Patents

Literature

130results about How to "Enhanced agitation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

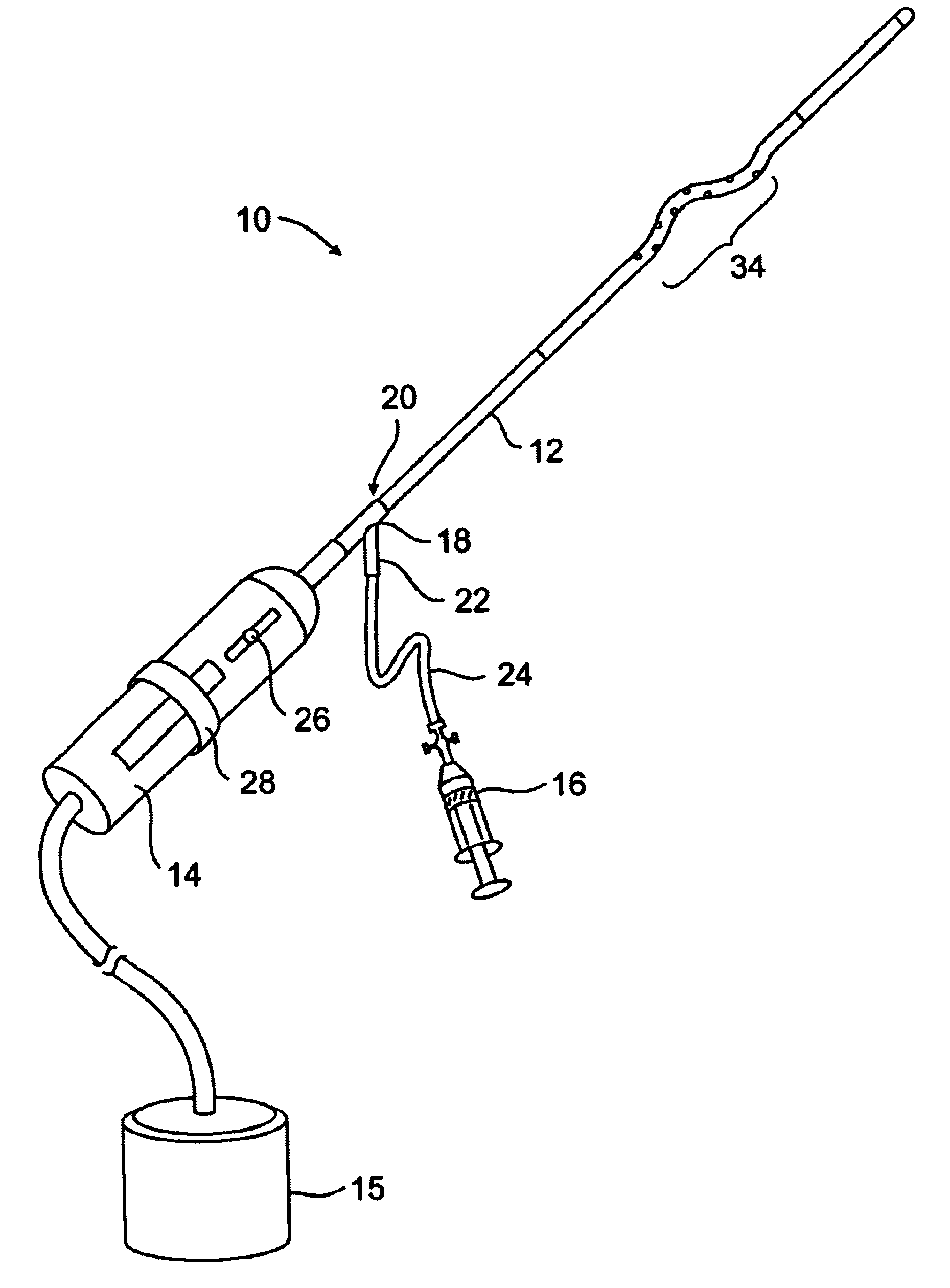

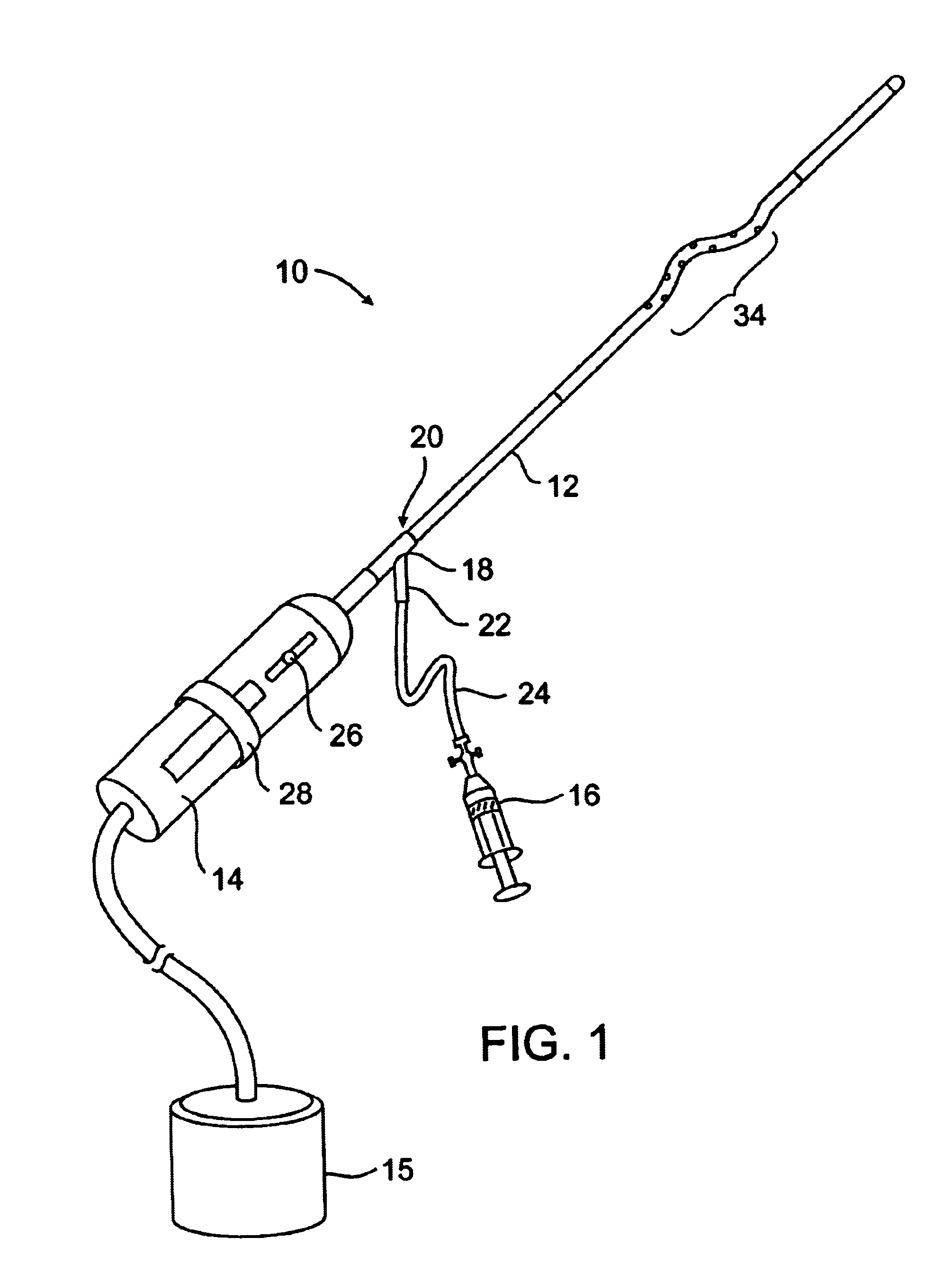

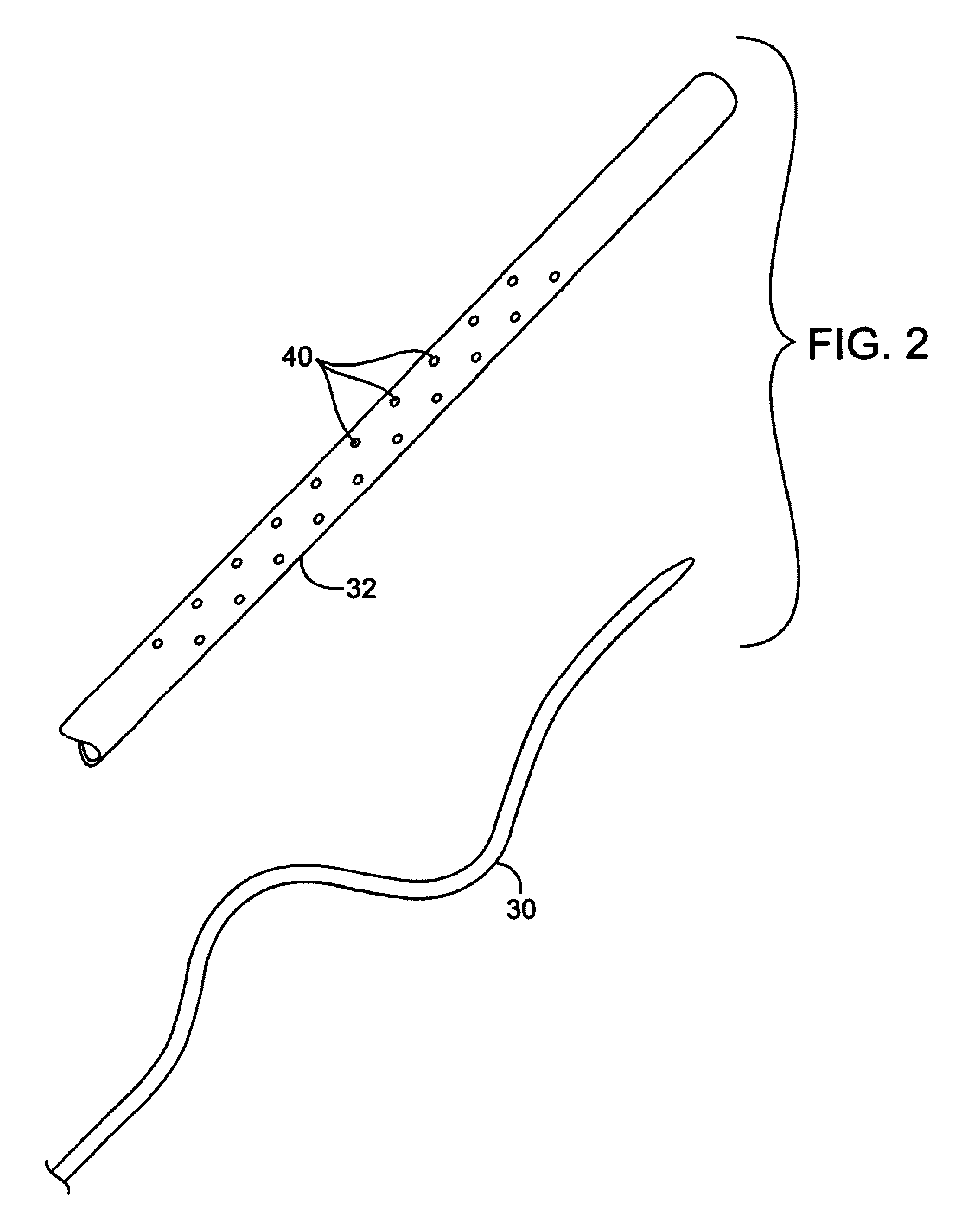

System and methods for clot dissolution

Clot disruption and dissolution are achieved using a catheter having both an agitator and the ability to deliver a thrombolytic agent. The catheter is introduced to a target region with a blood vessel and the agitator manipulated to engage and disrupt a region of clot therein. The thrombolytic agent, such as tPA, streptokinase, or urokinase, is directly released into the clot at the point where the agitator is engaging the clot. In this way, the thrombolytic activity of the agent is enhanced and the dissolution of the clot is improved.

Owner:TYCO HEALTHCARE GRP LP

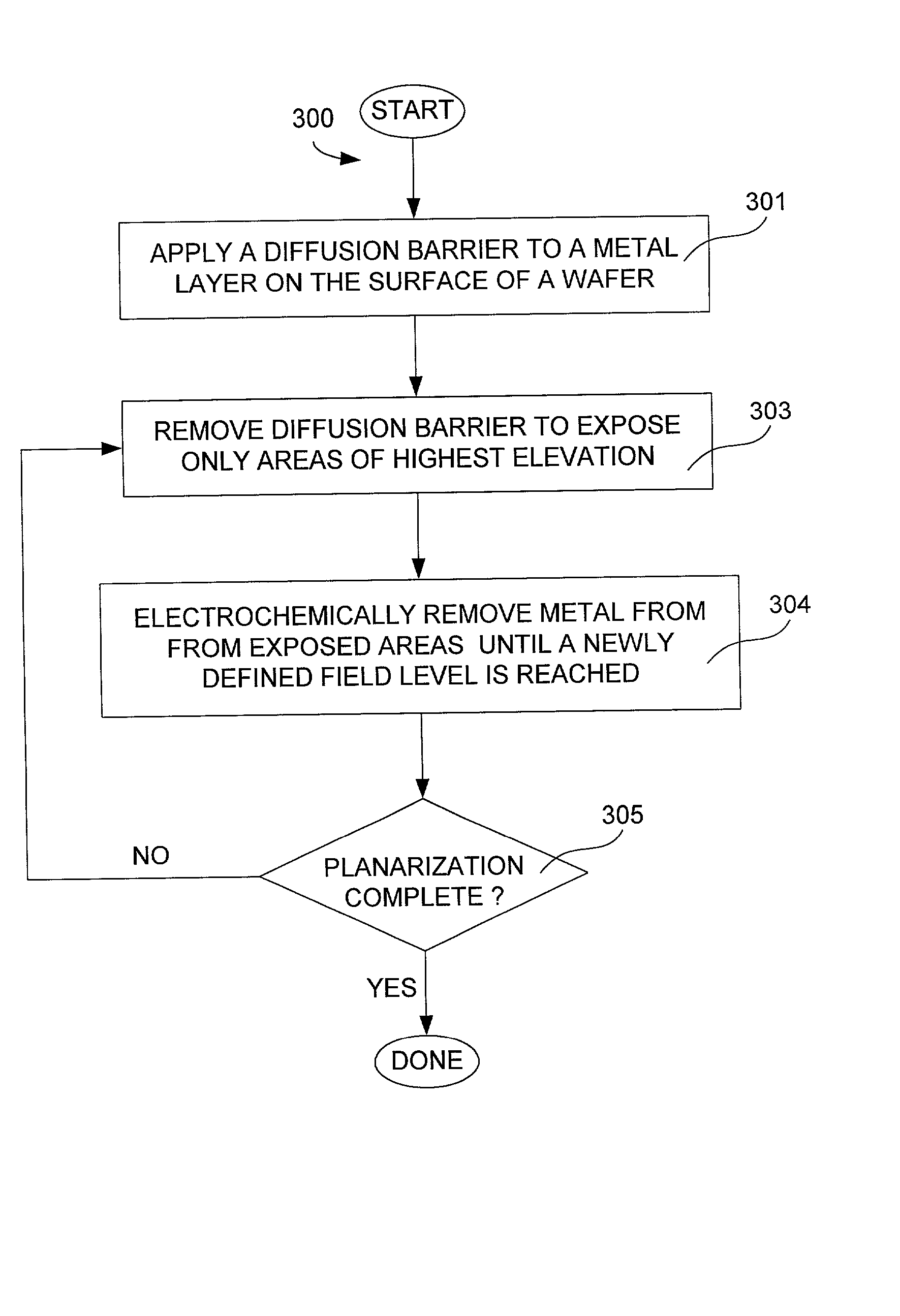

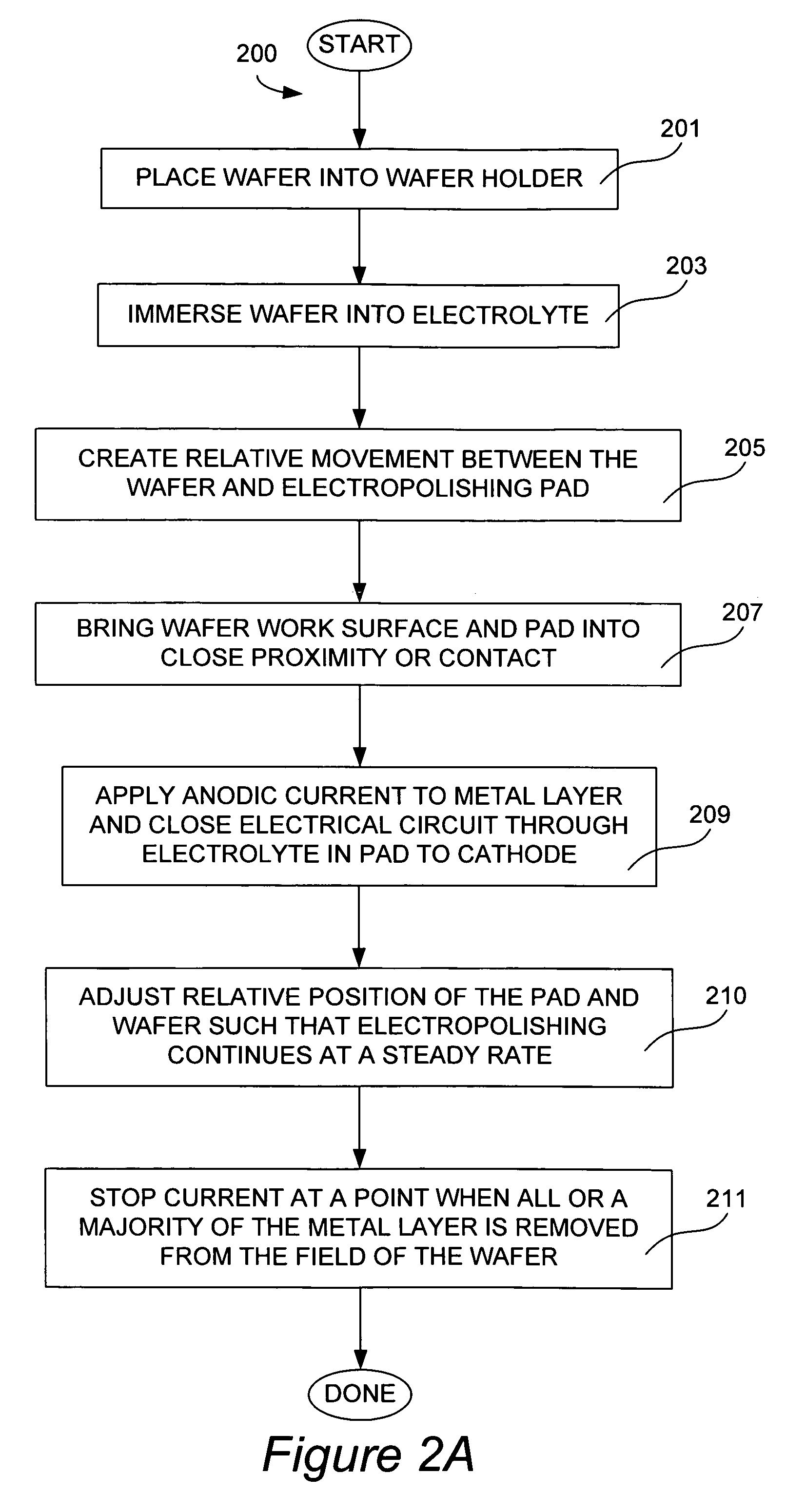

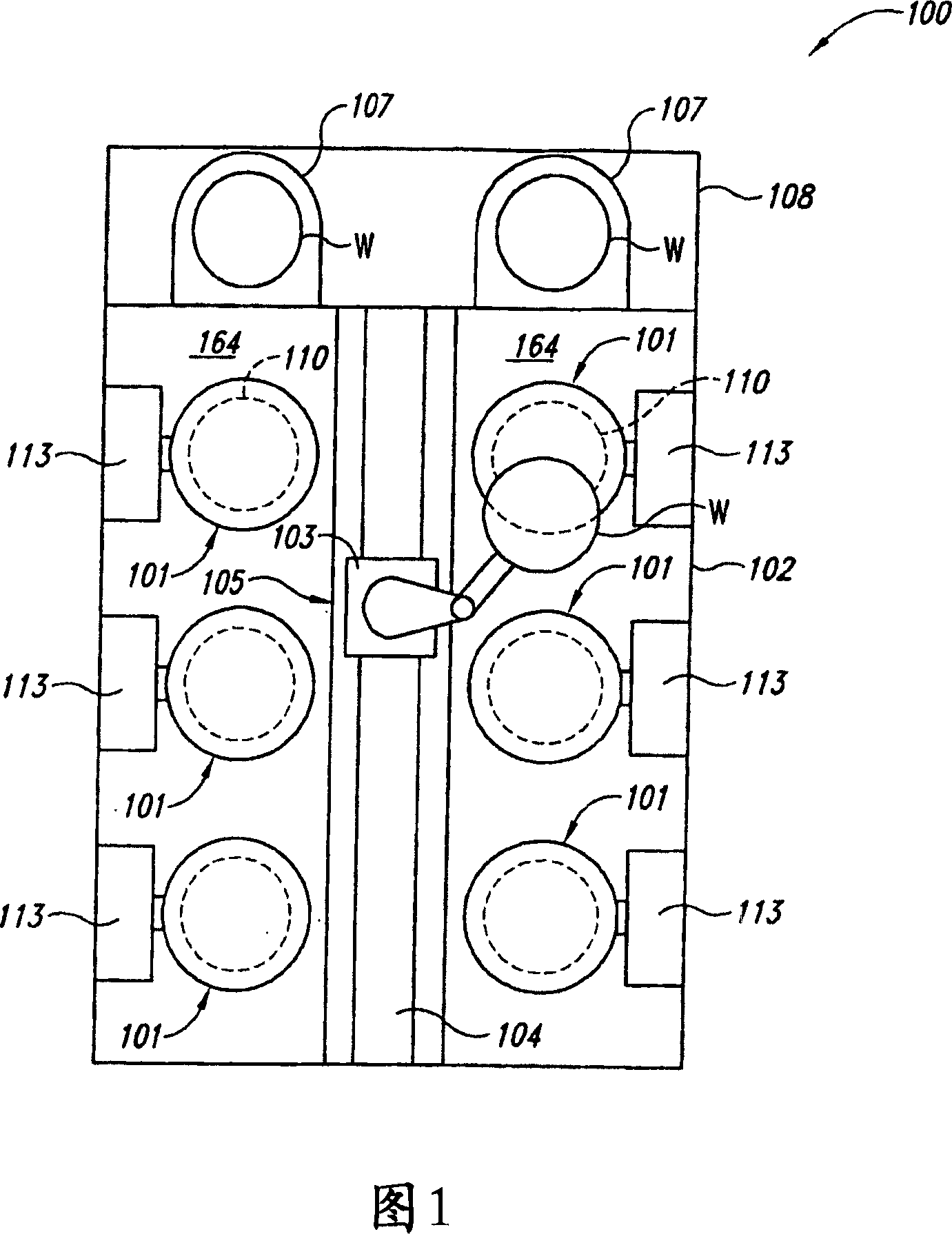

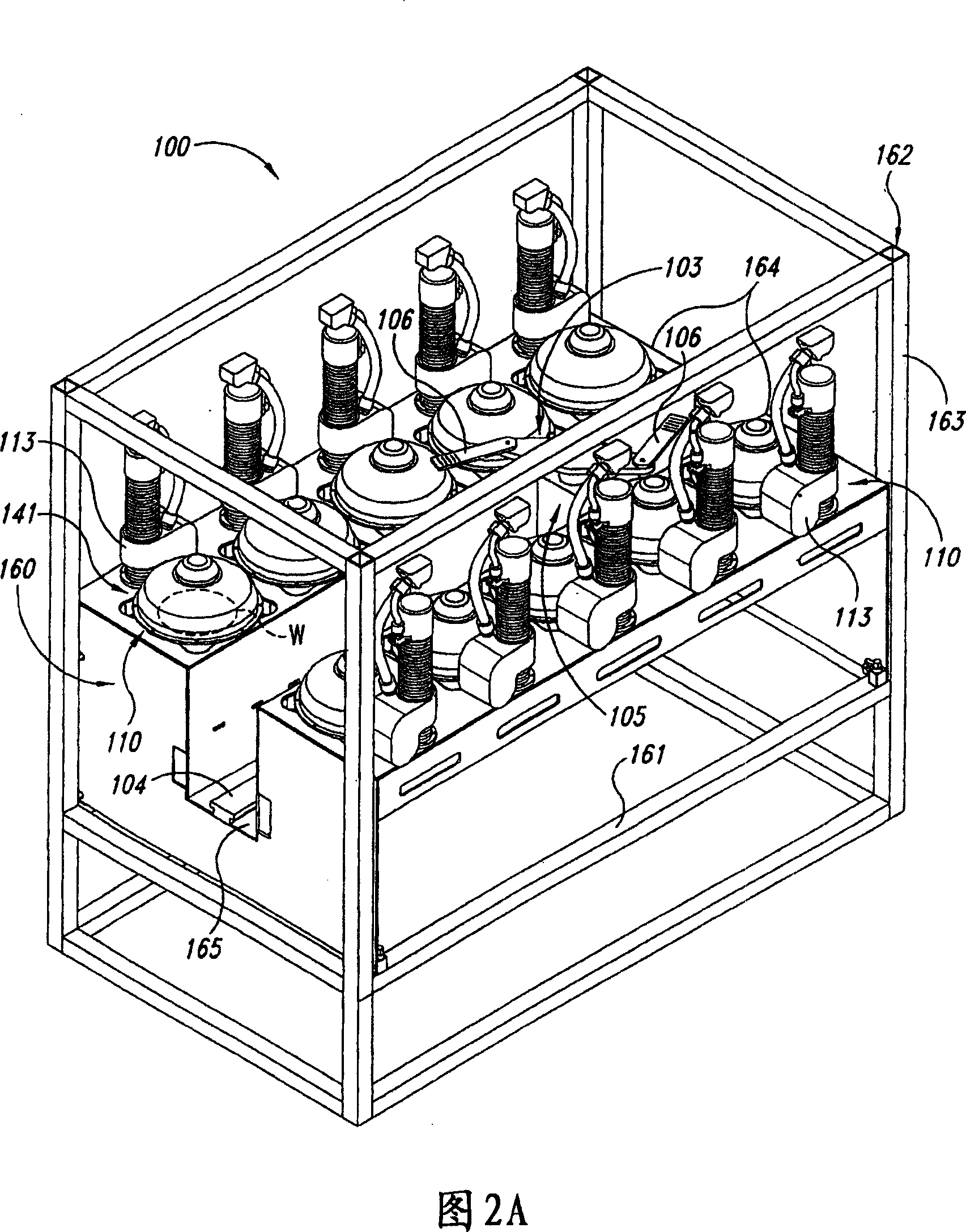

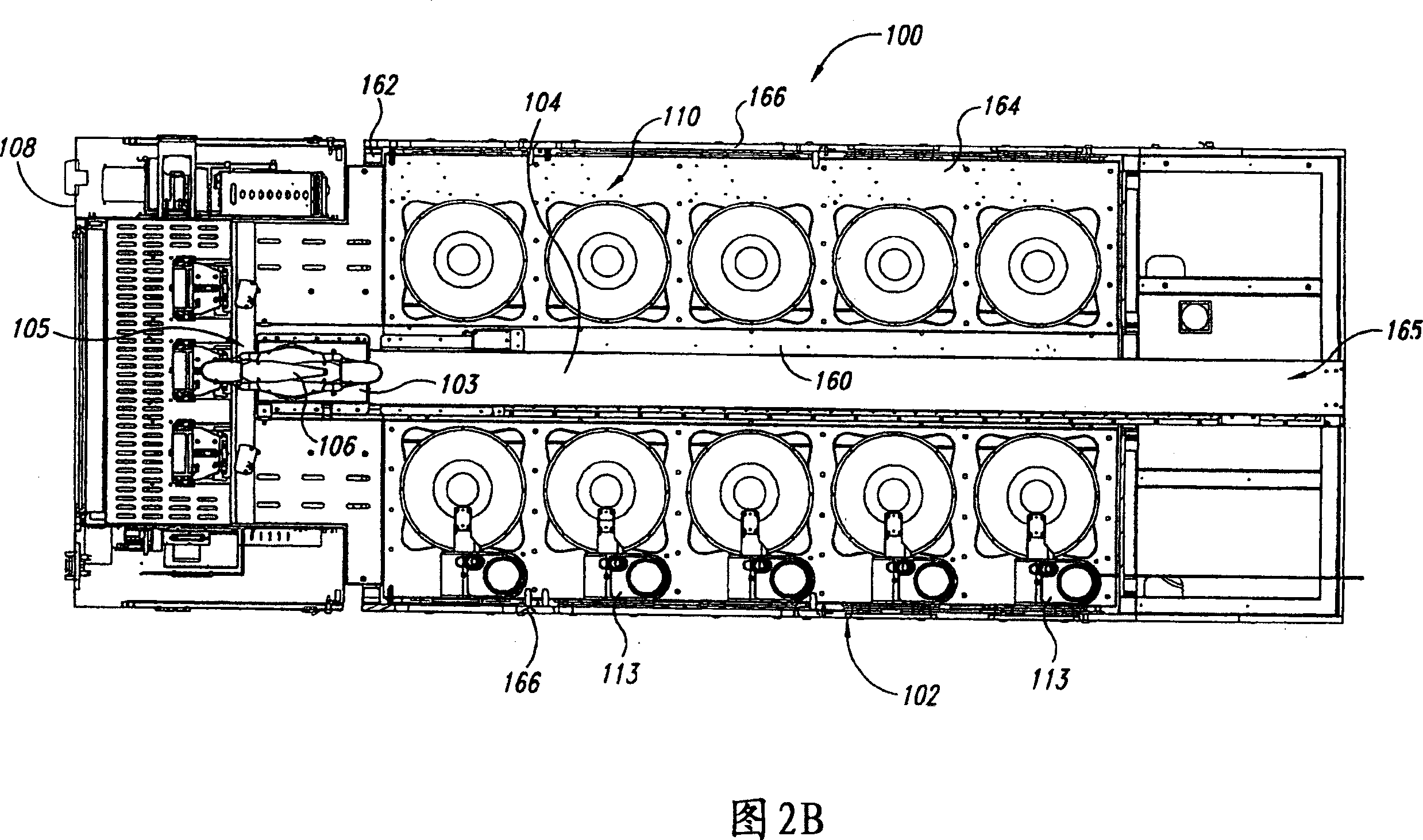

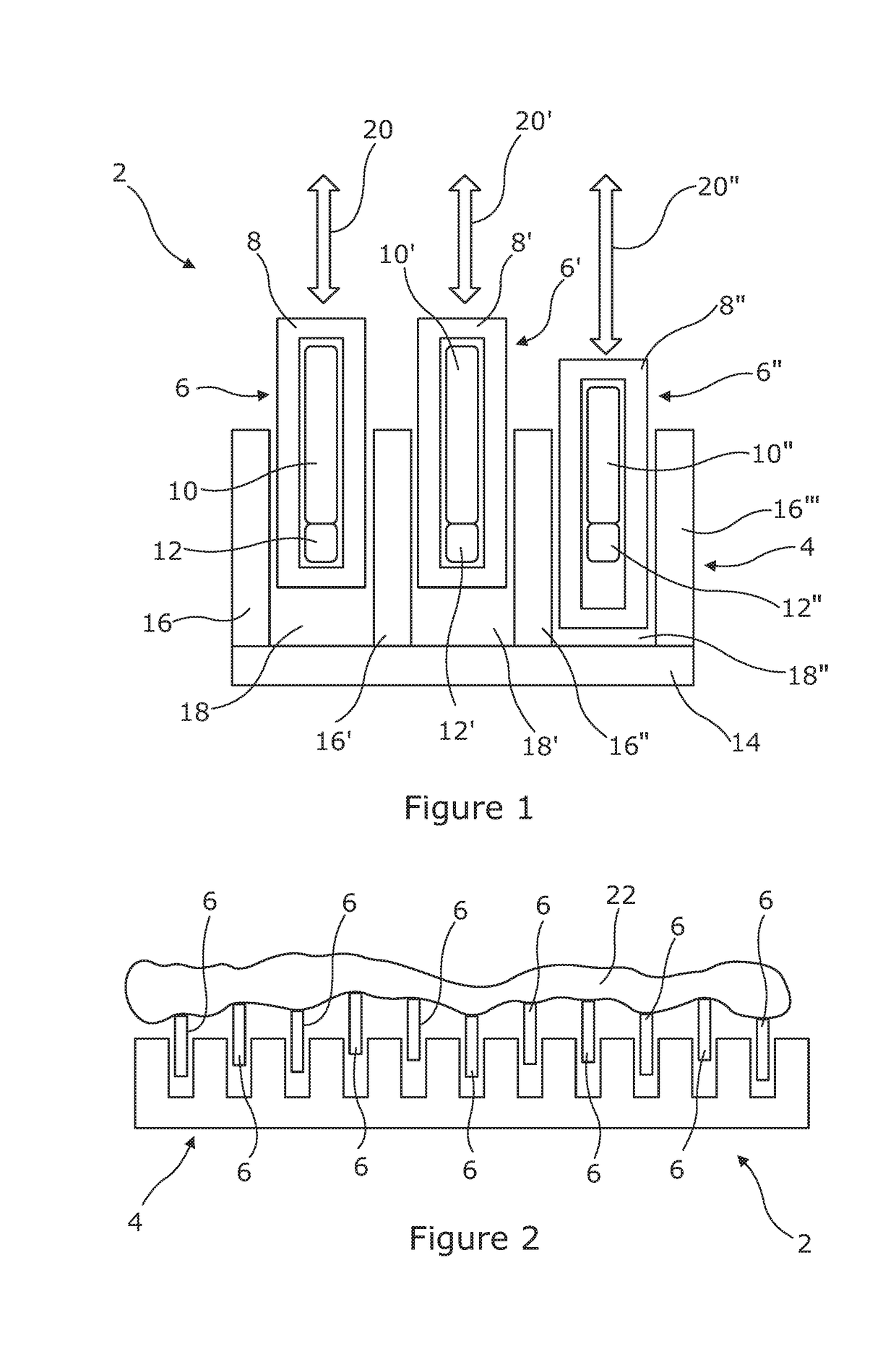

Method and apparatus for uniform electropolishing of damascene ic structures by selective agitation

