Energy saving type dyeing machine

A dyeing machine, energy-saving technology, applied in the field of dyeing machines, can solve problems such as wasting energy, achieve the effect of increasing heating efficiency, improving cooling effect, and increasing contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

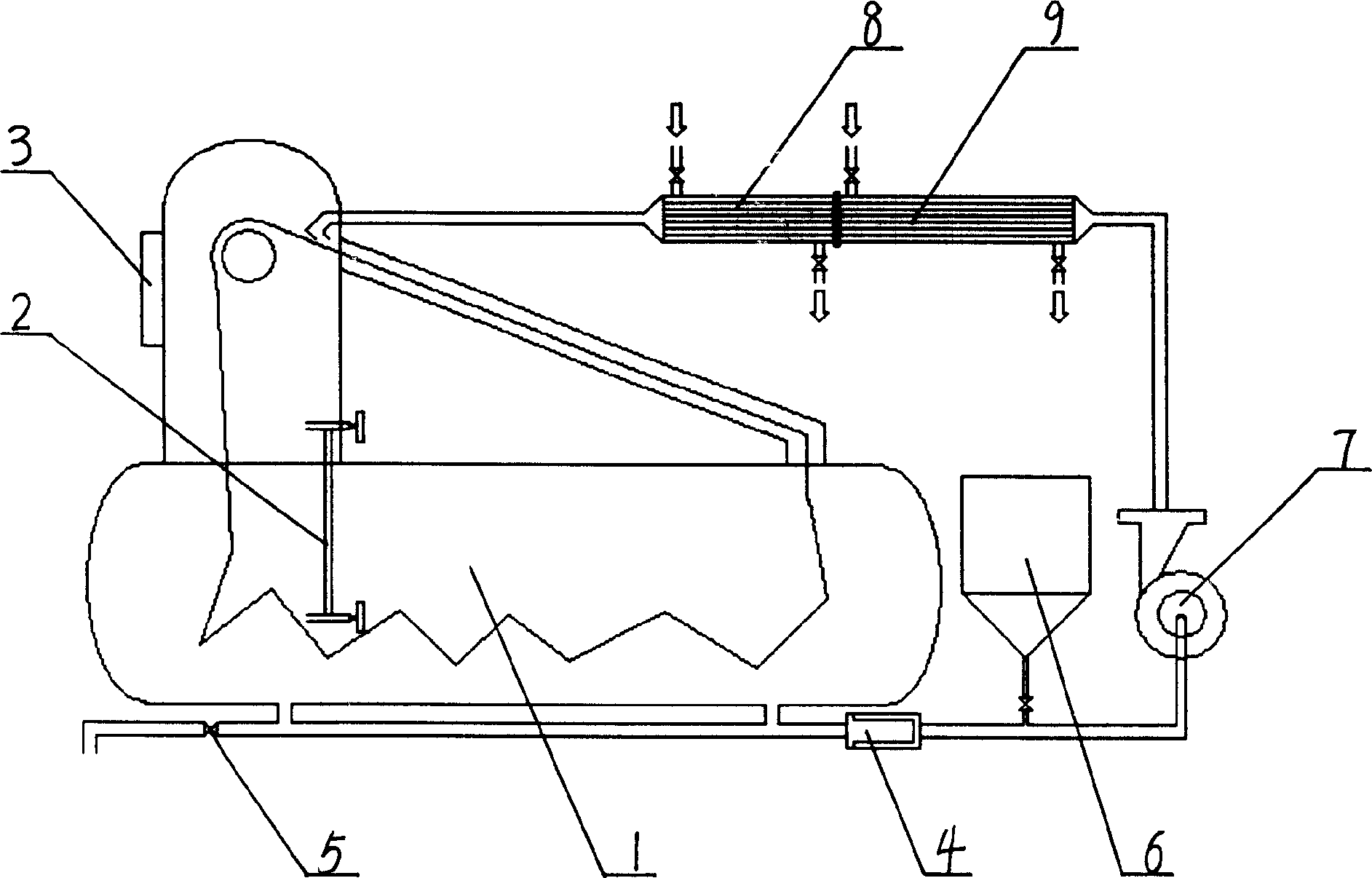

[0009] Such as figure 1 As shown, the present invention comprises a cloth dyeing cylinder 1, in which a water level pipe 2 is provided, and a cloth inlet and outlet 3 is provided on the upper side thereof, and the cloth dyeing cylinder 1 is respectively connected with the filter 4, The dye liquor supply and drainage valve 5 is connected, the other end of the filter 4 is connected with the feeding barrel 6 and the dye liquor circulating water pump 7 through pipelines, and there is a flange 10 in two connected between the dyeing cloth vat 1 and the dye liquor circulating water pump 7. It is a water cooling exchanger 8 and an oil heating exchanger 9, wherein the cavity at the junction is filled with a dye liquid head 16.

