Patents

Literature

82results about How to "Promote gasification reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluid bed electrode direct carbon fuel cell device

InactiveCN102324539AImprove performanceEasy inflowCell electrodesFuel cell auxillariesElectrochemical responseSolid carbon

The invention discloses a fluid bed electrode direct carbon fuel cell device, which belongs to the technical field of clean energy. The device comprises a fluid bed, two or more tubular single cells, collector plates, a composite carbon fuel, a gas circulating device, a screw feeder and a fuel tank. In the device, a conductor catalyst is added into a solid carbon fuel on the basis of a solid oxide direct carbon fuel cell to expand a direct electrochemical reaction interface of carbon from a two dimension to a three dimension and promote the gasification reaction of the carbon, thereby improving the performance of the cell; the collector plates are distributed on the wall surface of a reactor, so current is convenient to collect; and simultaneously, a fluid bed reactor forms a fluid bed electrode to further enhance heat transfer and mass transfer in the electrode, so not only problems about feeding are solved, but also the performance of the solid oxide direct carbon fuel cell is further improved.

Owner:TSINGHUA UNIV

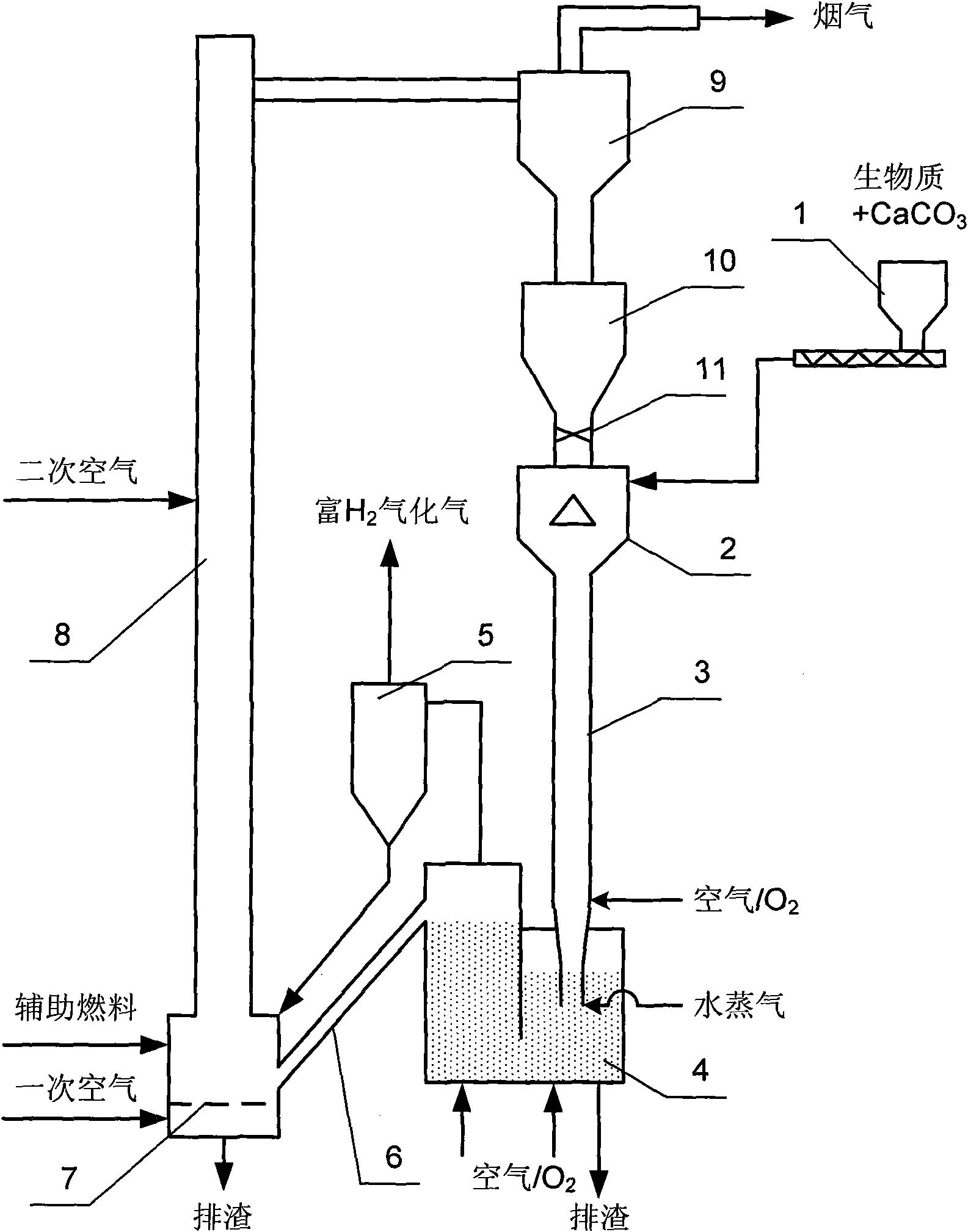

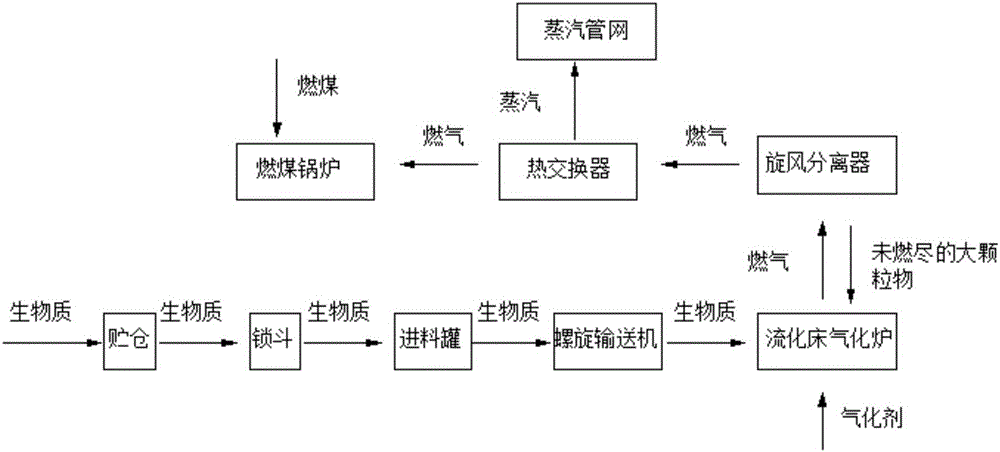

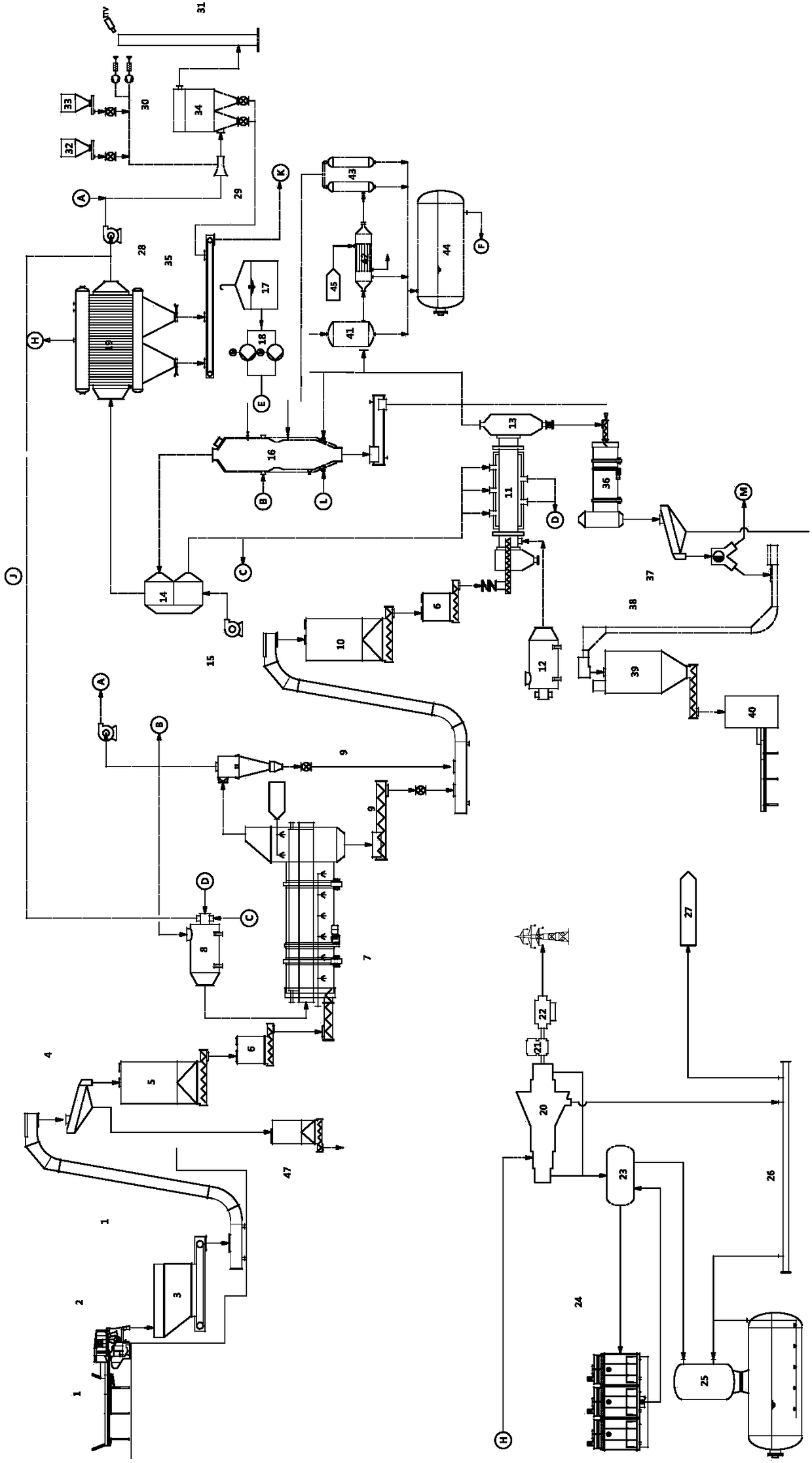

Gasification device and method for preparing hydrogen-rich synthetic gas from biomass

ActiveCN101880552AAvoid aggregate growthUniform temperature distributionGranular/pulverulent flues gasificationTarHeat carrier

The invention provides a gasification device and a gasification method for preparing hydrogen-rich synthetic gas from biomass. The device comprises a biomass feeder, a mixer, a pyrolysis chamber, a gasification chamber, a gasified gas separator, a combustion chamber, a flue gas separator, a bin and a butterfly valve. In the method, the biomass gasifying process is divided into three parts, namelybiomass pyrolysis, semicoke gasification and heat carrier circulation. Through the method and the device, the synthetic gas with the tar content less than 200mg / Nm<3> and the H2 / CO ratio more than 1.1 can be obtained, and the energy utilization rate and the process economy are obviously improved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Coal underground gasification process system

InactiveCN104018820AIncrease horizontal widthIncrease widthConstructionsCoal gasificationThermodynamicsWater vapor

The invention relates to a coal underground gasification process system. The coal underground gasification process system comprises a gasification agent injection drill hole, coal gas outlet drill holes, a main gasification channel, branch gasification channels, a drill hole supporting tube, a gasification agent injection tube, a combustion agent injection tube, a sealing device and an ignition point shifter. The gasification agent injection drill hole is connected with the coal gas outlet drill holes through the main gasification channel and the branch gasification channels, and the combustion agent injection tube is sleeved with the gasification agent injection tube and is connected through the sealing device. A gasification process includes the steps of carrying out ignition, judging whether water vapor is fed into, feeding into water vapor, judging whether an ignition point is moved forward, starting the ignition point shifter and continuing to conduct combustion. The coal underground gasification process system has the advantages that the transverse gasification area and longitudinal gasification area can be enlarged, coal reserves for gasification are increased, autoignition and controllable back gas injection are achieved in a well-free coal underground gasification process, meanwhile the problem of short circuit of gasification agents in the gasification channels is solved, the probability of back mixing of product gas and the gasification agents is lowered, and safety operation of the gasification process is guaranteed.