InactiveUS20020074238A1Small apertureSufficiently porousElectrolysis componentsSemiconductor/solid-state device manufacturingElectricityElectrolysis

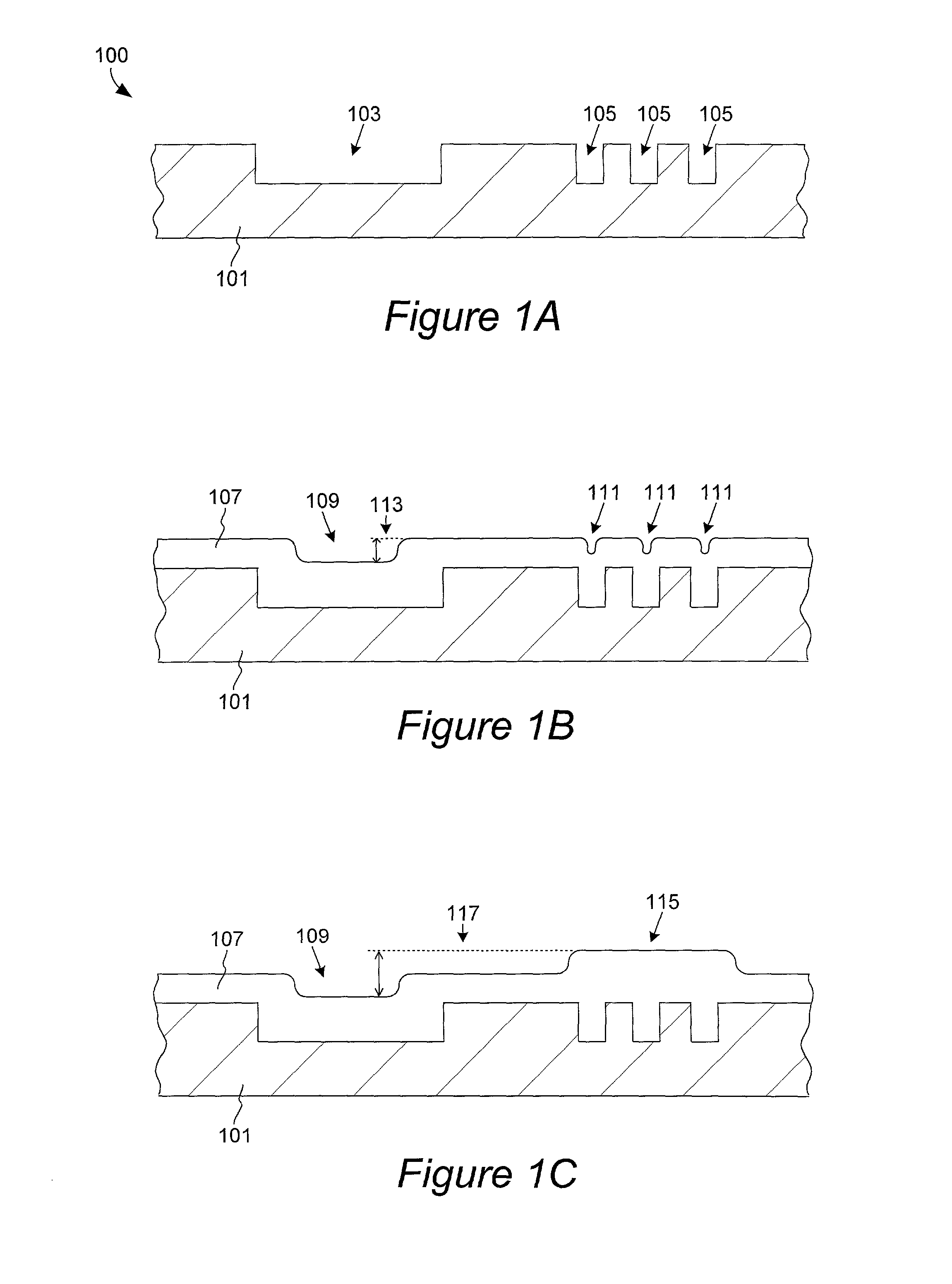

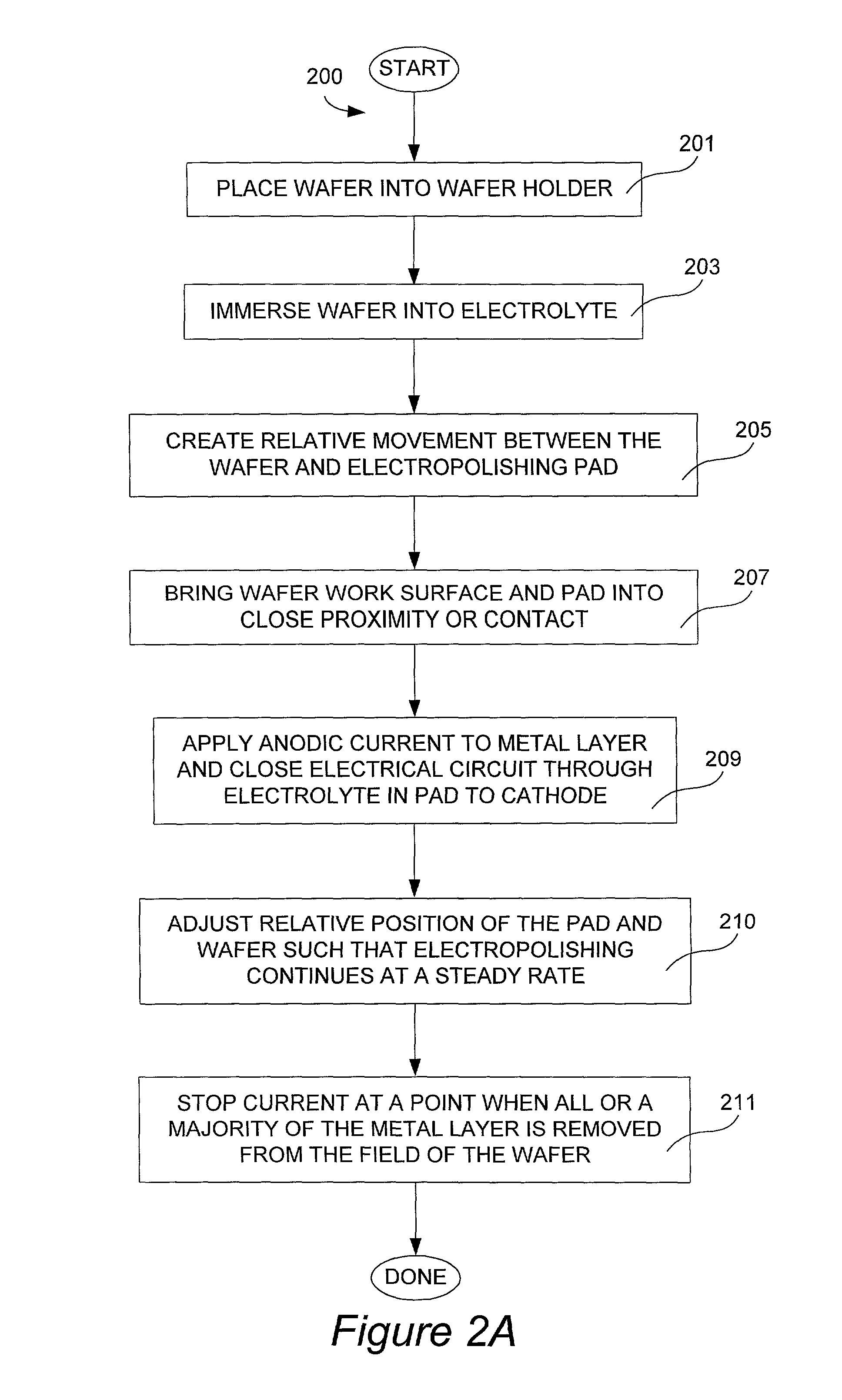

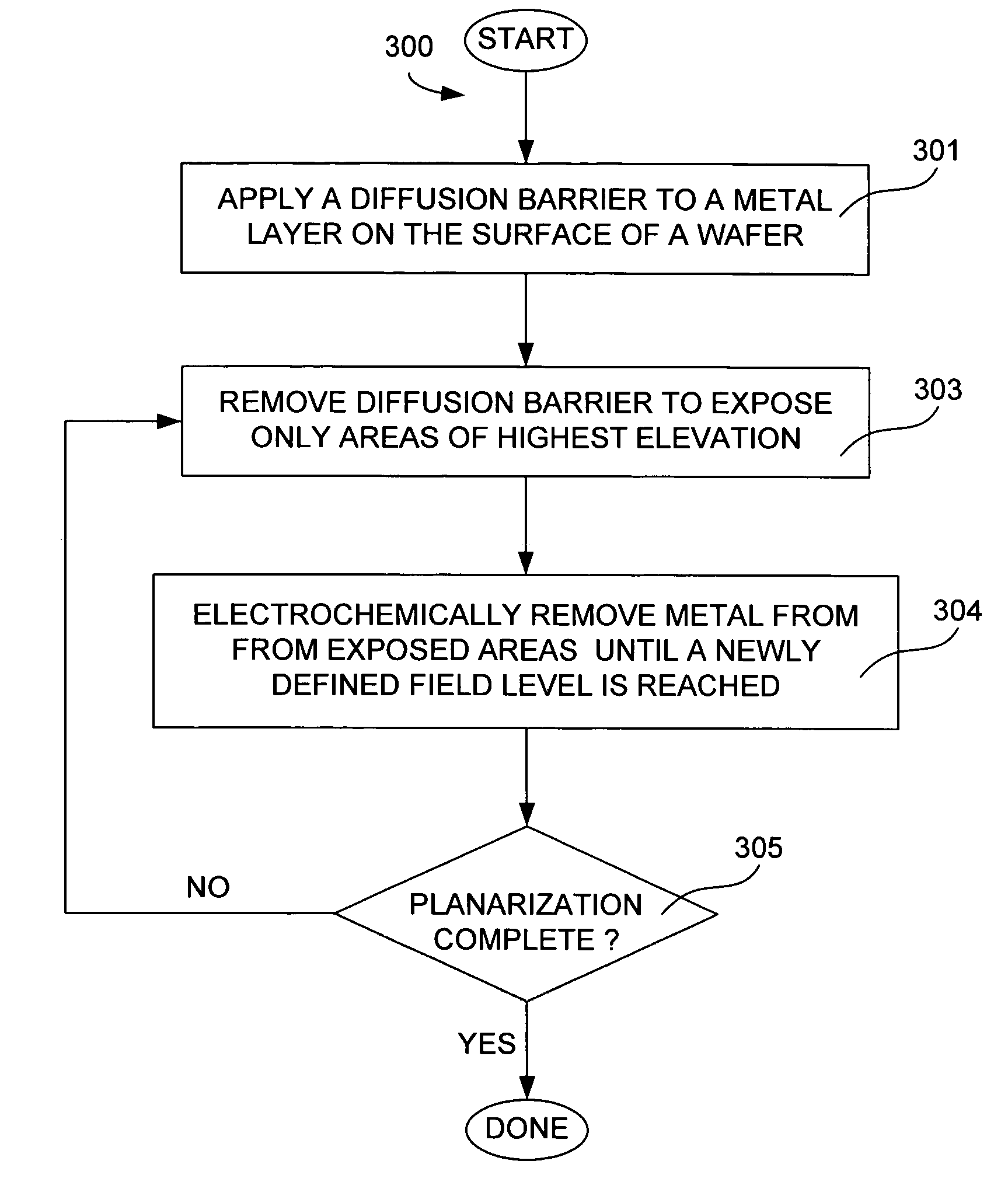

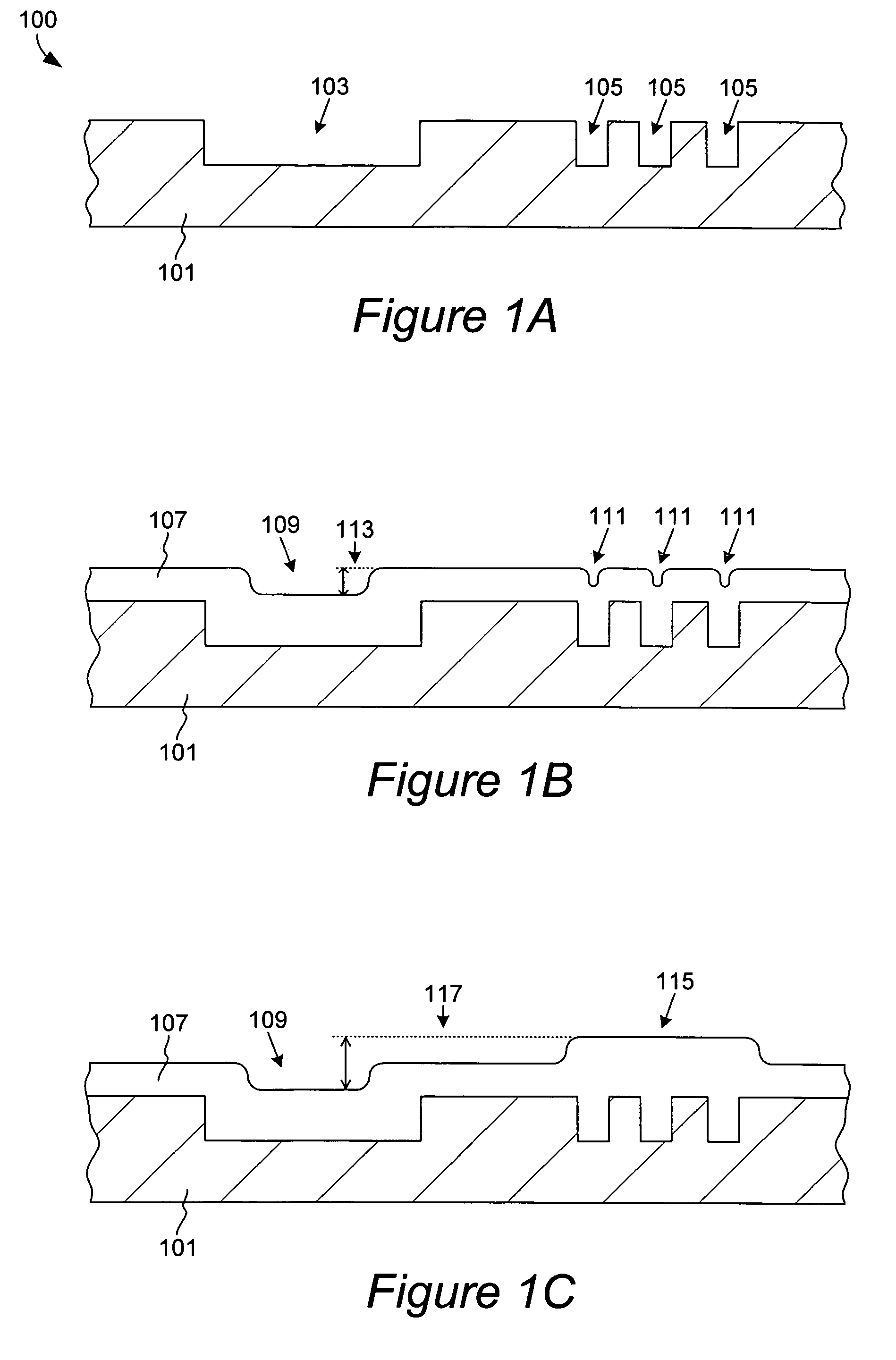

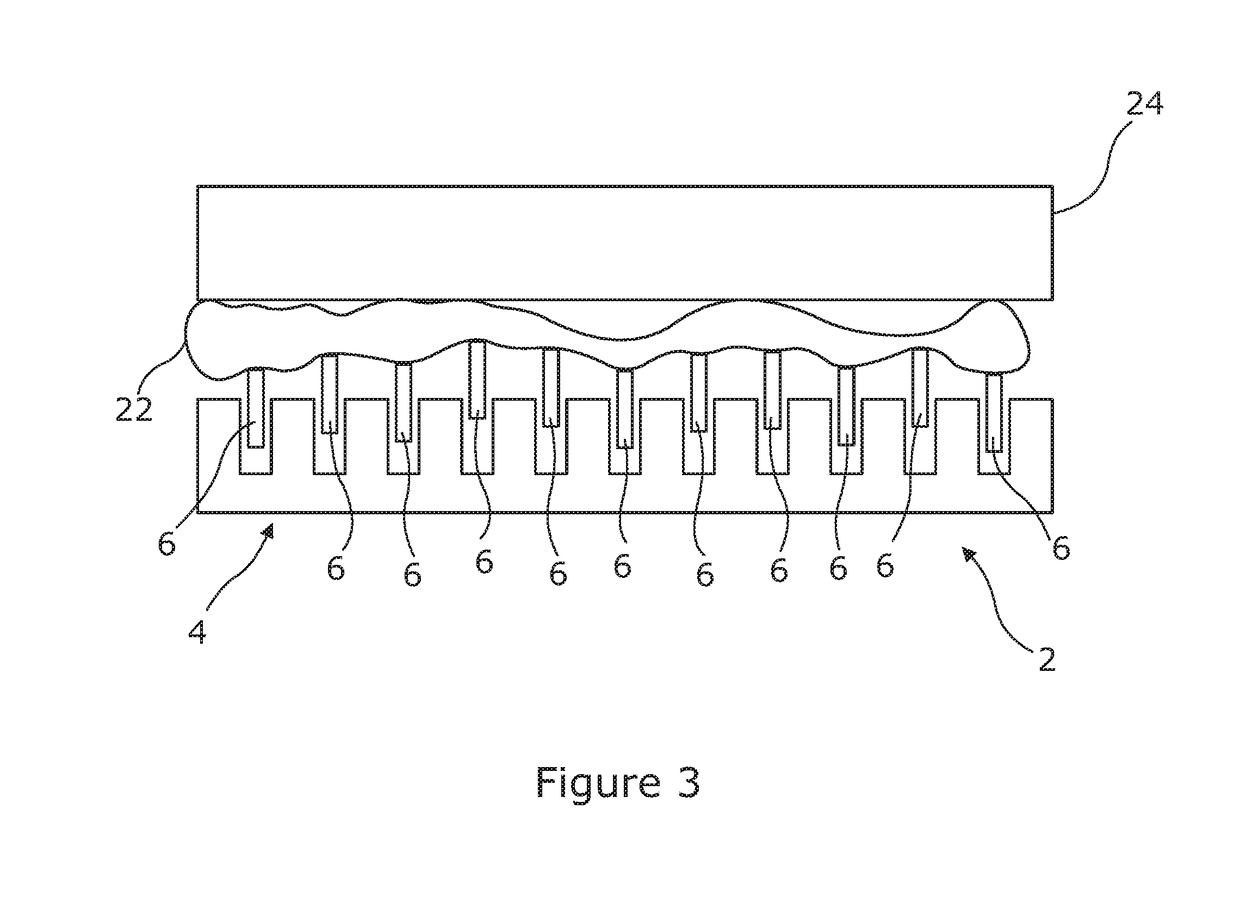

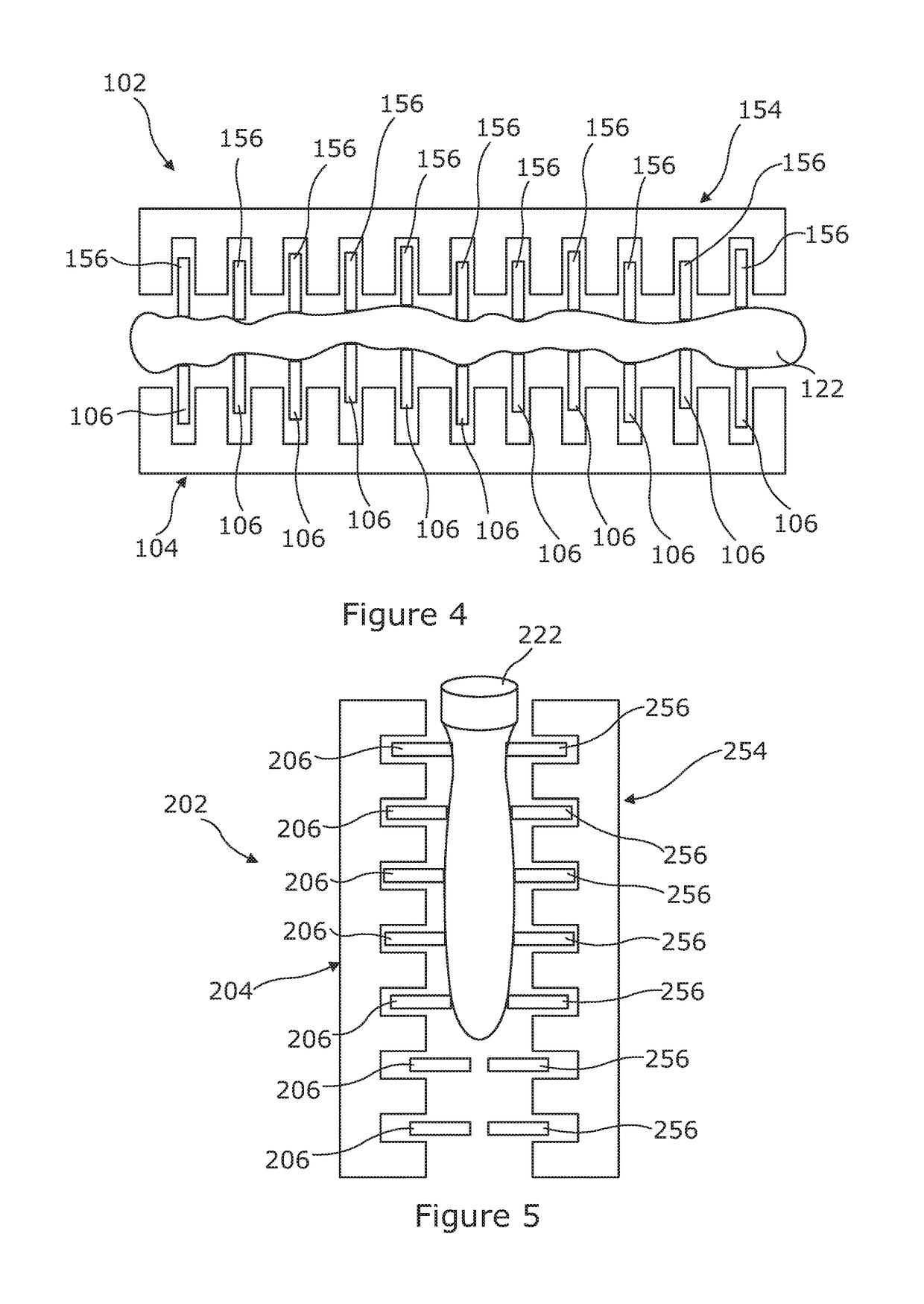

The present invention pertains to apparatus and methods for planarization of metal surfaces having both recessed and raised features, over a large range of feature sizes. The invention accomplishes this by increasing the fluid agitation in raised regions with respect to recessed regions. That is, the agitation of the electropolishing bath fluid is agitated or exchanged as a function of elevation on the metal film profile. The higher the elevation, the greater the movement or exchange rate of bath fluid. In preferred methods of the invention, this agitation is achieved through the use of a microporous electropolishing pad that moves over (either near or in contact with) the surface of the wafer during the electropolishing process. Thus, methods of the invention are electropolishing methods, which in some cases include mechanical polishing elements.

Owner:NOVELLUS SYSTEMS

Method and apparatus for uniform electropolishing of damascene IC structures by selective agitation

InactiveUS7531079B1Small apertureSufficiently porousElectrolysis componentsSemiconductor/solid-state device manufacturingBiomedical engineeringLarge range

The present invention pertains to apparatus and methods for planarization of metal surfaces having both recessed and raised features, over a large range of feature sizes. The invention accomplishes this by increasing the fluid agitation in raised regions with respect to recessed regions. That is, the agitation of the electropolishing bath fluid is agitated or exchanged as a function of elevation on the metal film profile. The higher the elevation, the greater the movement or exchange rate of bath fluid. In preferred methods of the invention, this agitation is achieved through the use of a microporous electropolishing pad that moves over (either near or in contact with) the surface of the wafer during the electropolishing process. Thus, methods of the invention are electropolishing methods, which in some cases include mechanical polishing elements.

Owner:NOVELLUS SYSTEMS

Methods and systems for processing microfeature workpieces with flow agitators and/or multiple electrodes

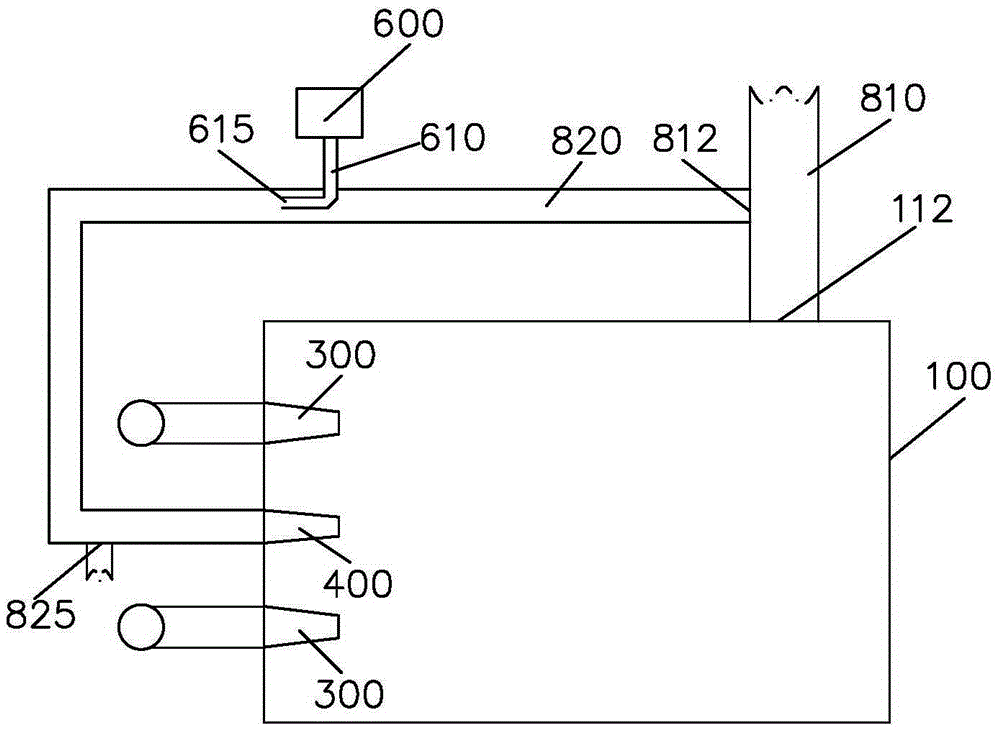

InactiveCN1960799AEnhanced agitationImprove quality transfer effectShaking/oscillating/vibrating mixersTanksElectricityComputer module

A tool with installation module is disclosed. The installation module has an aligning system and comprises a positioning element for precise positioning the reactor and the workpiece transferring device which moves the workpiece into and out of the reactor. The module is fixed at the relative position between the positioning elements of the reactor, therefore, the workpiece transferring device do not need to be re-marked when the reactor is detached and changed by another one. The reactor includes an agitator for agitating the treating fluid on the treated surface of the workpiece. The agitator, the reactor and the electrodes in the reactor is configured to reduce the probability of generating electric shadow by the agitator, and the 3-D effect to electric field, when the beater and / or workpiece receiver move relatively, is considered.

