Oil heating and heat recovering reaction pot

An oil heating and heat recovery technology, which is applied in heat exchanger types, lighting and heating equipment, chemical/physical/physicochemical fixed reactors, etc., can solve the problem of bulky reaction pots, waste of energy, and increased risk of use, etc. problem, to achieve the effect of improving cooling effect, increasing heating efficiency, and improving heat exchange rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

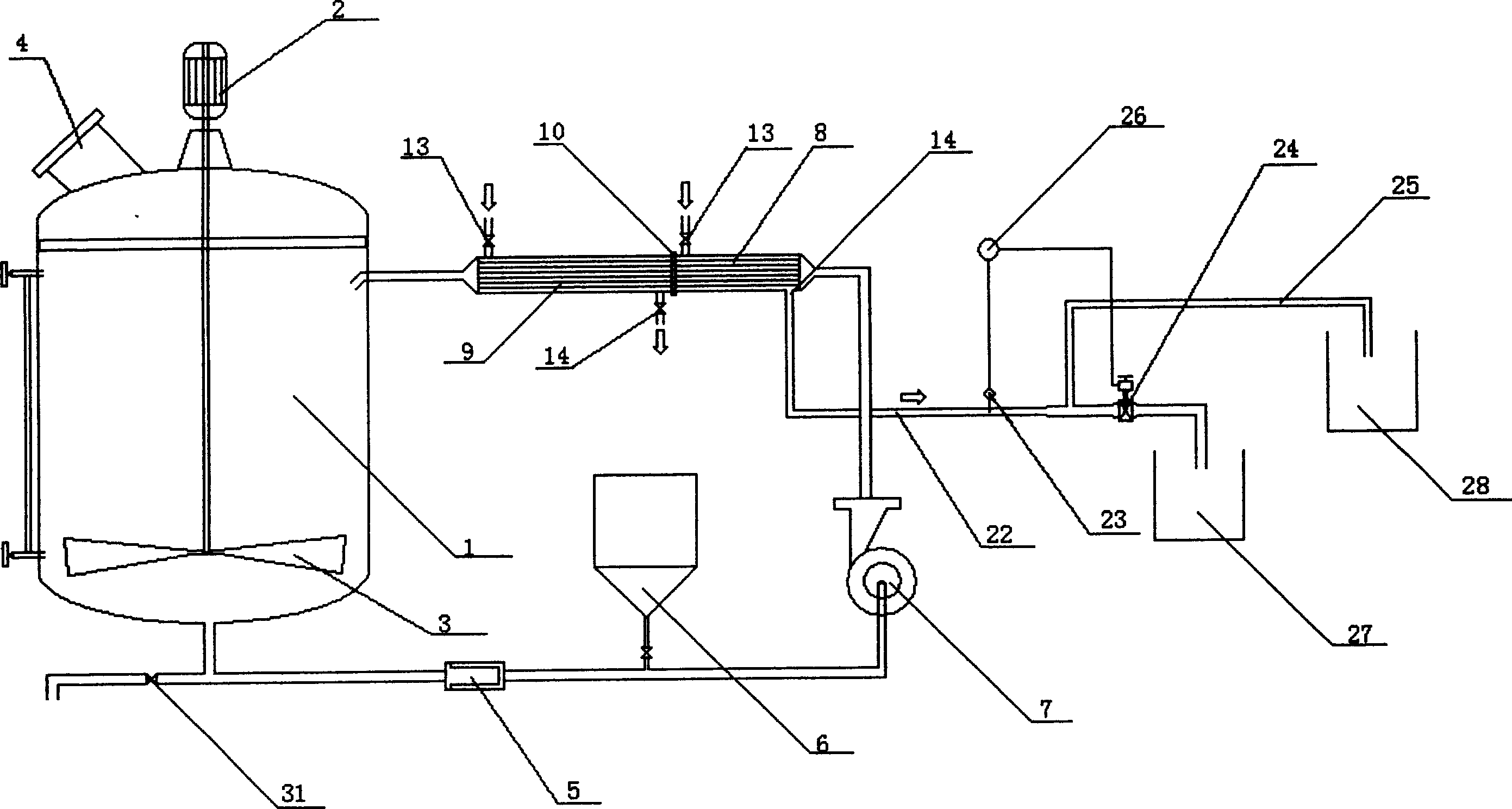

[0022] Embodiment 1: as figure 1 As shown, the present invention includes a pot body 1 and a motor 2. A stirrer 3 connected to the motor 2 is provided in the pot body 1, and an inlet and outlet 4 is provided on the upper side of the pot body 1. The pot body 1 is a single-layer The structure is connected with the filter 5 and the liquid supply and discharge valve 31 respectively through pipelines, and the other end of the filter 5 is connected with the feeding barrel 6 and the circulating water pump 7 through pipelines. There is a flange 10 connected between the pot body 1 and the circulating water pump 7 The water cooling exchanger 8 and the oil heating exchanger 9 combined into one.

