Patents

Literature

91results about How to "High heat transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

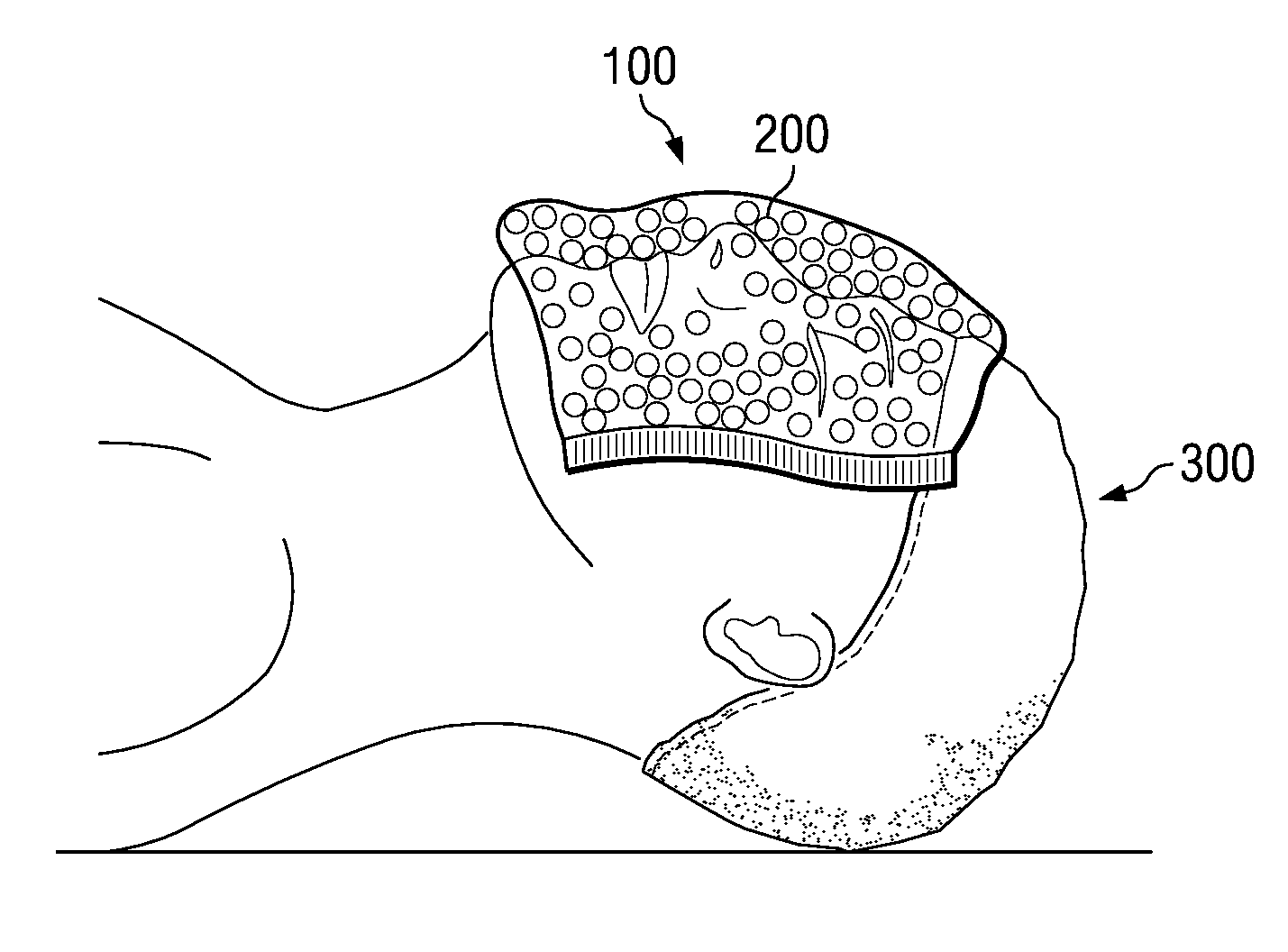

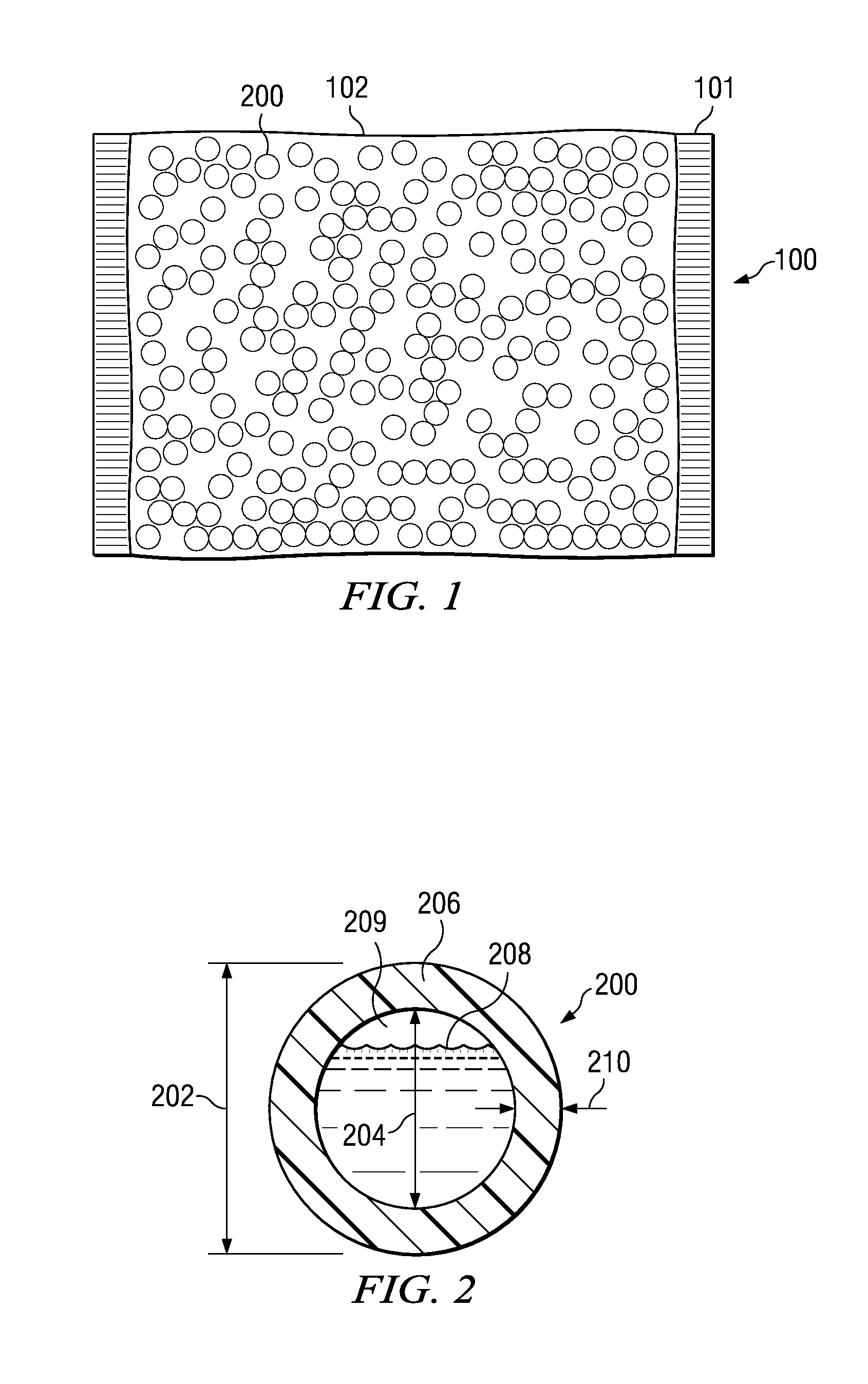

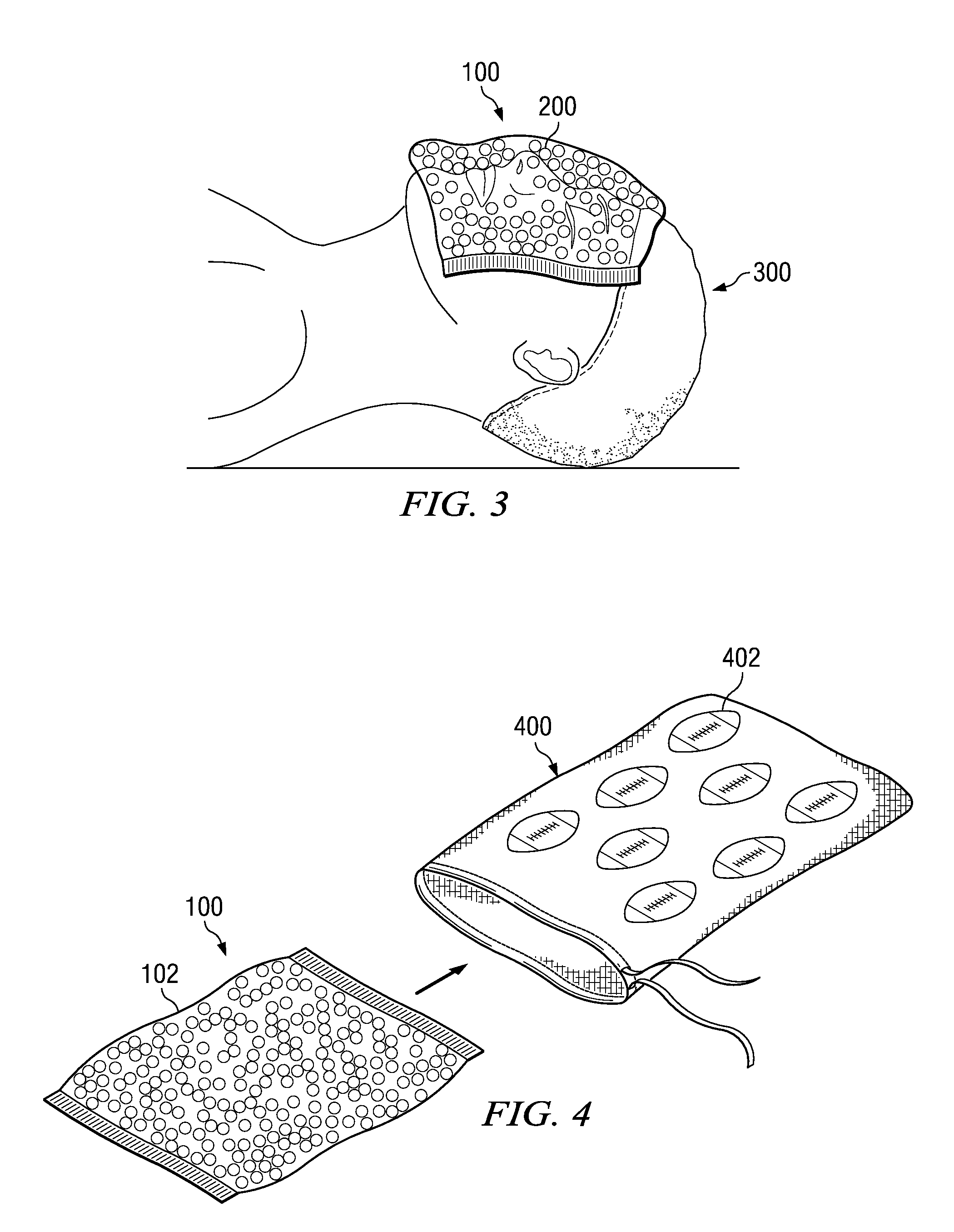

Cold compress for therapeutic cooling

InactiveUS20120165910A1High heat transferIncrease flexibilityTherapeutic coolingTherapeutic heatingCold compressesHeat transfer fluid

A novel cold compress designed for use as a cooling medium. The cold compress comprises a flexible bag having a plurality of spheres. Each sphere contains a heat transfer fluid. As the bag is cooled or frozen, each sphere and the fluid they contain become cool or frozen. The bag is then placed on a body part of the patient who is recovering from surgery or injury. The small spheres allow maximum surface contact with the body part. This allows maximum and efficient heat transfer.

Owner:CHOUCAIR RAMSEY JOE +2

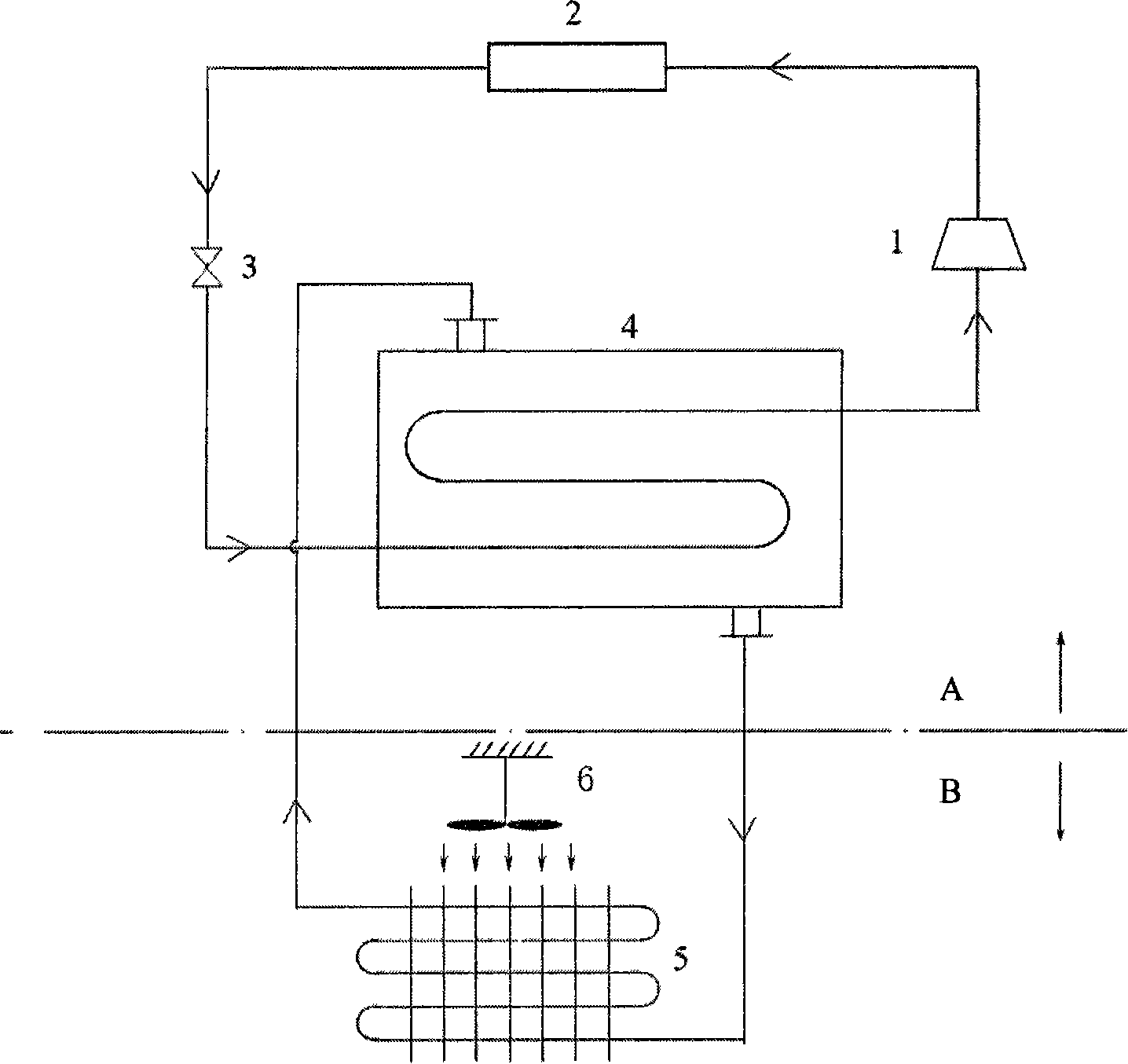

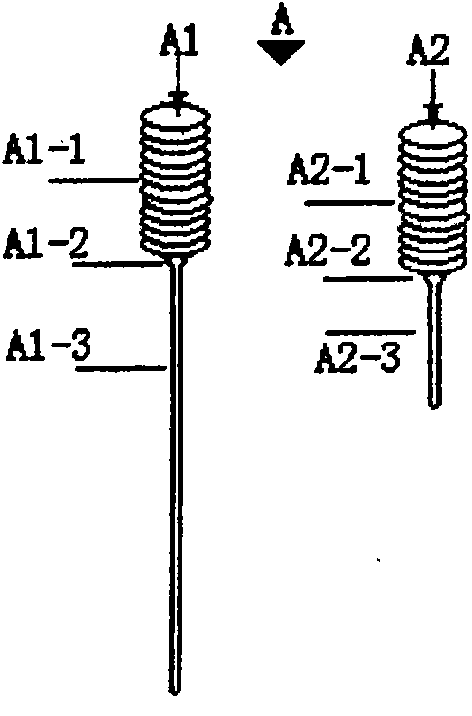

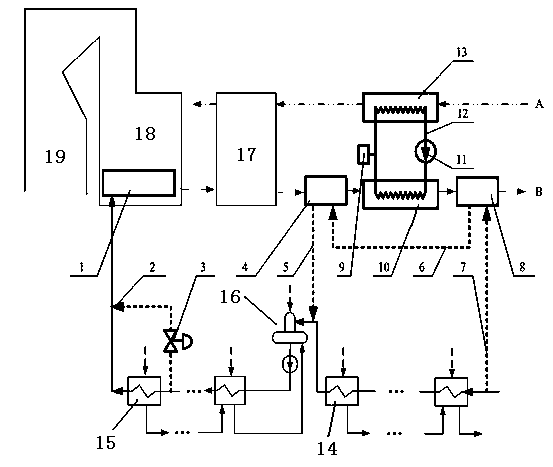

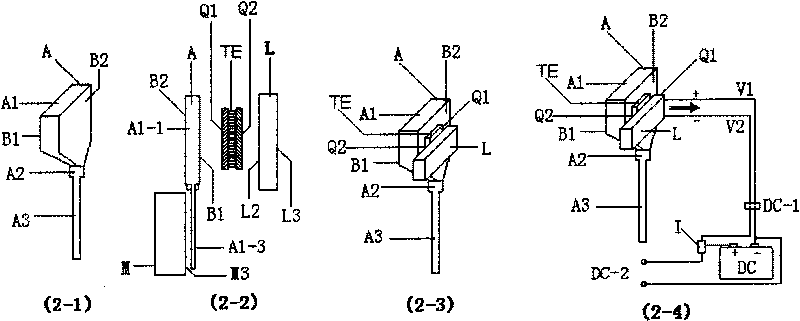

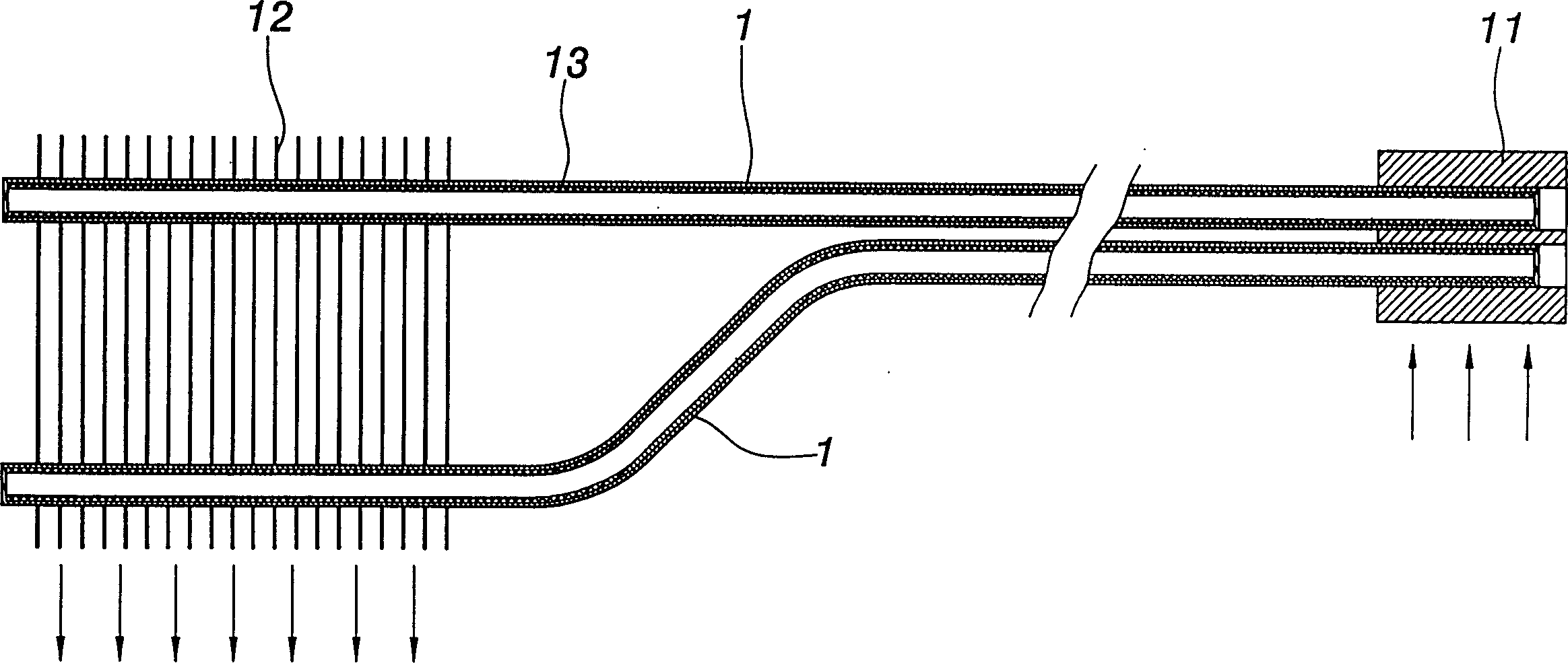

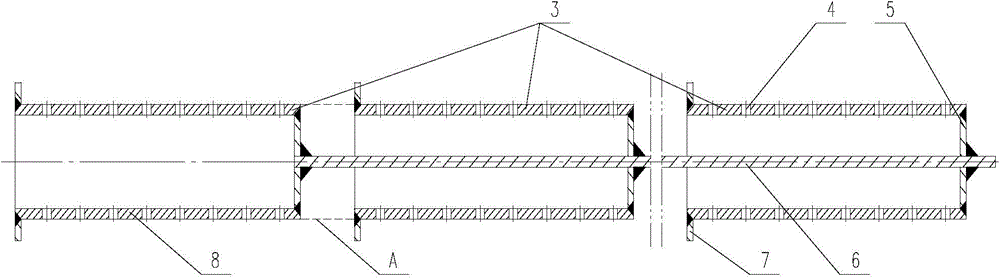

Temp lowering device for deep mine

InactiveCN101089366AEasy maintenance and managementReduce delivery volumeLighting and heating apparatusTunnel/mines ventillationEngineeringCirculating pump

The present invention discloses a deep exploitation wall temperature-dropping equipment. It includes ground machine unit A and underground machine unit B, and is characterized by that the ground machine unit A includes compressor, condenser, expansion valve and evaporative condenser, in which the inlet of compressor is connected with outlet of evaporative condenser, the outlet of compressor is connected with inlet of condenser, and the outlet of said condenser is connected with inlet of evaporative condenser by means of expansion valve. The underground machine unit B includes underground heat exchanger and air feeder, in which the bottom heat-exchanging working medium outlet of said evaporative condenser is connected with inlet of underground heat exchanger, and the outlet of underground heat exchanger is connected with top heat-exchanging working medium inlet of the evaporative condenser.