Owner:塞米用具公司

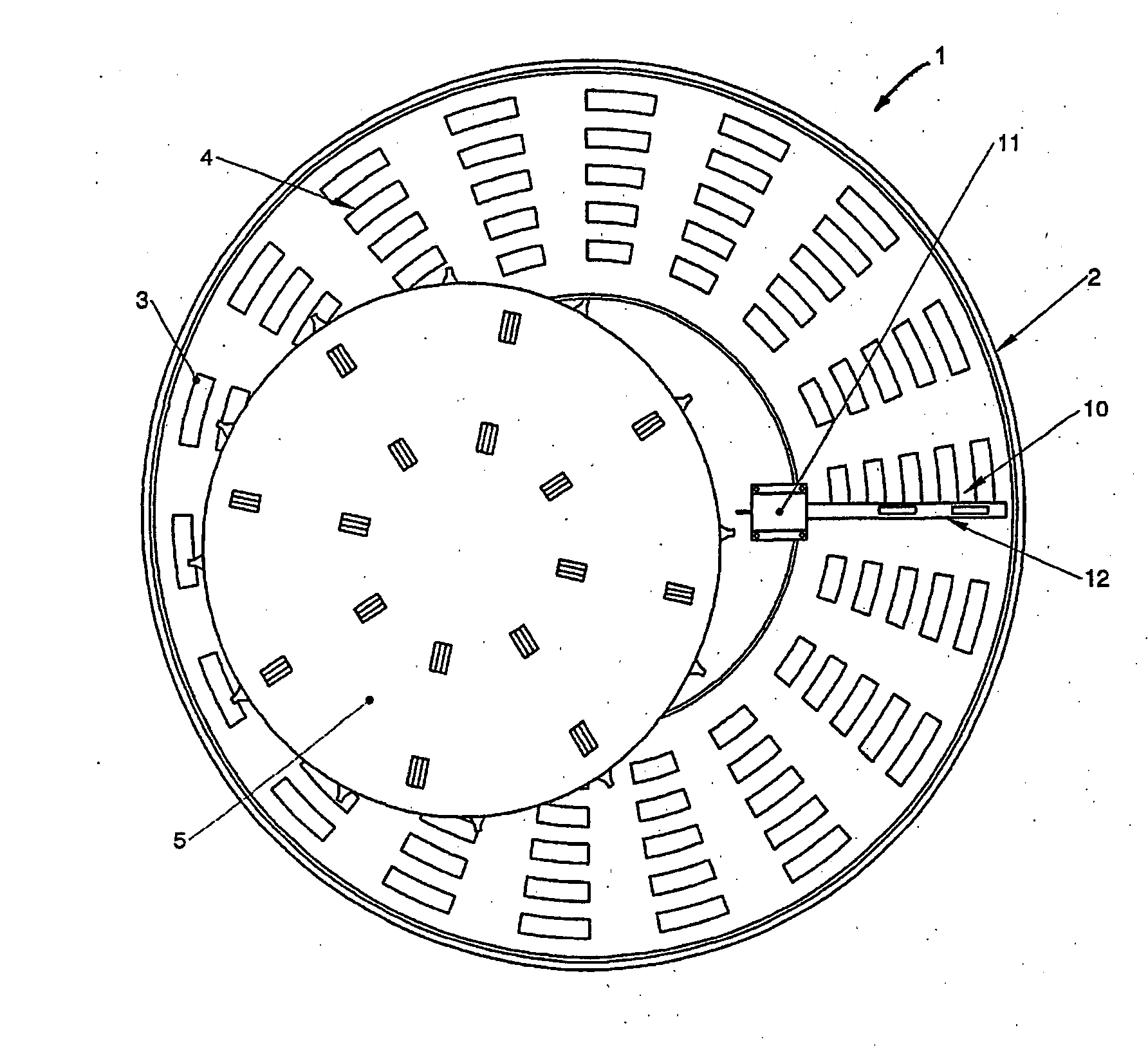

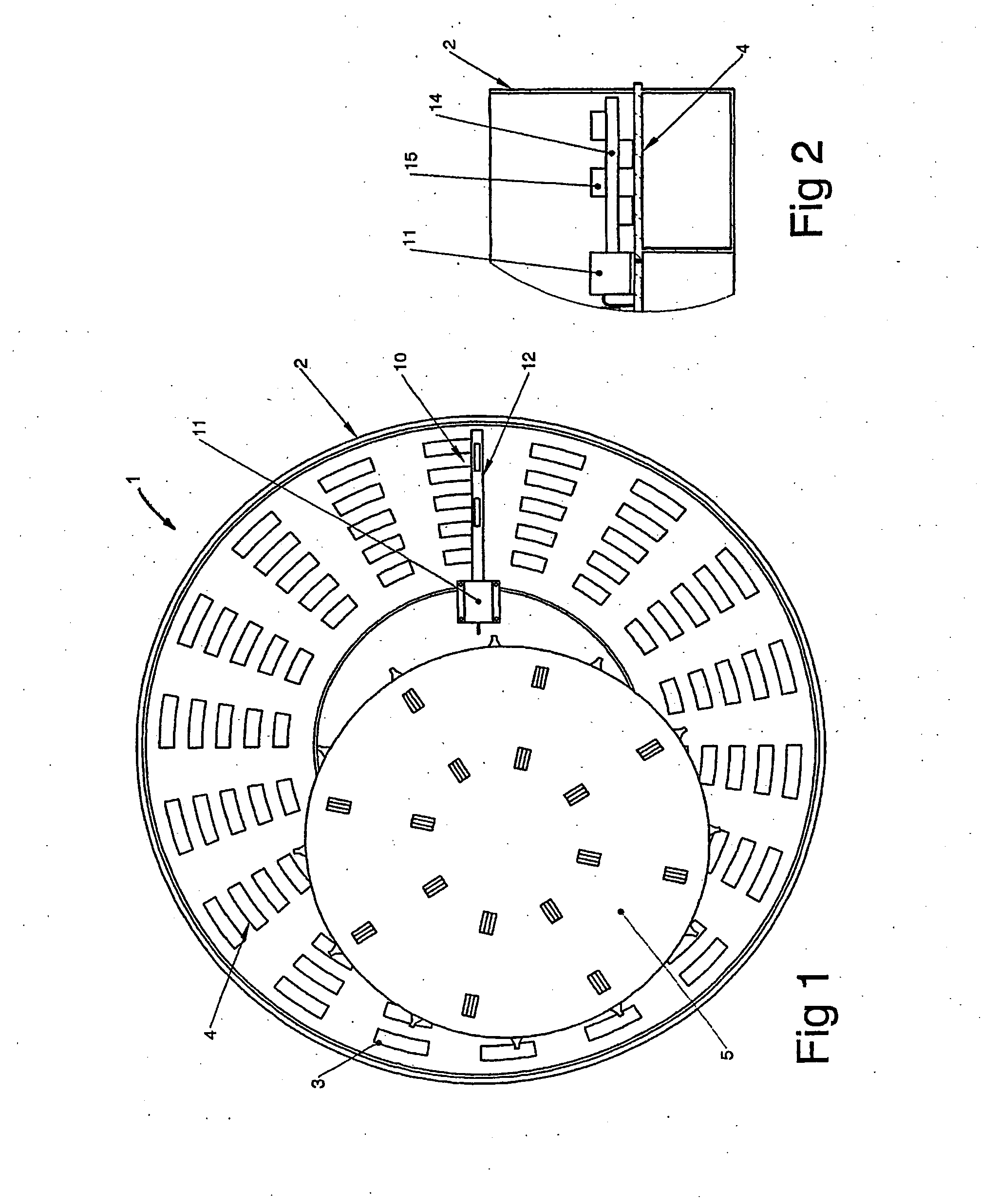

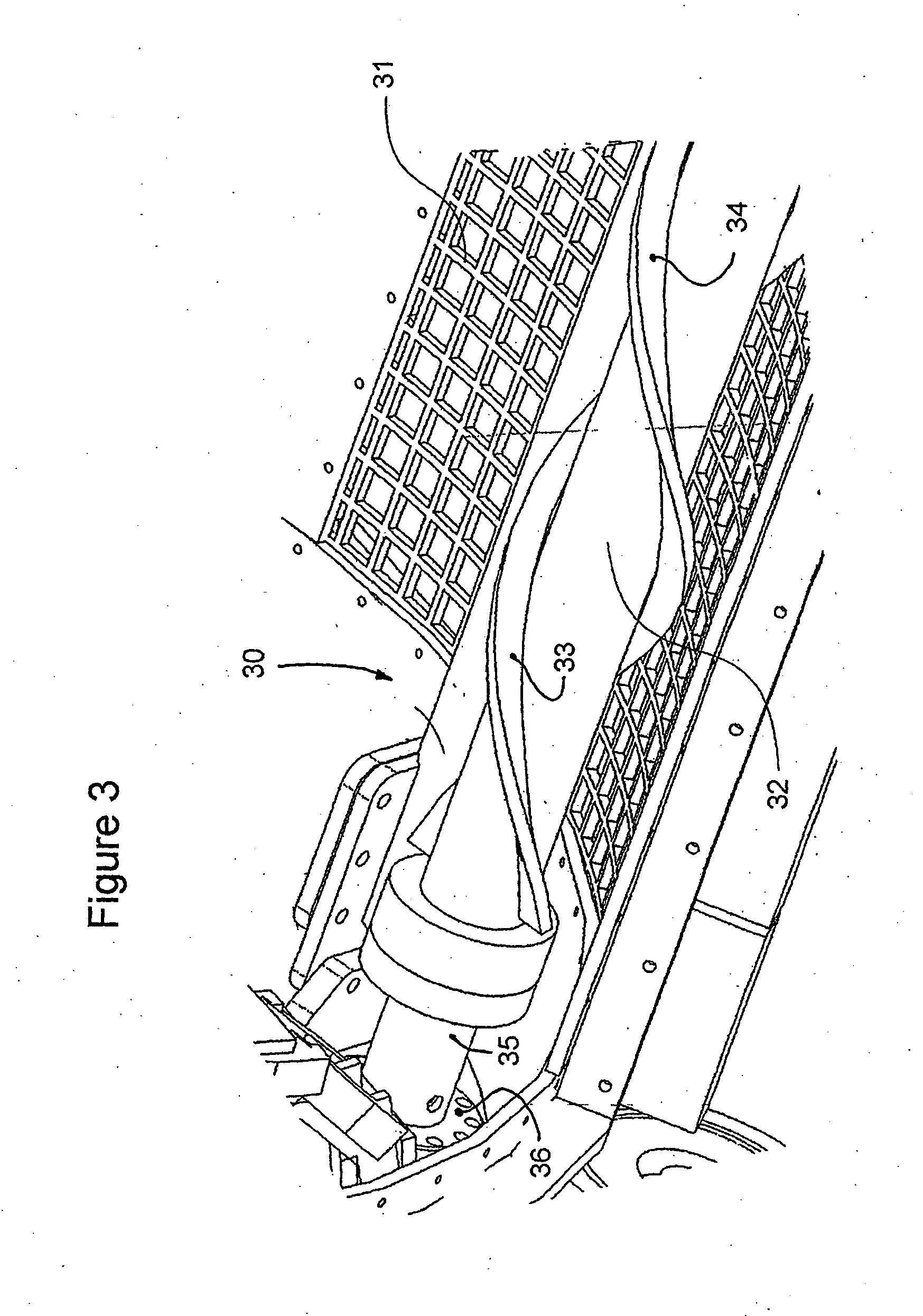

Dynamic screen process for hogging apparatus

InactiveUS20060219828A1Flexibility in positioningFlexibility in orientationSievingScreeningEngineering

The present invention relates to the use of an agitator (10) positioned near the screen (4) of a hogger to increase turbulence in that region. The induced turbulence from the driven blades (15) of the agitator (10) reorients material contained within the hogger (1), thereby representing the material to the screen (4) and grinding disc (5) with potential improvements in both screening and comminuting efficiency.

Owner:PROGRESSIVE IP

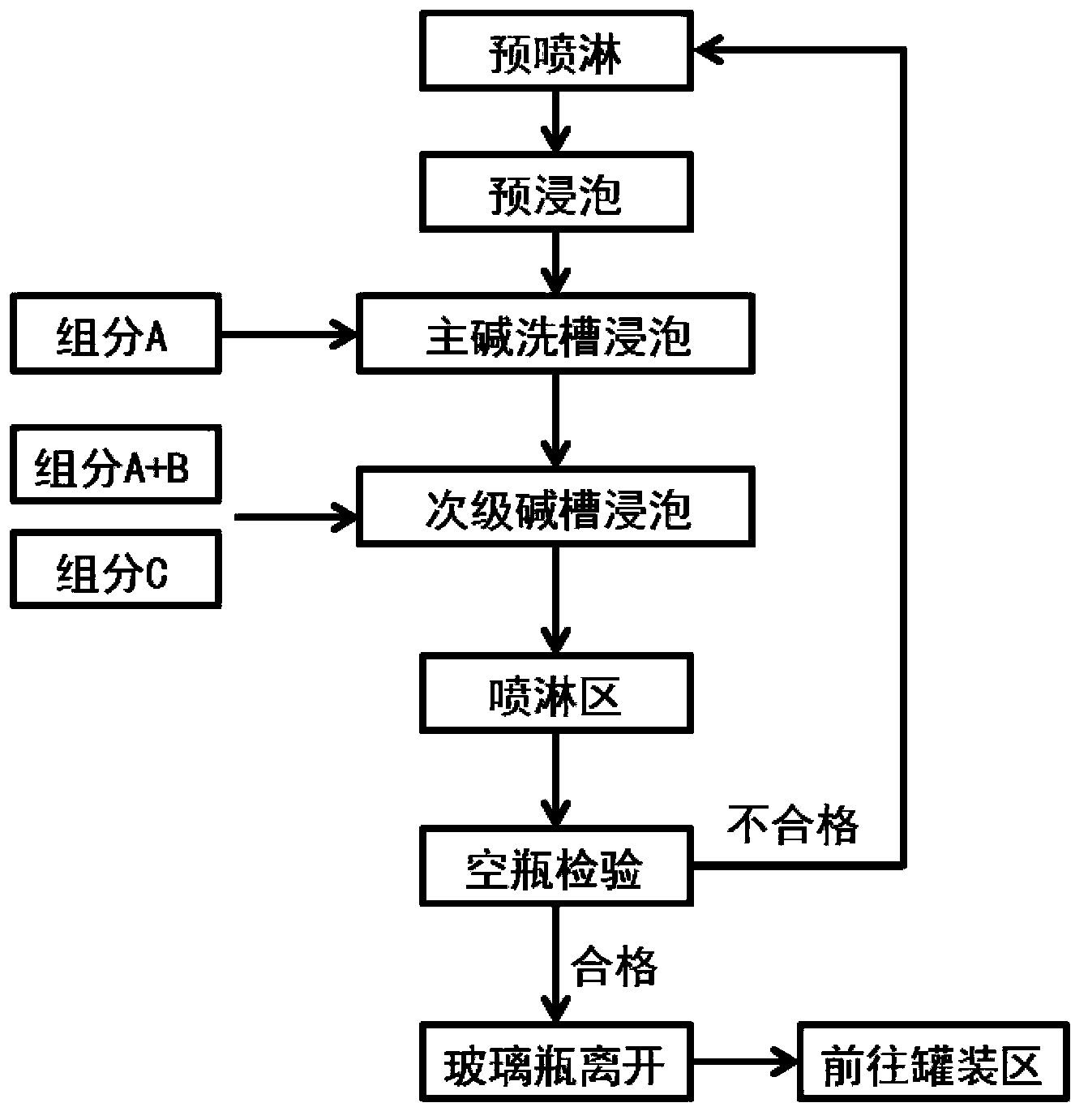

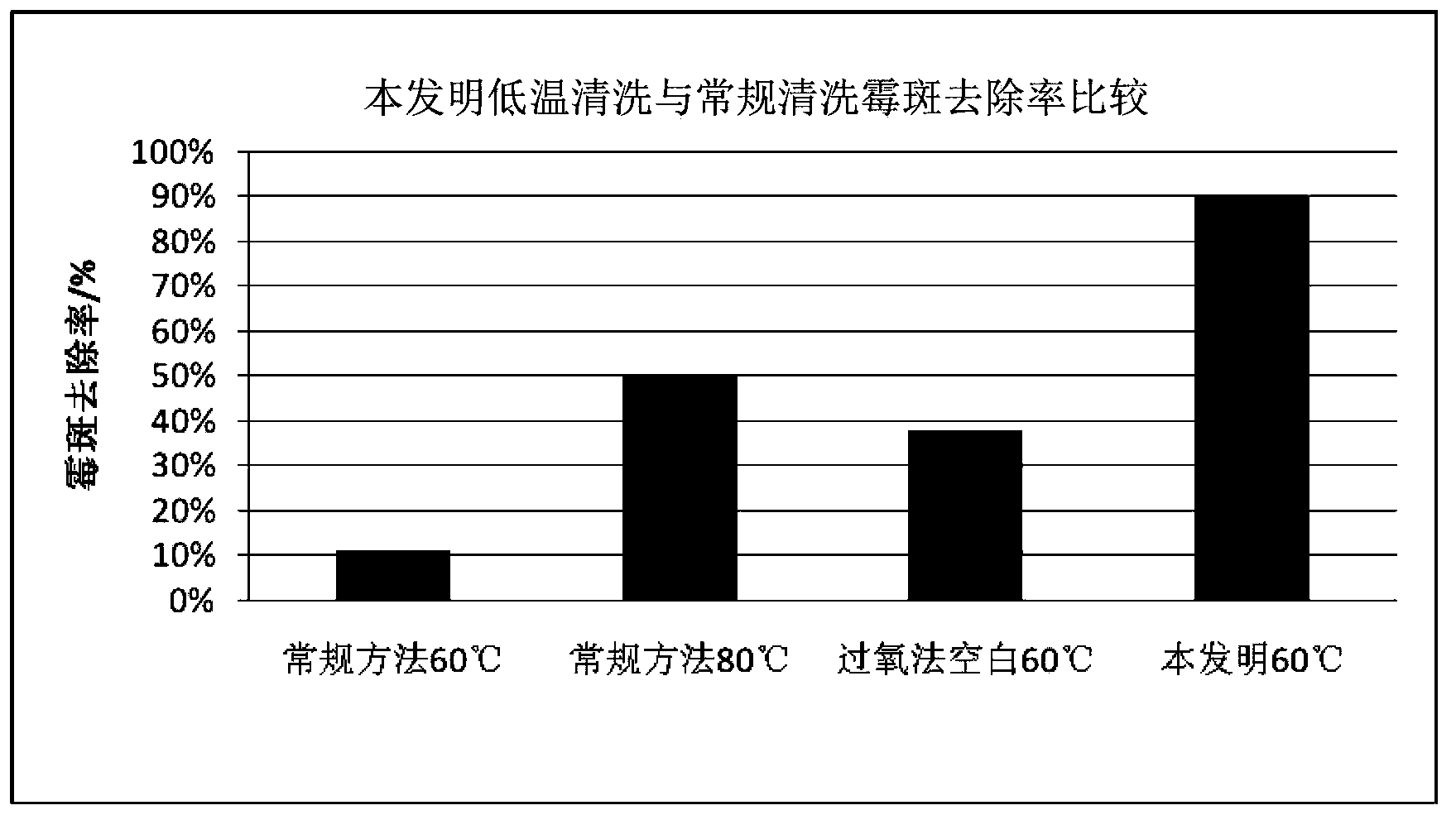

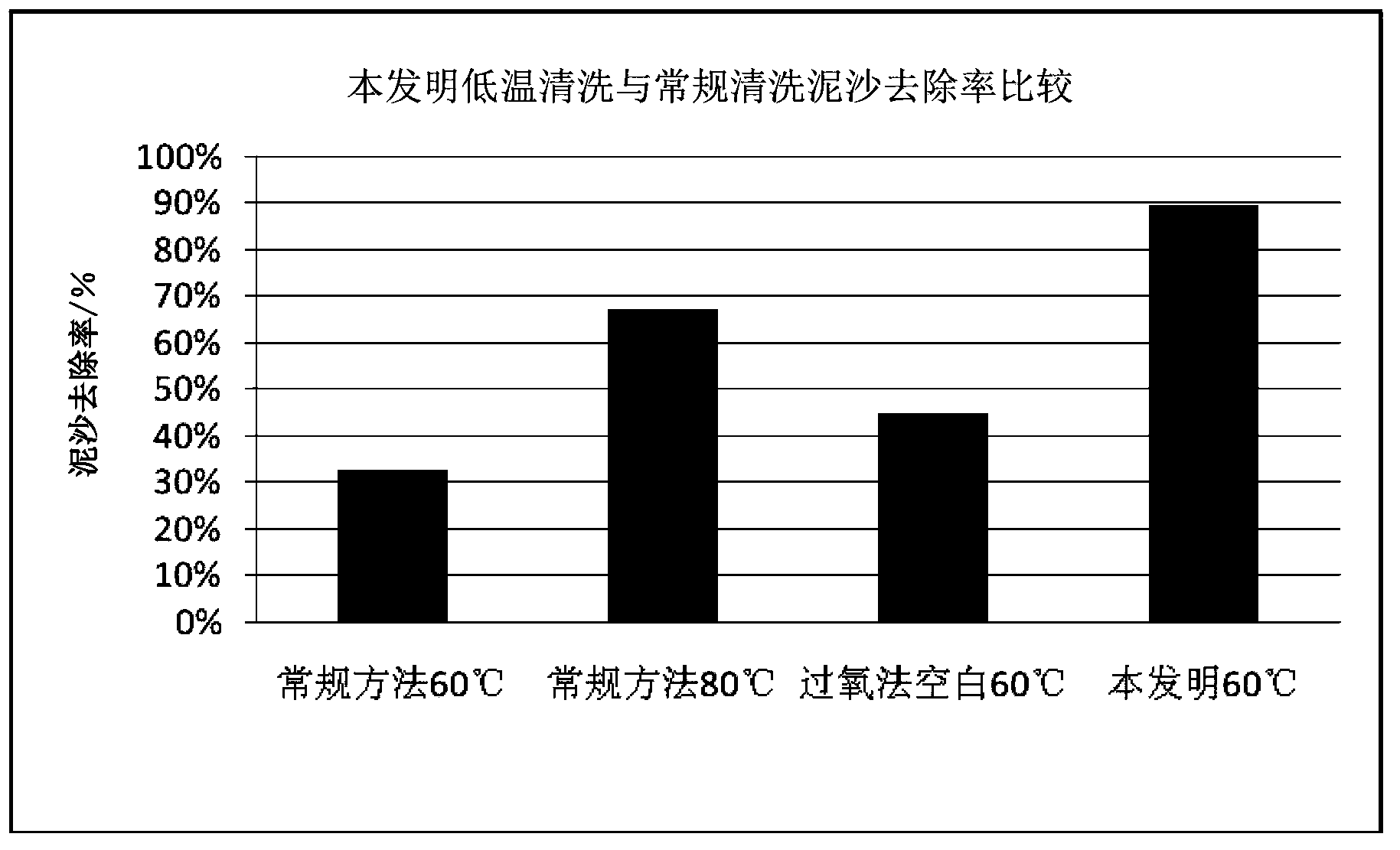

Cleaning additive and cleaning method adopting the cleaning additive

InactiveCN103849498AImprove solubilityLess corrosiveNon-ionic surface-active compoundsNon-surface-active detergent compositionsOrganic phosphorusBottle

The invention discloses a cleaning additive for glass bottles and a cleaning method of the glass bottles. The cleaning method and the cleaning additive are used for glass bottle cleaning by a primary alkaline bath and a secondary alkaline bath. The cleaning additive comprises a component A, a component B and a component C, wherein the component A comprises an organic phosphorus chelating agent, the component B comprises peroxide, the component C comprises a defoaming agent, the component A is added into the primary alkaline bath, the component B is selectively added into the primary alkaline bath, the component A and the component B are added into the secondary alkaline bath, and the component C is selectively added into the primary alkaline bath or the secondary alkaline bath. Based on the weight of alkaline solution in the primary alkaline bath or the secondary alkaline bath where the component is added, the adding amount of the component A is 0.05-5%, the adding amount of the component B is 0.1-0.5%, and the adding amount of the component C is 0-0.5%. The alkaline solution in the primary alkaline bath and the secondary alkaline bath is sodium hydroxide solution having a concentration of 1.5-3%. The cleaning additive and the cleaning method can achieve stable and good cleaning effects at a relatively low temperature that is usually 50-70 DEG C.