[0023] Such as Figure 5 As shown, the water cooling exchanger 8 and the oil heating exchanger 9 have the same structure, and both include a cylinder 16, which is provided with layered heat receiving tubes 11, and the heating tubes 11 can be metal round tubes or special-shaped tubes with high h...

Embodiment 2

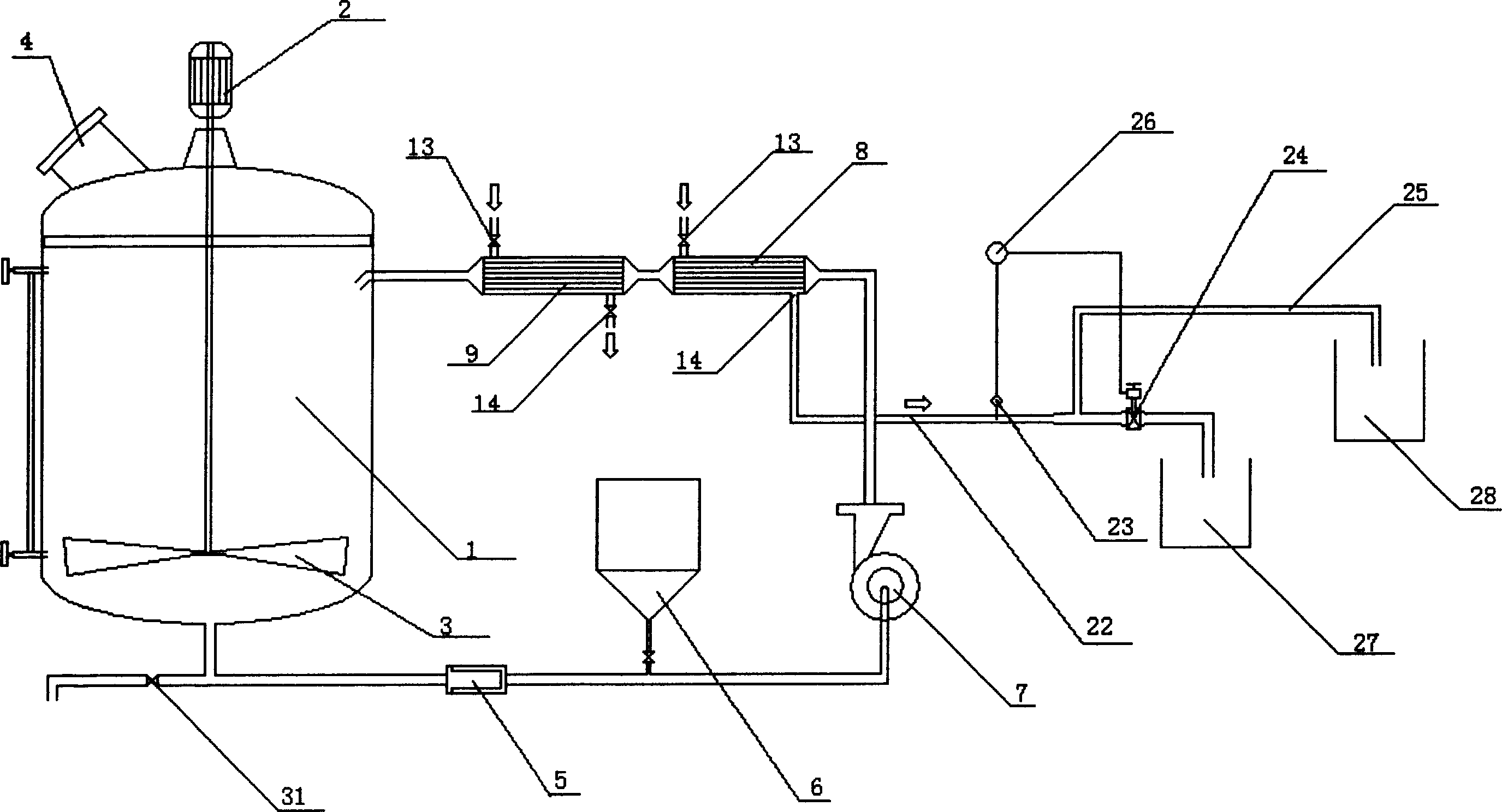

[0029]Embodiment 2: The basic structure of this embodiment is the same as that of Embodiment 1, except that a water cooling exchanger 8 and an oil heating exchanger 9 connected in series are connected between the pot body 1 and the circulating water pump 7, such as figure 2 , Figure 6 shown. Its working process is with embodiment 1.

