Pipeline system for producing alkaline etching solution

A pipeline system and etching solution technology, applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., can solve problems such as low resource utilization, low environmental protection, and difficult system maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

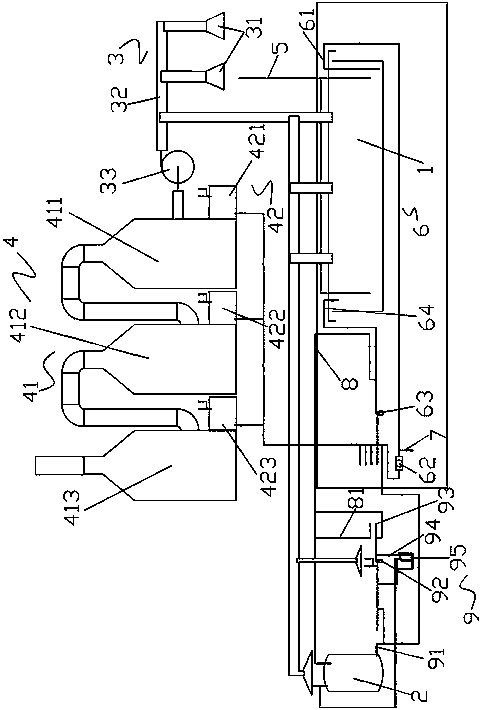

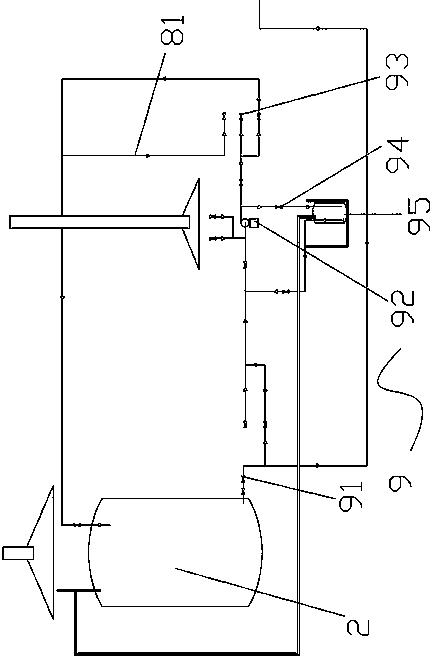

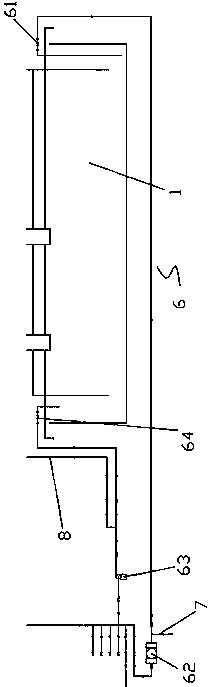

[0019] The technical solutions protected by the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0020] With reference to accompanying drawing, a kind of pipeline system that alkaline etching solution is produced comprises the production tank 1 that is used for etching solution production, the storage tank 2 that is used to store etching solution, the tail gas discharge device 3 that the tail gas that system produces is absorbed, and The tail gas treatment device 4 for treating the tail gas generated by the system, the tail gas treatment device 3 is connected with the tail gas discharge device 4, the production tank 1 and the storage tank 2 are connected to each other through pipelines, and the etching solution prepared in the production tank 1 is finished or semi-finished It is transported to the storage tank 2 through pipelines. When the etching solution in the storage tank 2 needs to adjust the concentration o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com