Owner:北京中矿科能煤炭地下气化技术研究中心

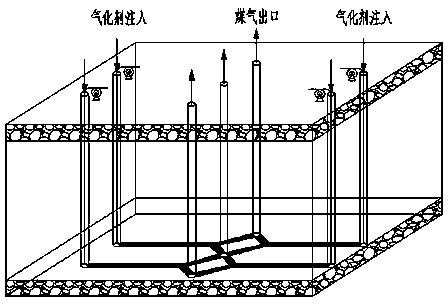

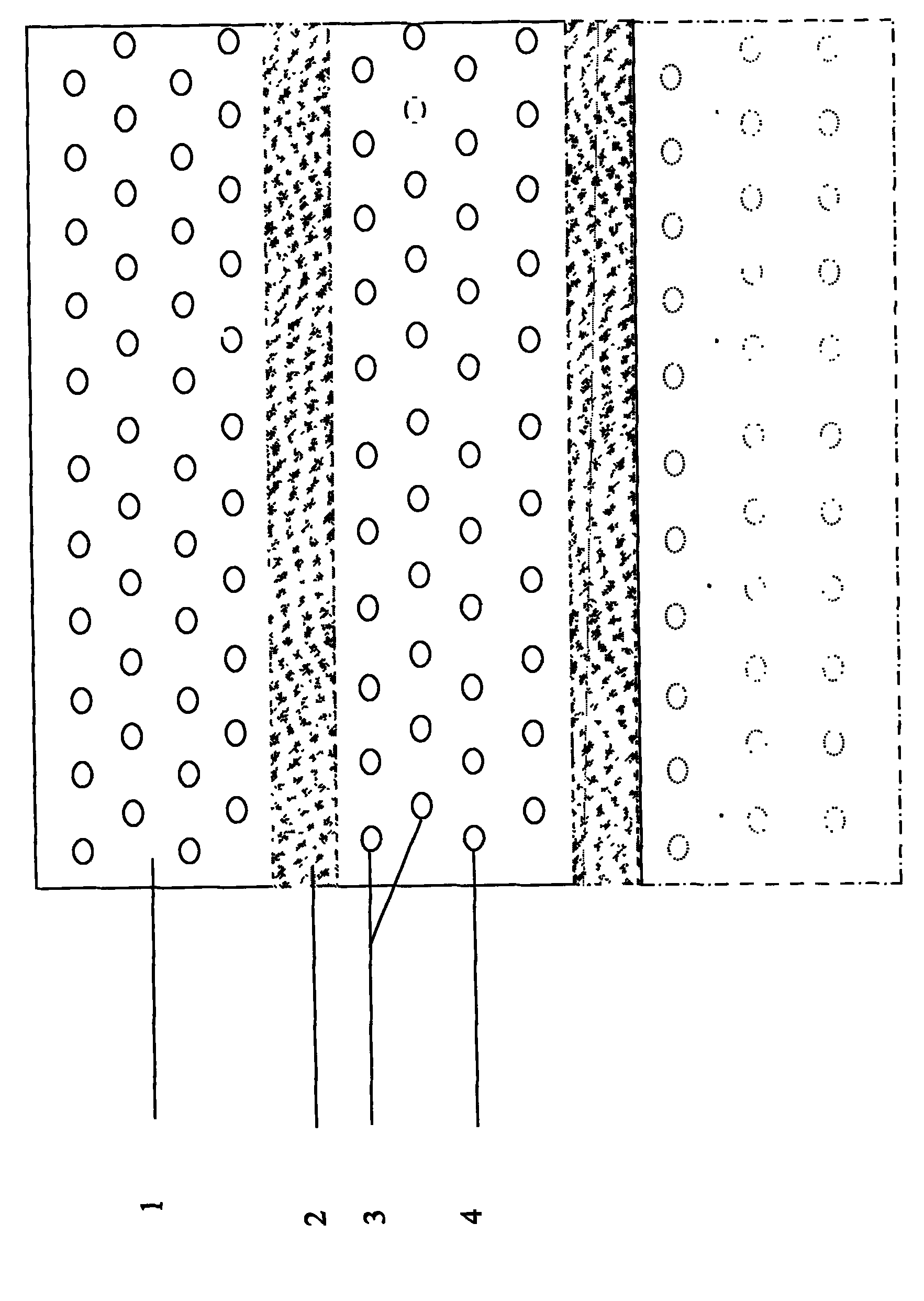

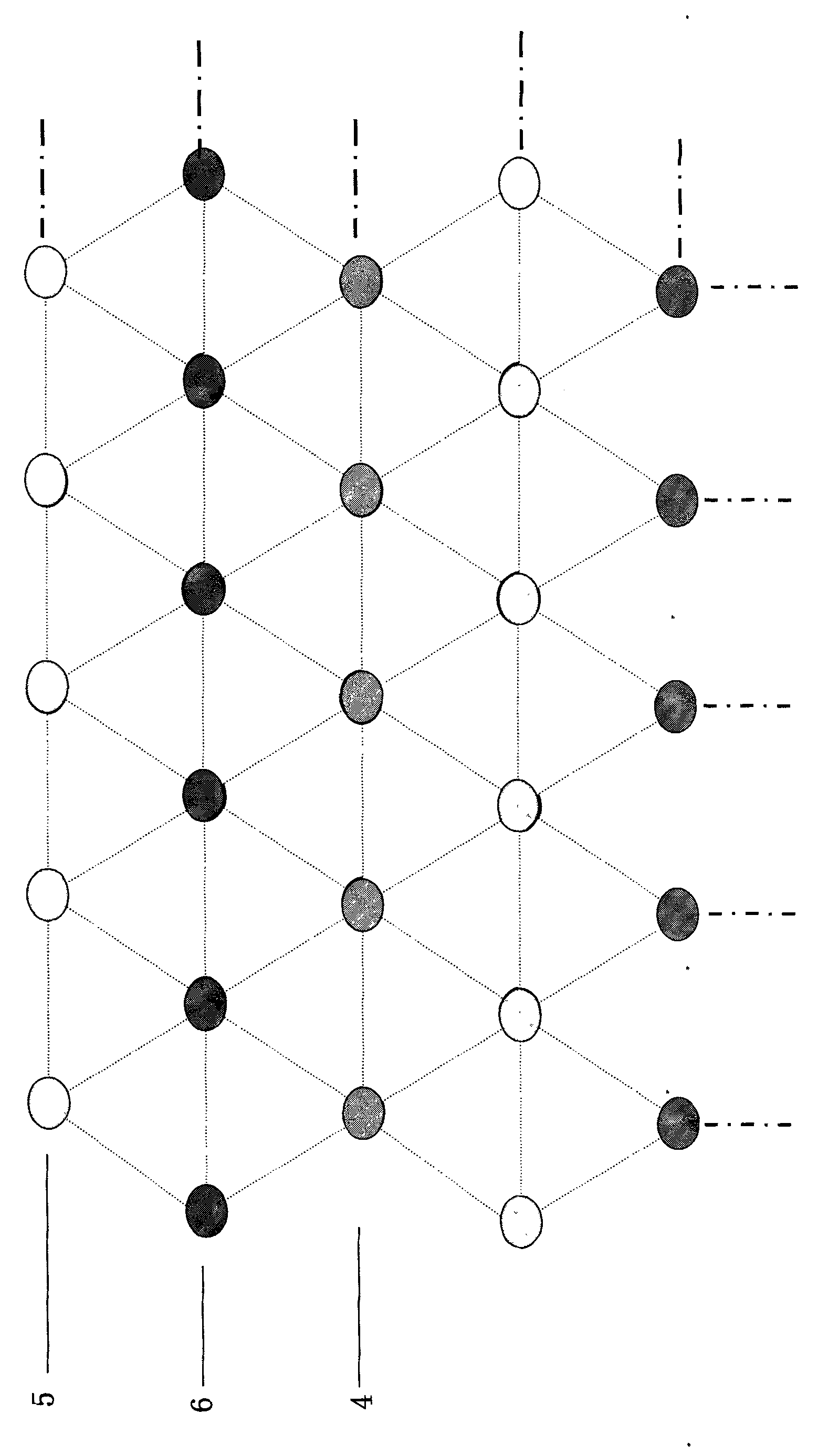

A method for underground coal gasification

InactiveCN102287177AEfficient developmentChange areaConstructionsFluid removalMultiple injectionChemical reaction

An underground coal gasification method. The method comprises disposing multiple injection wells (3) and gas collection wells (4) in a gasification operation zone; adding a catalyst and a propping agent into injection wells and gas collection wells by means of a fluid medium; fracturing and reforming the coal layer using a fracturing device to form large areas of fissures and cracks; forming gasification paths in the form of directional wells between the injection wells and gas collection wells; adding a gasification agent, a catalyst, and water through the injection wells to cause coal layer combustions and chemical reactions; collecting at the gas collection wells the gas produced by means of collection devices. The fissure paths between the wells formed by reforming large fractures, and the metal mineral particles used as a propping agent for the paths between wells effectively enable the maintenance of the effective communication in the injection well network for long durations; the metal mineral particles also function as a catalyst and an aggregating agent during gasification, thereby substantially enhancing the coal gasification volume.

Owner:秦勇 +2

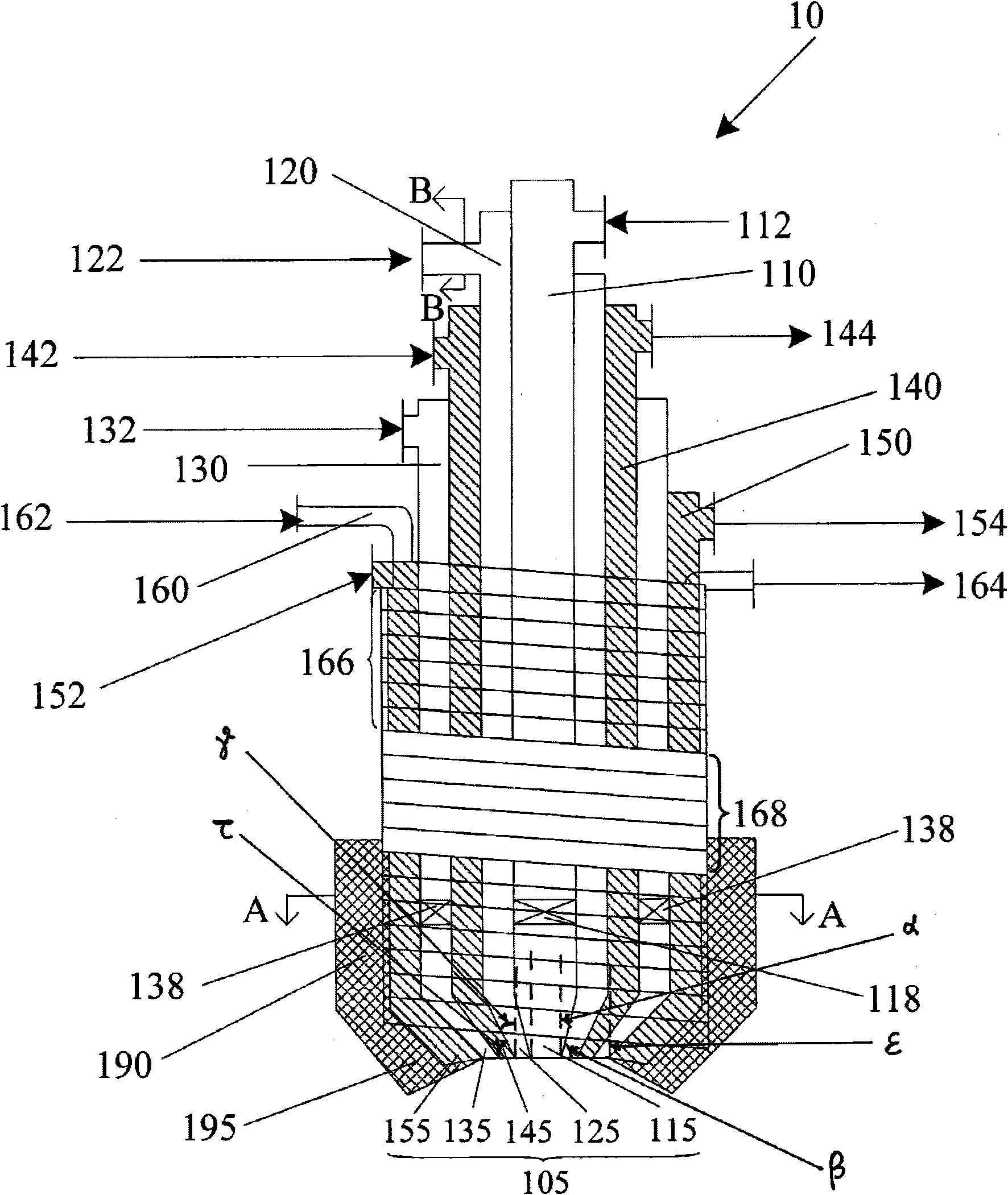

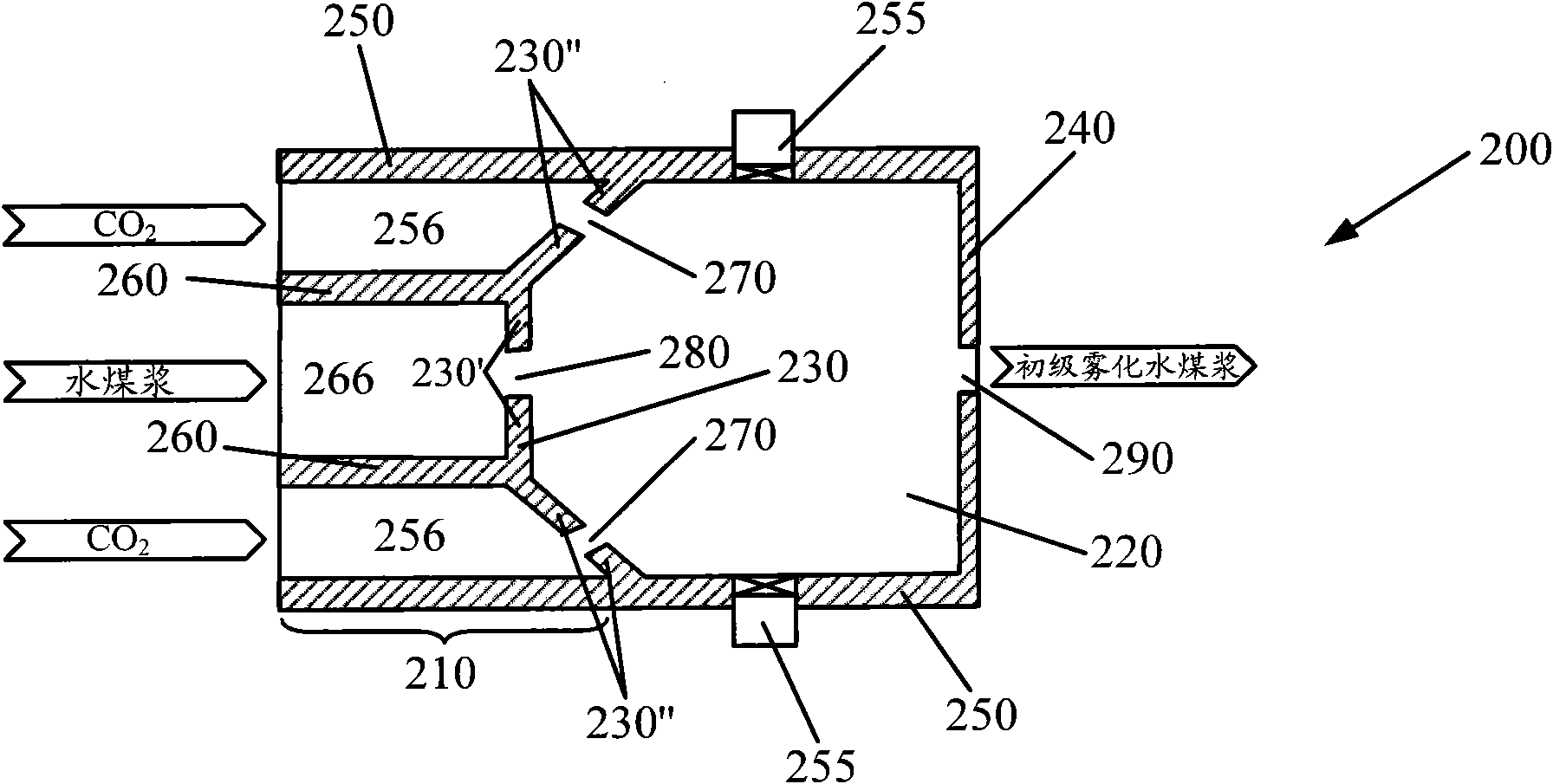

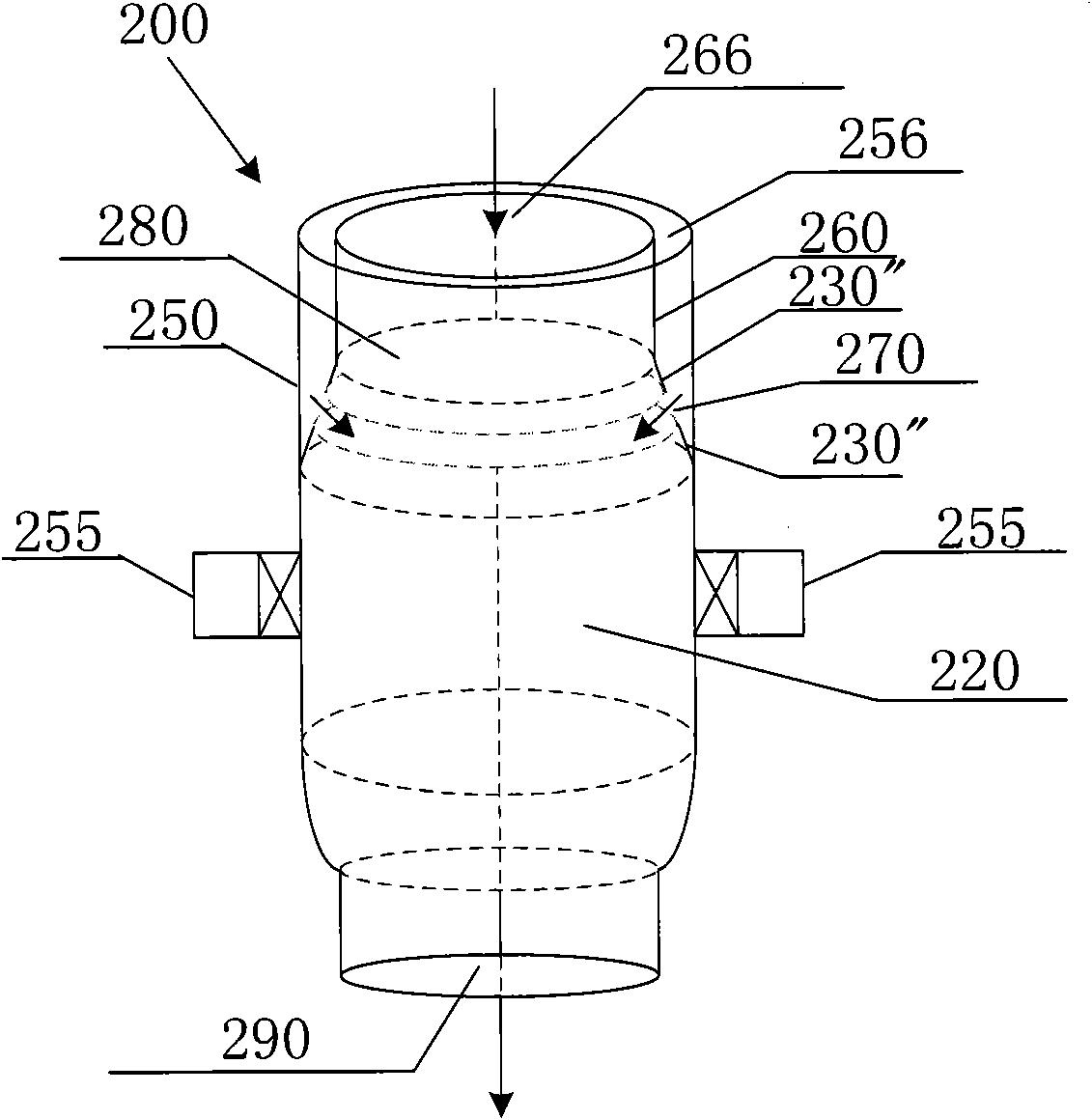

Process nozzle and system for gasifying water coal slurry and application thereof

