Patents

Literature

71results about How to "Reduce direct emissions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

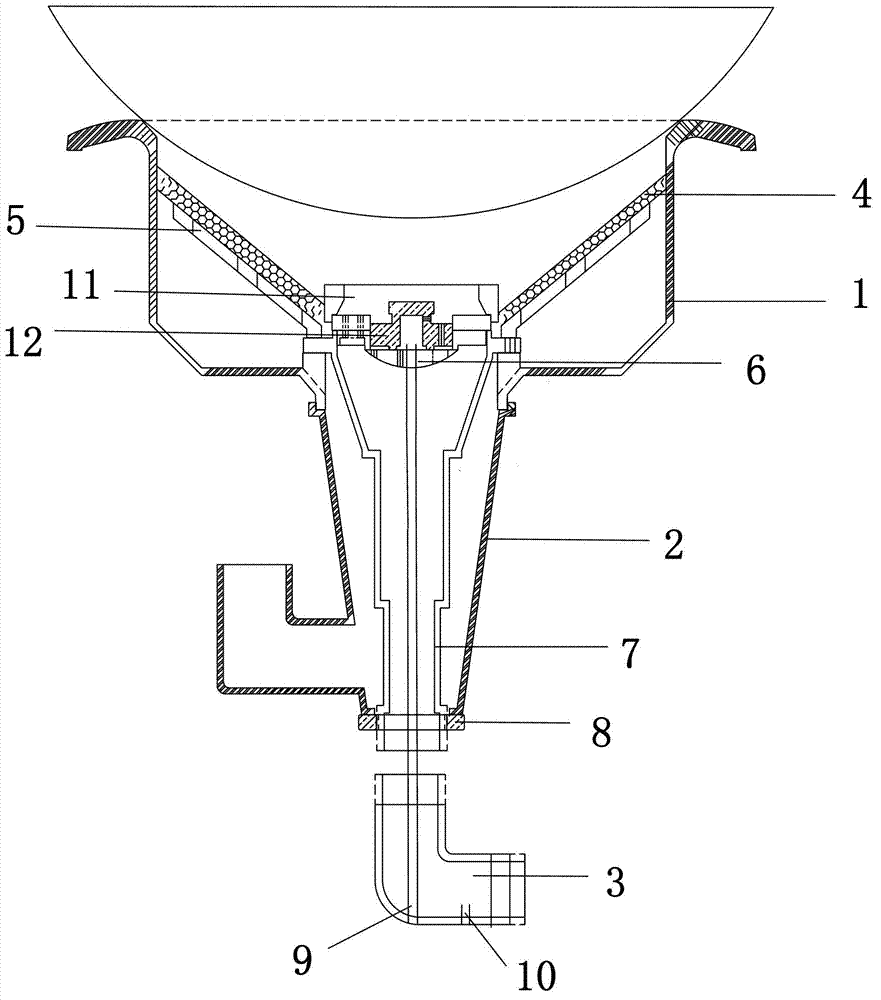

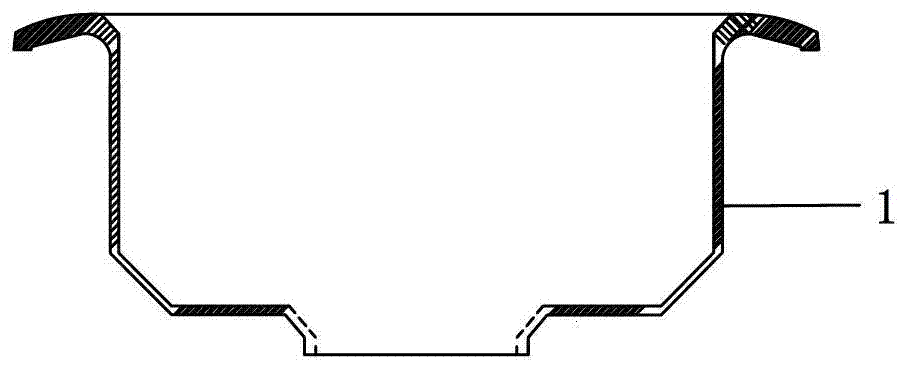

Energy-saving stove preheating premixed combustible gas by using after heat

ActiveCN102829495ATo achieve the purpose of warming upSufficient heat exchangeDomestic stoves or rangesIndirect carbon-dioxide mitigationCombustorWhole body

The invention relates to an energy-saving stove preheating premixed combustible gas by using after heat. The stove comprise a stove plate, a burner and a mixing chamber, wherein the burner is arrange in the middle of the bottom of the stove plate, and the burner is communicated with the mixing chamber; the stove also comprises a fume guide hood for guiding fume after heat in the stove plate to the outer wall of the mixing chamber to preheat the premixed combustible gas in the mixing chamber; a flanged edge contacting with a cooker is arranged at the border of the stove plate; the fume guide hood is communicated with the bottom of the stove plate, and is sleeved outside the mixing chamber; the fume guide hood is in sealed connection with the outer wall of the mixing chamber at the bottom; the fume guide hood is provided with an after heat discharge outlet; and the stove plate is internally provided with cellular porous ceramic which is obliquely erected through an energy gathering plate bracket. According to the energy-saving stove provided by the invention, the traditional fume emission notch at the upper part of the stove plate is omitted, direct discharge of fume whose after heat is not utilized is reduced; and through arranging the mixing chamber in the fume guide hood, a preheating device and the stove form a whole body, and the purpose of preheating the premixed combustible gas delivered into the stove can be achieved without need of splitting for independent use.

