Built-in multi-stage jet pipe type fin heat exchange pipe and manufacturing process thereof

A jet tube and finned tube technology, applied in the field of built-in multi-stage jet tube finned heat exchange tubes and its manufacturing process, can solve the problem that large and medium-sized heat exchangers cannot be used for waste heat recovery, and no heat exchange enhancement measures have been taken , unable to greatly improve the comprehensive heat transfer coefficient, etc., to achieve the effect of increasing heat transfer, improving heat transfer efficiency, and expanding heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

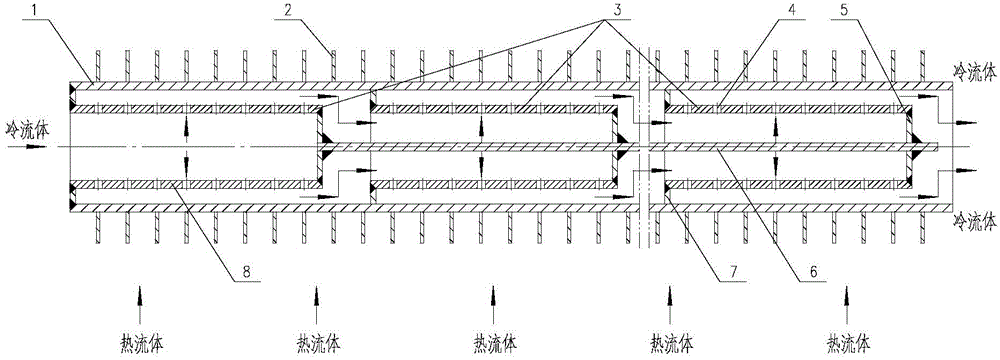

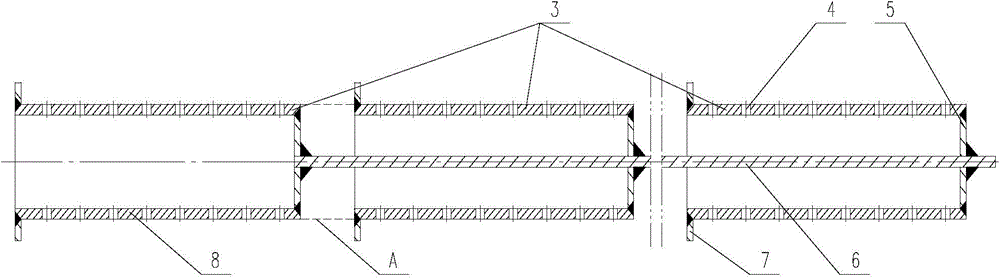

[0043] like figure 1 , 2 As shown, the built-in multi-stage jet tube finned heat exchange tube provided by the present invention includes a fin tube 1, and a multi-stage jet tube 3 is installed inside the fin tube, and the multi-stage jet tube 3 includes at least Two coaxial sub-level jet tubes connected in series; one end of each sub-level jet tube is open, and an annular cover 7 is welded on the outer wall at the open end, and a bottom cover with a central hole is welded at the other end 5. The open ends of the jet tubes of each sub-level are in the same direction, which is opposite to the flow direction of the cold fluid; put the tie rod 6 through the center hole of the bottom cover 5 of the jet tubes of each sub-level to ensure that the gap between the jet tubes of two adjacent sub-levels A certain distance is left, and then the tie rod 6 is welded step by step with the bottom cover 5 of each sub-stage jet tube, and connected in series to form a multi-stage jet tube 3 . Sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com