Embodiment 3

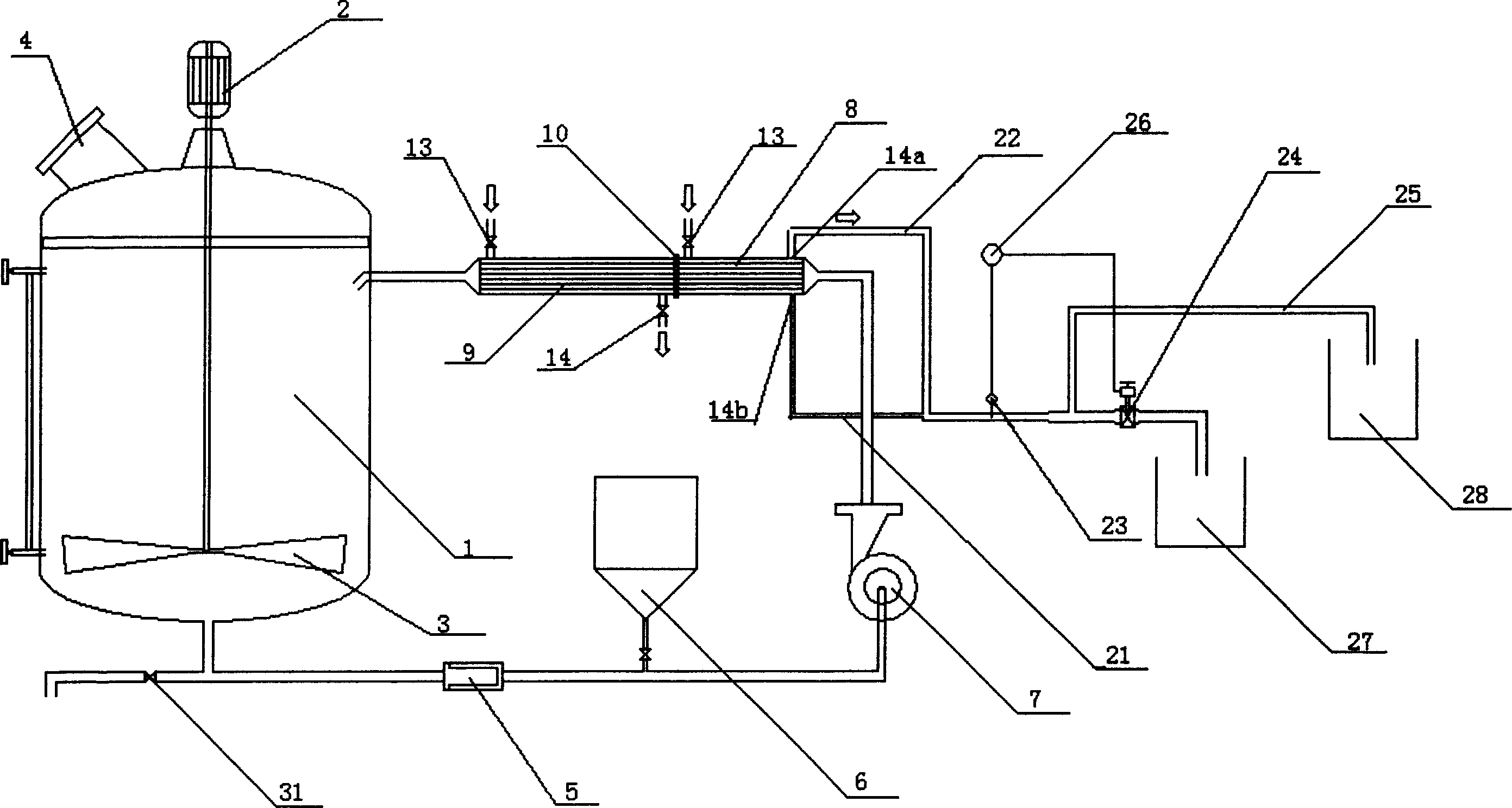

[0030] Embodiment 3: The basic structure of this embodiment is the same as that of Embodiment 1, except that the outlet 14 provided on the cylinder 16 of the water cooling exchanger 8 can be divided into a main outlet 14a and a secondary outlet 14b, wherein the main outlet 14a Located above the cylinder 16, the auxiliary outlet 14b is located below the cylinder 16, and the diameter of the auxiliary outlet 14b is smaller than that of the main outlet 14a. The main outlet 14a is connected with a pipe 22 , the auxiliary outlet 14b is connected with a pipe 21 , and the other end of the pipe 21 communicates with the pipe 22 . Such as image 3 , Figure 5 shown. The working process of this embodiment is the same as that of Embodiment 1, the difference is that when the cooling water is discharged, it can flow out from the main outlet 14a with a large flow rate, and flow out from the auxiliary outlet 14b with a small flow rate, and then divert to the diversion device after being aggr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com