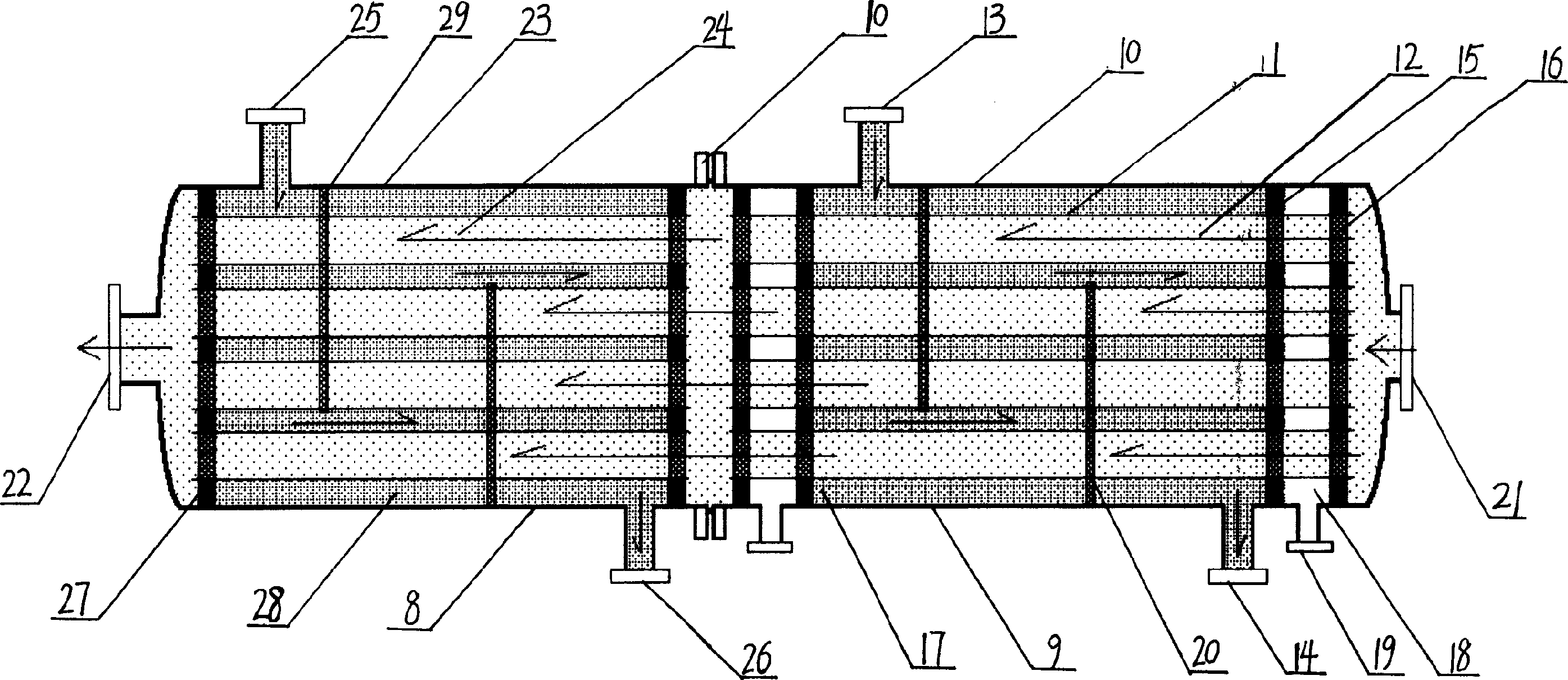

[0010] Such as figure 2 As shown, the oil heating exchanger 9 includes a cylinder body 10, which is provided with layered heating tubes 11, the dye solution 12 flows in the heating tubes 11, and the two ends of the cylinder body 10 shell are respectively prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com