Owner:珠海歌林能源科技有限公司

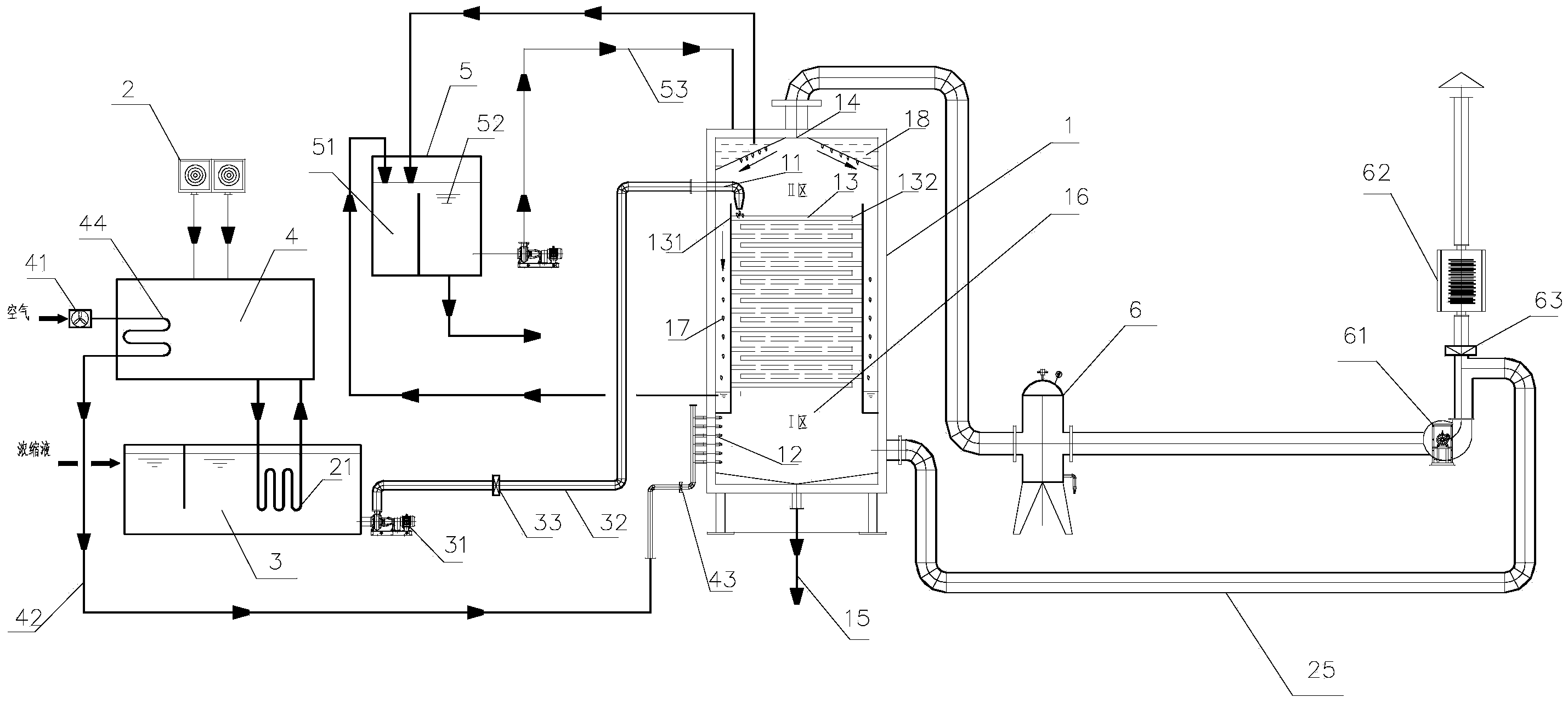

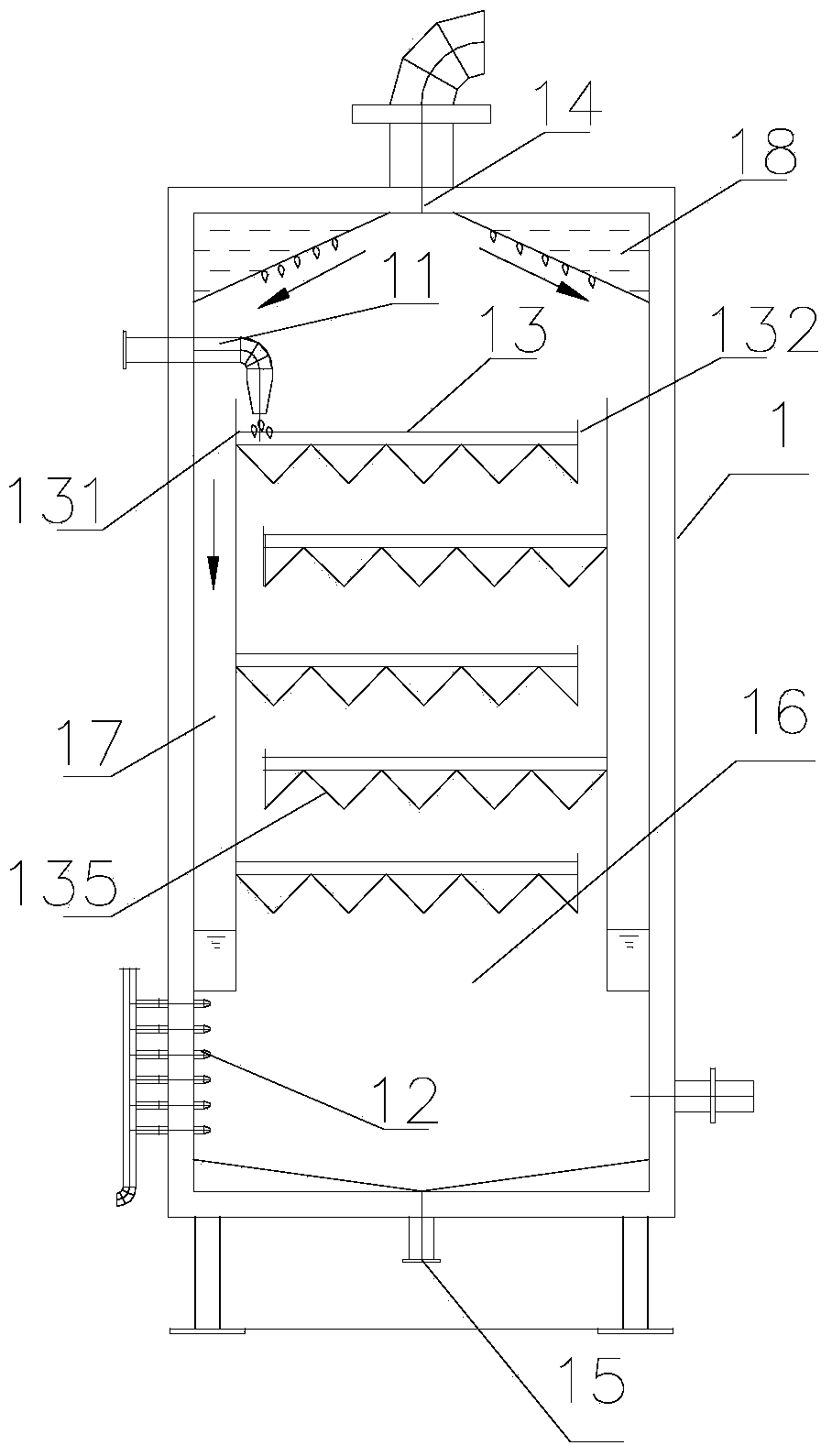

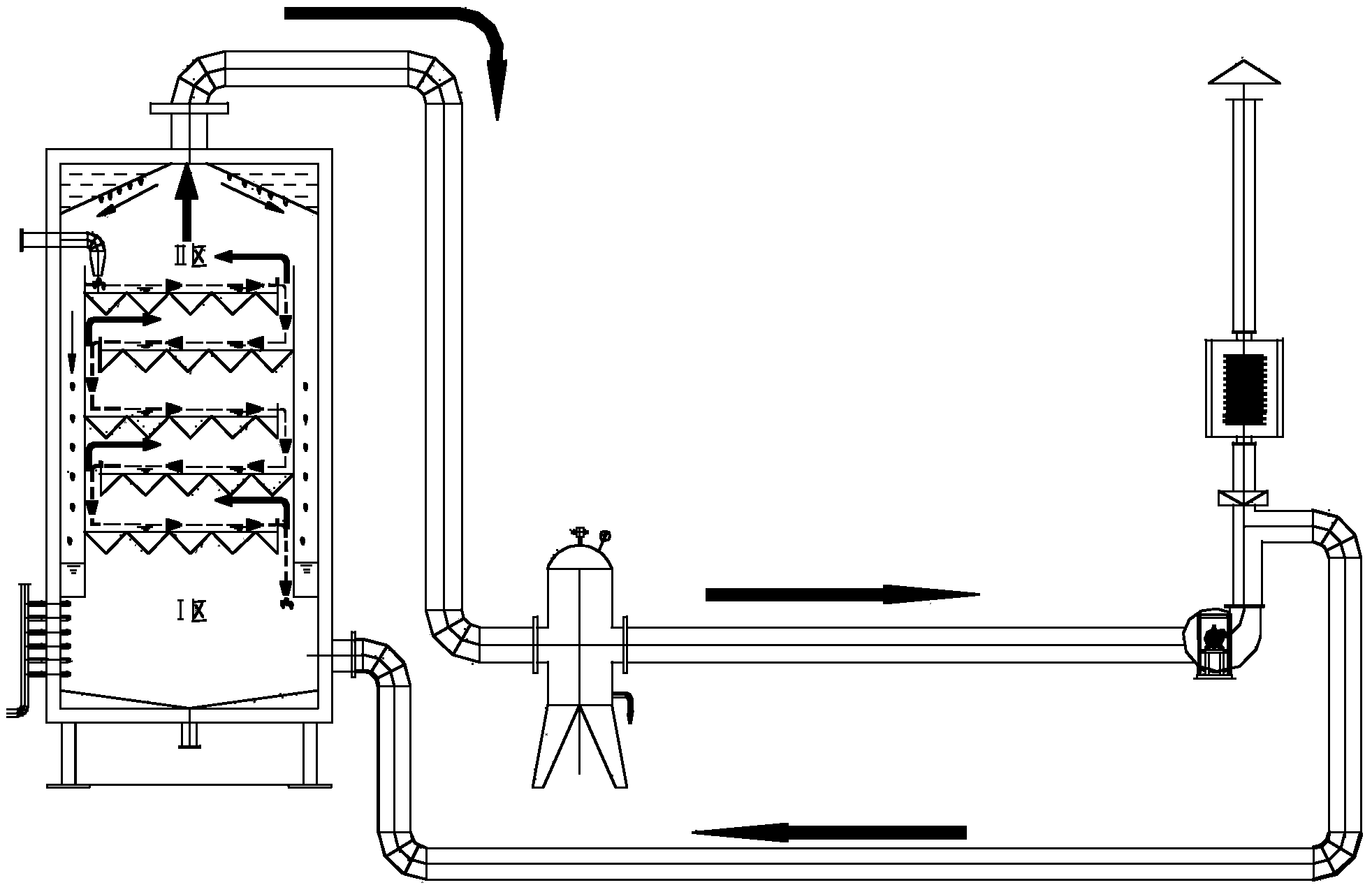

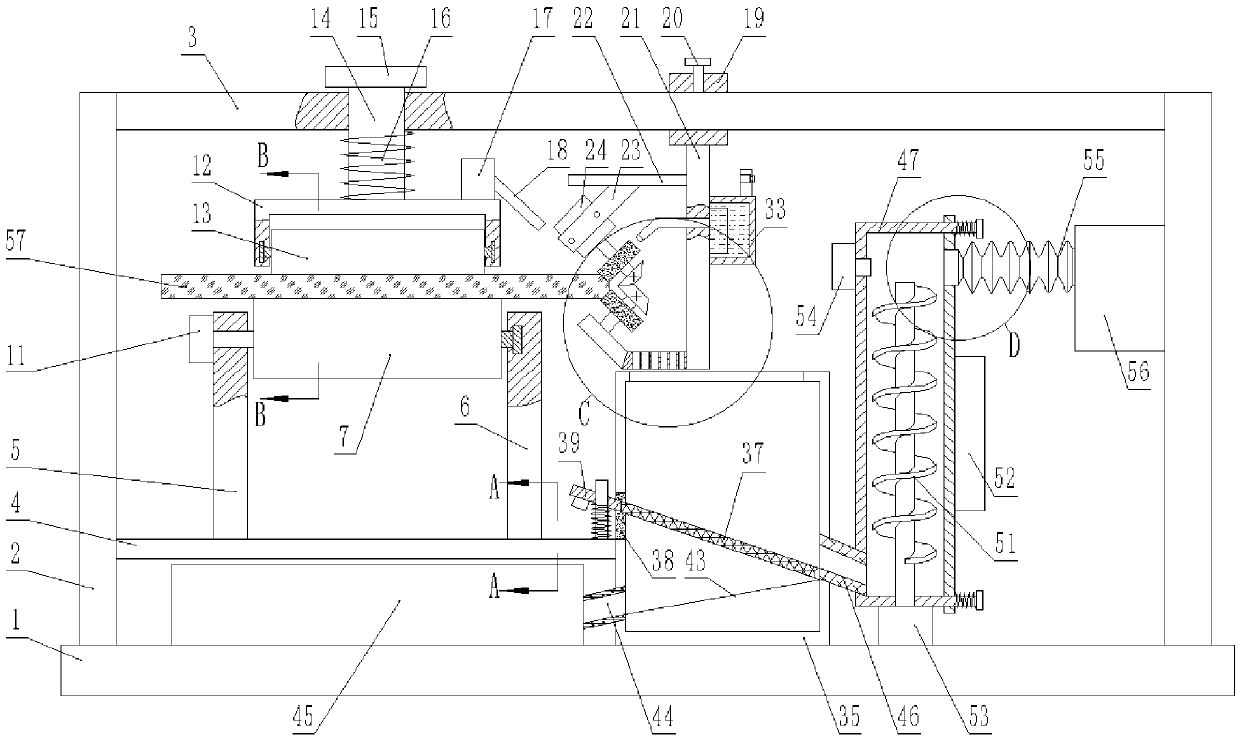

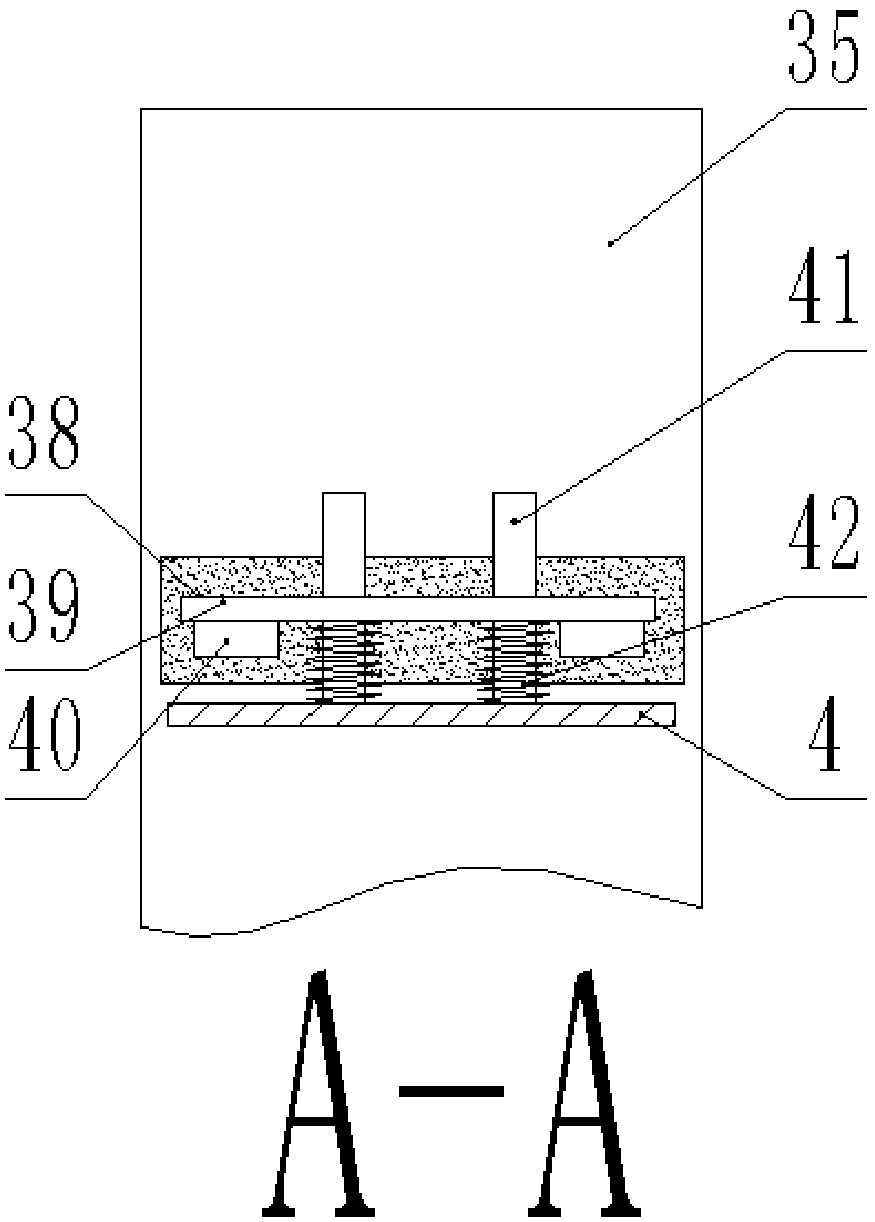

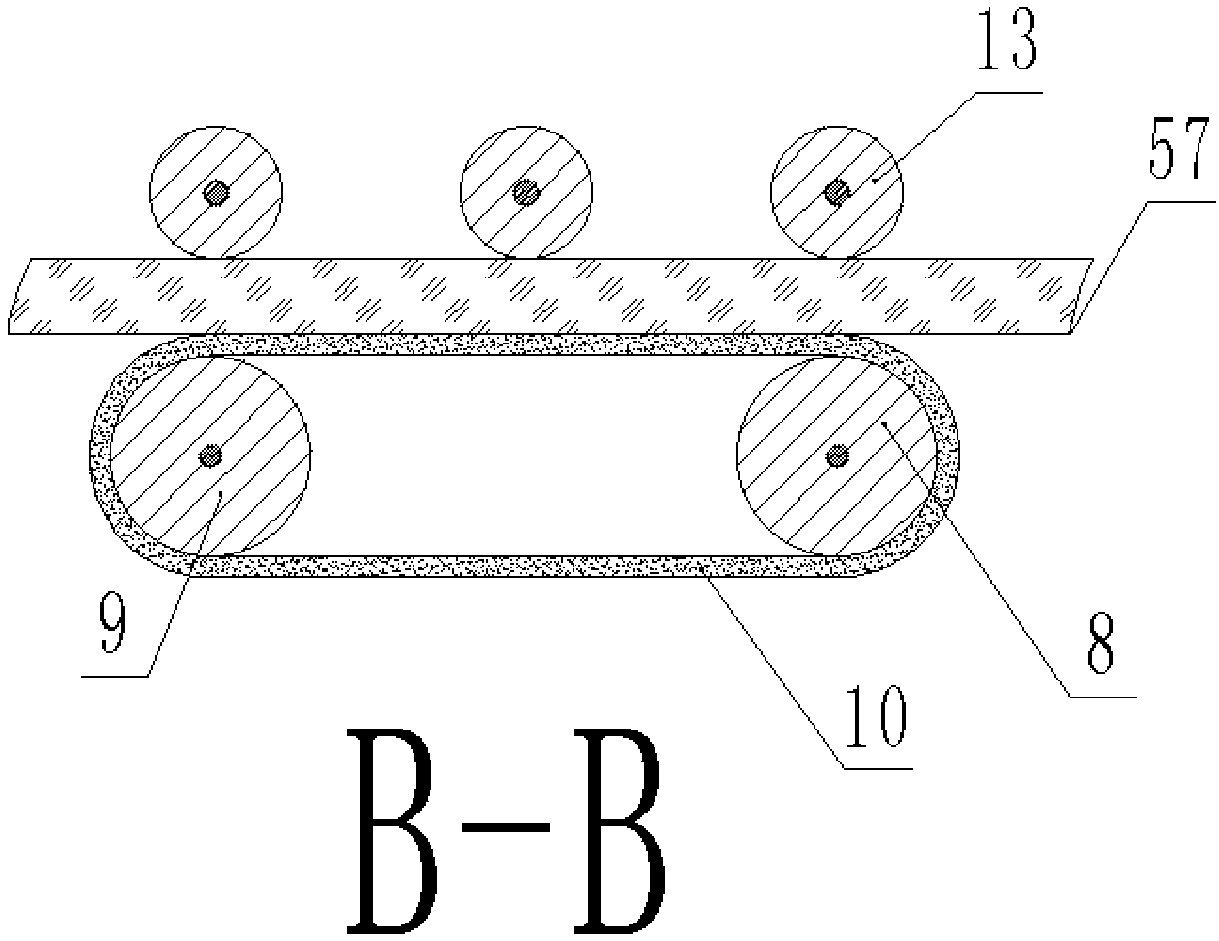

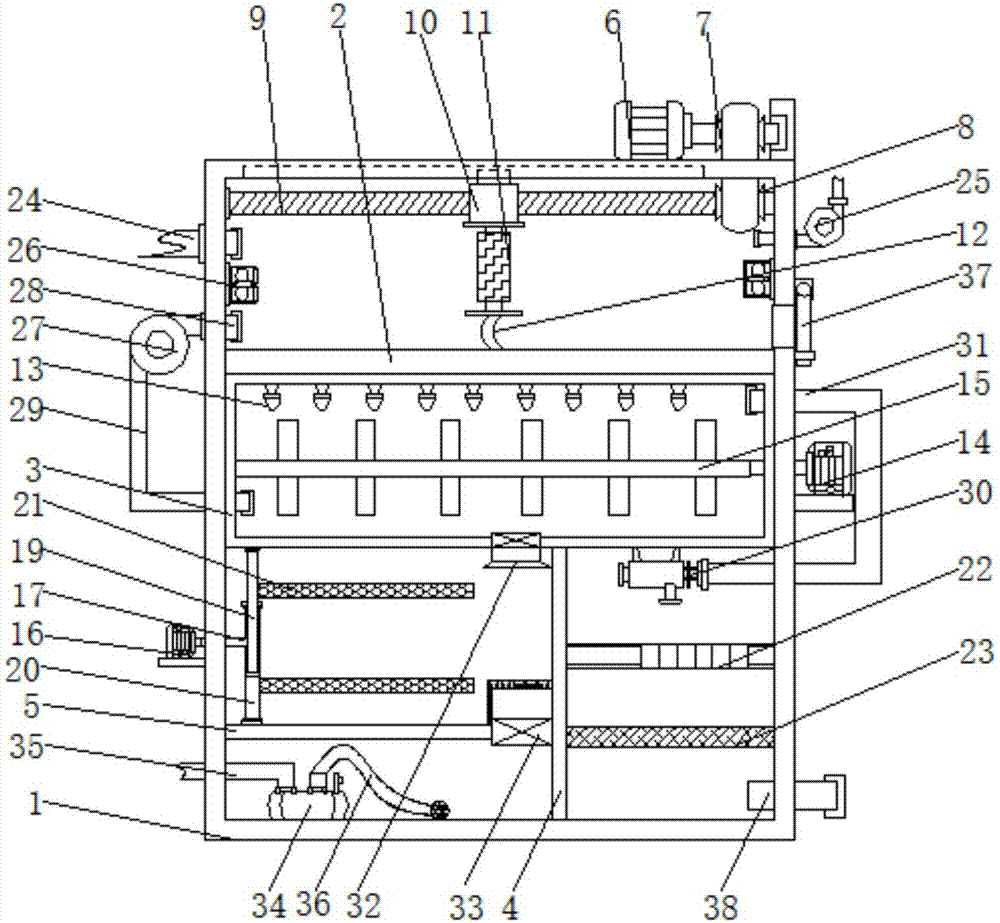

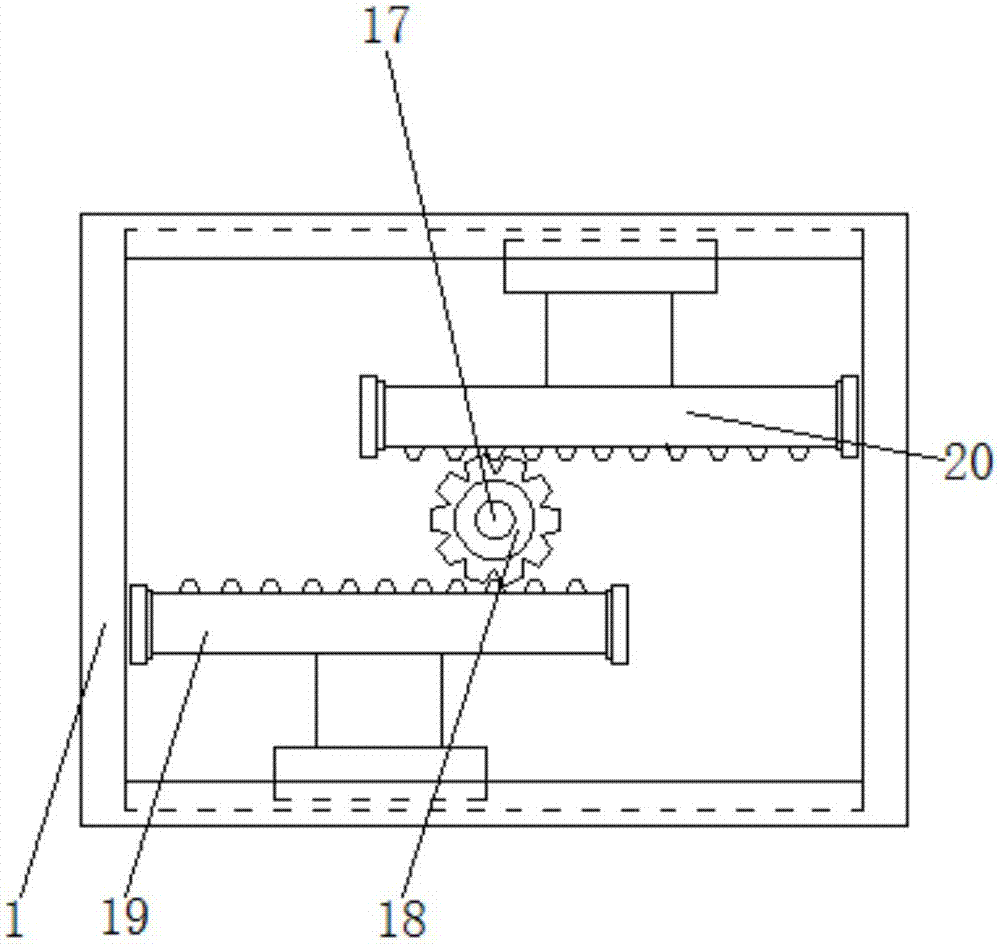

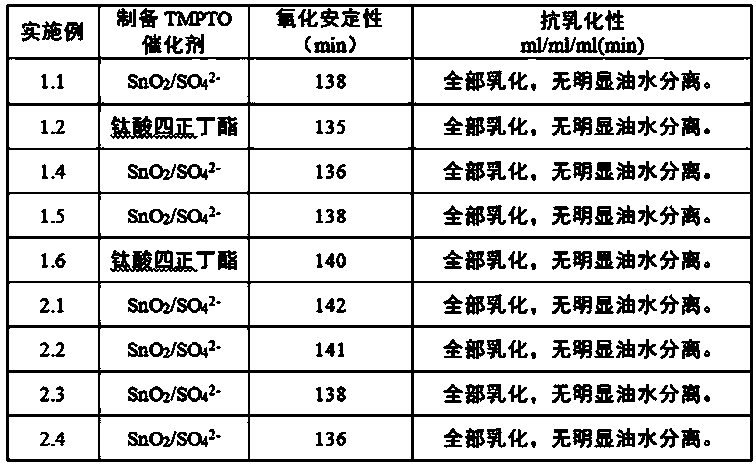

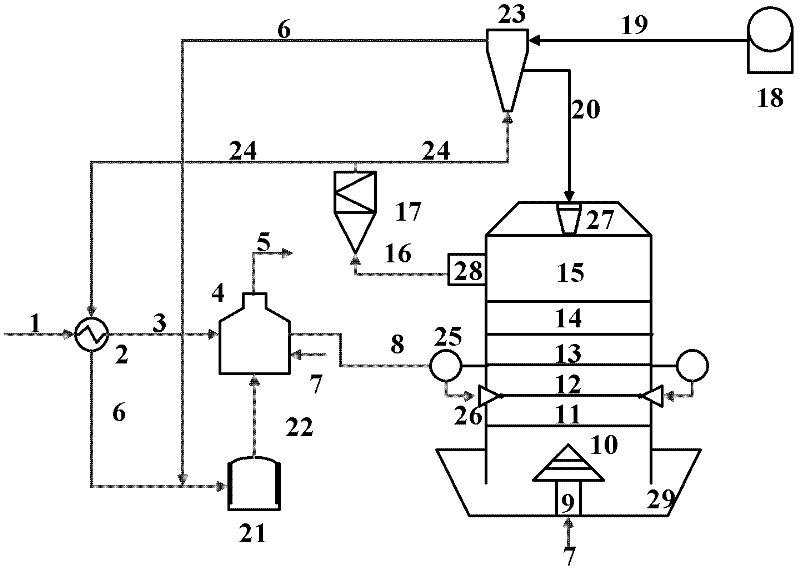

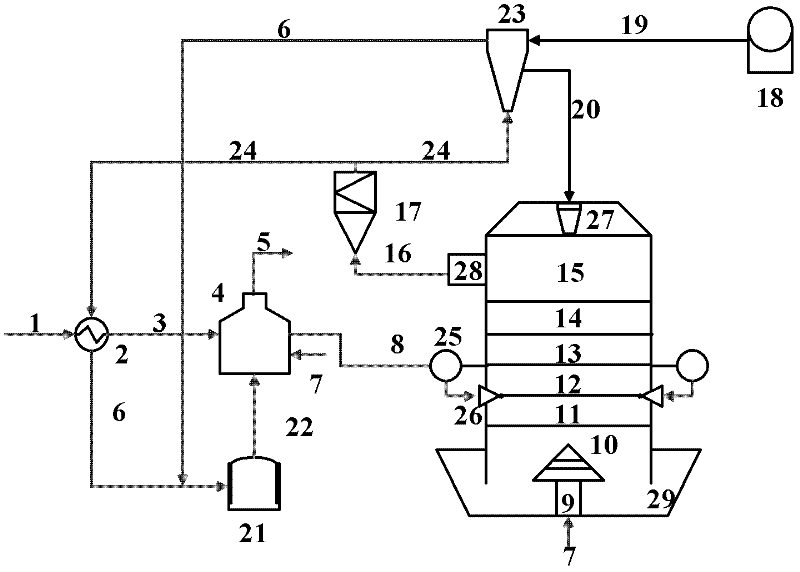

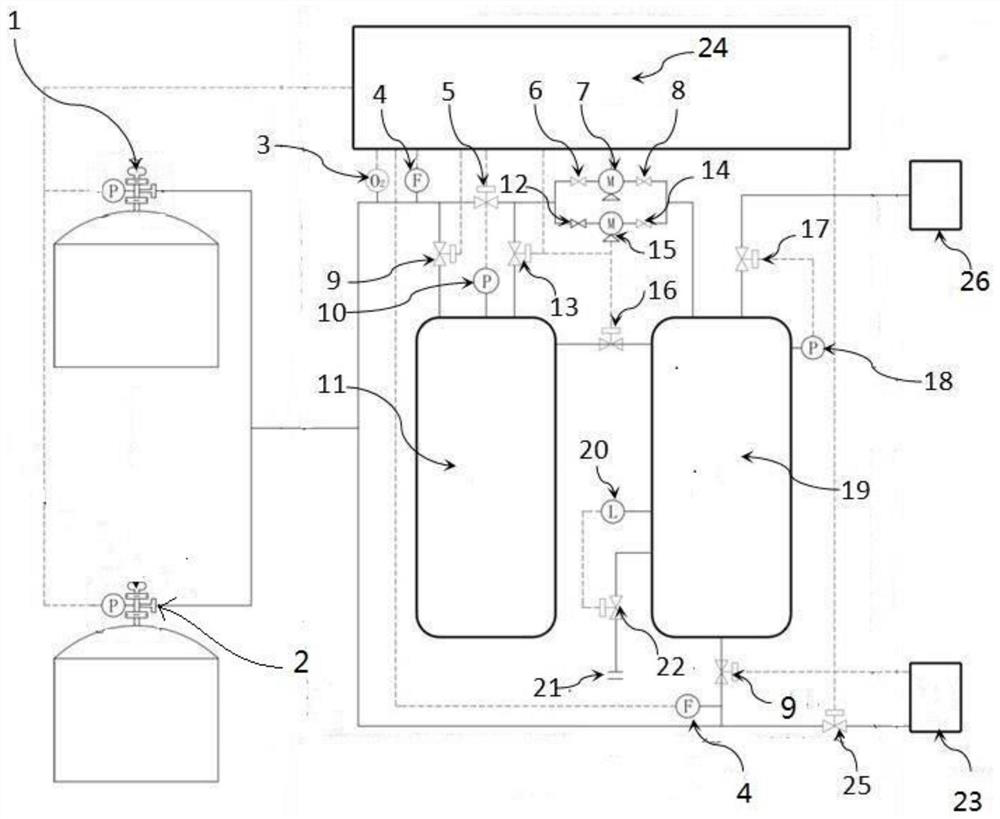

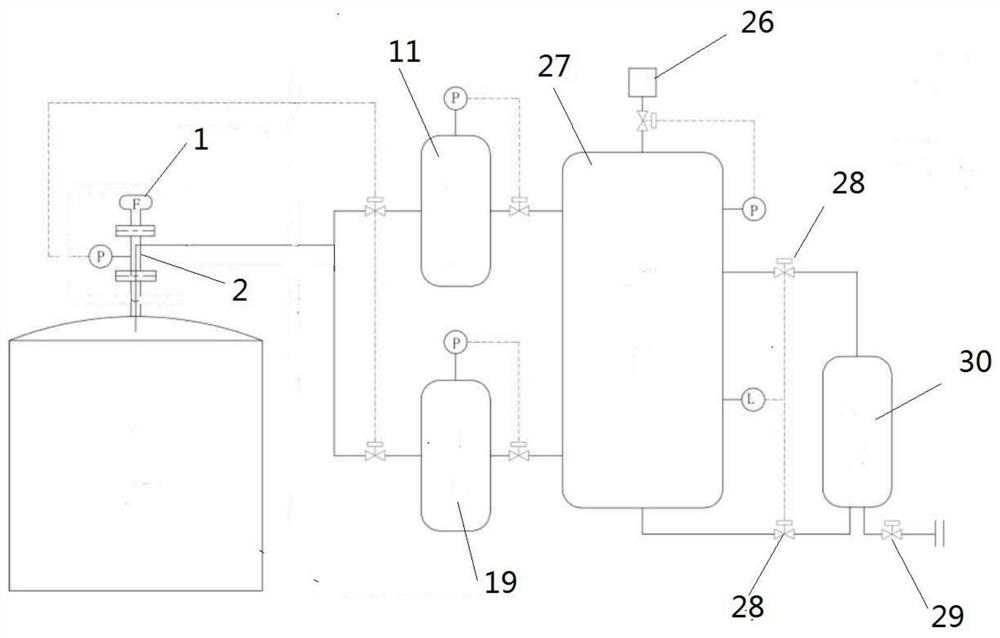

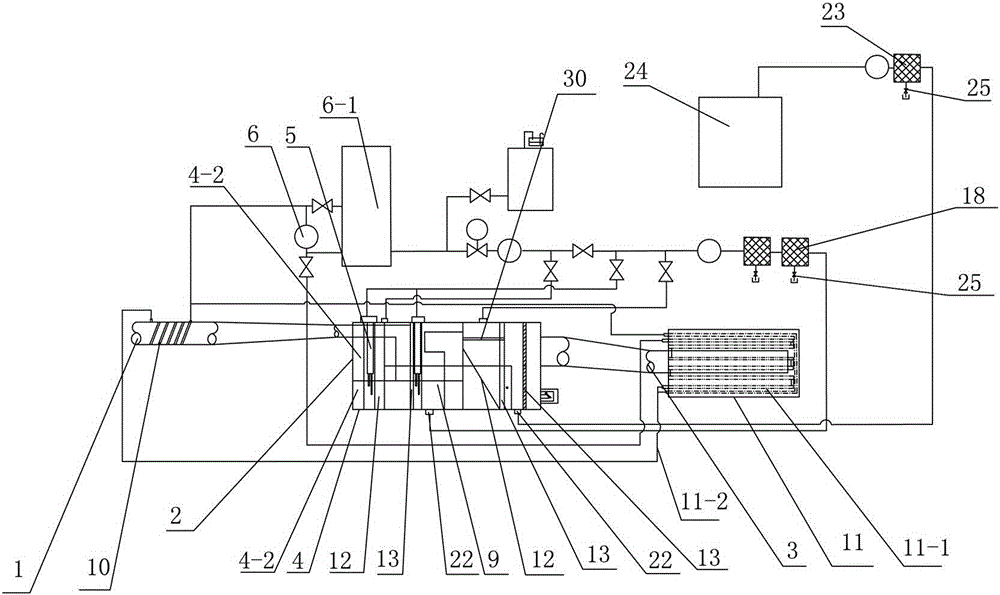

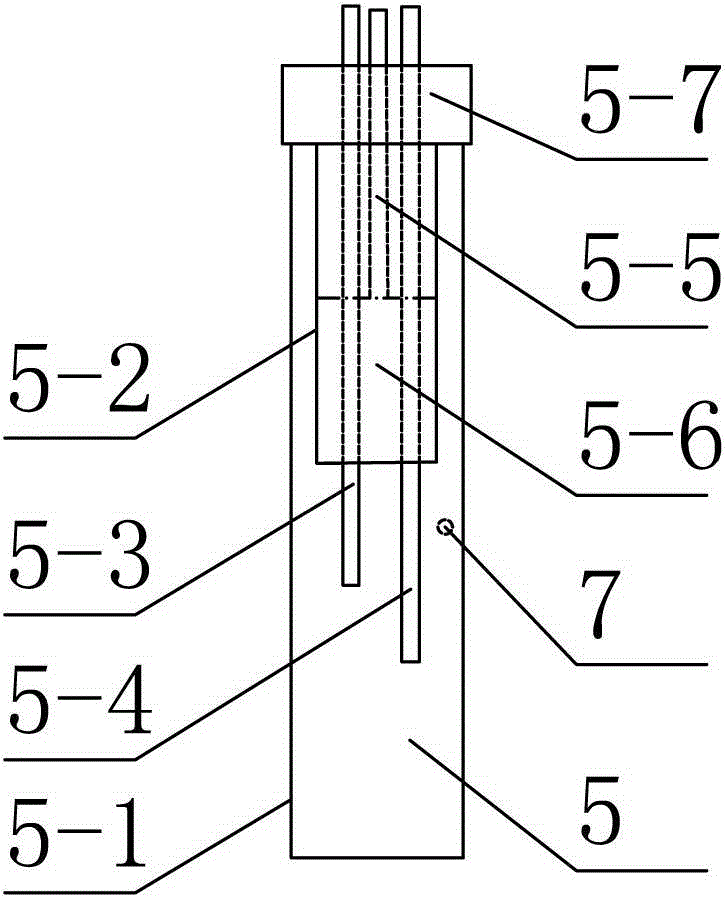

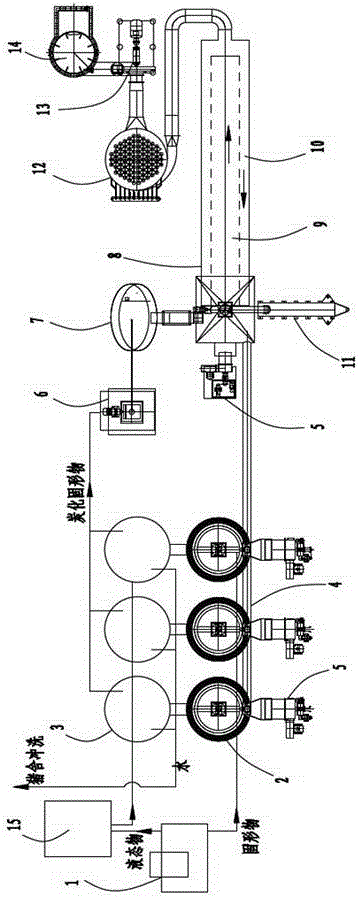

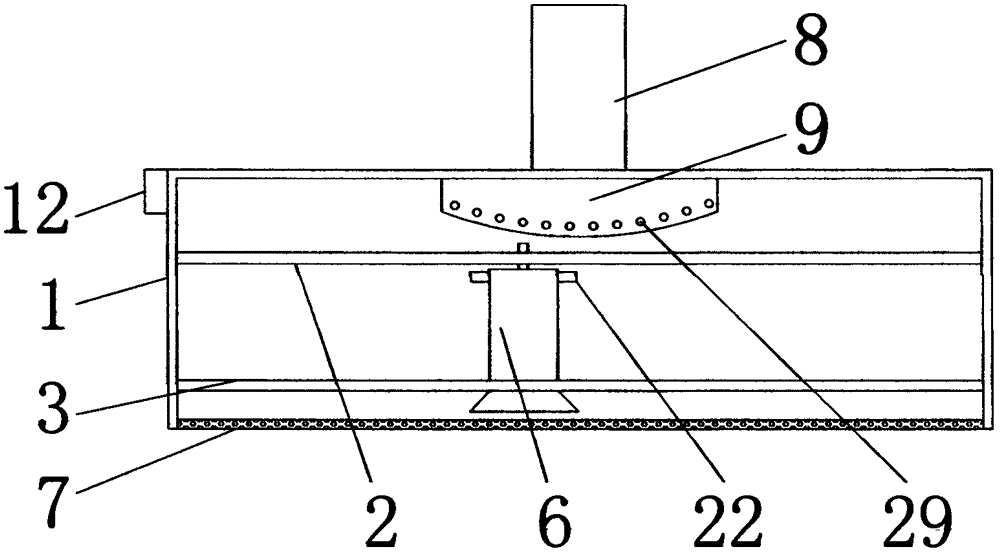

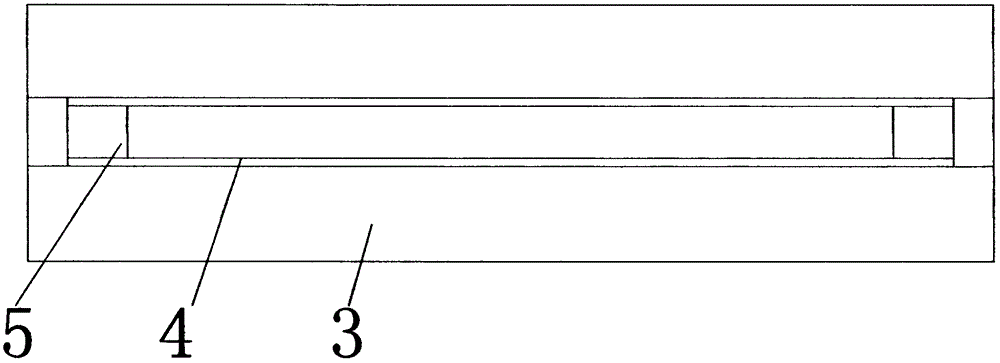

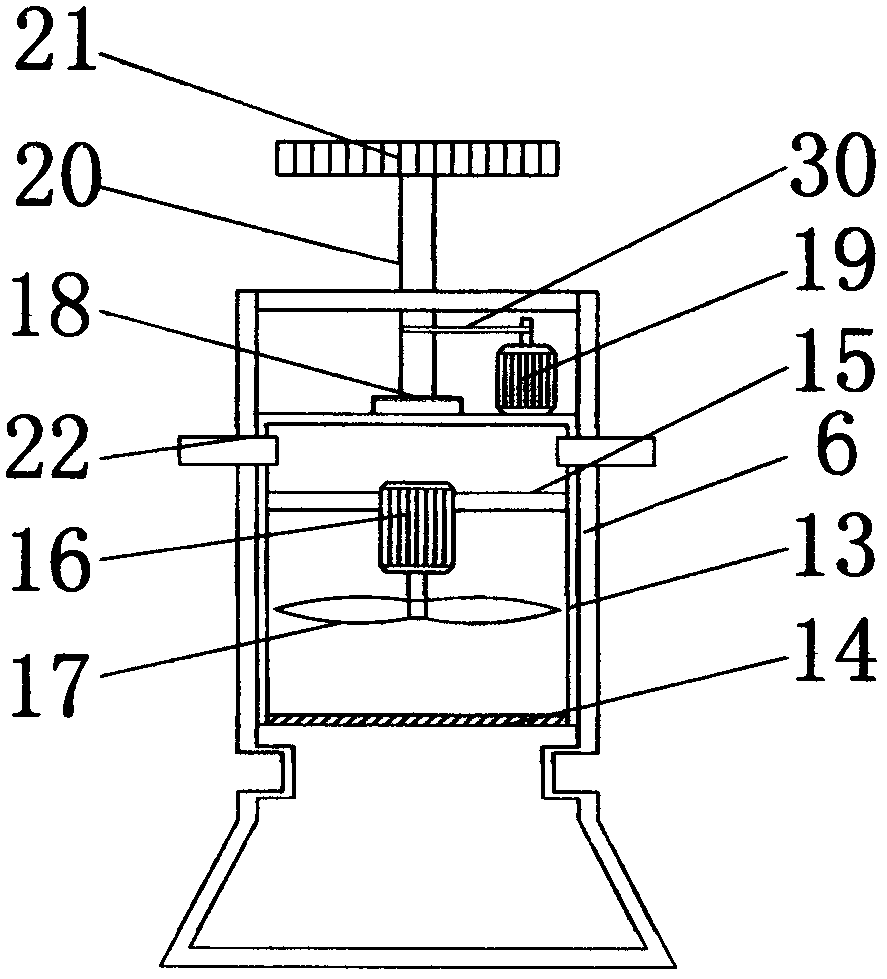

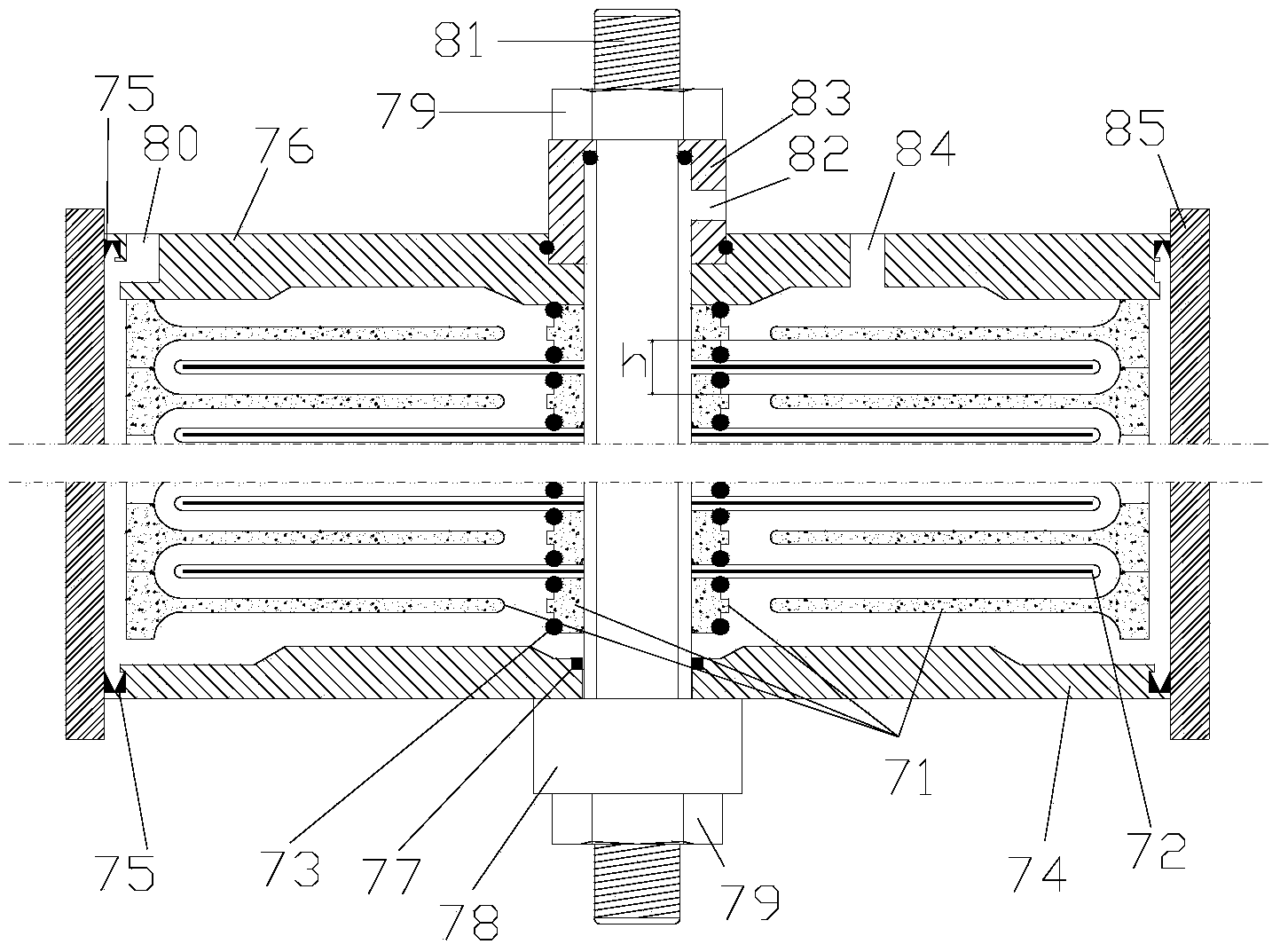

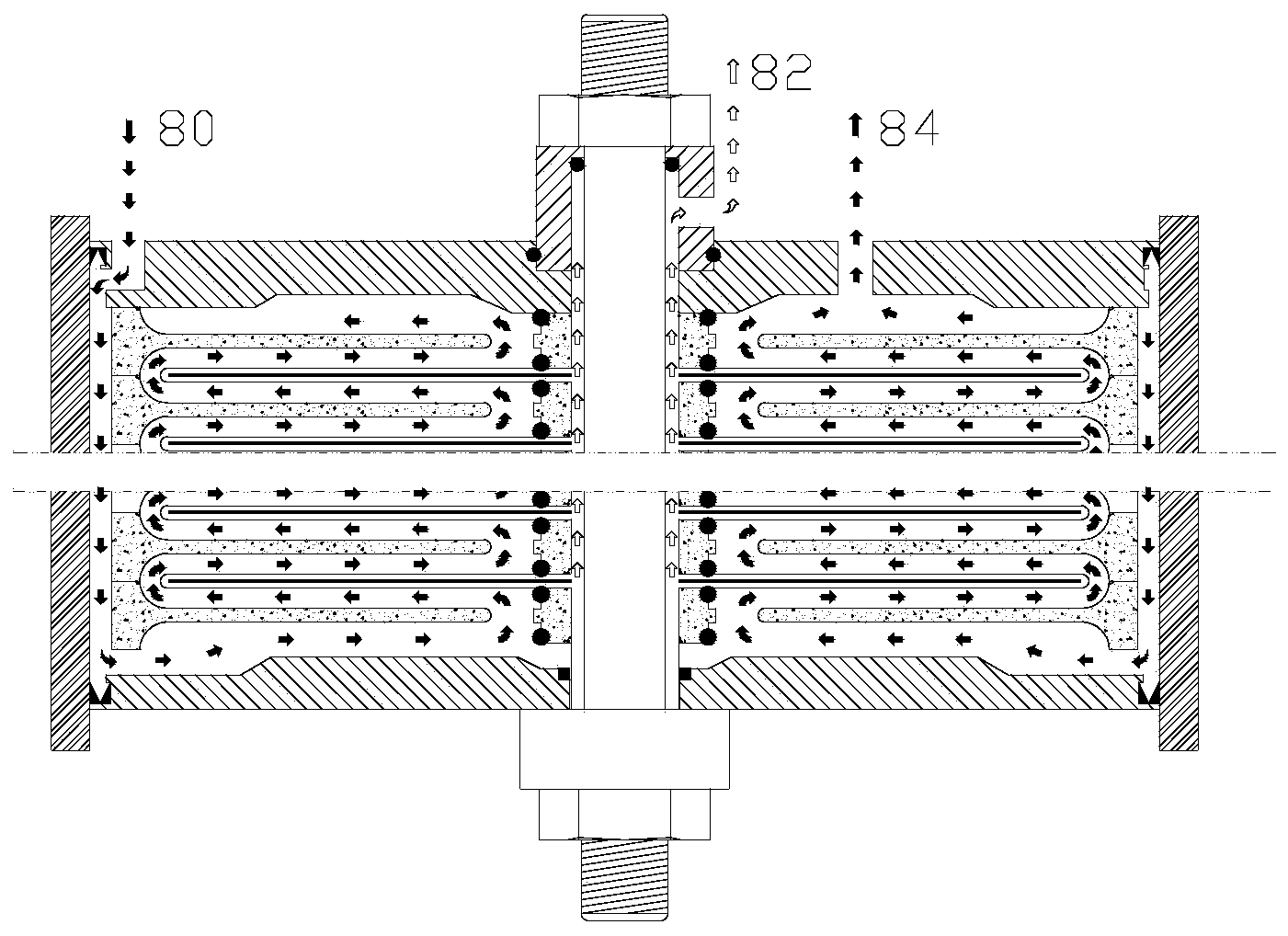