Owner:ECOLAB USA INC

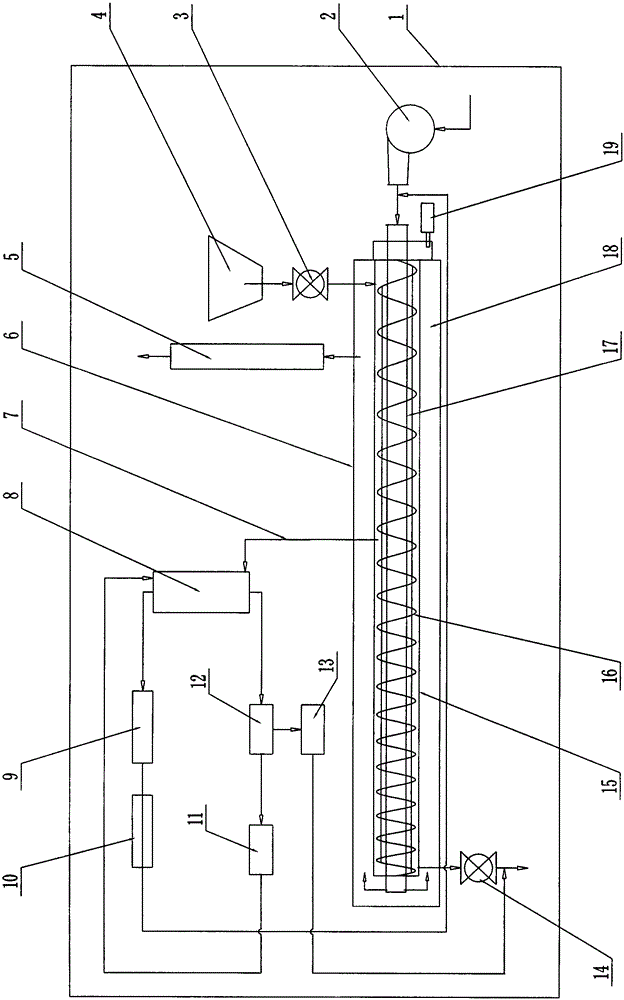

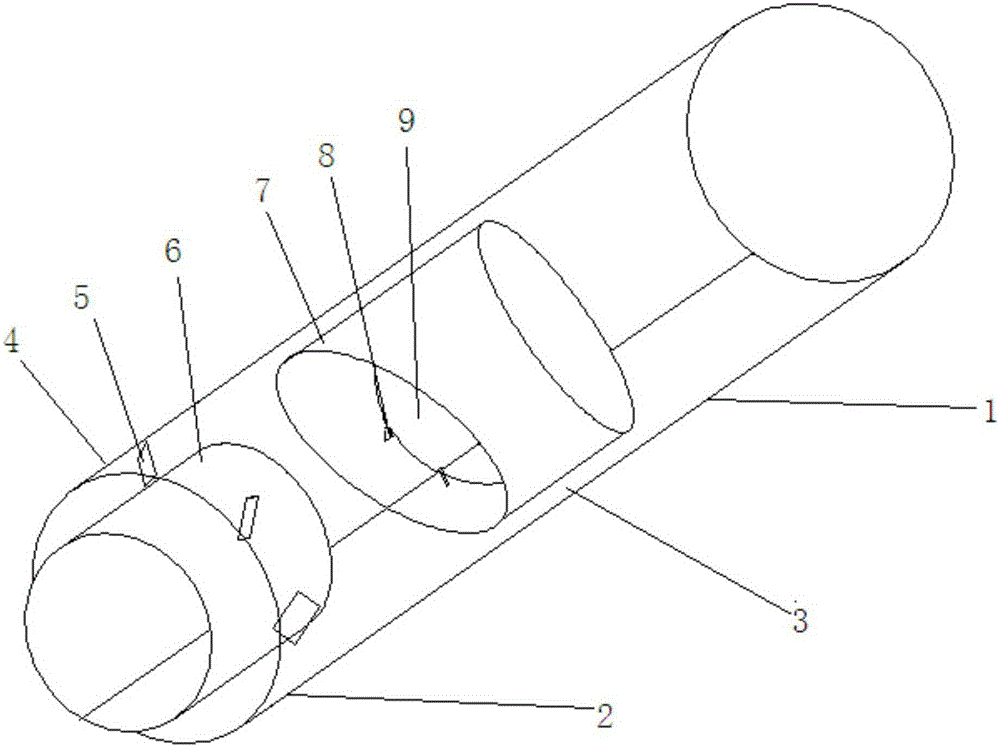

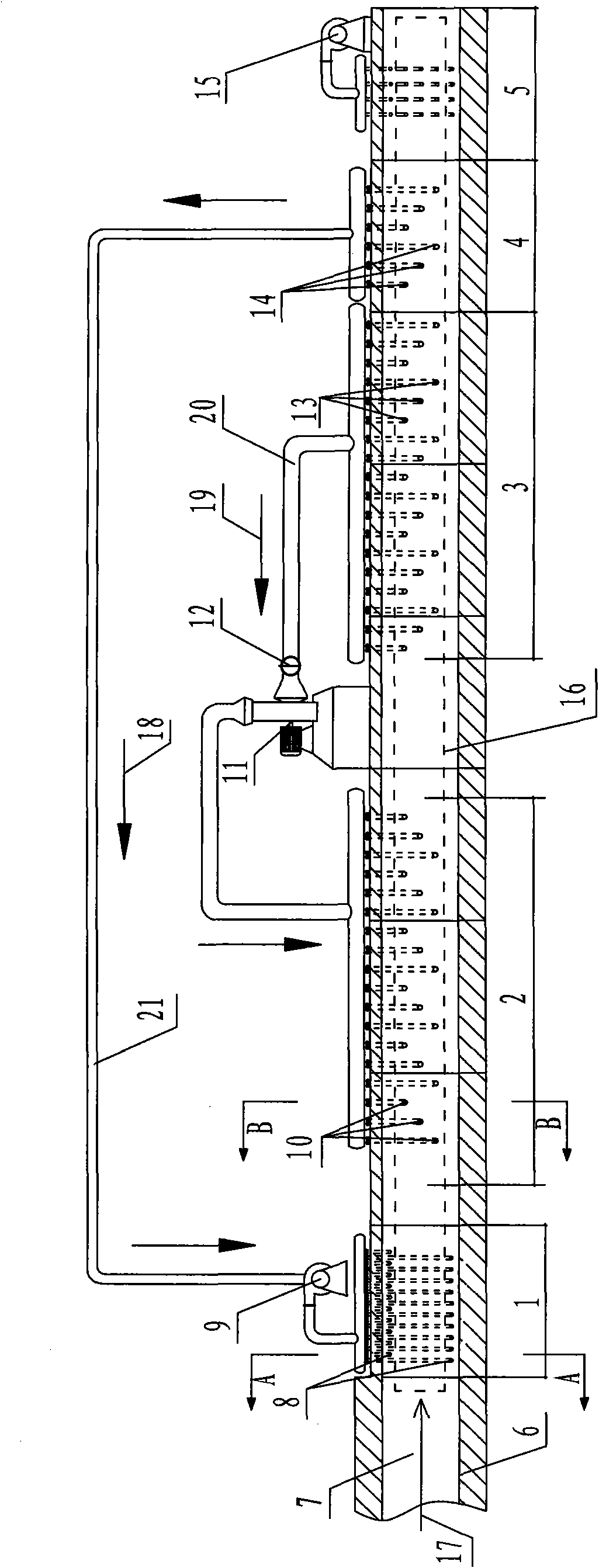

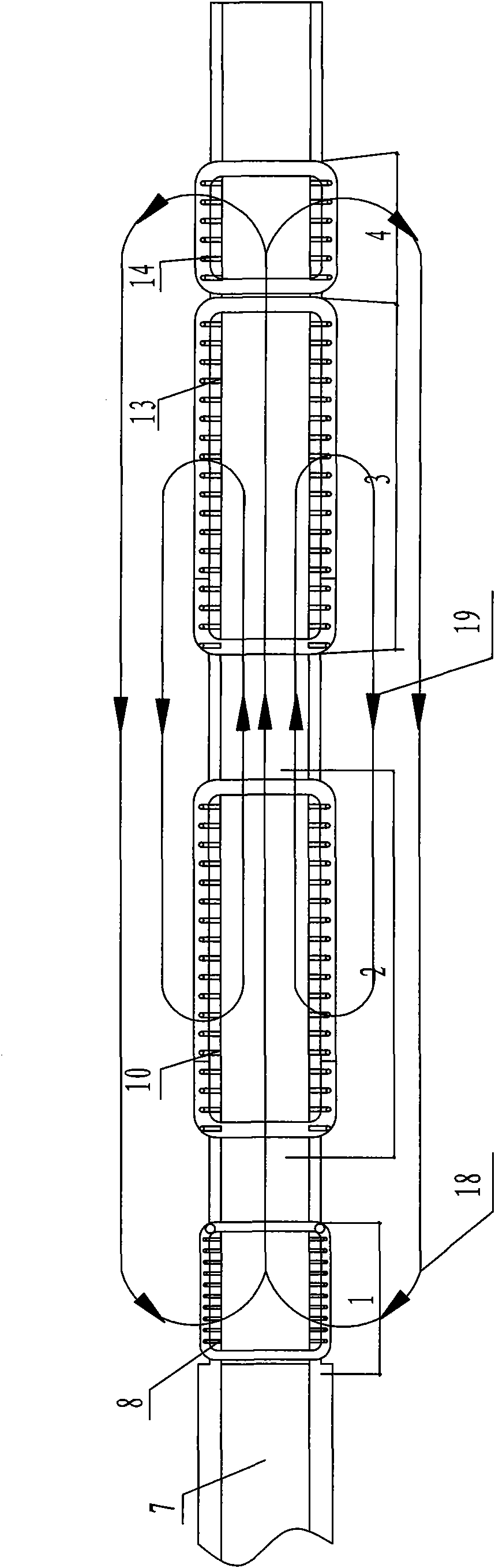

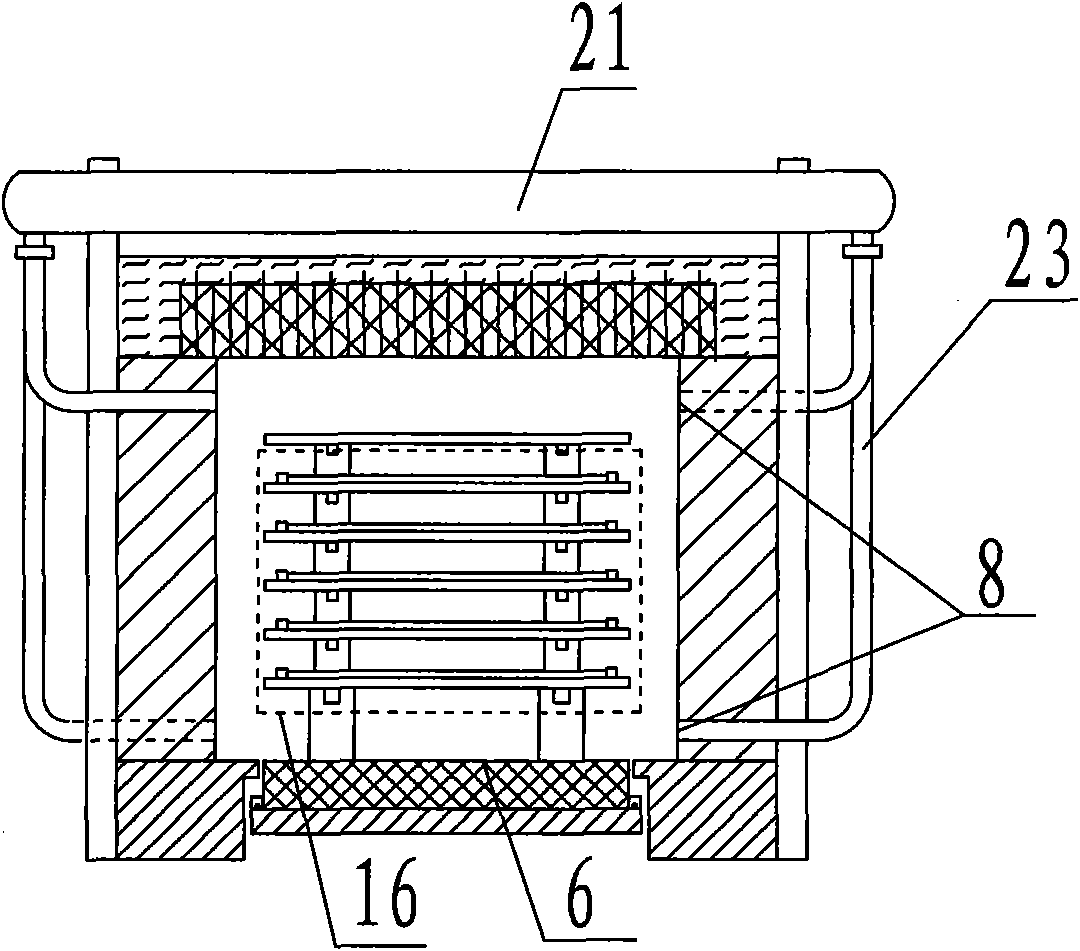

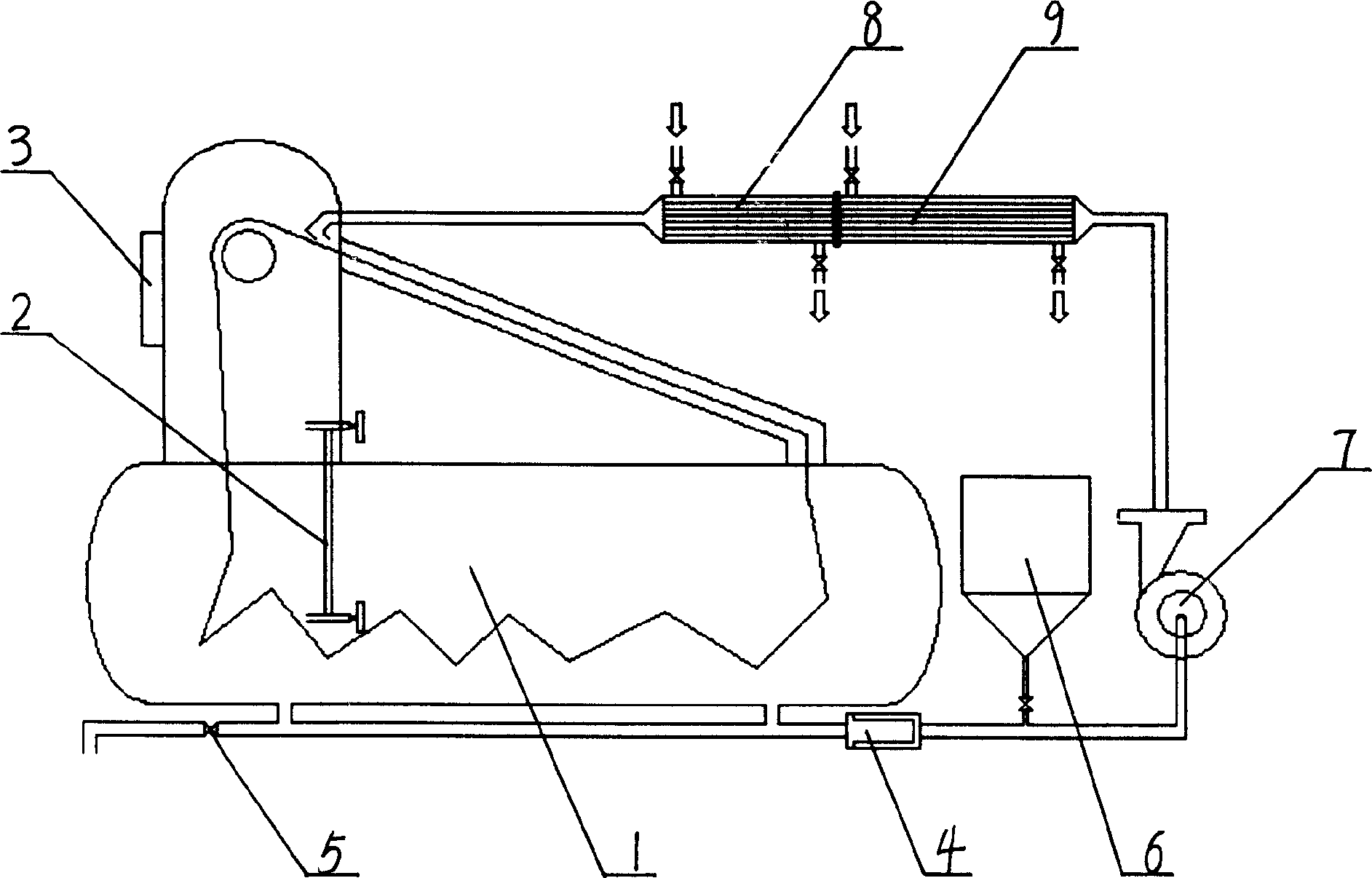

Efficient indirect thermal desorption device

ActiveCN105057337AEasy to solveHigh removal rateContaminated soil reclamationSpray towerActive carbon

The invention discloses an efficient indirect thermal desorption device, and belongs to a polluted soil remediation device. The efficient indirect thermal desorption device comprises a sledge body, wherein a material feeding hopper, a material feeding air lock, an outer barrel, a material discharging air lock, a motor, a combustor, a chimney, a spraying tower, an active carbon adsorption tank, a draught fan, an oil water separator, an air cooler and a water treatment device, wherein a heat preservation shell sleeves the outer barrel; a shaftless winch is arranged in the outer barrel; a combustion pipe is inserted into the shaftless winch; the outlet of the material feeding hopper is communicated with the inlet of the material feeding air lock; the outlet of the material feeding air lock is communicated with the material inlet above the right end of the outer barrel; the material outlet below the left end of the outer barrel is communicated with the inlet of the material discharging air lock. The efficient indirect thermal desorption device has the advantages of high treatment capacity, high pollutant removal rate, high thermal efficiency, good sealing property, smaller size and convenience in transportation and mounting when treating organic polluted soil, mercury polluted soil or petroleum polluted soil.

Owner:ZHEJIANG EASYCLEAN ENVIRONMENTAL TECH CO LTD

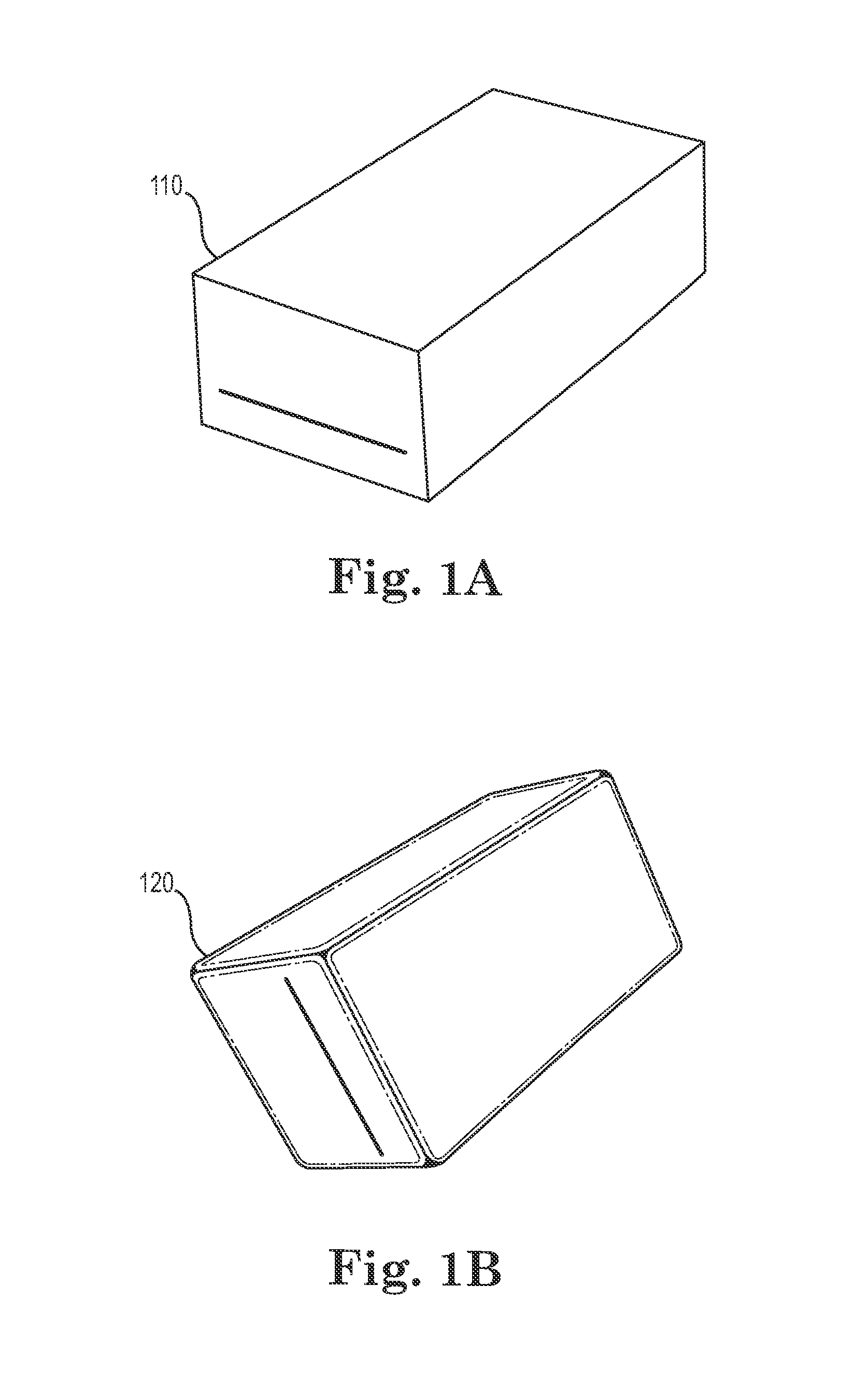

A device and method for heating or cooling a sample

ActiveUS20190075786A1Enhanced agitationImprove the heating effectHeating or cooling apparatusBiological substance pretreatmentsThermal energyCooling curve

A sample heating / cooling device comprises a plurality of members operable in use to heat and / or cool one or more samples. Each member has a sample contact surface and is biased towards a resting position under the operation of a biasing means. The members are movable independently of one another against said bias under the application of a force on the sample contact surface and so are able to conform to the shape of a sample placed on the members to provide a uniform heating / cooling profile. The members may be mounted in a heating / cooling element and adapted to conduct thermal energy between the sample and the element. The device is particularly suitable for thawing frozen sample bags having an irregular shape. A corresponding method is also described.

Owner:CELL THERAPY CATAPULT

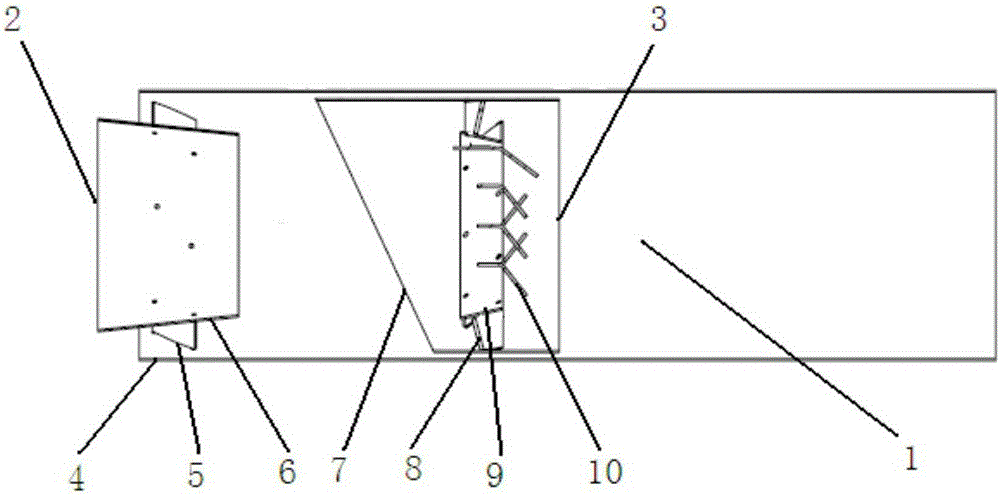

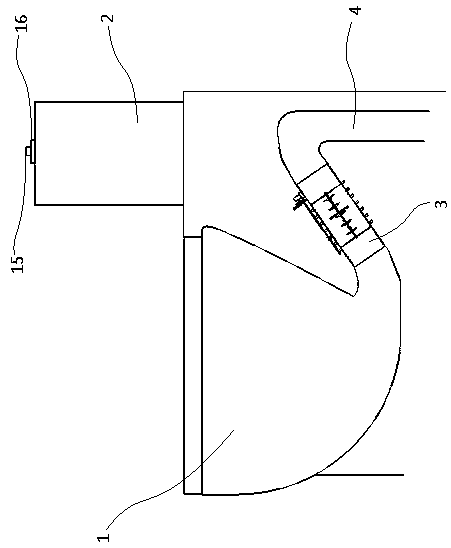

Urea mixer of SCR system

ActiveCN105201604AChange flow directionMixed changeExhaust apparatusSilencing apparatusExhaust fumesEnvironmental engineering

The invention provides a urea mixer of an SCR system. The mixer is capable of fully changing the flow direction of urea to make urea evenly mixed with waste gas and reducing blockages such as crystals and sediment on the urea jet breadth to avoid ammonia leakage. A blade device is installed behind a urea nozzle, the number of blades is increased, and airflow is changed by the blades to form intense perturbance so as to improve the mixing effect of a urea water solution and waste gas spray. Under the stirring action of the multiple blades, the flowing direction of the urea water solution is changed, and the urea water solution is fully mixed with the waste gas. Meanwhile, the structure of a flow guide ring in the mixer is changed, so that urea on the urea jet breadth falls off from the flow guide ring under driving of the airflow, the crystals and the sediment are reduced, and ammonia leakage is avoided.

Owner:NANJING IKAKAT EMISSIONS TECH CO LTD

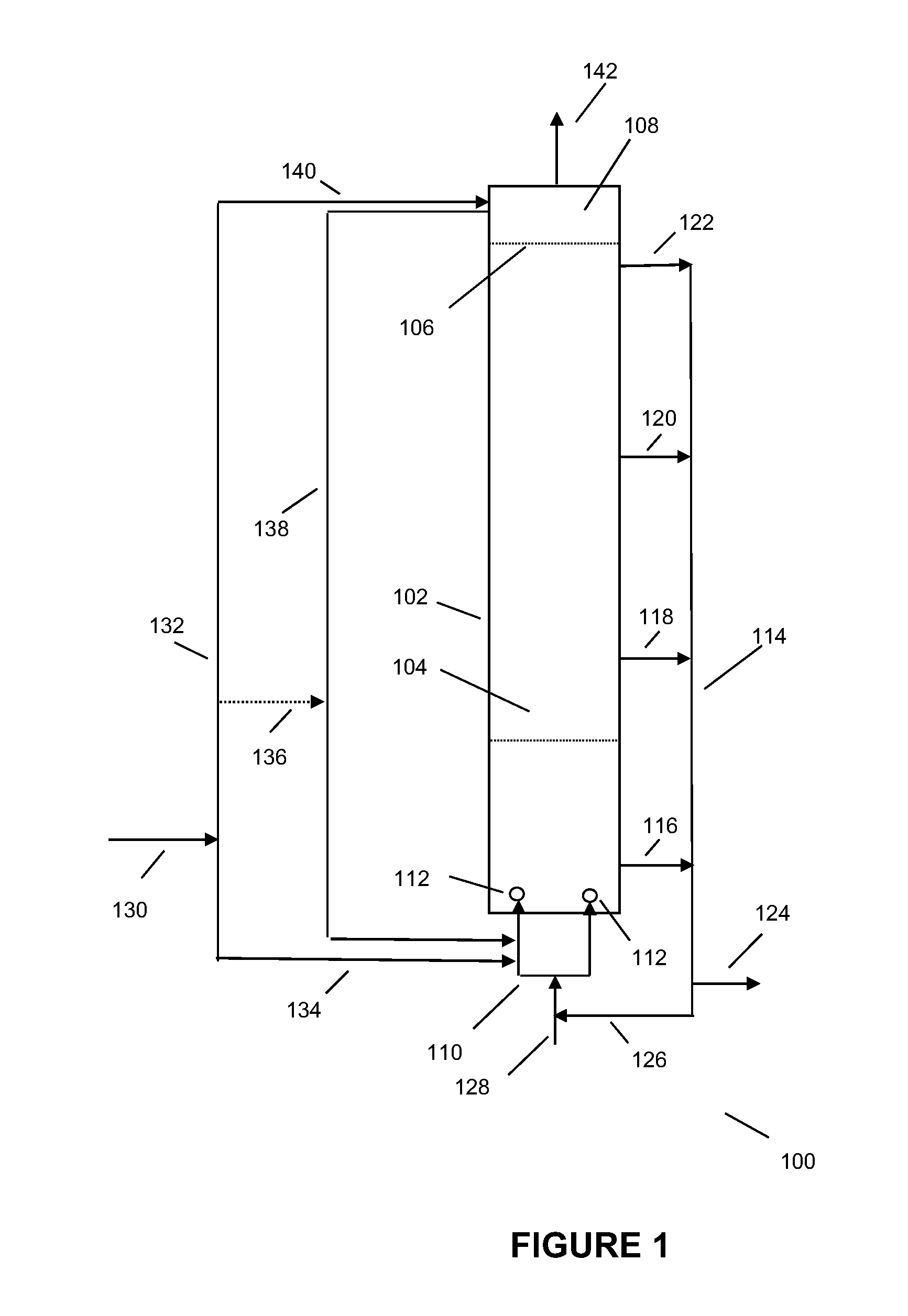

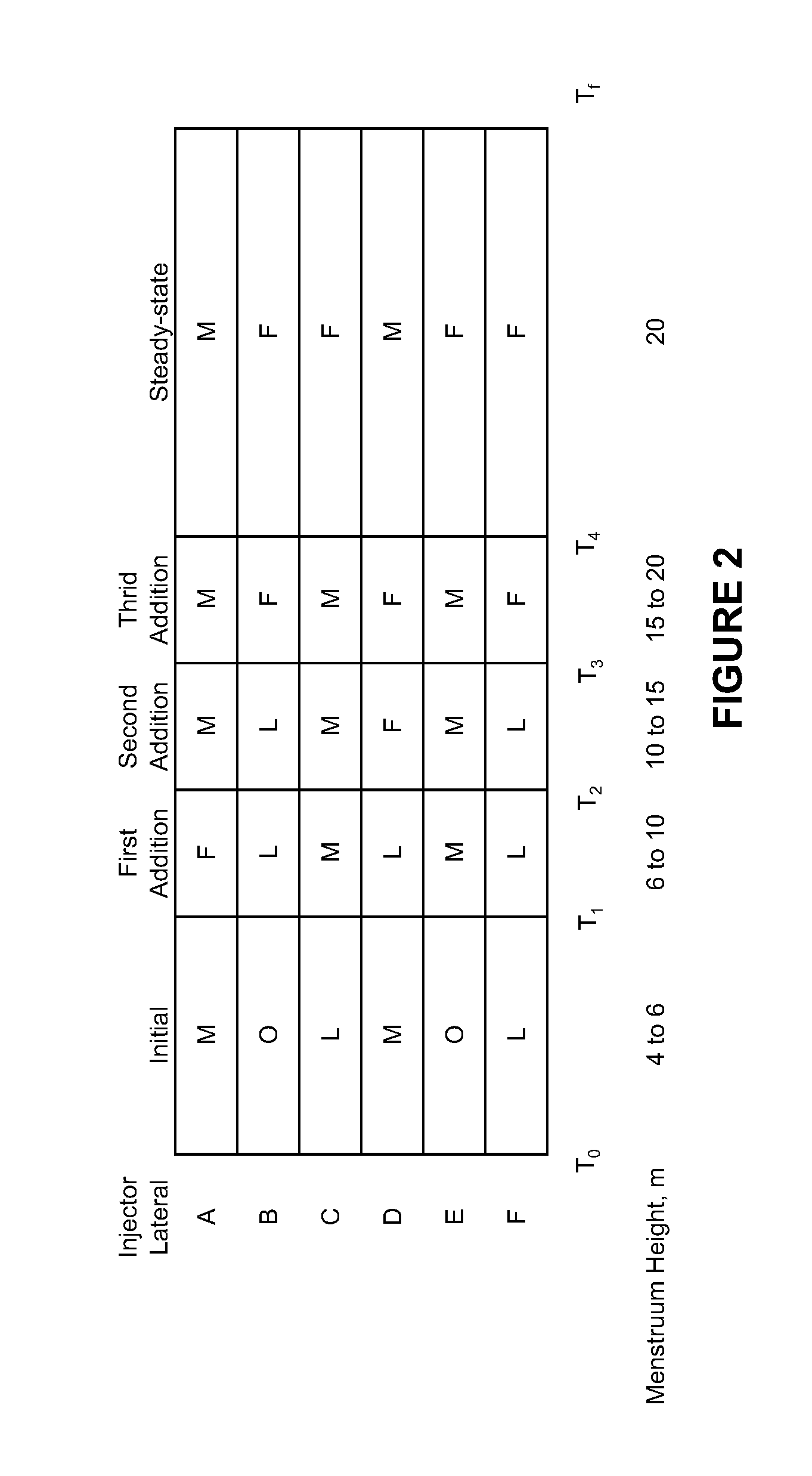

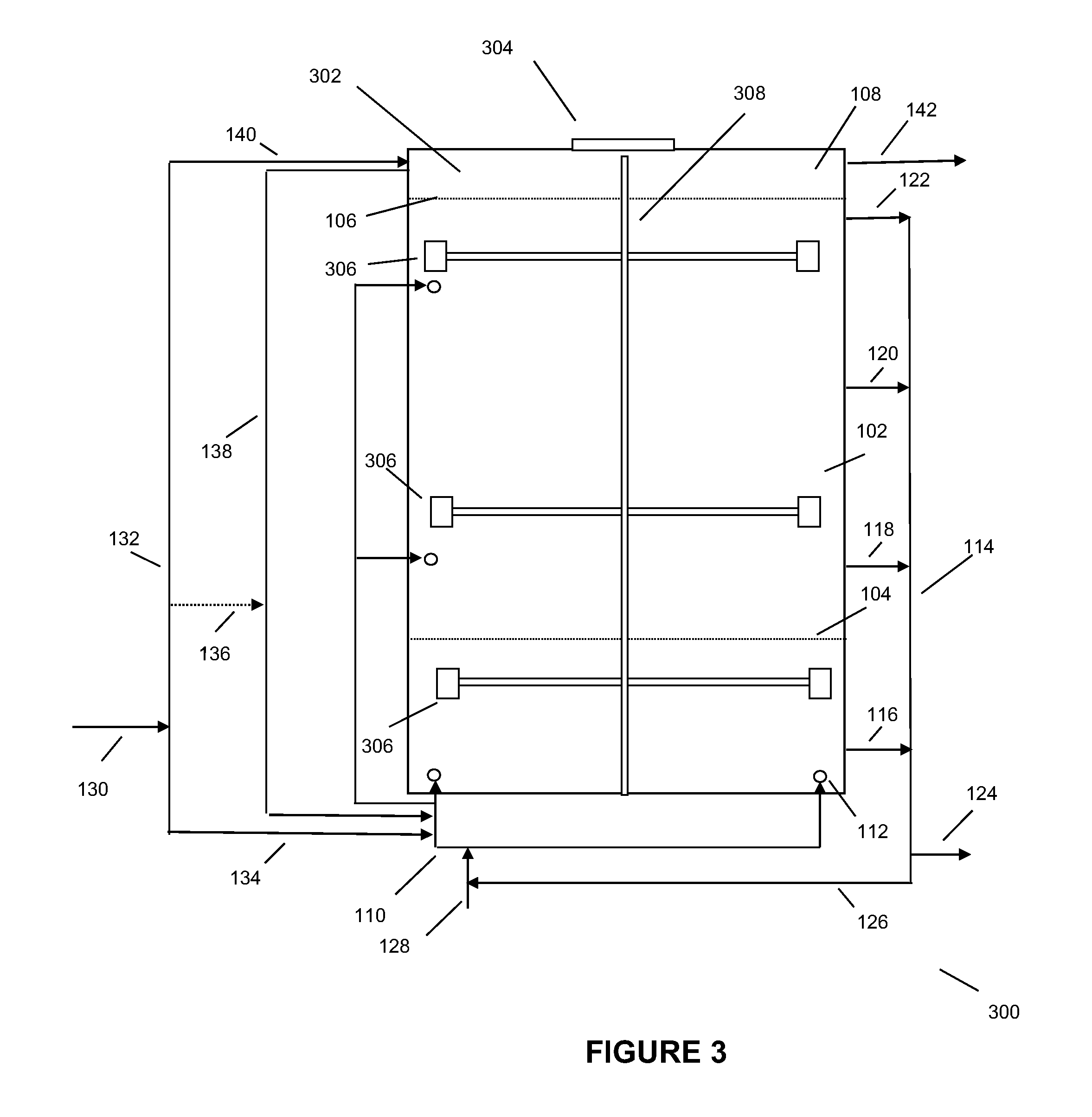

Processes for starting up deep tank anaerobic fermentation reactors for making oxygenated organic compound from carbon monoxide and hydrogen

ActiveUS20130078693A1Reduce riskPromotes robust growthBiochemistry apparatusBiofuelsOxygenOrganic compound

Processes are provided for starting up of anaerobic, deep tank fermentation systems used in the anaerobic bioconversion of hydrogen and carbon monoxide in a gaseous substrate stream to oxygenated organic compounds such as ethanol. In the processes injectors using a motive liquid are used to introduce gas substrate into the deep tank fermentation reactor where at least one of:(i) adjusting the gas to liquid flow ratio through an injector,(ii) changing the rate of liquid flow through an injector, and(iii) adjusting the carbon monoxide mole fraction in the gas feed by admixture with at least one other gas,wherein the mass transfer of carbon monoxide to an aqueous menstruum in the reactor is controlled to obtain the robust growth of the microorganism while maintaining the carbon monoxide concentration below that amount which is unduly adverse to the microorganism. In preferred aspects of the invention, recycled gas from the head space of the reactor is used to modulate the supply of carbon monoxide to the aqueous menstruum.

Owner:SYNATA BIO INC

Annealing and cooling treatment system for two-stage hot wind circulation of glass ceramic tunnel crystallization kiln

The invention belongs to the technical filed of glass ceramic annealing by a sintering method, and discloses an annealing and cooling treatment system for two-stage hot wind circulation of a glass ceramic tunnel crystallization kiln. The treatment system is characterized in that the upper part and the lower part of kiln walls at two sides of a quench zone are respectively installed with a row of fast cold wind blowing openings which are communicated with fast cold wind blowing opening branch pipes, the fast cold wind blowing openings are all communicated with the output ports of second hot wind circulation pipes; the kiln walls at two sides of the slow cooling segment of a cooling zone are respectively provided with three rows of hot circulation wind blowing openings which are communicated with the hot circulation wind blowing opening branch pipes, all hot circulation wind blowing opening branch pipes are communicated with the output ports of first hot wind circulation pipes; the first hot circulation wind suction opening blowing branch pipes are all communicated with the input ports of the first hot wind circulation pipes; and the second hot circulation wind suction opening blowing branch pipes are all communicated with the input ports of the second hot wind circulation pipes. The annealing and cooling treatment system can improve product quality, and reduce deformation, burst and other defects of the products.

