Smoke recycling auxiliary burning type aluminum melting furnace

A technology of flue gas recirculation and auxiliary combustion, applied in the field of aluminum melting furnace, can solve the problems of uneven heating, insufficient heating, unstable operation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

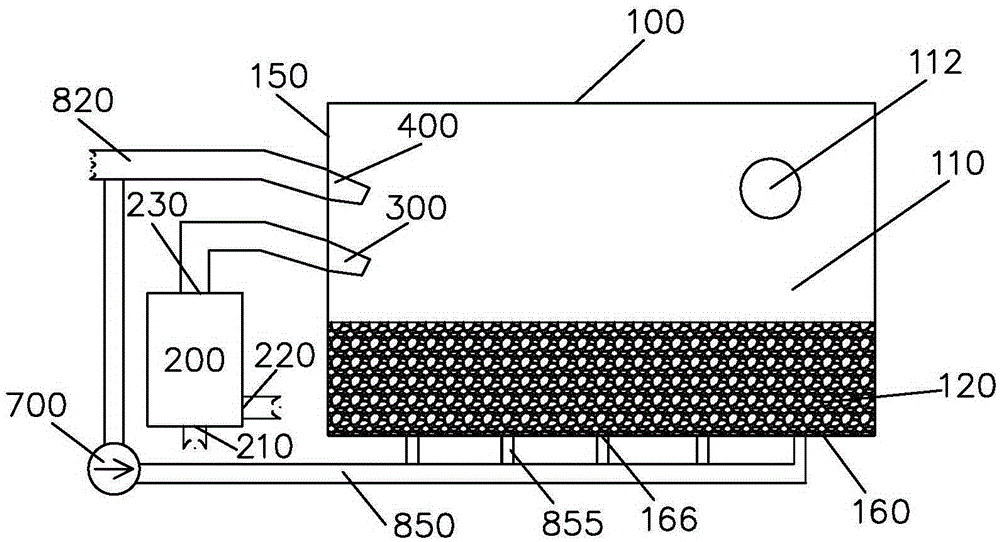

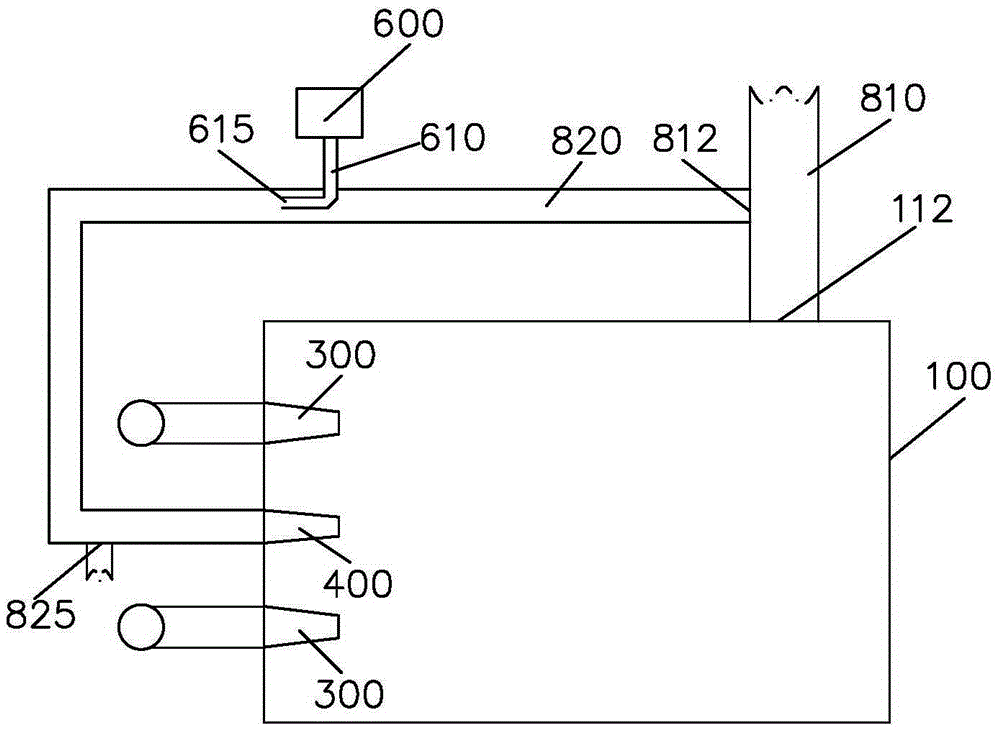

[0029] Please refer to figure 1 and figure 2 , according to an embodiment of the present invention, the flue gas recirculation auxiliary combustion type aluminum melting furnace includes: aluminum melting furnace body 100, mixer 200, two main combustion guns 300, auxiliary combustion gun 400, air compressor 600 and booster Press 700.

[0030] The aluminum melting furnace body 100 includes a hearth (not labeled) located inside, a combustion chamber 110 positioned at the middle and upper part of the hearth, a molten aluminum pool 120 positioned at the lower part of the hearth, and a furnace that is located on the side wall of the melting furnace body and communicates with the combustion chamber 110 High temperature flue gas outlet 112. The high-temperature flue gas outlet 112 is connected to a chimney (not shown in the figure) through a flue gas pipe 810 . Although not involved in this non-limiting embodiment, those skilled in the art can understand that one or more waste he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com