Plate loop thermosiphon equal temperature plate

A technology of vapor chamber and plate type, which is applied in the direction of cooling/ventilation/heating transformation, electrical components, electrical equipment construction parts, etc. The heat dissipation of the device and other issues can be achieved, and the effect of good heat transfer capacity, simple structure and flexible layout can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

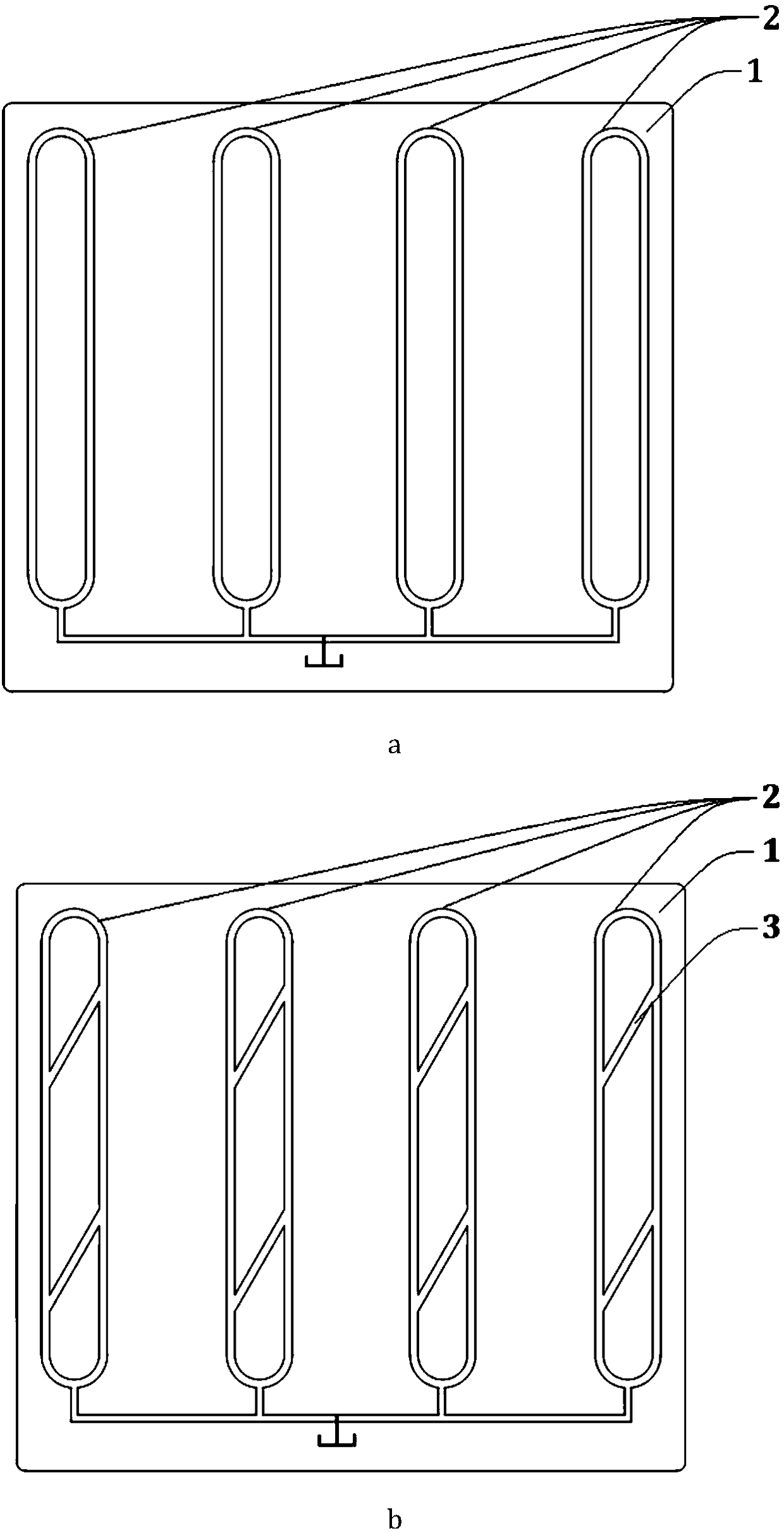

[0033] Such as figure 1 As shown in a, as the basic implementation of the present invention, this embodiment includes four