Owner:NANJING UNIV

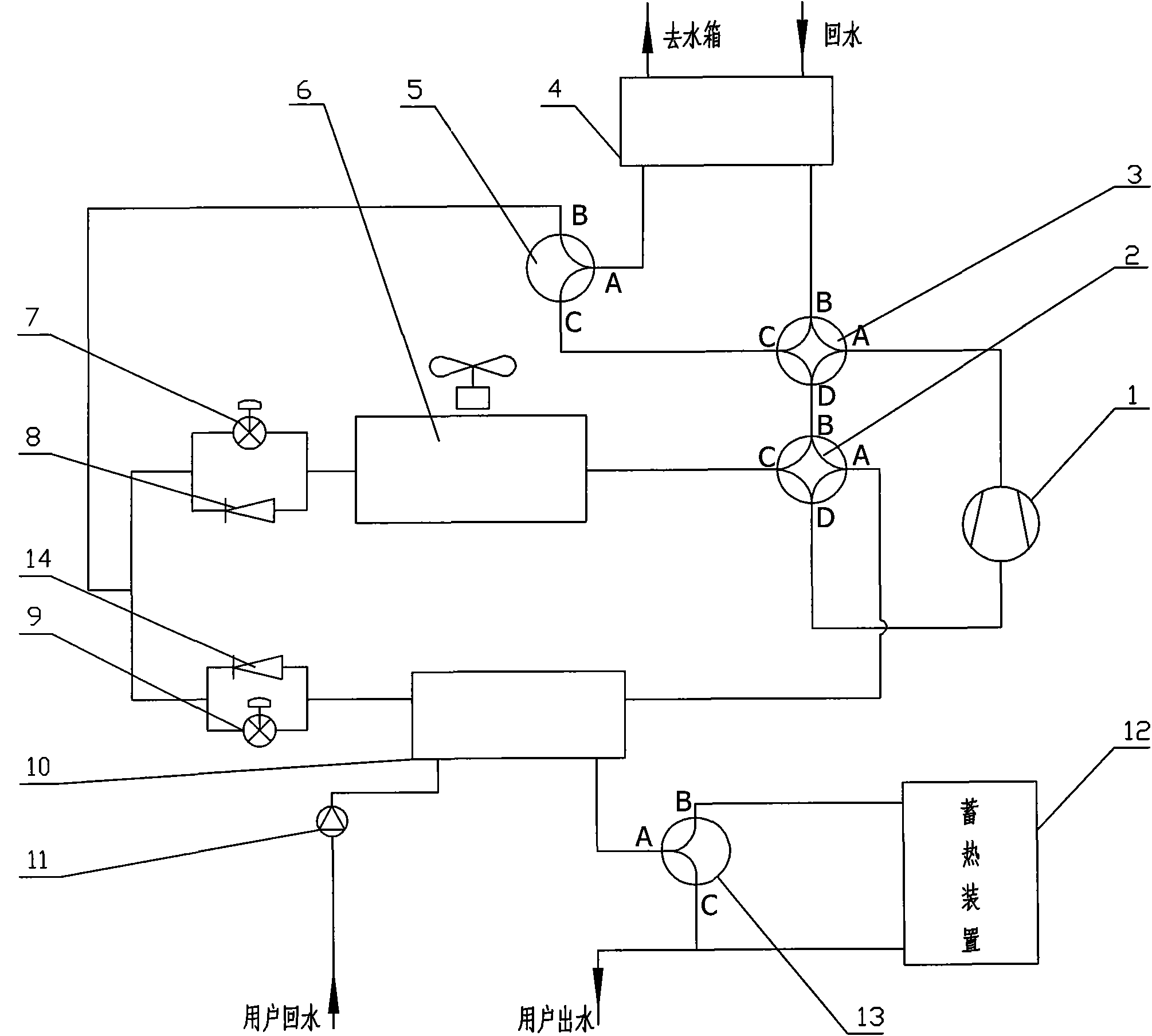

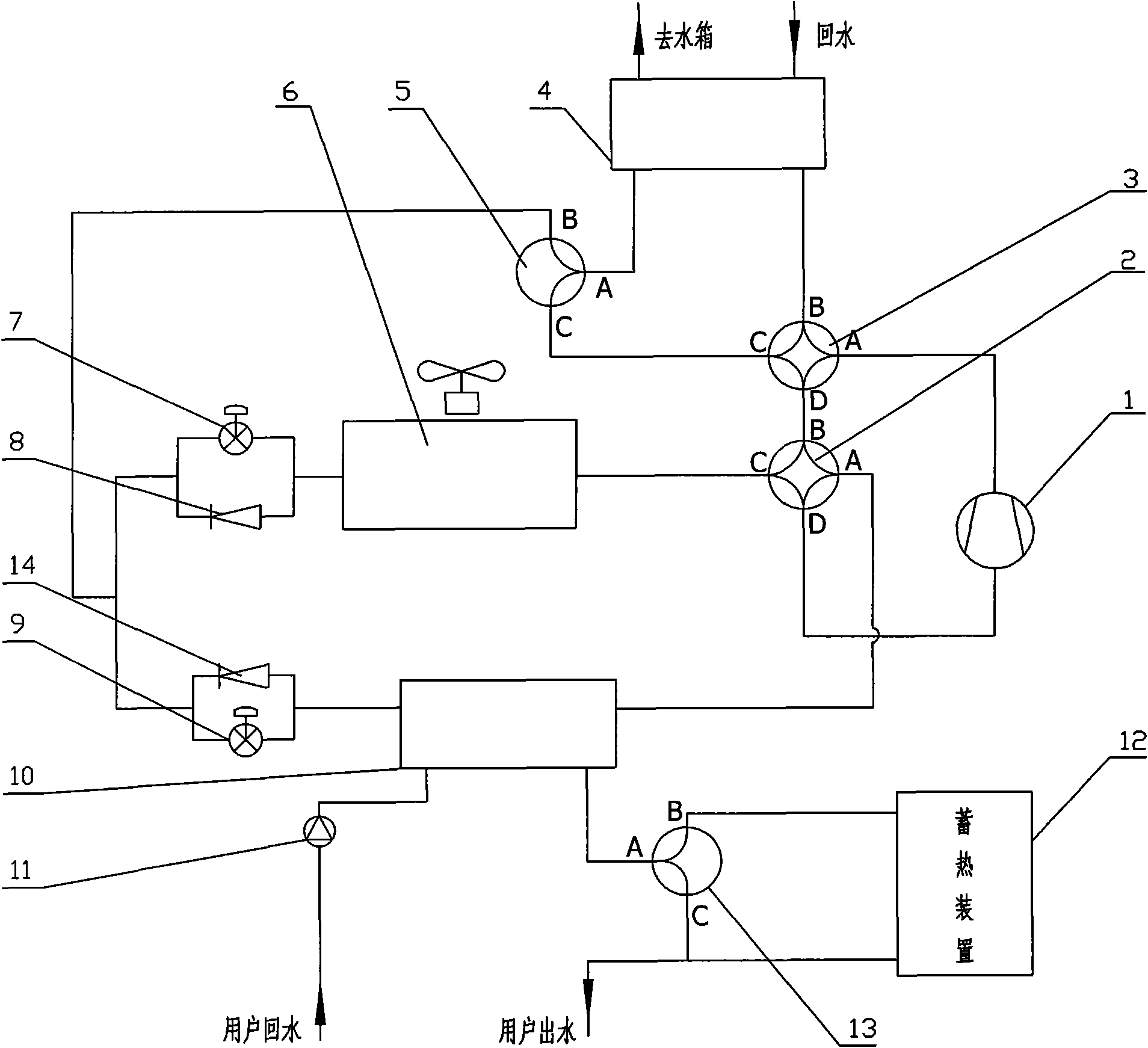

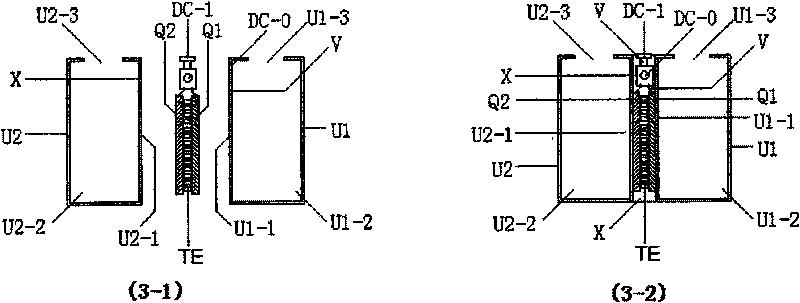

Energy-saving air-conditioning/hot water triple-supply system

InactiveCN101813401AOvercome efficiencyOvercome stabilityEnergy industryHeating and refrigeration combinationsBusiness efficiencyWater quality

The invention discloses an energy-saving air-conditioning / hot water triple-supply system, comprising a compressor (1), a hot water heat exchanger (4), an air heat exchanger (6), an air conditioning heat exchanger (10) and other parts; using main components of a heat pump system, the system adopts a structure with three heat exchangers interconnected in a mixed manner and double four-way reversing valves and has four working modes including refrigeration and water heating, water heating, heating and water heating, and defrosting, thus the triple supply of refrigeration, heating and clean hot water can be realized; the system has high heat exchange efficiency and simultaneously enhances energy efficiency ratio of system as well; by adopting the heat pipe exchangers, the system solves the problem that the heat exchanger is liable to leakage so as to pollute water, and overcomes the deficiency of large resistance when a plurality of heat exchangers are connected with each other in series.

Owner:江乐新

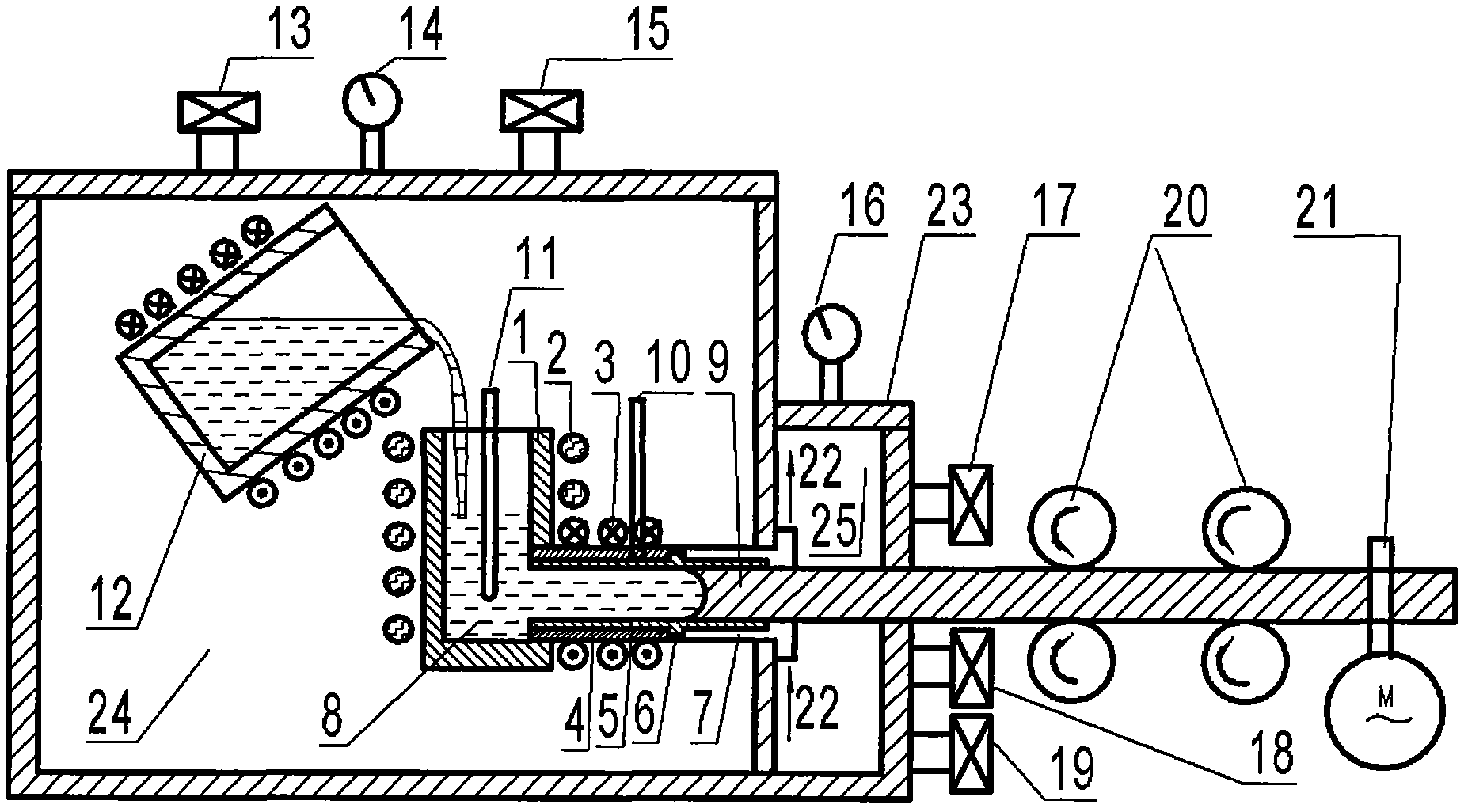

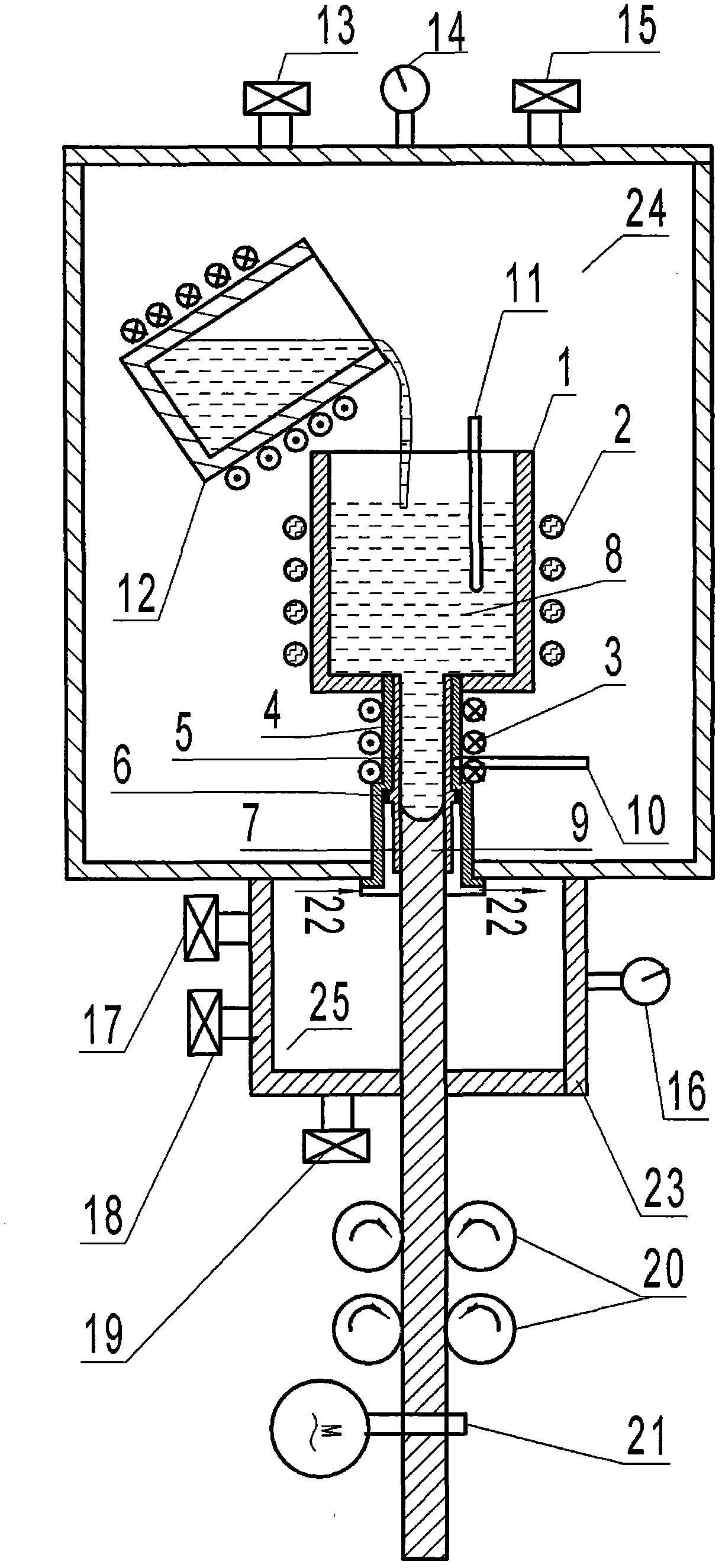

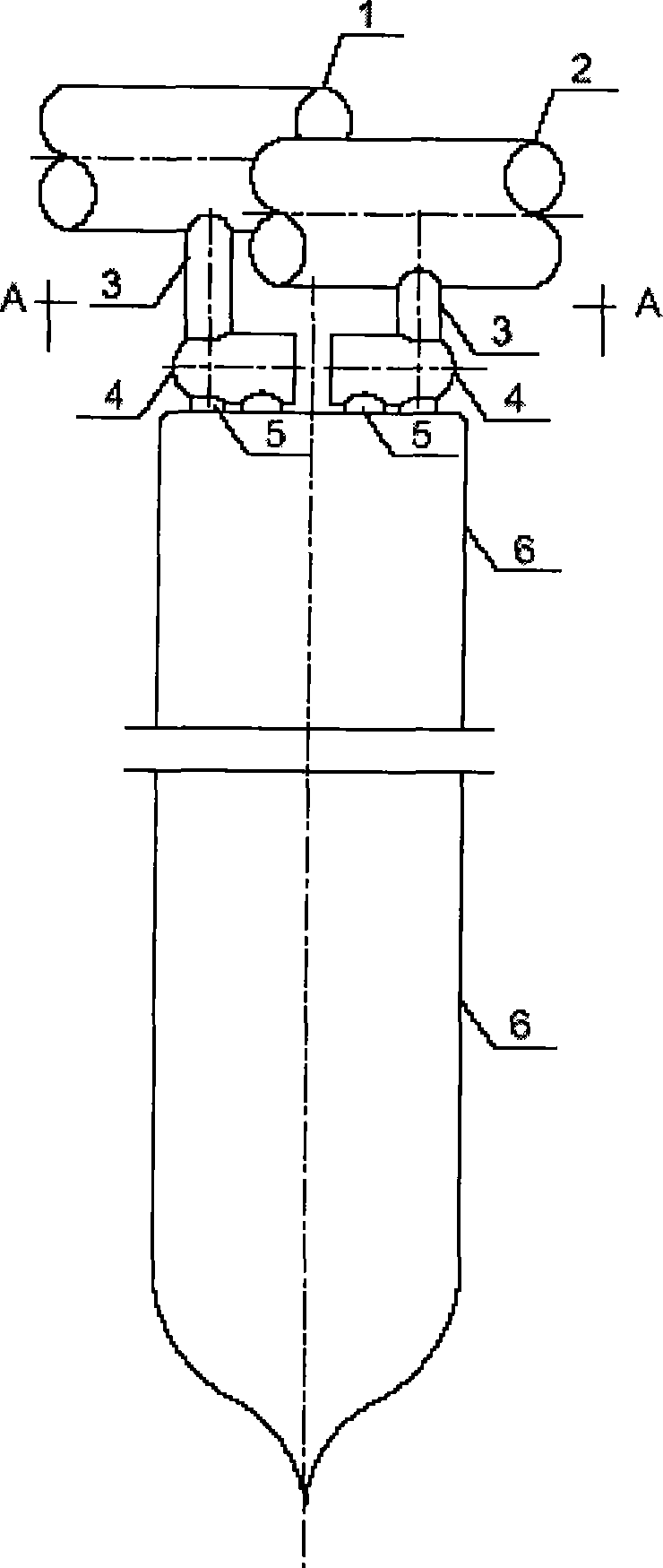

Device and method for continuously preparing bulk amorphous alloy ingots

The invention relates to a device and a method for continuously preparing bulk amorphous alloy ingots, which are characterized in that the preparation device comprises two vacuum chambers which are mutually independent. A main vacuum chamber is used for alloy melting and forming, and an auxiliary chamber is used for balancing pressure to facilitate throwing and secondary cooling. The primary cooling section of the preparation device and the method adopts a graphite pipe to be cast with a water cooling copper model embedding nest and is a main cooling part. The secondary cooling section adopts water cooling or natural cooling modes protected by inert gas and is an auxiliary cooling part. The device and the method have the advantages of having large cooling speed, meeting requirements of the bulk amorphous alloy ingots for formation, being simple in structure and capable of conveniently achieving metal continuous formation control and operation under vacuum inert gas atmosphere, and being strong in adaptability and capable of achieving continuous formation of ingots with various section shapes due to the fact that nesting cast with different inner cavity shapes and sizes, thereby being mainly suitable for continuous manufacture fields of the bulk amorphous alloy ingots.

Owner:王东

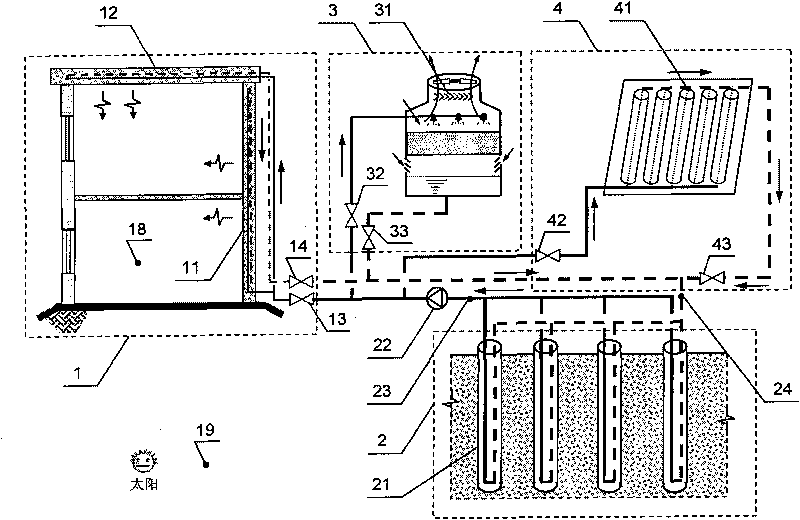

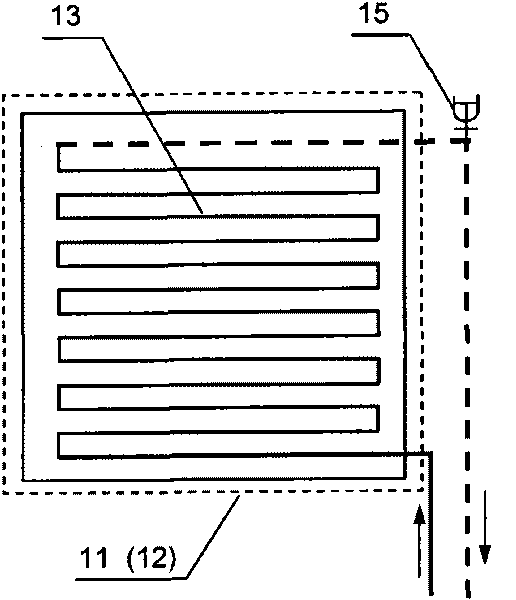

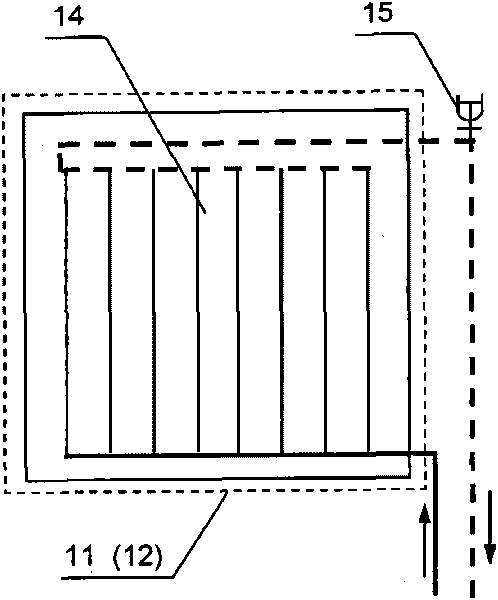

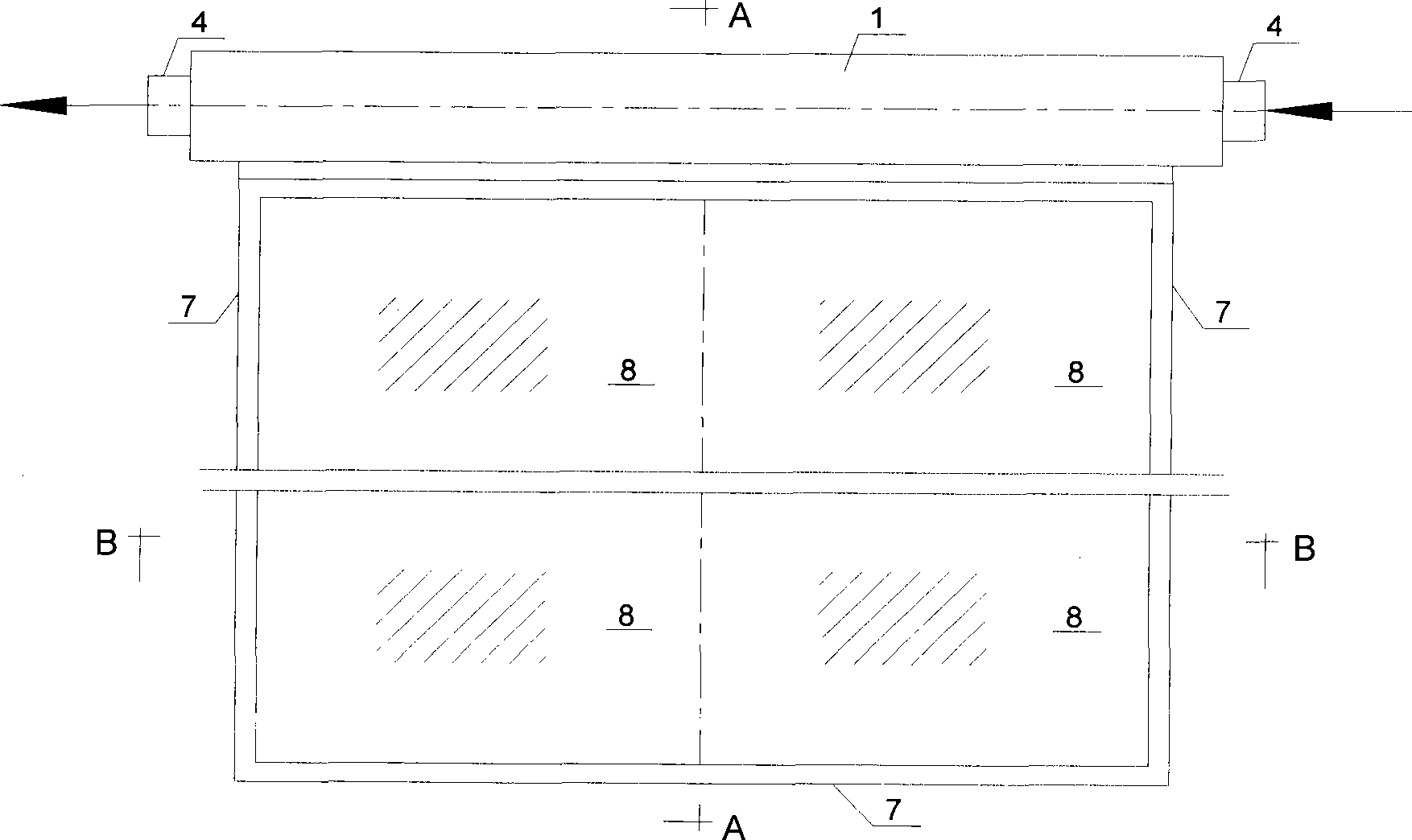

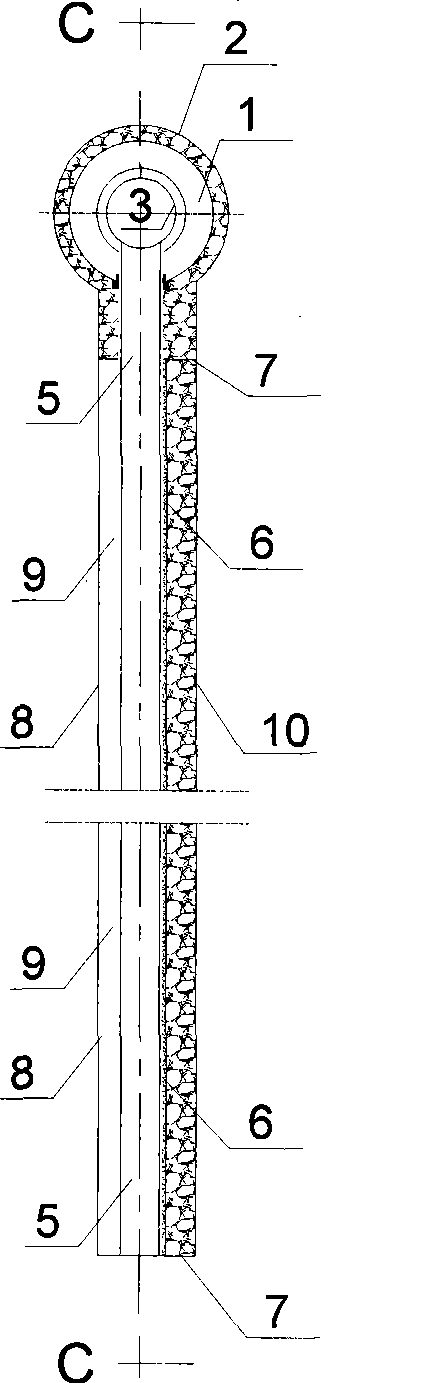

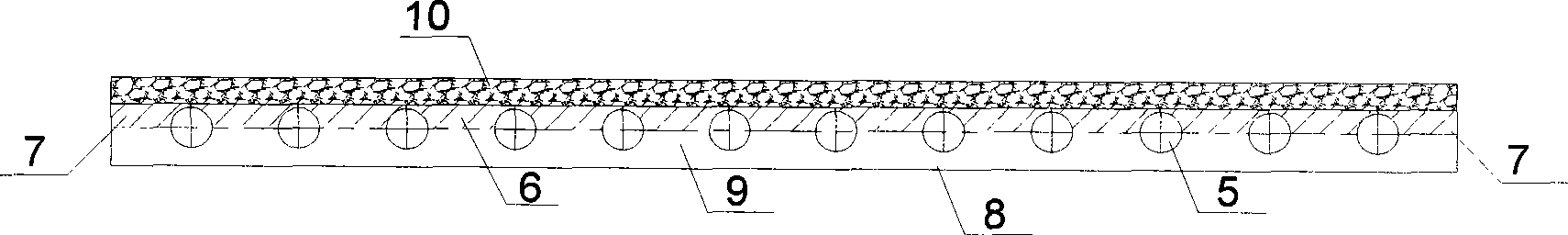

Embedded pipeline air-conditioning system of envelop enclosure and control method thereof

InactiveCN101761998AHigh heat transferImprove comfortSpace heating and ventilation safety systemsLighting and heating apparatusHeat transmissionLower grade

The invention discloses an embedded pipeline air-conditioning system of envelop enclosure and control method thereof, which belongs to the field of green air conditioning capable of using renewable low grade energy. The air-conditioning system includes a building heat exchange part, an energy storage part, an auxiliary cold source part, an auxiliary heat part, and a power conveying part. The invention embeds a pipeline in an envelop enclosure to enlarge the heat exchange area between a circulating fluid and the envelop enclosure so as to realize low temperature difference heat transmission when directly using the renewable low grade energy and obtain a large heat exchange volume so as to realize the direct storage of heat and cold energy simultaneously when heating and cooling, captures the renewable low grade energy through the auxiliary cold source part and the auxiliary heat part, and implements storage through the energy storage part so as to further improve the heating and cooling capacities of the system. The air-conditioning system can sufficiently use the renewable energy to reduce the influence of outdoor climate to the indoor environment, thereby greatly reducing and even canceling the dependence upon high grade energy for meeting the indoor comfort requirements.