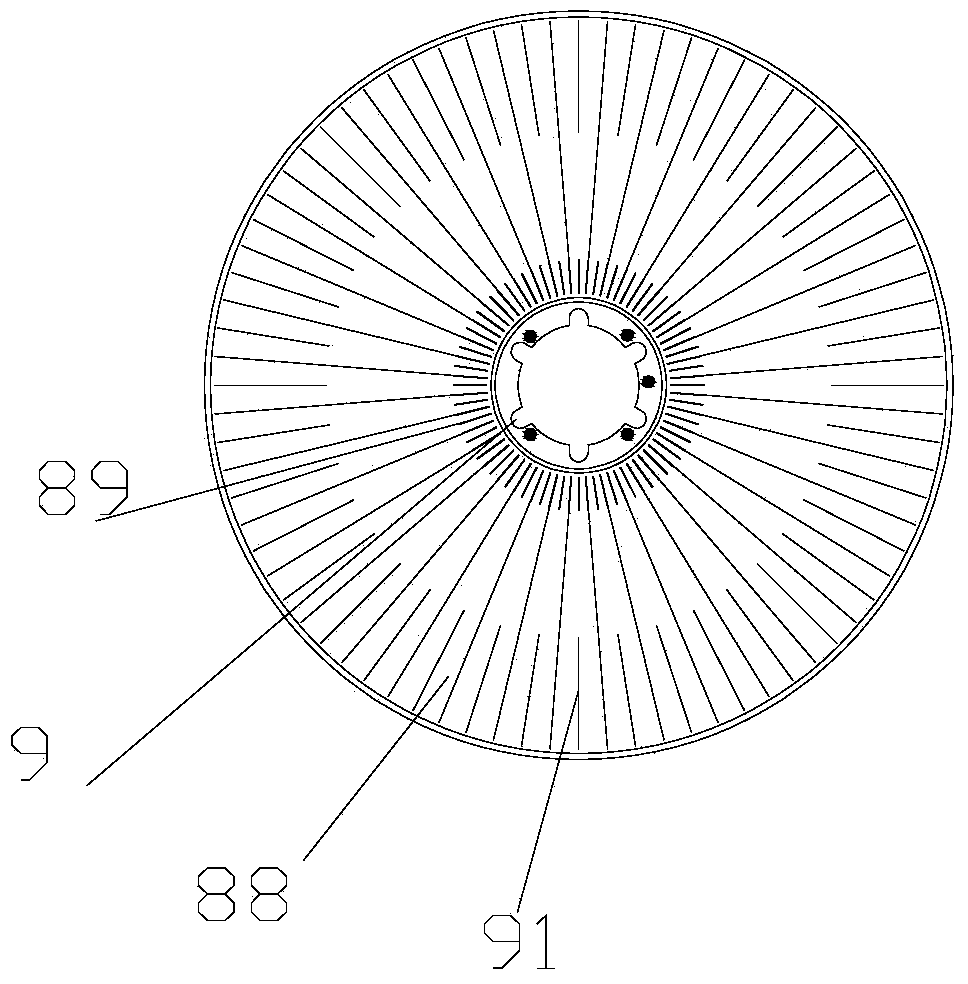

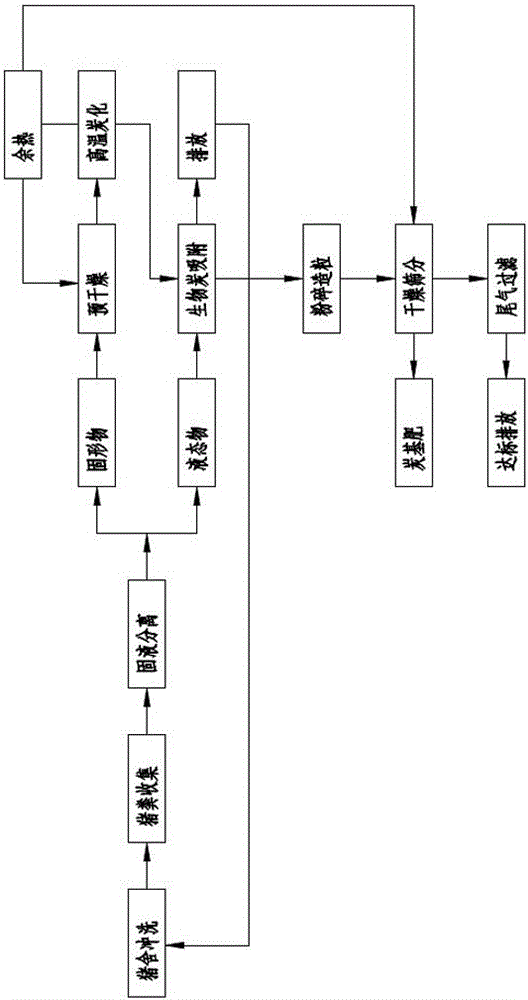

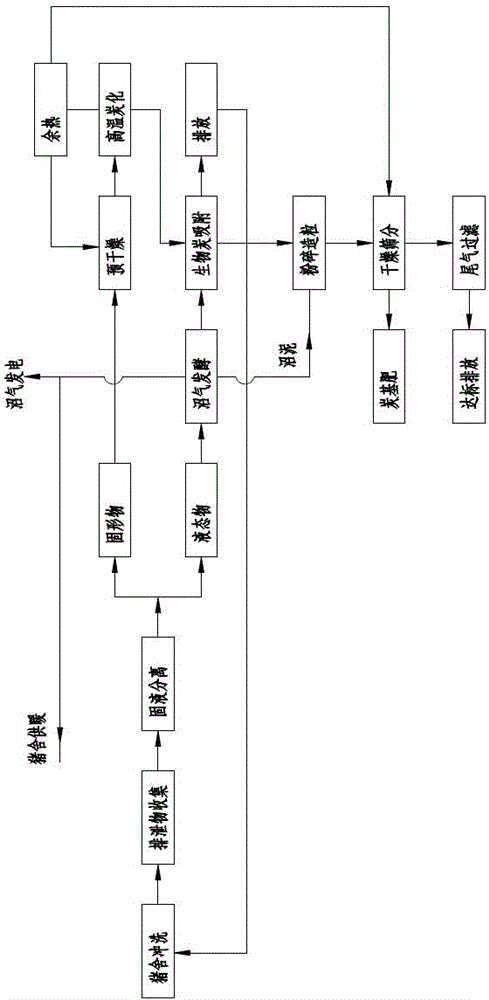

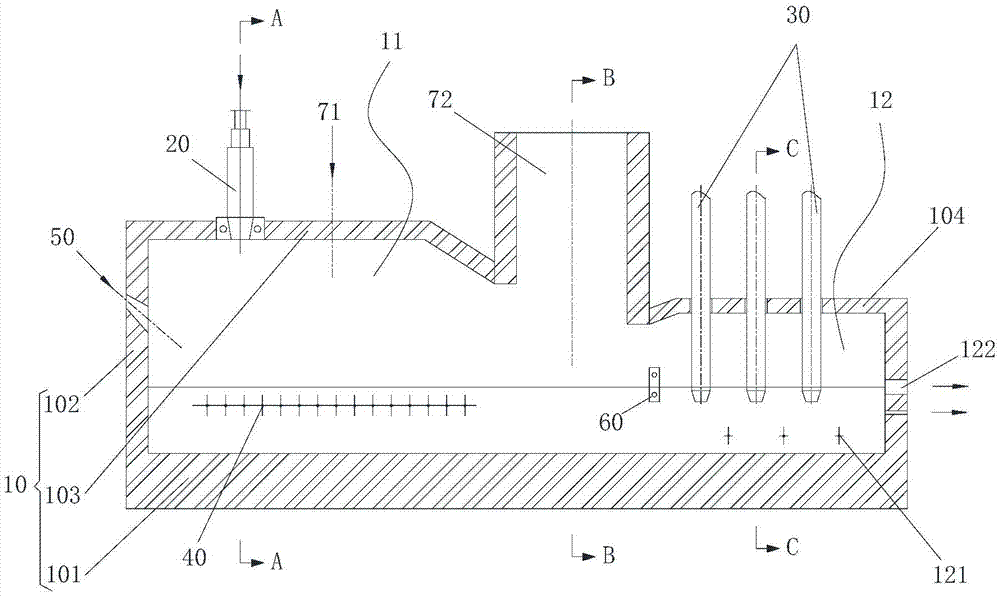

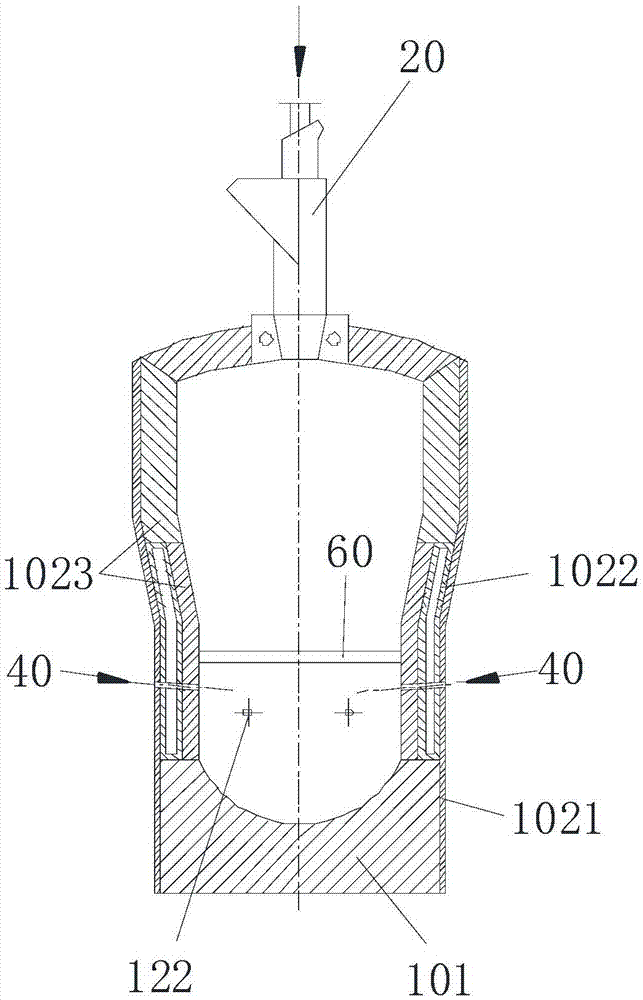

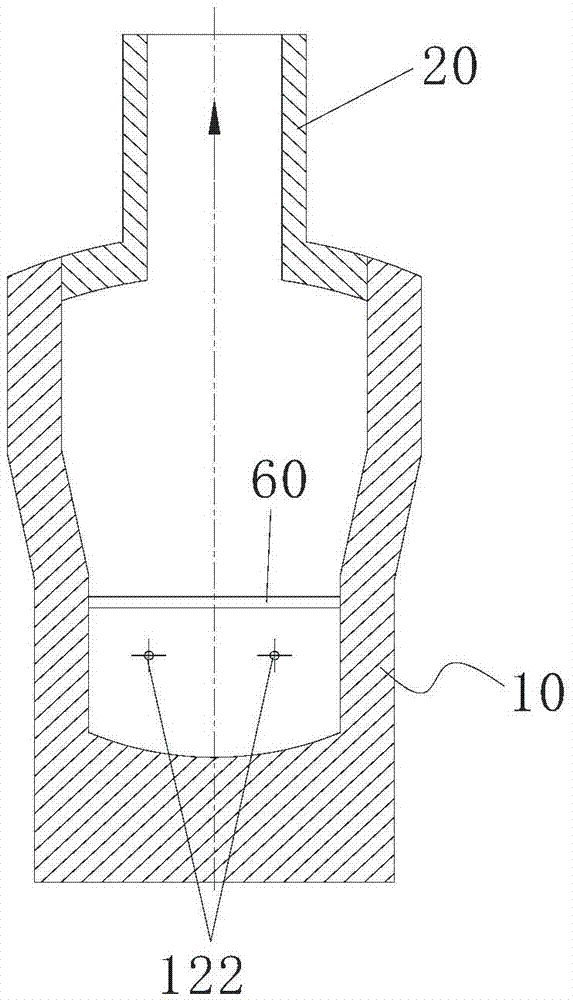

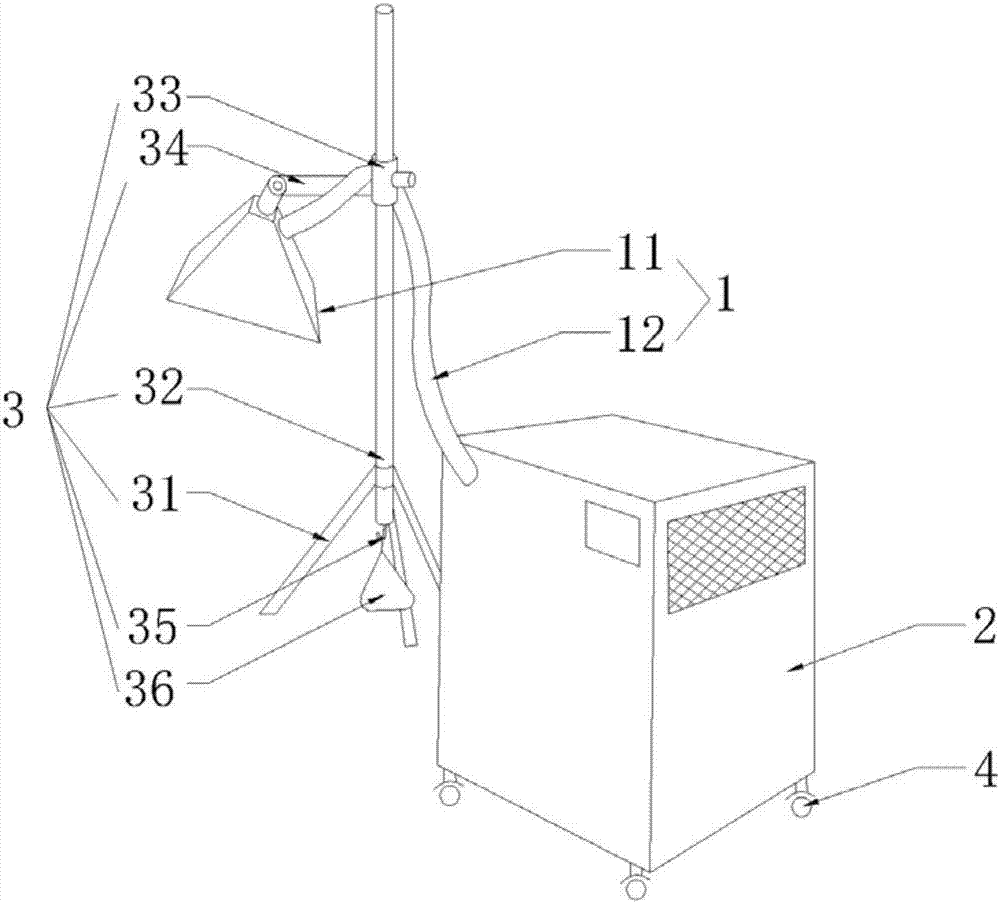

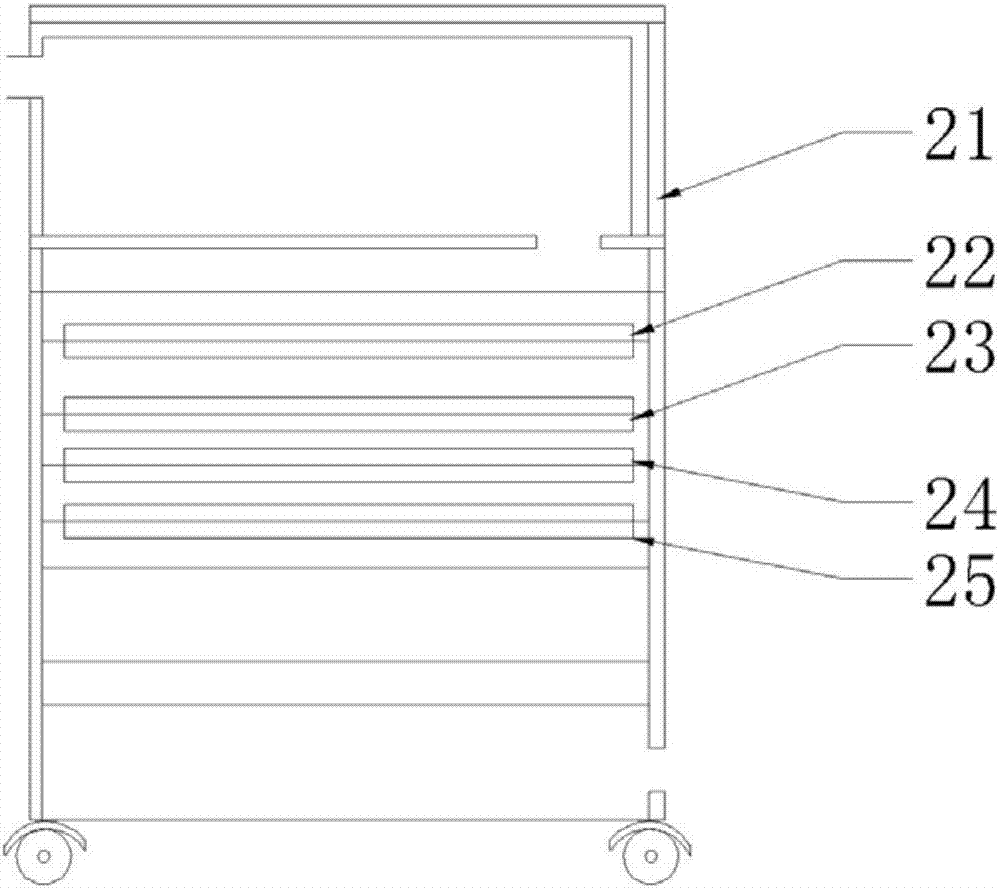

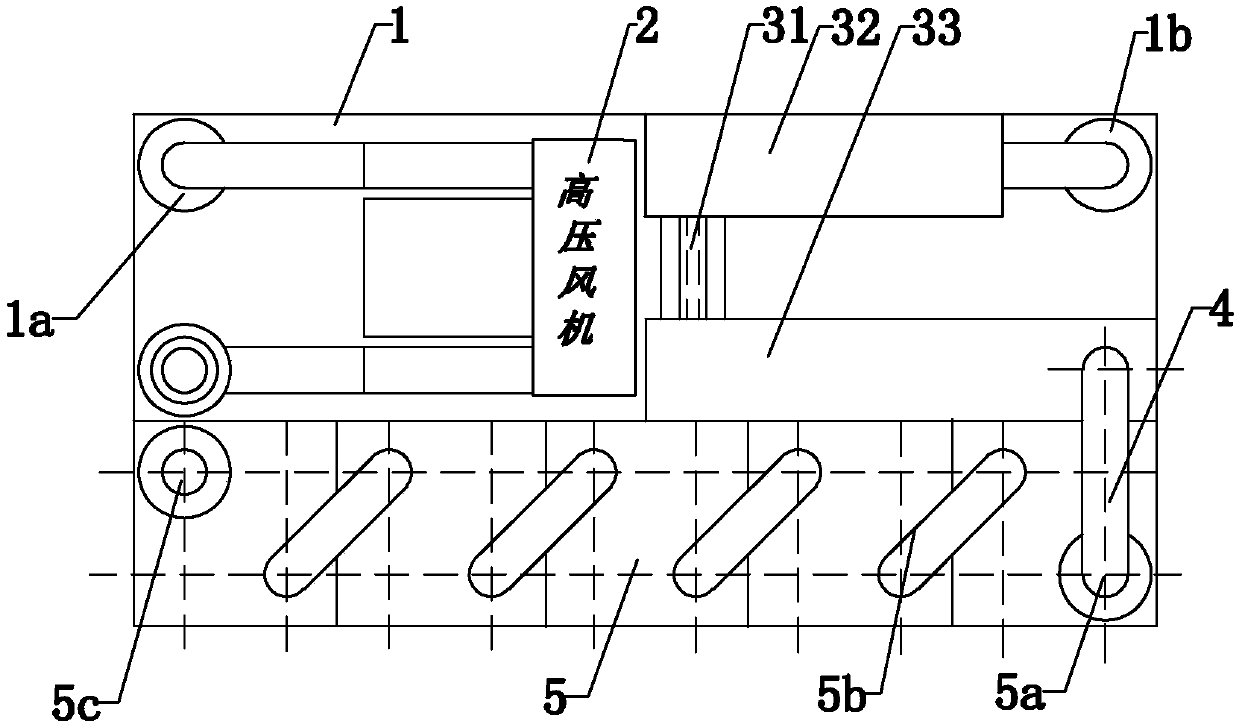

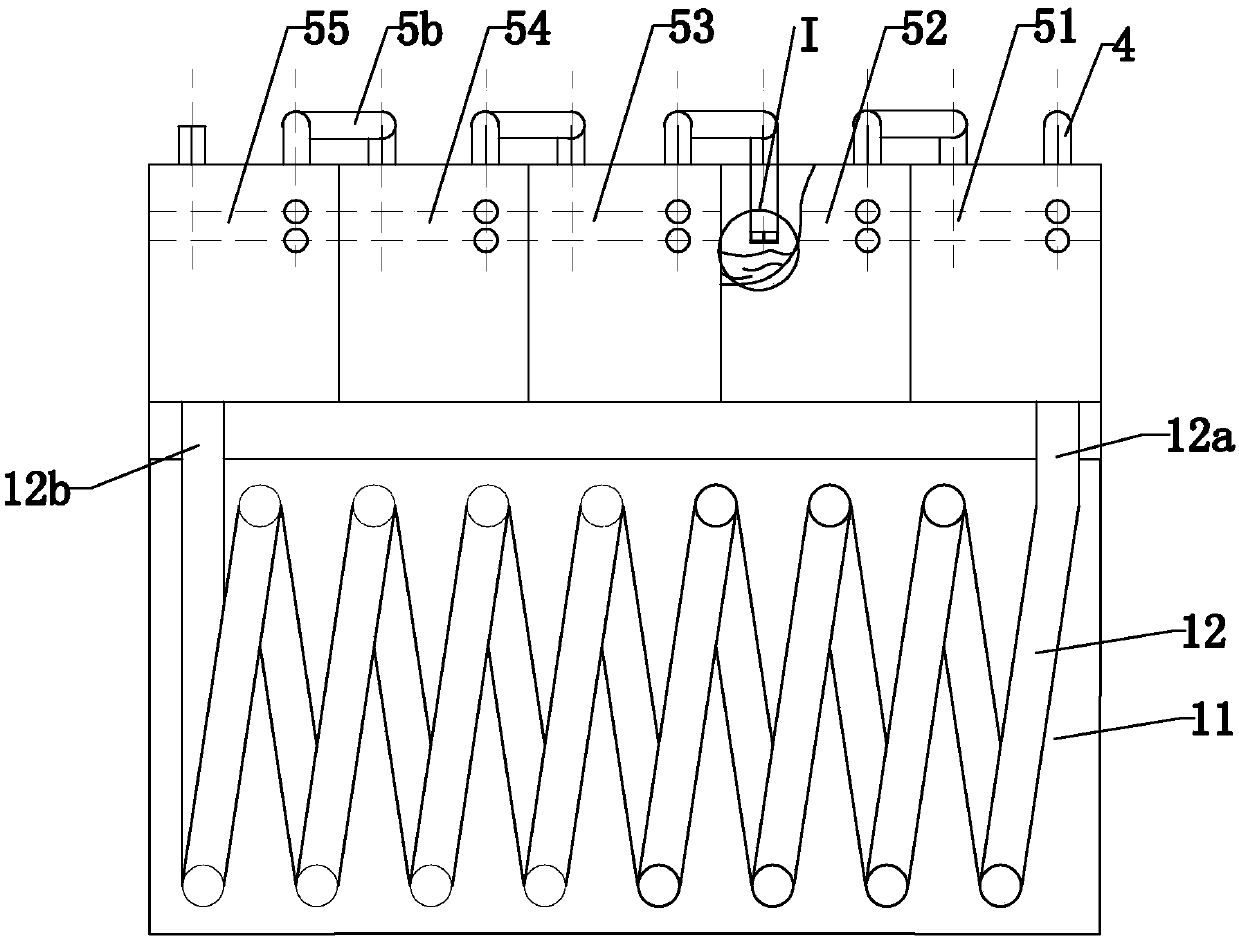

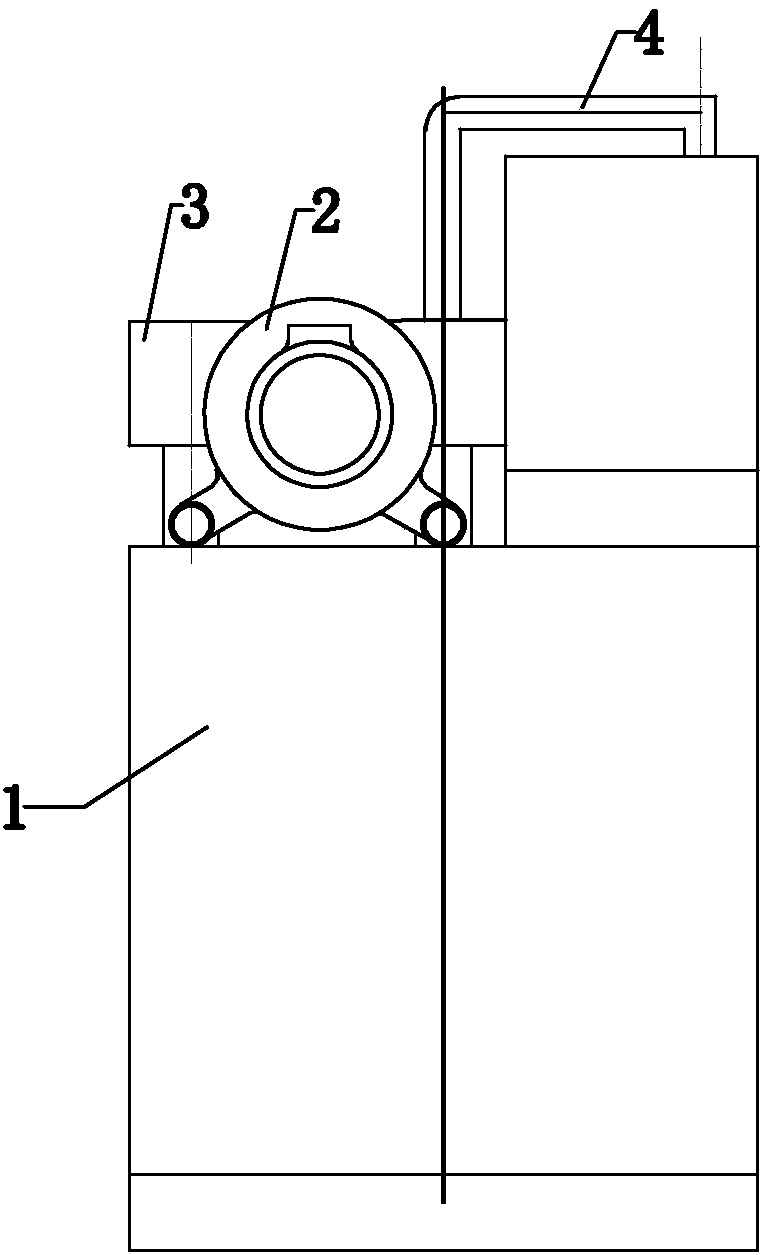

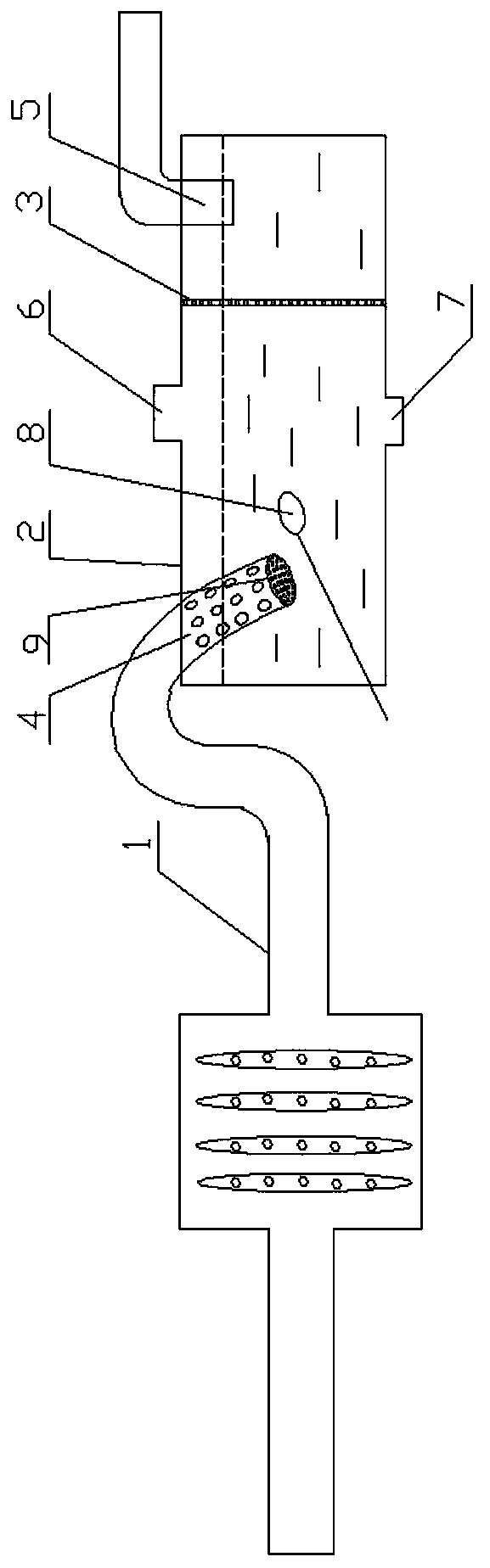

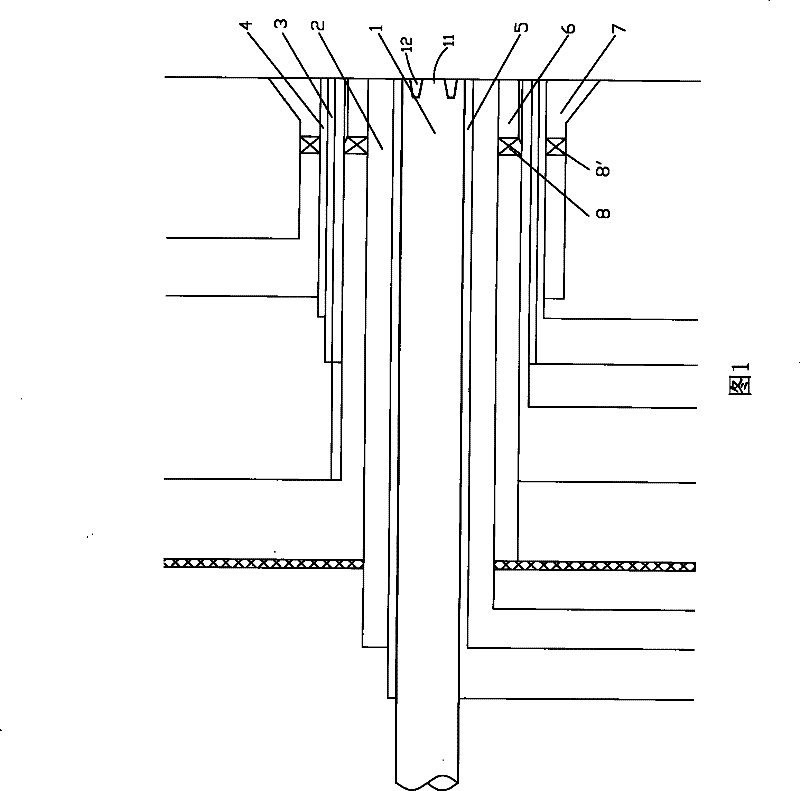

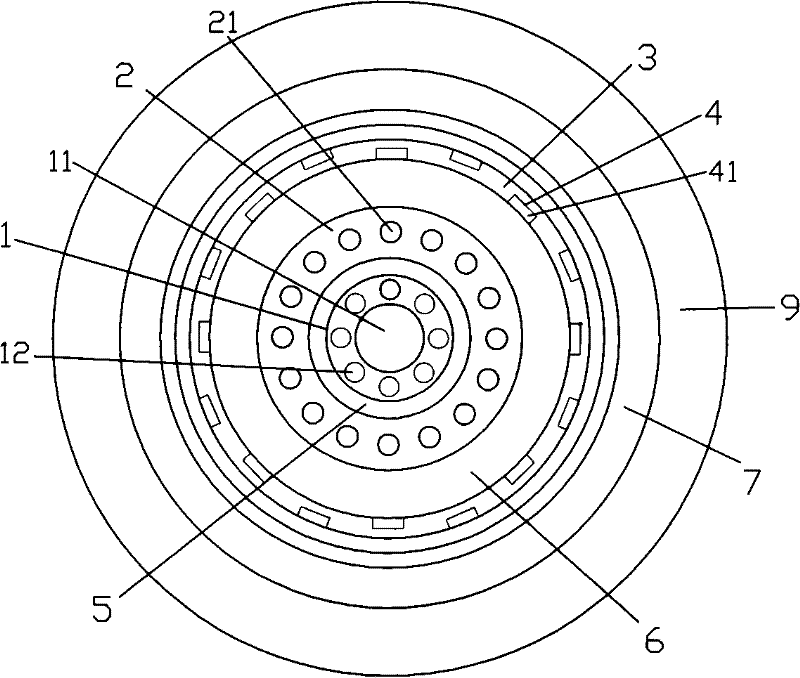

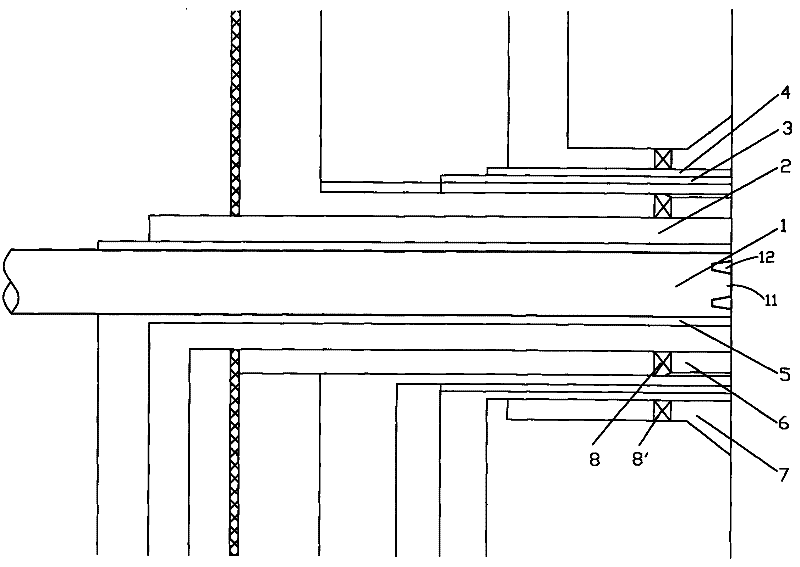

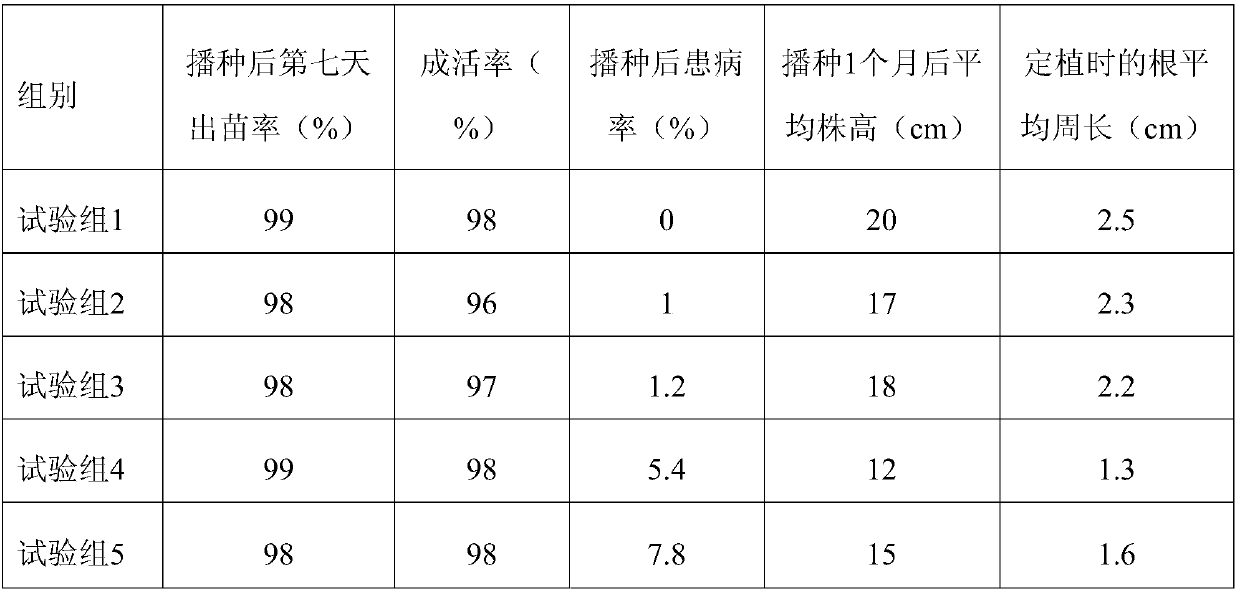

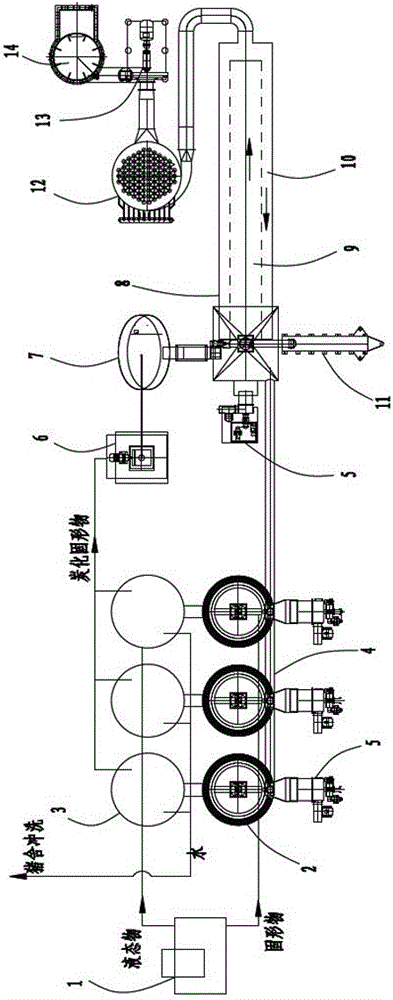

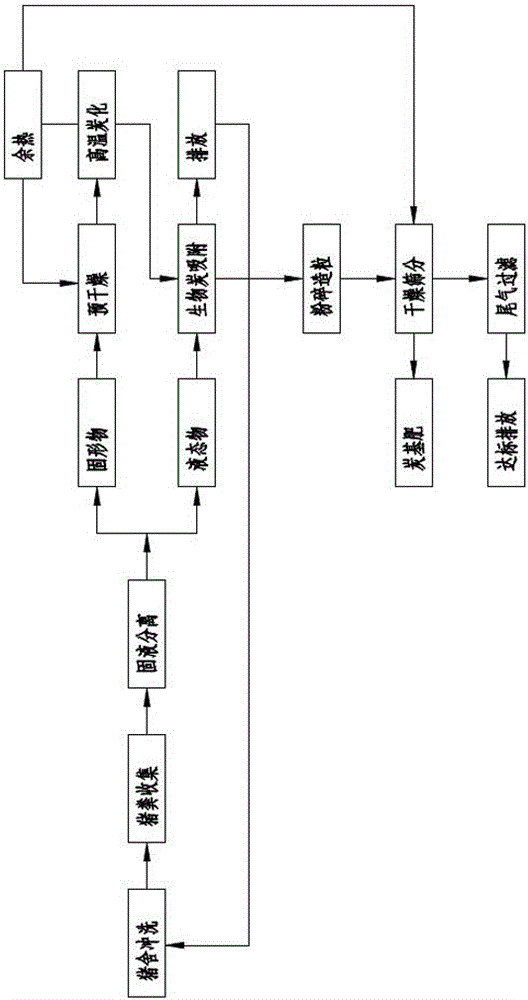

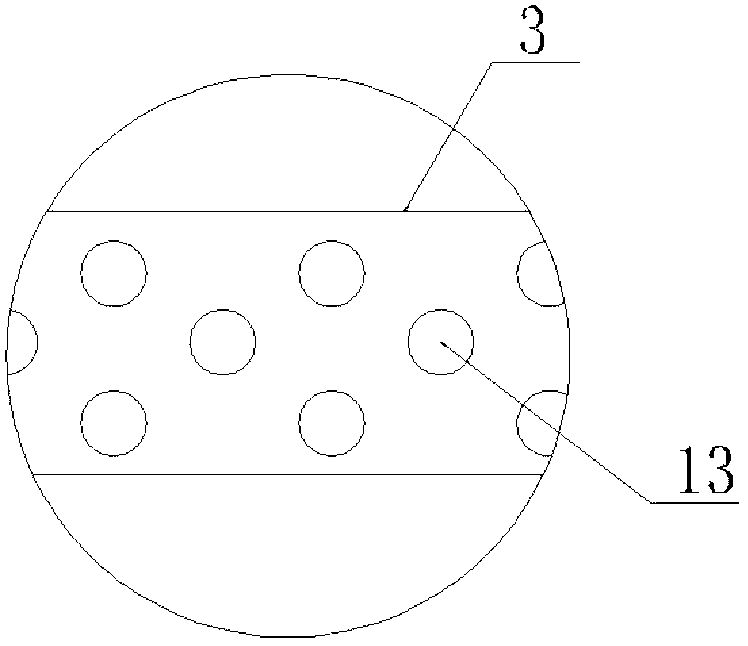

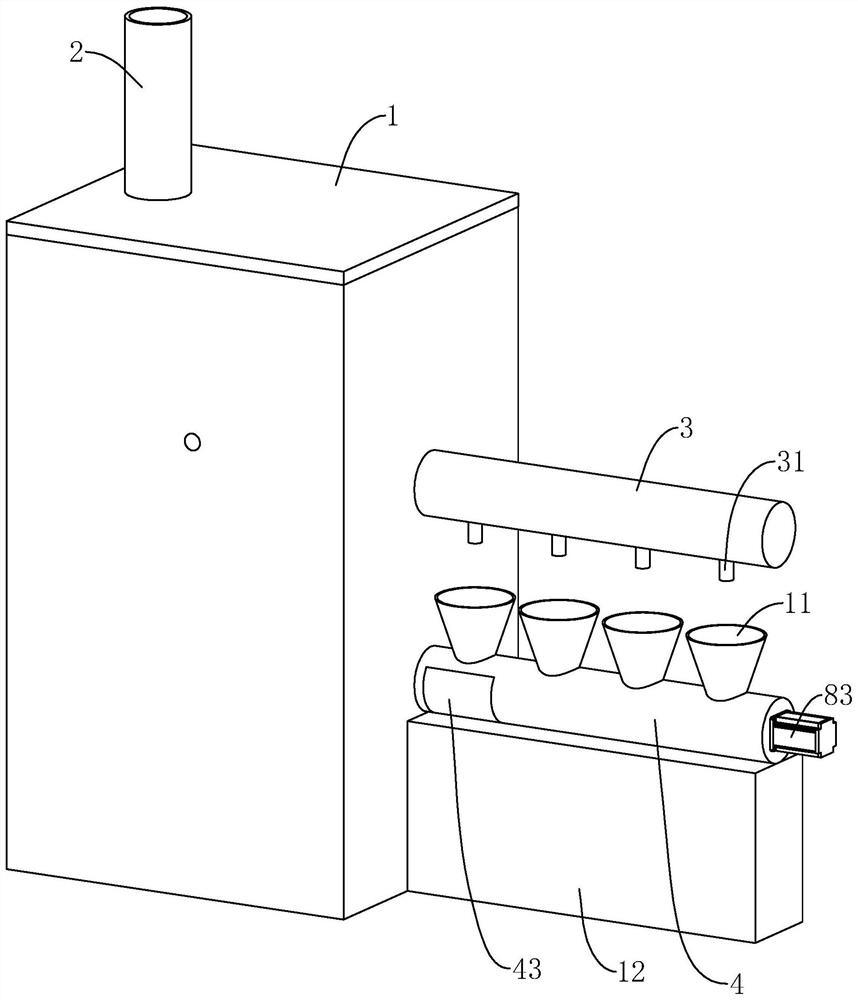

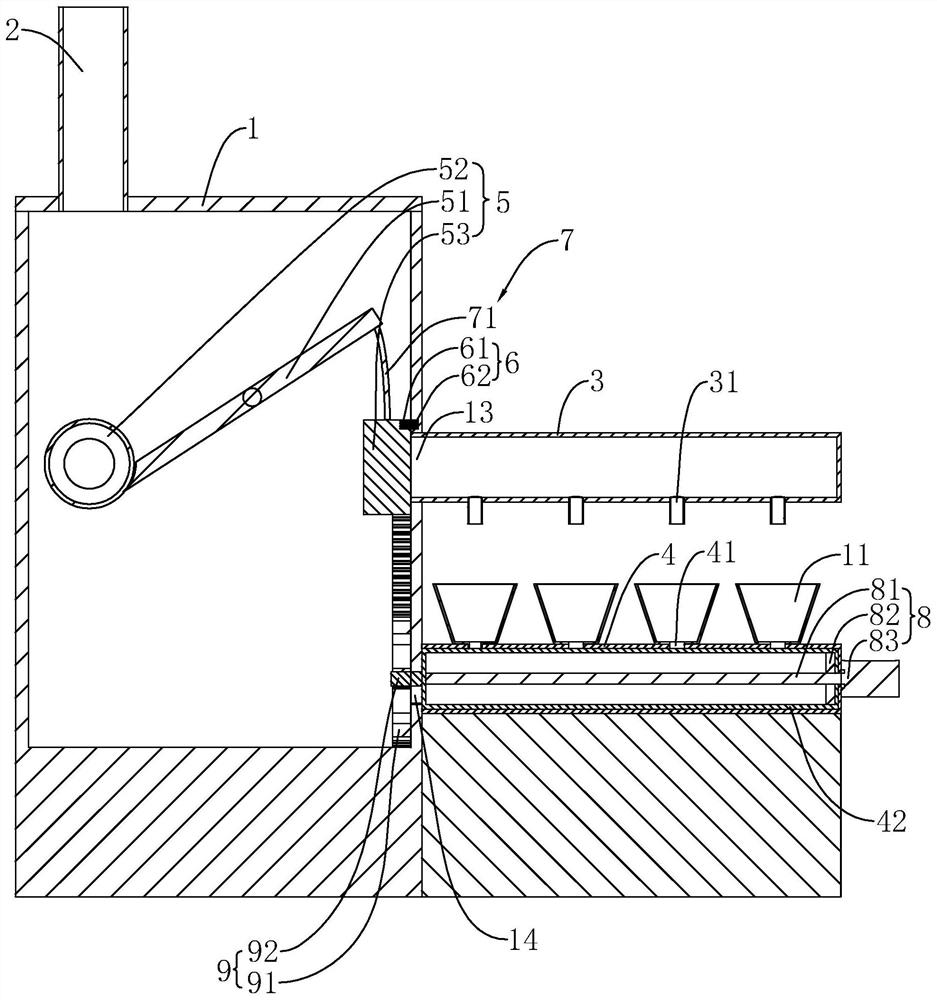

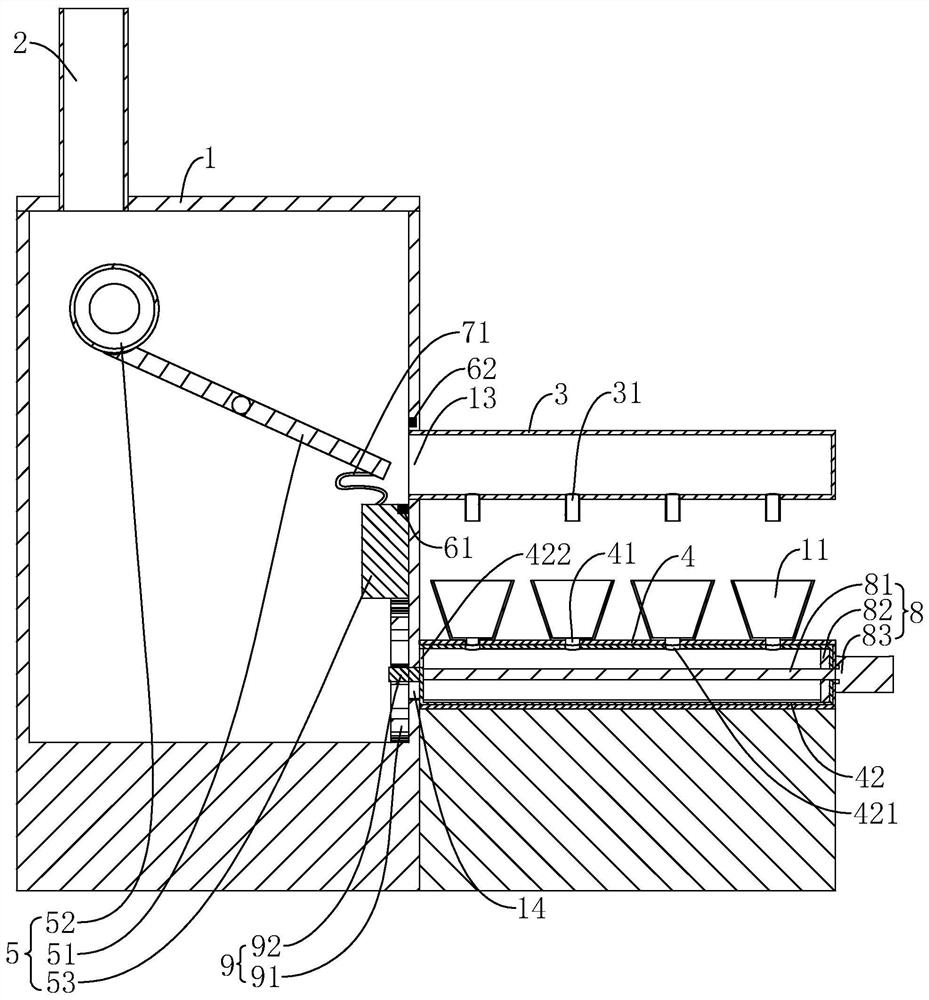

