Methods and systems for processing microfeature workpieces with flow agitators and/or multiple electrodes

A stirrer, micro-feature technology, applied in chemical instruments and methods, jitter/oscillation/vibration mixers, circuits, etc., can solve problems such as disturbing electric field uniformity, difficulty, affecting uniformity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] As used herein, the term "microfeature workpiece" or "workpiece" refers to a substrate on which and / or in which microelectronic devices are integrally formed. Typical microdevices include microelectronic circuits or components, thin film recording heads, data storage elements, microfluidic devices, and other products. Micromachines or micromachined devices are included within this definition because they are fabricated with techniques very similar to those used in integrated circuit fabrication. The substrate can be a semiconductor (such as a doped silicon wafer or a gallium arsenide wafer), a non-conductor (such as various ceramic substrates) or a conductor. In some cases, the workpiece is generally circular, while in other cases, the workpiece has other shapes, including rectilinear shapes.

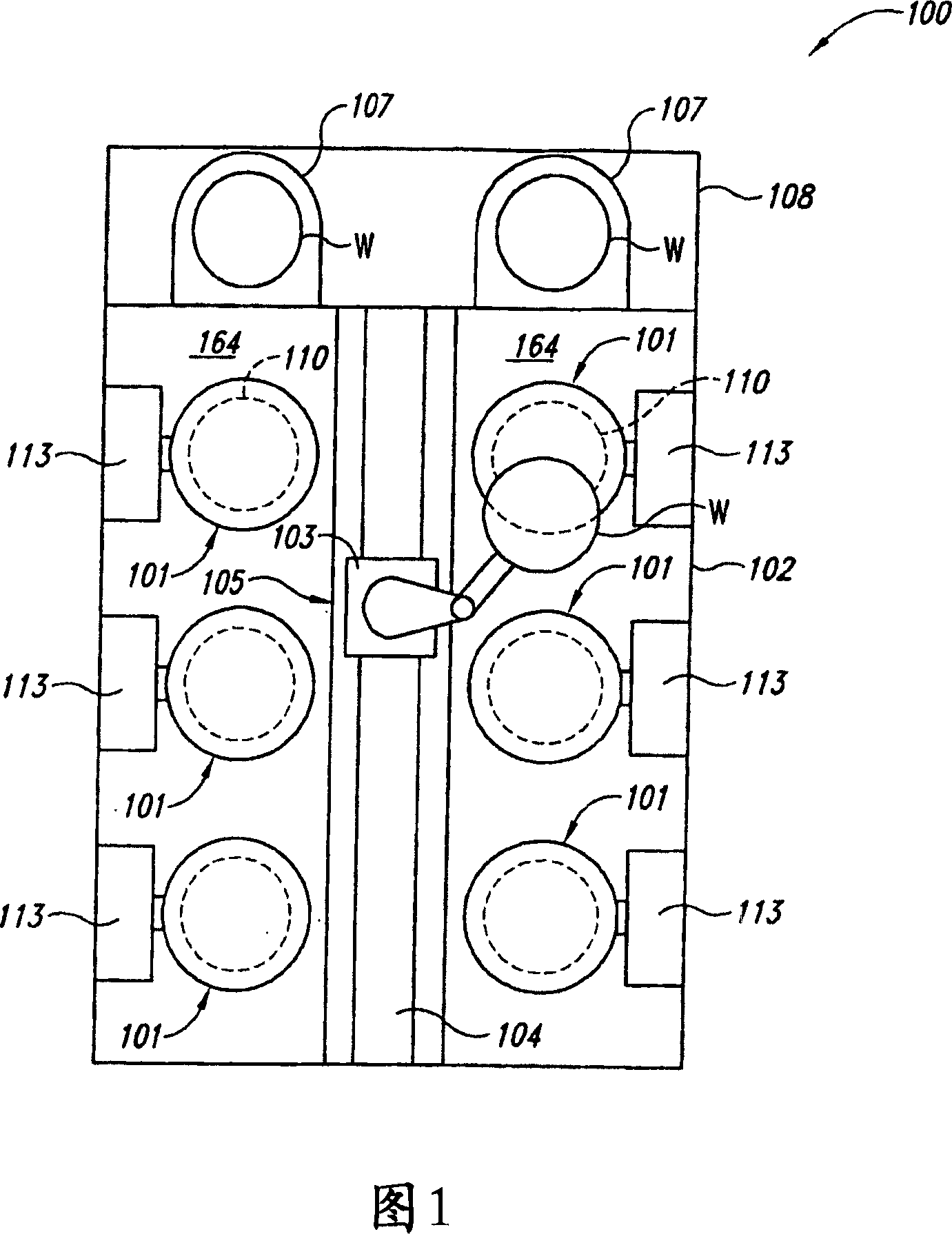

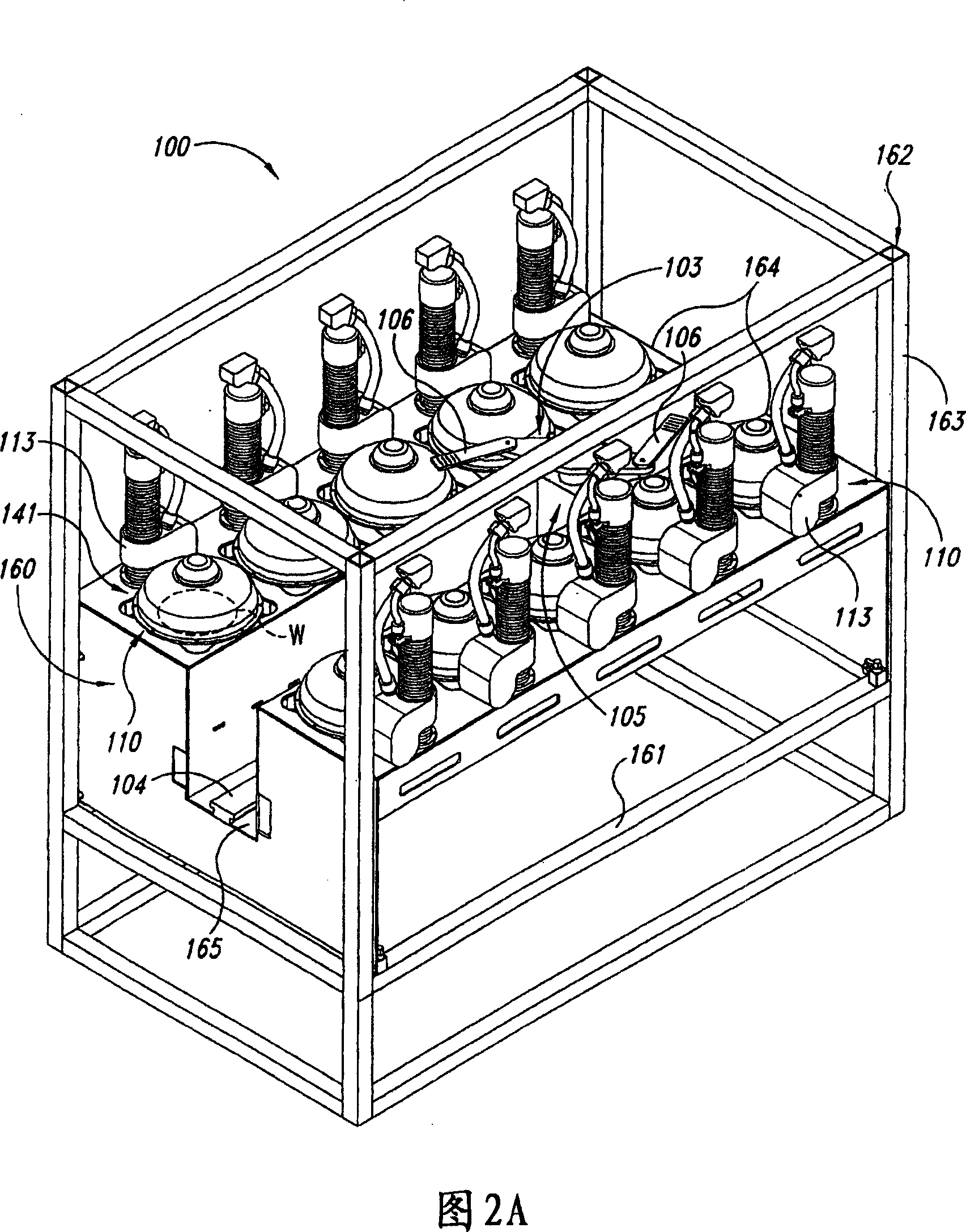

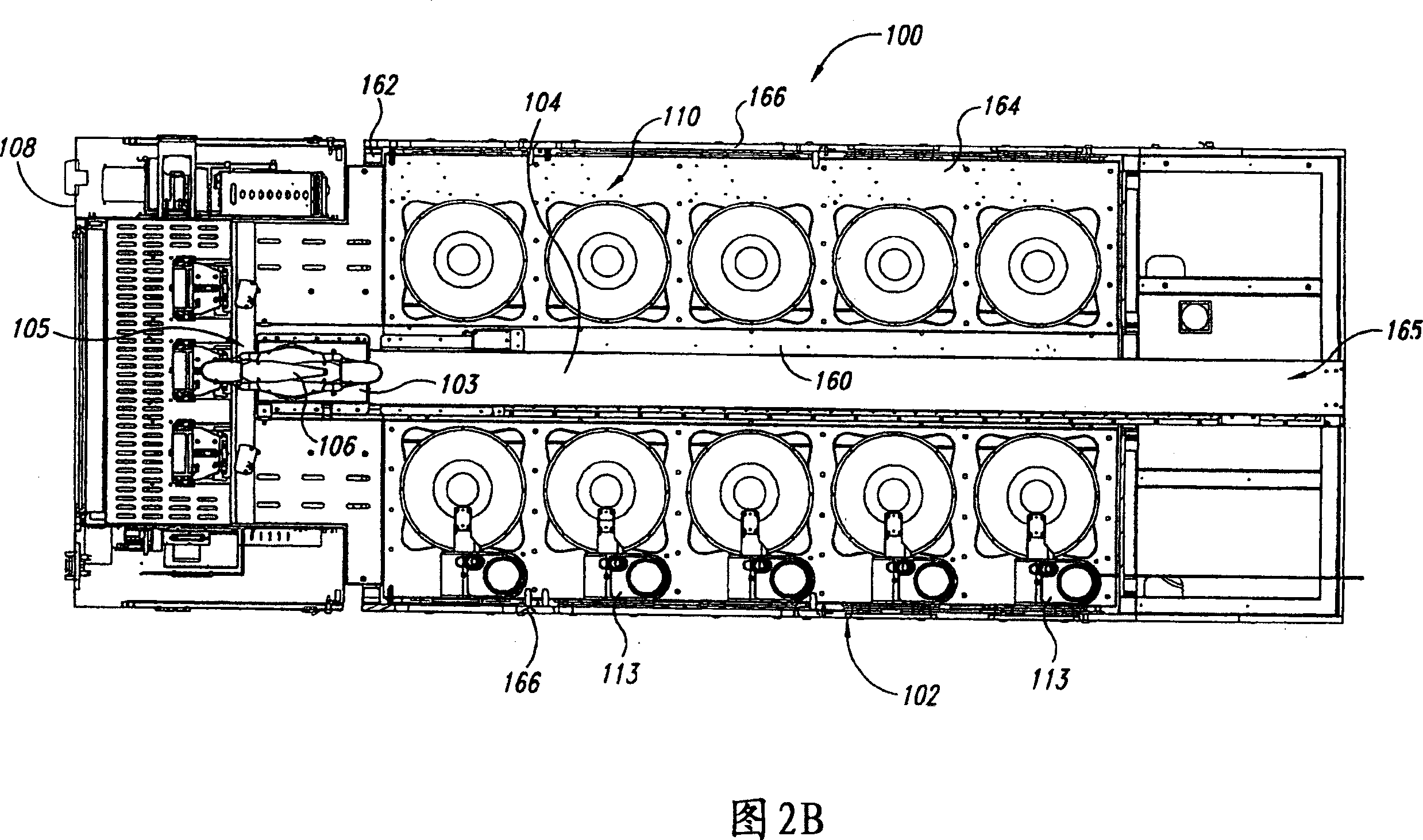

[0040] In the following, several embodiments of integrated tools for wet chemical processing of microfeatured workpieces are presented for depositing metal or electrophoretic re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com