Owner:HUAZHONG UNIV OF SCI & TECH

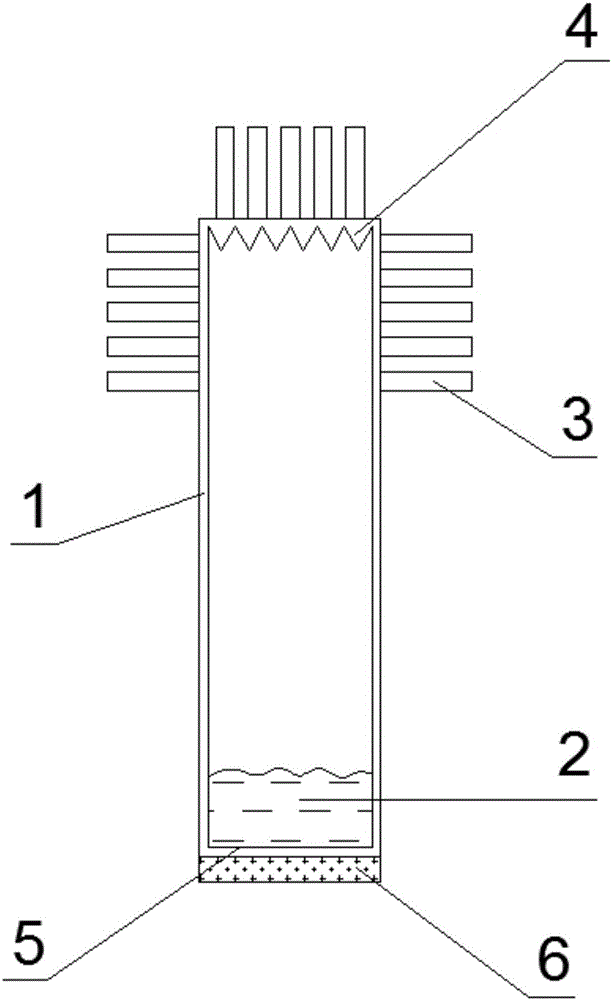

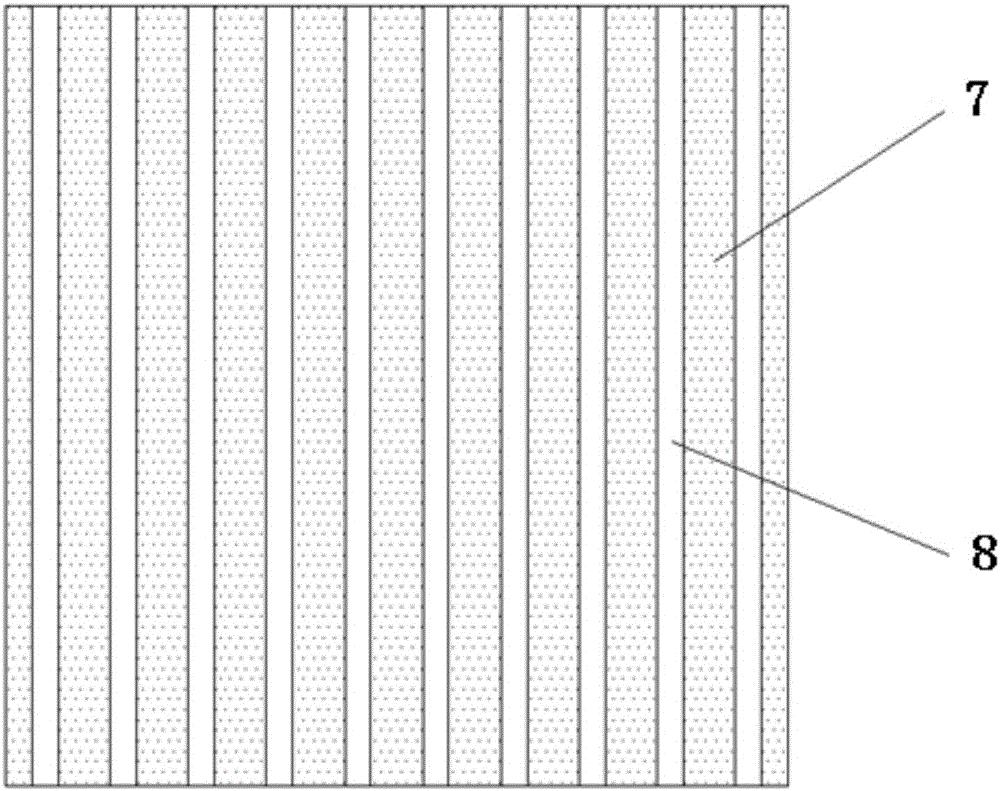

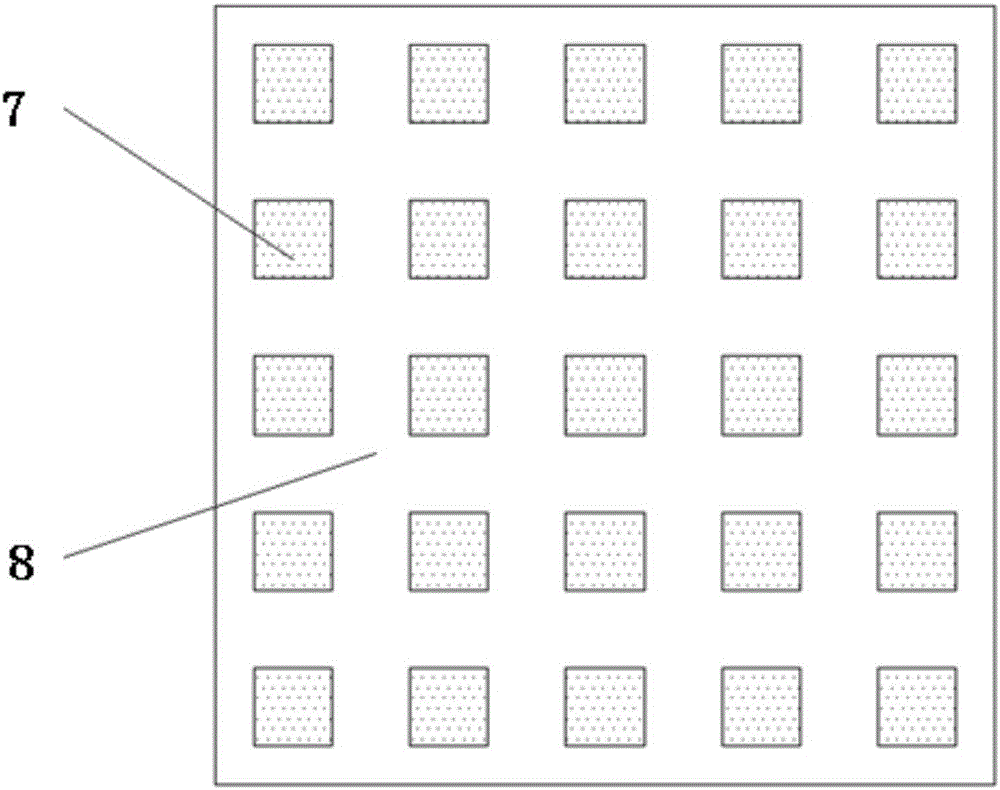

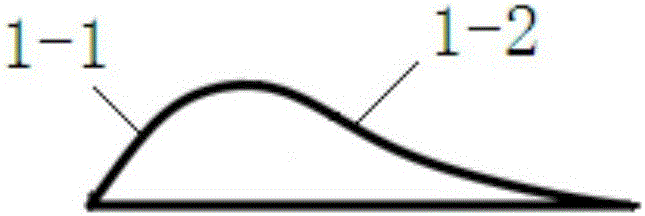

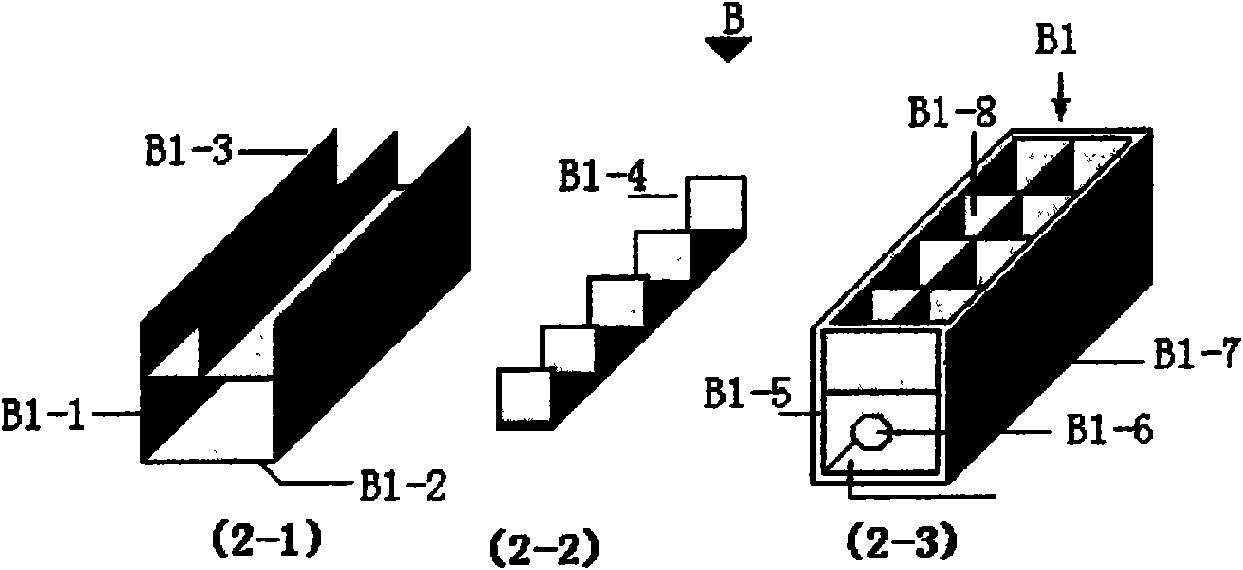

Preparation of uneven humid efficient phase changing coating and gravity assisted heat pipe device

The invention discloses an uneven humid efficient phase changing coating preparation and a gravity assisted heat pipe device. The gravity assisted heat pipe device comprises a pipe body with two sealed ends; liquid working medium is poured into the pipe body; the upper portion of the pipe body is a condensation section, and the lower portion of the pipe body is an evaporation section; the inner top wall of the condensation section is a zigzag-shaped structure face; the uneven humid coating covers the inner side wall of the condensation section, the zigzag-shaped structure face and the inner bottom face of the evaporation section; the uneven humid coating comprises dewatering areas and hydrophilic areas; the uneven humid coating covering the zigzag-shaped structure face of the condensation section is of the structure that the straight stripes of the dewatering areas and the hydrophilic areas are distributed alternately; and the direction of the straight stripes is perpendicular to the zigzag grooves of the zigzag-shaped structure face. The gravity assisted heat pipe device can improve heat flux of an evaporation process and a condensation process remarkably. According to gravity assisted heat pipe device, depending on the operation rules of gravity assisted heat pipes, drawbacks existing in current gravity assisted heat pipes are overcome; working medium cycling speed is improved; and heat transfer load of the heat pipes is strengthened.

Owner:SOUTH CHINA UNIV OF TECH

Solar collector-oven combined clothes drying device

InactiveCN102268806AEliminate the phenomenon of good imageImprove availabilityLaundry dryer apparatusTextiles and paperSocial benefitsAromatherapy

The invention relates to a solar heat collector-oven combined clothes drying device, comprising a solar drying box, the solar drying box includes a heat transfer pipe, a temperature and humidity meter, an incubator, a movable glass door, a fan and a regulating valve, and the heat preservation There are three rows of heat transfer pipes in the box, and regulating valves are installed on the heat transfer pipes. There are movable glass doors on the front and back of the incubator, fans are installed on the rear movable glass doors, and a temperature and humidity instrument is installed on the side. Inside the incubator. Compared with the prior art, the present invention occupies a small area, can be used indoors under the condition of completely imitating the "natural environment", and is equipped with an ultraviolet disinfection lamp and a hollowed-out aromatherapy box, which can dry clothes while drying them. Sterilization and fresh air achieve better results than outdoor drying. The invention can be effectively applied to various families, hotels, schools, etc., and has high practical value and economic and social benefits.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

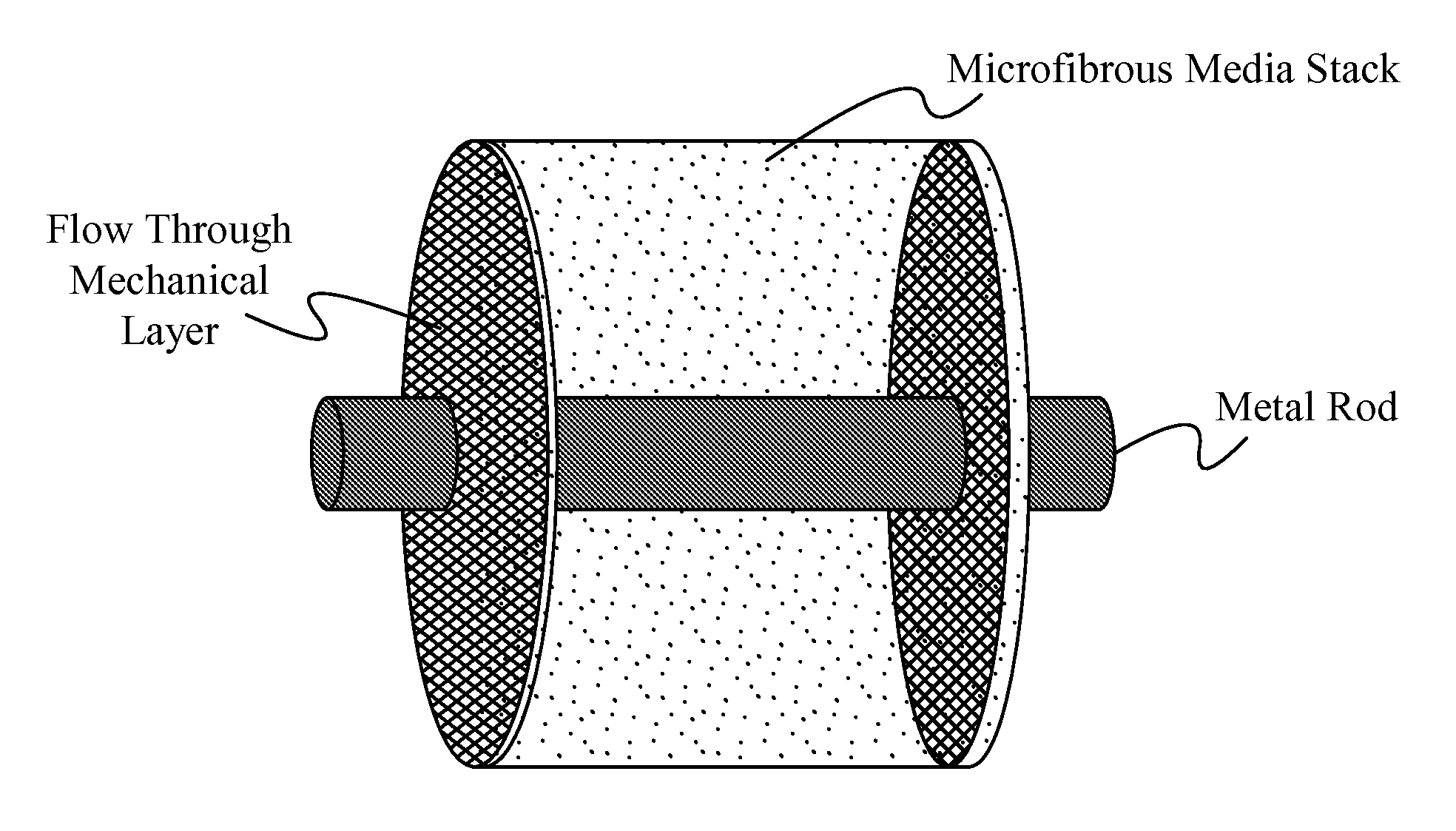

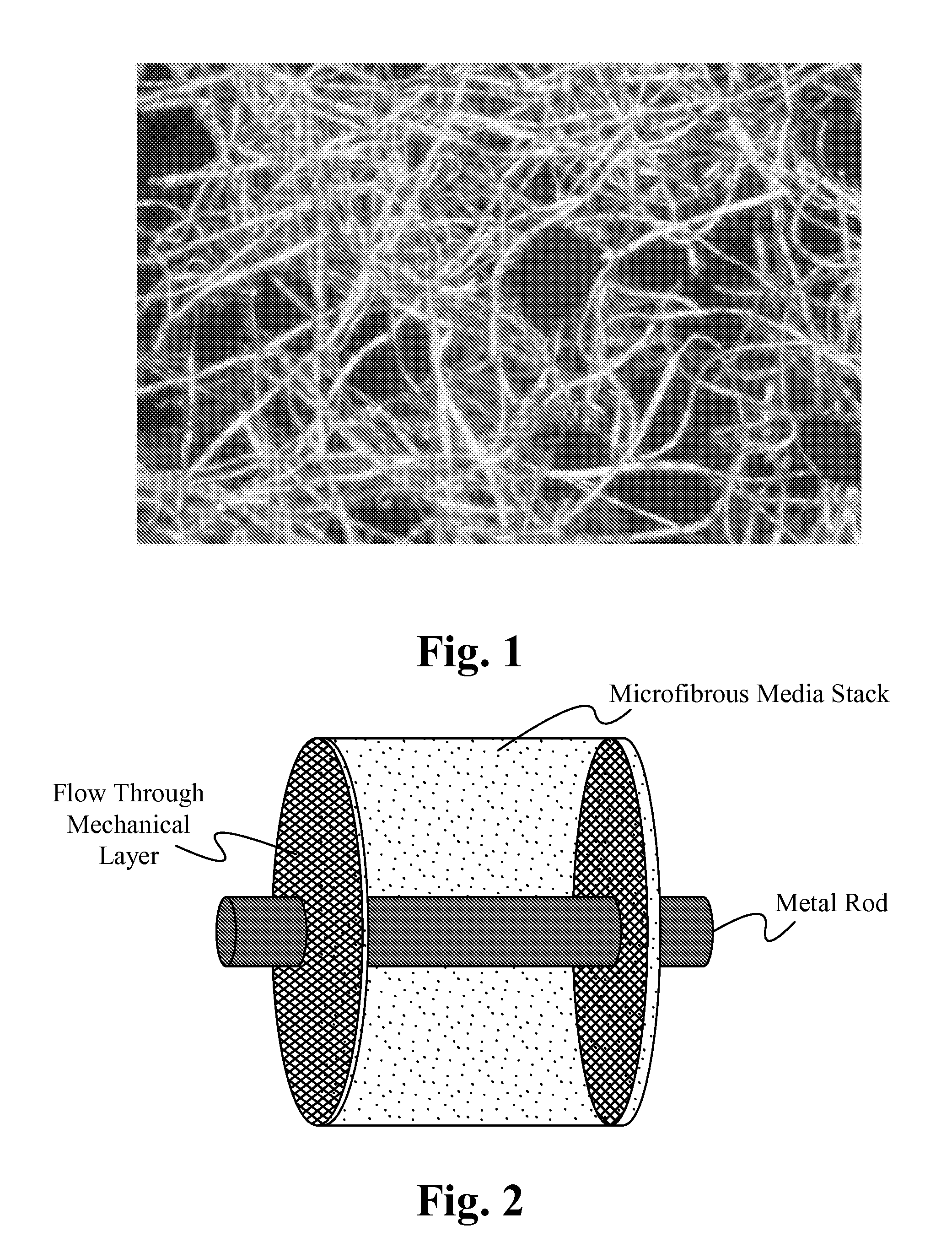

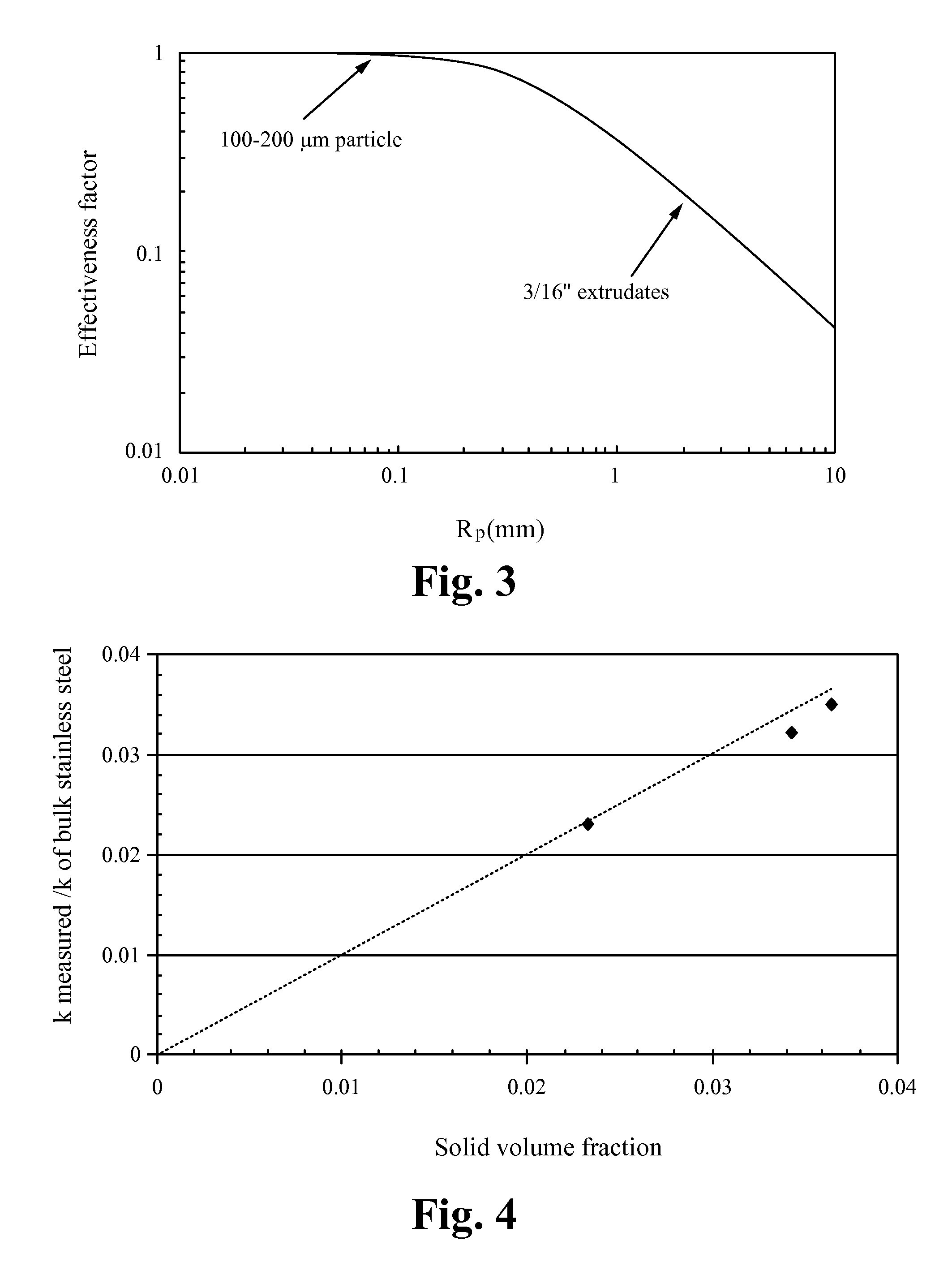

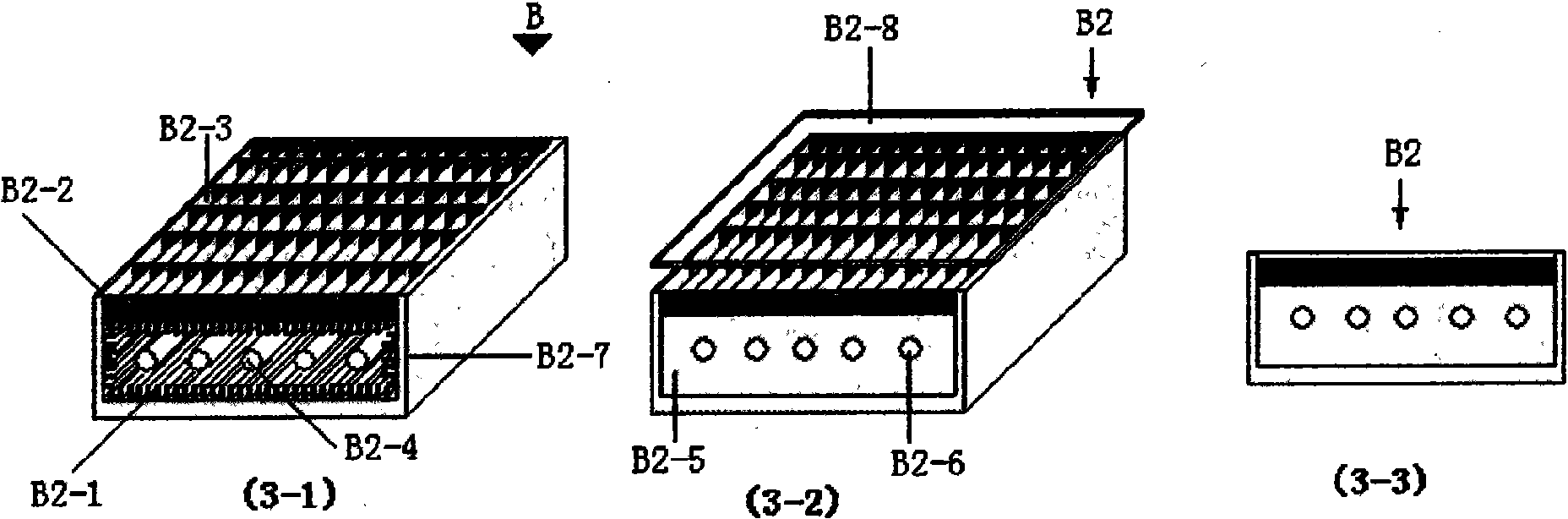

Microfibrous media and packing method for optimizing and controlling highly exothermic and highly endothermic reactions/processes

ActiveUS20110135543A1High thermal conductivityHigh heat transferPhysical/chemical process catalystsChemical/physical/physico-chemical processesChemistrySorption

A vessel packed with a microfibrous media made of micron-sized highly conductive fibers, which are able (and may be used) to immobilize various reactive materials including catalysts, sorbents, electrocatalysts, and other chemically reactive solids. The vessel enables fine temperature control and a uniform temperature profile for a range of highly endothermic or exothermic chemical reactions, sorptions, separation processes, mixing operations, and heat transfer applications.

