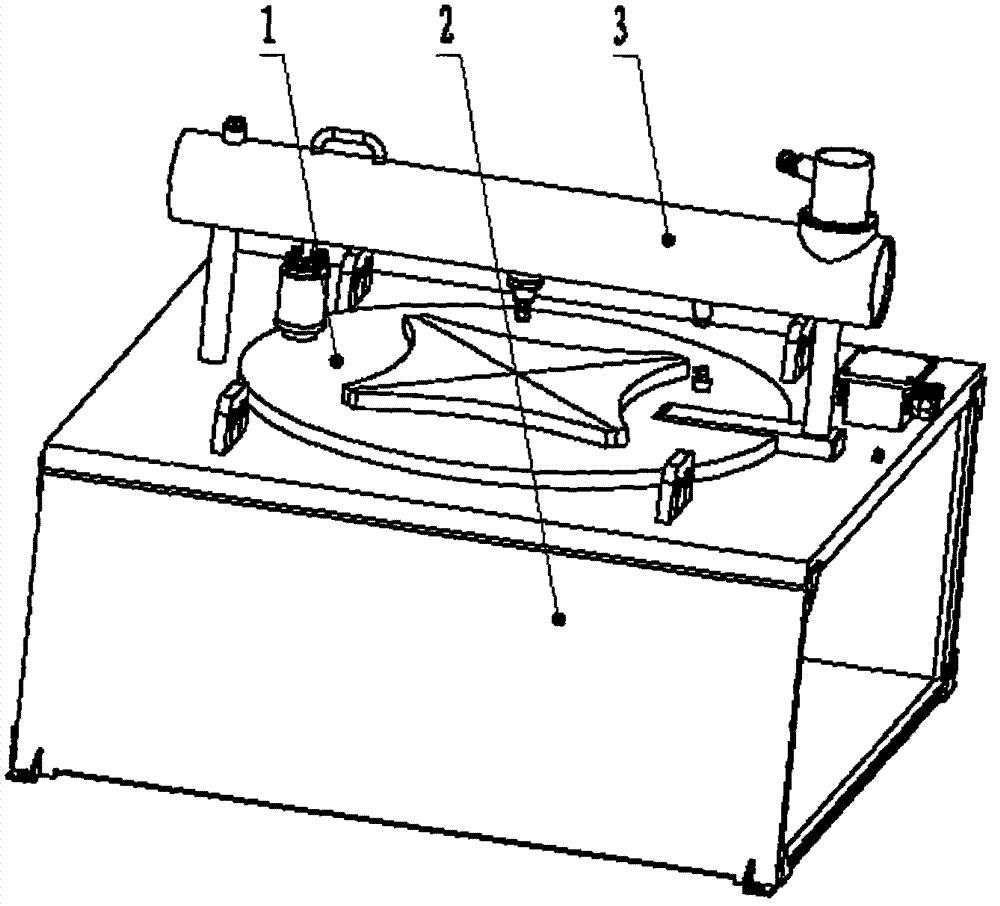

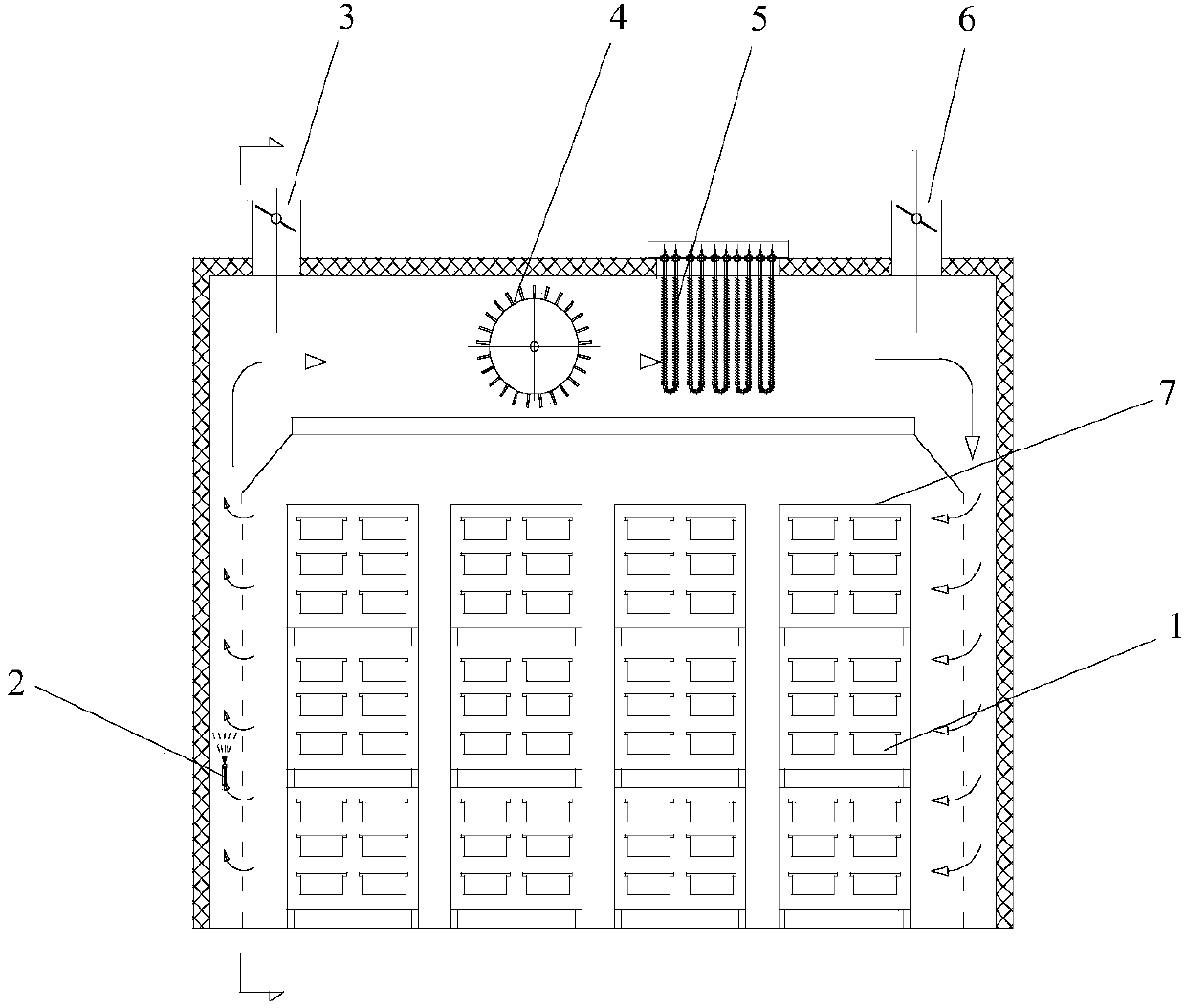

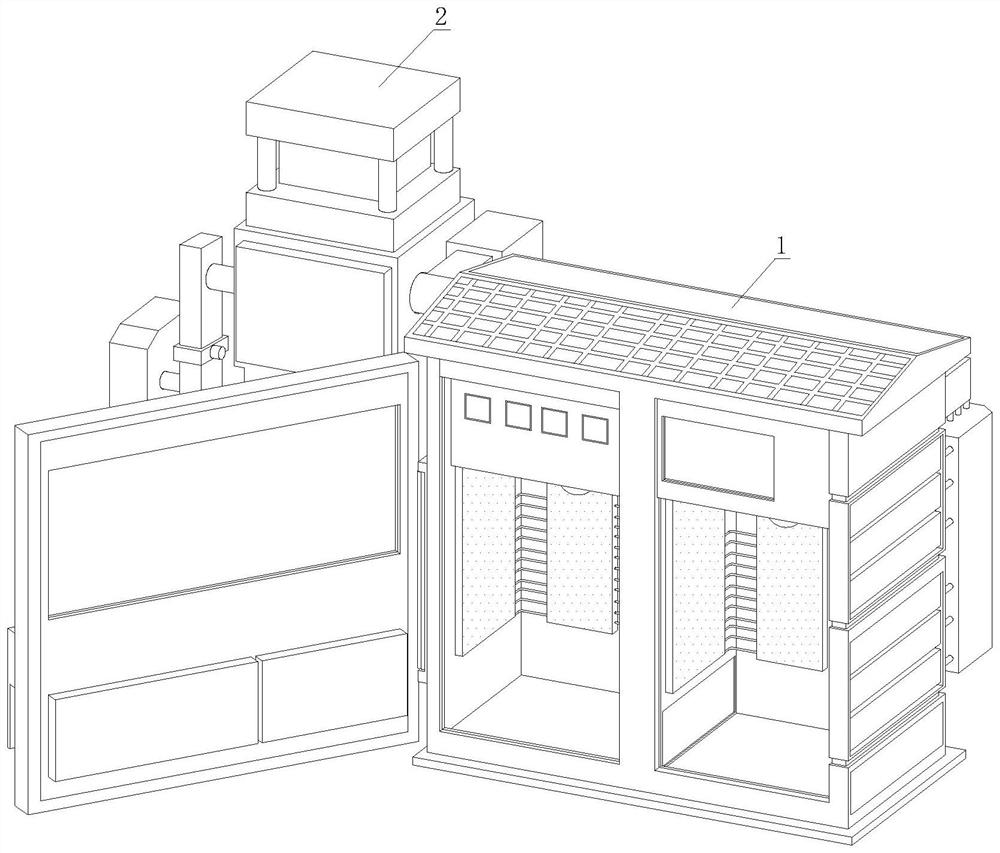

A curing system for polar plates

ActiveCN103531751BLow resistance cycleLow circulation resistanceLead-acid accumulator electrodesEngineeringLow resistance

The invention discloses a curing system for a polar plate, which comprises a curing chamber, a first fan and a regulating device. The regulating device is used for regulating the temperature and the humidity in the curing chamber; the curing chamber comprises a body, a curing chamber door and a separator; the front end of the body is provided with the curing chamber door and the rear end of the body is a closed end; the separator is arranged in the body from front to back and divides the body into a first chamber and a second chamber; a front turning air duct is formed between the curing chamber door and the front end of the separator; the first fan is provided with a cavity body; the cavity body is provided with an air outlet and an air