Owner:WUHAN UNIV OF TECH

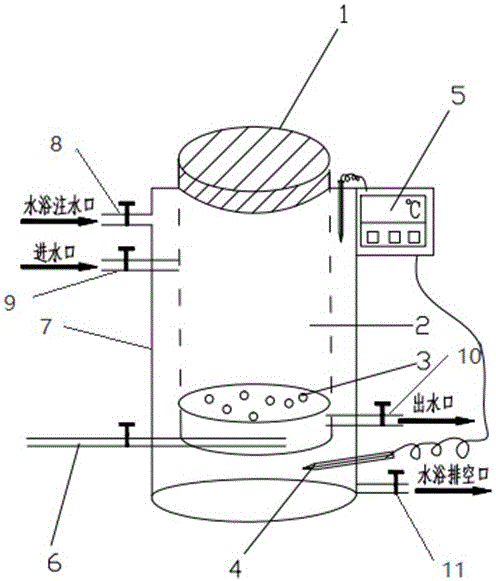

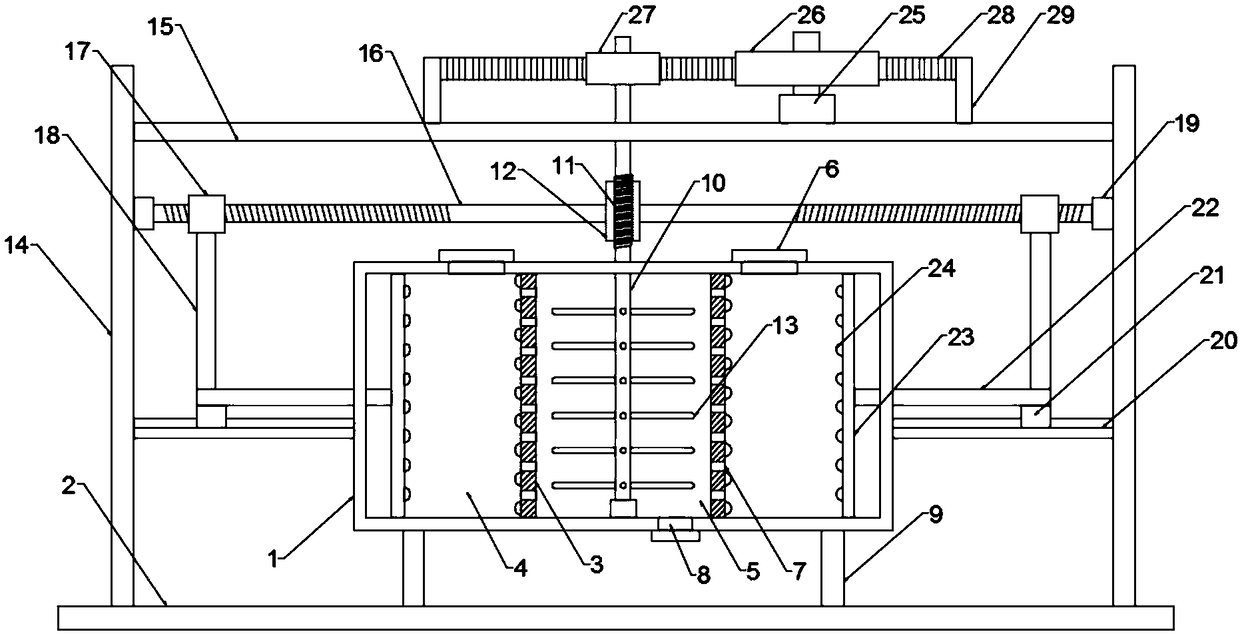

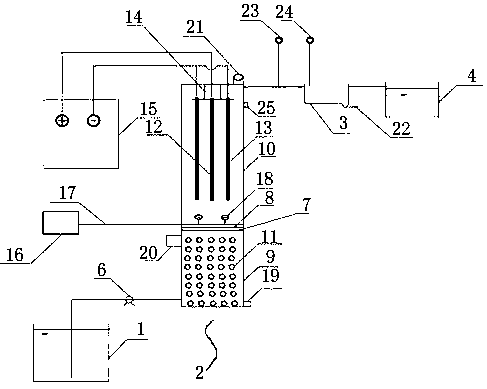

Experimental device and method for treating antibiotic wastewater through iron-carbon micro-electrolysis method

InactiveCN106630026AImprove biodegradabilityReach the environmental protection effect of "reduction"Multistage water/sewage treatmentNature of treatment waterTreatment effectElectrolysis

The invention discloses an experimental device and method for treating antibiotic wastewater through an iron-carbon micro-electrolysis method. An iron-carbon micro-electrolysis device comprises a top cover, a stuffing region, a multihole plate supporting layer, a heating stick, a temperature controller and an aeration pipe. The invention further discloses a method for treating the antibiotic wastewater by using the device. The method comprises the following steps: injecting the antibiotic wastewater into an adjustment pool, adjusting pH to be 2.0 to 4.0, then injecting the antibiotic wastewater into a reactor through a water inlet of an iron-carbon micro-electrolysis reactor, and enabling a fan to blow air through an air inlet for aeration, wherein discharged water flows back into the reactor from the water inlet through a backflow pump; enabling the water to stay for 4 to 8 hours, and then discharging the water from a water outlet, thus completing treatment of the wastewater. The experimental device has the advantages of good treatment effect, long service life, simple operation and low cost.

Owner:TONGJI UNIV

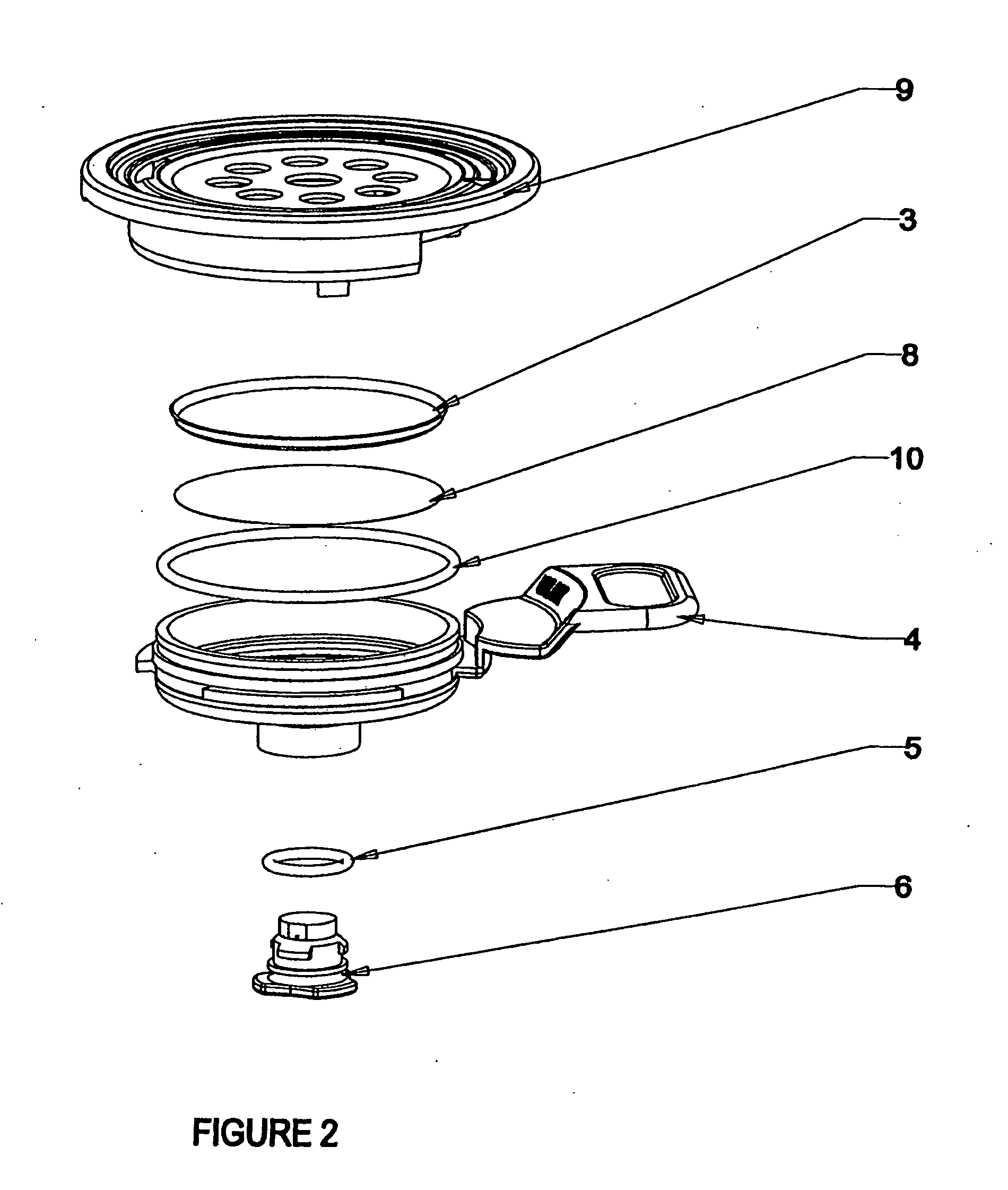

Brewing apparatus for preparing foam, froth, or crema under low pressure

InactiveUS20070028784A1Promote formationEnhanced agitationJuice extractionBeverage vesselsEngineeringStainless steel wire

The present invention pertains to a brewing filter apparatus capable of preparing foam, froth, or crema, particularly for coffee beverages, under low pressure. The apparatus can operate at pressures below 15 bar and as low as 1-3 bar. The apparatus comprises a mesh cover, coarse filter, fine filter, large O-ring, coffee container, small o-ring, and foam maker having two opposing holes. The holes have a diameter in the range of 0.3 to 1 mm. The crema is created by the turbulent contacting of two opposing jets of coffee, which enter the foam maker through the two opposing holes. To further increase agitation and the surface area for contact, a stainless steel wire mesh may be situated in the center of the foam maker directly in the path of and in between the opposing jets of coffee to facilitate the formation of more crema.

Owner:ELECTRICAL & ELECTRONICS LTD

Extruding type stirring mixing device for coating material for architectural ornament

InactiveCN108940091AEnhanced agitationWell mixedTransportation and packagingMixer accessoriesPush pullEngineering

The invention discloses an extruding type stirring mixing device for a coating material for architectural ornament. The extruding type stirring mixing device comprises a mixing box and a base substrate; two separating plates with lateral sides sealed and fixedly connected with inner walls of the mixing box are arranged in the mixing box; the interior of the mixing box is separated into two extruding chambers located on the two sides and a stirring mixing chamber located on the middle part by the two separating plates; two feeding ports are formed in a top wall of the mixing box; a vertical stirring rod shaft, the upper end of which is penetrated through the top wall of the mixing box, is arranged at the center in the stirring mixing chamber; a plurality of liquid-permeating holes are formed in the separating plates; extruding plates, lateral edges of which are in left-and-right sliding fit with the inner walls of the extruding chambers, are arranged in the extruding chambers; push-pullrods, the end parts of which are stretched out of the side walls of the mixing box, are arranged on the middle parts of the side walls of the extruding plates away from the separating plates; the endparts of the two push-pull rods are connected with the side wall of the vertical stirring rod shaft through a driving connecting mechanism. The extruding type stirring mixing device for the coating material for architectural ornament has the advantages of simple structure, sufficient and obvious mixing effect, convenience in operation and control and high practicability.

Owner:北京艺轩吉装饰工程有限公司

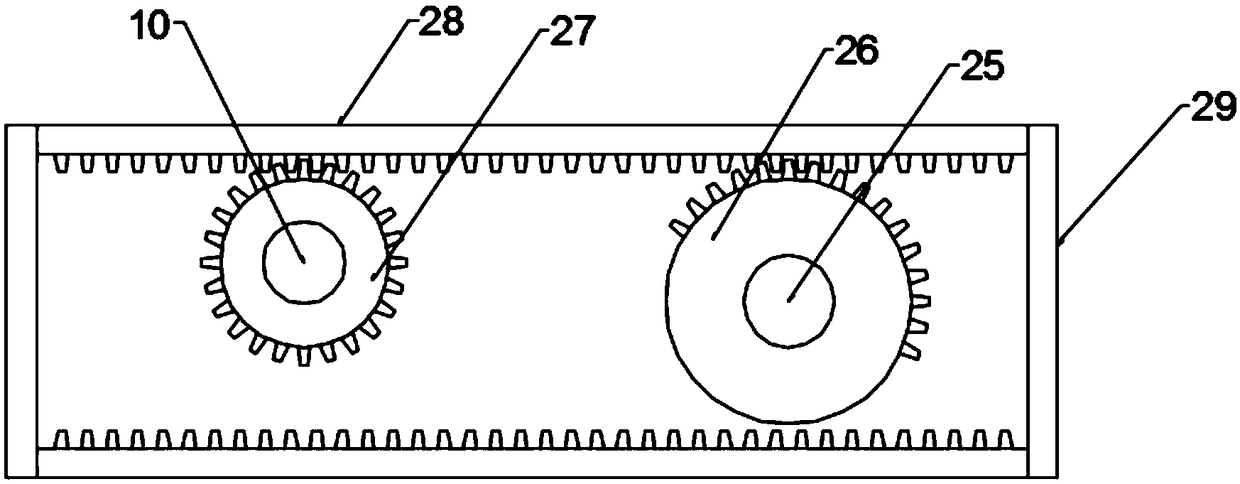

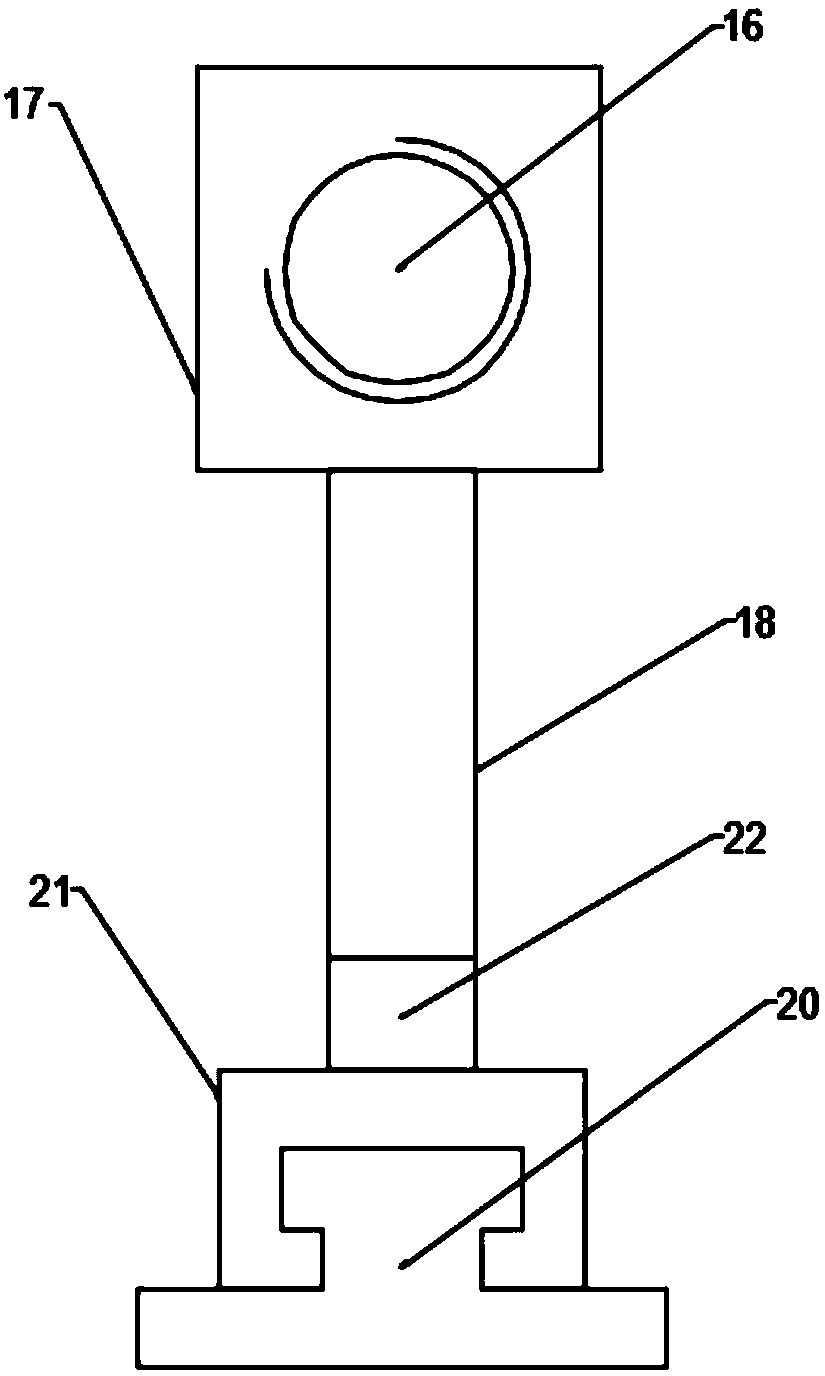

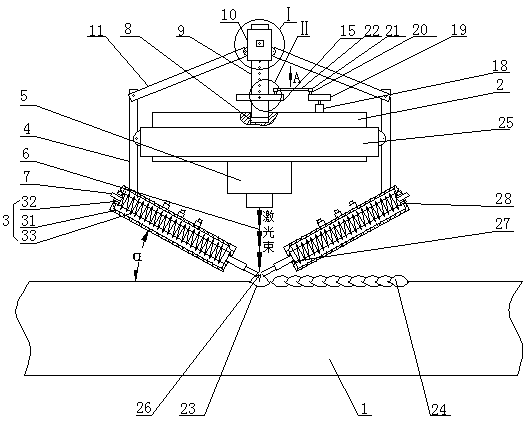

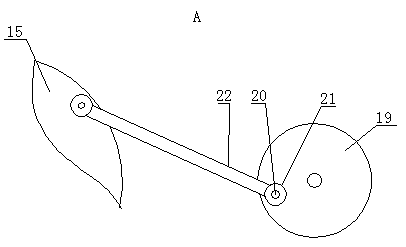

Induction heating fuse wire and laser compound based additive manufacturing device and method

ActiveCN108672936AEasy to integratePrecise control of ejection speedAdditive manufacturing apparatusLaser beam welding apparatusMulti materialMelting tank

An induction heating fuse wire and laser compound based additive manufacturing device comprises a bottom plate, wherein a transverse circular plate is arranged at the upper part of the bottom plate; acircular ring sleeves the outer circumference of the circular plate and is movably connected to the outer circumference of the circular plate through a bearing; a plurality of uniformly-distributed induction heating devices are arranged at the bottom part of the circular plate; the lower ends of the induction heating devices are pointed to a part where a central axis of the circular plate is connected to the top surface of the bottom plate; vertical rods are fixedly mounted at the upper ends of the induction heating devices, and the side parts of the vertical rods are connected to the side part of the circular ring by hinging. According to the device, an induction heating fuse wire and laser compound based additive manufacturing method is used for performing additive manufacturing; a fusewire is molten by induction heating; a laser beam is capable of promoting the stirring in a metal melting pond; the material feeding capacity per unit of time is high in the manufacturing process, and the formed metal melting pond is large, so that the additive manufacturing efficiency is high; and meanwhile, the fuse wires manufactured through a plurality of materials can be synchronously fed, so that the additive manufacturing of an alloy material is achieved; and a novel device and a novel method are provided to realize additive manufacturing.

Owner:HUNAN UNIV OF SCI & TECH

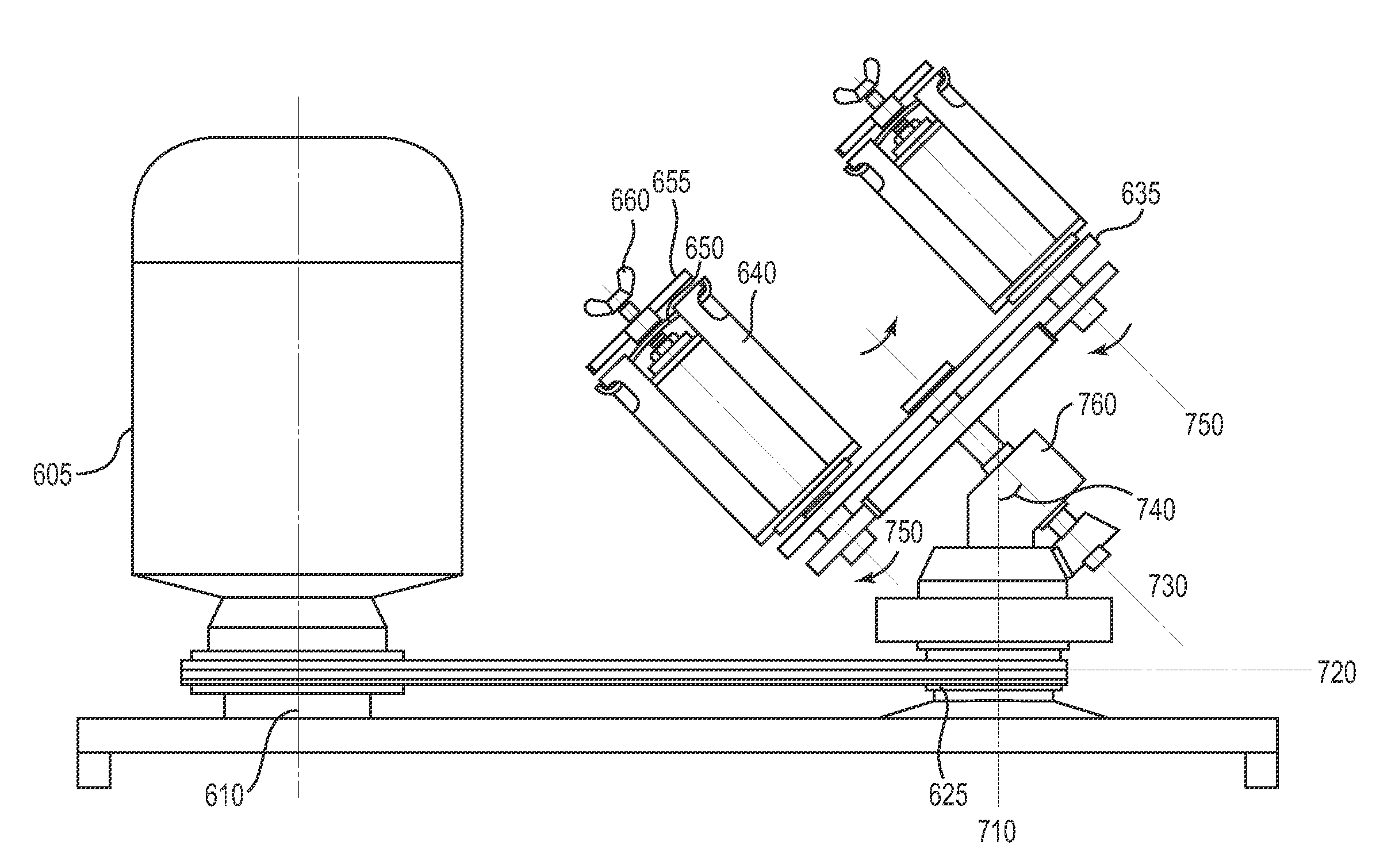

High speed barrel polishing device

InactiveUS20110256808A1Increase speedAvoid damageEdge grinding machinesPolishing machinesElectronic componentBall mill

A high speed polishing device useful for polishing a large number of miniature components, such as multi-layer electronic components, is disclosed. In various embodiments of the present invention, a vertical planetary ball mill or other barrel polishing device is modified to rotate polishing containers having a modified interior cavity structure. This interior cavity provides a smooth, gradually curved interior sidewall that improves circulation within the container during high-speed vertical polishing rotation. The improved circulation results in polishing for a larger number of components placed within the container and in less time than existing polishing container structures. In further embodiments, the containers are rotated around a generally tilted axis positioned at an angle between entirely vertical and horizontal positions. Rotation about a tilted axis further reduces collisions and increases relative polishing movement within the container.

Owner:IBM CORP

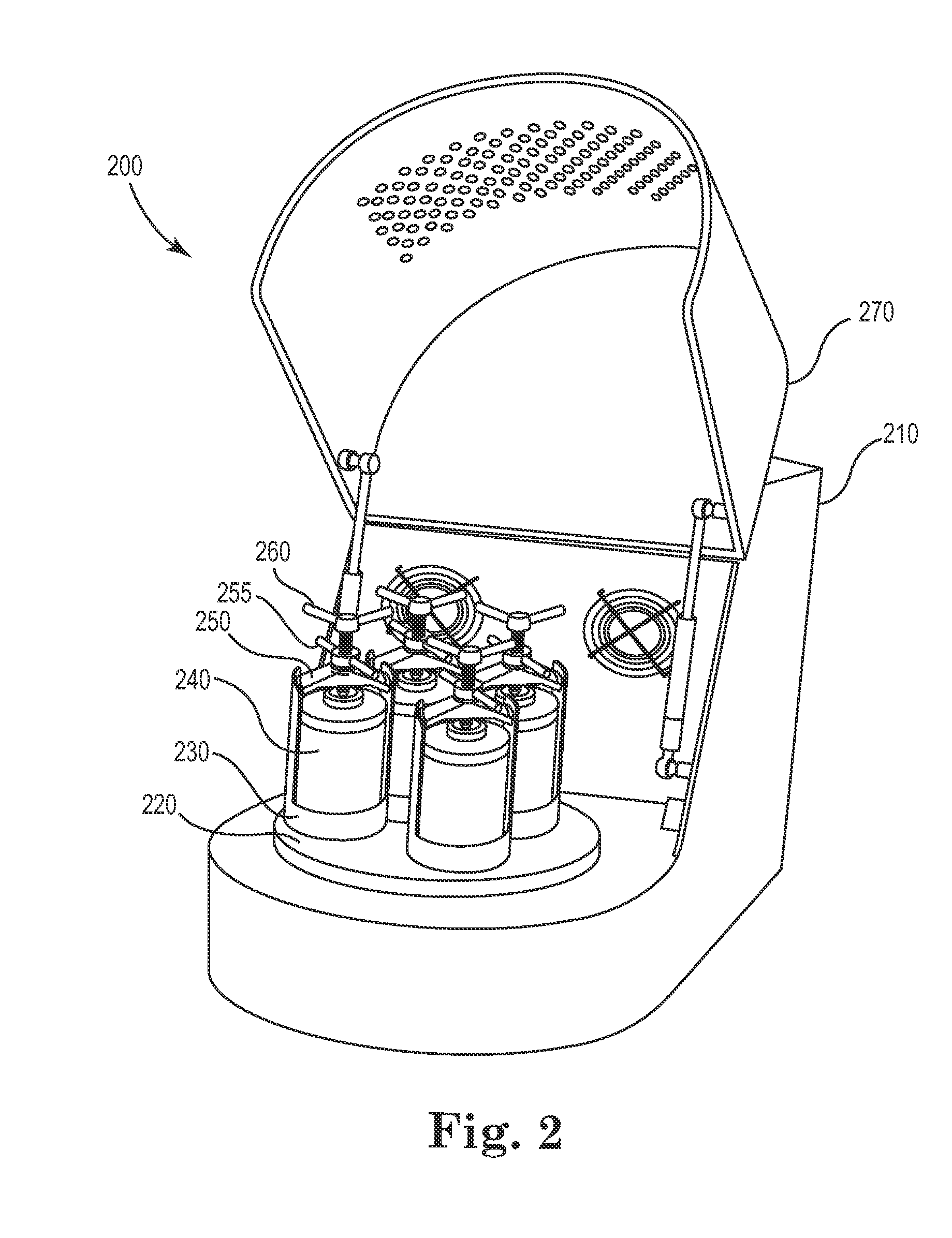

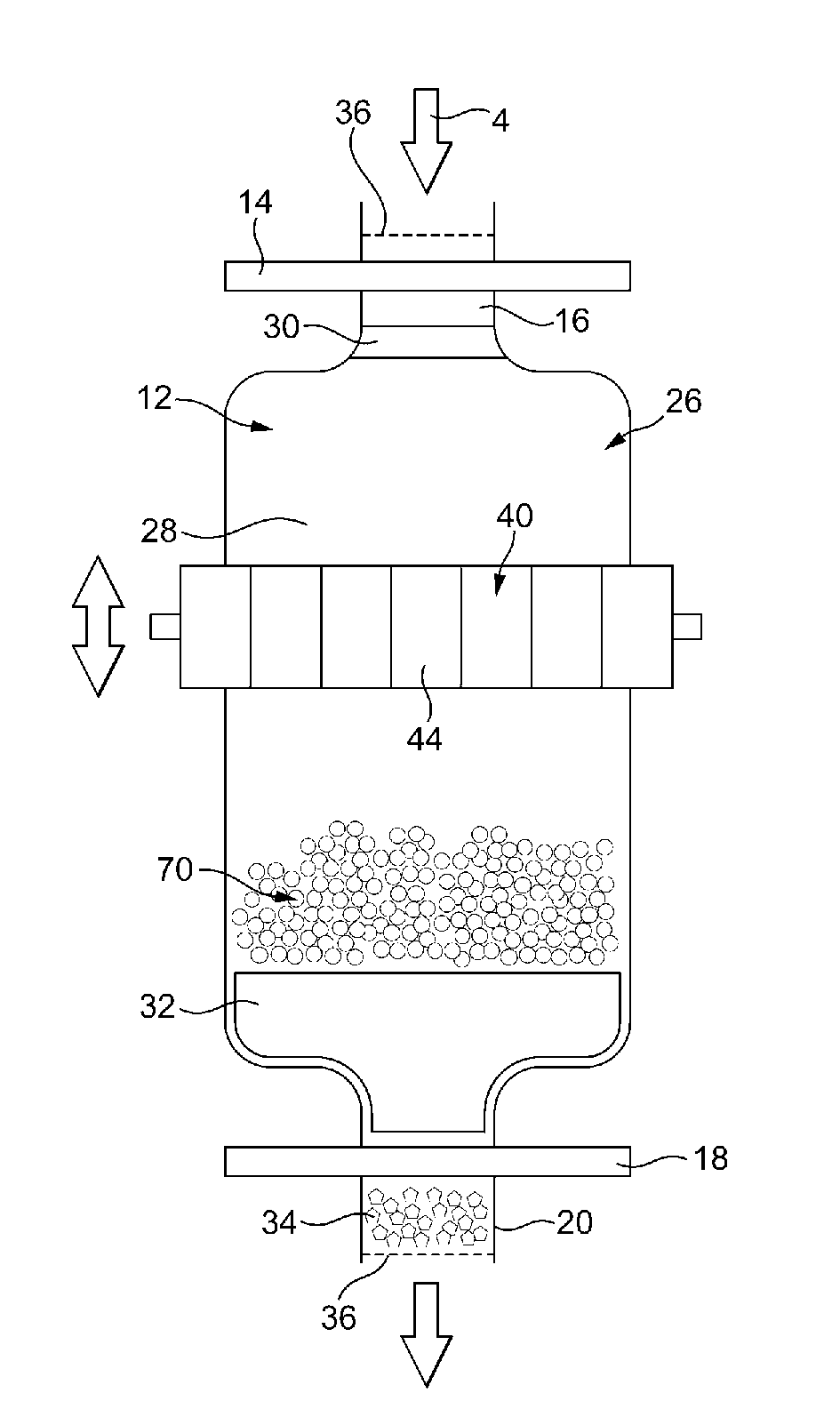

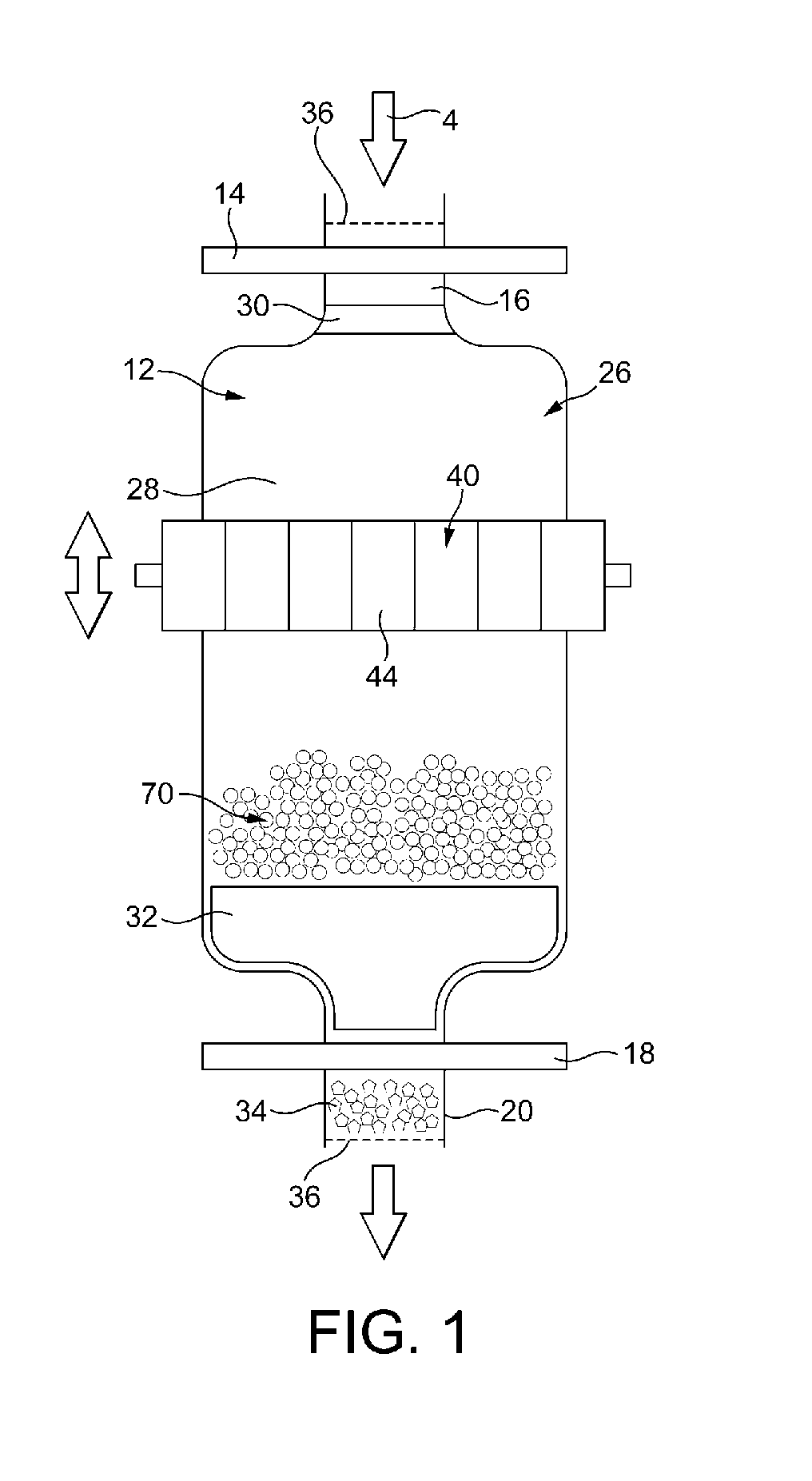

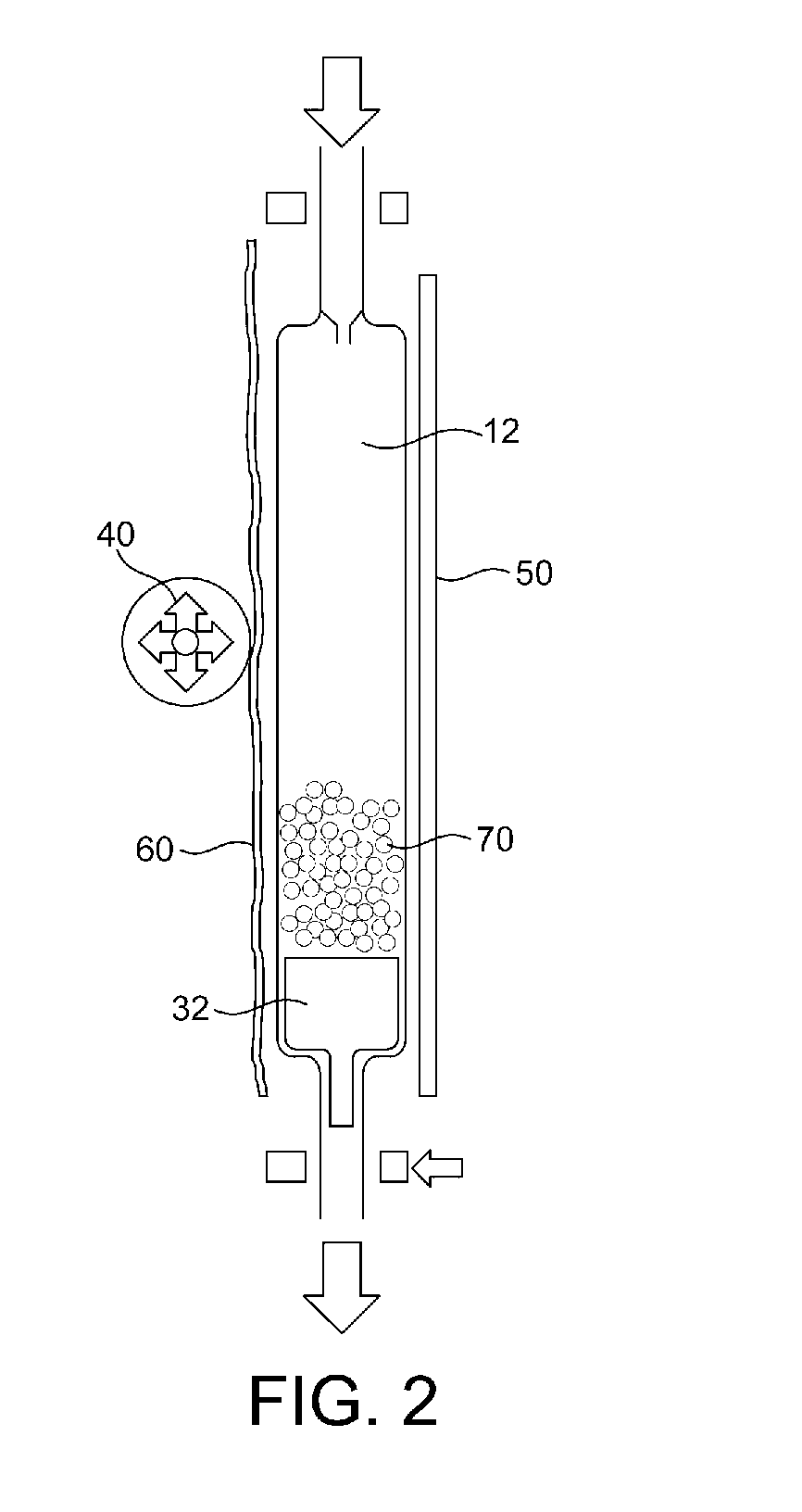

Beverage Dispensing Machine

ActiveUS20150289708A1Overcome problemsEliminate riskReady-for-oven doughsShaking/oscillating/vibrating mixersFreeze-dryingAdditive ingredient