Owner:INSTREETCARICRON +1

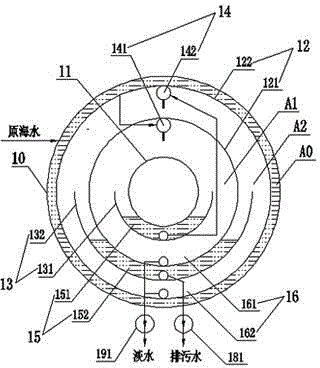

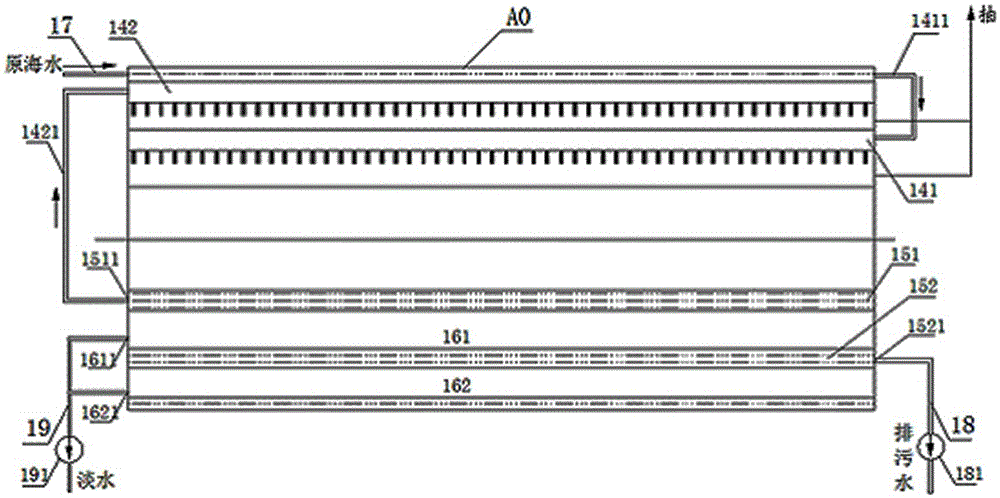

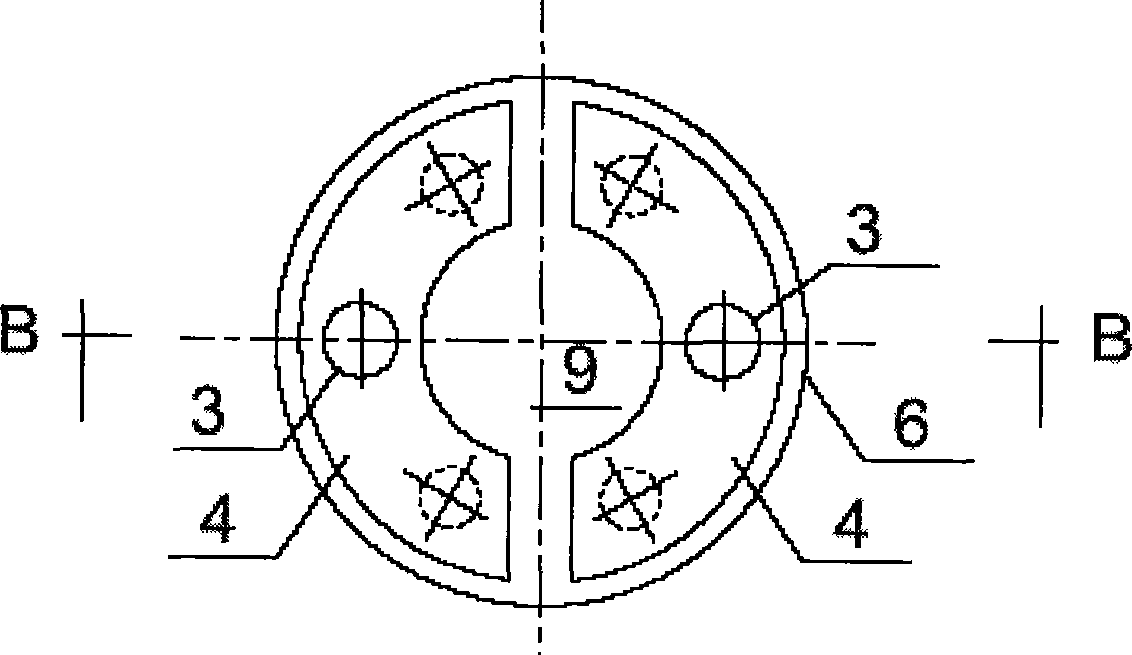

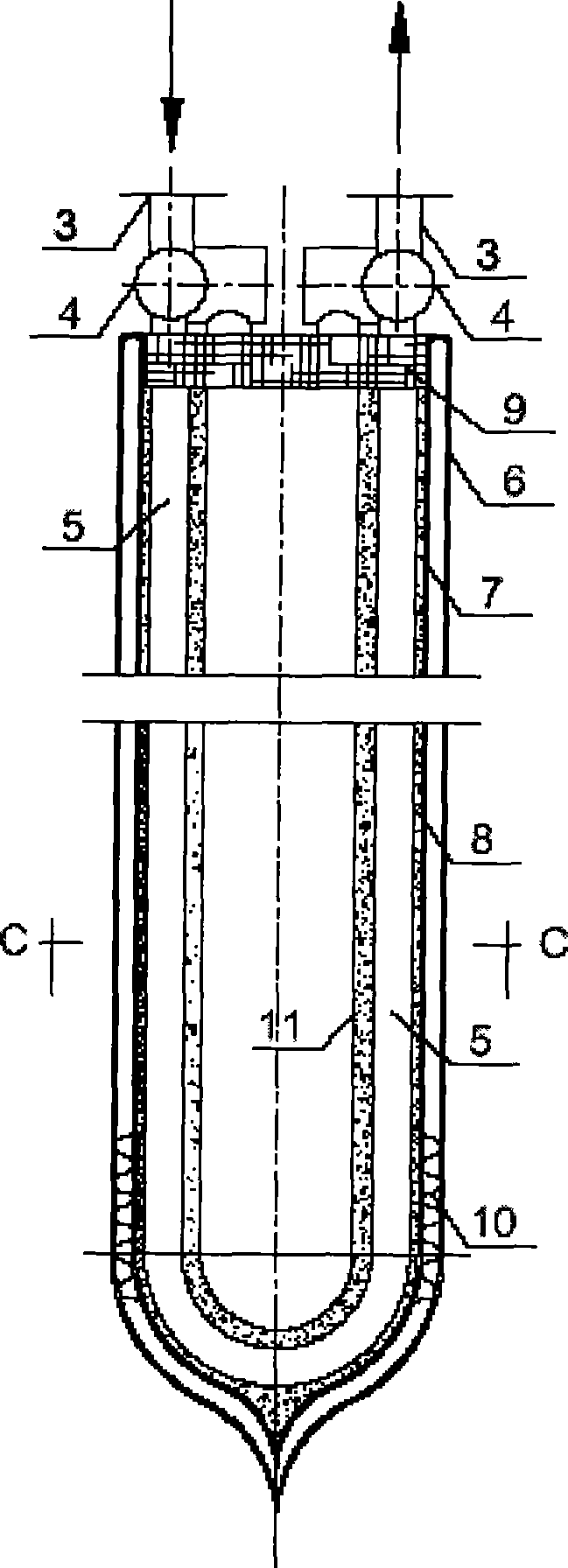

Loop heat pipe-type cylindrical solar seawater desalination device

ActiveCN104591327AIncrease heat transfer distanceHigh heat transferGeneral water supply conservationSeawater treatmentDistillationConcentration ratio

The invention discloses a loop heat pipe-type cylindrical solar seawater desalination device. The device comprises a cylindrical multiple-effect distiller, a light collection groove and a loop heat pipe. An evaporating pipe of the loop heat pipe is used as a solar heat collecting pipe and a condenser pipe of the loop heat pipe is used as a distiller heating pipe so that characteristics of good heat transfer performance and high integral efficiency are obtained. A heating pipe, a heat-transfer pipe, a semi-circular groove and a nozzle unit are tightly arranged in a heat-insulation cylinder inner-cavity so that a pre-heating chamber, a distillation chamber, a seawater tank and a fresh water tank are formed and thus the distiller structure is very compact, can be processed easily and is suitable for standard production. The distiller has the characteristics of repeated use of vaporization latent heat, reinforcement of inner heat and mass transfer processes and improvement of an operation temperature. The heat transfer areas of the distillation chamber are increased from inside to outside so that a small heat transfer temperature difference is kept, the whole distiller effective number is improved and a concentration ratio and a water yield are further improved. The loop heat pipe-type cylindrical solar seawater desalination device is suitable for low-cost modularization production and can be widely used in the field of solar energy seawater desalination.

Owner:JIMEI UNIV

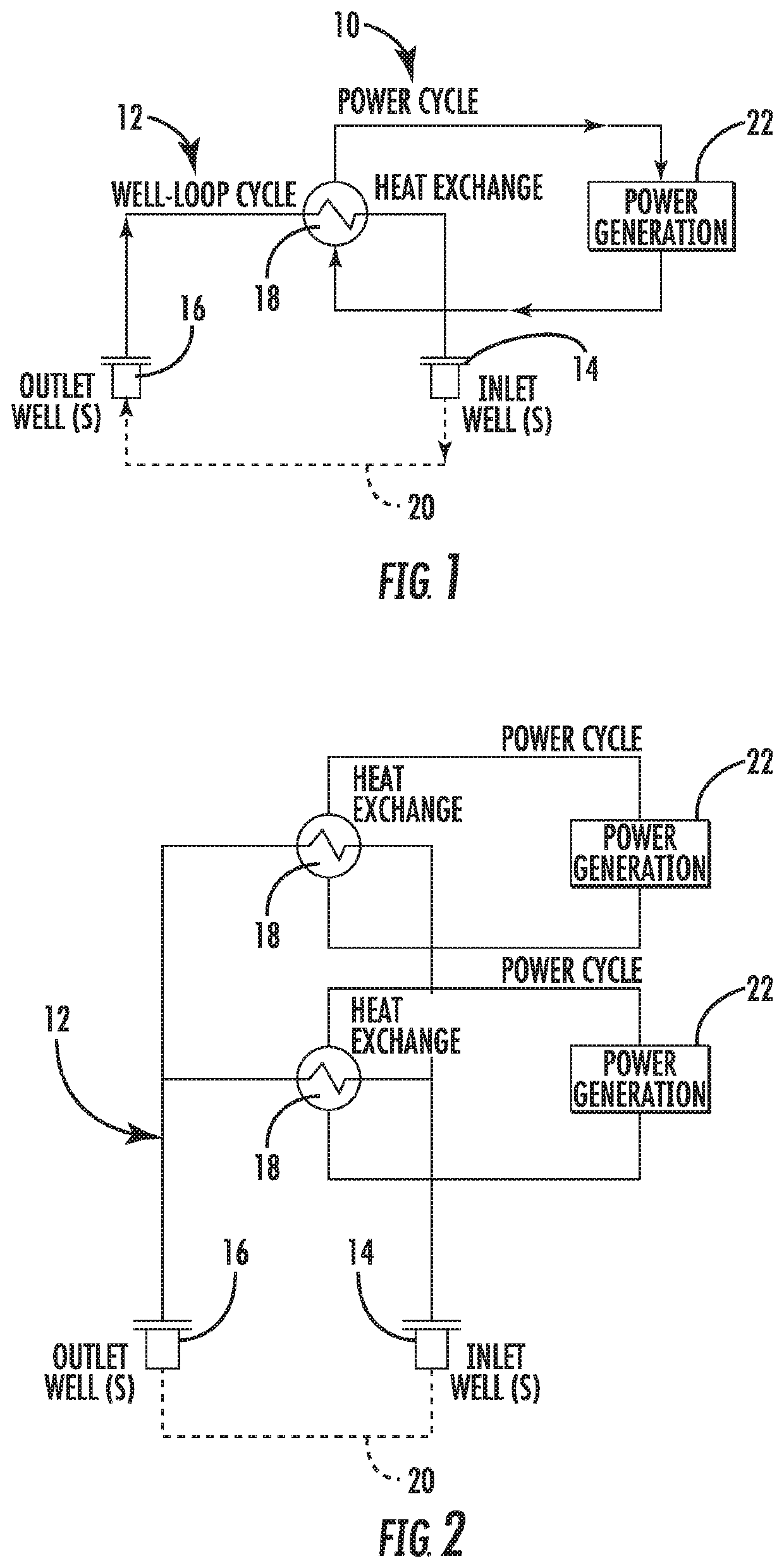

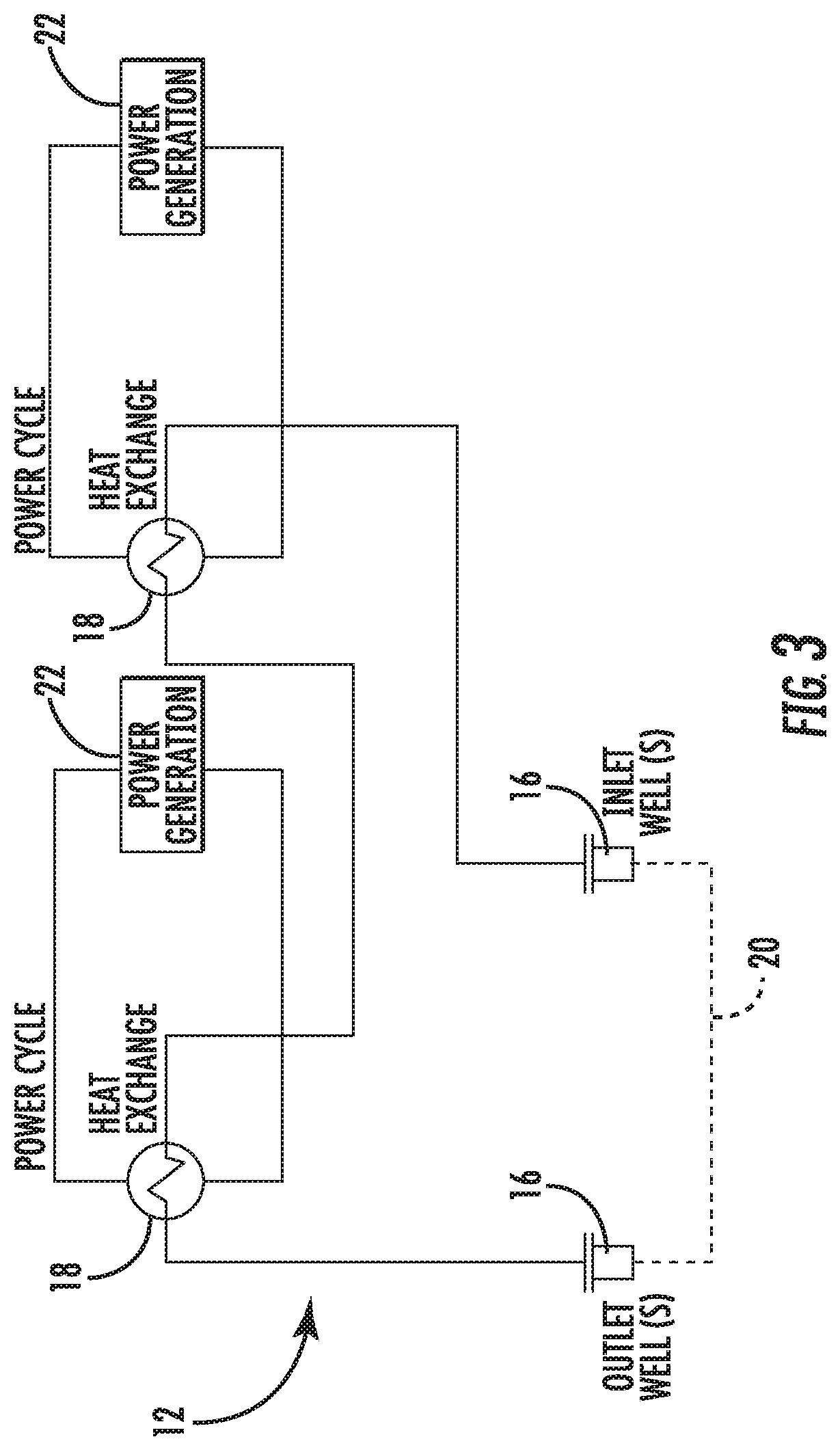

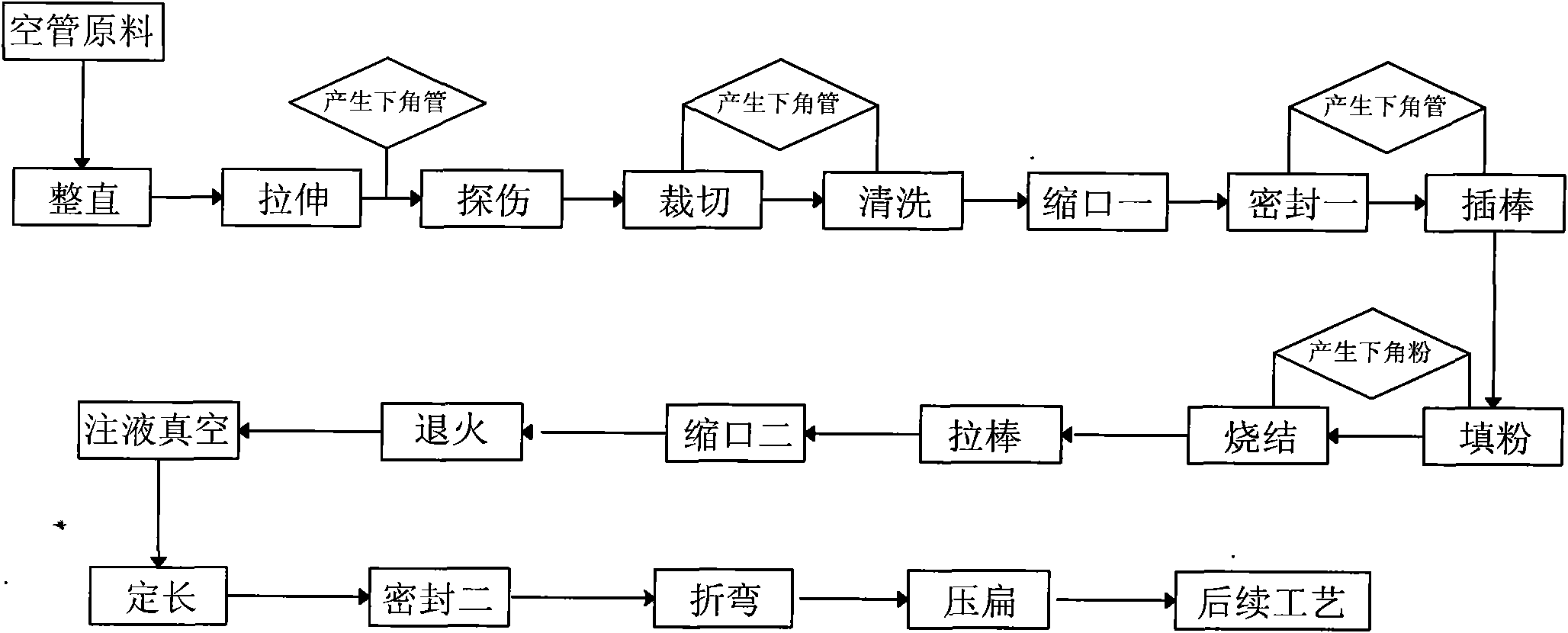

Fluid for use in power production environments

ActiveUS20190346181A1Wide applicabilityMaximize temperatureCollector components/accessoriesLighting and heating apparatusElectricityClosed loop

Fluid classes for use in energy recovery in well and geothermal environments for power production are disclosed. The fluids fall into the classes of fluids being capable of increasing thermodynamic efficiency of electricity and / or heat generation from a closed-loop geothermal system. Numerous methods are disclosed which exploit the thermodynamics of the fluids for optimum energy recovery.

Owner:EAVOR TECH INC

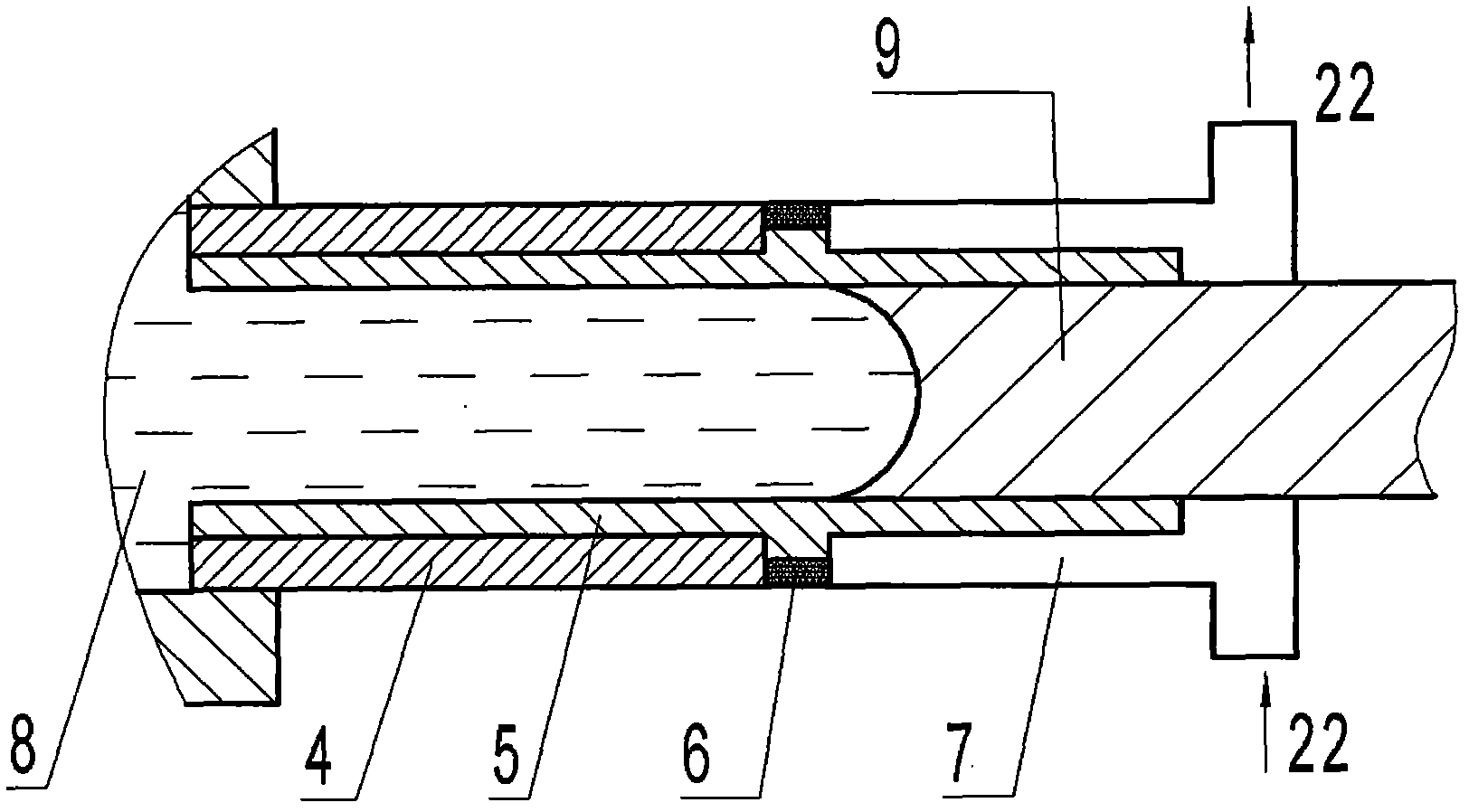

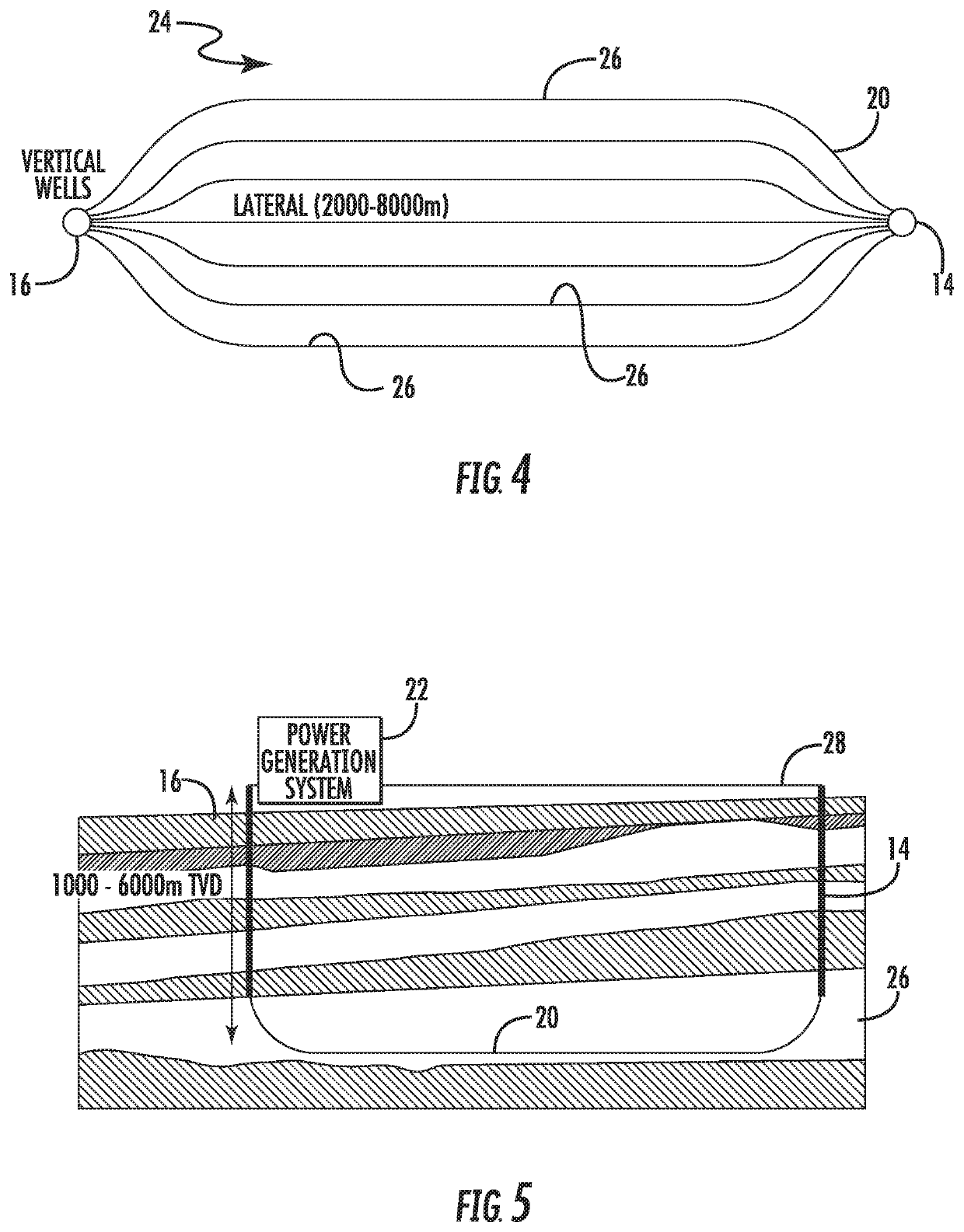

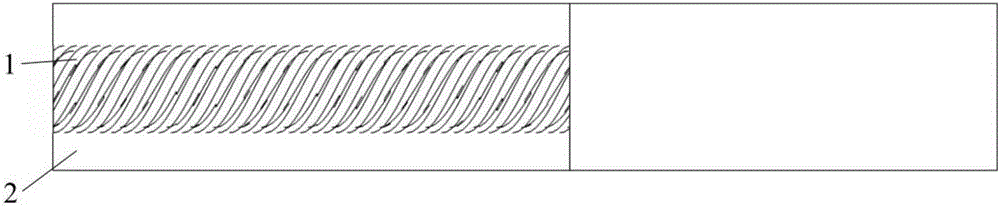

Manufacturing method of heat pipe

InactiveCN101799249AHigh thermal conductivityImprove flowIndirect heat exchangersHeat conductingEngineering

The invention discloses a manufacturing method of a heat pipe, comprising the following steps: preparing raw materials, cutting a blank pipe, necking down and sealing A, filling in powder, sintering, necking down, sealing B and flooding in vacuum. The heat pipe manufactured with the technical method of the invention is provided with a groove part on the inner wall to ensure that the groove part is favorable for steam to flow to a condensing zone from the heat zone of the heat pipe, thus improving heat conduction efficiency; the inner side of the groove part is provided with a powder sintering part, and powder is bigger than a groove gap so as to avoid adverse effect caused by the way that power is clamped into the groove; a capillary gap between powder sintering parts can store more moisture so as to amplify heat transfer amount, and the flow resistance of condensation hydraulic fluid in the capillary gap becomes small so as to assist in improving the heat-conducting property of the heat pipe.