ring grooves 2 arranged in parallel in the flat plate body 1, the bottoms of the ring grooves 2 are connected to each other, and the ring grooves 2 include: parallel The left main channel 21, the right main channel 22, the upper curved channel 23 and the lower curved channel 24 connecting the left main channel 21 and the right main channel 22 are provided.

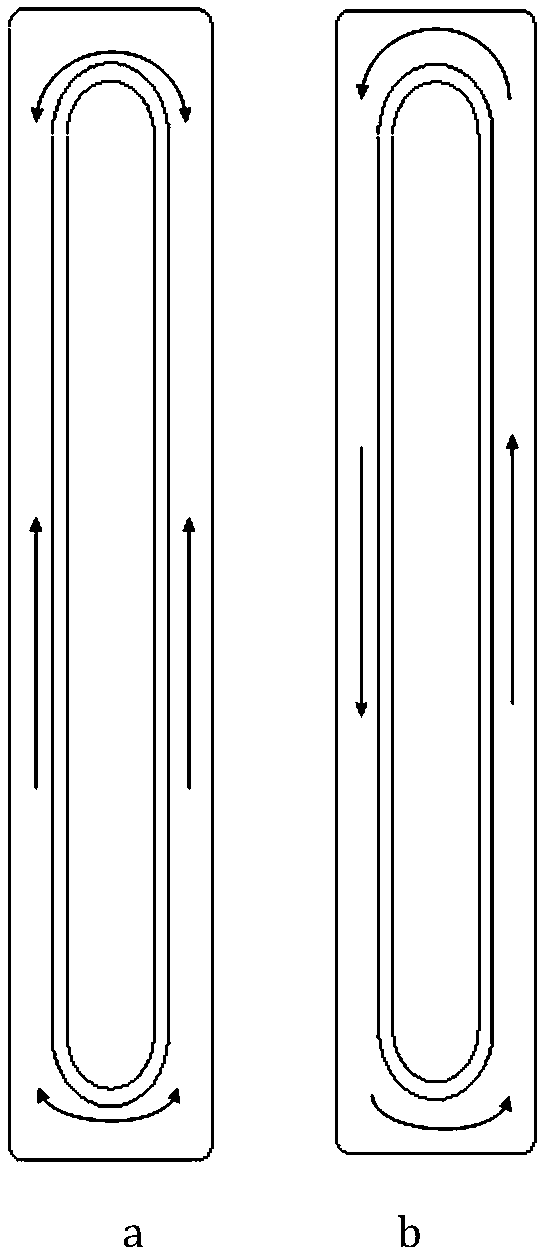

[0034] Such as figure 2 a and figure 2 As shown in b, it is a schematic diagram of the cycle in the basic realization mode of the device, where: a is a typical low-power flow mode, and b is a high-power flow mode.