A beverage dispensing machine (2) has a housing that provides a receptacle for receiving an expandable cartridge (12) that is coupled into the machine so that it can receive a charge of water. A kneading system (40) is provided to act on the cartridge within the receptacle. The kneading system is activated after water has been allowed to enter the cartridge and mechanically acts on or from the exterior of the cartridge in order to compress and release regions of the cartridge in order to create vigorous agitation to move the contents of the cartridge around inside the main compartment and bring them into close contact with a charge of water from the supply. Such a machine allows a wide variety of beverages to be created conveniently on demand from freeze-dried ingredients that can be stored inside the cartridges with a long shelf life.

Owner:ZENDEGII

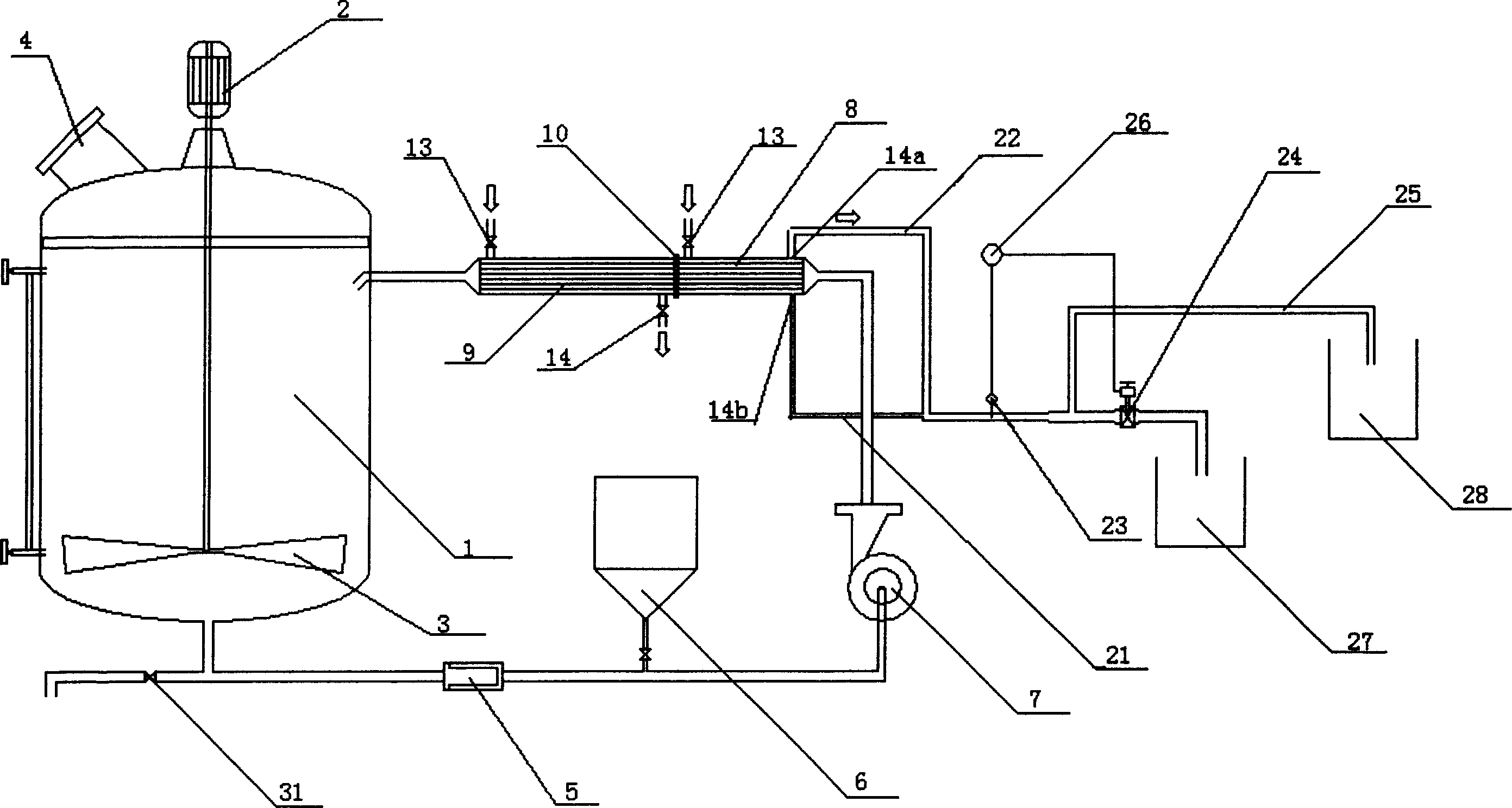

Smoke recycling auxiliary burning type aluminum melting furnace

ActiveCN105403040AAvoid increased furnace pressureImprove combustion efficiencyCrucible furnacesAluminiumCombustion chamber

The invention discloses a smoke recycling auxiliary burning type aluminum melting furnace. The smoke recycling auxiliary burning type aluminum melting furnace comprises an aluminum melting furnace body, at least one main burning gun and a smoke pipe; the aluminum melting furnace body comprises a hearth arranged insides, a burning chamber located at the upper middle portion of the hearth, a molten aluminum pool located at the lower portion of the hearth and a high temperature smoke outlet formed in the lateral wall of the aluminum melting furnace body and communicated with the burning chamber; the at least one main burning gun is arranged on one end wall of the aluminum melting furnace body and used for jetting fuel to the interior of the burning chamber for burning and heat releasing so as to melt aluminum in the molten aluminum pool into molten aluminum; and the high temperature smoke outlet is connected to a chimney through the smoke pipe. The smoke recycling auxiliary burning type aluminum melting furnace further comprises an auxiliary burning gun and a smoke backflow pipe, wherein the auxiliary burning gun and the at least one main burning gun are arranged on one end wall of the aluminum melting furnace body in a spaced manner, and the smoke backflow pipe and the smoke pipe are communicated to enable part of high temperature smoke in the smoke pipe to flow back to the auxiliary burning gun for burning supporting.

Owner:广东能效科技有限公司

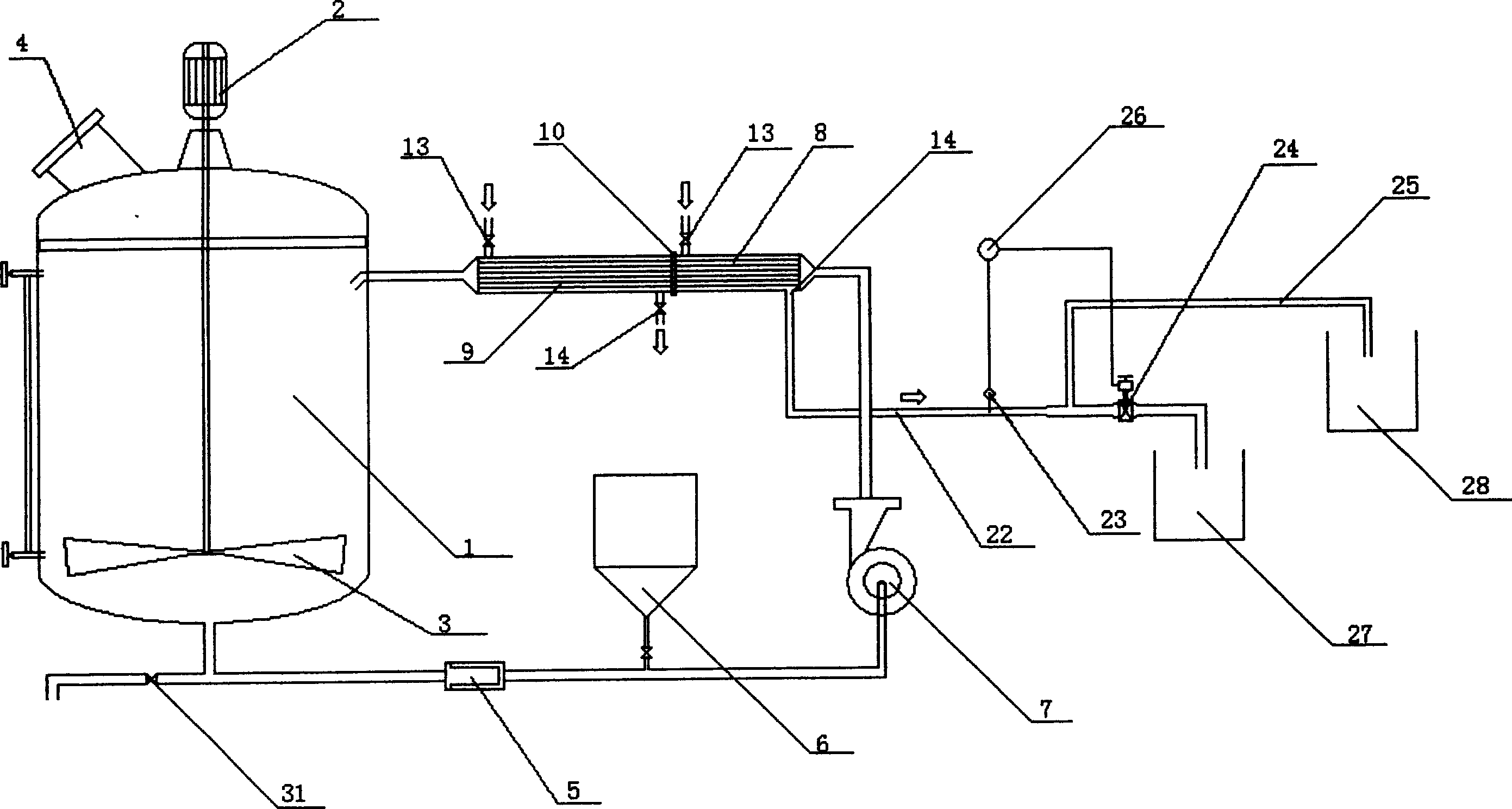

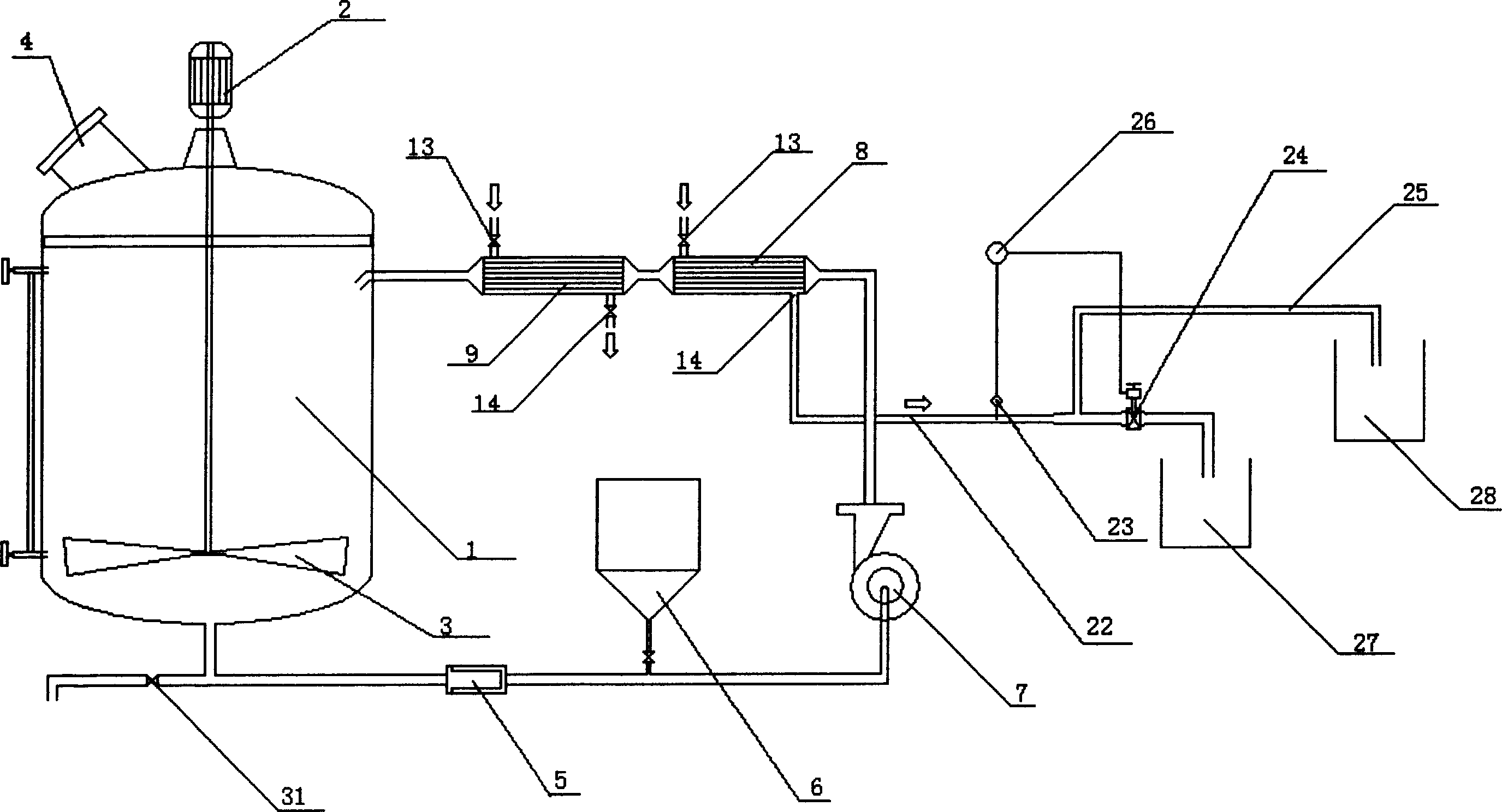

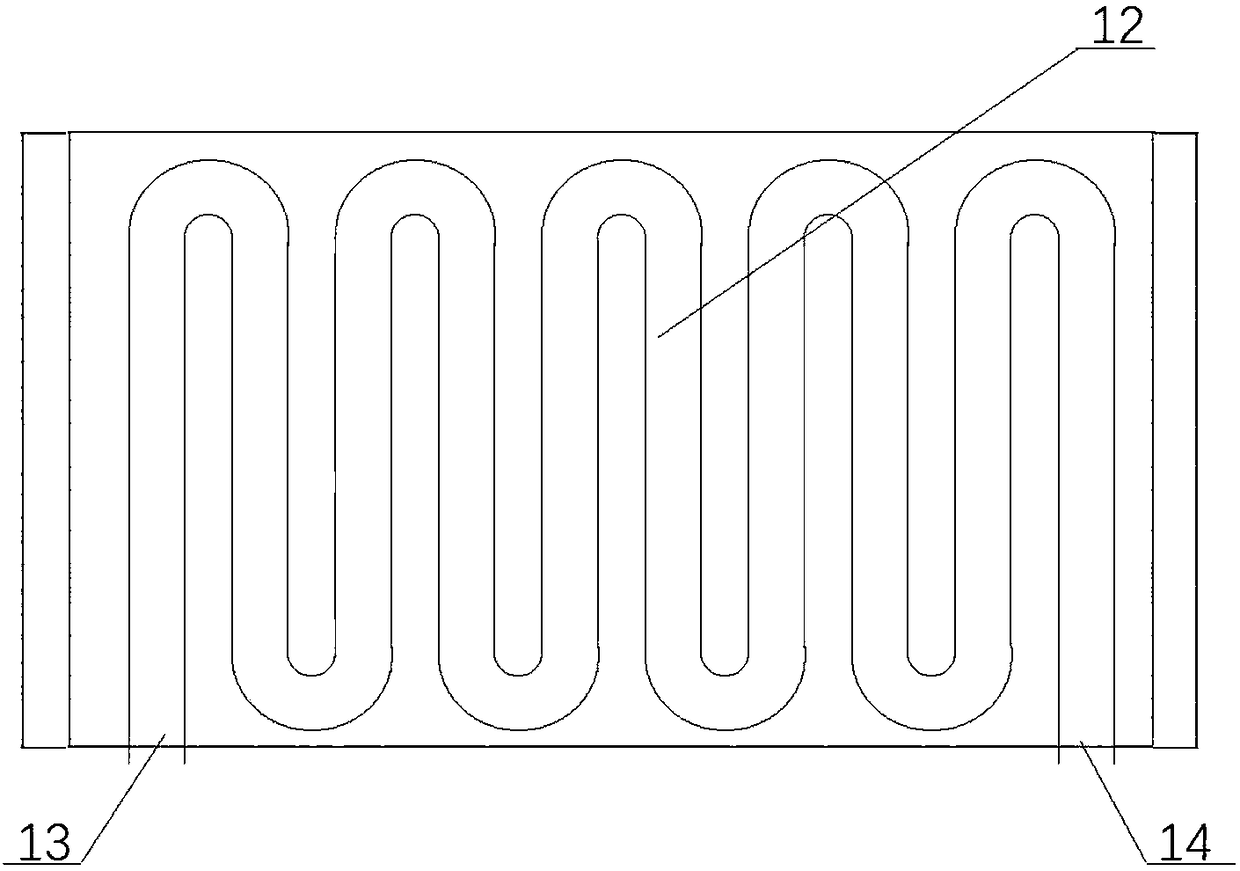

Energy saving type dyeing machine

InactiveCN1648318AIncrease heat exchange rateImprove heating efficiencyTextile treatment machine arrangementsLiquid/gas/vapor textile treatmentLiquid temperatureDyeing

The present invention relates to dyeing machine, and especially a kind of energy saving dyeing machine. The energy saving dyeing machine has cloth dyeing vat with inside water level pipe and cloth inlet and outlet, filter, dyeing liquid inlet and outlet valves, material barrel, dyeing circulating pump connected via pipeline. Between the cloth dyeing vat and the dyeing circulating pump, are connected water cooling exchanger and oil heating exchanger combined integrally with flanges. By means of the water cooling exchanger and the oil heating exchanger combined integrally to cool and heat the dyeing liquid separately, the present invention reaches the technologically required dyeing liquid temperature.