Owner:ZHONGSHAN WEIQIANG TECH

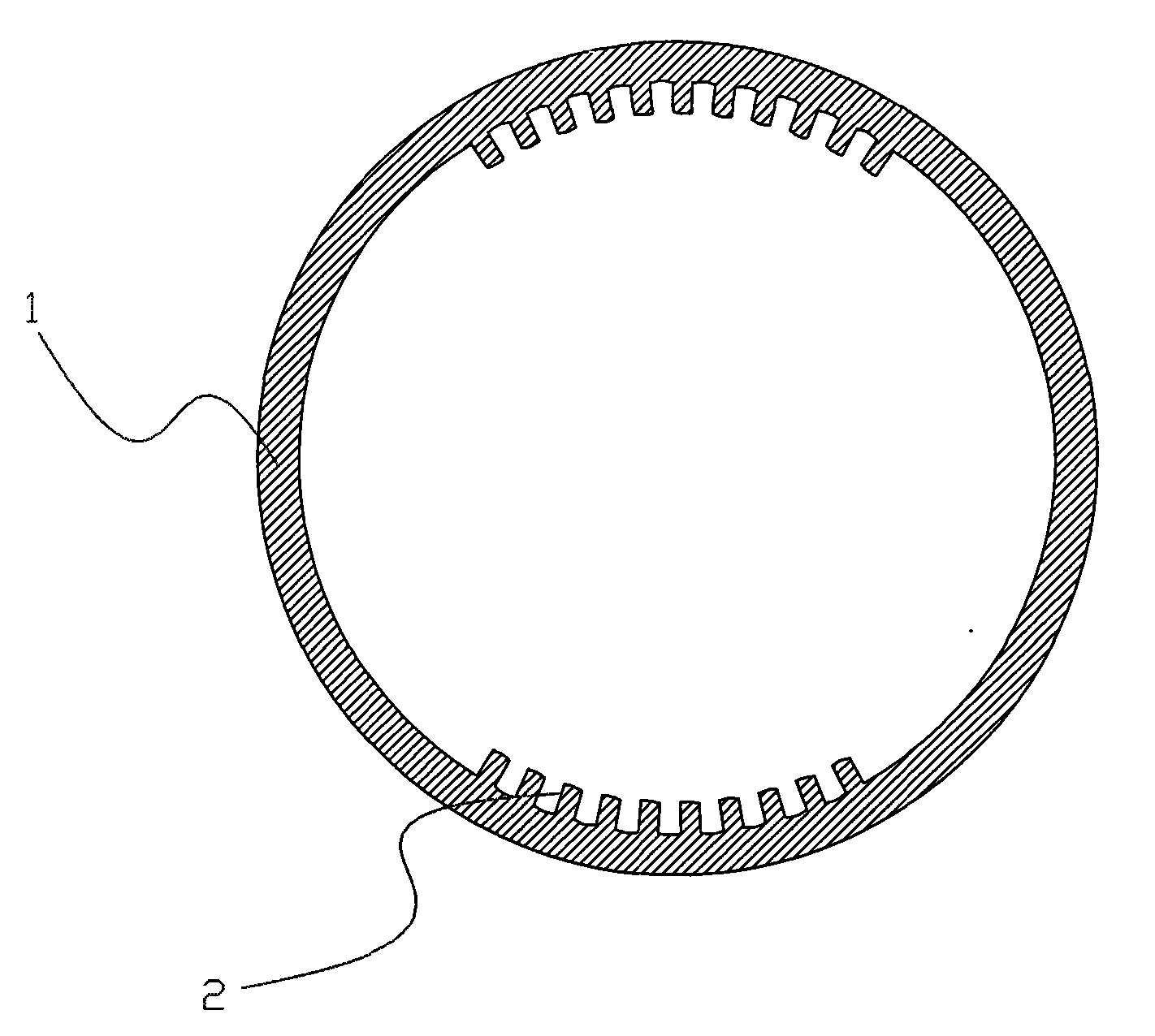

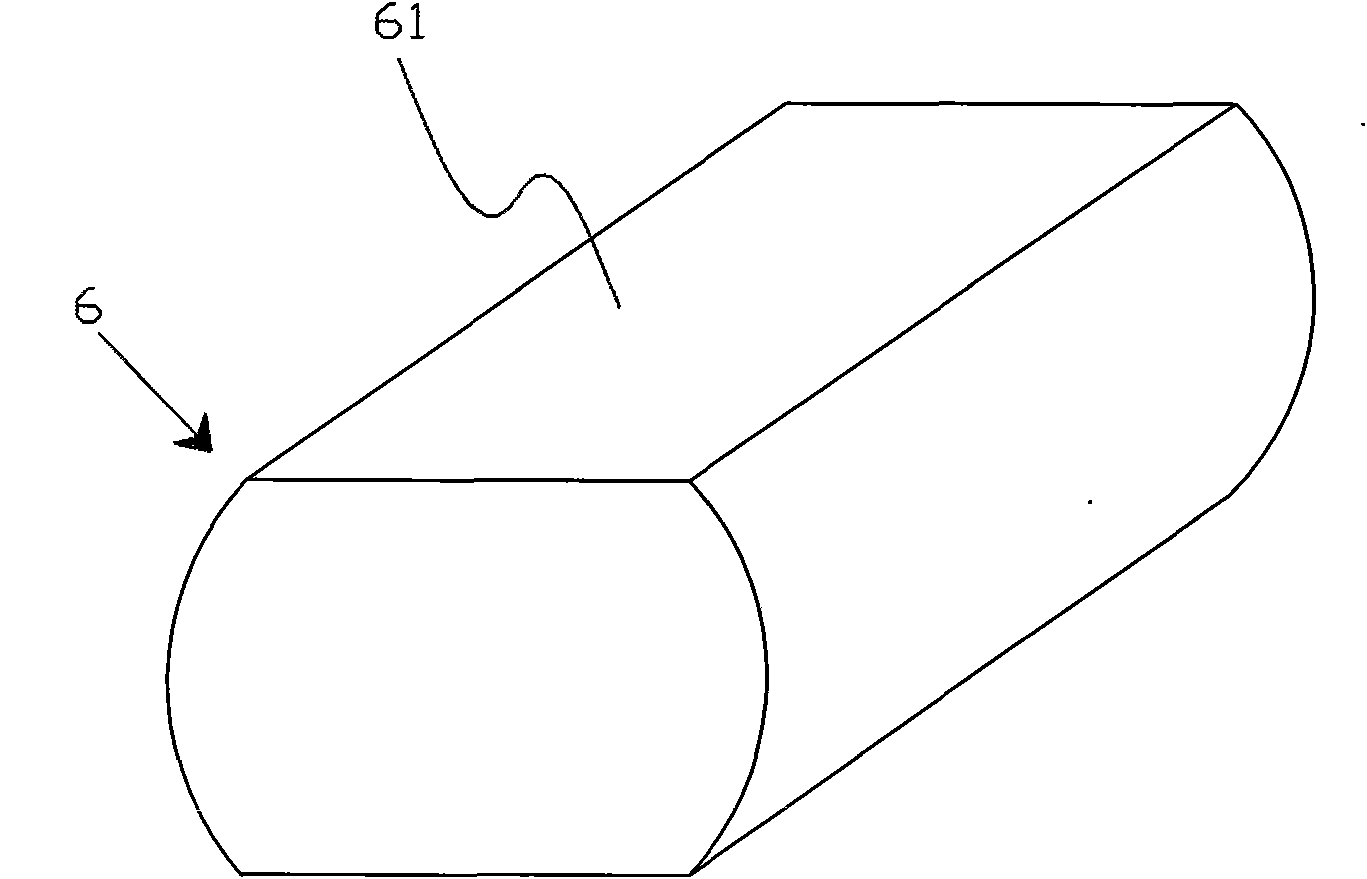

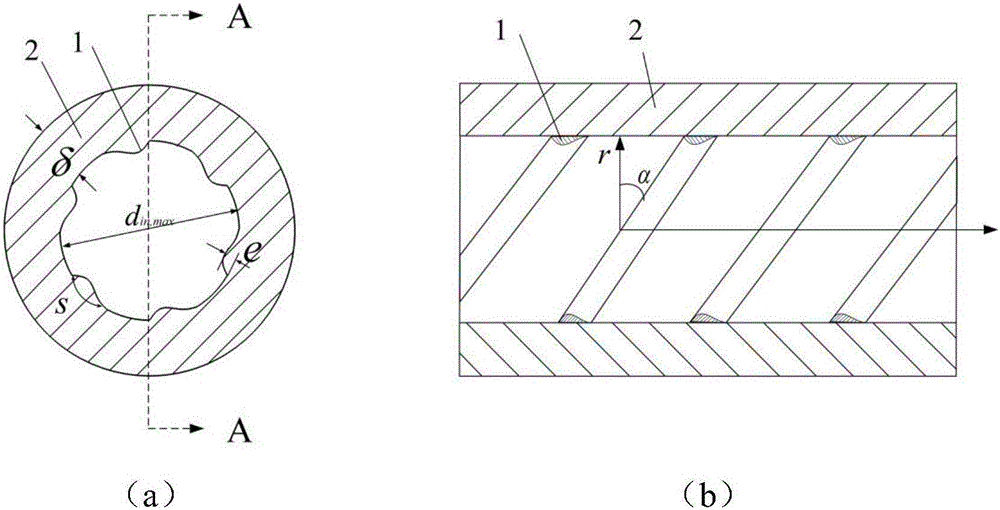

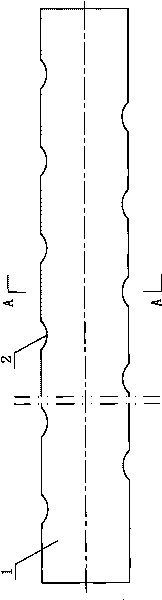

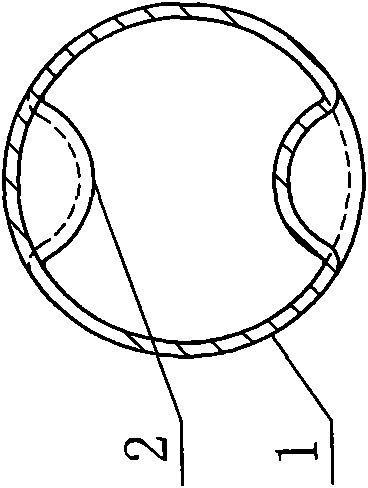

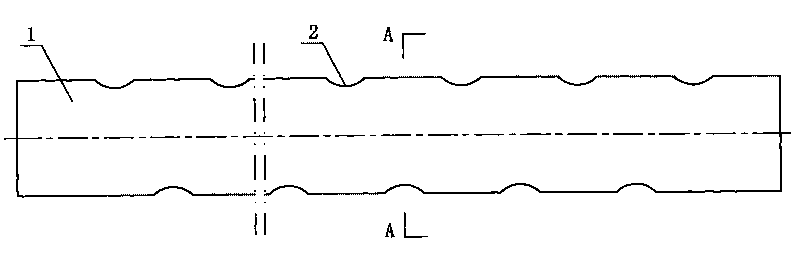

Boiler water-cooled wall inner threaded pipe with streamline-section inner ribs

ActiveCN105806127AImprove heat transfer performanceImprove heat transfer efficiencyCasings/liningsSteam boilersThreaded pipeEngineering

The invention discloses a boiler water-cooled wall inner threaded pipe with stream-line-section inner ribs. The boiler water-cooled wall inner threaded pipe comprises a pipe body and the ribs spirally arranged on the inner wall of the pipe body in the axial direction, wherein the cross sections of the ribs are in streamline shapes. The ribs which are spirally arranged are distributed at equal intervals, and the number of the ribs is 4 to 8. The included angle between the spiral direction of the ribs and a cross section is controlled within the range of 30 degrees to 60 degrees. The circumferential bottom width of the ribs of the boiler water-cooled wall inner threaded pipe is controlled within the range of 4 mm to 10 mm. The height of the highest point of the ribs of the boiler water-cooled wall inner threaded pipe is controlled within the range of 0.5 mm to 1.5 mm. The position of the highest point of the ribs is at the position of one third of the rib bottom width. By means of the novel boiler water-cooled wall inner threaded pipe, vortexes on the back flow sides of the ribs are avoided or reduced through the streamline inner ribs, so that the heat transfer capability of the inner wall face of the pipe is effectively improved, and the temperature level near rib roots on the back flow sides of the ribs is lowered. Therefore, the heat transfer performance of the boiler water-cooled wall inner threaded pipe can be further enhanced through the pipe shape.

Owner:XI AN JIAOTONG UNIV

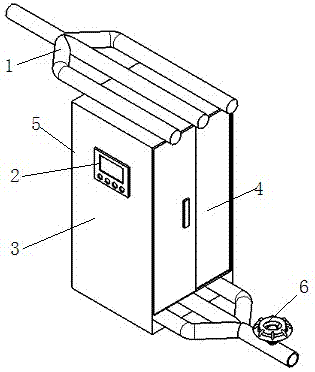

Hot water supply system device with solar energy metal honeycomb collection, instantaneous water heating of superconducting pipe

InactiveCN101672493AReduce weightSimple structureSolar heat devicesStorage heatersCollector deviceEngineering

The invention relates to a hot water supply system device with solar energy metal honeycomb collection, instantaneous water heating of a superconducting pipe, which consists of a solar energy metal high-efficiency honeycomb heat collector matrix and a straw instantaneous water heater and a superconducting warmer which are heated by a superconducting heat pipe. The hot water supply system device adopts the technology of series heat collection and heating, namely output water in a small section of outputted water pipe is only heated. Compared with the prior boiler, the technology saves over 60 percent of fuels. The hot water supply system device adopts a series heating mode of 'a honeycomb metal heat collector' and 'an instantaneous water heater of the superconducting heat pipe', realizes quick water temperature rise and instantaneous heating, eliminates the conventional boiler system, does not use non-renewable fuels, can save over 80 percent of electricity, is particularly suitable forno-electric areas, and saves electricity or does not consume no electricity. The hot water supply system device is characterized in that: the efficiency of the heat collection and heat conduction ofthe honeycomb metal heat collector is higher than that of a glass pipe; and the honeycomb metal heat collector has light weight, simple structure, uniform temperature distribution, large quantity of heat transfer, long distance of the heat transfer, electricity conservation, reliability and low cost, is convenient for popularization and application, has the social and economic benefits of energy conservation and emission reduction, is the inevitable trend of current and future development, and has great significance.

Owner:陈绍勇 +1

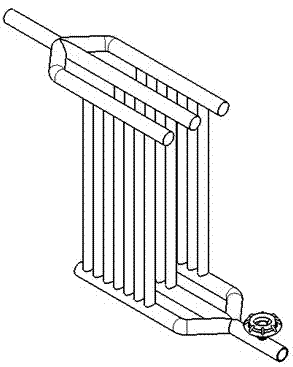

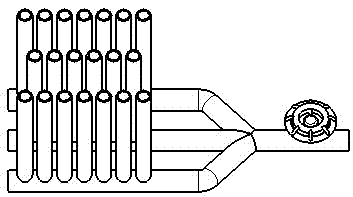

Multi-row pit heat exchange tube

InactiveCN101701779AGuaranteed heat transfer efficiencyEasy to processCorrosion preventionTubular elementsEngineeringImpurity

The invention relates to a multi-row pit heat exchange tube, comprising a stainless steel tube body. The multi-row pit heat exchange tube is characterized in that the surface of the stainless steel tube body is provided with a plurality of rows of pits along an axial direction and the positions of adjacent two rows of pits are staggered. The multirow pit heat exchange tube has the advantages that: 1. the diameter of the heat exchange tube can be produced less than 5 mm while the heat exchange tube ensures the heat exchange efficiency and the heat change tube is easy to process for molding; 2. the tube body has small diameter, relatively high heat exchange surface area ratio and larger heat transfer quantity under the condition that the medium temperature and the temperature needed to be displaced are the same; and meanwhile, the pits on the stainless steel are deeper than spiral grooves on a tube body with the same diameter, thus the turbulence phenomenon of gases passing through the heat exchange tube is enlarged, the heat exchange coefficient is greatly improved and the heat exchange effect is intensified; 3. due to the small diameter of the tube body, the installation space can be saved, and compared with common heat exchange tubes, obviously less heat exchange tubes with small diameter are used in a device with same heat exchange requirements; and 4. the service life is prolonged and the pits can reduce the retention and deposition of the impurities of media in the tube compared with the spiral grooves.

Owner:锦州秀亭制管有限公司

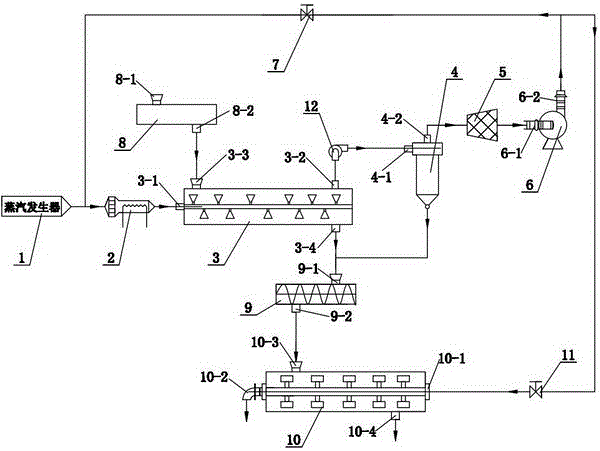

Sludge two-grade united energy-saving drying device and method

PendingCN106517727AFully recover latent heatFully recover part of the sensible heatSludge treatment by de-watering/drying/thickeningSludgePulp and paper industry

The invention relates to a sludge two-grade united energy-saving drying device and a sludge two-grade united energy-saving drying method. The sludge two-grade united energy-saving drying device includes a steam generator, a heater, a direct stirring dryer, a blower, a cyclone dust collector, a filter, a steam compressor, a valve, a sludge pump, an indirect sludge dryer and a spiral feeder. The sludge pump, the direct stirring dryer, the spiral feeder, and the indirect sludge dryer are formed to be a material access; the steam generator, the heater, the direct stirring dryer, the blower, the cyclone dust collector, the filter, the steam compressor, and the valve are formed to be a first-grade drying gas flow access; the valve and the indirect sludge dryer are formed to be a secondary-grade drying gas flow access. The invention has the beneficial effects of crossing through a sludge viscous zone through a two-grade drying method, and solving the viscous problem caused by high water content of sludge in indirect drying; besides, residual steam is used as the hot source for the next-grade drying, the potential heat and a part of sensible heat of the excessive steam can be generated during the recycling and drying processes, and thus the gradient utilization of energy can be realized.