suction port; one of the air outlet and the air suction port face towards the first chamber and the other one of the air outlet and the air suction port face towards the second chamber; a rear turning air duct is formed in the cavity body; and a ring-shaped air flow passage is formed among the first chamber, the rear turning air duct, the second chamber and the front turning air duct. According to the invention, an air flow circulation path is prolonged; low-resistance circulation of indoor air can be implemented without an external air duct; the air circulating resistance is low; the air distribution is uniform; no convection dead angle is generated; the polar plate is uniformly humidified and heated; and the effect of curing the polar plate is good.

Owner:LEOCH BATTERY

Air conditioner refrigeration device

ActiveCN104197580ALow circulation resistanceImprove heat transfer effectMechanical apparatusSpace heating and ventilation detailsWater productionEngineering

Owner:刘雄

Steam and water separation device for steam dome

ActiveCN102230613BGood cycle conditionReduced chance of blown pipesSteam separation arrangementsEngineeringProduct gas

The invention discloses a steam and water separation device for a steam dome, and the device provided by the invention comprises a primary separation device and a secondary separation device, wherein the primary separation device is arranged on the mouth of an ascending tube used for inputting a steam and water mixture in a steam dome body; and the secondary separation device is arranged on the mouth of a steam extraction tube for outputting gas in the steam dome body. The device has a simple structure and is convenient to manufacture, install and overhaul; meanwhile, good water circulation working condition can be guaranteed, and overlarge circulation resistance can be avoided; and in addition, the device can effectively carry out steam and water separation so as to lower the tube explosion possibility of the superheater, and satisfies the operation reliability of the boiler and user requirements.