ActiveCN102031152AEffective protectionImprove cooling effectLiquid spraying apparatusGranular/pulverulent flues gasificationCoal slurryWater jacket

The invention provides a process nozzle and a system for gasifying water coal slurry. The process nozzle comprises a first oxygen channel, a water coal slurry channel, a second oxygen channel, a first cooling water jacket and a cooling water coil, wherein the first oxygen channel comprises a first oxygen channel inlet and a first oxygen channel outlet; the water coal slurry channel comprises at least one water coal slurry channel inlet and a water coal slurry channel outlet; the second oxygen channel comprises a second oxygen channel inlet and a second oxygen channel outlet; the first cooling water jacket comprises a first cooling water jacket inlet and a first cooling water jacket outlet; and the cooling water coil comprises a cooling water coil inlet and a cooling water coil outlet. The process nozzle is characterized in that: the first oxygen channel is positioned at the central position of the process nozzle; the water coal slurry channel is positioned between the first oxygen channel and the second oxygen channel and surrounds the periphery of the first oxygen channel; and the second oxygen channel surrounds the periphery of the water coal slurry channel. The process nozzle reduces the length of combustion flame more effectively, reduces the ablation of flame on a refractory brick, promotes the mixing and atomization of water coal slurry and oxygen and improves gasification efficiency.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Multi-nozzle multi-stage oxygen supplying entrained-flow gasifier and gasification method thereof

ActiveCN102453550ASolution to short lifeSimple processHydrogenGranular/pulverulent flues gasificationSlagFire brick

The present invention discloses a multi-nozzle multi-stage oxygen supplying entrained-flow gasifier. The entrained-flow gasifier comprises a top closed type gasifier body, an ignition nozzle chamber, a gasifier outlet, and at least two process nozzle chambers, wherein process nozzles are arranged inside the process nozzle chambers. The entrained-flow gasifier further comprises at least two secondary oxygen supplying nozzle chambers, wherein secondary oxygen supplying nozzles are arranged inside the secondary oxygen supplying nozzle chambers, the secondary oxygen supplying nozzle chambers are arranged between the process nozzle chambers and the gasifier outlet, and are symmetrically arranged on the circumference of the gasifier body, and the secondary oxygen supplying nozzles are arranged inside the secondary oxygen supplying nozzle chambers. The present invention further discloses a gasification method of the gasifier. According to the gasification method, an oxidizing agent is introduced to the secondary oxygen supplying nozzle during the reaction process to promote the further gasification reaction. With the present invention, a plurality of the nozzles are adopted to carry out multi-stage oxygen supplying on the gasifier, such that the service life of the fire brick structure on the upper space of the gasifier is substantially prolonged so as to substantially improve the operating rate and the performance of the gasifier. In addition, with the present invention, the liquid slag tapping of the gasifier is ensured, and the phenomenon of slag blocking of the outlet is avoided.

Owner:EAST CHINA UNIV OF SCI & TECH

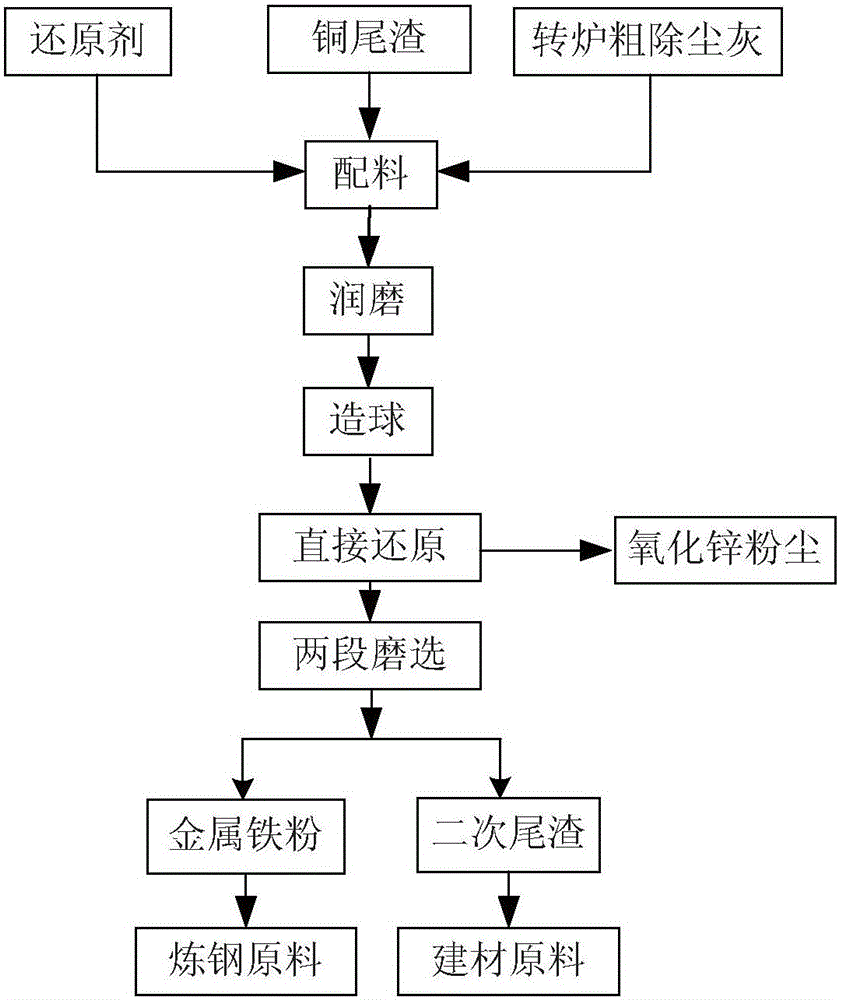

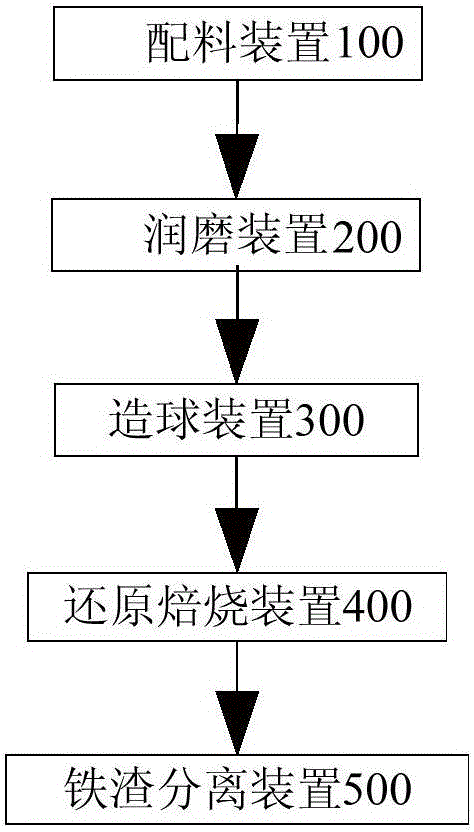

Method and system for comprehensive utilization of copper tailings and converter coarse dust ash

ActiveCN106676263AHigh activityPromote gasification reactionFluidised-bed furnacesBrickReducing agent

The invention provides a method and system for comprehensive utilization of copper tailings and converter coarse dust ash. The method and system relate to separating and enriching of iron and zinc in the copper tailings and the converter coarse dust ash. Specifically, the copper tailings, the converter coarse dust ash and a carbon-containing reducing agent are used as raw materials, and by means of material mixing, wet grinding-pelletizing, reduction roasting, and ore grinding-magnetic separation work procedures, metal iron powder and copper slag secondary tailings are obtained. The produced metal iron powder can serve as raw materials of steel making of an electric furnace or a converter, the copper slag secondary tailings can be used for producing building materials such as cement and baking-free bricks, and therefore iron resources and secondary tailings can be fully utilized, and the comprehensive utilization of the copper tailings and the converter coarse dust ash is achieved. The method can also meet the requirements of the non-ferrous industry, the iron and steel industry and the building material industry, and has good social and economic benefits.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

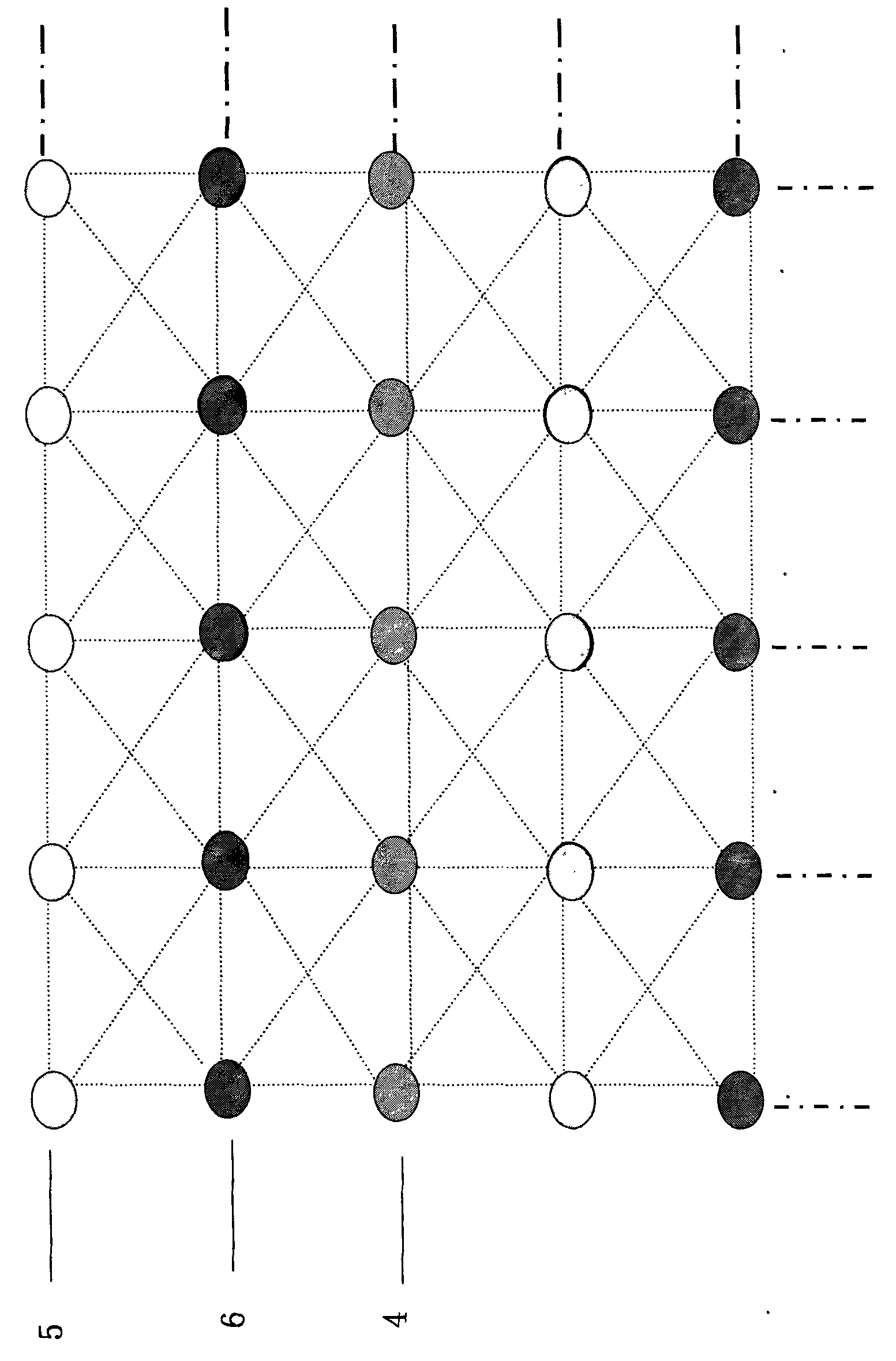

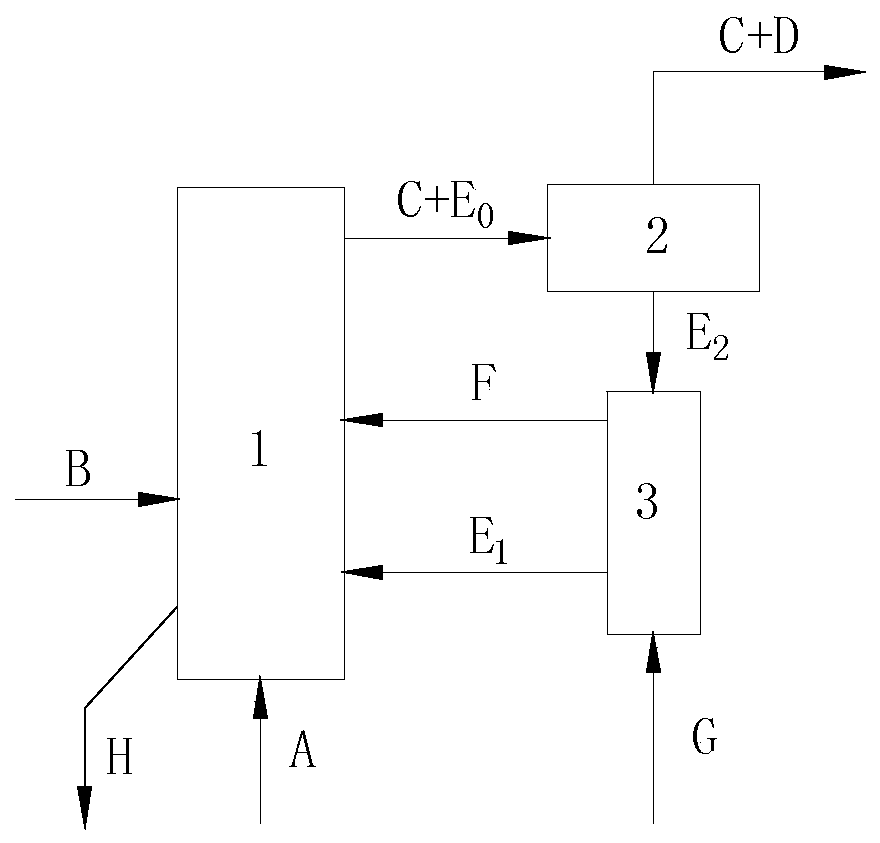

Method for separating CO2 through chemical looping combustion in coal pressure high-density circulating fluidized bed

ActiveCN102183014AIncrease the combustion reaction rateSolving the Response Matching ProblemFluidized bed combustionIndirect carbon-dioxide mitigationCycloneHigh density

The invention provides a method for separating CO2 through chemical looping combustion in a coal pressure high-density circulating fluidized bed, which comprises the following steps: coal particles and a gasifying agent are subjected to gasification reaction in a fuel reactor 1 of the coal pressure high-density circulating fluidized bed, and gasified products and oxygen carriers which return to the fuel reactor are subjected to combustion reaction to produce CO2 and H2O; smoke which is produced during the reaction and carries oxygen-lost oxygen carriers and carbon-containing coal ash enters a primary cyclone separator 2 for separation, and separated oxygen-lost oxygen carriers are in contact with transversely passing air for reaction in an air reactor 5 of a cross flow moving bed to be regenerated and are turned to the combustion reactor through a primary material returning device 8 to continuously participate in the combustion reaction; and separated smoke in the primary cyclone separator 2 further enters a secondary cyclone separator 10 for separation, solid particles secondarily separated are returned to the fuel reactor 1 through a secondary material returning device 13 to continuously participate in the combustion reaction, and H2O is removed from the separated gases through condensation to obtain high-purity CO2.