Owner:NANCHANG HANGKONG UNIVERSITY

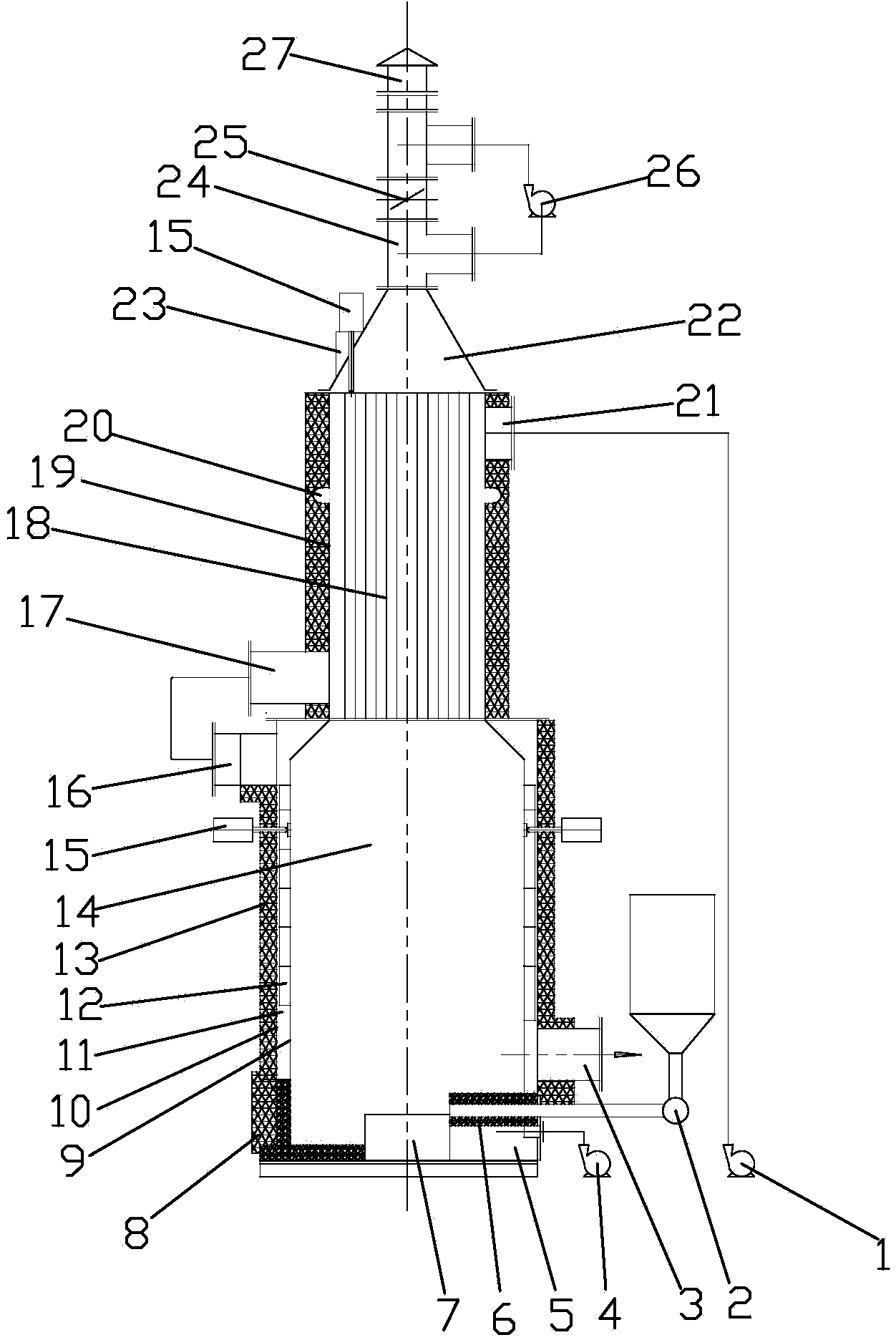

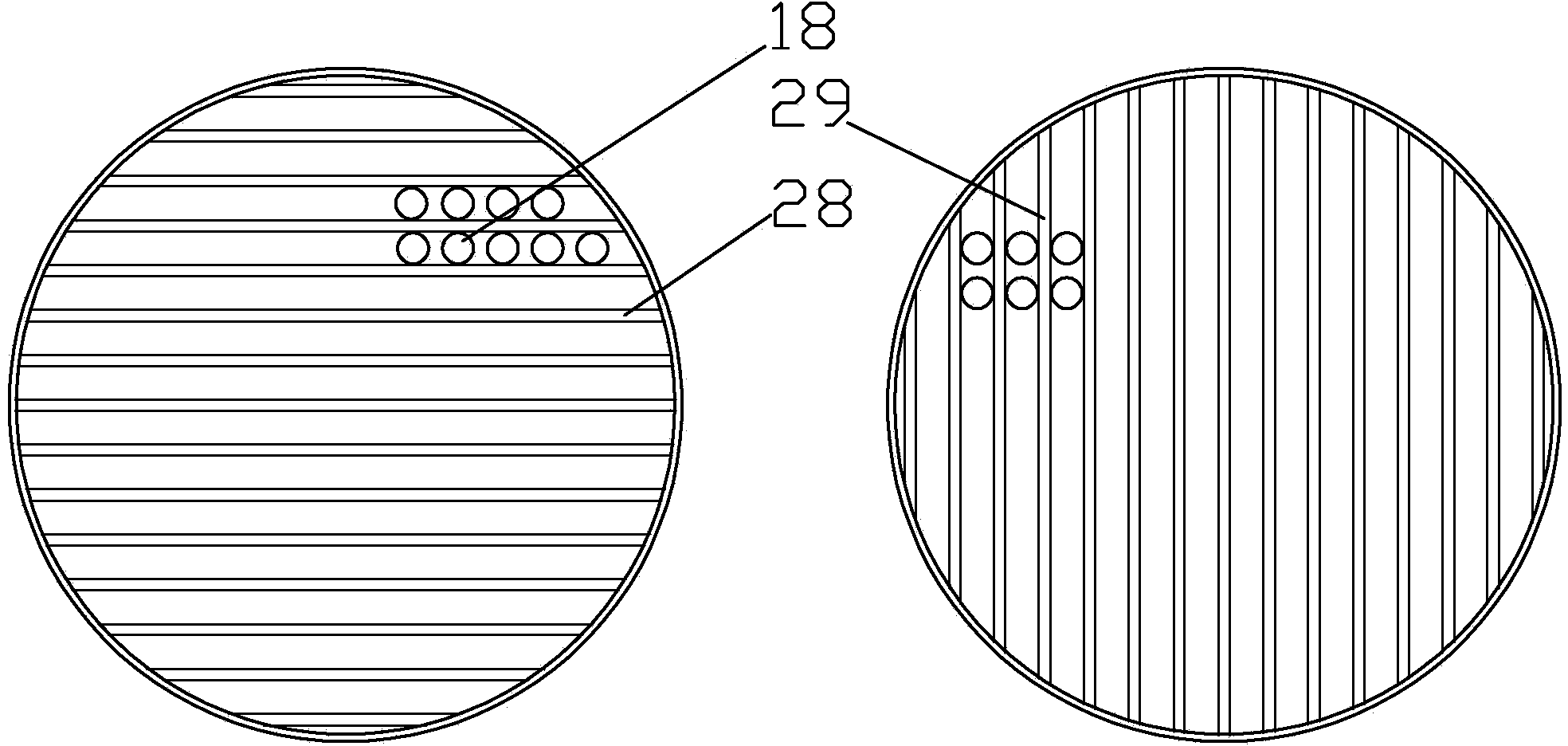

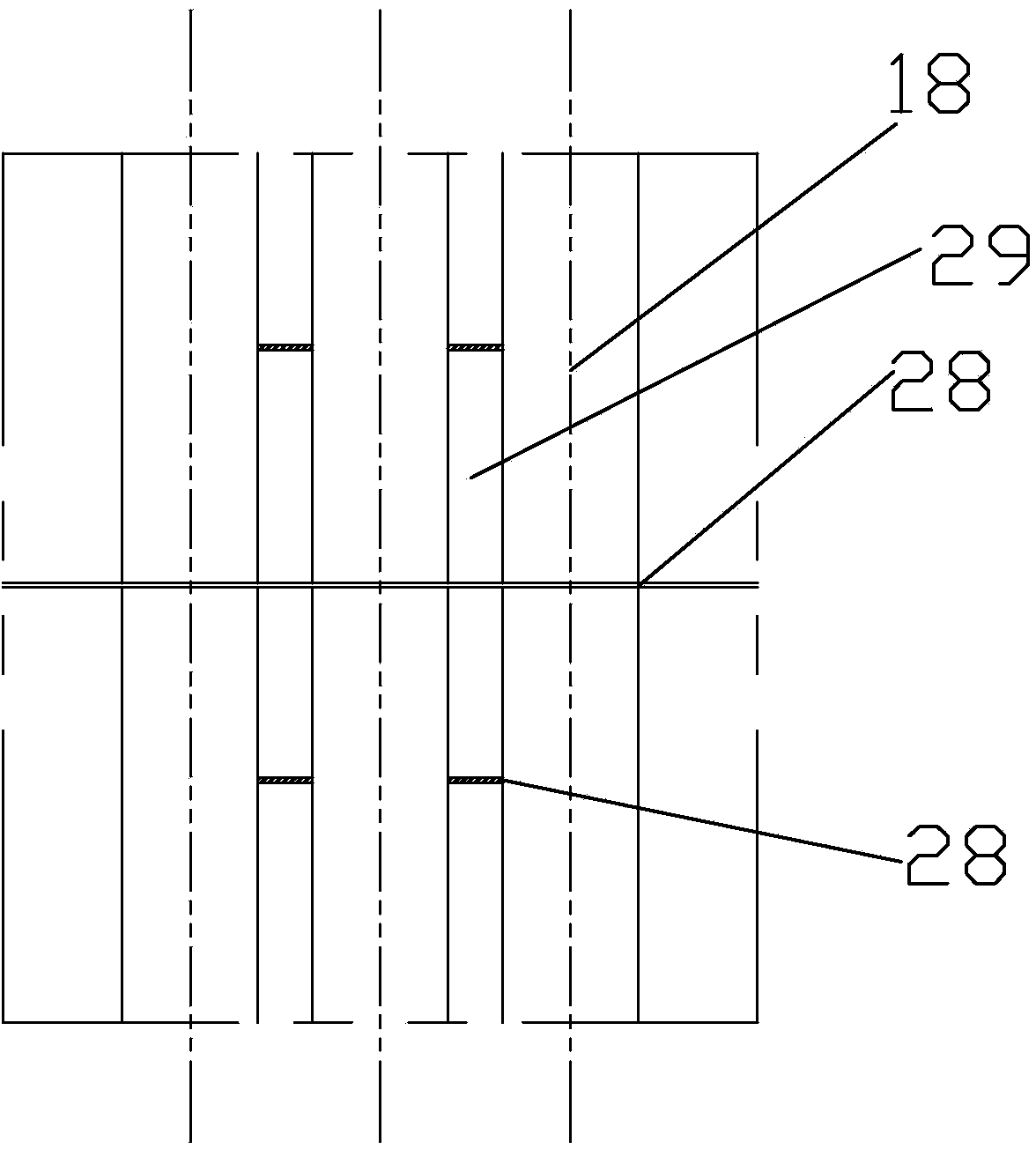

Cylindrical high-temperature biomass hot blast furnace

The invention relates to a cylindrical high-temperature biomass hot blast furnace. The cylindrical high-temperature biomass hot blast furnace comprises a cylindrical heat exchanger and a cylindrical hearth section. The cylindrical heat exchanger is perpendicularly installed on the upper portion of the cylindrical hearth section and is a convective heat transfer section, and the cylindrical hearth section is a radiative heat transfer section. A biomass combustor assembly is installed at the bottom of the cylindrical hearth section. A slurry removing door is installed on the left side of the bottom of the cylindrical hearth section. Electromagnetic vibrators are installed on the cylindrical hearth section and the cylindrical heat exchanger respectively. The hot blast temperature of the cylindrical high-temperature biomass hot blast furnace can reach 450DEG C, ash removing inside a hearth and ash removing of smoke wall surfaces of the heat exchanger are carried out together, namely, ash cleaning is carried out in the hearth and ash removing rooms and corresponding furnace doors are reduced, and therefore the cylindrical high-temperature biomass hot blast furnace is compact in structure. Because the electromagnetic vibrators are installed, ash accumulated in a heat exchanging pipe and ash accumulated on heat exchanging surfaces can be automatically removed in the operation process, permanent and efficient heat transmission can be kept, and ash forming and scale forming can be effectively avoided. The volume and structure of the hearth of the furnace are designed according to the principles of heat transfer theories so that heat transfer amount of the radiation section is large, metal heat transfer surface temperature and fault rate are low, and the cylindrical high-temperature biomass hot blast furnace is long in service life.

Owner:浙江光炎节能环保科技股份有限公司

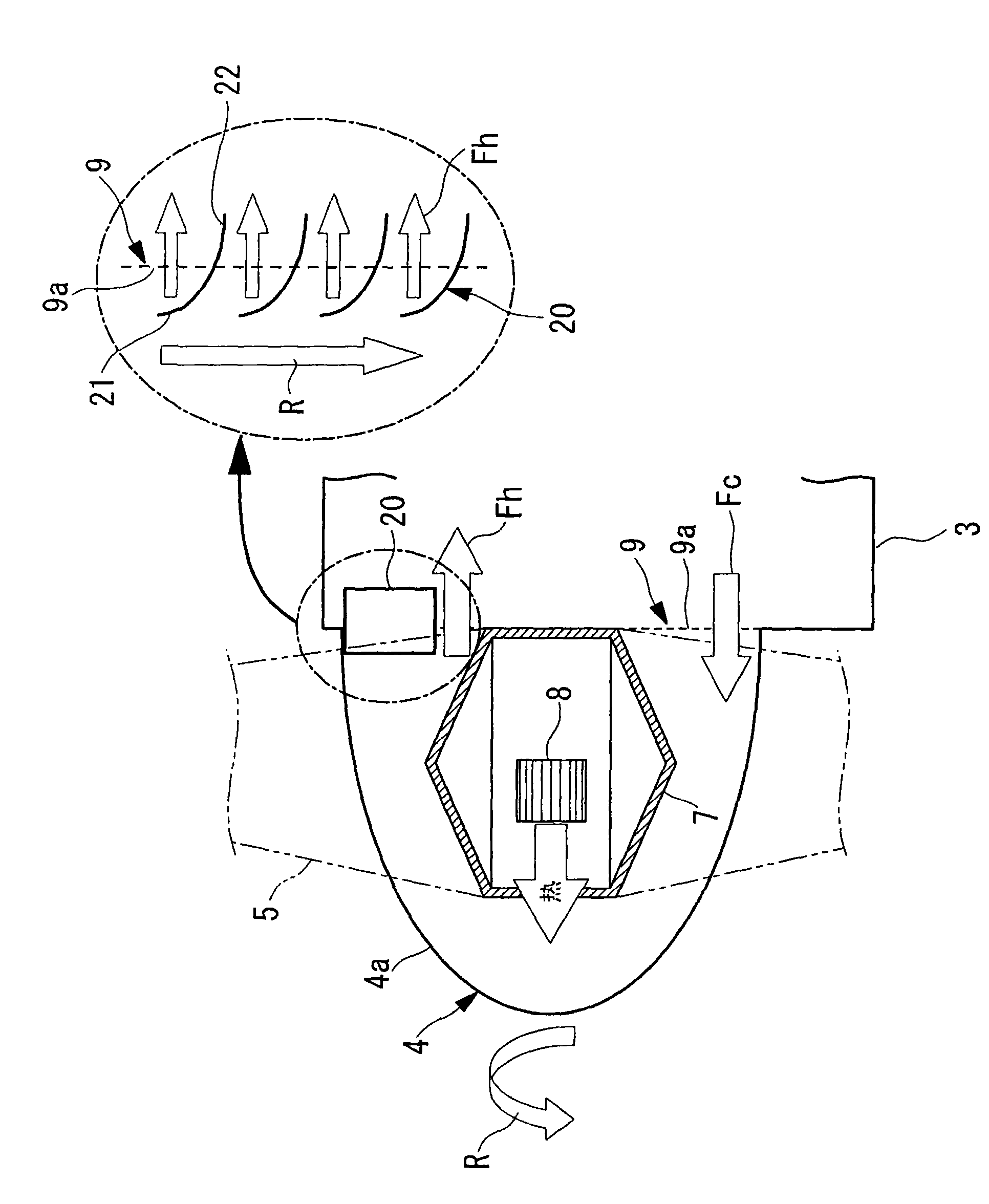

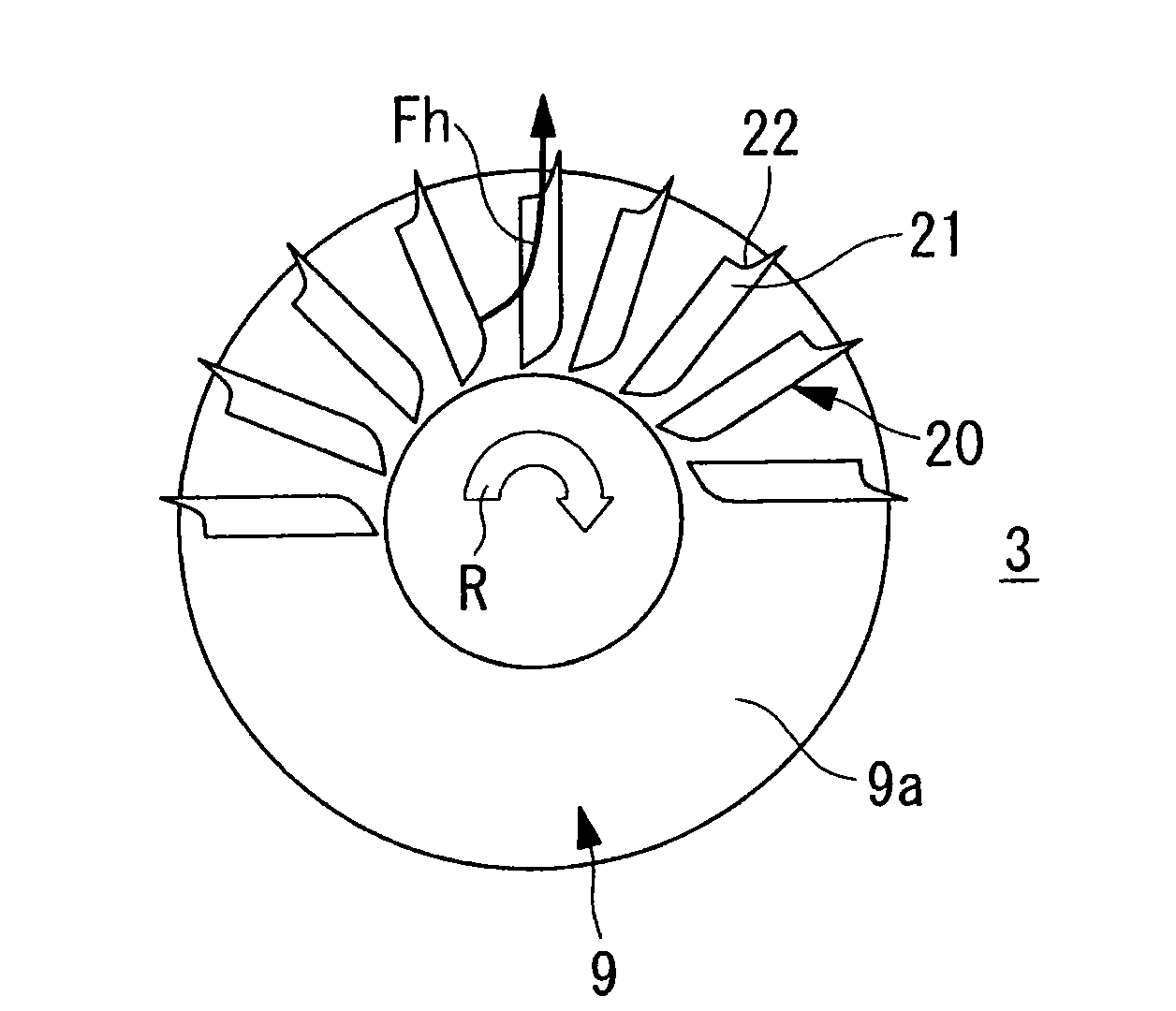

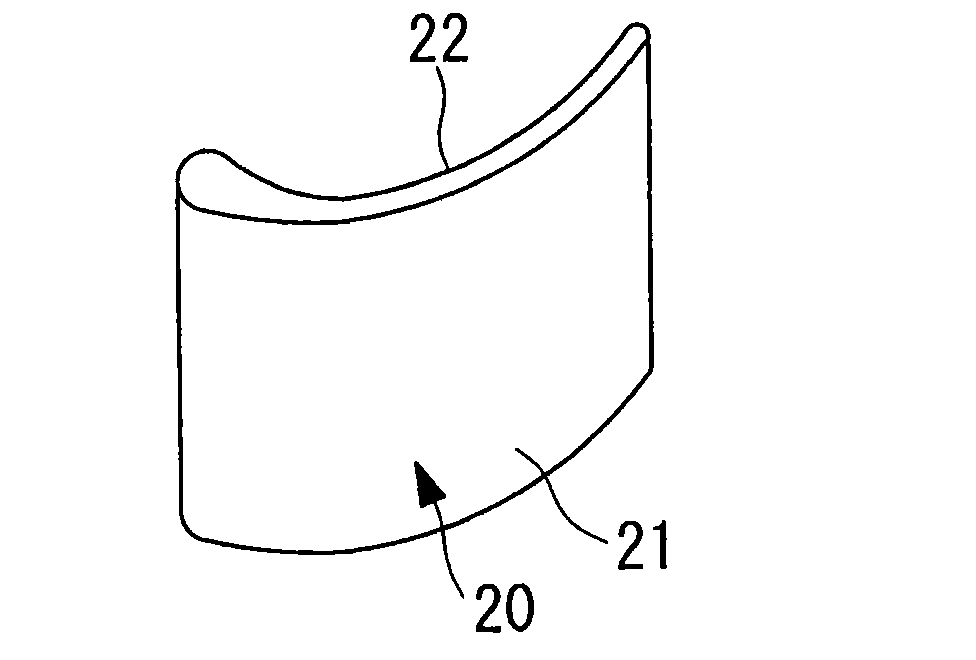

Wind driven electric power generator

InactiveCN101657637AImprove reliabilityIncreased durabilityEngine fuctionsMachines/enginesAir cycleWind driven

The invention provides a wind power generation device enabling to manage the temperature inside a rotor head. The wind power generation device 1 comprises a drive-generation mechanism connected to therotor head 4 mounted with a windmill blade 5 and stored and installed in a nacelle 3, and control equipment and the like stored and installed in a hub 7 of the rotor head 4. Herein, an air circulation guide 20 is provided for circulating air between the inside of the rotor head 4 and the inside of the nacelle 3 via a communication passage 9 formed between the rotor head 4 and the nacelle 3.

Owner:MITSUBISHI HEAVY IND LTD

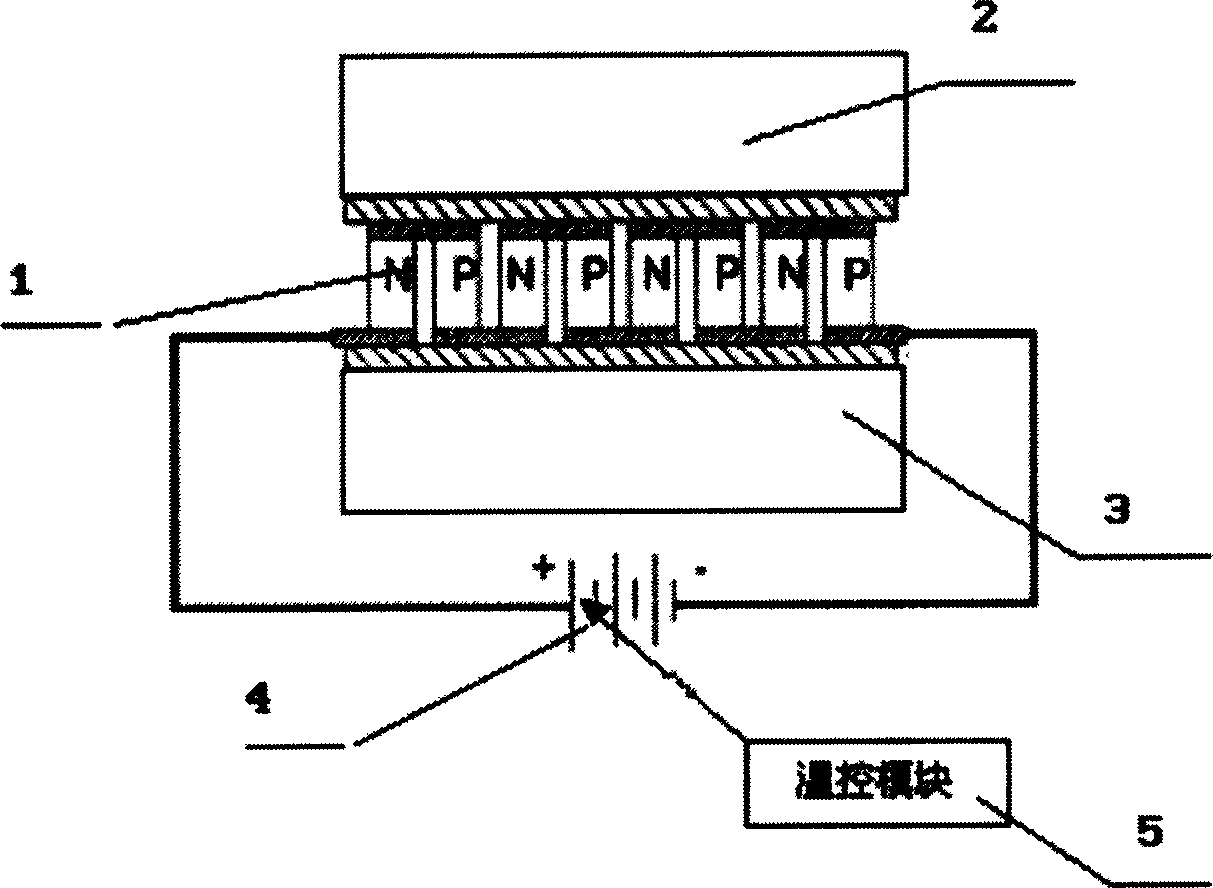

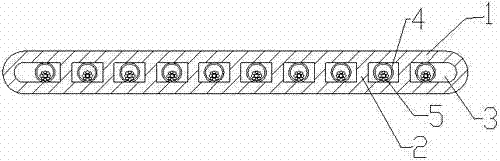

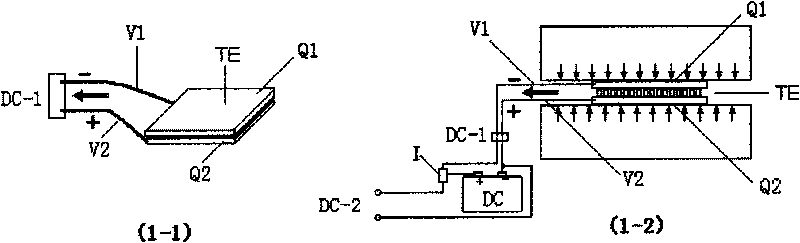

Cooling/heating electronic sleeping bag based on semiconductor refrigerating and heat superconducting tech

InactiveCN1833582ASpeed up distributionHigh heat transferSleeping rugSemiconductor/solid-state device detailsFiberTemperature control

A sleeping bag based on semiconductor refrigerating and thermal superconductor techniques for warming its user or dissipating the heat from its user is composed of a bag body made of fabric, power supply, semiconductor refrigerating unit connected to power supply, thermal superconductor radiator, fibrous thermal super conductor type heat conductor with temp sensor, and temp controller.

Owner:ZHEJIANG UNIV OF TECH

Composite microarray flat heat pipe

InactiveCN102401588AUniform temperature distributionReduce thermal resistanceIndirect heat exchangersHeat resistanceEngineering

The invention discloses a composite microarray flat heat pipe, comprising a flat hollow shell, wherein the hollow shell is provided with a plurality of supporting structures, the cavity of the shell body is divided into a number of relatively independent channels by the supporting structures, the channels run through from front to back and are arranged side by side, metal networks are arranged inside the channels, multiple strands of metal wires are arranged in the metal networks ; the channels are also arranged with working medium , and two ends of the channels are sealed by seal structures. The invention of the composite microarray flat heat pipe is characterized by uniform temperature distribution, small heat resistance, fast thermal response, large heat transfer (making use of latent heat ), light weight and small volume ( hollow container ), simple structure, and being capable of operating in the absence of gravity.

Owner:苏州雪林电器科技有限公司

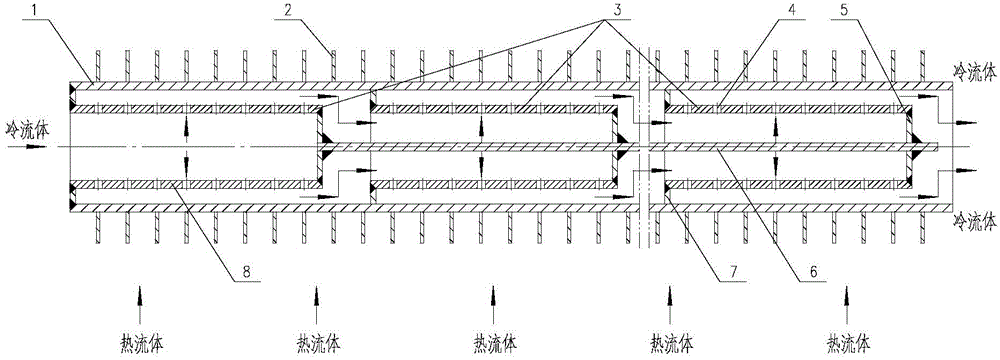

Cascade utilization method and device of waste gas of flue gas of boiler for thermal power unit

ActiveCN103453513ALarge drop in temperatureIncrease temperatureFeed-water heatersAir preheaterDeaerator

The invention discloses a cascade utilization method and device of waste gas of flue gas of a boiler for a thermal power unit. A first low pressure heater heat exchanger is arranged between an air preheater and a flue gas-oil heat exchanger, and a second low pressure heater heat exchanger is arranged at the flue gas outlet side of the flue gas-oil heat exchanger; a diversion pipe is additionally arranged on a low pressure water supply manifold which is arranged at the back of a condenser and in front of a first-stage low pressure heater, and a water inlet pipe is additionally arranged at the water inlet side of a deaerator; the diversion pipe is connected with a water inlet of the second low pressure heater heat exchanger, and the water inlet pipe is connected with a water outlet of the first low pressure heater heat exchanger; and a low pressure water supply pipeline is arranged between the water inlet of the first low pressure heater heat exchanger and the water outlet of the second low pressure heater heat exchanger. Through the arrangement of an additional economizer heating surface, the low pressure heat exchanger, the flue gas-oil heat exchanger and an air-oil heat exchanger, the temperature counterpart and cascade utilization of flue gas waste heat are realized, the boiler efficiency and the unit power generation efficiency are improved, the energy consumption of the thermal power unit is reduced, and meanwhile the carbon dioxide emission is reduced.

