Experimental device and method for treating antibiotic wastewater through iron-carbon micro-electrolysis method

An iron-carbon micro-electrolysis and antibiotic wastewater technology, applied in water/sewage treatment, natural water treatment, chemical instruments and methods, etc. Biochemical ability, simple operation, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

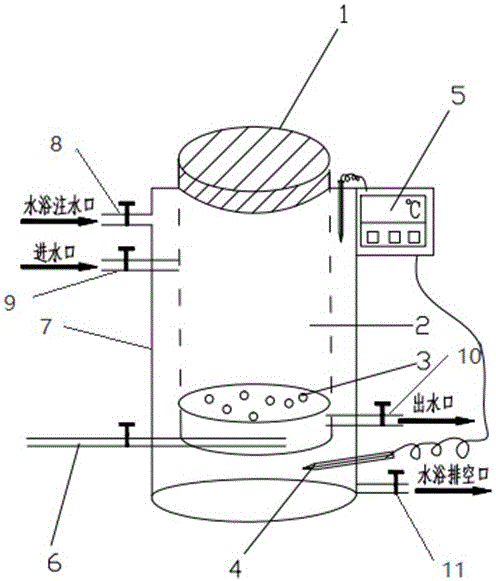

[0026] Embodiment 1: A device for treating antibiotic wastewater based on iron-carbon micro-electrolysis method provided by the present invention mainly includes:

[0027] The iron-carbon micro-electrolysis reactor, packing area, aeration area, and water bath area, among which the packing area and aeration area are collectively referred to as the reaction area. The filling area 2 is evenly stacked with iron-carbon materials, the aeration area and the filling area are separated by a porous partition 3, and a perforated aeration hose 6 is evenly laid under the porous partition to supply oxygen to the reaction area, enhance micro-electrolysis, and It acts as agitator to prevent iron-carbon agglomeration. The iron-carbon micro-electrolysis reactor is composed of a shell 7 and a top cover 1, the upper part of the side wall is provided with a water inlet, and the lower part of the side wall is provided with a water outlet. The outside of the reaction zone is the water bath area, wh...

Embodiment 2

[0029] At room temperature, it is taken from laboratory water, 20mg / l sulfamethazine solution, the initial pH is 7.80.

[0030] Using the device described in Example 1, adjust the pH of the raw water to 2 with 10% hydrochloric acid, then pass the antibiotic waste water with a pH of 2 into the iron-carbon micro-electrolysis reactor, and at the same time aerate the reactor to provide the reaction area with oxygen. After reacting for a certain period of time, the reflux device in the reactor is turned on to circulate the waste water in the reactor to improve the mass transfer conditions of the system. After the water stays in the reactor for 8 hours, the water comes out. After treatment, the removal rate of sulfamerazine reached 87%, the removal rate of TOC reached 50%, and the pH was 5.8.

Embodiment 3

[0032] At normal temperature, it is taken from the laboratory distribution water, 20mg / l penicillin G sodium solution, the initial pH is 7.

[0033] Using the device described in Example 1, adjust the pH of the raw water to 2 with 10% hydrochloric acid, then pass the antibiotic waste water with a pH of 2 into the iron-carbon micro-electrolysis reactor, and at the same time aerate the reactor to provide the reaction area with oxygen. After reacting for a certain period of time, the reflux device in the reactor is turned on to circulate the waste water in the reactor to improve the mass transfer conditions of the system. After the water stays in the reactor for 8 hours, the water comes out. After treatment, the removal rate of penicillin reached 95%, the removal rate of TOC reached 54%, and the pH was 5.6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com