Owner:SOUTHEAST UNIV

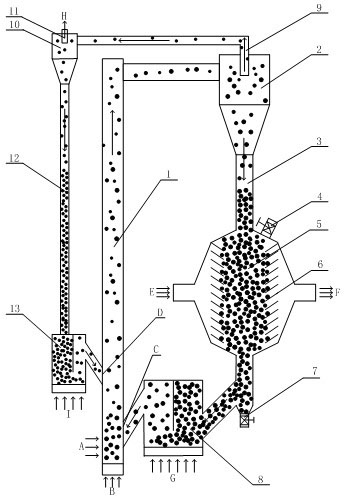

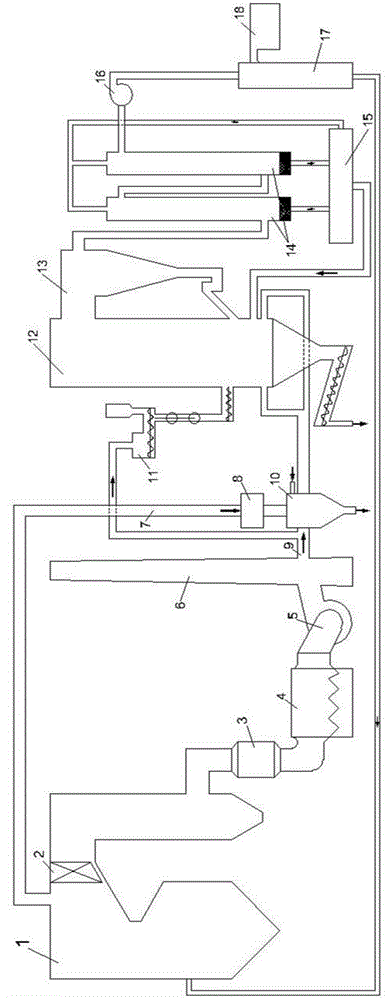

Biomass gasification power-generation process

InactiveCN106244246AHigh strengthImprove gasification efficiencyGasifier feeding meansGasification processes detailsParticulatesFood consumption

The invention discloses a biomass gasification power-generation process. The biomass gasification power-generation process comprises the following steps of step (I), pressurizing biomass granules until the gauge pressure is 0.1-4.0Mpa, then discharging materials to a charging tank, then conveying the discharged materials to a fluidized-bed gasifier, and performing a gasification reaction with a gasification agent so as to obtain fuel gas for standby application; step II, performing cyclone dust removal on the fuel gas prepared in step (I) through a cyclone separator, performing separation to obtain large particles which are not burn-out, and returning the large particles to the fluidized-bed gasifier for gasifying once again; and step (III), cooling the flue gas which is subjected to dust removal by the cyclone separator to 300-700 DEG C through a heat exchanger, and enabling the cooled flue gas to be led into a coal boiler to be subjected to mixed combustion with the coal for power generation. According to the biomass gasification power-generation process disclosed by the invention, the biomass granules are sent to a large-scale coal boiler through the fuel gas generated by gasification to be subjected to combined combustion with the coal for power generation, so that the coal consumption required for power generation is reduced, the amount of CO2 generated during combustion is reduced, greenhouse effects caused by CO2 can be alleviated, and emission of NOX by power plants is reduced.

Owner:武汉高斯生态能源技术有限公司

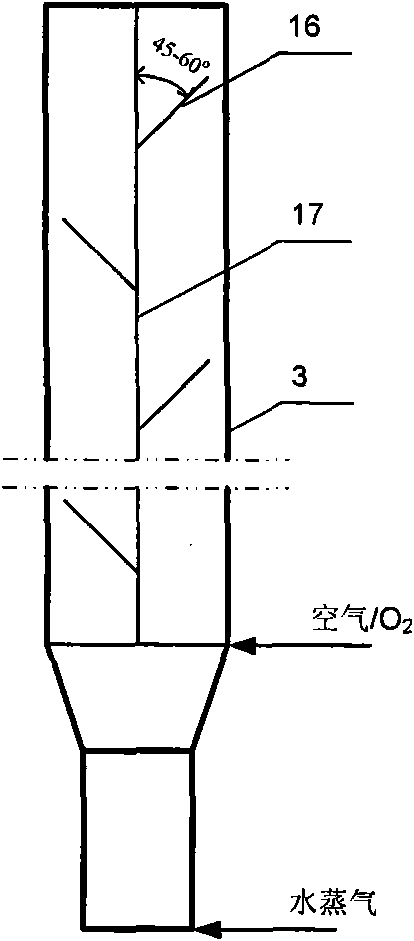

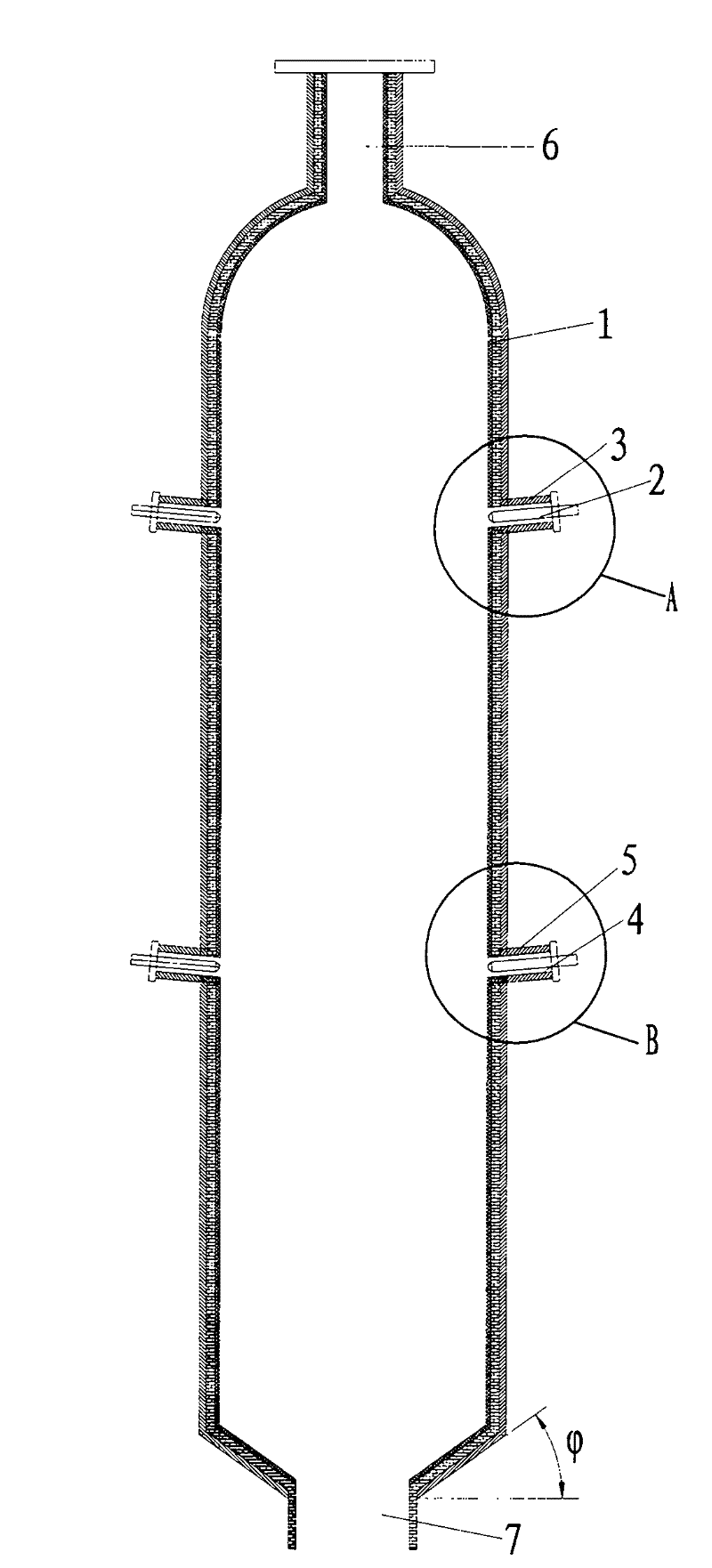

Coal underground gasification device and gasification method thereof

ActiveCN104564008ADoes not affect shockDoes not reduce the temperature excessivelyConstructionsFluid removalWater dischargeSprayer

The invention provides a coal underground gasification device and a gasification method of the coal. The device comprises an air injection pipe, a water inlet pipe arranged in the air injection pipe, and a sprayer fixedly connected with the air injection pipe; a water jacket communicated with the water inlet pipe is arranged outside the sprayer in sleeving manner; a plurality of water jetting holes for water to flow out are formed in the axial wall of the water jacket. Wherein, a water jetting control sleeve for controlling water discharge is arranged outside the water jacket in a sleeving manner, the water jetting control sleeve is connected with a pull rod sleeved with a spring; one end of the spring is fixed on the air injection pipe by a spring plate and the other end is placed against the water jetting control sleeve. The method comprises four steps of preparing, forming a low pressure gasification burned out area, cooling the sprayer and finishing the coal underground gasification. The temperature of the burned out area is not reduced excessively while the sprayer is protected, a fresh coal bed is cut completely to form more clearances, the ignition speed can be reduced, the temperature of the burned out area near the sprayer is reduced, the evaporation of water is reduced, and the permeability of underground coal bed is improved.

Owner:ENN SCI & TECH DEV

System for preparing high-caloric-value biomass gasified gas by using high-temperature flue gas of oxygen-enriched combustion boiler

ActiveCN104629809AImprove energy efficiencyImprove qualityGaseous fuel feeder/distributionEnergy inputThermal energyFluidized bed gasifier

The invention discloses a system for preparing biomass gasified gas by using flue gas of an oxygen-enriched combustion boiler. The system is characterized by comprising a circulating fluidized-bed gasifier and a cyclone separator, wherein the circulating fluidized-bed gasifier is provided with a charging opening which is used for inputting a biomass material to the circulating fluidized-bed gasifier; the circulating fluidized-bed gasifier is further provided with a gas inlet which is used for inputting the flue gas of the oxygen-enriched combustion boiler; the circulating fluidized-bed gasifier is used for gasifying the biomass material under the action of the flue gas of the oxygen-enriched combustion boiler, so as to obtain the gasified gas; the cyclone separator is connected with the circulating fluidized-bed gasifier and is used for separating the gasified gas. A biomass gasification system and an oxygen-enriched combustion boiler system are used in a matched manner, and the flue gas of the oxygen-enriched combustion boiler is adopted as a gasifying agent for biomass gasification reaction, so that the energy utilization efficiency of the oxygen-enriched combustion boiler system is increased, the quality of the biomass gasified gas is improved, the whole heat energy utilization efficiency is increased, and the production cost is reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

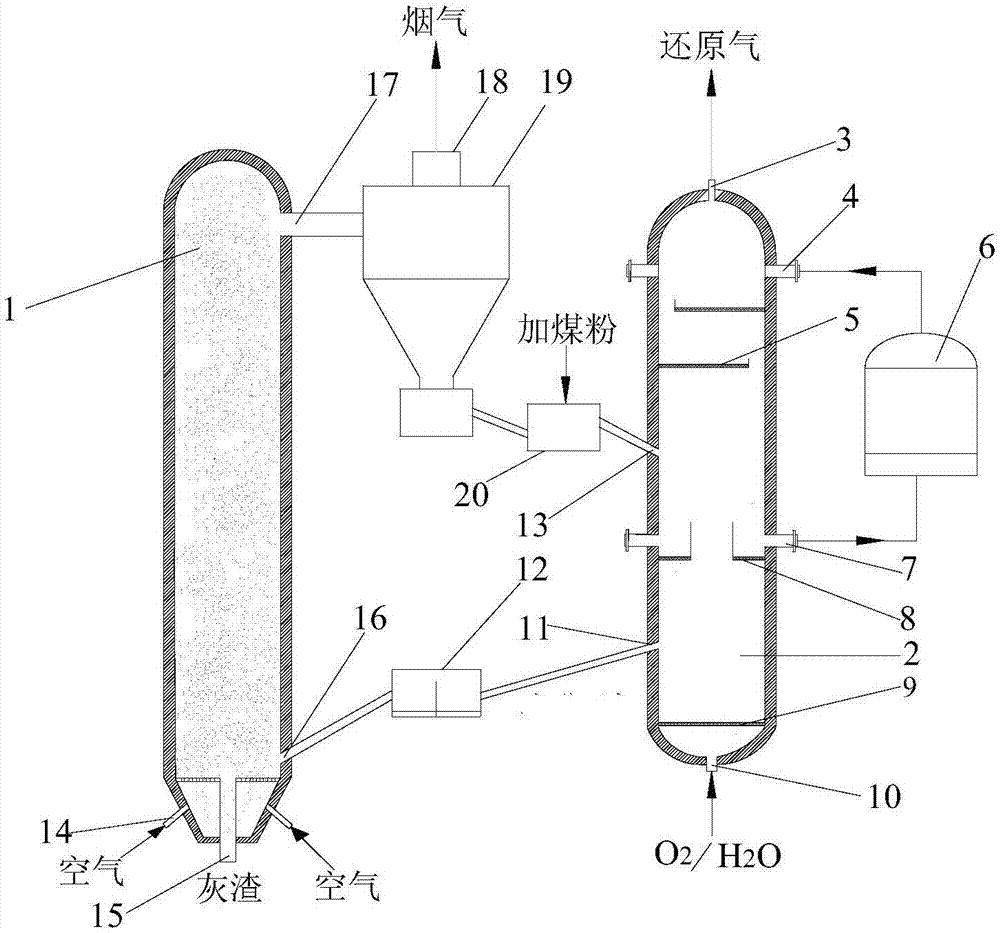

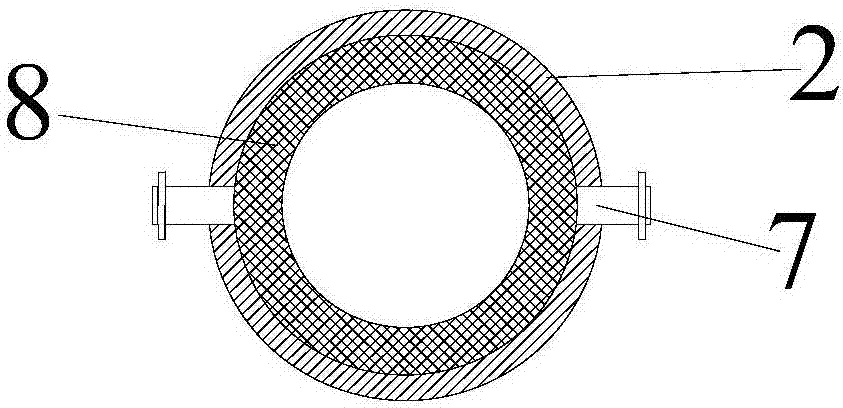

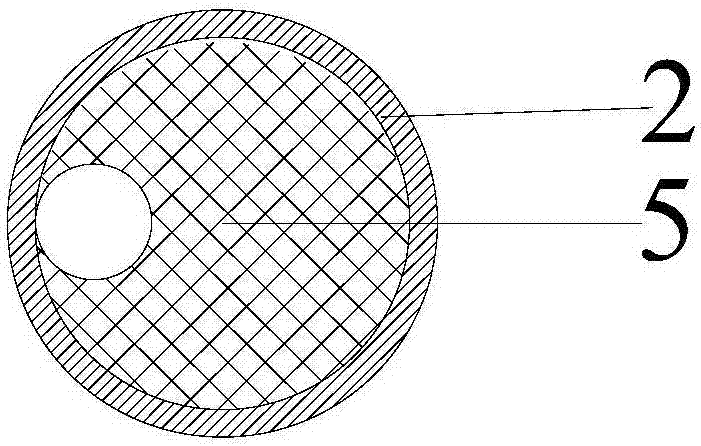

System and method for preparing reducing gas through lignite double-bed gasification

ActiveCN107118807ARich reservesGood catalytic propertiesGasification processes detailsGranular/pulverulent flues gasificationCombustionFlue gas

The invention provides a system and a method for preparing reducing gas through lignite double-bed gasification. The system comprises a combustion furnace, a gasification furnace, a gas solid separator, a material return device, a catalyst tank and a pulverized coal mixing device; the combustion furnace is provided with a flue gas outlet, a semi-coke / ash inlet, an ash residue outlet and an air inlet; a gasifying agent distribution plate, a semi-coke collecting plate and a catalyst supporting plate are arranged in the gasification furnace; a semi-coke / ash outlet, a semi-coke outlet, a catalyst inlet and a feeding port are formed in the side wall of the gasification furnace; the semi-coke / ash outlet is connected with the semi-coke / ash inlet through the material return device; the semi-coke outlet is connected with a catalyst inlet of the catalyst tank; the catalyst inlet is connected with a catalyst outlet of the catalyst tank; and the feeding port is connected with a discharging port of the pulverized coal mixing device. By utilization of the system, the reducing gas can be prepared from the lignite, and the reducing gas can be applied to a gas-based shaft furnace to perform direct reduction iron making without needing a conversion device to adjust gas components.