Owner:山东英电环保科技有限公司

High-strength antibacterial wood preparation method and high-strength antibacterial wood

ActiveCN110253703AIncreased nanovoidsImprove adsorption capacityWood compressionElectric wood treatmentSulfite saltMildew

The invention discloses a high-strength antibacterial wood preparation method and a high-strength antibacterial wood. During the use, the mildew of wood is serious, such that the performances of the material are reduced, and the service life is shortened. According to the method, lignin and hemicellulose are removed from wood, the obtained wood is infiltrated with polyaniline, and the polyaniline-containing pretreated wood is placed in an electroplating solution and is electroplated to obtain a metal-plated wood complex; and the metal-plated wood complex is placed in a hot pressing machine, and is subjected to hot pressing. According to the present invention, lignin and hemicellulose are removed from wood by using a sodium sulfite solution so as to substantially increase the nanometer gaps inside the wood and improve the adsorption capacity of the wood; polyaniline is uniformly distributed inside the wood, such that the wood has electrical conductivity; and the hot pressing drying technology promotes the internal moisture of the wood to move to the outside.

Owner:HANGZHOU DIANZI UNIV

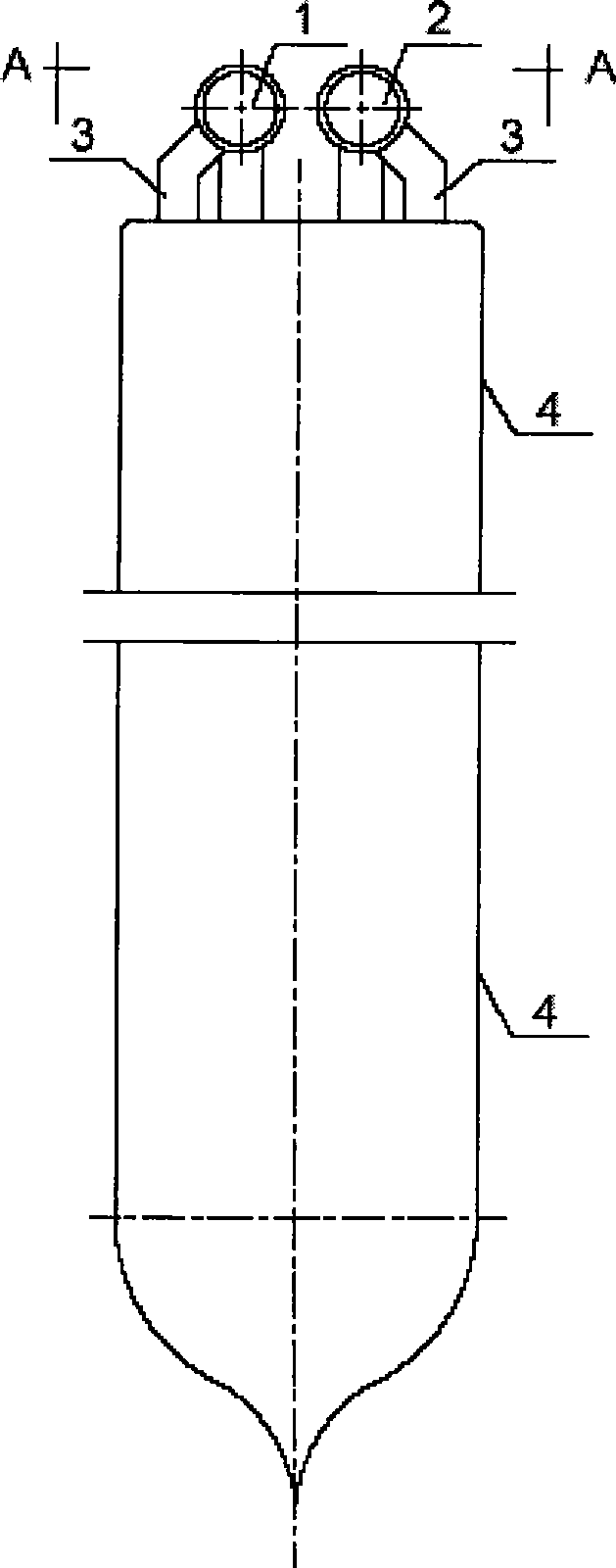

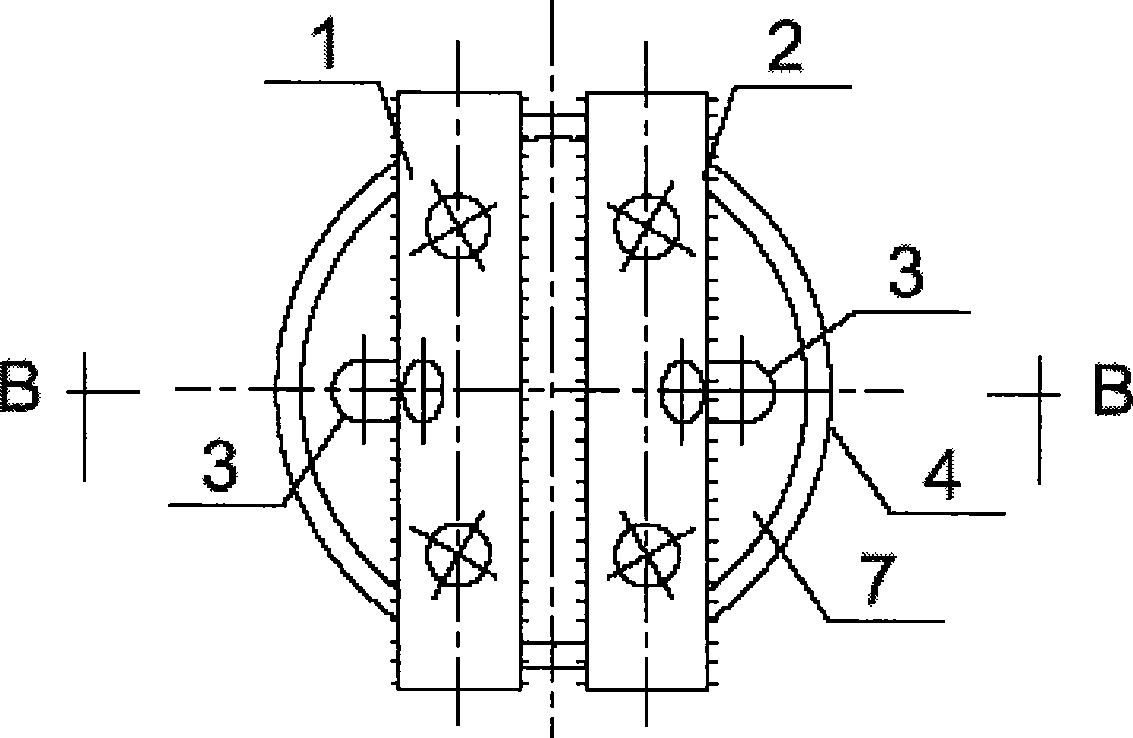

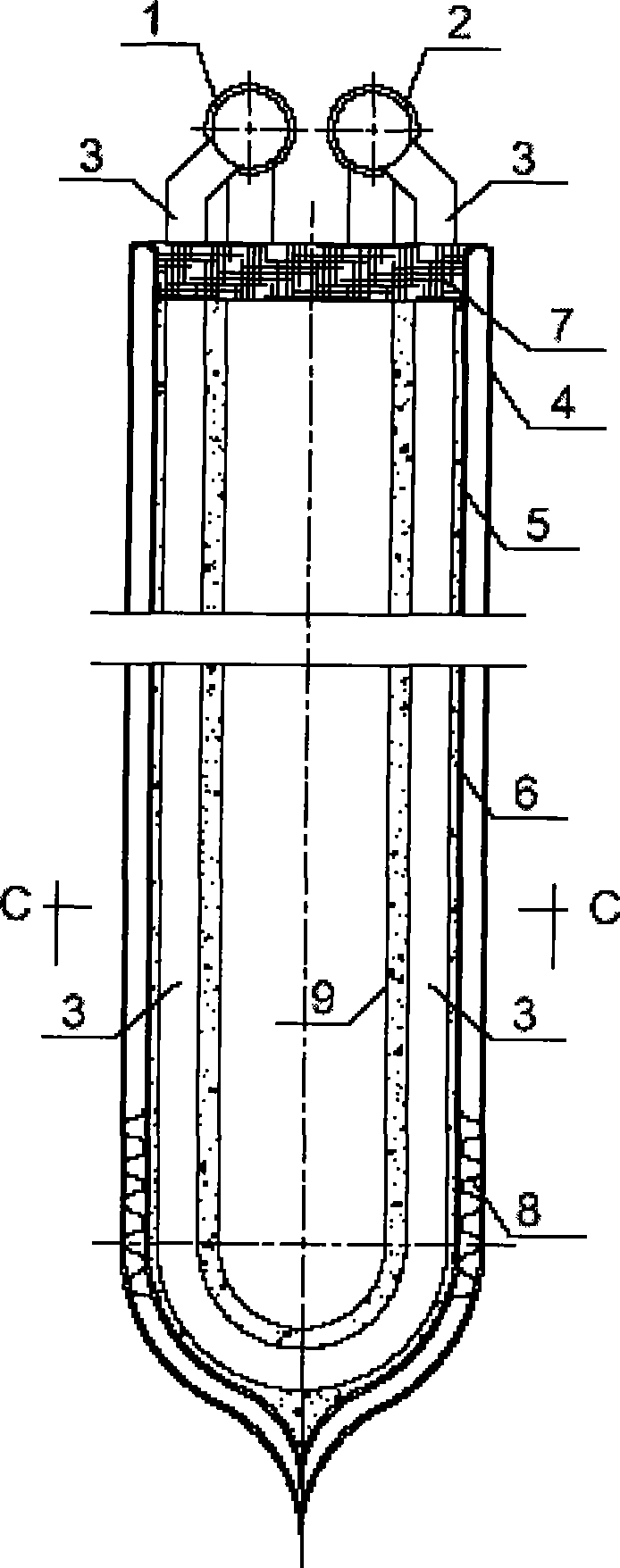

Graphite-filled vacuum glass tube closed-loop capillary pipe solar thermal-collecting tube

InactiveCN101387447AHigh heat transferHigh thermal conductivitySolar heating energySolar heat devicesClosed loopEngineering

The invention discloses a graphite filled vacuum glass tube closed loop capillary solar heat collection tube, which belongs to the field of solar heat collector. The solar heat collection tube is characterized in that the device comprises a finned header tube, capillary metal tubes, an external glass tube, an internal glass tube, graphite packing, a thermal insulated seal head, an elastic support and a thermal insulated liner tube; according to the vacuum glass tube, the external surface of the internal glass tube is coated with solar energy selective absorption paint, and space between the internal and external glass tubes is vacuumed; the graphite packing is compactly packed among the internal glass tube, the capillary metal tubes and the thermal insulated liner tube; and the inner diameter of each capillary metal tube is between 2 and 5 millimeters, and the capillary metal tubes are connected with the finned header tube to form a closed pipeline system. The capillary metal tubes are filled with water, Freon or other heat transfer mediums so as to complete the process of solar heat collection and conveying. The graphite filled vacuum glass tube closed loop capillary solar heat collection tube has the advantages that a plurality of U-shaped capillary tubes increase the heat exchange area of the working media within the limited space of the glass tubes, and improve the heat transfer performance of the heat collection tube; and simultaneously the graphite packing facilitates the improvement of the heat collection efficiency of the heat collection tube.

Owner:DALIAN UNIV OF TECH

Closed-loop capillary pipe plate type solar heat collector

InactiveCN101387451AImprove heat collection effectImprove the heat collection performance, which is beneficial to increase the heat supply temperature of the heat collectorSolar heating energySolar heat devicesInsulation layerCollector device

The invention discloses a closed loop capillary flat plate type solar heat collector, which belongs to the field of solar heat collector. The solar heat collector is characterized in that the device comprises a header tube, a fin tube, capillary metal tubes, a graphite heat transfer layer, a metal frame, plate glass and an insulation layer; the inner diameter of each capillary metal tube is between 2 and 5 millimeters, and the capillary metal tubes are connected with the fin tube to form a closed pipe system. The capillary metal tubes are filled with a heat transfer medium; during work, after absorbing solar energy, the heat transfer medium forms a vapor and liquid alternated column, enters the fin tube along the capillary metal tubes, flows back to the capillary metal tubes after being cooled down and condensed by media outside the tube, and then absorbs solar energy again for vaporization; and the cycle is repeatedly carried out. The closed loop capillary flat plate type solar heat collector has the advantages that the oscillatory flow heat pipe effect caused by the closed loop capillary metal tubes increases the heat transfer rate of the heat collector; the graphite heat transfer layer facilitates the improvement of the heat collection performance of the heat collector; and the tube diameter of each capillary metal tube is small, thereby improving the bearing capacity of the heat collection tube.

Owner:DALIAN UNIV OF TECH

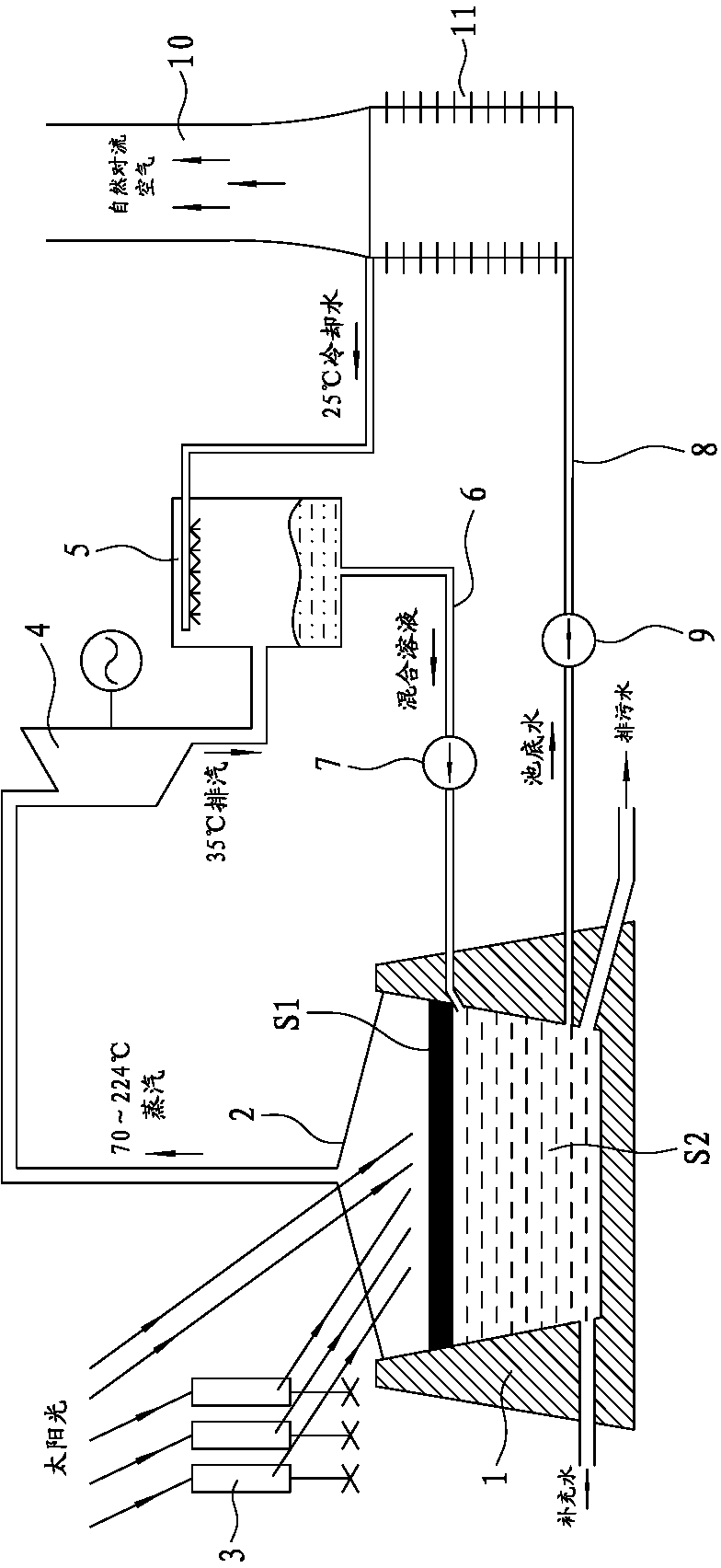

Tank-surface-evaporation solar thermal power generation system

InactiveCN103470460AHigh heat transferImprove efficiencyFrom solar energySteam engine plantsCooling towerEvaporation

The invention discloses a tank-surface-evaporation solar thermal power generation system comprising an evaporation tank, a light-permeable ceiling, a mirror array, a steam turbine generator set, a hybrid condenser, a mixed solution pipeline, a solution pump, a cooling water pipeline, a cooling water pump, a cooling column, and an air cooler. Liquid in the evaporation tank is composed of low-boiling-point medium layer and a fresh water layer; radiant energy of sunlight is transmitted to the low-boiling-point medium layer by means of direct irradiation and reflection; obtained high-pressure steam dives the steam turbine generator set to act to generate power; cooling water led from the bed of the evaporation tank dissipates heat through the cooling column, enters the hybrid condenser and contacts and condenses to discharged so that mixed solution is formed; the mixed solution is delivered back into the evaporation tank by the solution pump; the low-boiling-point medium and the fresh water are unable to dissolve due to density difference and automatically layer. The tank-surface-evaporation solar thermal power generation system is simple in structure, high in heat collection efficiency, high in energy conversion rate, high in circulating efficiency, high in station capacity, low in building cost, suitable for low-cost large-scale production, and widely applicable to the technical field of solar thermal power generation technologies.

Owner:JIMEI UNIV

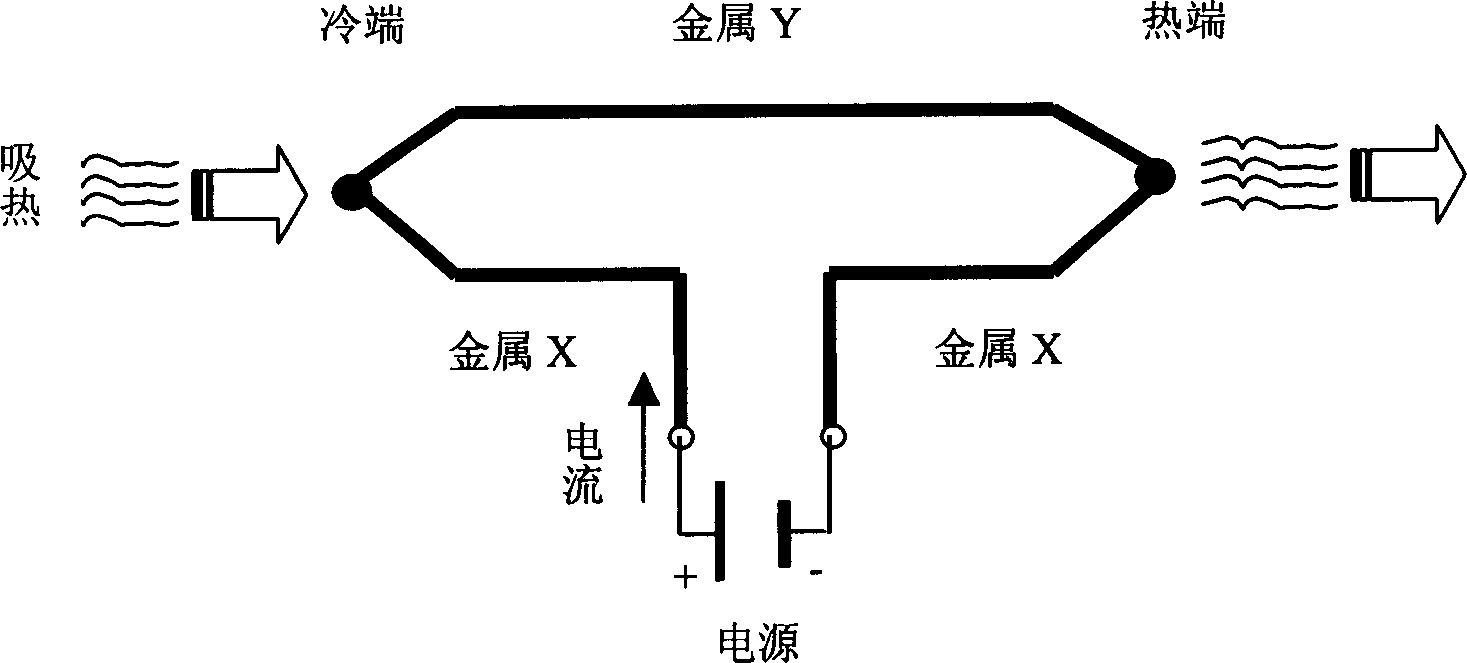

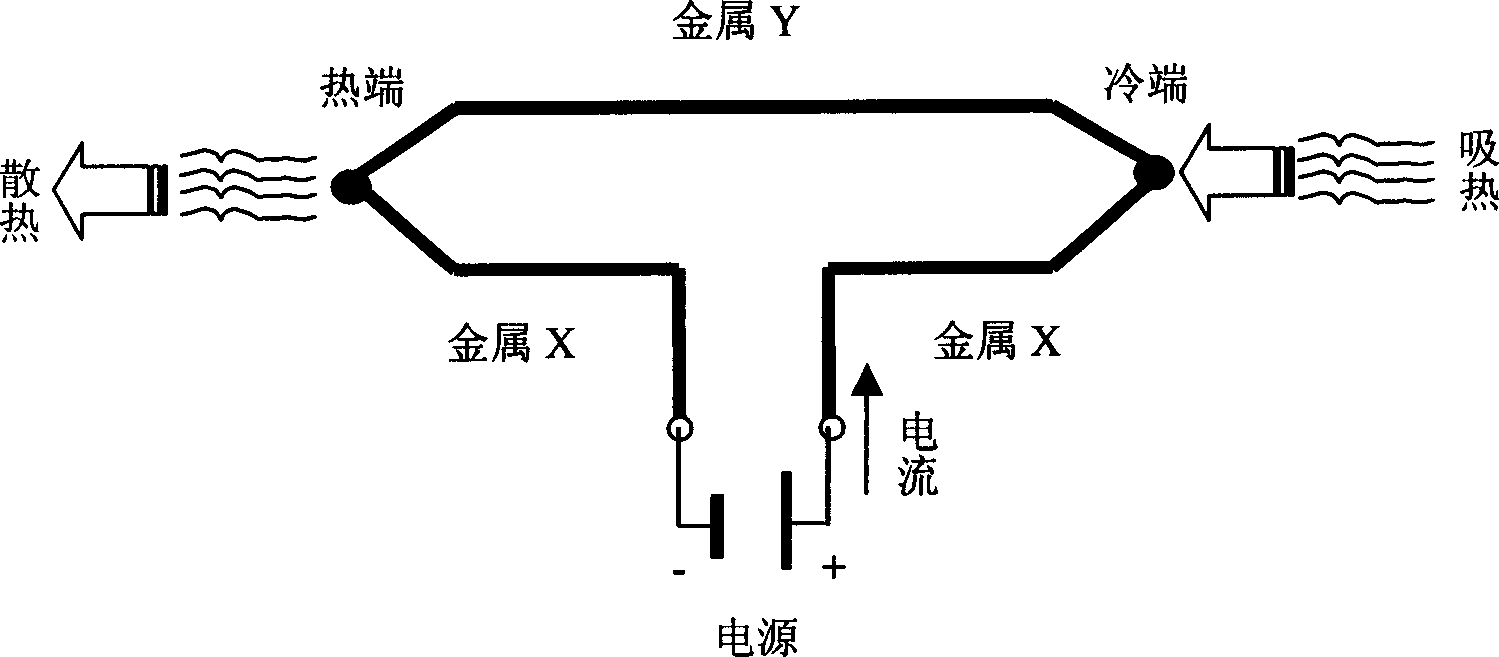

Cold-hot water mobile phone charging and coal/gas stove semiconductor temperature difference power generation device

InactiveCN101714765AReduce weightSimple structureBatteries circuit arrangementsElectric powerWater dischargeLight-emitting diode

The invention discloses a cold-hot water mobile phone charging and coal / gas stove semiconductor temperature difference power generation device, which comprises a superconductive heat tube, a semiconductor cooling plate, a heat collector, a storage battery, a current regulator, a power supply connecting seat, a home appliance connecting seat, a charging regulator, a cold water cup, a hot water cup, a stove, a heat source, briquets, carbon, firewood or fuel gas, an insulating ring a cold water tank, a water discharge / supply value, a drainage valve, an electromagnetic valve, a fan, a light emitting diode lamp, a power supply switch and a computer / television. The device of the invention can generate power upon pouring hot water and running water in the two cups respectively to charge the mobile phone and, in the coal / gas stove, uses waste heat to generate power. The device can be placed in any facility cooled by water (or air) to generate power, has obvious waste heat recycling, energy saving and consumption reducing effects, is easy to manufacture, long in service life, reliable, low in cost and convenient to popularize and promote, has energy-saving and emission-reducing social and economic benefits, represents an inevitable development trend at present and in future. Thus, the device has a great significance.

Owner:陈绍勇 +1

Graphite-filled vacuum glass tube open type capillary pipe solar thermal-collecting tube

InactiveCN101387449AHigh heat transferHigh thermal conductivitySolar heating energySolar heat devicesGraphiteFreon

The invention discloses a graphite filled vacuum glass tube open type capillary solar heat collection tube, which belongs to the field of solar heat collector. The solar heat collection tube is characterized in that the device comprises a header tube, a header connecting tube, liquid distribution and collection tubes, capillary metal tubes, an external glass tube, an internal glass tube, graphite packing, a thermal insulated seal head, and an elastic support; the graphite packing is compactly packed among the internal glass tube, the capillary metal tubes and the thermal insulated liner tube to reinforce the heat transfer performance; the inner diameter of each capillary metal tube is between 2 and 5 millimeters, and the capillary metal tubes are connected with the liquid distribution and collection tubes; and water, Freon or other heat transfer media enter the U-shaped capillary metal tubes through the header tube, the header connecting tube and the liquid distribution tube, are heated after absorbing solar energy of the vacuum glass tubes, and then enter the header tube through the liquid collection tube and are discharged so as to complete the process of solar heat collection, working media heating and heat conveying. The graphite filled vacuum glass tube open type capillary solar heat collection tube has the advantages that a plurality of capillary tubes increase the heat exchange area of the working media and improve the heat transfer performance of the heat collection tube; and simultaneously the heat supply temperature of the heat collection tube is increased.