Owner:ANHUI CONCH KAWASAKI ENERGY CONSERVATION EQUIP

Outdoor energy-saving and heat-dissipating alternating-current low-voltage distribution box

InactiveCN112670870AImprove recycling ratesRapid coolingSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsCold airEngineering

The invention discloses an outdoor energy-saving heat-dissipating alternating-current low-voltage distribution box, which comprises a distribution box mechanism and an exchange refrigeration mechanism; a liquid inlet end of the distribution box mechanism is connected with the exchange refrigeration mechanism. The distribution box can monitor the internal temperature of the distribution box body in real time through the temperature sensor, if the internal temperature of the distribution box body exceeds a preset safety valve value, a liquid conveying electromagnetic valve, a liquid discharging electromagnetic valve and an electric control air cylinder can be synchronously opened, and the electric control air cylinder drives a push rod to push a T-shaped piston body to move downwards; consequently, the bottom pressure of the inner cavity of an infusion treatment pump body rises; the cooling liquid in a cold liquid storage barrel is conveyed into a first cold-coated thin bag through the cold liquid conveying pipe and then conveyed into a second cold-coated thin bag through the liquid discharging guide pipe; meanwhile, the flowing cooling liquid is used for quickly cooling and dissipating heat of the surface of the electric part; cold air is conveyed into the liquid conveying processing pump body and the cold liquid storage barrel through the annular cold air conveying pipe, and after being cooled to a certain degree, the cold air is conveyed into the first cold-coated thin bag and the second cold-coated thin bag again for circulating cooling.

Owner:孟玉梅

A vehicle cooling system and its control method, and a vehicle equipped with the system

ActiveCN105756763BImprove braking effectReduce resistanceLiquid coolingCoolant flow controlWater jacketAutomotive engineering

The invention relates to the technical field of vehicle cooling systems and particularly relates to a vehicle cooling system and a control method thereof as well as a vehicle provided with the system. The vehicle cooling system comprises a water pump, a heat radiator, an engine water jacket and a hydraulic retarder, wherein a cooling circuit is formed by connecting the heat radiator, the water pump and the engine water jacket in series; a cooling water path of the hydraulic retarder is connected with the engine water jacket in parallel; and an adjusting valve is arranged among the water pump, the hydraulic retarder and the engine water jacket and is used for adjusting the quantity of water which is introduced into the hydraulic retarder and the engine water jacket by the water pump. The cooling capability of the vehicle cooling system is improved; and furthermore, the braking efficiency of the hydraulic retarder is improved.

Owner:WEICHAI POWER CO LTD

Multi-loop evaporator capable of achieving two-way air inflow

InactiveCN104990311ALow circulation resistanceSimple design methodEvaporators/condensersEvaporationEngineering

The invention discloses a multi-loop evaporator capable of achieving two-way air inflow. The multi-loop evaporator comprises an evaporator body and stainless steel plates installed on the two sides of the evaporator body. A plurality of insertion holes arranged in order are formed on the stainless steel plates. An evaporation pipe is inserted into the insertion holes in a detouring manner to form a disc face evaporation device. The insertion holes are provided with refrigerant inflow holes and refrigerant discharging holes. The refrigerant inflow holes and the refrigerant discharging holes are formed in the straight line. The disc face evaporation device comprises a left side air inflow evaporation device body and a right side air inflow evaporation device body. The left side air inflow evaporation device body and the right side air inflow evaporation device body are sequentially and longitudinally arranged and staggered. According to the multi-loop evaporator, the frosting quantity of the evaporator and the frosting speed are lowered through two-way air inflow, so that the circulation resistance is decreased, and the working efficiency is greatly improved.