Owner:CERI ENERGY & AIR PROTECTION TECH CO LTD +1

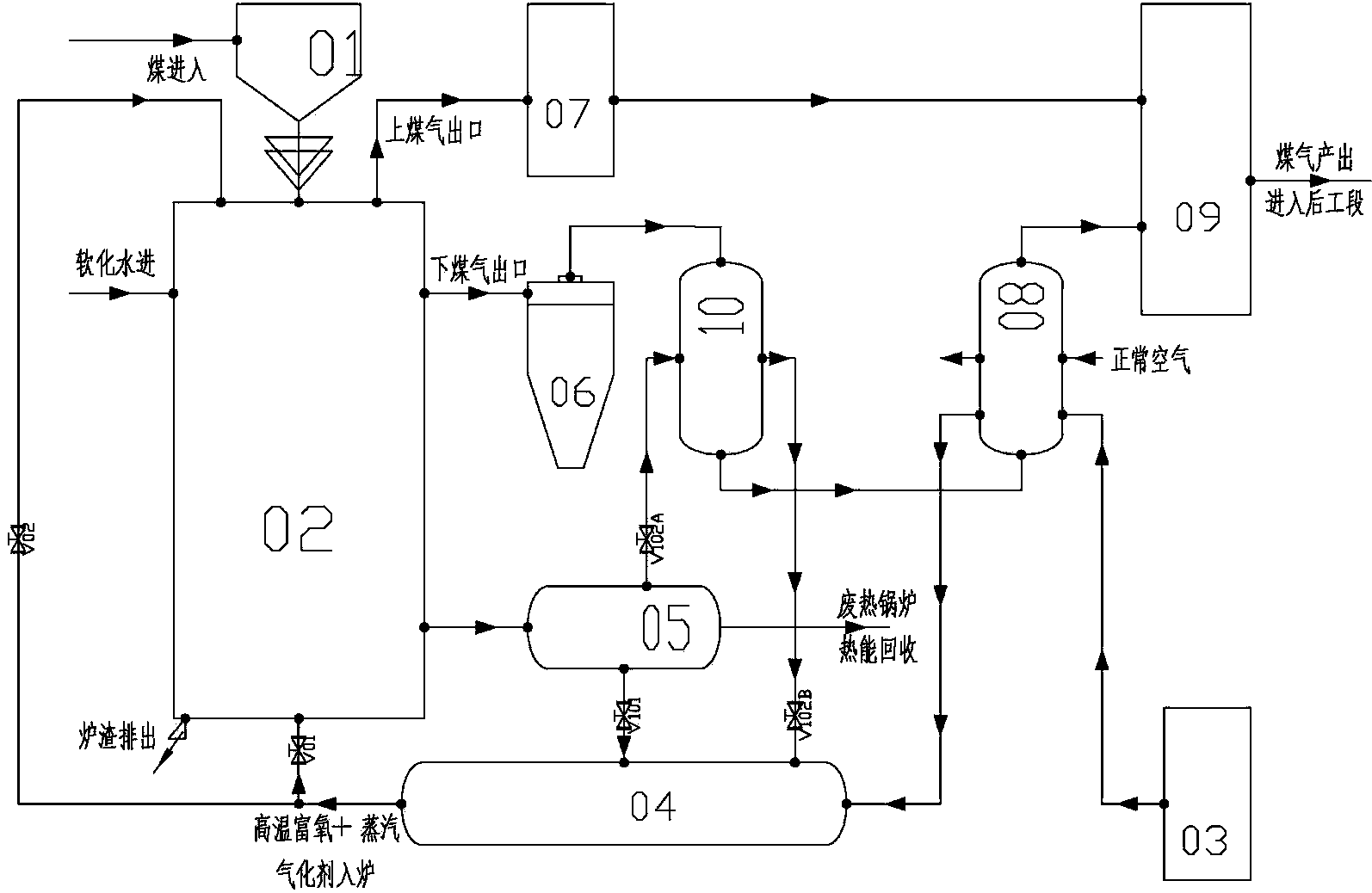

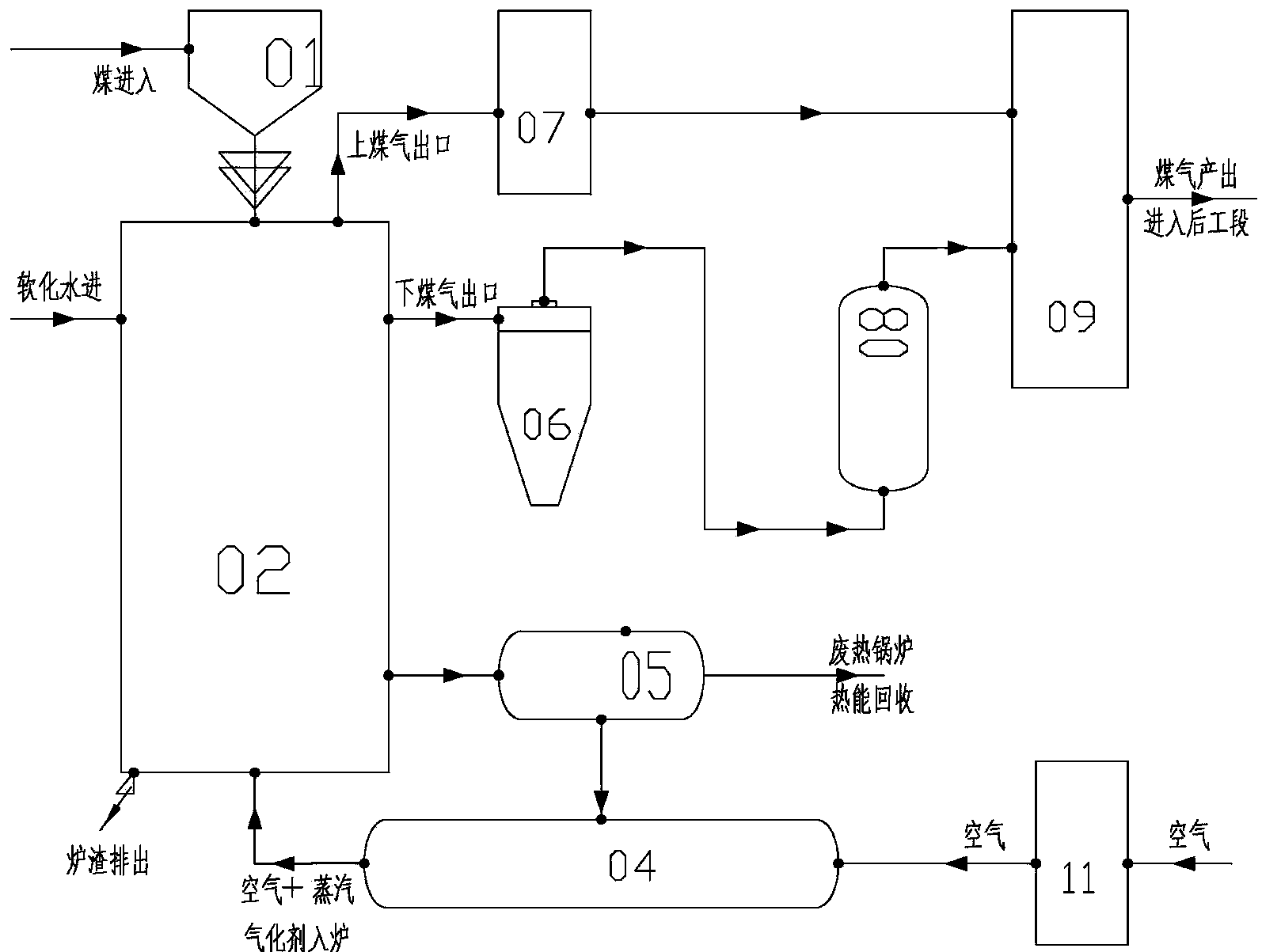

Coal gas production method and device using high-temperature rich oxygen and high temperature steam as gasification agent

ActiveCN103525465AReduce unit consumptionOvercoming technical defects of furnace gas productionCombustible gas productionFixed bedControl valves

The invention belongs to the technical field of chemical coal made gas, and particularly relates to a coal gas production method and device using high-temperature rich oxygen and high temperature steam as a gasification agent. The coal gas production method and device adopt oxygen-enriched air with the oxygen concentration of 25 ~ 30% and with the oxygen temperature of 120 ~ 220 DEG C and the high temperature steam with the temperature of 120 ~ 220 DEG C as the gasification agent for coal gas production; and accordingly, an oxygen-enriched air source and related a heat exchanger, a control valve and pipelines are additionally arranged in an original coal gas production device. The coal gas production method and device well overcome the technical defects of coal gas production by use of a traditional atmospheric-pressure fixed bed gas producer, increase the coal gas producer yield and the coal gas calorific value, reduce the carbon content of ash, and reduce sensible heat loss, and the coal gas unit consumption is reduced by 10 ~ 30%.

Owner:上海穗杉实业股份有限公司

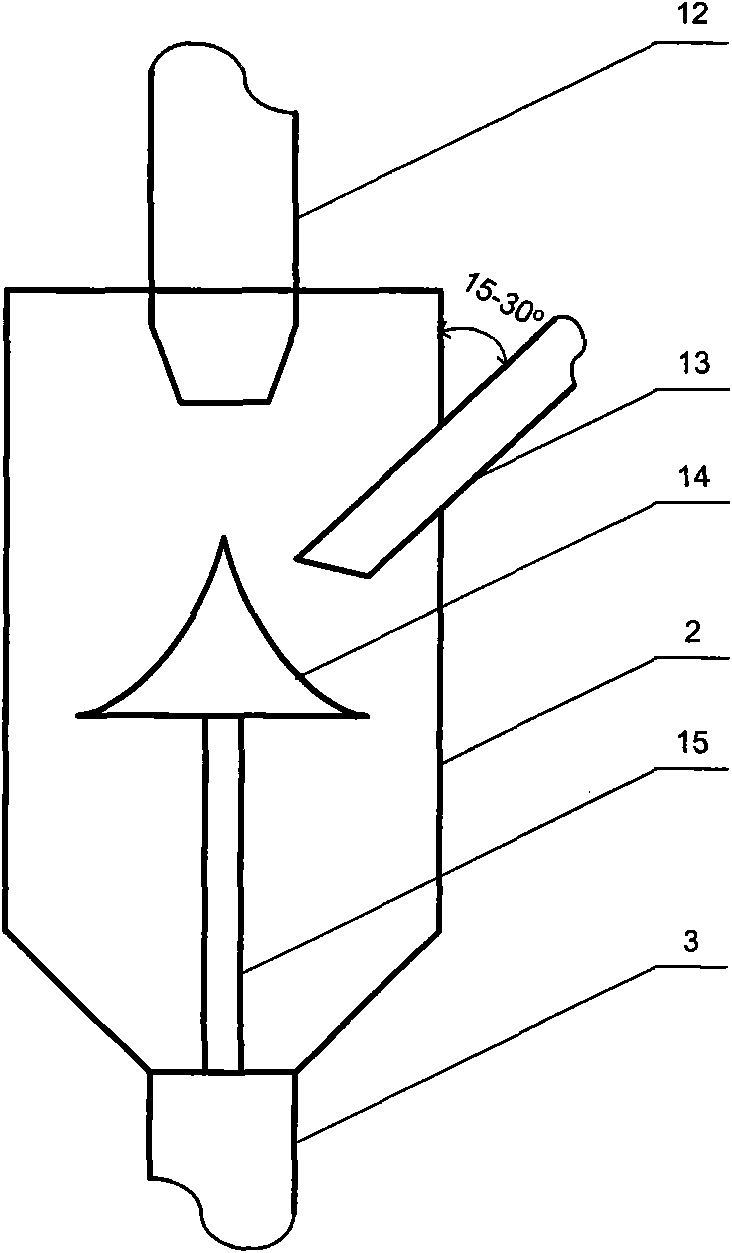

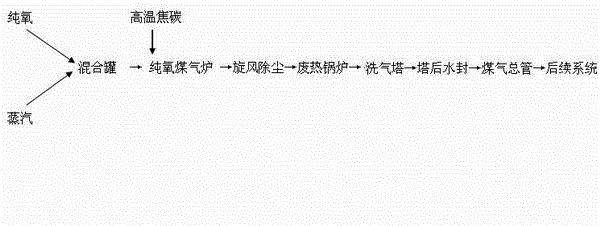

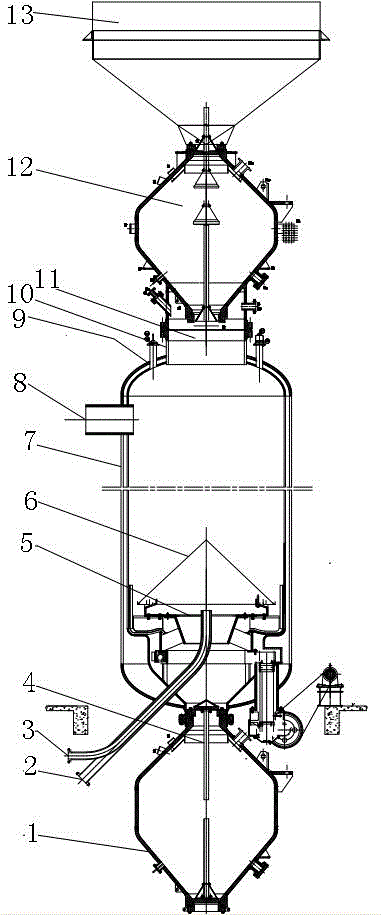

Direct high-temperature coke gasification technology and gasifier employed by same

InactiveCN104673390AEliminate energy waste and environmental pollutionReduce consumptionGasifier feeding meansGasification processes detailsCooling towerSensible heat

The invention relates to a coke gasification technology and a gasifier employed by the same, and belongs to the technical field of coal gasification. High-temperature coke which is not quenched is fed into the gasifier to be subjected to a continuous redox reaction with a gasifying agent to produce water gas. The water gas is subjected to dust removal, sensible heat recycling, and cooling and washing by a high-efficiency dust remover, a heat recycling device and a purifying, washing and cooling tower respectively; and the clean water gas discharged out of the tower stays in a normal temperature state, can be conveyed to a follow-up sequence for production of various chemical products, and can also be used as industrial or domestic fuel gas. Practice proves that the coke gasification technology and the gasifier are economical and practical, the sensible heat of the high-temperature coke is effectively utilized, the quality of produced water gas is high, the gas yield of the single gasifier is high, the coke conversion rate is high, a little residue and coke residual are produced, the consumption of each material is low, environment and safety problems are avoided, equipment can operate stably for a long period, and the maintenance cost is low. Therefore, the coke gasification technology and the gasifier have remarkable economic and social benefits and wide application prospects.

