Fuel gas type aluminum enamel heating curing oven capable of recycling residual heat in flue

A flue waste heat, heating and curing technology, used in lighting and heating equipment, furnaces, waste heat treatment and other directions, can solve problems such as large energy loss and hidden safety hazards in production workshops, reduce energy consumption and production costs, reduce direct emissions, The effect of reducing environmental pollution and safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

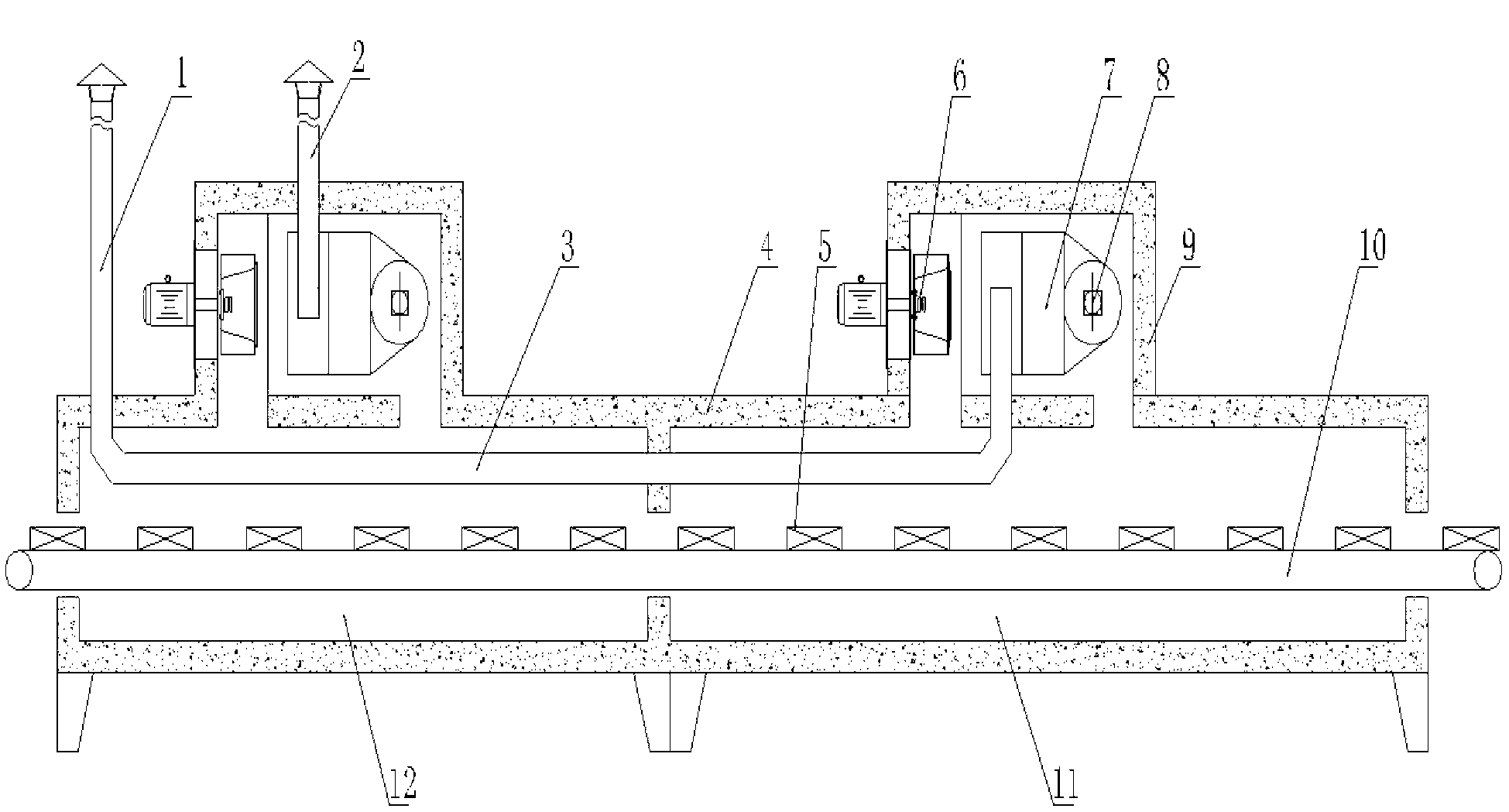

[0012] The aluminum enamel heating and curing furnace of the present invention includes a furnace body 4 and a conveying device 10 , the conveying device 10 is arranged in the furnace chamber of the furnace body 4 , and can drive the workpiece 5 to be heated to pass through the furnace chamber of the furnace body 4 .

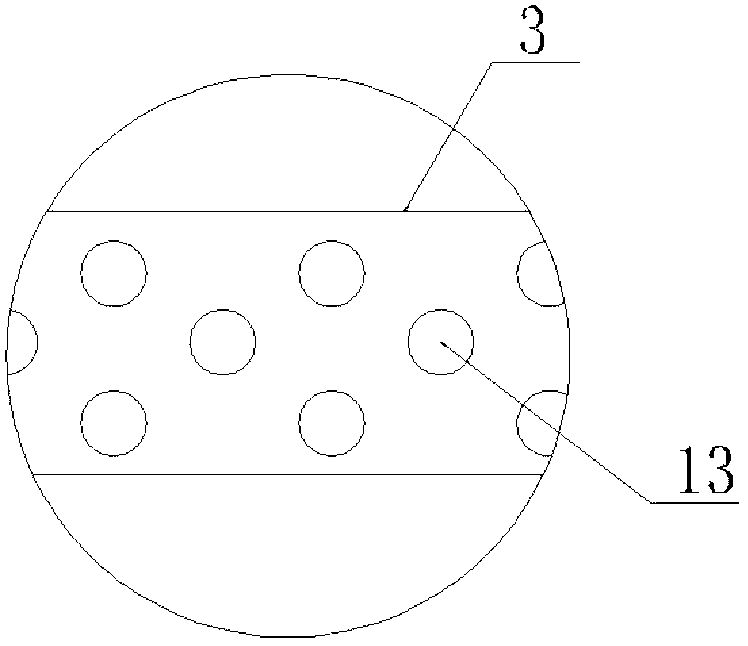

[0013] The furnace body 4 is provided with a low temperature zone 12 and a high temperature zone 11, and the furnace body 4 of the low temperature zone 12 and the high temperature zone 11 are respectively provided with a heat exchange chamber 9. Each heat exchange chamber 9 is provided with a circulation fan 6 , a combustion chamber 7 and a gas burner 8 . The combustion head of the gas-fired burner 8 is arranged in the combustion chamber 7, the circulation fan 6 is fixed on the heat exchange chamber 9, and the combustion chamber 7 is provided with exhaust pipes 1,2.

[0014] The smoke exhaust pipe 2 of the combustion chamber in the low temperature zone 12 is dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com