Continuous type infrared corncob drying machine

A corn cob and drying machine technology, which is applied in the fields of drying and preserving seeds, food processing, etc., can solve the problems of slow heat transfer, long drying time, and inconvenient packaging, etc., and achieve reduced hindrance and fast drying speed , Improve the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

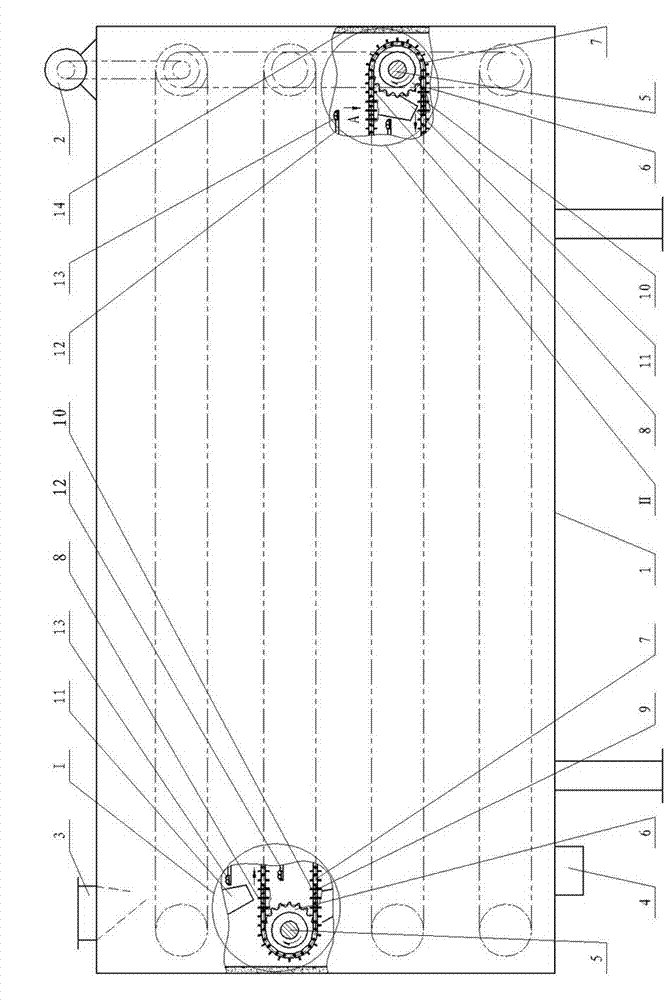

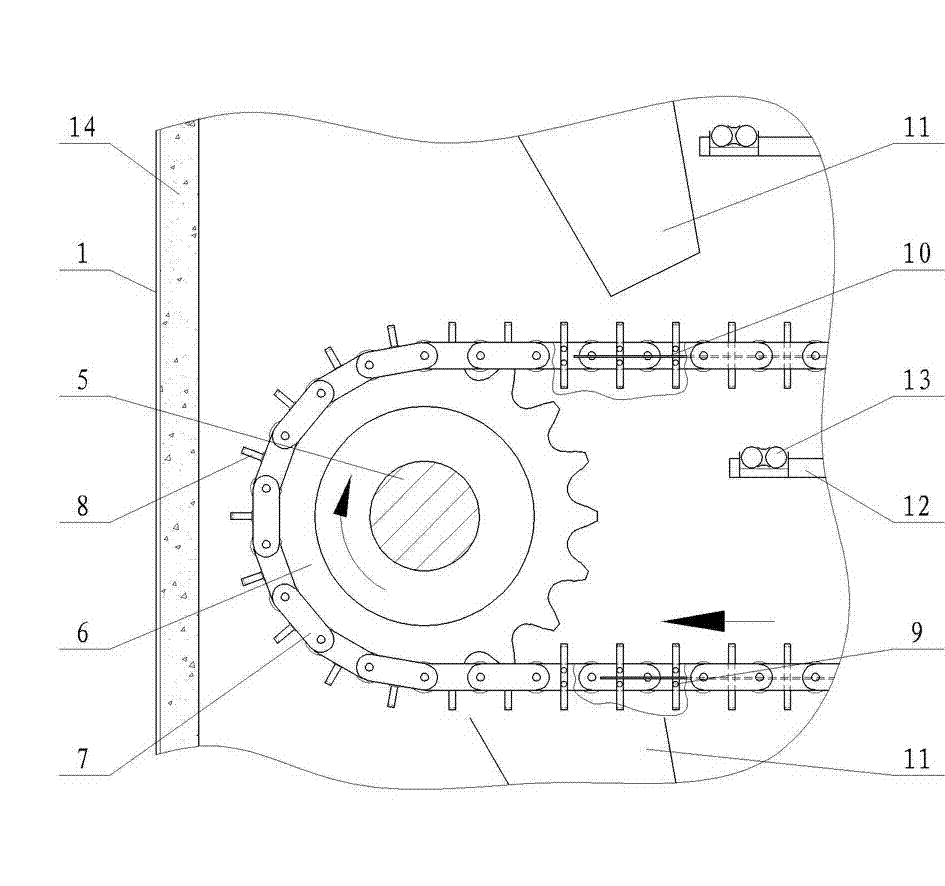

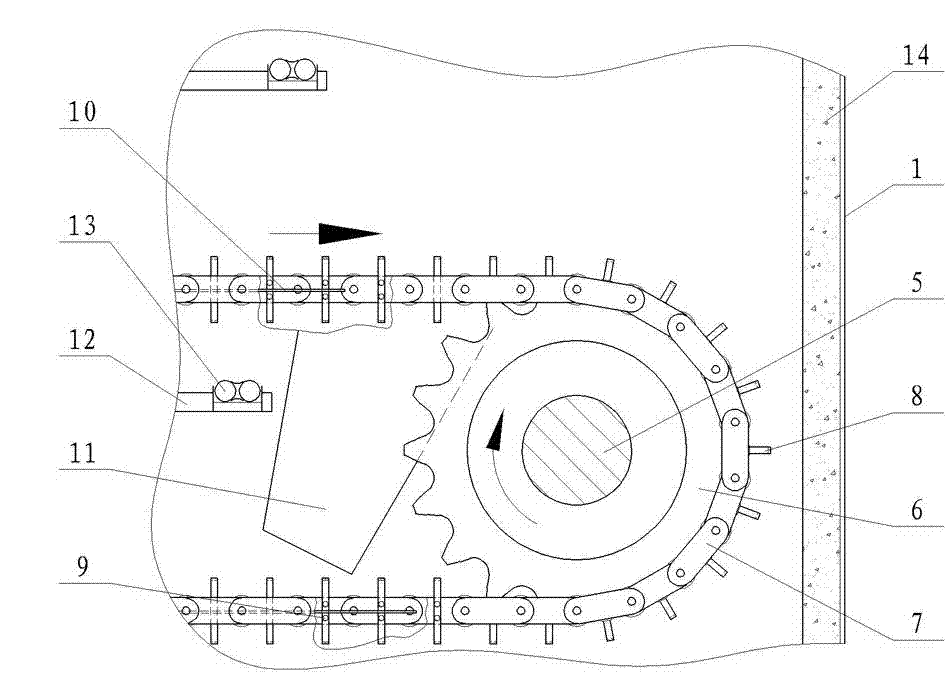

[0019] 1. Box body 2, transmission device 3, material inlet 4, material outlet 5, shaft 6, sprocket 7, chain 8, material lever 9, screw 10, support plate 11, material guide trough 12, radiation frame 13. Infrared radiation element 14. Thermal insulation layer.

[0020] exist Figure 1~5 In the shown embodiment: the top left end of the rectangular box body 1 is provided with a material inlet 3 , and the same end is provided with a material outlet 4 at the bottom of the box body 1 . There are four conveying devices along the length direction in the box body 1, and two shafts 5 of the same conveying device are arranged horizontally at both ends of the box body 1 along the length direction, and both ends of the two shafts 5 are supported on the vertical wall of the box body 1 , and the axis of the shaft 5 is perpendicular to the length direction of the box body 1; the transmission device 2 installed on the top of the box body 1 away from the right end of the feed port 3 passes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com