Owner:江西昌昱实业有限公司

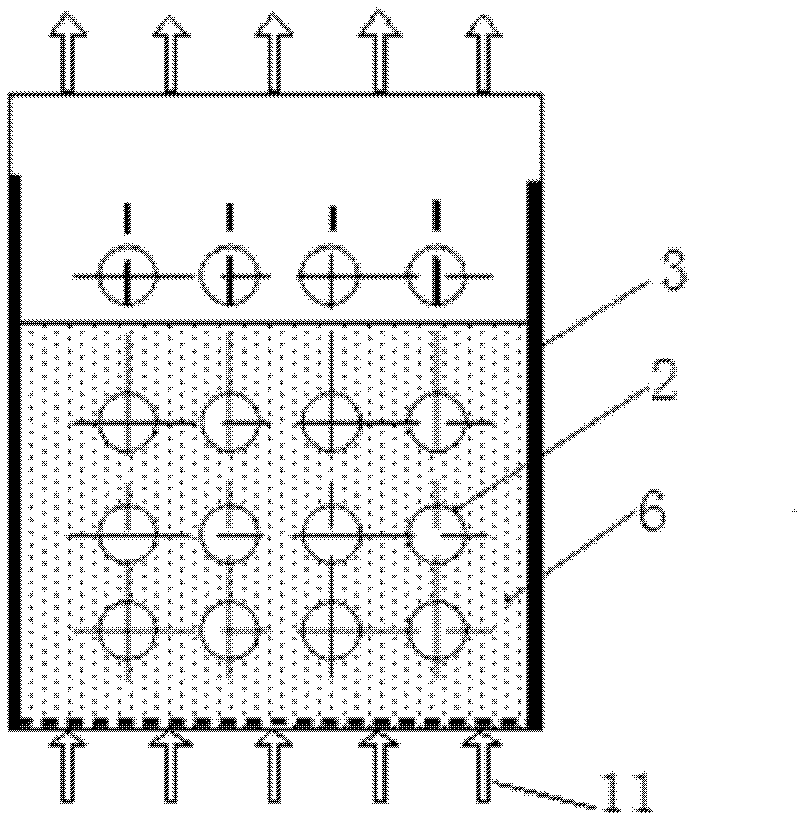

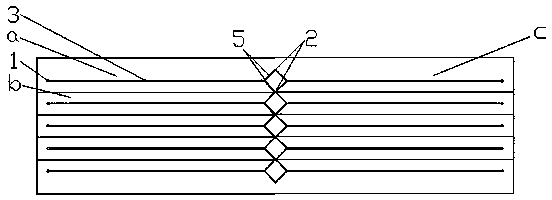

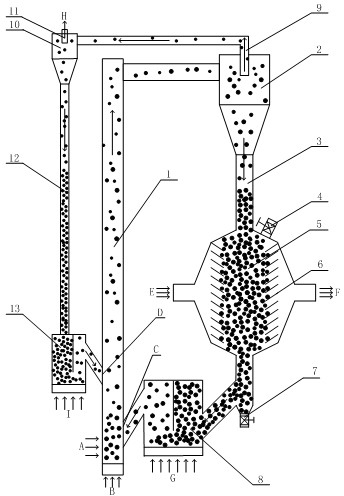

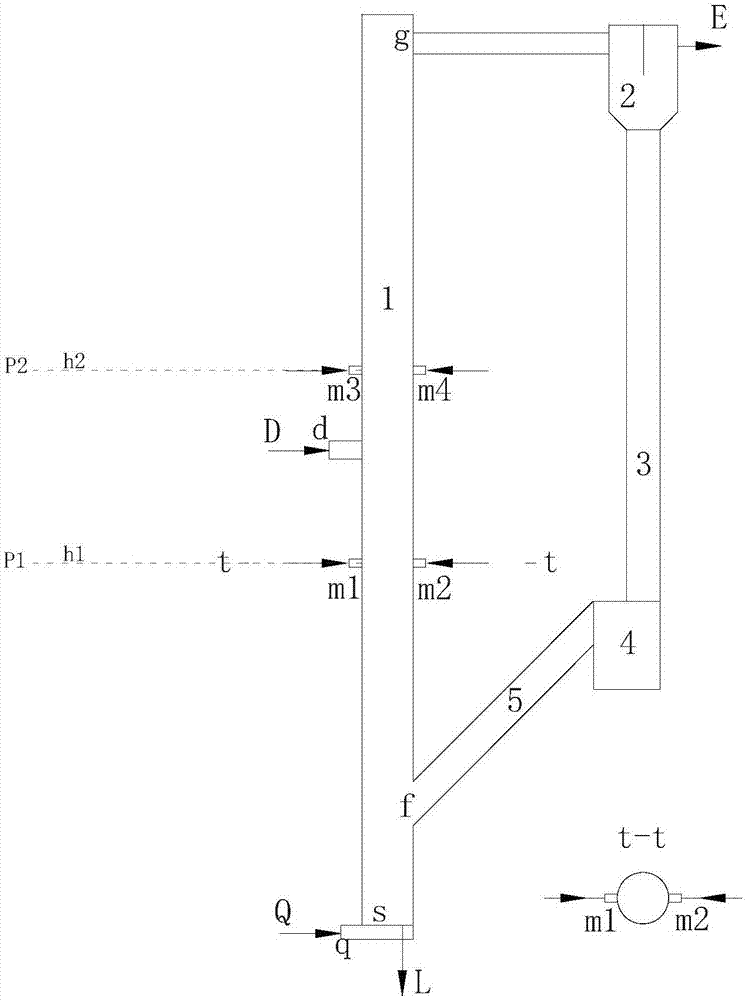

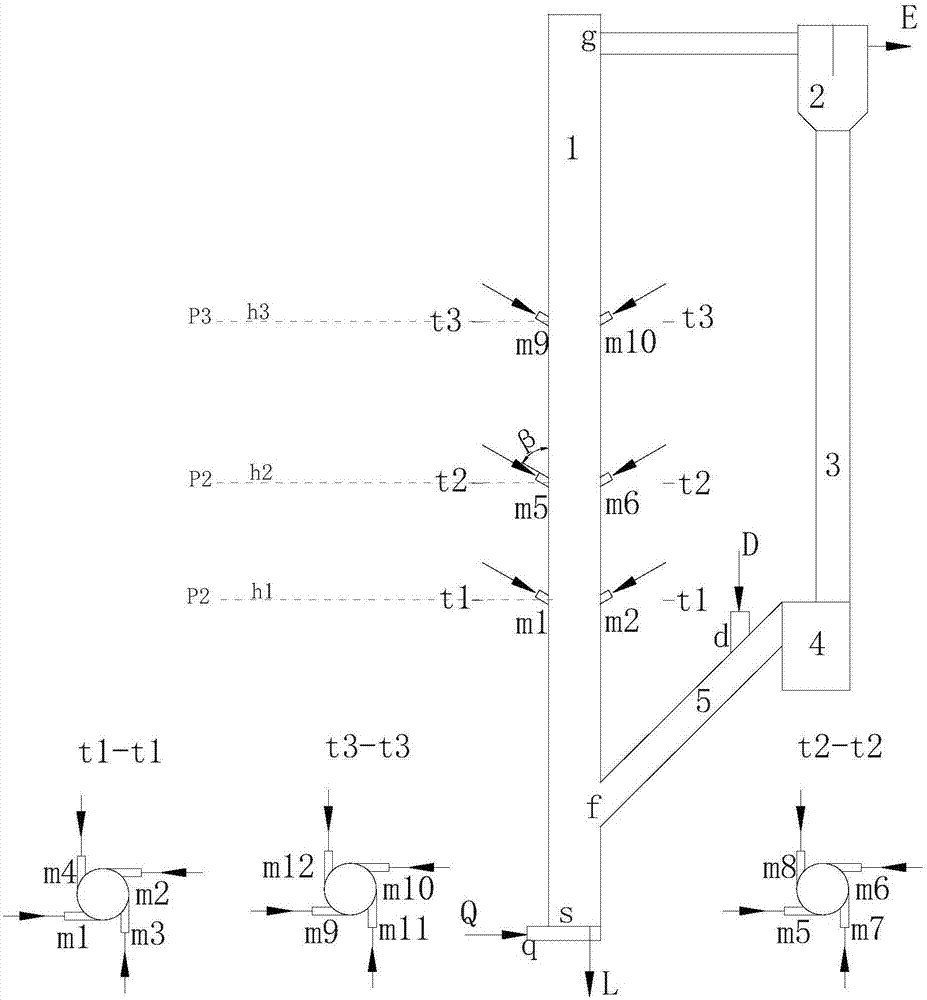

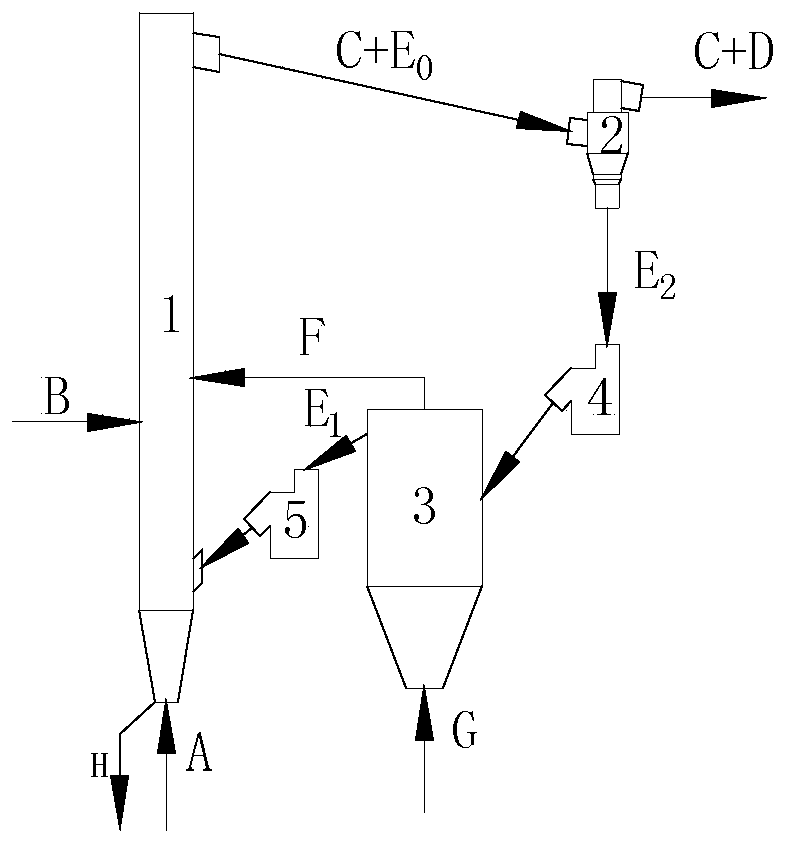

Circulating fluidized bed gasification device and gasification method with grading air distribution effect

PendingCN107312575AReduce consumptionHigh yieldGasifier feeding meansGasification processes detailsProcess engineeringFluidized bed

A circulating fluidized bed gasification device with a grading air distribution effect comprises a hearth (1), a gas-solid separation device (2) and a returning system, wherein the hearth (1) is provided with auxiliary gasification agent inlets (m1 to m4). The invention also provides a circulating fluidized bed gasification method with the grading air distribution effect. By means of the circulating fluidized bed gasification device and gasification method with the grading air distribution effect, the gasification efficiency is improved, and the carbon content in fly ash is reduced.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