Owner:姚旺东

System and method for evaporating liquefied natural gas by utilizing intermediate medium

ActiveCN102518935BNot easy to freezeLow costPressure vesselsStationary tubular conduit assembliesEngineeringLiquefied natural gas

The invention provides a system for evaporating liquefied natural gas by utilizing an intermediate medium. The system comprises an upper part cavity and a lower part cavity which are communicated with each other, wherein the upper part cavity internally comprises a heat exchange relation of the intermediate medium and the liquefied natural gas, the lower part cavity internally comprises a heat exchange relation of a second medium and the intermediate medium, the intermediate medium in a steam form is raised to the upper part cavity to perform heat exchange with the liquefied natural gas, and simultaneously, condensation is performed to the intermediate medium in the steam form. The invention also provides a method for evaporating the liquefied natural gas by utilizing the intermediate medium. The method comprises the steps of: heating the liquefied natural gas by utilizing the intermediate medium, utilizing water with normal temperature as the second medium to heat the intermediate medium, and utilizing the generated intermediate medium in the steam form for heating the liquefied natural gas, therefore, additional condensation equipment is not needed for performing temperature reduction to the intermediate medium in the steam form, circulating resistance of the intermediate medium is reduced and the energy efficiency is improved.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU +1

Pre-water cycle heat exchange solar water heating engineering system

InactiveCN104180537BLow circulation resistanceHigh cycle strengthSolar heating energySolar heat devicesWater circulationDistributor

The invention provides a front water circulation heat exchange solar water heating engineering system which comprises a water consumption pond, a coarse filter screen, a circulating pump, a heat absorbing plate, a water distributor, a water collecting tank and a fine filter. The water consumption pond is connected with the coarse filter screen by a first pipeline, and the coarse filter screen is further connected with the circulating pump by a second pipeline; the circulating pump is connected with the water distributor by a third pipeline, and the water distributor is positioned above a high-end water inlet of the heat absorbing plate; the heat absorbing plate is positioned at a high location with sufficient illumination; the water collecting tank is positioned below a low-end water outlet of the heat absorbing plate and is further connected with the fine filter by a fourth pipeline, and the fine filter is further connected with the water consumption pond by a fifth pipeline. The front water circulation heat exchange solar water heating engineering system has the advantages that the integral system is simple in structure and high in heat efficiency; water is low in circulating resistance, high in circulating strength and low in required water pump lift and motor power; the front water circulation heat exchange solar water heating engineering system is low in engineering manufacturing cost and system running cost and can be easily accepted.

Owner:赵水华

Water and electricity separation energy-saving water dispenser

InactiveCN101822491BLow circulation resistanceThe water flow system is scientific and reasonableBeverage vesselsWater savingMagnetic heating

The invention relates to an energy-saving water dispenser with separation of water and electricity. A water tank and an electric control device are installed on the box body. At normal pressure, an independent boiling water tank is fixed on the box, and an internal heating electromagnetic heater is installed on the boiling water tank. There is a circulating water outlet on the lower part of the tank, and a circulating water inlet on the upper part. The circulating water outlet is connected to the water inlet hole at the bottom of the boiling water tank. The circulating water inlet is connected to the inner tank of the internal heating electromagnetic heater. Electrically connected with the electric control device. This type of water dispenser, by independently setting the boiling water tank and its internal heating electromagnetic heater outside the water storage tank, the water flows in the boiling water tank and the internal heating electromagnetic heater in a cycle from bottom to top, which can improve Thermal efficiency, water and electricity separation heating, it is difficult to generate scale in the water dispenser, the heated and boiled water will be well activated and magnetized, and it has the advantages of good drinking water taste, good health and heating safety.

Owner:GUANGDONG BILI DRINKING WATER EQUIPMENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com