Owner:DALIAN UNIV OF TECH

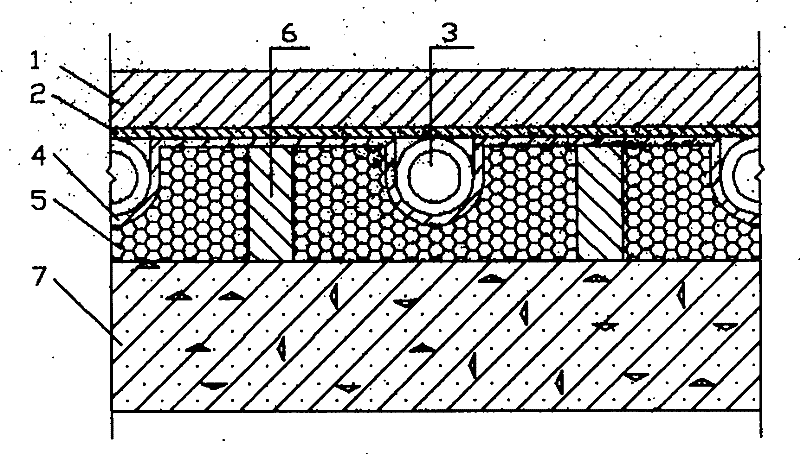

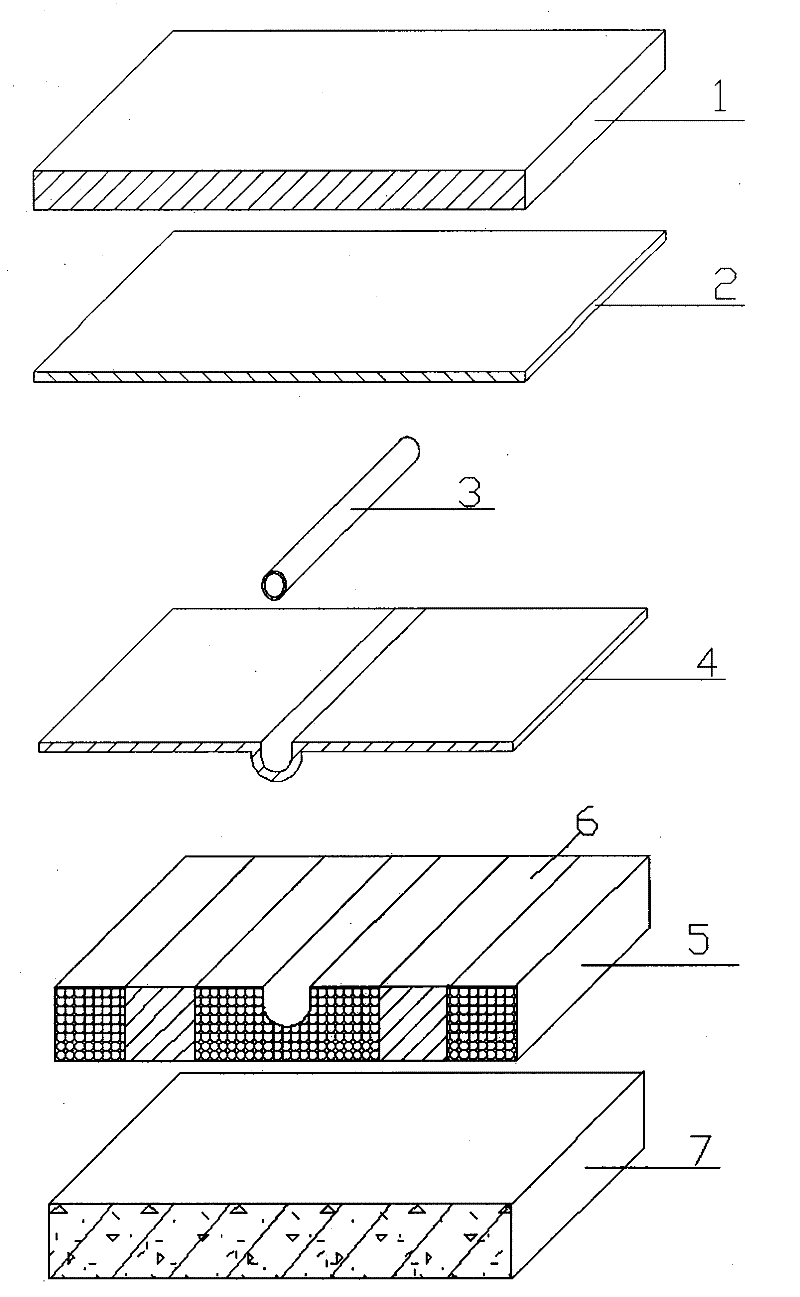

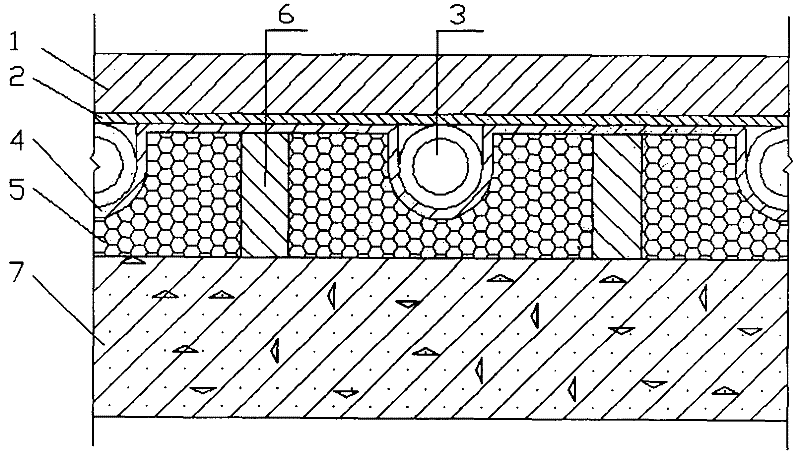

Dry-type hot water heating floor

InactiveCN101298799BIncrease contact areaIncreased load-bearing capacityBuilding componentsFlooringFloor slabKeel

A dry hot water heating floor, belonging to the technical field of floor radioactive heating, comprises a floor decorative layer, an upper layer of metal heat conductive film, a heating pipe, a lower layer of metal heat conductive film, an insulated layer, a wood joist and a floor slab (or a ground). The heating pipe is adhered in an insulated material pipe groove, and is equipped with the metal heat conductive film extending around up and down so as to expand the heating surface thereof and make temperature of the floor surface uniform with reduced heat loss downwards; the wood joist has relative compact structure without hollow volume inside, so as to improve heat engineering mechanical property; the pipe diameter of the heating pipe is smaller than that of a heating pipe of an ordinarywet floor, but greater than that of a heating pipe of an integrated dry floor, so as to reduce thickness of construction layer and floor load, with low request of water quality, and low system resistance, and reduce cycle water bump power consumption. The floor structure can be pre-cast, or pre-cast partly, or assembled and paved in site, with simple construction, convenient maintenance, which isappropriate for new building heating, and building heat as well.

Owner:北京建筑工程学院

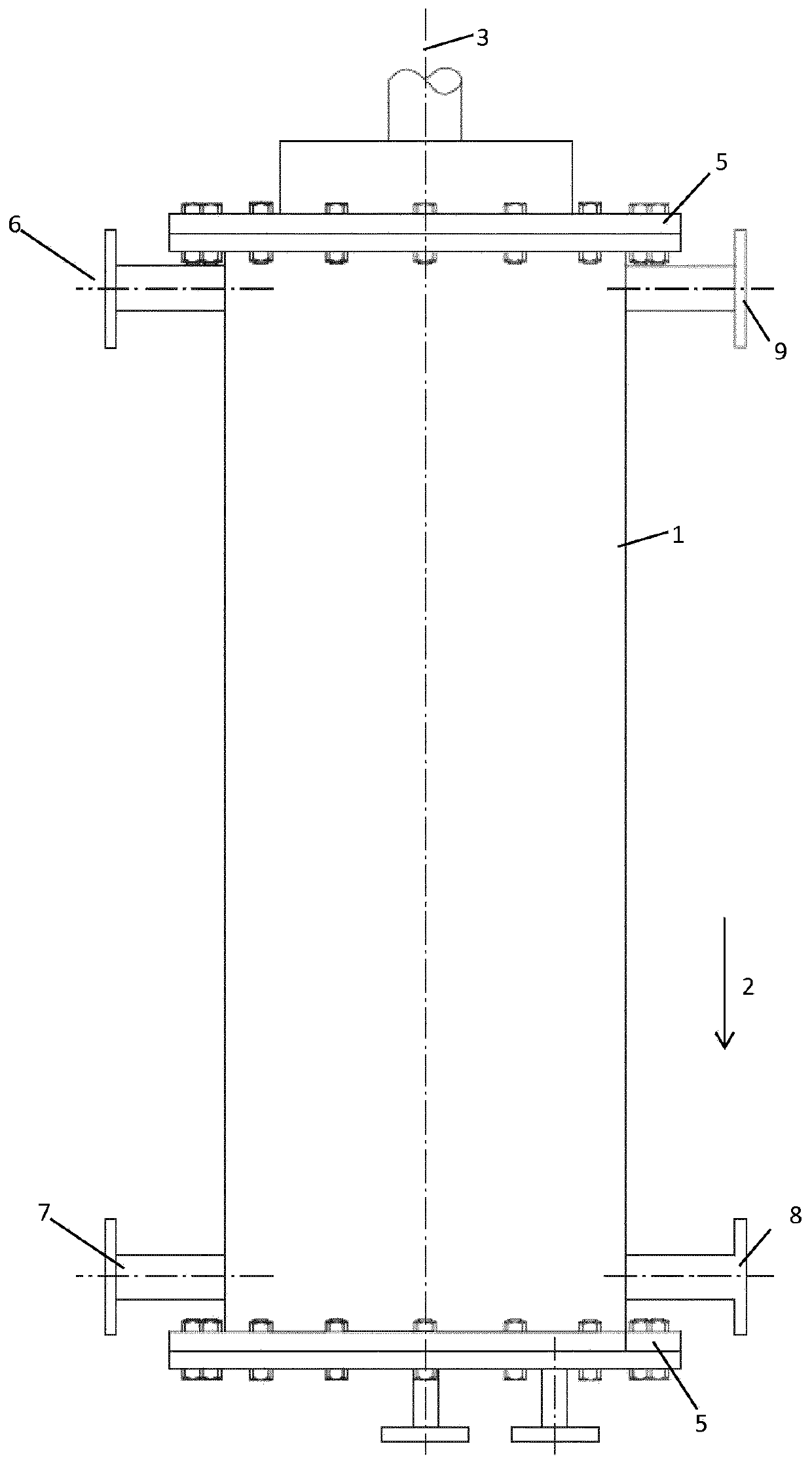

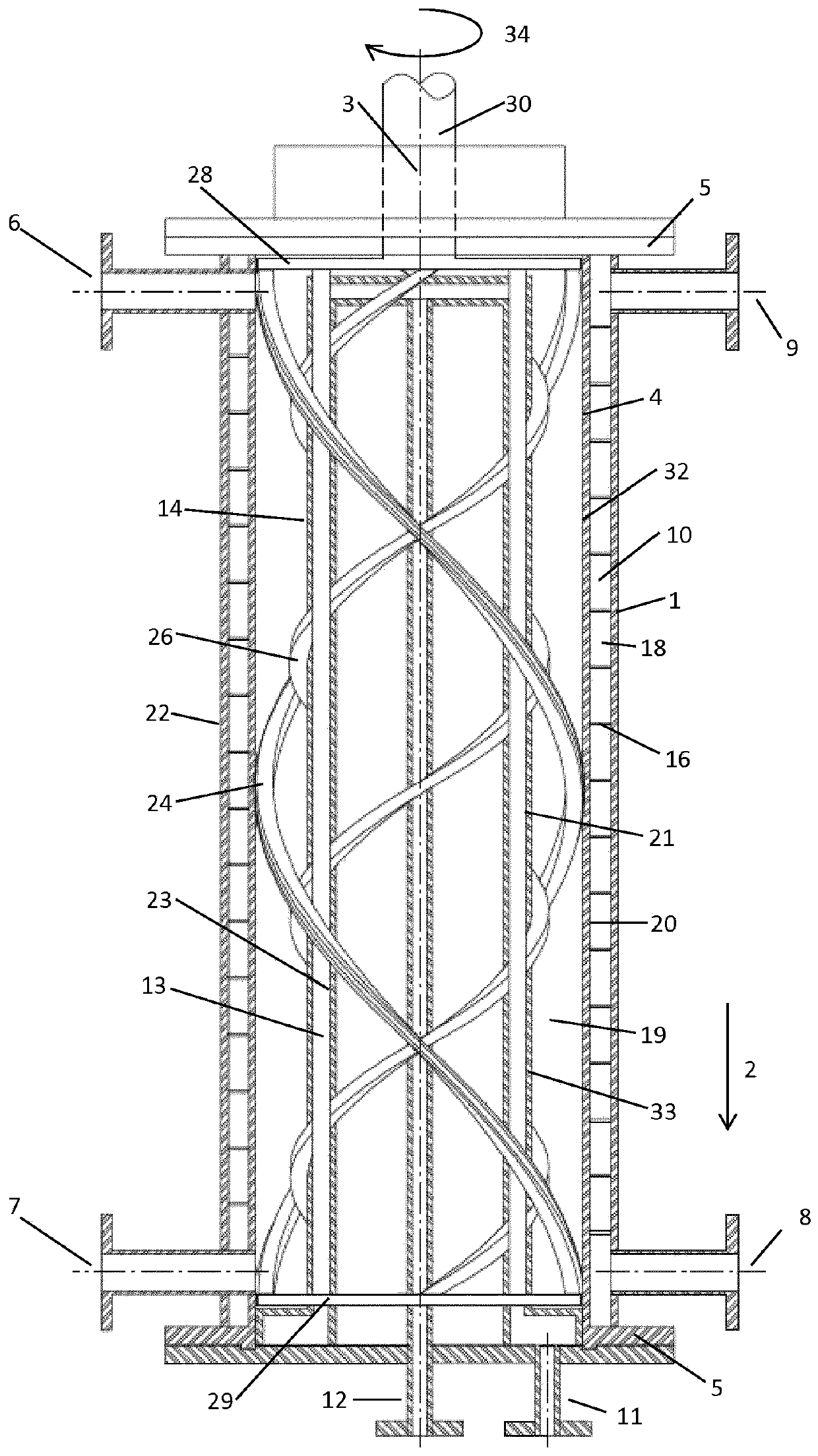

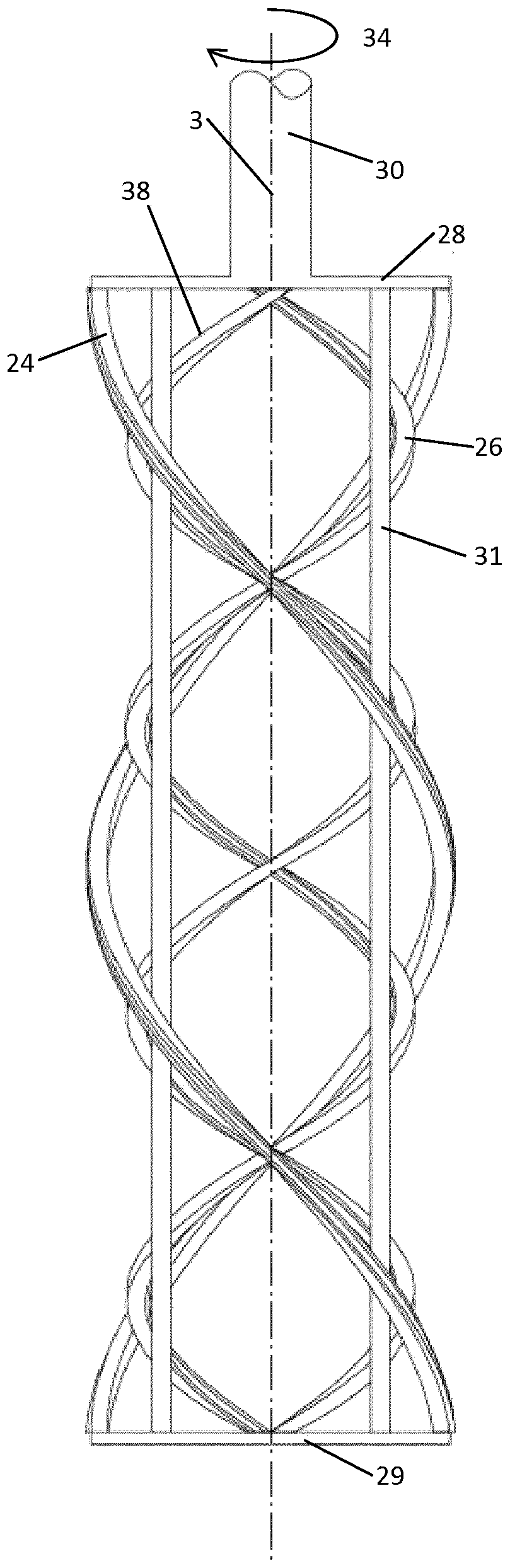

Reactor and method for continuous polymerisation

ActiveCN111032210ALow viscosityHigh heat transferChemical/physical/physico-chemical stationary reactorsEnergy based chemical/physical/physico-chemical processesPolymer scienceSynthetic rubber

The invention relates to a reactor and to a method for continuous polymerisation, in which said reactor for the continuous production of polymers, particularly synthetic rubbers, contains at least onesubstantially tubular reactor housing (4), wherein said reactor housing (4) has a drive shaft (30) that is connected to at least one agitator (38) arranged such that it can rotate inside the reactorhousing (4), and the agitator contains at least one, and preferably two, three or four helical mixing elements (24) which are designed to be preferably close to the wall or to come into contact with the wall.

Owner:ARLANXEO DEUT GMBH

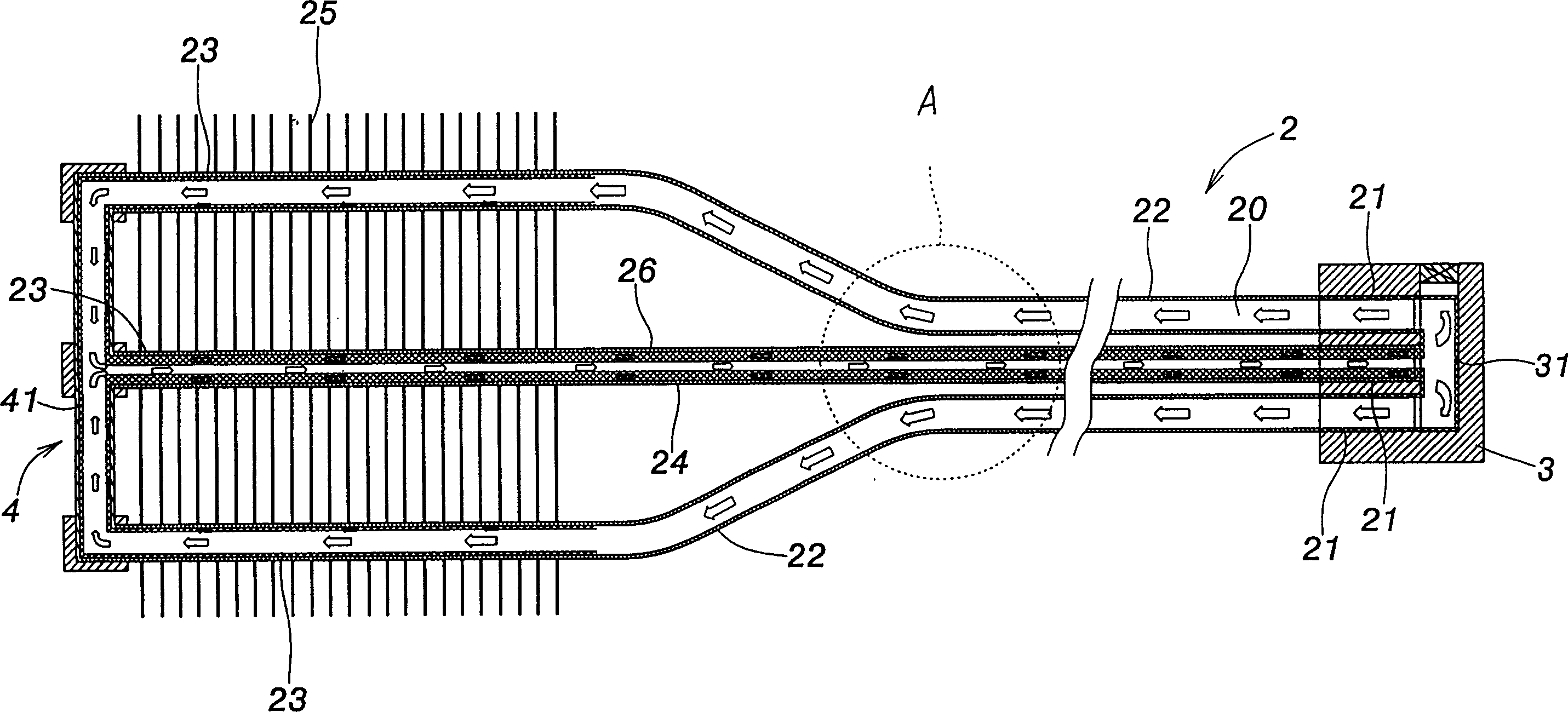

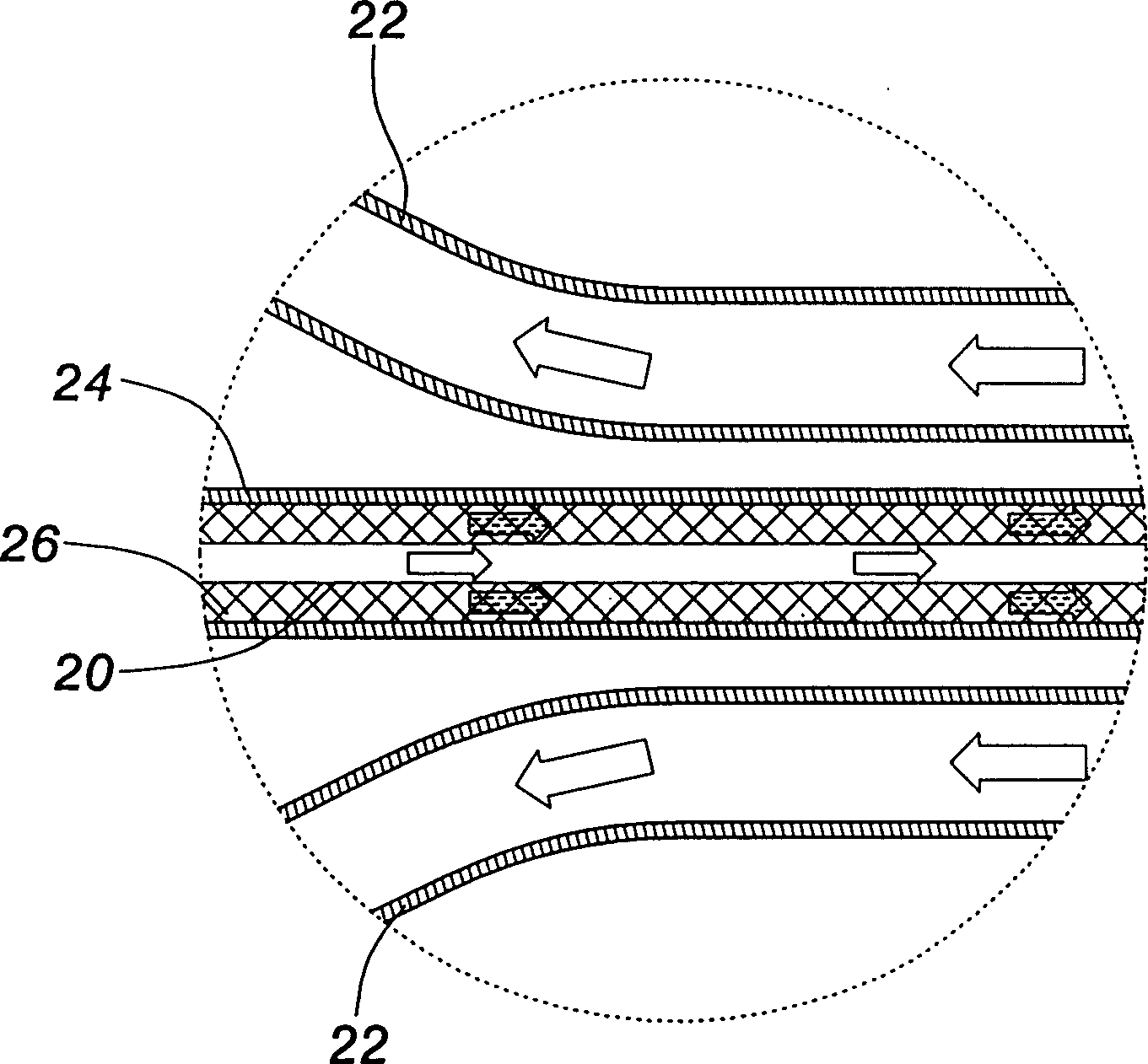

Heat exchange assembly for looped heat pipe

InactiveCN1220028CHigh heat transferImprove heat transfer performanceIndirect heat exchangersEngineeringReturn channel

A circulating-loop hot-tube heat exchange unit has a loop filled with liquid and composed in sequence of serial evaporating part, steam channel, condensing part and fluid return channel. The flowing resistance of fluid in the fluid return channel is higher than that in the steam channel. Its advantages are high heat conductivity, low cost, and long service life.

Owner:李嘉豪

Built-in multi-stage jet pipe type fin heat exchange pipe and manufacturing process thereof

ActiveCN104807359AEnhanced convective heat transferImprove heat transfer efficiencyTubular elementsConvection heatHeat transfer

The invention provides a built-in multi-stage jet pipe type fin heat exchange pipe. The built-in multi-stage jet pipe type fin heat exchange pipe comprises a fin pipe, and a multi-stage jet pipe mounted in the fin pipe, wherein the multi-stage jet pipe comprises at least two second-stage jet pipes which are coaxially connected in series; an opening is formed in one end of each second-stage jet pipe, and an annular sealing cover is welded on the outer wall of the opening end; a bottom cover is welded at the other end of each second-stage jet pipe; the opening ends of the second-stage jet pipes are toward the same direction and in the direction opposite to the cold liquid flowing direction; a certain of space is set between every two adjacent second-stage jet pipes, and the every two adjacent second-stage jet pipes are fixedly connected in series through a pulling rod to form the multi-stage jet pipe; a spraying hole is formed in the wall of each second-stage jet pipe. According to the built-in multi-stage jet pipe type fin heat exchange pipe, the convection heat exchange in the pipe is enhanced through the multi-stage jet pipe; the heat transfer is enhanced at the outside of the pipe by a manner of increasing the heat exchange area through welding fins; therefore, the total heat exchange efficiency can be obviously increased; the heat exchange pipes can be connected in parallel and flexibly designed to be large, medium and small-size heat exchangers according to the demand of the production process.

Owner:NANJING SHENGNUO HEAT PIPE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com