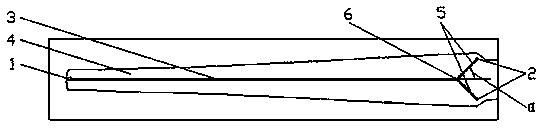

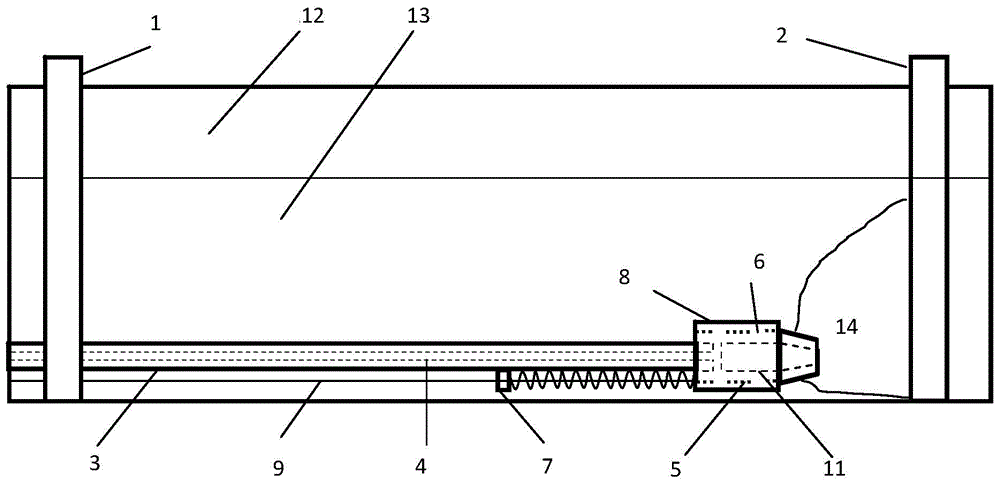

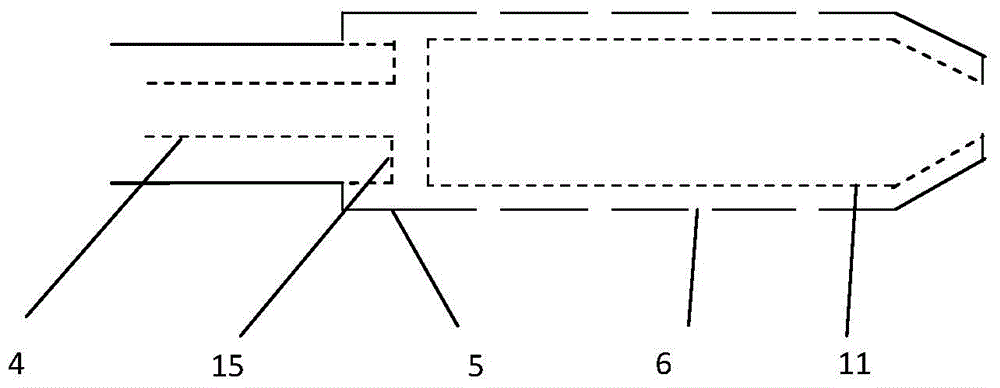

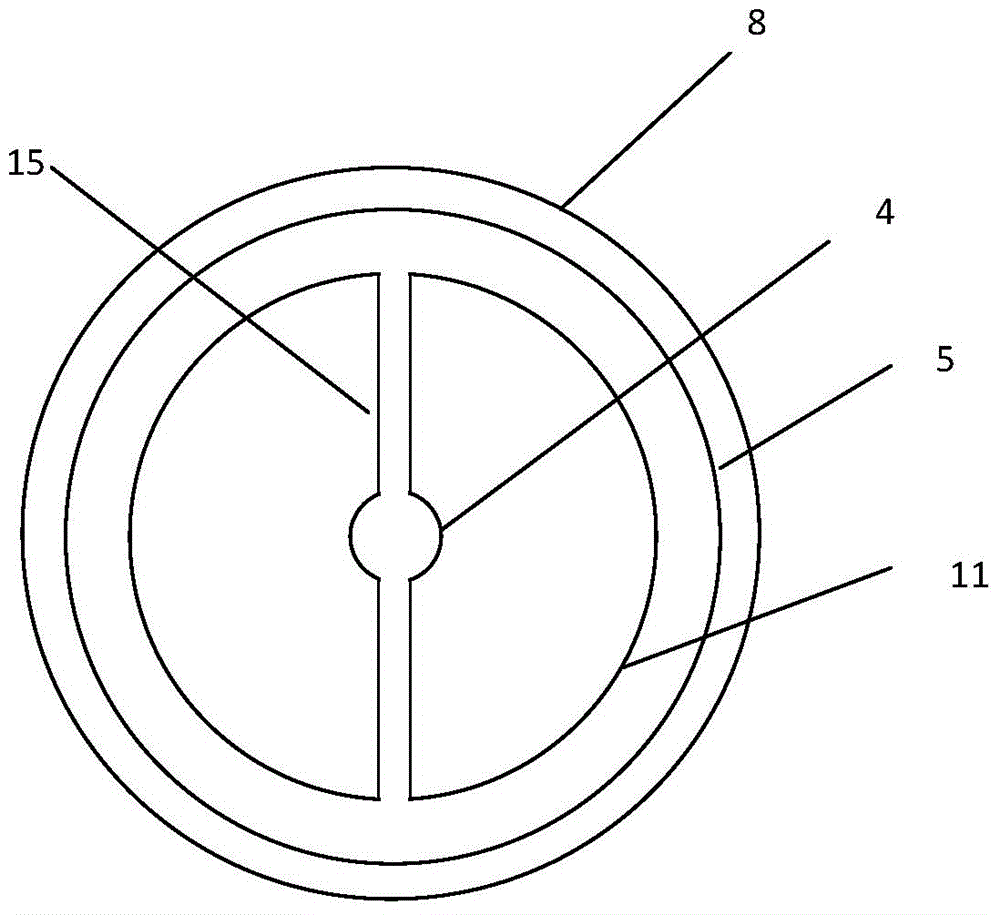

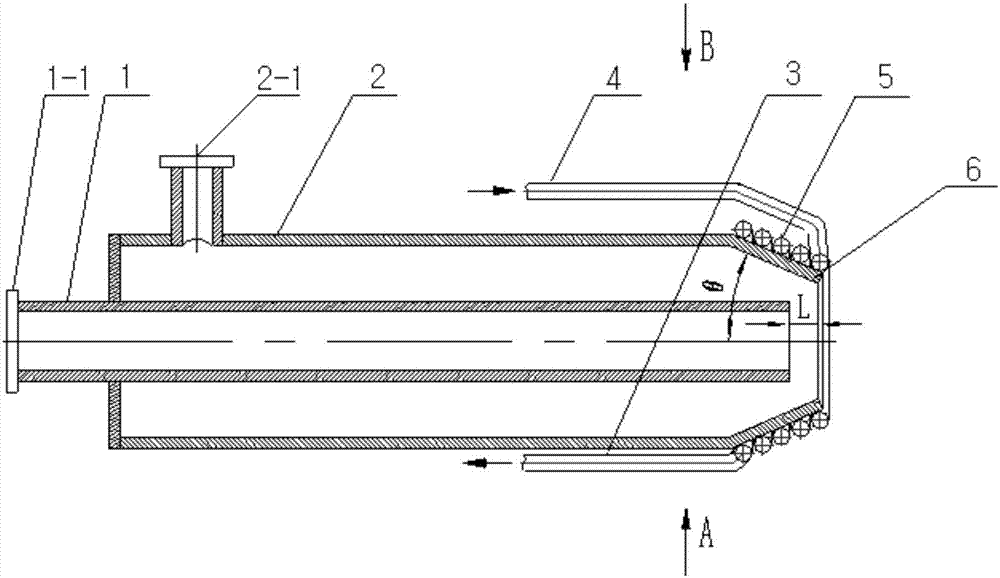

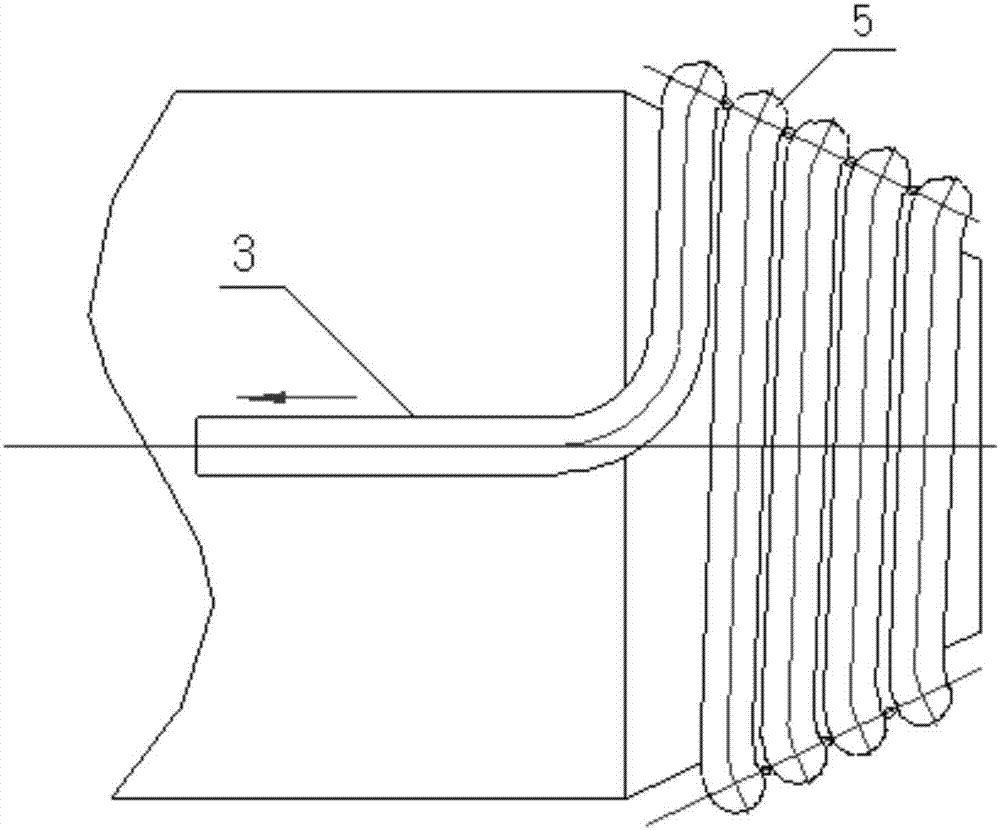

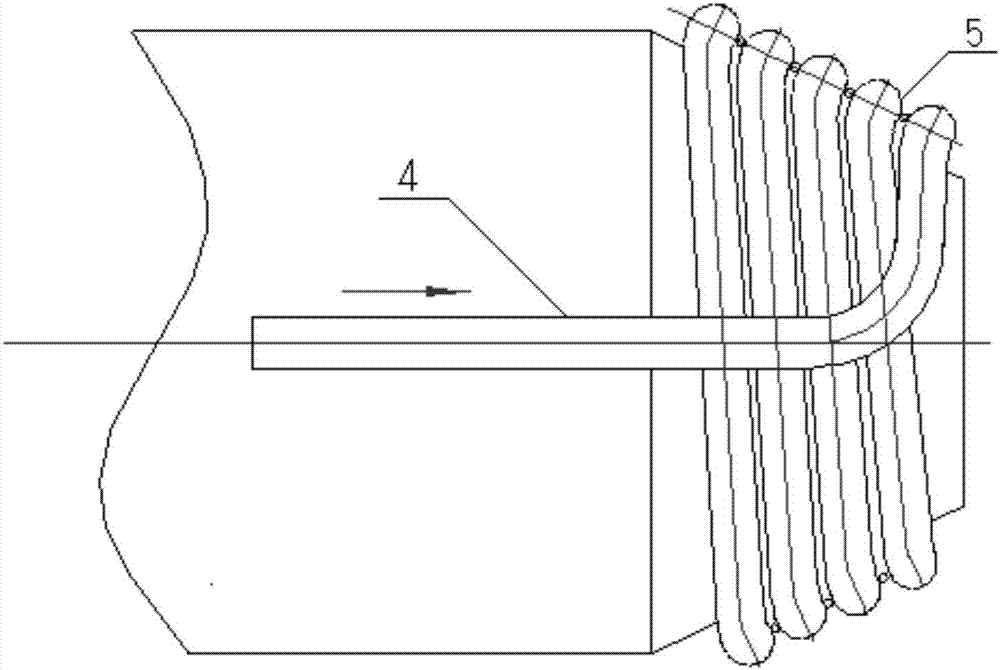

Gasifier burner with water-cooled coiled tube protection for dry feed entrained flow bed

InactiveCN107022379ASimple structureReduce manufacturing costGasifier feeding meansGranular/pulverulent flues gasificationCoal pipelineEngineering

The invention discloses a gasifier burner with water-cool that ed coiled tube protection for a dry feed entrained flow bed, and relates to the gasifier burner. The invention aims at solving the problems of an existing gasifier burner that manufacturing cost is high, burning loss is easy to cause in a gasifier under the high temperature condition, and the service life is short, so that shutdown of the gasifier often occurs. A pulverized coal pipeline and a gasifying agent pipeline are coaxially arranged from inside to outside; one end, away from the head of the burner, of the gasifying agent pipeline is connected with the outer side wall of the pulverized coal pipeline in a sealing manner; a pulverized coal air current inlet is formed in the top end of the pulverized coal pipeline; a gasifying agent inlet is formed close to the top end of the gasifying agent pipeline; a cooling water inlet pipe and a cooling water outlet pipe are respectively arranged at two ends of the water-cooled coiled tube; a contraction opening is formed in the outlet end of the gasifying agent pipeline. The cost of the burner disclosed by the invention is 0.5 to 1 million yuan and is about 30 to 50 percent of the manufacture cost of an existing burner; by trial firing, the burner disclosed by the invention has no ablation phenomenon; the temperature of a position 100mm away from an outlet of the burner is kept at about 1000DEG C; the service life of the burner can reach 2 to 3 years or longer, and is 4 to 6 times that of the existing burner.

Owner:HARBIN INST OF TECH

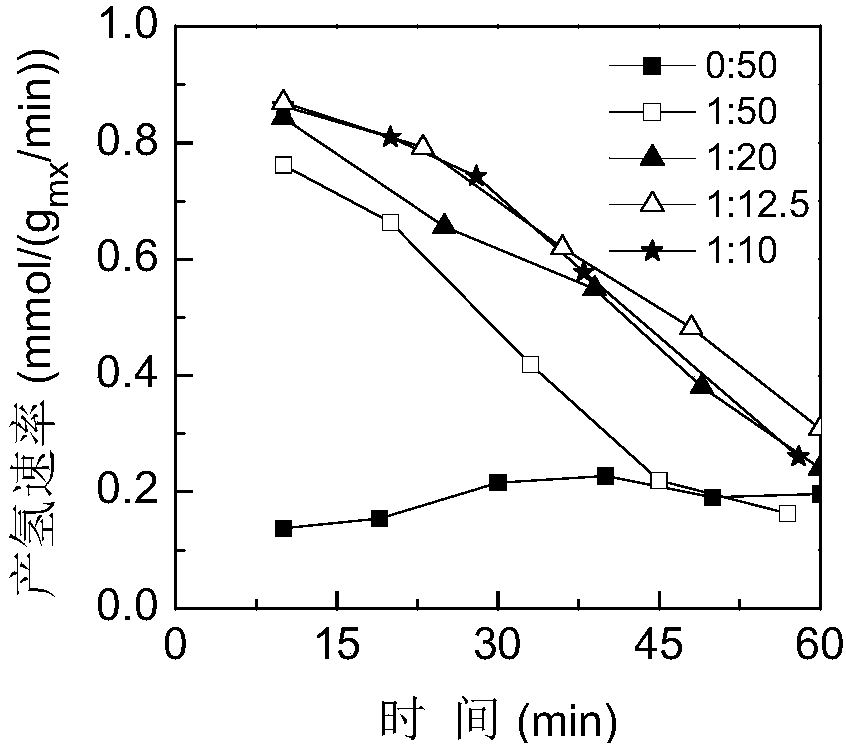

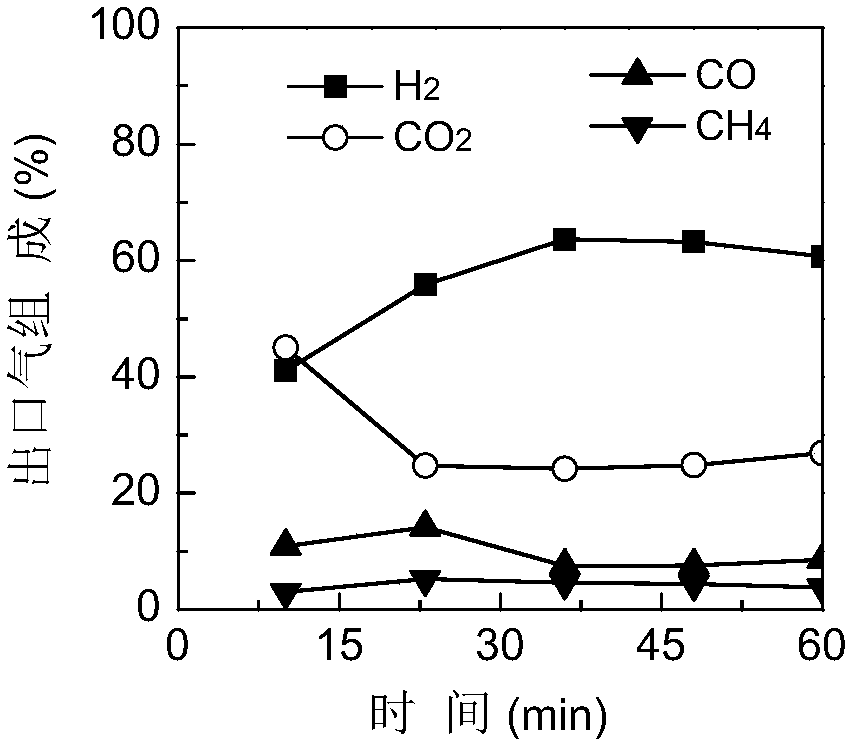

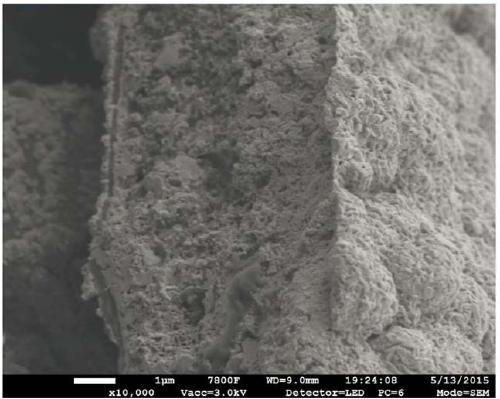

Preparation method of metal catalyst loaded on porous carbon by means of coal or biomass gasification

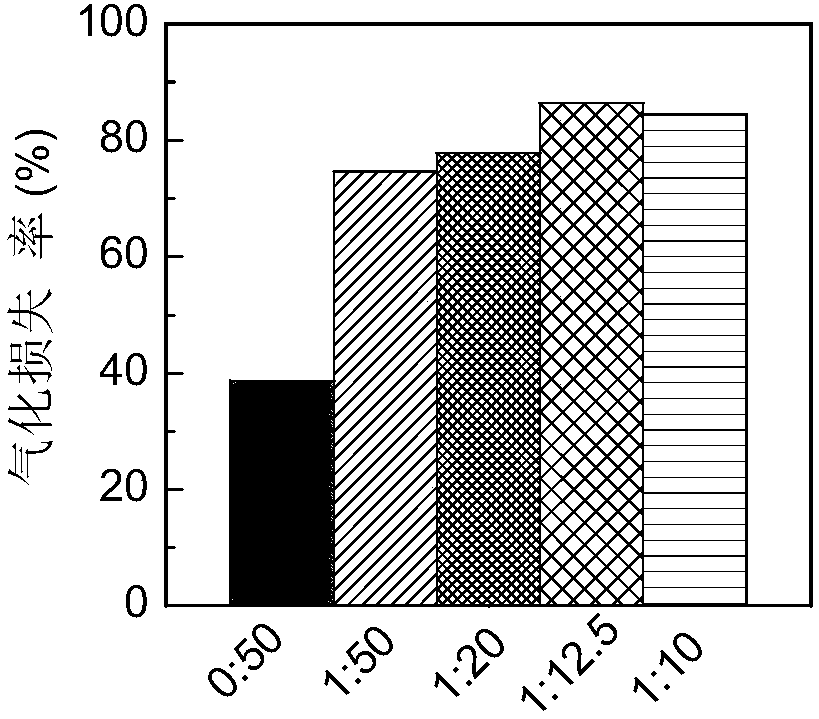

ActiveCN107649134APromote gasification reactionRealize in-situ loadingHydrogenMetal/metal-oxides/metal-hydroxide catalystsOxideBiomass feedstock

The invention discloses a preparation method of a metal catalyst loaded on porous carbon by means of coal or biomass gasification. Raw materials of coal or biomass are ground, and particles of carbon-based materials are obtained; the precursor of a main component of the catalyst is uniformly mixed with the particles of the carbon-based materials, and then preheating treatment is conducted, so thatmetal oxide loaded on semicoke is formed; the metal oxide loaded on the semicoke is used as a material of a gasification reaction, and the gasification reaction is carried out in a reactor; residuesafter the reaction of the step three are cooled to 100 DEGC or below in the protection of an inert gas, and the metal catalyst loaded on the porous carbon is obtained. By means of the technical elements that the product of coal or biomass subjected to the gasification reaction is hydrogen-rich gas and catalytic gasification of coal or biomass can be promoted by the porous carbon and the metal oxide, the purpose that the preparation process of the catalyst is regulated by means of process parameters of the coal or biomass gasification reaction is achieved, and a novel technology that the metalcatalyst is loaded on the porous carbon in situ and can be reduced in situ is developed.

