Low-carbon aluminum product oxidation heating system with biomass gasifier

A heating system and biomass gas technology, applied in lighting and heating equipment, reducing greenhouse gases, producing combustible gas, etc., can solve the problems of limited utilization of biomass gas, single energy supply method, and large environmental hazards, and achieve the goal of supplying The thermal effect is stable, the heat exchange area is increased, and the pollution degree is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

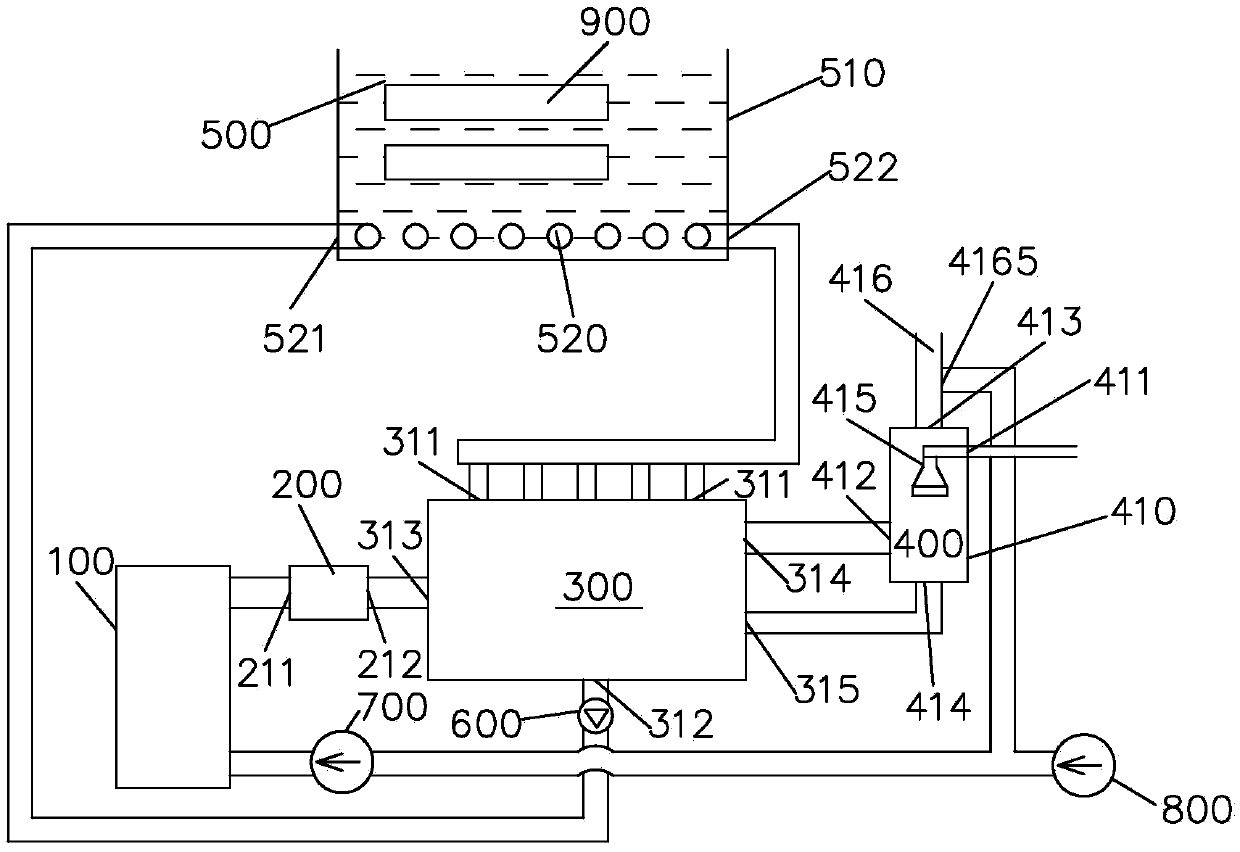

[0039] Please refer to figure 1 According to one embodiment of the present invention, the low-carbon aluminum oxidation heating system using a biomass gasifier includes: a biomass gasifier 100, a burner 200, a primary spray heat exchange chamber 300, a secondary spray Heat exchange chamber 400, aluminum material oxidation pool 500, water pump 600, fan 700.