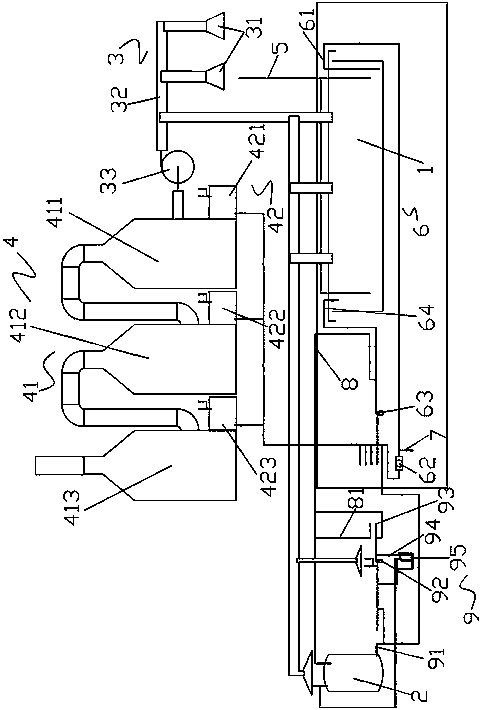

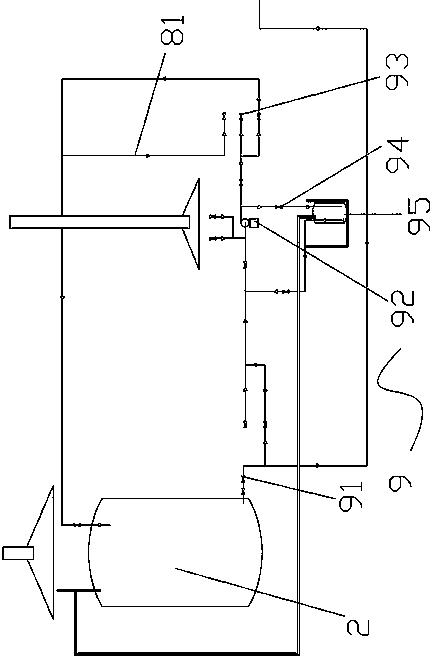

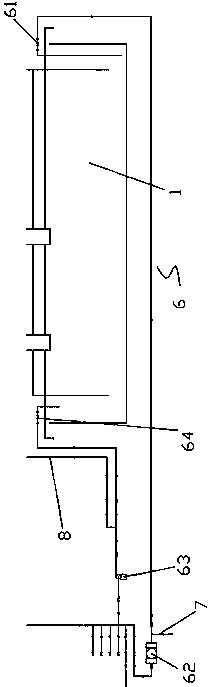

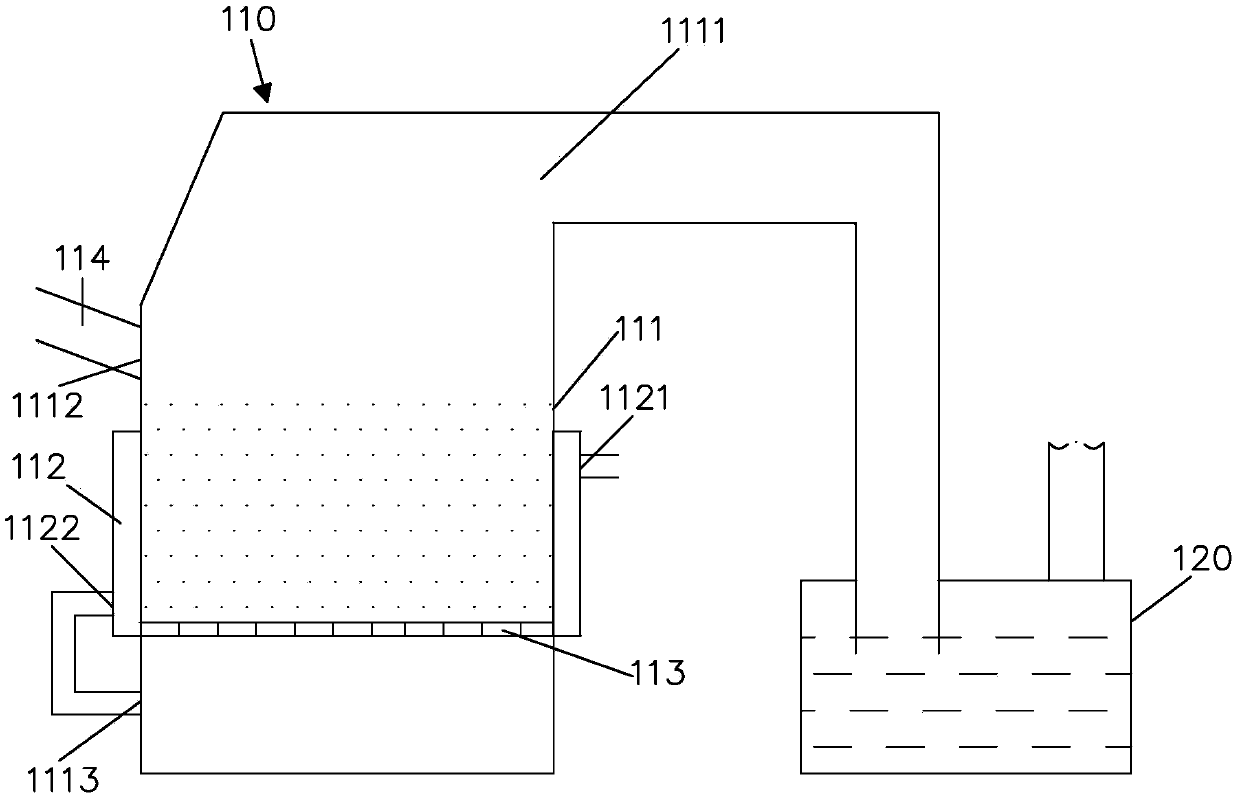

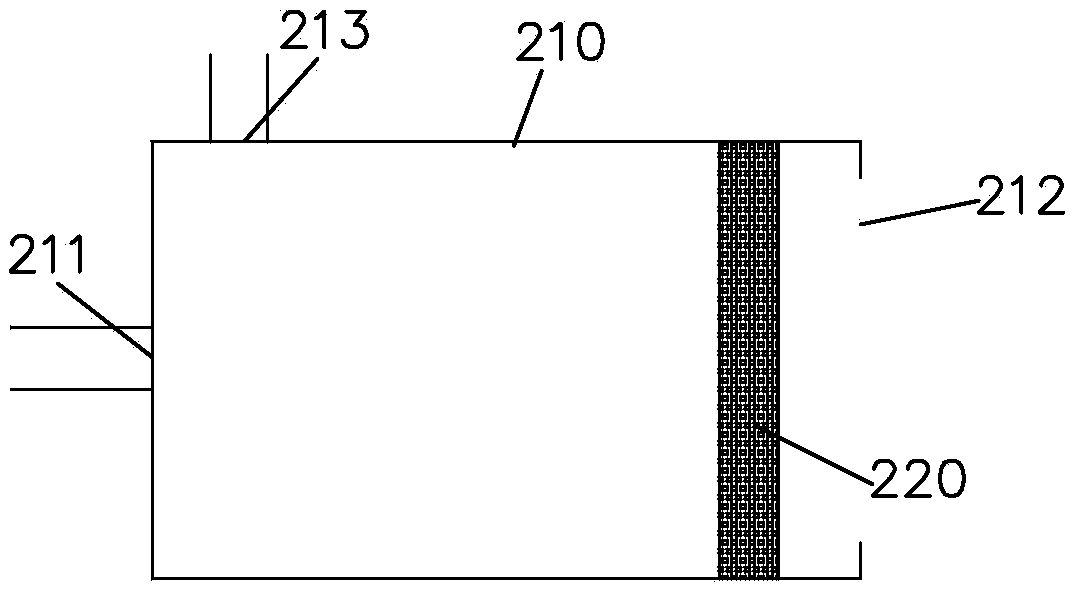

An experiment system and an experiment method used for studying dielectric barrier discharge processing of SF[6] gases

InactiveCN105698850AReduce direct emissionsCurb global warmingComponent separationColor/spectral properties measurementsBottleVacuum pump

The invention discloses an experiment system and an experiment method used for studying dielectric barrier discharge treatment of SF[6] gases. The experiment system comprises a gas distribution system, an SF[6] gas processing system, a parameter detection system and a tail gas processing system. The gas distribution system comprises a gas bottle, a gas pressure-reducing valve, a gas distribution instrument and a bubbler. The SF[6] gas processing system comprises a pressure regulator, a plasma power supply and a dielectric barrier discharge reactor. The parameter detection system comprises a high-voltage probe, a sampling resistor, a sampling capacitor, a coaxial cable, a single-pole double-throw switch, an oscilloscope, a fiber optical spectrometer, an optical fiber, a collimating mirror, a computer and a gas chromatograph. The tail gas processing system mainly comprises a vacuum pump, a digital display pressure vacuum meter and an alkaline hydrolysis absorption cell. According to the experiment method, preparation work such as connecting and cleaning of the experiment system is carried out; then the SF[6] gas processing system is used to process the SF[6] gasses; a parameter detection system is utilized to carry out detection of required parameters; and finally, cleaning work after the experiment is completed.