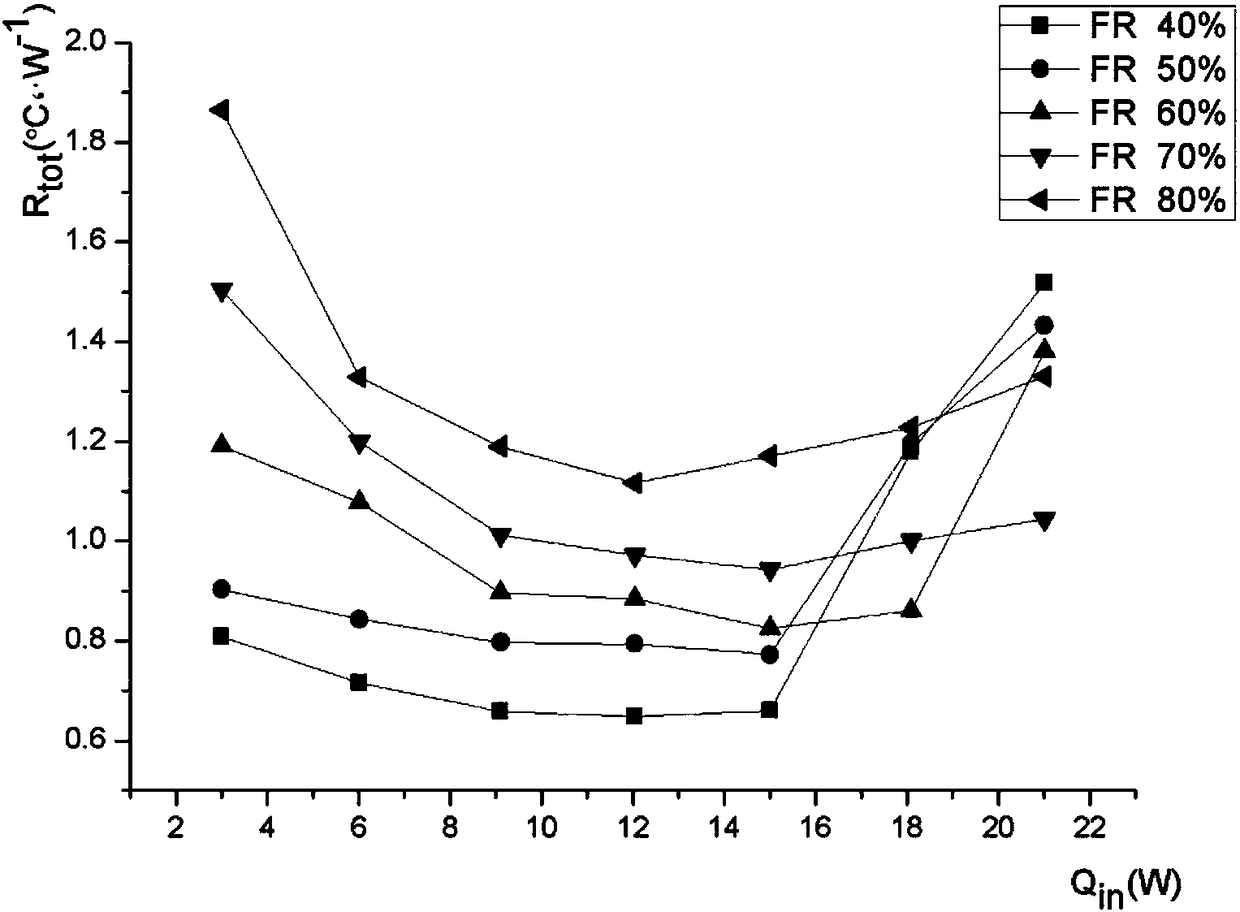

[0035] Such as image 3 As shown, it is a general diagram of the heat transfer performance of the liquid filling rate from 40% to 80% in this embodiment.

Embodiment 2

[0037] Such as figure 1 As shown in b, compared with the embodiment 1, the communication channel 3 arranged obliquely is connected between the left main channel 21 and the right main channel 22 in this embodiment, and the inclination angle is 30°-60°.

[0038] Described communication channel 3 comprises: the first chute 31 and the second chute 32 that are arranged in parallel, wherein: the second chute 32 is positioned at the evaporation section 1, and the bottom of the second chute 32 is far from the bottom of the ring groove The distance is less than 1 / 2 of the height of the evaporation section I, preferably 1 / 4 to 1 / 3 of the height of the evaporation section I; the first chute 31 is located in the condensation section II, and the distance between the bottom of the first chute 31 and the top of the ring groove The distance is 1 / 2 of the height of condensation section II.

[0039] Preferably, the condensation section II is provided with a cooling fin structure.

[0040] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com