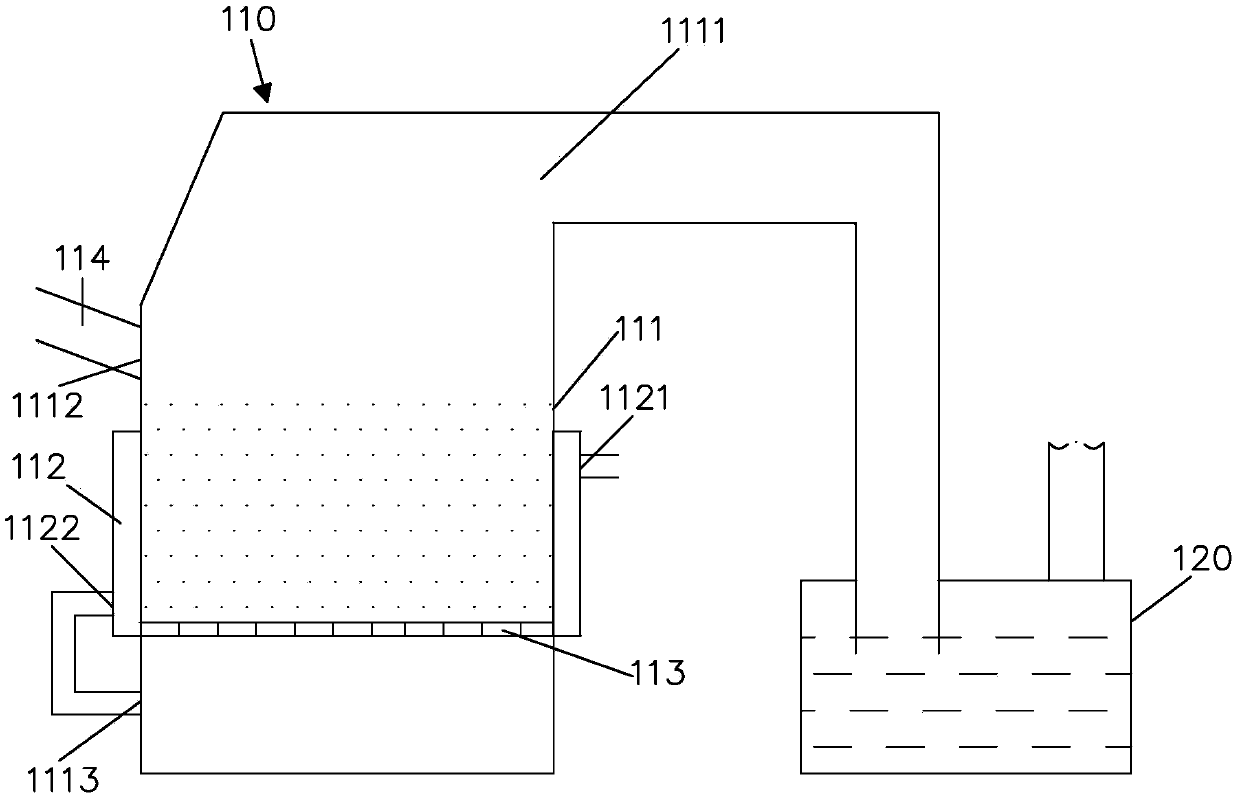

[0040] Such as figure 2 As shown, the biomass gasifier 100 includes a furnace body 110 for generating biomass gas. The furnace body 110 includes a main body 111 , an air jacket 112 located at the middle and lower part of the main body 111 and arranged around the main body 111 , a fire grate 113 located at a lower position inside the main body 111 , and a feed pipe 114 located on the side wall of the main body 111 . The side wall of the body 111 is provided with a biomass feed port 1112, a biomass gas outlet 1111 for discharging biomass gas, a gasification agent inlet 1113 is provided at the lower side of the side wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com