Owner:WUHAN UNIV

Treatment method of low-temperature evaporation high-concentration sewage

ActiveCN103848464AReduce contentComply with primary emission standardsEnergy based wastewater treatmentWater/sewage treatment by heatingHigh concentrationEvaporation

The invention discloses a treatment method of low-temperature evaporation high-concentration sewage. The method comprises the following steps: feeding the preheated hot air to a hot air inlet end of a low-temperature plate evaporator; feeding the preheated sewage to a sewage inlet end of the low-temperature plate evaporator, wherein the low-temperature plate evaporator is mainly formed by a plurality of layers of evaporation plates in a stacking manner; the sewage entering inside a flow control component forms a continuous laminar liquid film from top to bottom through the flow control component; the hot air entering an air pre-heating component forms a continuous ascend airflow from bottom to top, so that the continuous ascend airflow and the continuous laminar liquid film are subjected to countercurrent contact; saturated steam is finally formed by the continuous ascend airflow through the multi-layer evaporation plate, so that the saturated steam is discharged through a hot air outlet at the top; the continuous laminar liquid film is separated out in a form of a crystal substance after being fully evaporated, the un-evaporated sewage is discharged from a sewage outlet at the bottom. Thus, the treatment method disclosed by the invention is small in investment, good in treatment effect, low in energy consumption, green and environmentally friendly.

Owner:湖南北控威保特环境科技股份有限公司

Glass edge grinding device

InactiveCN107855868AEasy to useGuaranteed continuityEdge grinding machinesGrinding carriagesDrive wheelWater resources

The invention discloses a glass edge grinding device. The glass edge grinding device comprises a base; a supporting frame is fixedly arranged at the top end of the base; a fixing plate A is fixedly connected at the top end of the supporting frame; a supporting plate is fixedly connected in the position, close to the base, on one side of the supporting frame; a vertical fixing plate A and a vertical fixing plate B are fixedly arranged at the top end of the supporting plate; and a conveying device is arranged between the vertical fixing plate A and the vertical fixing plate B and comprises a driving wheel, a driven wheel and a conveying belt. According to the glass edge grinding device, glass edges can be ground continuously by the aid of the conveying device, so that the working continuityis guaranteed; besides, under cooperation of pressing rollers and the conveying device, and by the aid of the grinding device capable of moving freely, the glass edges in different sizes and thicknesses can be ground; in addition, sewage is effectively treated in a sewage treatment box, so that water resources can be recycled to the maximum extent; and in the sewage treatment process, fragment impurities filtered out of the sewage can be subjected to grinding and crushing treatment simultaneously.

Owner:ZHONGSHAN CHUANGKE RES TECH SERVICE

Technique for recycling purge gas of device used for synthesizing methyl alcohol by utilizing synthesis gas

The invention relates to a technique for synthesizing methyl alcohol by utilizing synthesis gas in the field of chemical industry and in particular relates to a technique for recycling purge gas of device used for synthesizing methyl alcohol by utilizing synthesis gas. The technique comprises the following steps of: carrying out a water vapour transformation reaction on the purge gas of the methyl alcohol synthesizing device, wherein carbon oxide in the purge gas is converted into carbon dioxide and hydrogen, and methyl alcohol in the purge gas is reformed and decomposed into carbon dioxide and hydrogen; carrying out pressure swing adsorption separation purification on the purge gas after the transformation reaction, so as to obtain hydrogen with higher purity; and returning the hydrogen after pressure swing adsorption purification to a methyl alcohol synthesis process, so as to achieve higher feed gas utilization rate. According to the technique for recycling the purge gas of the device used for synthesizing methyl alcohol by utilizing the synthesis gas, content of hydrogen in the purge gas is increased, and discharge of carbon monoxide effective gas is also reduced; direct discharge of methyl alcohol is eliminated, and recycling of the methyl alcohol in the purge gas is realized; and the total consumption of the synthesis gas in methyl alcohol synthesis front processes such as low temperature transformation reaction and pressure swing adsorption decarbonisation is reduced, and direct discharge of carbon dioxide and methyl alcohol synthesis cost are reduced.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

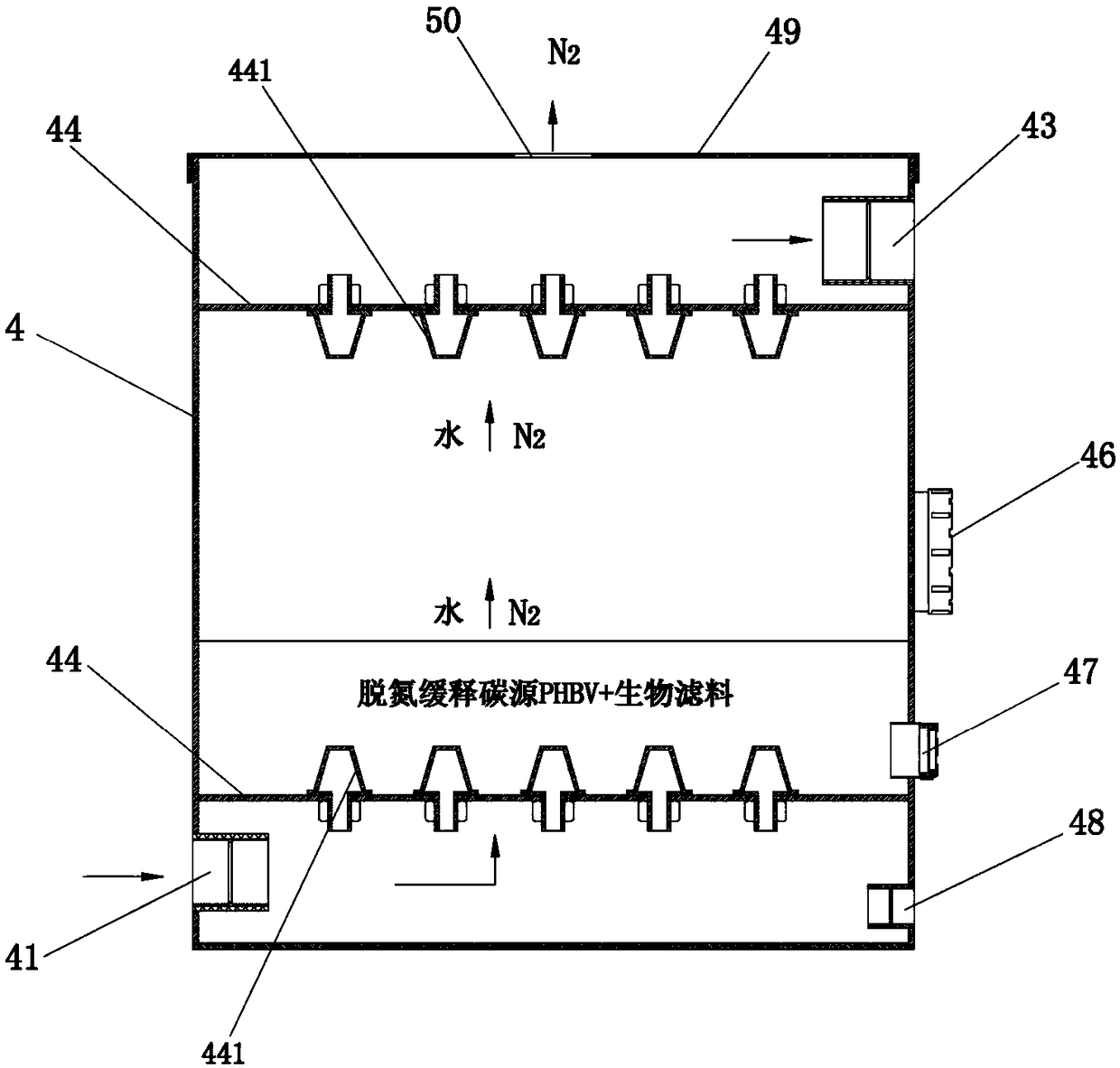

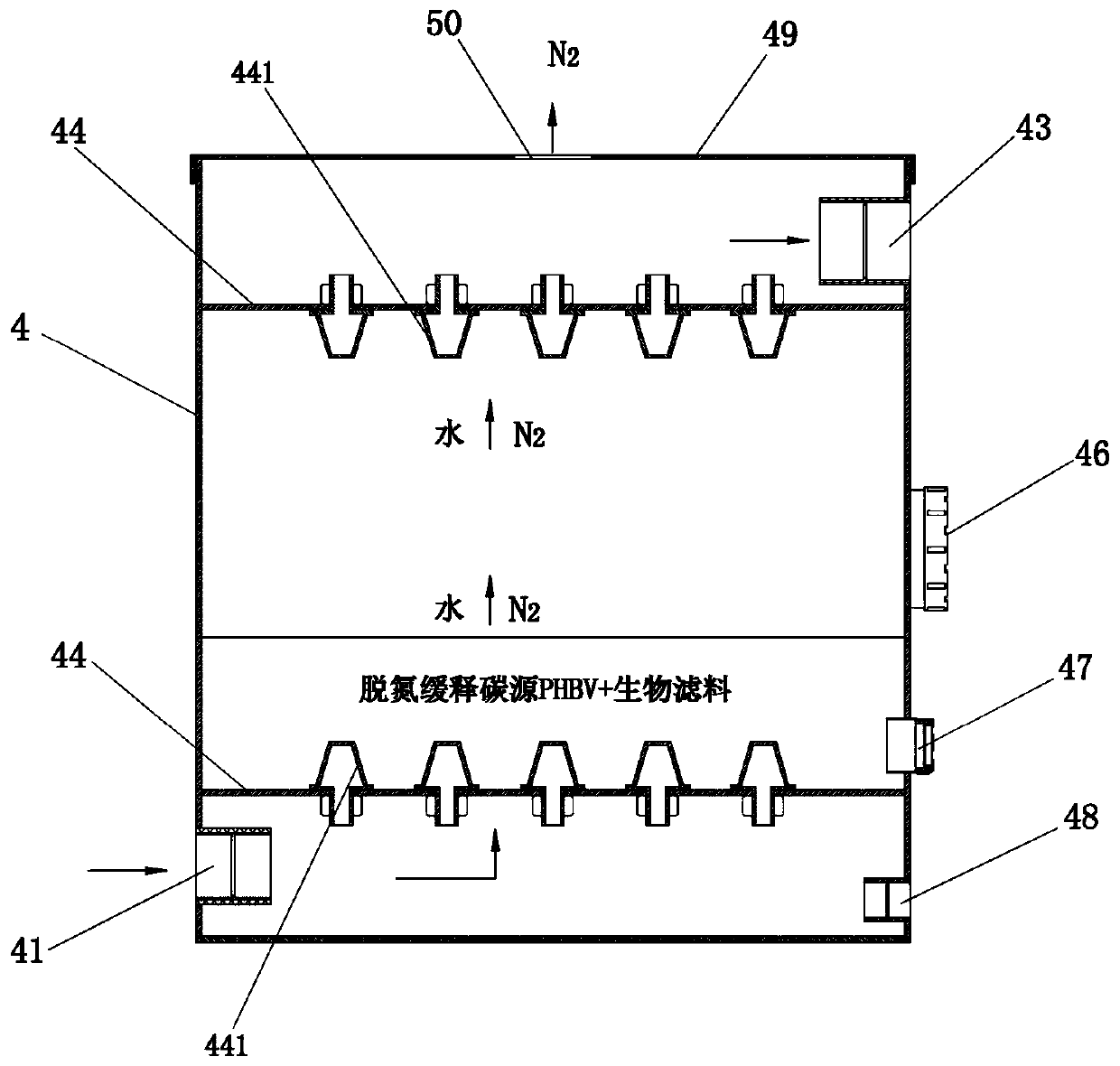

Low-carbon zero-emission plant circulation water breeding system based anaerobic denitrification

PendingCN108271730ASolve the accumulationReduce water changesTreatment using aerobic processesWater/sewage treatment by irradiationFresh water organismBiological filter

The invention discloses a low-carbon zero-emission plant circulation water breeding system based on anaerobic denitrification. The low-carbon zero-emission plant circulation water breeding system comprises a circulation water breeding pool, a microfiltration machine, a water pump, a denitrification device, a CO2 reducing drip biological filter, a movable biofilter, an ultrasonic sterilizing sterilizer, an efficient pure oxygen mixer and a settling pond; an anaerobic denitrification device is a cylinder or a cuboid, solid denitrification is utilized to release a carbon source as biological stuffing and is used as a carrier of anaerobic denitrification bacteria, and meanwhile, through biodegradation, the carbon source and transfer electrons can be provided for denitrification; a settling pond sewage collecting system is used for collecting periodically drained sewage of a vertex solid-liquid separator, the microfiltration machine and a biofilter, liquid supernatant of the settling pond sewage collecting system can be used for a circulation water breeding system again, and settling liquid can be squeezed as vegetable organic fertilizer. Zero drainage of the plant circulation water breeding system is achieved in real sense, and the low-carbon zero-emission plant circulation water breeding system is applicable to high-density plant circulation water breeding of all freshwater and seawater high-quality fish varieties.

Owner:青岛蓝谷鲲鹏海洋科技有限公司

Fuel automobile tail gas treatment device

ActiveCN107503828AImprove processing efficiencyReduce processing costsExhaust apparatusSilencing apparatusCouplingEngineering

The invention discloses a fuel automobile tail gas treatment device. The fuel automobile tail gas treatment device comprises a fixing box; a fixing plate is fixedly connected between the two sides of the inner wall of the fixing box; the bottom of the fixing plate is fixedly connected with a dissolving box; a partition plate is fixedly connected between the bottom of the dissolving box and the bottom of the inner wall of the fixing box; a supporting plate is fixedly connected between the left side of the partition plate and one side of the inner wall of the fixing box; a first motor is fixedly connected to the top of the fixing box; and an output shaft of the first motor is fixedly connected with a first belt wheel through a coupler. The invention relates to the technical field of tail gas treatment. The fuel automobile tail gas treatment device solves the problems that an existing tail gas treatment device is poor in treatment effect and low in treatment speed, and tail gas cannot be thoroughly treated, improves the tail gas treatment efficiency, reduces the tail gas treatment cost, provides clean air for people and avoids that the health of people is threatened.

Owner:NANPI JINLIYANG ELECTRONICS

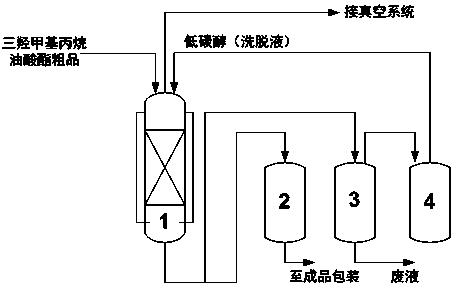

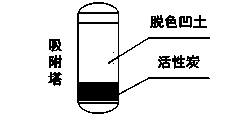

Continuous regeneration adsorption purification process of trimethylolpropane trioleate

ActiveCN104387271AEffectively remove antioxidantEffective removal of demulsibilityPreparation by ester-hydroxy reactionOrganic compound preparationSorbentOxidation stability

The invention discloses a continuous regeneration adsorption purification process of trimethylolpropane trioleate. The process comprises the following operation steps: (1) putting an adsorbing agent into an adsorption tower or a plurality of adsorption towers which are connected in series; (2) enabling a trimethylolpropane trioleate crude product to continuously pass through the adsorption tower filled with the adsorbing agent at certain flow velocity and temperature to ensure that impurities such as micro solid particles, gelatine and the like which can influence the oxidation resistance and emulsification resistance of the product are adsorbed by the adsorbing agent; and (3) continuously regenerating the adsorbing agent: performing circulating washing by using low carbon alcohol to remove organic impurities such as the gelatine and the like adsorbed by the adsorbing agent, then purging by using inert gas, and performing vacuum drying and regeneration to obtain a regenerated adsorbing agent which can be recycled. Trimethylolpropane trioleate prepared by virtue of the process disclosed by the invention has excellent oxidation stability and emulsification resistance, and can be better used as base oil of various lubricating oil.

Owner:NANJING WELL BIOCHEM

Blast furnace gas enrichment apparatus and method

ActiveCN102391892AReduce direct emissionsSolve problemsCombustible gas productionCoal briquetteGas heater

A blast furnace gas enrichment apparatus and a method belong to the technical field of blast furnace gas. The apparatus comprise a feeder, a coal briquette preheater, a distributor, a heat exchanger, a gas-heating furnace, a gas bustle pipe, gas spray guns, a shunt, an ash tray, a gas enrichment furnace, a deduster, a gas storage tank, an oxygen pipeline and a gas outlet pipeline. Blast furnace gas is adopted as material, gas is adopted as energy, oxygen is adopted as oxidizer, and non-coking coal, nut coke and the like are adopted as reducers; after nitrogen is removed from the blast furnacegas and the blast furnace gas passes through a preheater and is enriched, the gas carries out heat exchange, and enters a gas heater, the gas heater utilizes the high-heat value gas to burn with oxygen to provide heat for the blast furnace gas, so that the temperature of the blast furnace gas reaches 800 DEG C to 900 DEG C, the blast furnace gas is blown into the furnace from around the furnace wall, coal briquettes are packed in the gas enrichment furnace, the main reduction task is fulfilled in the coal briquette-packed bed, and thereby high-heat value gas is produced. The invention has theadvantages that: the heat value of the blast furnace gas is increased, and the emission of carbon dioxide is reduced.

Owner:SHOUGANG CORPORATION

Oil gas volatilization inhibition system and method with inert gas protection function

PendingCN111846675AAchieve inhibitionReduce direct emissionsLarge containersGas protectionBuffer tank

The invention belongs to the technical field of oil product storage tank safety and environmental protection, and discloses an oil gas volatilization inhibition system with an inert gas protection function. The oil gas volatilization inhibition system is applied to a storage tank for storing oil products, and comprises a buffer tank, a first gas storage tank and a first compressor, wherein the buffer tank is provided with a gas outlet and a gas inlet communicating with at least one storage tank, and the buffer tank is used for receiving redundant gas in the tank when the gas pressure in the storage tank is too high; the first gas storage tank is provided with a gas outlet and a gas inlet communicating with the gas outlet of the buffer tank, and the first gas storage tank is used for discharging gas in the first gas storage tank into the storage tank through the gas outlet of the first gas storage tank when the gas pressure in the storage tank is too low. The invention further disclosesan oil gas volatilization inhibition method with the inert gas protection function. According to the oil gas volatilization inhibition system and method with the inert gas protection function, when the pressure of the tank top is unbalanced, original oil gas in the tank can be used for rapid supplementing and adjusting, so that the balance is achieved again, the breathing action of a breathing valve can be prevented, the purposes of energy conservation and emission reduction are achieved, and inert protection can be carried out on the storage tank.