Owner:劳关明

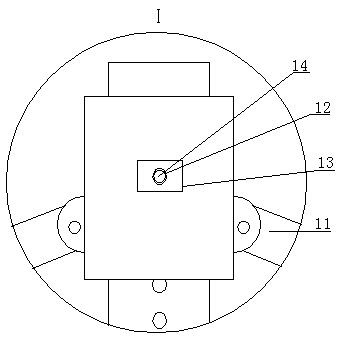

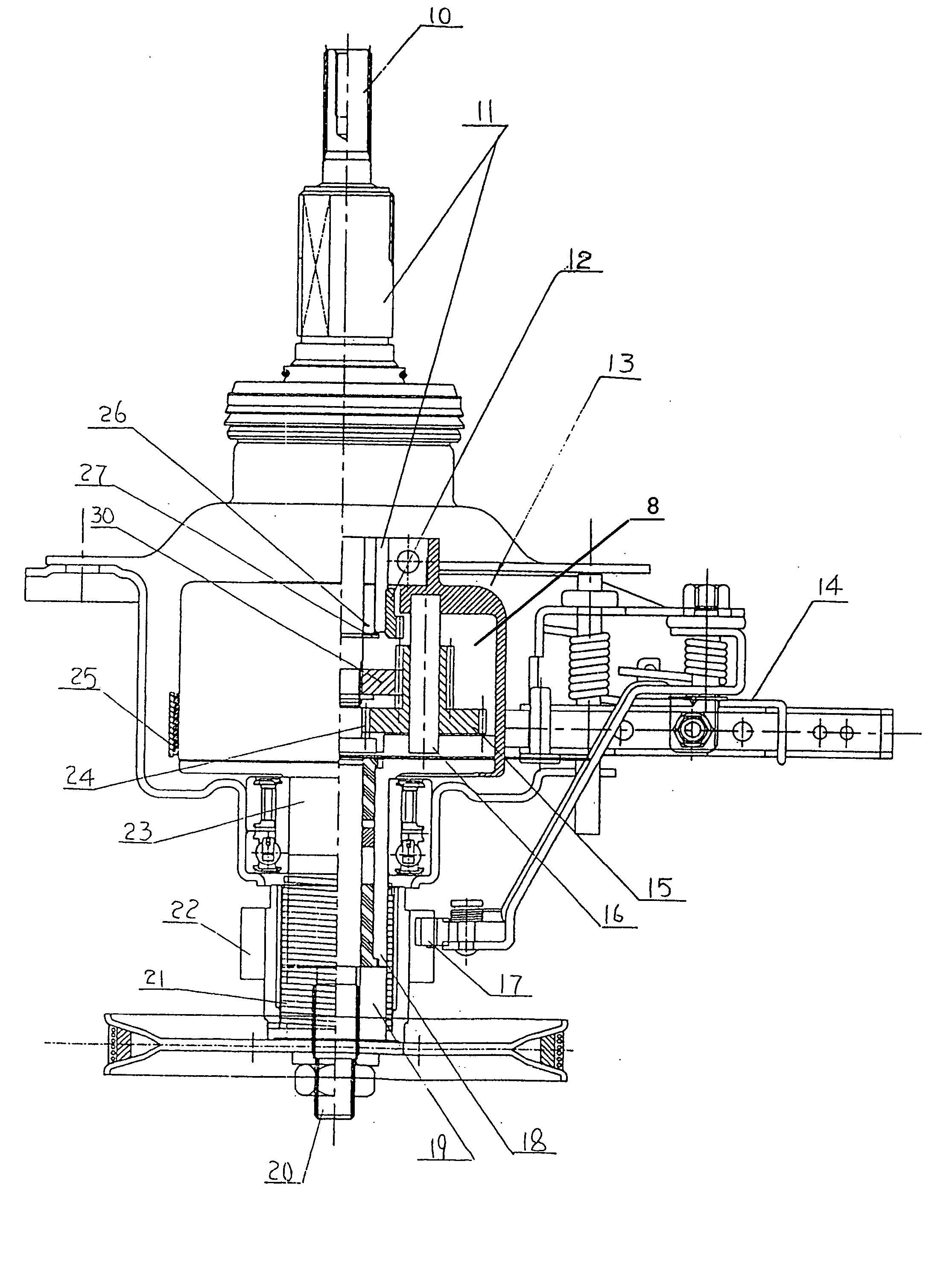

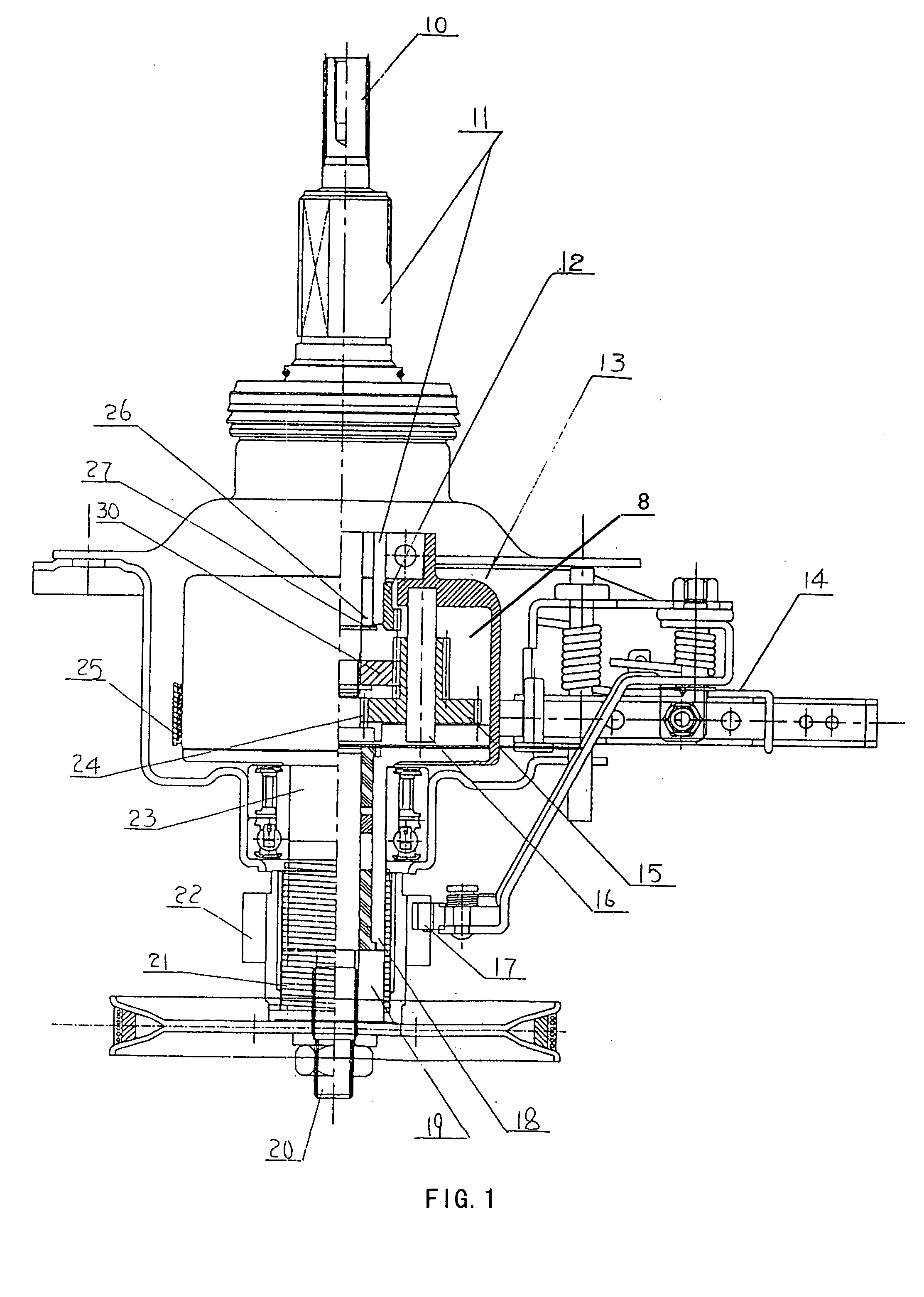

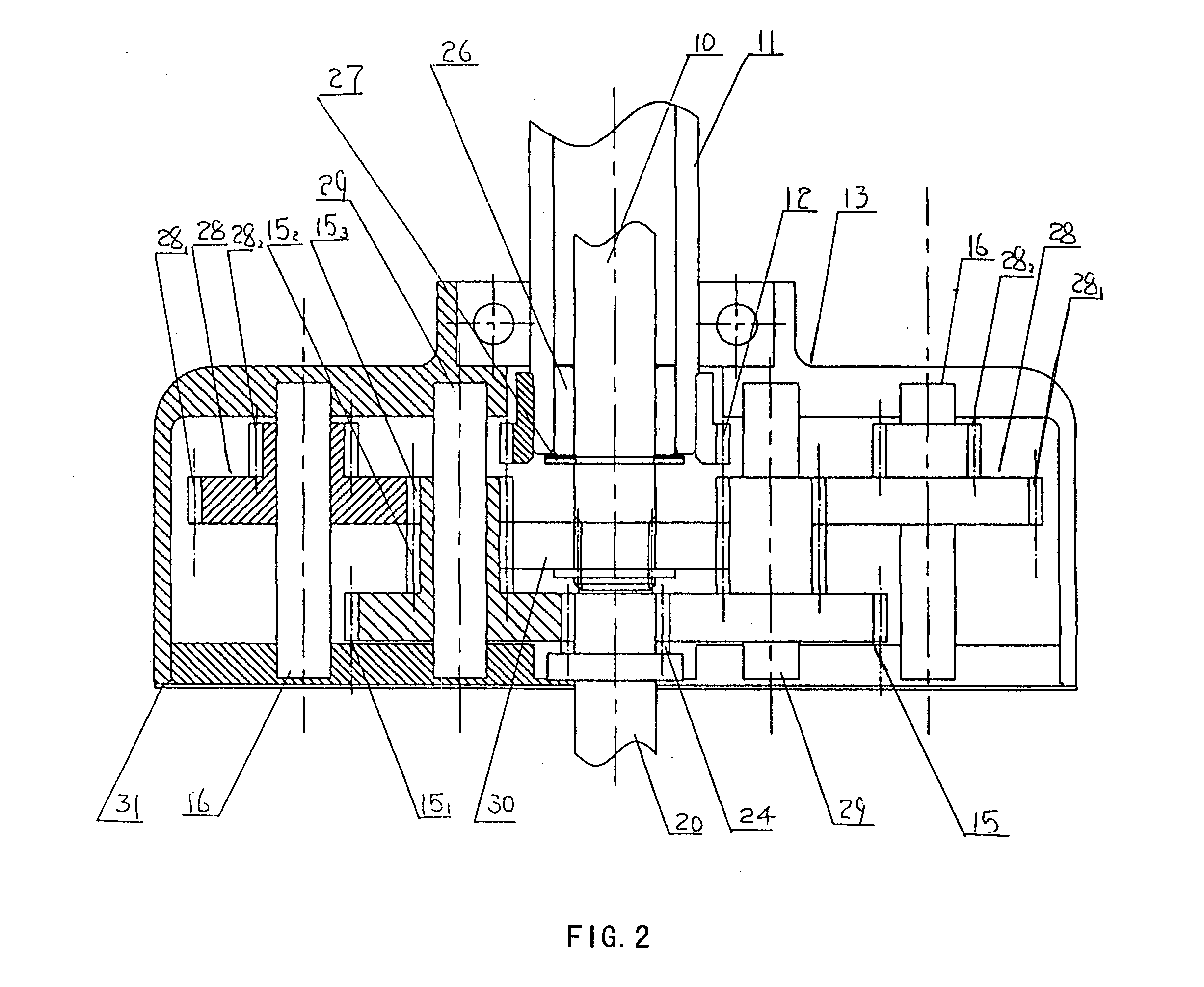

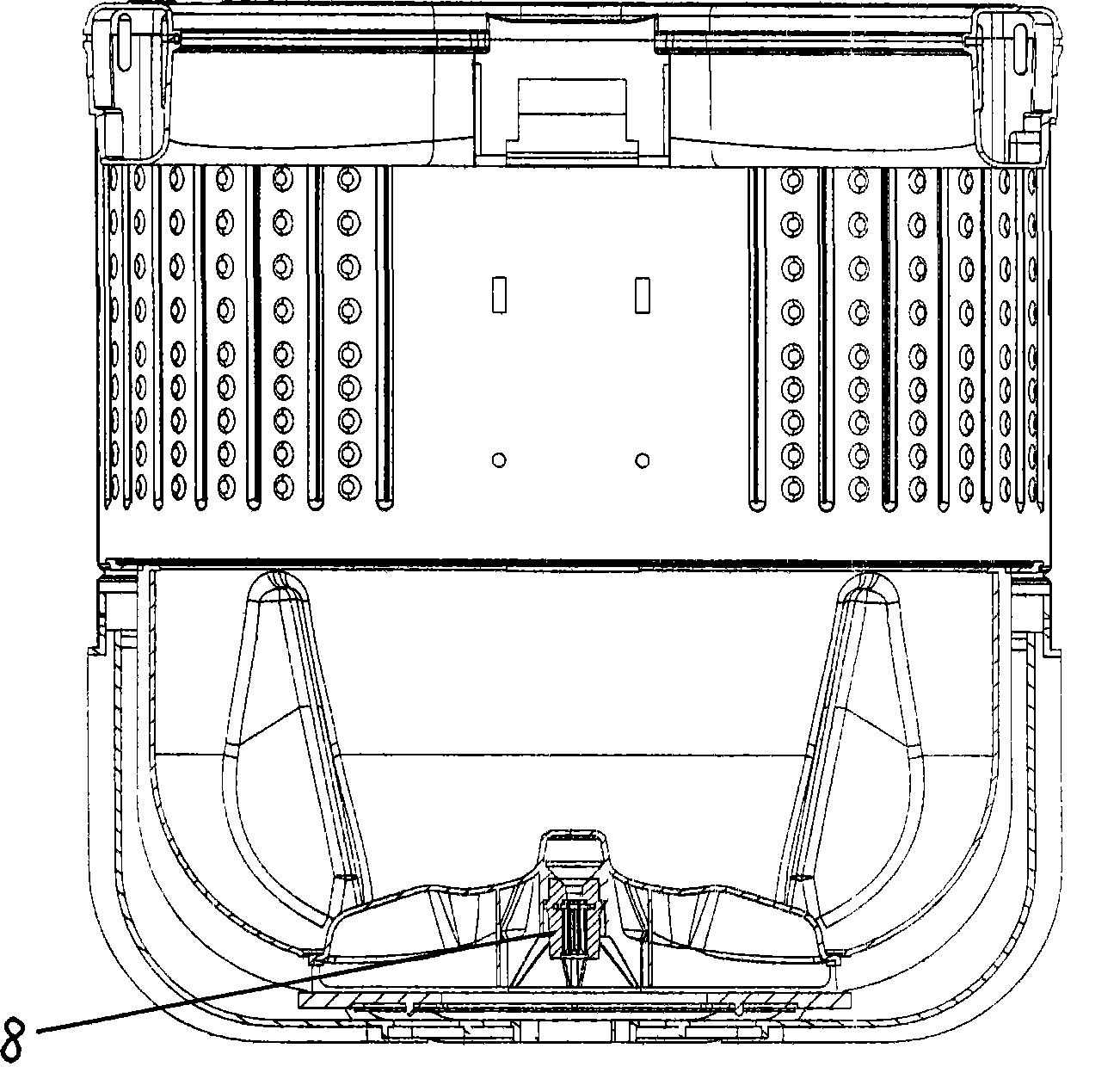

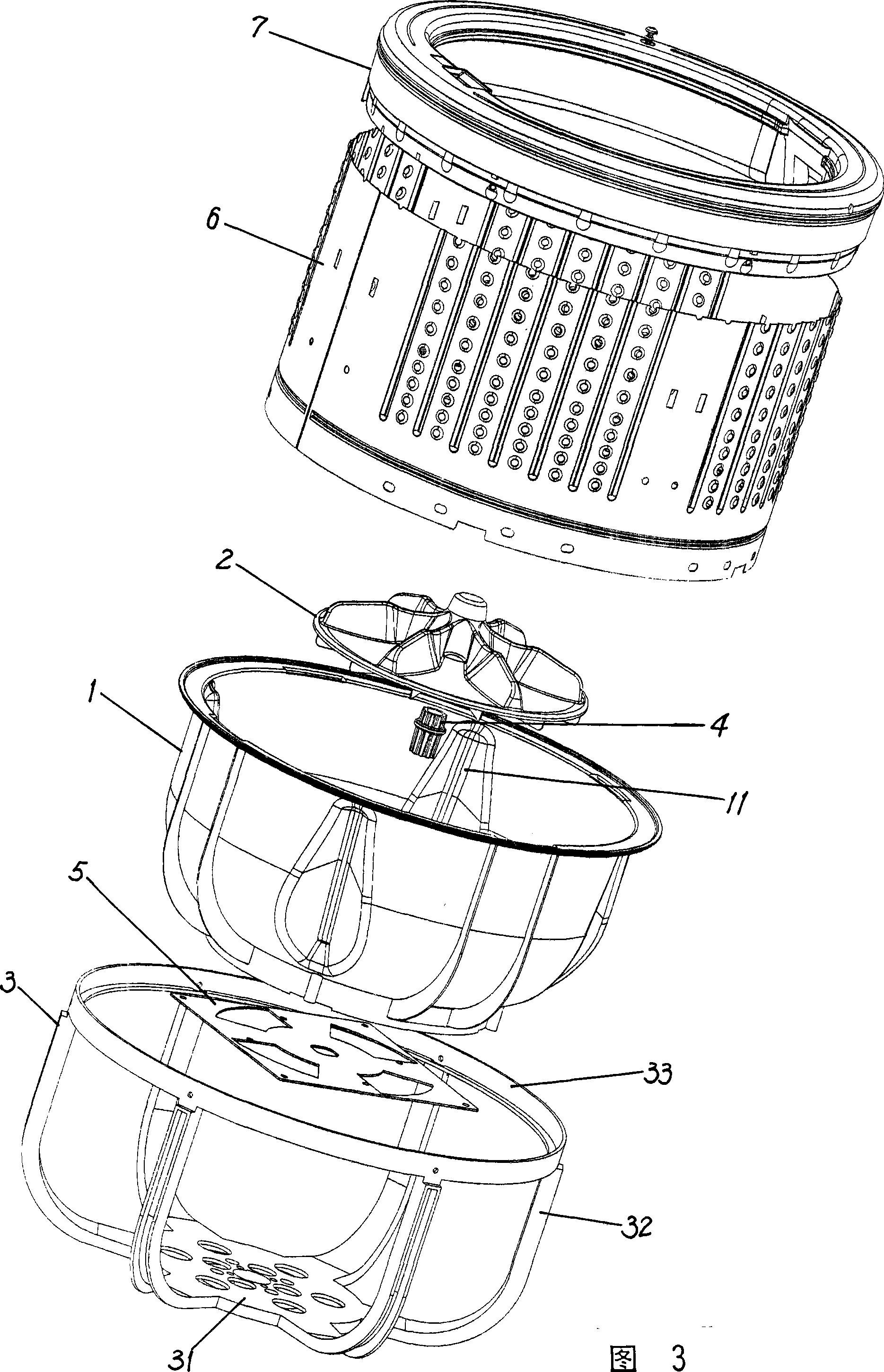

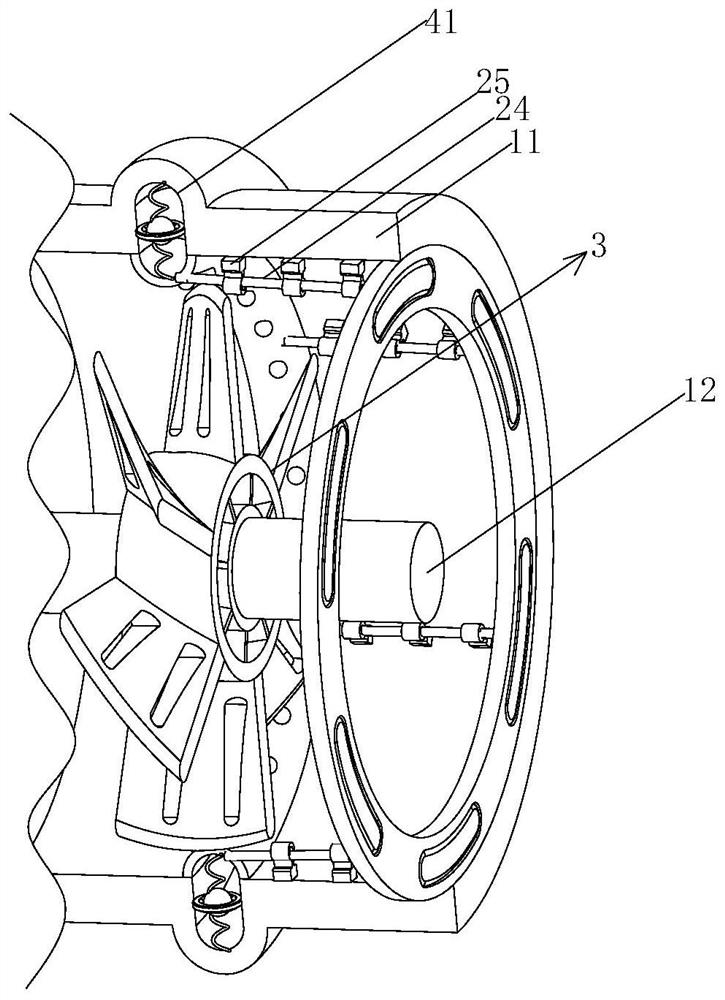

Counter-rotation wash method and transmission machine

InactiveUS20050039496A1Compact structureSmall volumeOther washing machinesWashing machine with receptaclesLaundry washing machineControl engineering

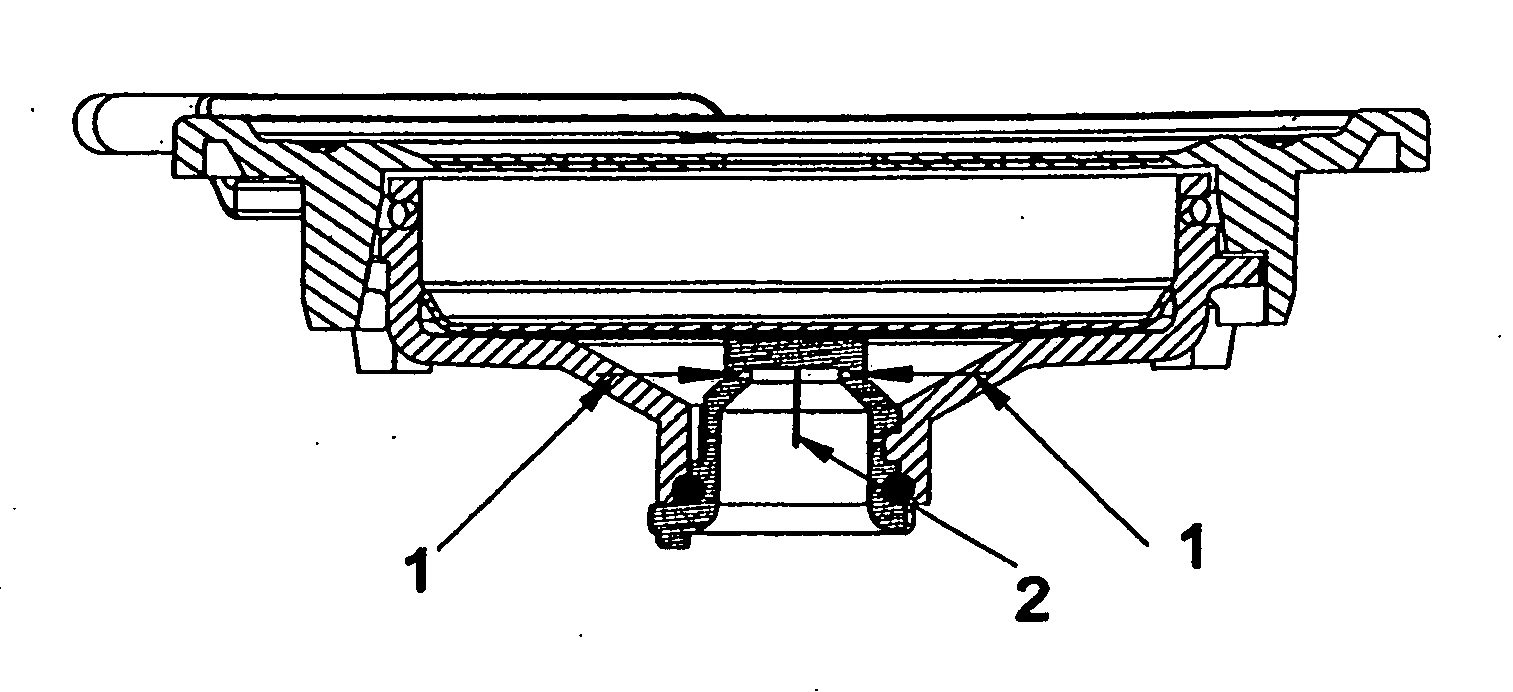

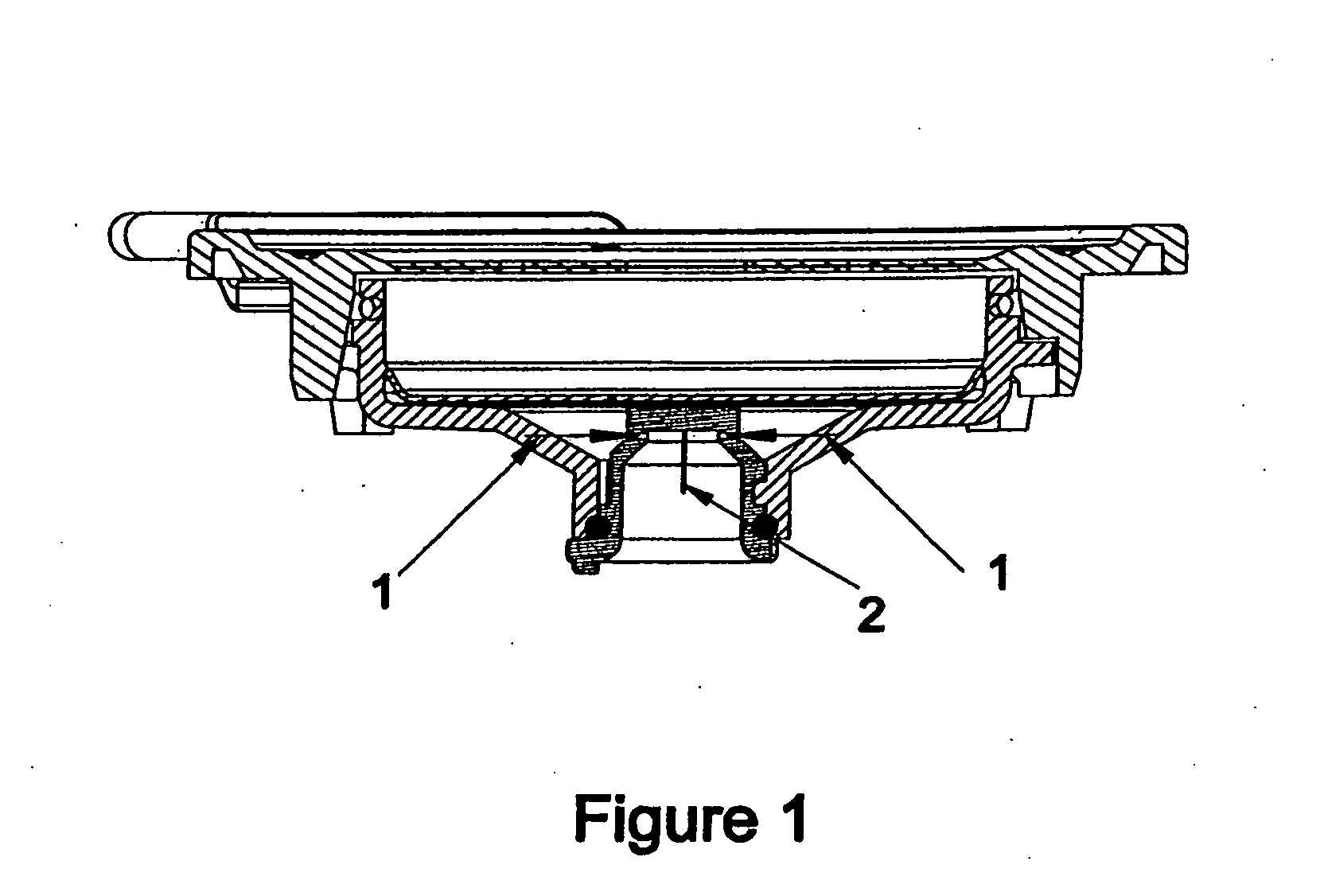

A transmission mechanism suitable to be used in a washing machine for creating dual-direction driving comprises a drive power input end and two drive power output ends, in which one of drive power output ends is connected to an agitator shaft (10) to drive the agitator shaft rotating in a first direction; while the other of drive power output ends is connected with an inner basket shaft (11) to drive the inner basket shaft rotating in a second direction opposed to the first direction. A washing machine for creating dual-direction washing and a washing method for creating dual-direction washing in a washing machine are disclosed in the present invention. Furthermore, an agitator and an inner basket suitable to be used in the washing machine are disclosed in the present invention.

Owner:HAIER GRP AN HAIER ELECTRIC APPLIANCES INT

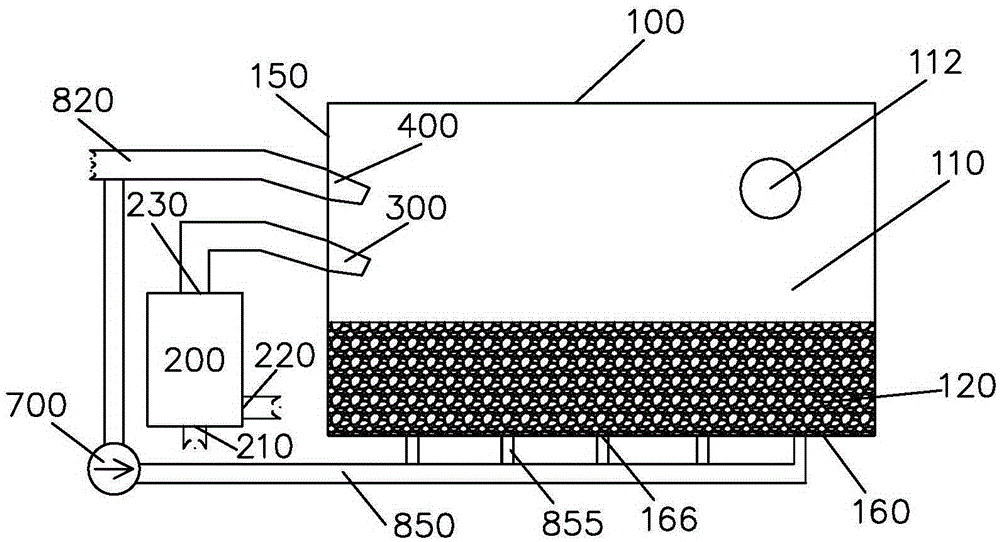

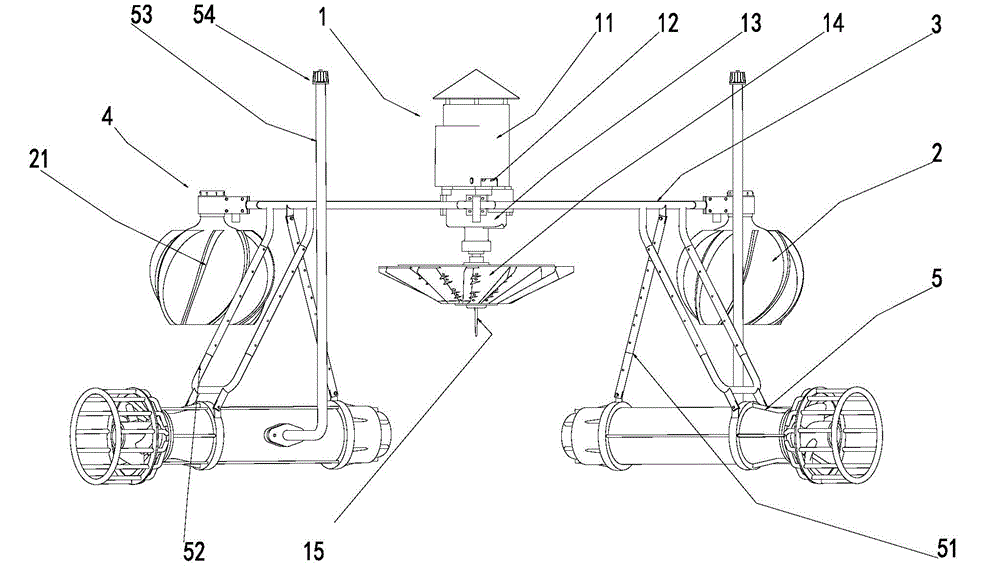

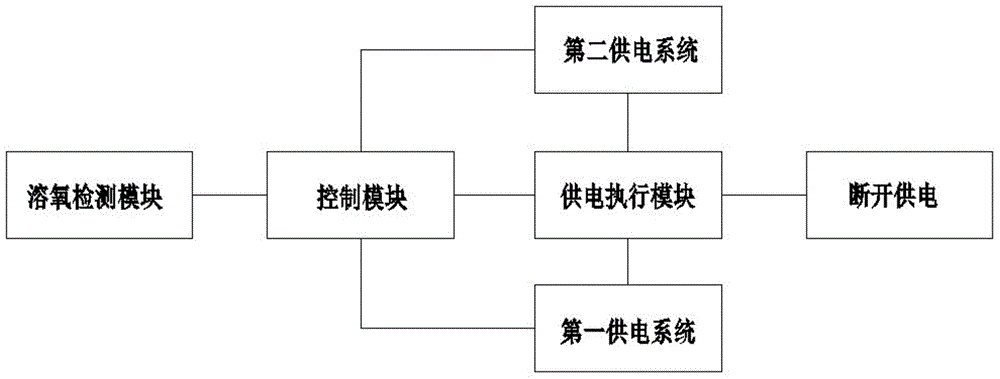

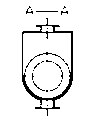

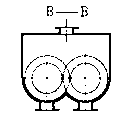

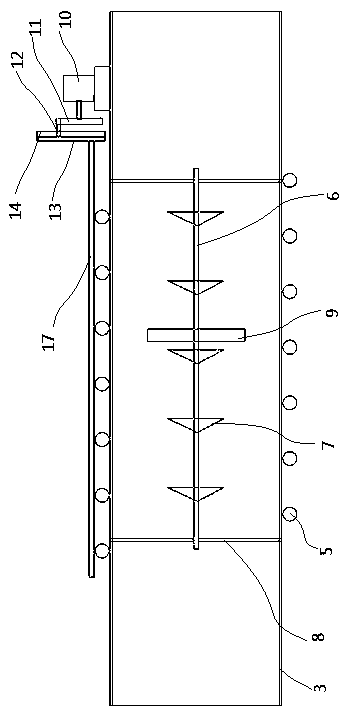

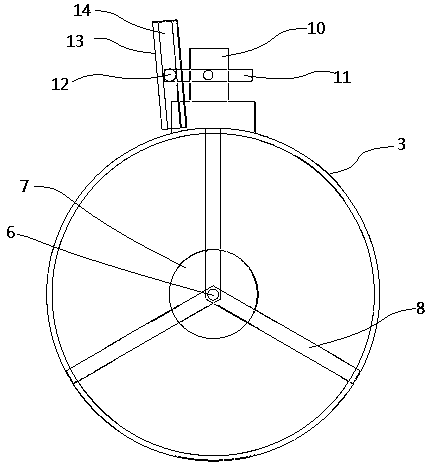

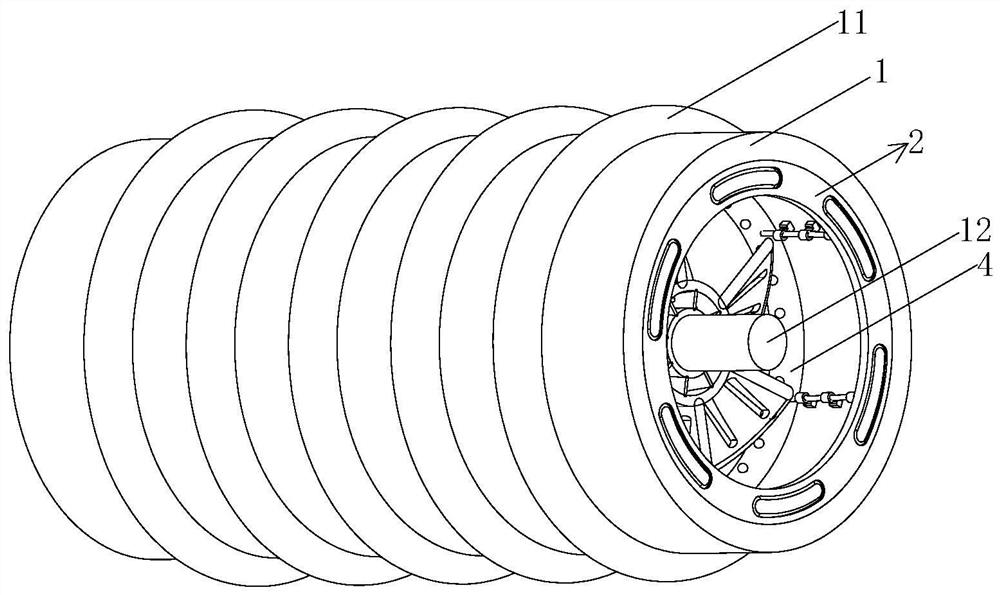

Jet floating ball aerator

ActiveCN103947603AEnhanced agitationIncrease contact areaPisciculture and aquariaSurface layerMarine engineering

The invention discloses a jet floating ball aerator, which comprises a main aerator body, at least two floating balls, and supports with the same number as the floating balls, wherein the floating balls are connected with the main aerator body through the supports, and the floating balls are arranged below the supports and rotate by taking joints of the floating balls and the supports as an axis; spiral blades for stirring the water surface are arranged on the outer surfaces of the floating balls, and the lower parts of the supports are connected with at least one submersible jet aerator. According to the jet floating ball aerator provided by the invention, the floating balls rotate by taking joints of the floating balls and the supports as an axis, the spiral blades for stirring the water surface are arranged on the outer surfaces of the floating balls, and the lower parts of the supports are connected with at least one submersible jet aerator, accordingly, the stirring of a surface layer water body can be increased, the contact area of the water body and air can be increased, the large-range flowing exchange between the surface layer water body and a bottom layer water body can be promoted, so that the aeration range is expanded, and the aeration effect is further improved.

