Built-in spring tubular reactor

A tubular reactor and built-in spring technology, applied in the field of reactors, can solve the problems of continuous and stable operation of the reactor, difficulty in the flow of the reaction liquid, blockage of the reaction tube, etc., achieve good reaction effect, enhance convective heat transfer, and eliminate air bubbles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

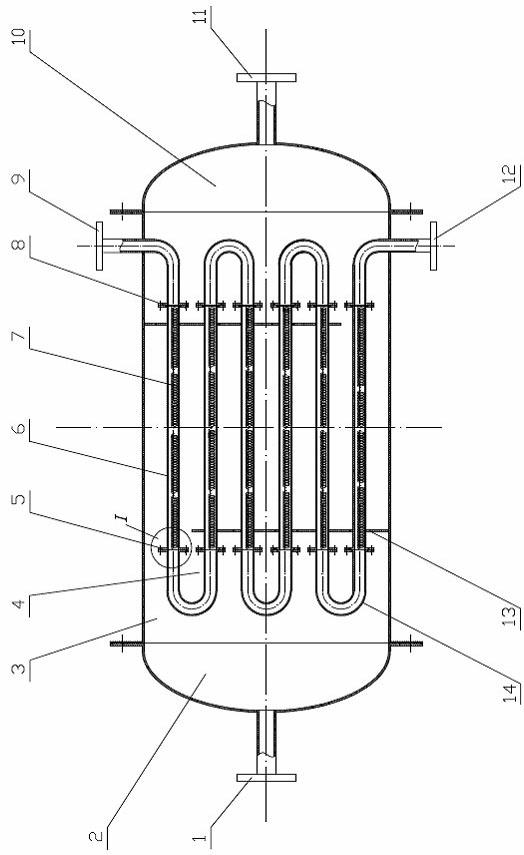

[0026] The inner diameter of the inner spring tubular reactor is 150 mm, and the inner diameter of the serpentine reaction tube is lined with Teflon (such as polytetrafluoroethylene, fluorinated ethylene propylene copolymer or polyfluoroalkoxy) non-stick coating, used for the use of excess nitric acid Nitrification reaction. The structure of the tubular reactor is shown in the appendix figure 1 to attach image 3 .

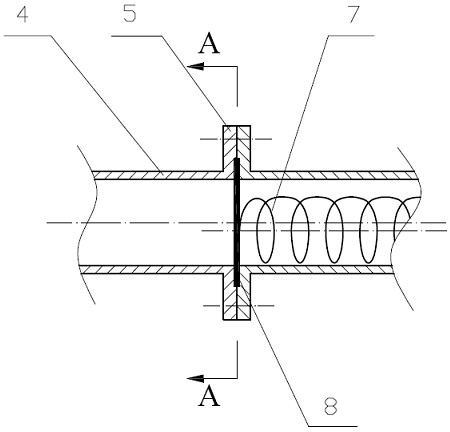

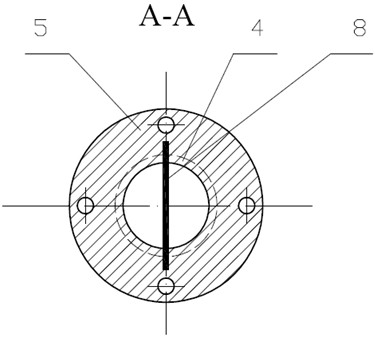

[0027] The reaction section consists of 6 straight reaction pipes connected in series to provide sufficient reaction space and residence time. Multiple straight reaction tubes are connected with U-shaped connecting tubes. The center of the pipe flange is engraved with a card slot, and the stainless steel metal thin rod is embedded in the card slot, and is fastened and fixed by the left and right flanges. The springs in each reaction tube are divided into 6 sections, the two end springs are positioned by thin metal rods, the two ends of the springs are tightly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com