Owner:眉山麦克在线设备股份有限公司

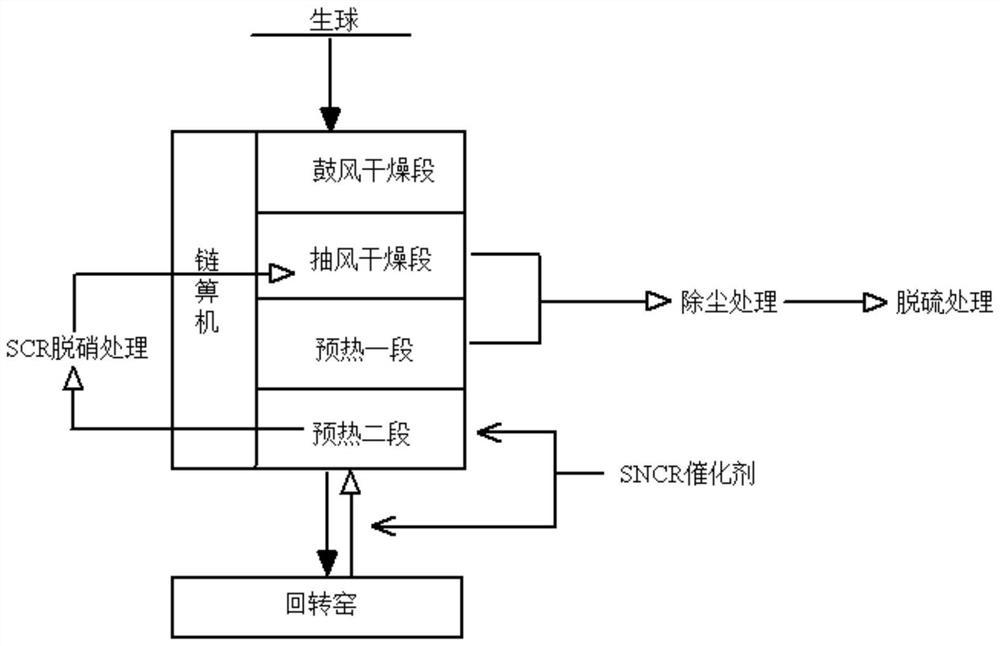

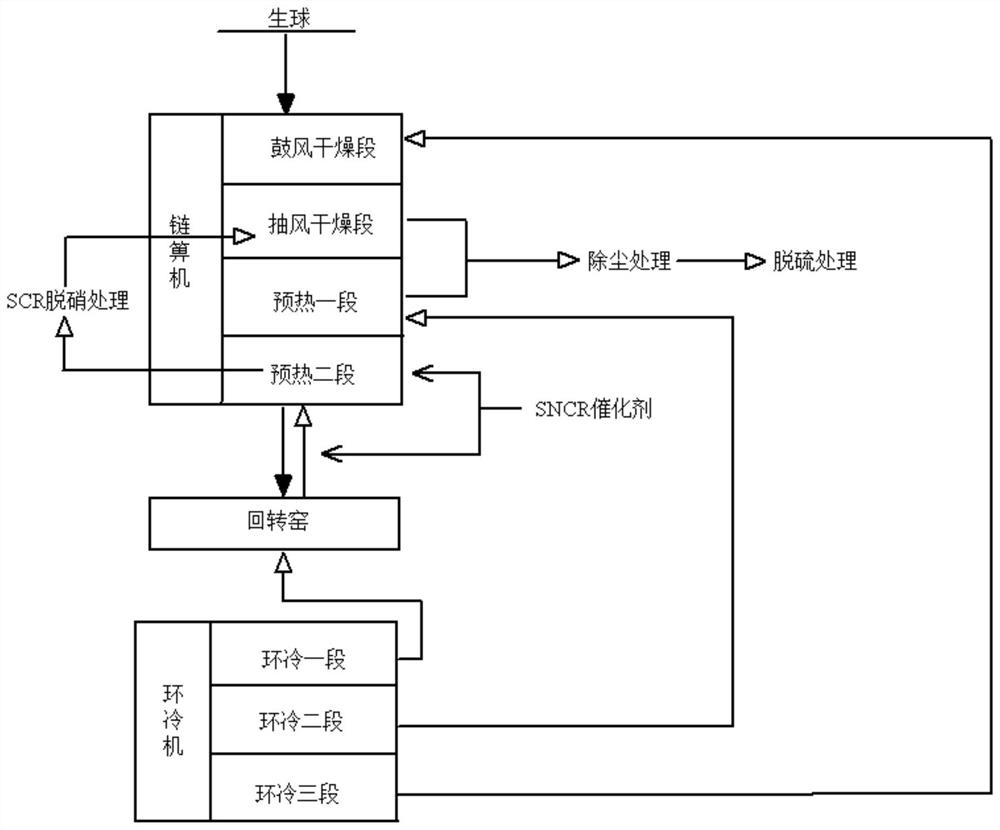

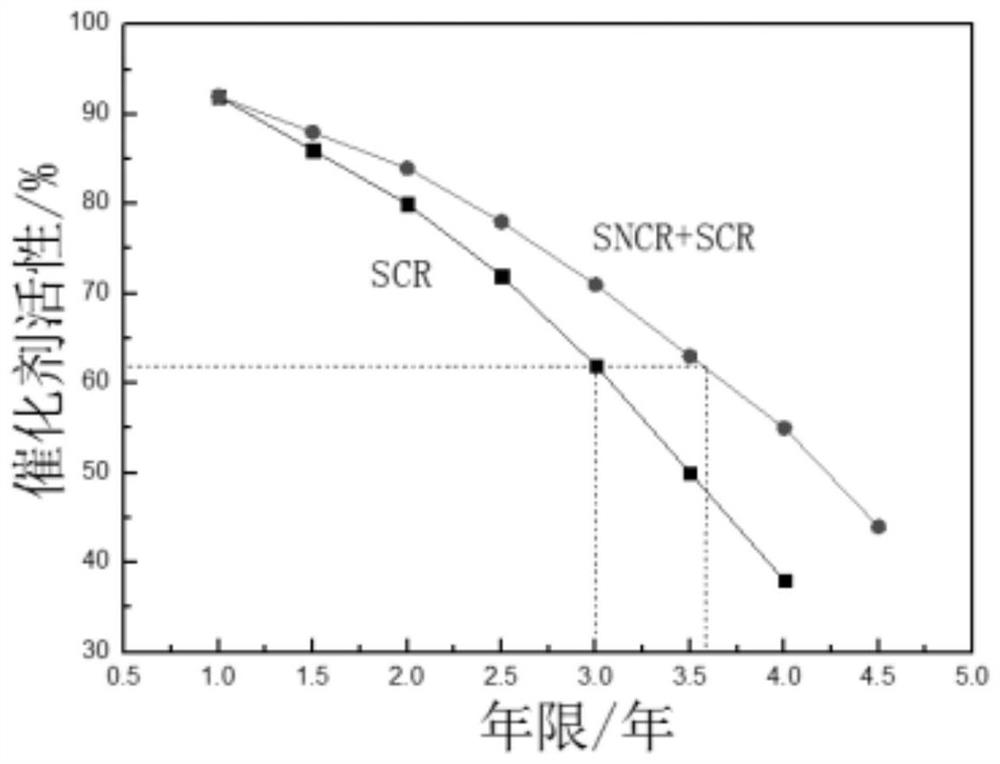

Flue gas treatment process and treatment system

ActiveCN113908677ALow investment costLow running costGas treatmentRotary drum furnacesPtru catalystThermodynamics

The invention discloses a chain grate-rotary kiln flue gas treatment process and treatment system. A control method of an SNCR-SCR coupling denitration system is adopted, a composite additive is added into an SNCR denitration catalyst or a novel SNCR composite ammonia agent is provided; and meanwhile, a movable airflow balance plate is additionally arranged between a PH section and a TPH section of a chain grate, the air pressure of the TPH section is controlled to be larger than or equal to the air pressure of the PH section by utilizing the position change of the airflow balance plate, so that the problem that the content of NOx in flue gas of the TPH section is increased due to the fact that high-NOx-content waste gas of the PH section flees towards the TPH section is prevented. The optimal coupling ultralow NOx emission technology can be formed, the denitration efficiency can be effectively guaranteed on the premise that SNCR ammonia consumption is reduced, meanwhile, the service lifetime of an SCR denitration catalyst can be prolonged, and the denitration operation cost and investment cost of the system are obviously reduced. The utilization efficiency of a flue gas denitration reducing agent is further improved, and the escape amount of NH3 is reduced.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

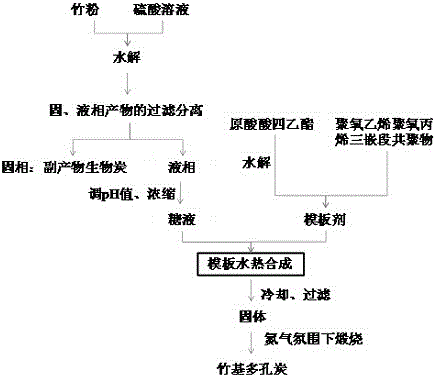

Bamboo-based porous carbon preparation method

ActiveCN106241770AReduce direct emissionsImprove the utilization rate of bamboo resourcesPorous carbonNitrogen gas

The invention provides a bamboo-based porous carbon preparation method, wherein bamboo waste is used as a raw material for preparing a porous carbon, the raw material is hydrolyzed with an acid to produce a sugar liquid and by-produce a bamboo charcoal, the sugar liquid and a templating agent are mixed, hydrothermal synthesis is performed, and the obtained solid-phase product is subjected to high temperature calcining in a nitrogen atmosphere to prepare the porous carbon. According to the present invention, the porous carbon preparation process using the bamboo as the raw material is provided, such that the comprehensive utilization rate of the bamboo waste is increased; the preparation process is simple and controllable, the recycling of the resources is achieved, the direct discharge of the waste is reduced, and the ecological benefits are good; and the prepared product can be used in the fields of adsorption separation, catalyst carriers and the like, and the by-product charcoal can further be used as the energy source or function material.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Noise reduction and purification device for automobile exhaust gas

ActiveCN105179048ANo cavitationGuaranteed cleanlinessExhaust apparatusSilencing apparatusExhaust gasNoise reduction

The invention provides a noise reduction and purification device for automobile exhaust gas. The noise reduction and purification device is simple in structure and good in purification effect and comprises an exhaust gas inlet, a noise reduction and purification device body and an exhaust outlet. Exhaust gas enters the noise reduction and purification device body through the exhaust gas inlet and then exhausted through the exhaust outlet after noise reduction and purification are performed on the exhaust gas through the noise reduction and purification device body. The noise reduction and purification device body comprises a first-grade purification chamber. A purification pool and a gas-water purification cavity are arranged inside the first-grade purification chamber. A purification solution is contained inside the purification pool. The exhaust gas inlet is communicated with the first-grade purification chamber. The upper edge of an opening of the exhaust gas inlet is higher than the upper surface of the purification solution inside the purification pool. A water level indicator is arranged inside the purification pool of the first-grade purification chamber and induces the height of the purification solution inside the purification pool. The purification pool is connected with a purification solution adding pump. The purification solution adding pump supplements the purification solution inside the purification pool. An atomization filter net is arranged between the gas-water purification cavity and the purification pool. A gas-water separation filter net is arranged at an outlet of the gas-water purification cavity.

Owner:方冰熔

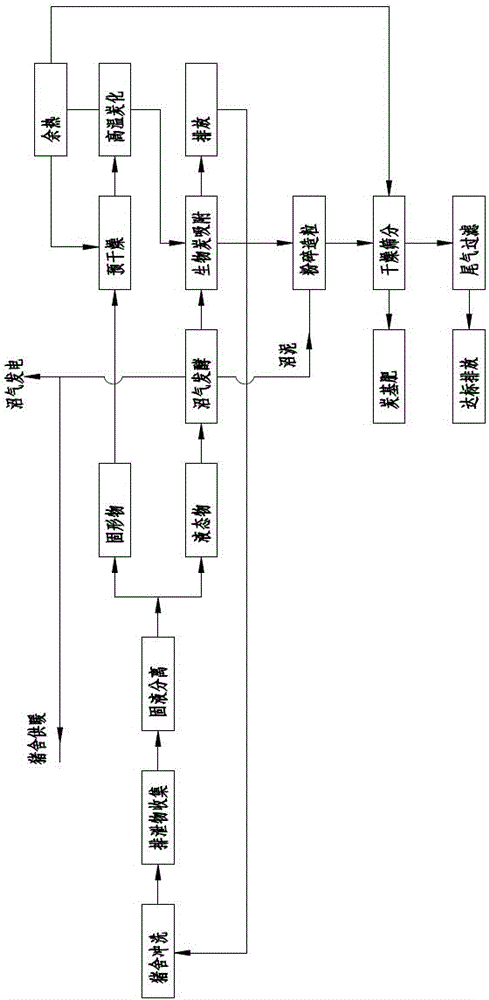

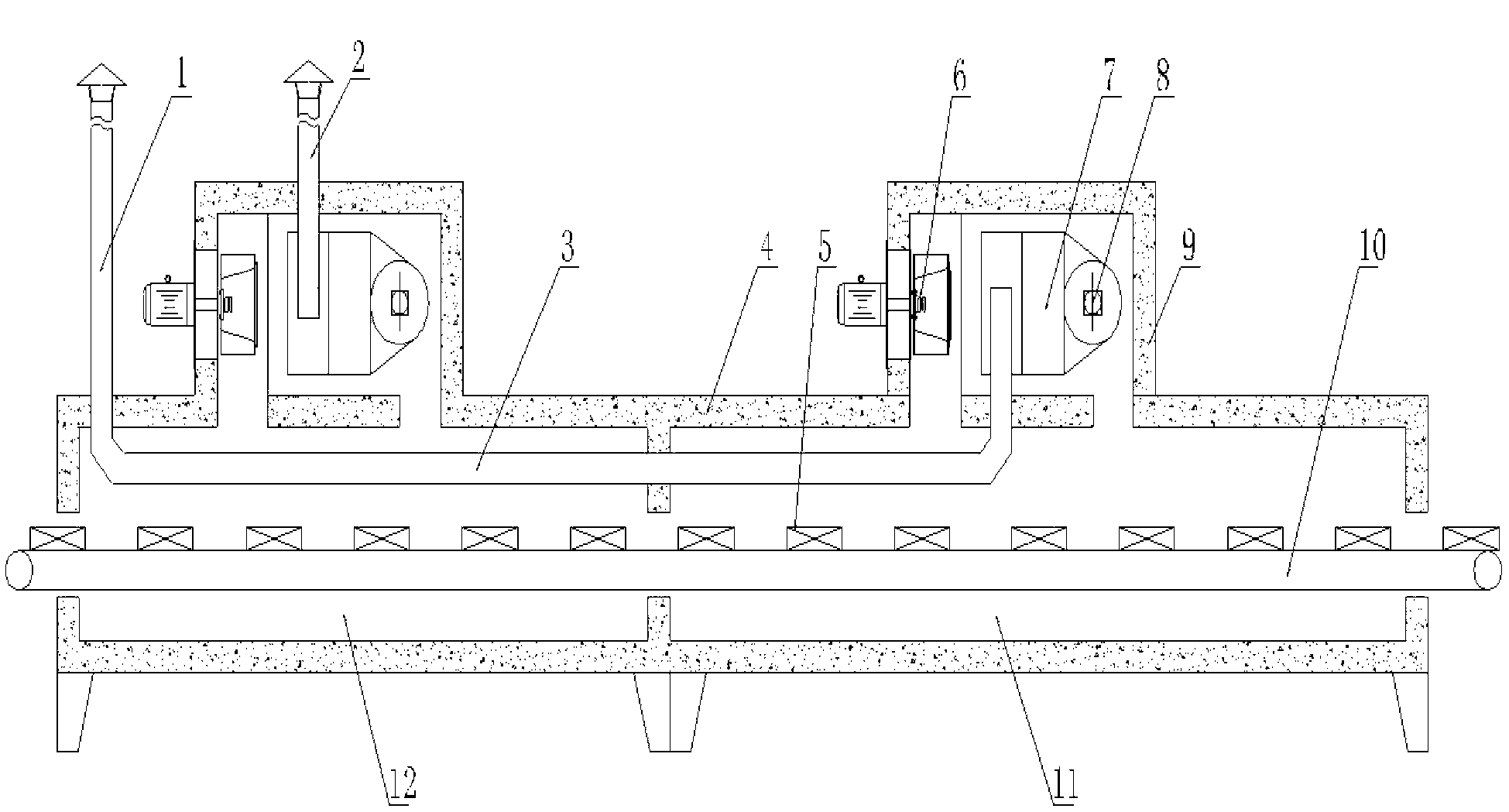

Livestock manure charring fertilizer making system

InactiveCN105906411AReduce direct emissionsReduce water consumptionBioreactor/fermenter combinationsExcrement fertilisersBiogasLivestock

The invention relates to a livestock manure charring fertilizer making system, and solves the problems of large quantity and great disposal difficulty of livestock manure in livestock breeding sites. The device comprises a solid-liquid separator, a liquid outlet of the solid-liquid separator is connected to a methane tank, and a biogas slurry outlet of the methane tank is connected to liquid storage cylinders. A solid outlet of the solid-liquid separator is connected to charring furnaces, one sides of the charring furnaces are provided with combustion furnaces supplying heat, discharge ports of the charring furnaces are connected to the liquid storage cylinders, liquid outlets of the liquid storage cylinders are connected to a drain pipe, solid outlets of the liquid storage cylinders are connected to a granulator, and the granulator is connected to a dryer. The equipment provided by the invention carries out solid-liquid separation on livestock manure, conducts solid charring, and liquid adsorption with the charred solid to prepare a carbon-based fertilizer for returning to filed, reduces direct discharge of livestock manure, and recycles the liquid for flushing of breeding sites, reduces water consumption, and saves water resources.

Owner:浙江长兴布莱蒙农业机械科技有限公司

Ordinary mortar containing regenerated fine aggregate

The invention discloses ordinary mortar containing regenerated fine aggregate. The ordinary mortar containing the regenerated fine aggregate is characterized by comprising the following materials in parts by weight: 210 parts of cement, 90 parts of coal ash, 150 to 600 parts of regenerated fine aggregate and 900 to 1350 parts of artificial sand, wherein the regenerated fine aggregate is obtained by mechanically crushing waste concrete, and the grain size of the regenerated fine aggregate is 1.9 mm. Various performance indexes of the ordinary mortar containing the regenerated fine aggregate meet the requirements of related standard, norm and engineering use, the direct discharging quantity of building wastes is reduced, the ordinary mortar containing the regenerated fine aggregate is economic and environment-friendly, the problem that the waste concrete generated by daily increment of disassembling and modification projects of the original buildings (structures) cannot be treated properly is solved, and the tensile adhesive strength of the ordinary mortar containing the regenerated fine aggregate is obviously higher than that of the ordinary mortar without the regenerated fine aggregate.

Owner:DALIAN UNIV OF TECH

High-efficiency household range hood

InactiveCN107435966AReduce direct emissionsImprove smoking efficiencyDomestic stoves or rangesLighting and heating apparatusEngineeringAir blower

The invention discloses a high-efficiency household range hood, which comprises a range hood. The interior of the range hood is sequentially provided with racks and partitions from top to bottom. The partition is provided with grooves. Both ends are provided with limit blocks, the groove is provided with a smoking device matching the groove, the bottom of the range fume table is fixed with a primary filter, and the top of the range fume table is provided with a smoke exhaust device. The top of the inner wall of the range fume table is provided with a smoke box, the top of the inner wall of the smoke box is fixedly installed with a blower, and the output end of the blower is connected with a smoke inlet pipe. This high-efficiency household range hood, through the setting of the smoking device, enables the smoking device to move left and right between the partitions, so that it can absorb the oil fume floating from any direction at the bottom of the range hood, and improves the smoking efficiency of the smoking device. It is convenient for people to use, and reduces the direct discharge of oil fume, effectively protecting the environment.

Owner:岑立峰

Reverse osmosis device and reverse osmosis treatment system for treating high-concentration sewage

ActiveCN103848479AReduce fouling on the membrane surfaceReduce membrane foulingWater/sewage treatment bu osmosis/dialysisReverse osmosisHigh concentrationSewage

The invention relates to a reverse osmosis device and a reverse osmosis treatment system for treating high-concentration sewage. The reverse osmosis device comprises a housing and a connecting rod which is arranged at the center of the housing, wherein a connection flange and a tail end flange, which are connected to two ends of the housing in a sealing manner, are respectively provided with a sewage inlet, a permeate outlet and a concentrated liquid outlet, a plurality of layers of laminar flow discs and filter membrane assemblies are sleeved on the connecting rod, a permeate passage which is communicated to the permeate outlet is arranged between each laminar flow disc and the connecting rod, an inner opening of each filter membrane assembly is communicated to the permeate passage, a plurality of elongated distributing holes are uniformly distributed on each laminar flow disc and close to a central hole, and the surface of each laminar flow disc is provided with a plurality of spoke-shaped guide passages along the radiation direction of the elongated distributing holes. The reverse osmosis treatment system comprises a treatment device for evaporating the high-concentration sewage at a low temperature and the reverse osmosis device, wherein the treatment device comprises a sewage preheating assembly, an air preheating assembly, a low-temperature plate-type evaporation device and a recycling assembly. The reverse osmosis device has the advantages of high sewage treatment efficiency, high water yield, good water outlet effect, low energy consumption and the like and the service life of the membrane is long.

Owner:湖南北控威保特环境科技股份有限公司

Livestock manure harmless treatment technology

InactiveCN105906383AReduce direct emissionsReduce water consumptionBio-organic fraction processingClimate change adaptationLivestock manureWater resources

The invention relates to a livestock manure harmless treatment technology, and solves the problems of large quantity and great disposal difficulty of livestock manure. The technology comprises the steps of: 1. flushing a breeding site, and collecting livestock manure; 2. performing solid-liquid separation on the excrement, conveying the liquid to liquid storage cylinders, and transporting solid to a carbonization furnace; 3. conducting solid high temperature carbonization to form a carbonized solid; 4. putting the carbonized solid into liquid storage cylinders, and conducting static adsorption of ammonia nitrogen in the liquid; 5. after adsorption of ammonia nitrogen by the carbonized solid, carrying out crushing granulation to form a granular fertilizer; and 6. drying and sieving the granular fertilizer to form a carbon-based fertilizer finished product. The technology provided by the invention carries out solid-liquid separation on the livestock manure, performs carbonization on the solid, and conducts adsorption on the liquid with the carbonized solid to prepare the carbon-based fertilizer for returning to filed, reduces direct discharge of livestock manure, also reduces water consumption, and saves water resources.

Owner:浙江长兴布莱蒙农业机械科技有限公司

Metallurgical furnace

InactiveCN106996695ASmall footprintReduce configuration height differenceCharge treatment typeFurnace typesSlagElectric energy

The invention provides a metallurgical furnace. A melting reduction cavity and a depletion cavity which are communicated are formed by a furnace body of the metallurgical furnace, a main nozzle communicated with a chamber of the melting reduction cavity is formed in the wall of the melting reduction cavity, the main nozzle is used for spraying ore charges into the melting reduction cavity, the ore charges are melted, a plurality of depletion electrodes are arranged on the wall of the depletion cavity, the ends of the multiple depletion electrodes are inserted into molten liquid in the depletion cavity to carry out depletion reduction on the molten liquid, and a metal discharging opening and a slag discharging opening are formed in the wall of the depletion cavity. The metallurgical furnace can solve the problems that in the prior art, the smelting flow needs a large amount of electric energy or coke, consequently, the cost of lateritic ore smelting is high, and a lateritic ore smelting plant is difficultly built in the area without electricity or lack of electricity.

Owner:CHINA ENFI ENGINEERING CORPORATION

Mobile collection and treatment system of exhaust gas, peculiar smell, dust and paint mist and processor

InactiveCN106902635AReduce concentrationProtect your healthGas treatmentDispersed particle filtrationAir cleaningExhaust fumes

The invention provides a mobile collection and treatment system of exhaust gas, peculiar smell, dust and paint mist and a processor, and relates to the field of an air purification device. The mobile collection and treatment system comprises a strutting apparatus, a collecting apparatus and a processing apparatus. The strutting apparatus is equipped with a touchdown end and a telescopic structure for height adjustment. The collecting apparatus is provided with an exhaust gas collection port, which is in fixed connection with the strutting apparatus for adjusting the height with the telescopic structure. The processing apparatus is used for treating exhaust gas collected by the collecting apparatus and is provided with a walking structure facilitating movement. The strutting apparatus is put on the ground by using the touchdown end, and the processing apparatus is provided with the walking structure facilitating walking, so that the whole collection and treatment system can be moved and arranged conveniently and is convenient for being disposed near the working space. The exhaust gas collection port moves with the telescopic structure of the strutting apparatus, adjusts the height, can accurately adjust the position of the exhaust gas collection port, and facilitates improvement of exhaust gas collection efficiency.

Owner:赖斌

Waste gas treatment equipment and process

PendingCN107754553AImprove adsorption capacityImprove release abilityGas treatmentDispersed particle separationEnvironmental engineeringSmall footprint

The invention provides waste gas treatment equipment and exhaust gas treatment process, and belongs to the field of waste gas treatment. The waste gas treatment equipment comprises a cooling device and a waste gas treatment pipeline, wherein an air outlet of the cooling device is connected with the waste gas treatment pipeline; the waste gas treatment pipeline is filled with a loofah sponge; the waste gas treatment pipeline comprises an inlet pipe, an intermediate pipe and an outlet pipe which communicate in sequence; the pipe diameter of the intermediate pipe is smaller than those of the inlet pipe and the outlet pipe; one end of the inlet pipe is provided with a gas inlet communicating with the cooling device; and one end of the outlet pipe is provided with an gas outlet. The treatment process comprises three steps of cooling, reducing treatment and micro-treatment. The waste gas treatment equipment provided by the invention has the advantages of simple structure, small volume, smalloccupied area, small power, and low manufacturing cost; and the waste gas treatment process has the advantages of less steps, short flow and convenient operation, can greatly reduce the waste gas treatment cost, and is suitable for treating waste gases generated by various industries of rubber and plastic, cast iron, paint spraying and the like.

Owner:绍兴市英强橡塑科技有限公司

Device for purifying tail gas dust-haze of automobile

InactiveCN103422949AReduce direct emissionsIncrease temperatureInternal combustion piston enginesExhaust apparatusAtmospheric airSewage

The invention relates to a device for purifying tail gas dust-haze of an automobile, which aims at eliminating tail gas dust-haze, improving the air quality, improving the environmental condition and ensuring human health. The device for purifying tail gas dust-haze comprises an exhaust tube and a silencer, and is characterized in that a barrier filter screen is arranged in the silencer; the silencer is partitioned into at least two units by the barrier filter screen; the silencer is made into a water tank type silencer; liquid is injected into the silencer; an exhaust tube inlet, an exhaust tube outlet and a liquid injection hole are formed in the top of the silencer; a liquid sewage draining hole is formed in the bottom of the silencer; and a high-edge indicator for monitoring the water level is arranged in the silencer. The device has the beneficial effects that the tail gas dust-haze of the automobile is purified; and if about 200,000,000 existing used automobile in China are refitted and new automobiles which are not delivered are arranged according to the design, automobile tail gas pollutants which are directly discharged into the atmospheric air can be reduced greatly, the environmental protection level is raised, and the environmental temperature is improved.