Owner:广州市高级技工学校

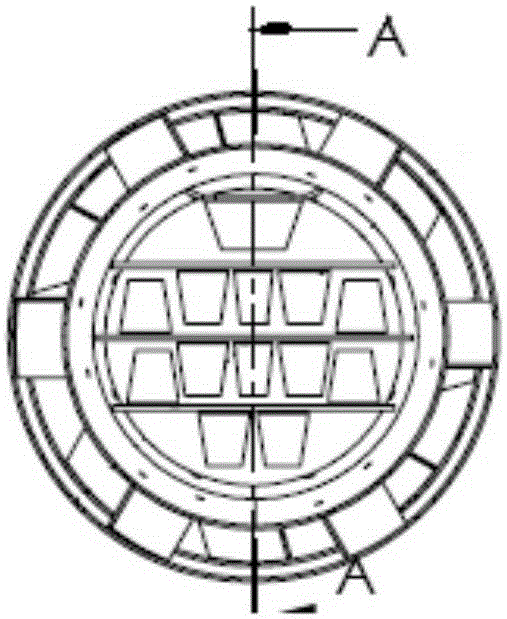

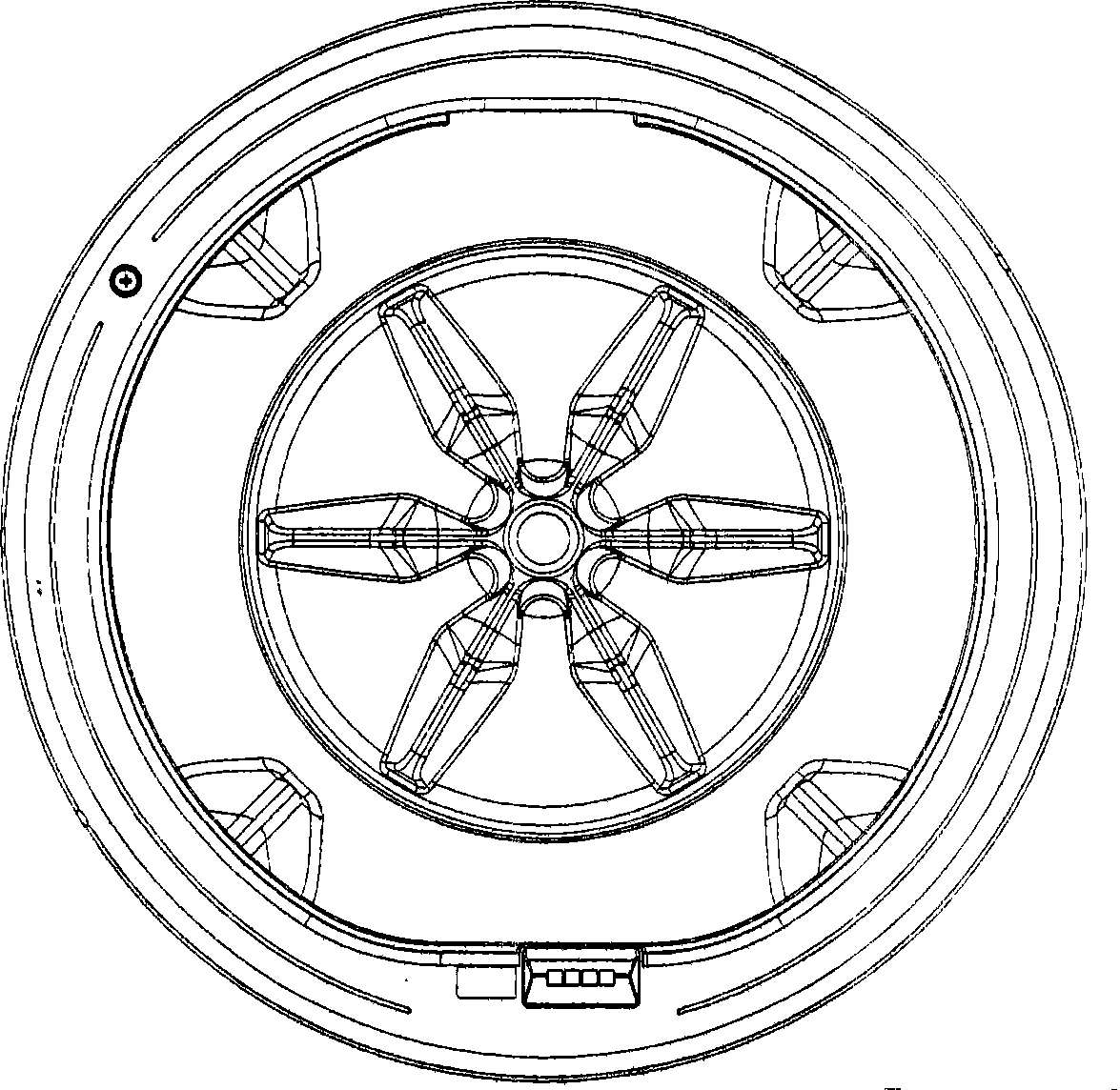

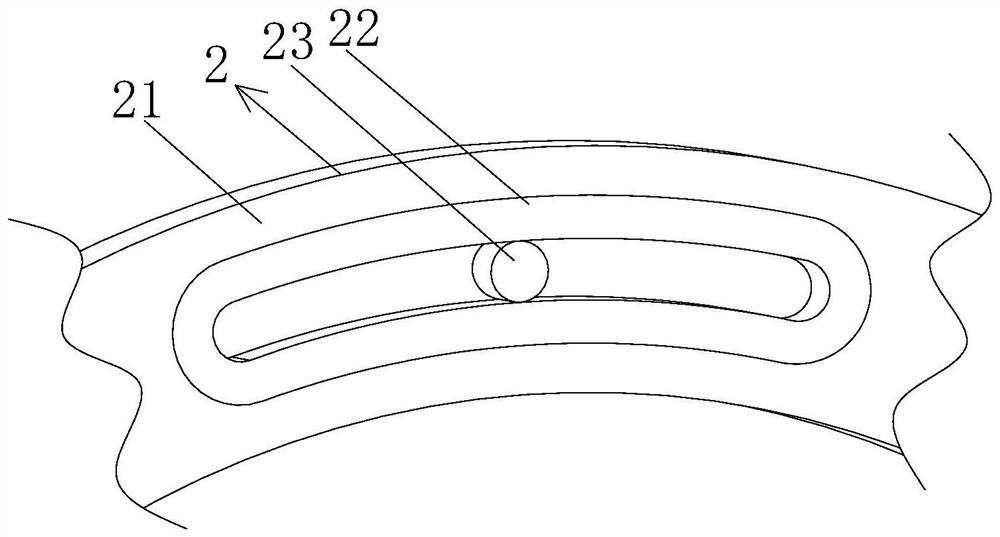

Washing machine having big and small wave wheels independently running

InactiveCN101372803AEnhanced agitationImprove washing effectWashing machine with receptaclesTextiles and paperTropical cycloneWater flow

The invention relates to a washing-machine provided with a large wave wheal and a small wave wheel which run respectively. The washing-machine comprises a water holding cylinder, a washing dewatering cylinder and the wave wheels. The wave wheels include the large wave wheel and the small wave wheel; wherein, the large wave wheel is a pelviform wave wheel and the small wave wheel is arranged in the center inside the pelviform wave wheel; the inner wall of the pelviform wave wheel is provided with a salient; the pelviform wave wheel is sheathed in the bracket of the wave wheel by a connection flange. The washing dewatering cylinder is fixedly connected with the bracket of the wave wheel by a connector. The bracket of the wave wheel, the pelviform wave wheel and the small wave wheel are connected with three rotation shafts; therefore, the running directions of the pelviform wave wheel and the small wave wheel are opposite but the washing dewatering cylinder does not run when washing; when dewatering, the pelviform wave wheel, the small wave wheel and the washing dewatering cylinder run simultaneously with the same direction. When the washing-machine is running, the two wave wheels respectively run in opposite directions, thus generating a water flow similar to a tropical cyclone; simultaneously, the reasonable arrangement of running and stopping of single wave wheel is syncretized, thus enlarging the vibration of the water flow and further improving the washing effect.

Owner:WHIRLPOOLCHINA INVESTEMENT

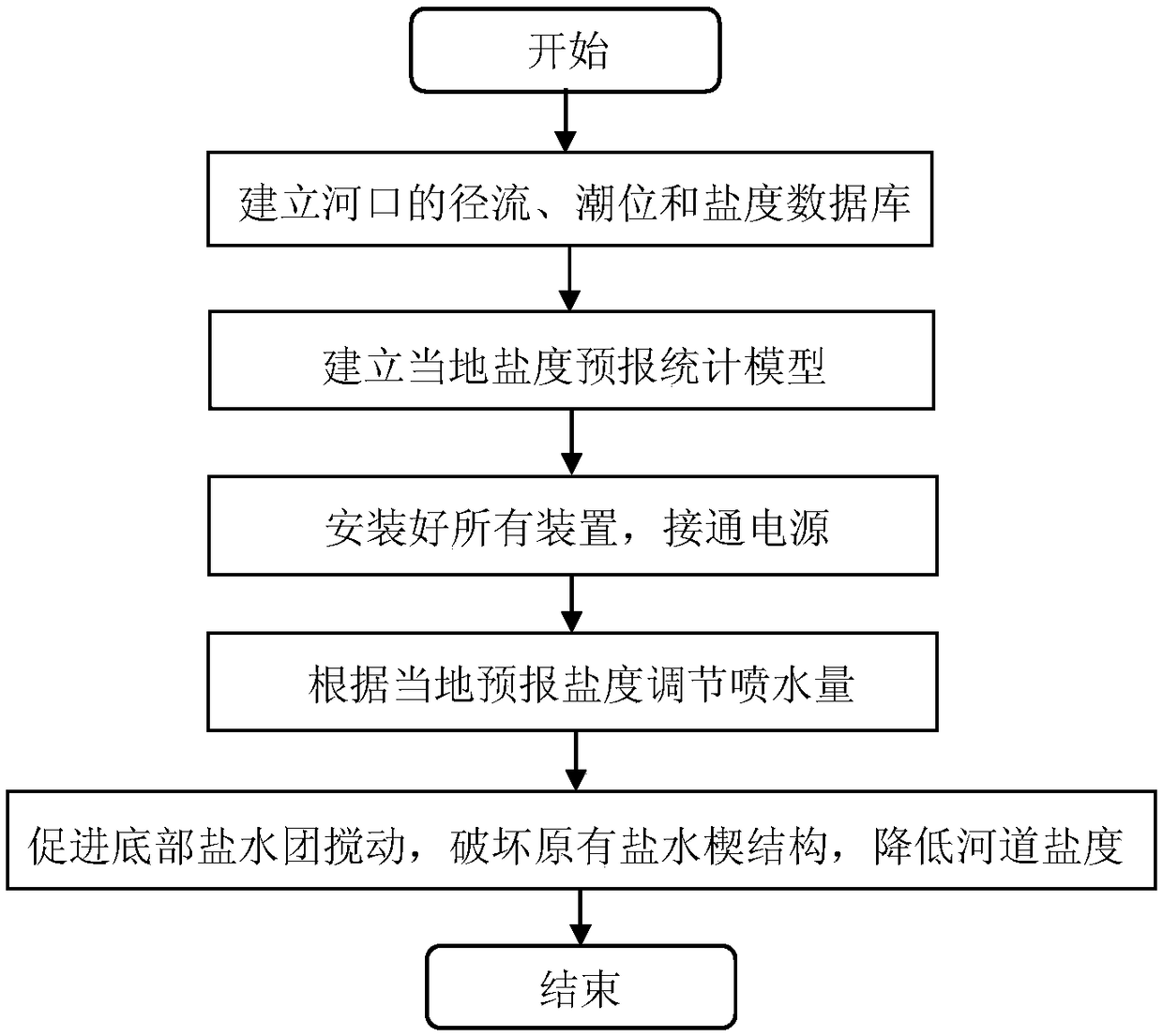

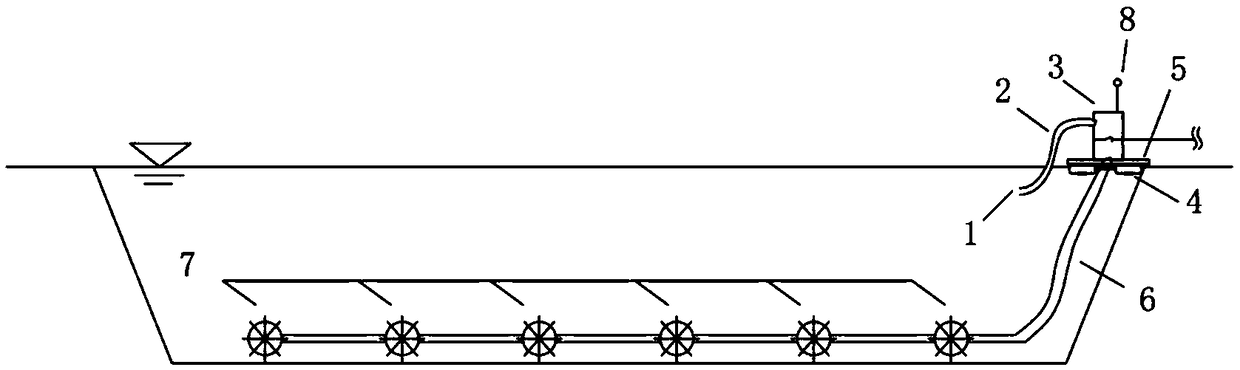

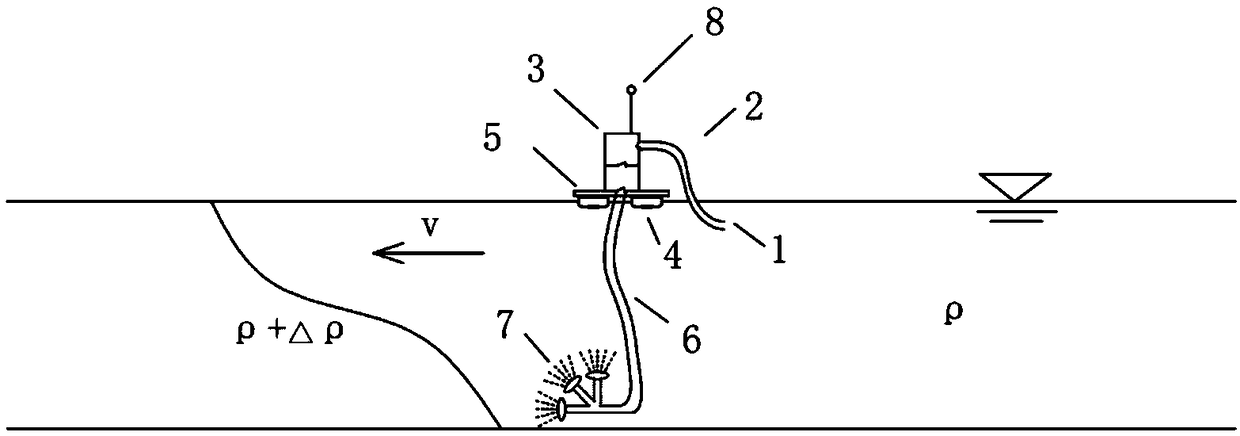

Underwater water curtain method for controlling salt tide of estuary

ActiveCN108914875AEnhanced agitationFully contactedMarine site engineeringHydraulic modelsSaline waterFresh water organism

The invention discloses an underwater water curtain method for controlling a salt tide of an estuary. An observation station arranged in an estuary area is utilized to monitor upstream runoff, open sea tide level and upstream salinity of the area to construct a database of long sequences; the change relationship of the upstream runoff, the open sea tide level and the upstream salinity and local salinity is studied, and an empirical model forecasting the local salt tide is formed by means of statistical means such as relevance. According to the underwater water curtain method, by sucking upperlayer fresh water and make the fresh water sprayed out from the bottom, bottom salt water mass stirring is started and promoted, a salt water wedge structure is damaged, and the riverway salinity is reduced. The water spraying amount is automatically adjusted according to locally forecasted salinity, the water spraying amount is reduced when the salinity is low, and the water spraying amount is improved when the salinity is high, the salt water mass comes into full contact with the fresh water, the riverway salinity is reduced, and the basis is provided for taking water from the estuary area.

Owner:HOHAI UNIV

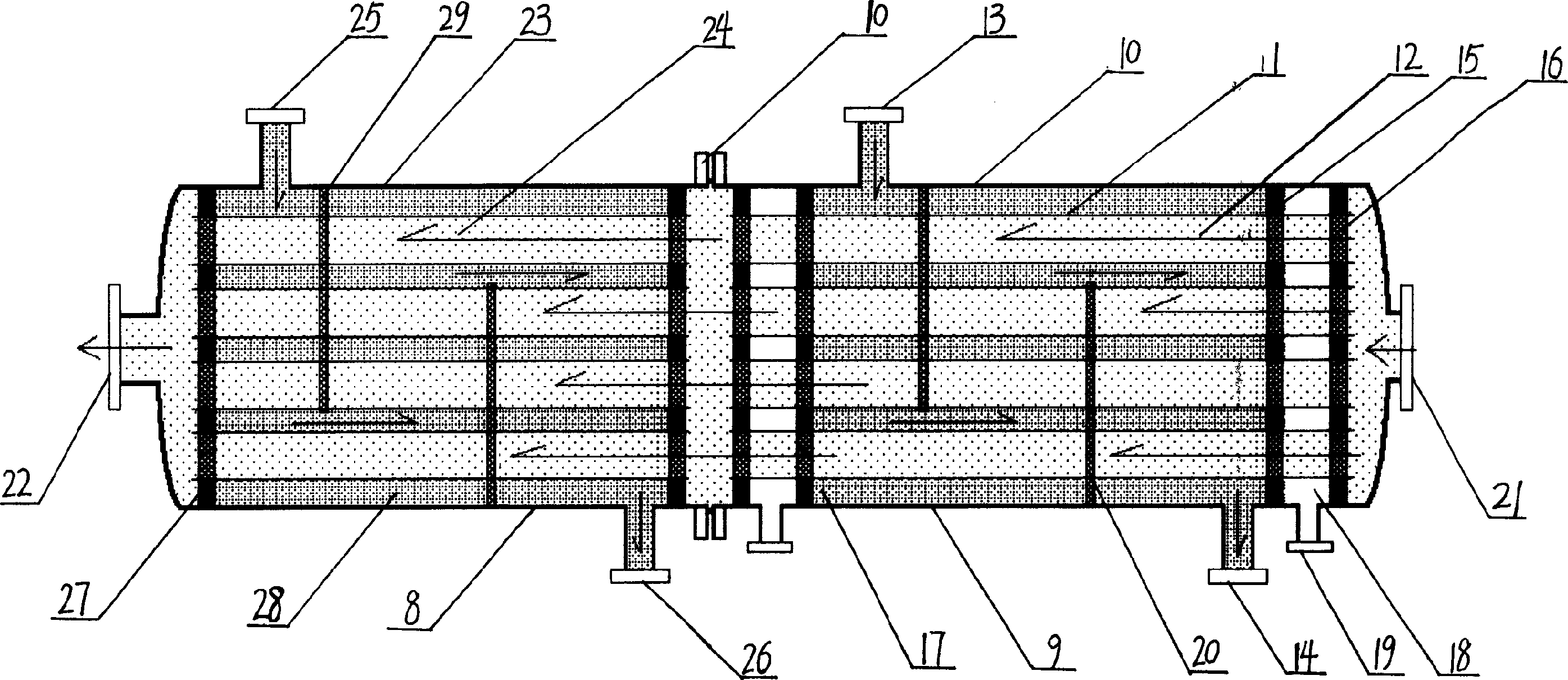

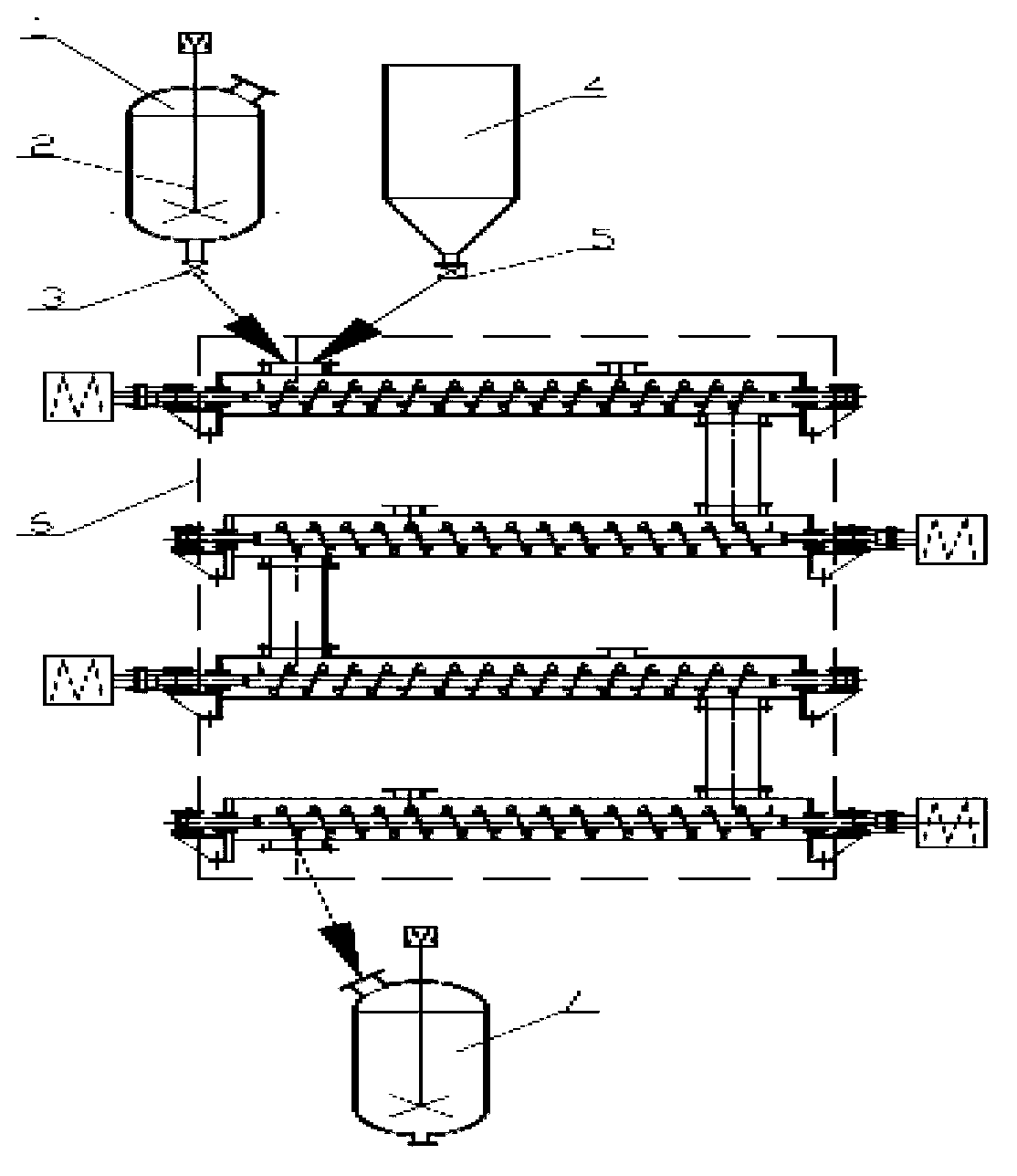

Reaction device and method for producing aluminum oxide

InactiveCN103214014AEnhanced agitationEnhanced mixing processAluminium compoundsProcess engineeringPulverized fuel ash

The invention relates to a reaction device and method for producing aluminum oxide, and particularly relates to a reaction device and method for producing aluminum oxide by taking pulverized fuel ash as a raw material. The reaction device comprises an ammonium sulfate pre-mixing measuring tank, a pulverized fuel ash storing-measuring bin, a combined spiral reactor, a material receiving tank and a gas collecting pipe, wherein the ammonium sulfate pre-mixing measuring tank and the pulverized fuel ash storing-measuring bin are arranged above the combined spiral reactor and are connected with an upmost inlet in the combined spiral reactor through connecting pipes at the bottom parts of the ammonium sulfate pre-mixing measuring tank and the pulverized fuel ash storing-measuring bin; and the material receiving tank is arranged below the combined spiral reactor and is connected with a lowest outlet in the combined spiral reactor through a connecting pipe at the top part of the material receiving tank. By the device and the method, the problems related to large-scaled production are solved; the device and the method have the characteristics of continuous production, high capacity of single-set device, reaction stability, high utilization rate or conversion rate of the raw material, and the like; the combined spiral reactor has the advantages of long service life, low production cost and the like; and the device and the method have a broad market prospect.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

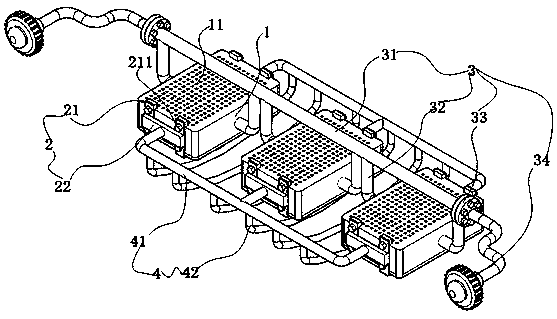

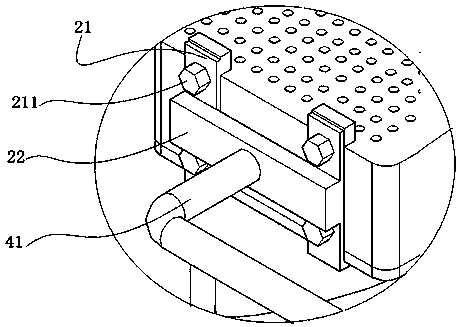

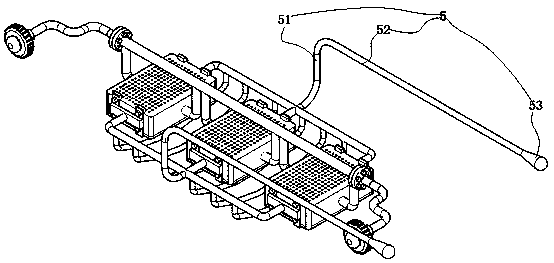

Toilet bowl dredging device

ActiveCN108222170ASimplify the inner structureSolution to short lifeWater closetsDomestic plumbingEngineeringToilet

The invention discloses a toilet bowl dredging device, and relates to the technical field of toilet bowls. The toilet bowl dredging device comprises a toilet bowl, a water tank, a water sealing pipe and a discharge pipe. The toilet bowl dredging device is characterized in that a dredging anti-blocking mechanism is arranged on the water sealing pipe and comprises an electromagnetic coil and a magnet column, the electromagnetic coil is rotatably connected outside the water sealing pipe in a sleeving manner, the magnet column is arranged in the water sealing pipe, stirring bodies are uniformly arranged on the magnet column, and elastic positioning frames are fixedly connected at the left end and the right end of the magnet column and rotatably connected with the inner wall of the water sealing pipe. The toilet bowl dredging device has the advantages that an inner structure of a pipeline is optimized, the outside of the pipeline is controlled, and a dredging and anti-blocking function is more effectively achieved.

Owner:如东县升泰新农村开发建设有限公司

Urban sewage treatment device with high treatment efficiency

InactiveCN111392849ARealize the function of large area aerationRealize large area aerationWater aerationSustainable biological treatmentEngineeringMunicipal sewage

The invention discloses an urban sewage treatment device with high treatment efficiency. The urban sewage treatment device comprises a plurality of aeration plates arranged at intervals in the left-and-right direction, and a plurality of aeration through holes are formed in the tops of the aeration plates and the bottoms of the aeration plates; the urban sewage treatment device with the high treatment efficiency further comprises an aeration assembly communicating with a plurality of aeration plates. The aeration assembly comprises an aeration air inlet pipe communicated with the side wall ofthe aeration plate, the aeration assembly further comprises a horizontal transverse pipe communicated with the aeration air inlet pipe, and the horizontal transverse pipe is communicated with an aerator; the device further comprises a suspension assembly. The suspension assembly comprises connecting rods which are fixedly connected to the front side wall and the rear side wall of the aeration plates; a plurality of arc-shaped shaking rods are fixedly connected between the connecting rods and arranged at intervals in the left-right direction. The aeration direction of the aeration holes is automatically changed through the components of the device so that the effect of increasing the aeration area is achieved, and large-area aeration in sewage is achieved.

Owner:胡增永

Sewage conveying pipeline

ActiveCN113883357AReduces buildup on the inner walls of pipesEnhanced agitationHollow article cleaningPipe elementsStructural engineeringSewage

The invention discloses a sewage conveying pipeline which comprises a pipeline body. A plurality of reinforcing rings are fixedly connected to the outer wall of the pipeline body, a fixing shaft is fixedly connected to the interior of the pipeline body, a plurality of anti-blocking mechanisms are arranged on the fixing shaft, auxiliary cleaning mechanisms are fixedly connected to the inner wall of the pipeline body, a connecting ring is arranged between the auxiliary cleaning mechanisms, and the connecting ring is fixedly connected to the inner wall of the pipeline body. Compared with the prior art, sewage can generate impact on the surfaces of driving fan blades in the conveying process, so that a movable ring can rotate under the driving of the driving fan blades, and the situation that the sewage is accumulated on the inner wall of the pipeline due to internal precipitation and slow standing in the conveying process can be reduced; and meanwhile, an elastic sheet can drive the movable ring to do irregular circular motion under the action of the sewage, so that stirring of the driving fan blades on the sewage can be further enhanced, and the situation that the pipeline is blocked due to standing of sediment can be further reduced.

Owner:洪江市盛翔牧业有限责任公司

Oil heating and heat recovering reaction pot

InactiveCN1772367AReduce volumeRelieve pressureFlow mixersRotary stirring mixersThermal energyEngineering

The present invention discloses one kind of oil heating and heat recovering reaction pot, and belongs to the field of chemical material processing apparatus technology. The oil heating and heat recovering reaction pot includes a pot body, a filter and a circulating water pump connected successively, as well as combined or serially connected water cooling heat exchanger with shunt and oil heating heat exchanger connected between the pot body and the circulating water pump. By means of the water cooling heat exchanger and the oil heating heat exchanger, the mixed liquid may be cooled and heated to the required temperature, and the water exhausted from the heat exchanger may be made to flow into the hot water or cold water returning unit to utilize the heat energy fully.

Owner:劳关明

Electroplating wastewater treatment device and method

InactiveCN109650609AStir wellEasy to operateWater contaminantsTreatment involving filtrationWater qualitySedimentation

The invention discloses a high-efficiency treatment device and method for electroplating wastewater. Microwave high-temperature modified pyrrhotite is used as a filter layer filler to efficiently remove various heavy metal ions in wastewater, and pyrrhotite produces iron ions for electric Fenton reaction. Supplemented by microporous aeration as an electric Fenton gas source, liquid phase mass transfer efficiency and oxidant production are increased, and organic pollutants in wastewater are rapidly oxidized and decomposed without adding additional oxidant or iron ions. The treatment effluent enters a clear water tank after coagulating sedimentation, and the water quality meets the national Electroplating Pollutant Emission Standard (GB21900-2008). The device of the invention is an integrated portable device. The required raw materials are recycled waste resources. In addition, the invention has application advantages of good environmental friendliness and low cost. The technology of treating the electroplating wastewater can realize the synergistic and efficient removal of heavy metals and organic pollutants, has advantages of high reaction speed and stable treatment performance, and is suitable for the treatment of various electroplating wastewaters.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

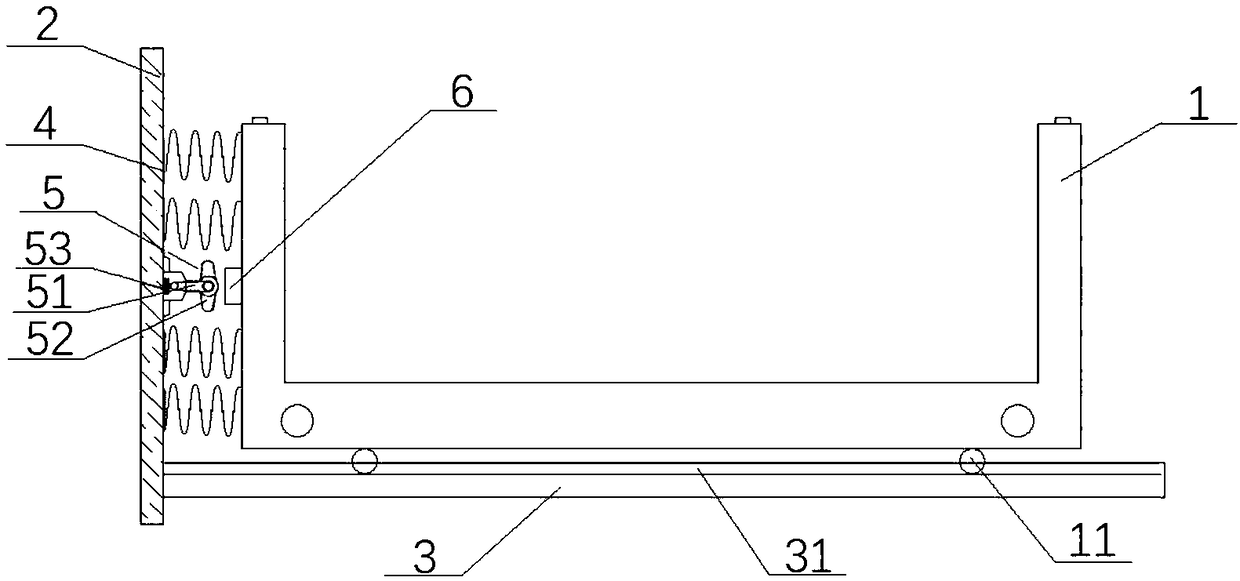

Auxilary device for casting mould

PendingCN108515163ASolve the problem of high defect rate and heavy repair workloadEnhanced agitationEngineeringPulley

The invention relates to the technical field of casting, in particular to an auxilary device for a casting mould. The auxilary device comprises a box body used for containing a casting box, a baffle and a bottom plate, wherein a sliding chute is formed in the bottom plate, pulleys are arranged at the bottom of the box body, and the pulleys slide in the sliding chute so that the box body can be insliding connection with the bottom plate; the baffle is arranged on one side of the bottom plate; the baffle stretches out transversely in the direction of facing the box body, forming a vibrating spring and a telescopic part; and the other end of the vibrating sprign is installed on the box body, the telescopic part abuts against the box body intermittently, the minimum length of the vibrating spring during compression is larger than that of the telescopic part during contraction. The auxilary device has the benificial effects that in the pouring process, left-anf-right direction vibration isprovided for a pouring mold, and the problems of a high defect rate and a heavy repair workload during cooling of an existing casting are solved.

Owner:上海中振有色金属铸造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com