Owner:苏立暖

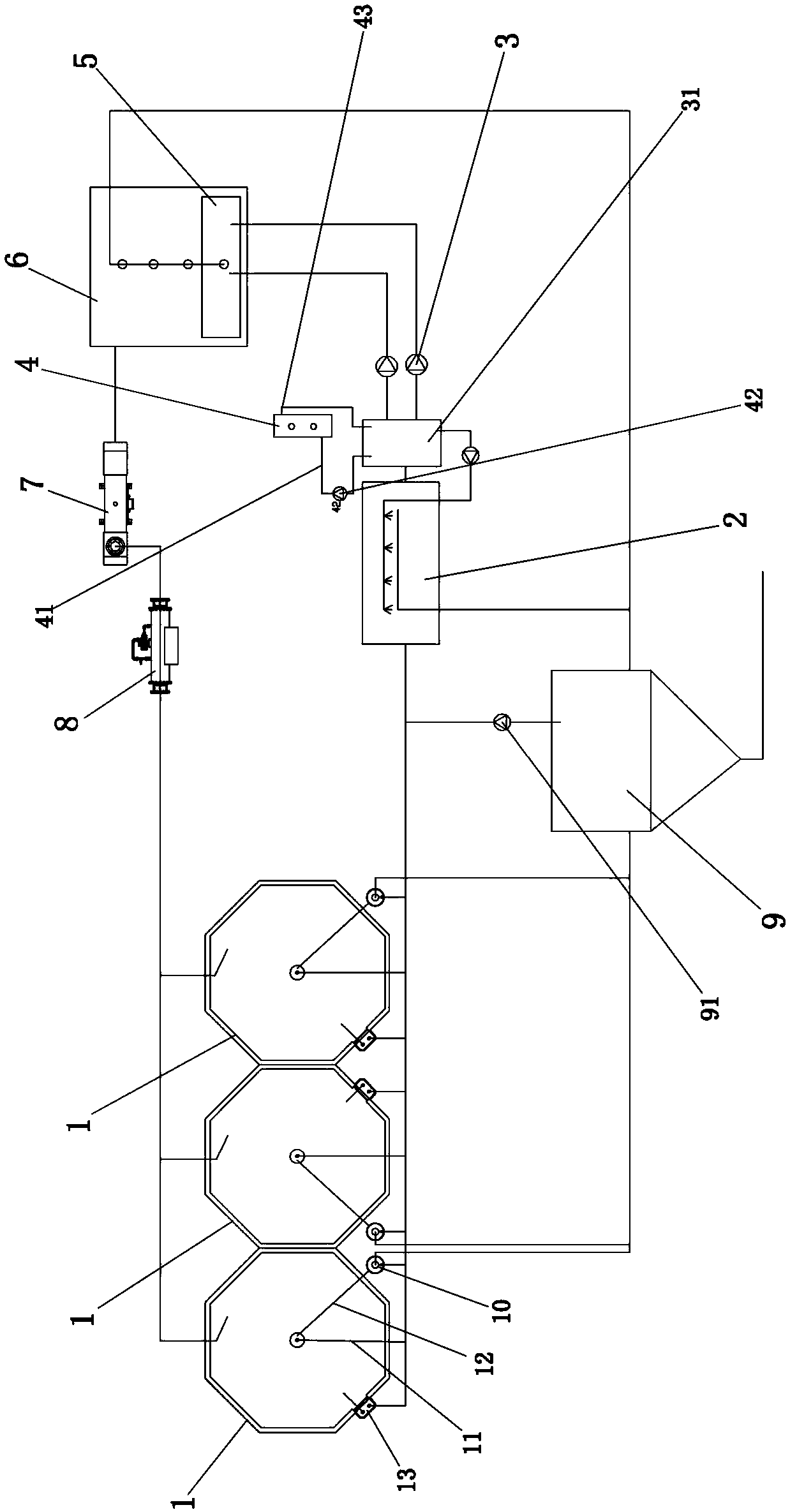

Aquaculture system with anaerobic denitrification device

InactiveCN110720420ASolve the accumulationReduce water changesPisciculture and aquariaAntiseptic sterilizationWater trap

The invention discloses an aquaculture system with an anaerobic denitrification device, which comprises a circulating aquaculture pond, a microfilter, a water pump, a denitrification device, a CO2 stripping trickle biofilter, a movable biological filter bed, an ultraviolet sterilizer, an efficient pure oxygen mixer and a sedimentation pond; the anaerobic denitrification device is a cylinder or a cuboid, a carbon source released by solid denitrification is used as a biological filler to serve as a carrier for anaerobic denitrification bacteria, and a carbon source and transfer electrons can beprovided for denitrification through biodegradation; a sedimentation pond sewage collection system is used for collecting regularly discharged sewage from a vortex solid-liquid separator, the microfilter and the biofilter, a supernatant liquid of the sedimentation pond sewage collection system can be used again in the circulating water culture system, and a sedimentation liquid can be used for pressing to prepare vegetable organic fertilizers; the invention truly realizes zero discharge of the industrialized circulating aquaculture system, and the system is suitable for high-density industrialized circulating aquaculture of various freshwater and seawater high-quality fish varieties.

Owner:张丽

Method and device thereof for stably burning various fuel gases with high-low calorific values

InactiveCN101614394BStable combustionIncrease disturbanceGaseous fuel burnerSmelting processProcess engineering

The invention relates to a method for stably burning various fuel gases with high-low calorific values, wherein the fuel gases are divided into four independent fuel gas channels according to high, medium and low calorific values and are arranged in a concentric mode, the nozzle orifices of the fuel gas channels are arranged in layers at intervals at the outlet of a burning device, and air ducts are arranged between the fuel gas channels and blow out air in rotational flow and direct flow modes respectively to cooperate with fuel gas jet flows to achieve highly stable burning; and multi-channel, independent type and multi-hole crossing jet flows are formed to achieve the highly stable burning of various fuel gasses with high, medium and low calorific values. The method solves the problemsof reasonably and effectively utilizing various byproduct gases generated in the smelting processes by iron and steel enterprises, and the method achieves the interchanging highly stable burning of various gasses with high, medium and low calorific values by using the principle of various orifice resistances and flow rate difference characteristics.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Cumquat seedling culture method

InactiveCN107896781AReduce cumbersome stepsImprove germination rateBiocideCalcareous fertilisersFertilizerDisease

The invention discloses a cumquat seedling culture method, and belongs to the technical field of cumquat planting. The method includes the following steps of S1, germinating seeds; S2, preparing a seedling breeding land, and applying special seedling breeding fertilizer; S3, sowing the seeds; S4, managing water and fertilizer; S5, preventing and treating diseases and insect pests, and spraying anti-disease and anti-insect liquid; S6, completing the culturing of cumquat seedlings and directly transplanting the cumquat seedlings out of the seedling breeding land to be planted when the cumquat seedlings grow to be 35-45 cm high. By means of the method, the emergence rate and survival rate of the cumquat can be increased, and the cumquat seedlings are uniform in growth vigor, high in uniformity, strong in resistance, low in plant morbidity and beneficial for later-period planting management; the cumquat seedling cultured through the method can be directly planted, and the problems of mutation, variety degeneration, fruiting delay and the like of cumquat after planting can be solved.

Owner:荔浦市万家兴果蔬专业合作社

Livestock manure harmless treatment device

InactiveCN105906410AReduce direct emissionsReduce water consumptionWater contaminantsWaste water treatment from animal husbandryFecesCombustion

The invention relates to a livestock manure harmless treatment device, and solves the problems of large quantity and great disposal difficulty of livestock manure in livestock breeding sites. The equipment comprises a solid-liquid separator, and a liquid outlet of the solid-liquid separator is connected to liquid storage cylinders; a solid outlet of the solid-liquid separator is connected to carbonization furnaces, one sides of the carbonization furnaces are provided with combustion furnaces supplying heat, the discharge ports of the carbonization furnaces are connected to the liquid storage cylinders, liquid outlets of the liquid storage cylinders are connected to a drainage pipe, solid outlets of the liquid storage cylinders are connected to a granulator, and the granulator is connected to a dryer. The equipment provided by the invention carries out solid-liquid separation on the livestock manure, performs carbonization on the solid, and conducts adsorption on the liquid with the carbonized solid to prepare a carbon-based fertilizer for returning to filed, reduces direct discharge of livestock manure, also recycles the liquid for flushing of breeding sites, reduces water consumption, and saves water resources.

Owner:浙江长兴布莱蒙农业机械科技有限公司

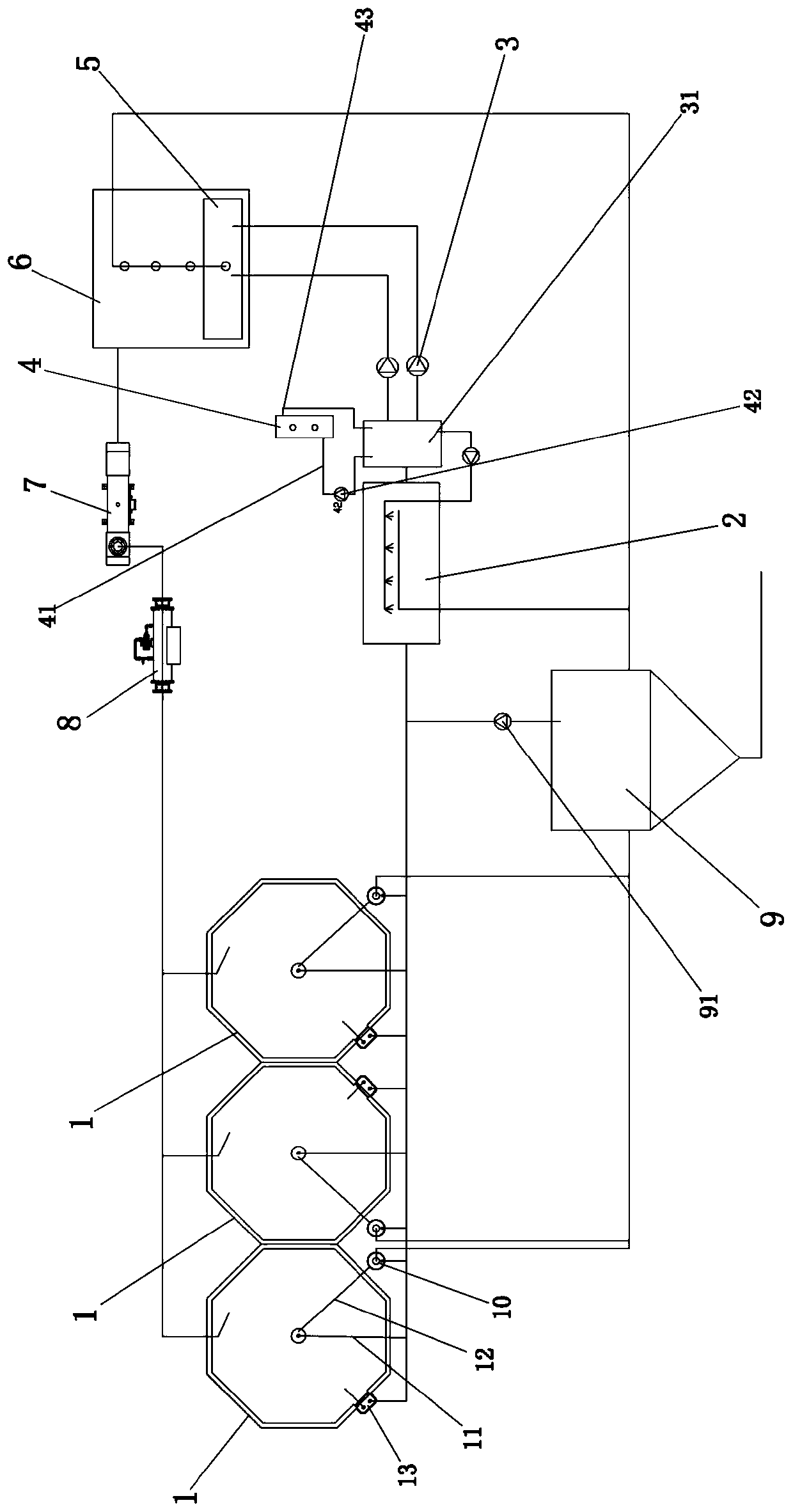

Fuel gas type aluminum enamel heating curing oven capable of recycling residual heat in flue

ActiveCN103278019AReduce direct emissionsReduce pollutionIncreasing energy efficiencyWaste heat treatmentFlueExhaust fumes

The invention relates to a fuel gas type aluminum enamel heating curing oven capable of recycling residual heat in a flue. The fuel gas type aluminum enamel heating curing oven capable of recycling the residual heat in the flue comprises a furnace body 4 and a transport device 1, wherein a low temperature zone 12 and a high temperature zone 11 are arranged in the furnace body 4, two heat exchange chambers 9 are respectively arranged on portions of the furnace body 4, where the low temperature zone 12 and the high temperature zone 11 are arranged on, and a circulating fan 6, a combustor 7 and a fuel gas type combustion engine 8 are arranged in each heat exchange chamber 9. A smoke discharge pipeline 2 of a combustor of the low temperature zone 12 can directly discharge smoke out of the furnace body 4, and a long waste heat recovery pipeline 3 is connected between a smoke discharge pipeline 1 of a combustor of the high temperature zone 11 and the combustor 7, and furthermore the waste heat recovery pipeline 3 sequentially passes through the high temperature zone 11 and the low temperature zone 12 in the furnace body 4, then is connected to the smoke discharge pipeline 1 and finally extends out from the furnace body 4. The fuel gas type aluminum enamel heating curing oven capable of recycling the residual heat in the flue has the advantages of recycling heat energy of flue gas discharged from the combustor of the high temperature zone through the waste heat recovery pipeline, conveying the heat energy of the flue gas to the low temperature zone, adding heat energy of the low temperature zone, and fully recycling waste heat of the flue gas so as to achieve a purpose of energy conservation and emission reduction.

Owner:YANCHENG FEIYALI MACHINERY

Air conditioner condensate water recovery device

ActiveCN112984766AReduce direct emissionsIncrease profitCondensate preventionLighting and heating apparatusEnvironmental engineeringMechanical engineering

The invention relates to an air conditioner condensate water recovery device, and relates to the technical field of building. The device comprises a box body, a water inlet pipe and an irrigation pipe which are arranged on the box body, the water inlet pipe communicates with a water collecting disc of an air conditioner indoor unit, a plurality of flowerpots are arranged below the irrigation pipe, a plurality of irrigation openings corresponding to the flowerpots are formed in the bottom of the irrigation pipe, a water outlet communicating with the irrigation pipe is formed in the box body, and a switch valve for controlling the water outlet to be opened and closed along with the ascending and descending of the liquid level is arranged in the box body. The irrigation pipe is arranged, and the switch valve is used for controlling the water outlet to be opened and closed along with the ascending and descending of the liquid level, so that the collected condensate water passes through the irrigation pipe and then is irrigated on the flowerpots, the condensate water is prevented from being directly discharged to the outside, the condensate water is recycled, the energy-saving and environmental-friendly effects are achieved, and therefore, the air conditioner condensate water utilization rate is improved.

Owner:浙江韶华建设有限公司

Pipeline system for producing alkaline etching solution

PendingCN110107811AImprove product qualityExtended service lifeDispersed particle separationPipeline systemsResource utilizationProcess engineering

The invention discloses a pipeline system for producing an alkaline etching liquid. The pipeline system for producing the alkaline etching liquid comprises a production tank for producing the etchingliquid, a storage tank for storing the etching liquid, a tail gas discharge device for absorbing tail gas generated by the system and a tail gas treatment device for treating tail gas generated by thesystem, wherein the tail gas treatment device is connected with the tail gas discharge device; the production tank and the storage tank are respectively connected with each other through pipelines; the production tank is provided with a feeding pipeline for feeding; and the tail gas discharge device can absorb leaked gas in the production tank, the feeding pipeline and the storage tank. Accordingto the pipeline system for producing the alkaline etching liquid, the recycling of resources is achieved, the direct discharge of harmful gas or liquid is reduced, the energy is saved, the environment is protected, the production efficiency is improved, the production quality of the etching liquid is improved through a filtering pipeline, the components of the etching liquid in a collecting barrel and a water tank can be recycled, the resource utilization rate is improved, the cost is reduced, and the service life of the pipeline system is long.

Owner:惠州市鸿宇泰科技有限公司

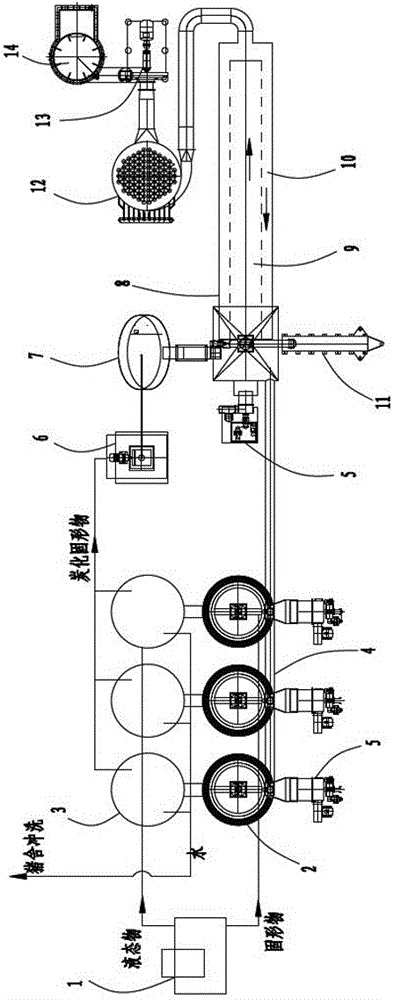

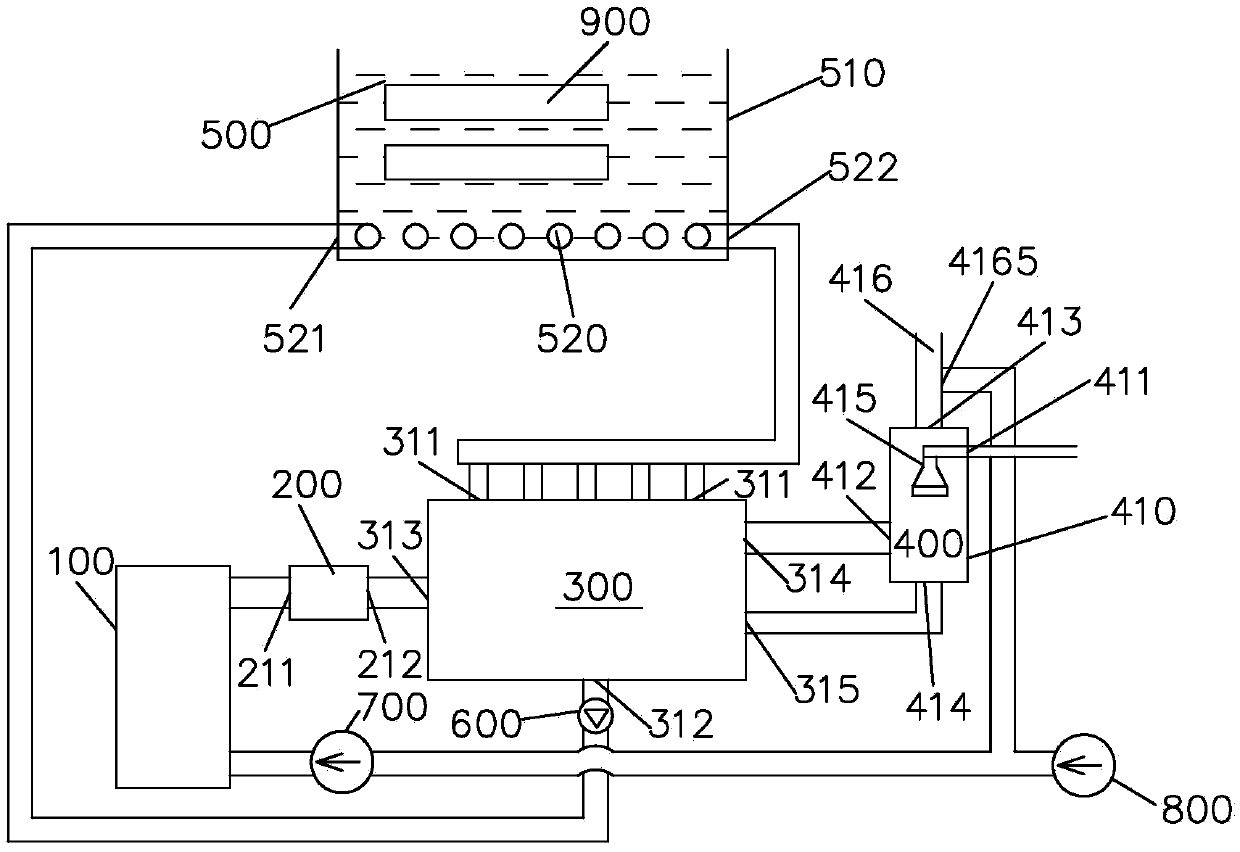

Low-carbon aluminum product oxidation heating system with biomass gasifier

ActiveCN105369230AReduce pollutionHigh thermal efficiencyLighting and heating apparatusEnergy inputCombustorEngineering

The invention discloses a low-carbon aluminum product oxidation heating system with a biomass gasifier. The system comprises the biomass gasifier, a burner, a primary spraying heat-exchange chamber, a secondary spraying heat-exchange chamber and an aluminum product oxidation pond. Biomass gas generated in the biomass gasifier is combusted in the burner and exchanges heat with water in the primary spraying heat-exchange chamber and the secondary spraying heat-exchange chamber, hot water obtained after heat exchange enters a heat exchange coil pipe in the aluminum product oxidation pond to heat aluminum product oxidation liquid medicine, and part of smoke exhausted from the secondary spraying heat-exchange chamber enters the biomass gasifier again to be combusted. According to the system, heat generated by combustion of biomass fuel is used for heating the oxidation liquid medicine in the aluminum product oxidation pond, part of the smoke is guided to return to the biomass gasifier to be reutilized, smoke waste heat is fully utilized, and low carbon and environment protection are achieved.

Owner:GUANGDONG HAOMEI ALUMINUM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![An experiment system and an experiment method used for studying dielectric barrier discharge processing of SF[6] gases An experiment system and an experiment method used for studying dielectric barrier discharge processing of SF[6] gases](https://images-eureka.patsnap.com/patent_img/93f46ca5-cf8c-4ab1-8623-4a0925de9a8a/HDA0000916457760000011.PNG)

![An experiment system and an experiment method used for studying dielectric barrier discharge processing of SF[6] gases An experiment system and an experiment method used for studying dielectric barrier discharge processing of SF[6] gases](https://images-eureka.patsnap.com/patent_img/93f46ca5-cf8c-4ab1-8623-4a0925de9a8a/HDA0000916457760000012.PNG)

![An experiment system and an experiment method used for studying dielectric barrier discharge processing of SF[6] gases An experiment system and an experiment method used for studying dielectric barrier discharge processing of SF[6] gases](https://images-eureka.patsnap.com/patent_img/93f46ca5-cf8c-4ab1-8623-4a0925de9a8a/HDA0000916457760000021.PNG)