Owner:NORTHWEST UNIV

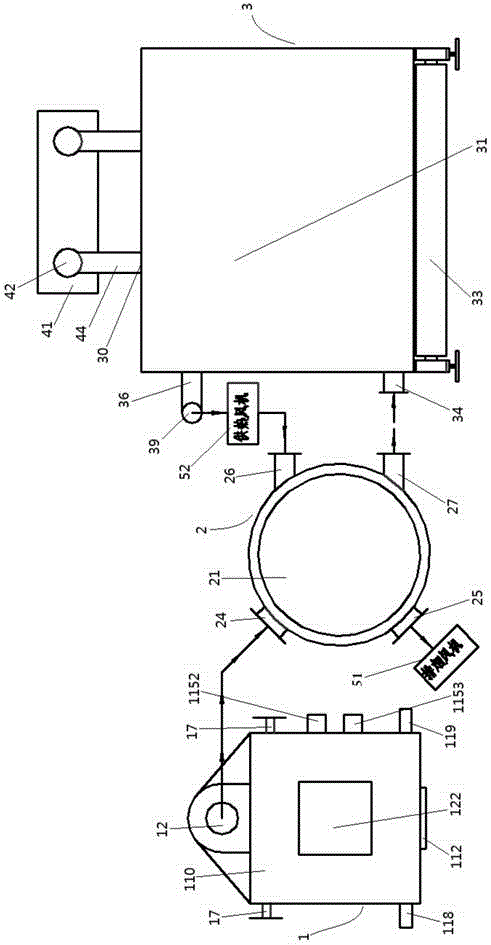

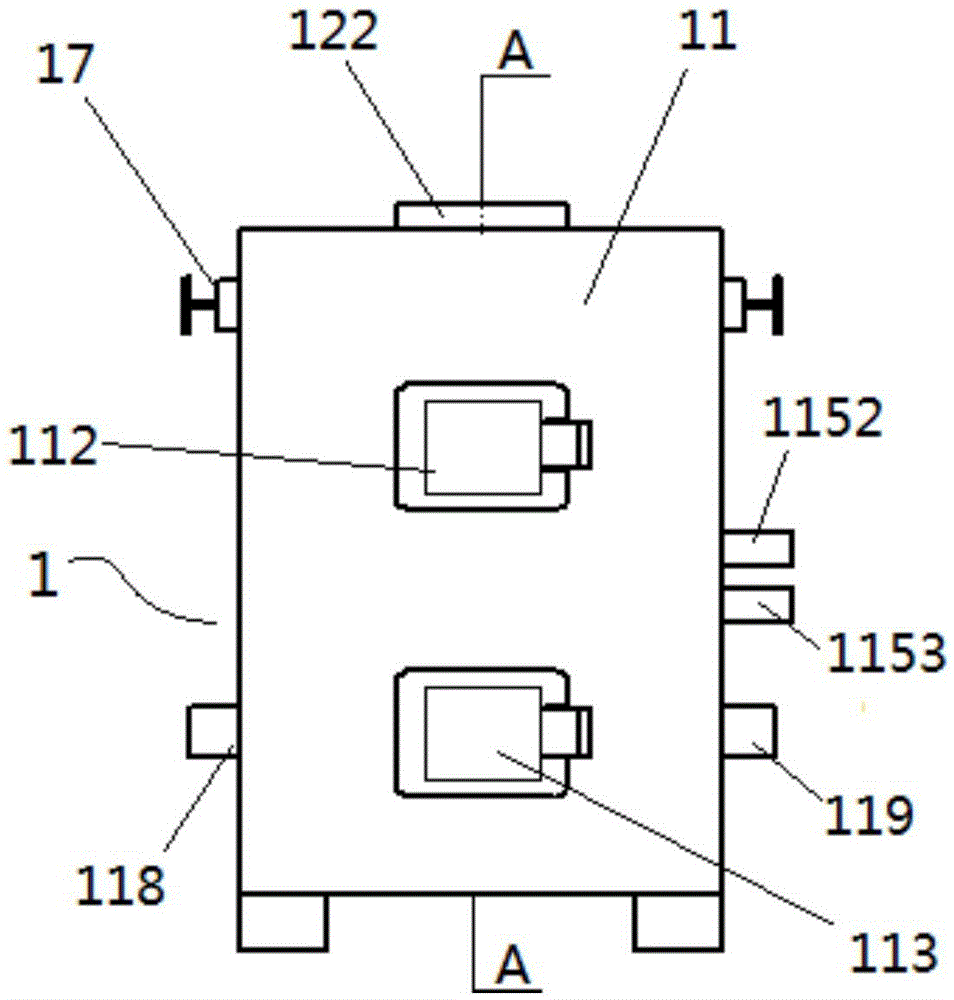

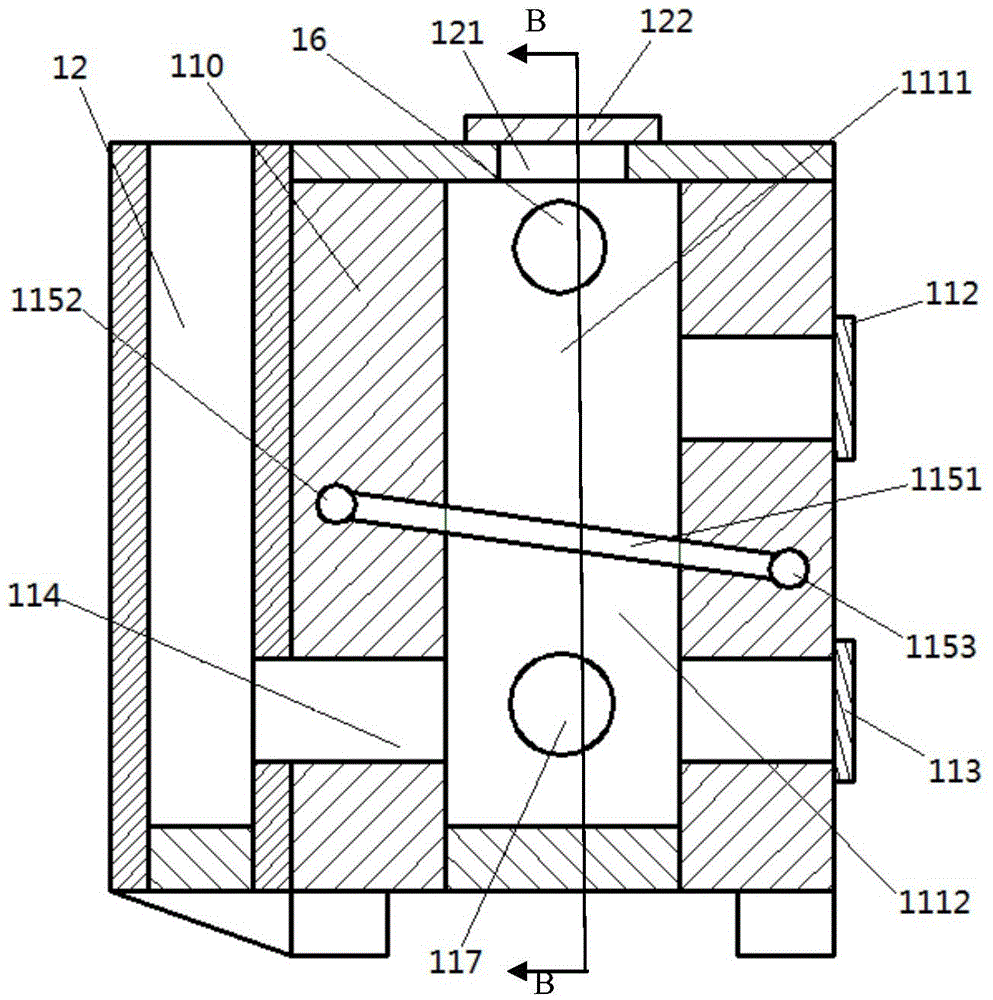

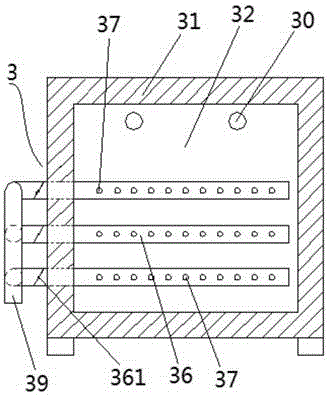

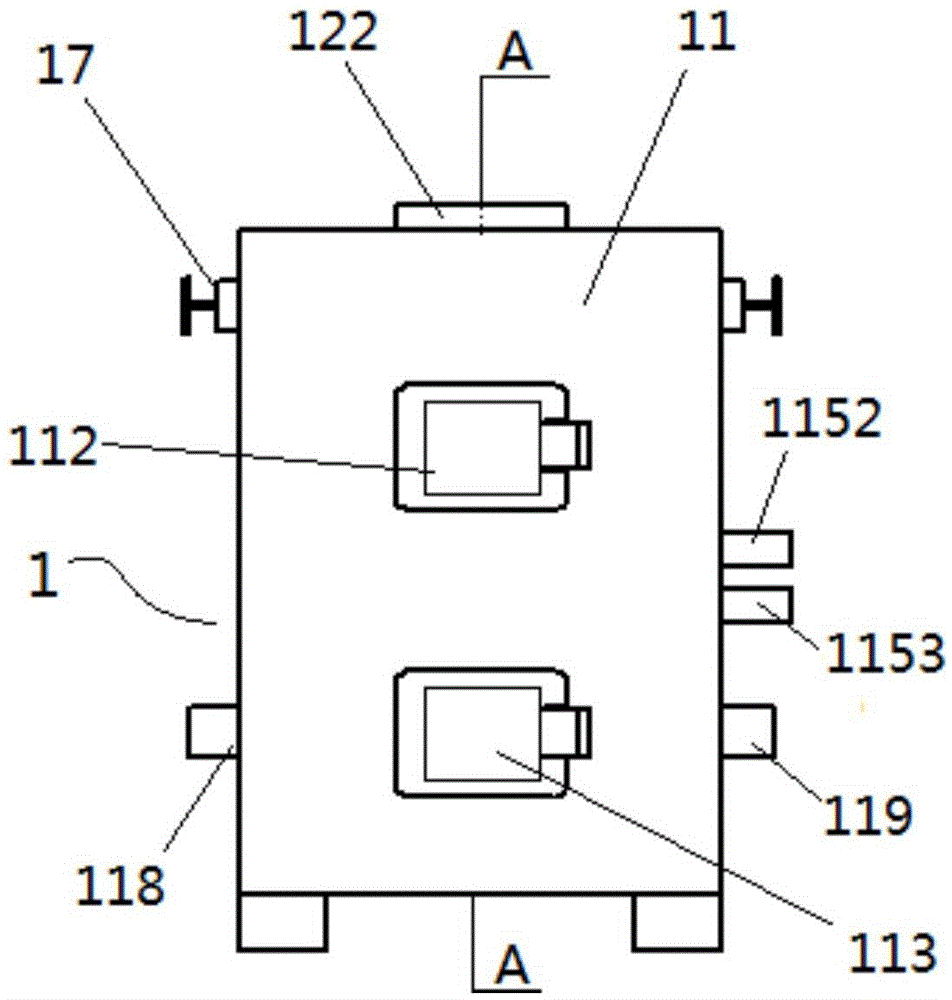

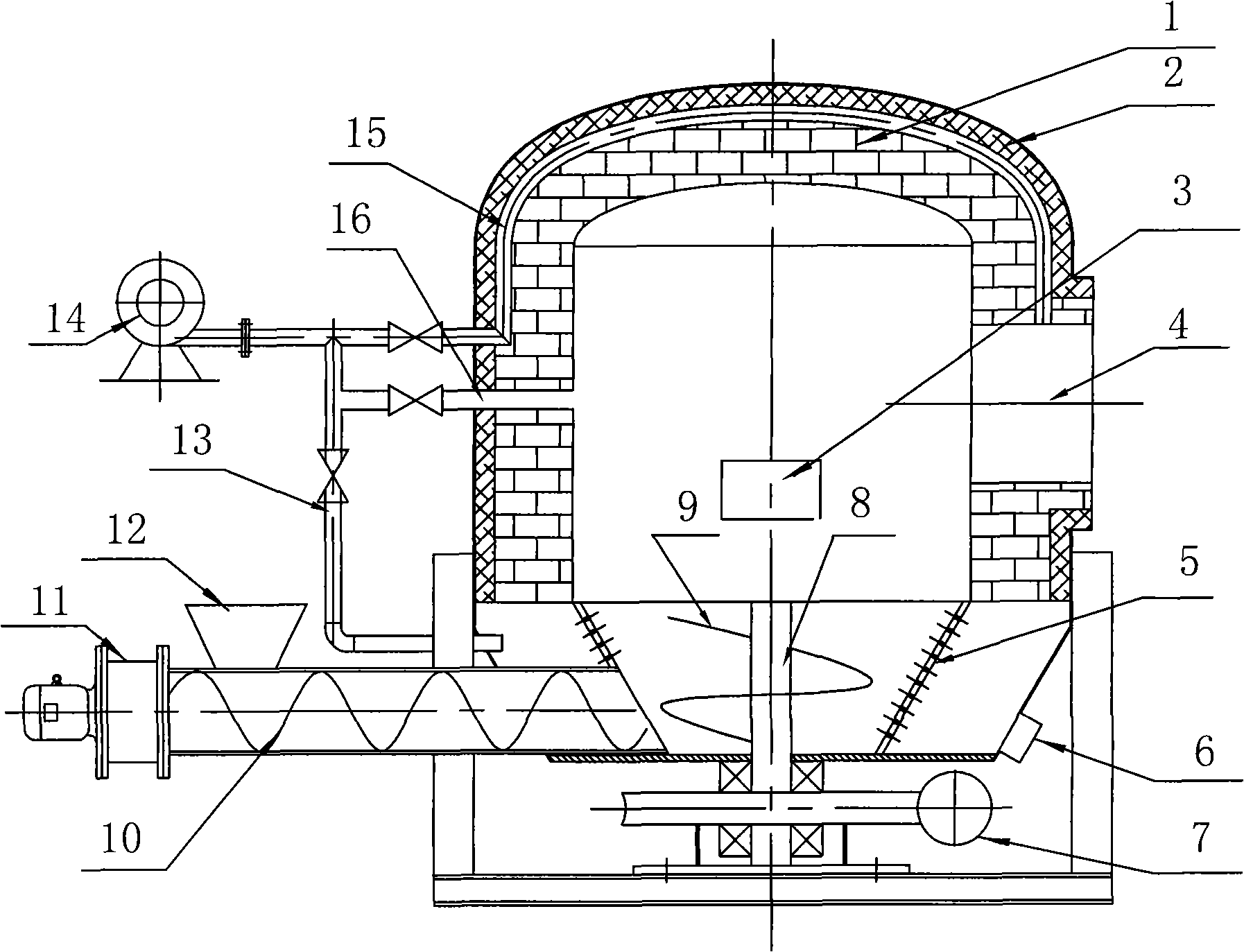

Wood thermal modification treatment device

ActiveCN106166779AWide variety of sourcesLess investmentWood treatment detailsThermal wood treatmentCombustionEngineering

The invention discloses a wood thermal modification treatment device. The device comprises a gasification combustion device, a heat exchange, a thermal modification device, a volatile organic compound (VOC) collecting device and a fan device which are sequentially connected through a connecting pipe. According to the treatment device, heat generated by the gasification combustion device is provided to the thermal modification device under the effect of the fan system to perform thermal modification treatment on wood, and VOCs generated by the thermal modification treatment of the wood are collected. The treatment device is simple in structure and high in thermal efficiency; plant source biomass, such as forestry and agricultural waste, remainders and wood processing remainders, serves as fuel, a heat source is provided for the thermal modification treatment of the wood through gasification reverse burning / reverse burning and efficient heat exchange, the device investment cost and running cost are remarkably reduced on the premise of guaranteeing quality of the wood undergoing high temperature thermal modification treatment, and discharge of the VOCs and thermal pollution in the wood thermal modification treatment process are avoided.

Owner:BEIJING FORESTRY UNIVERSITY

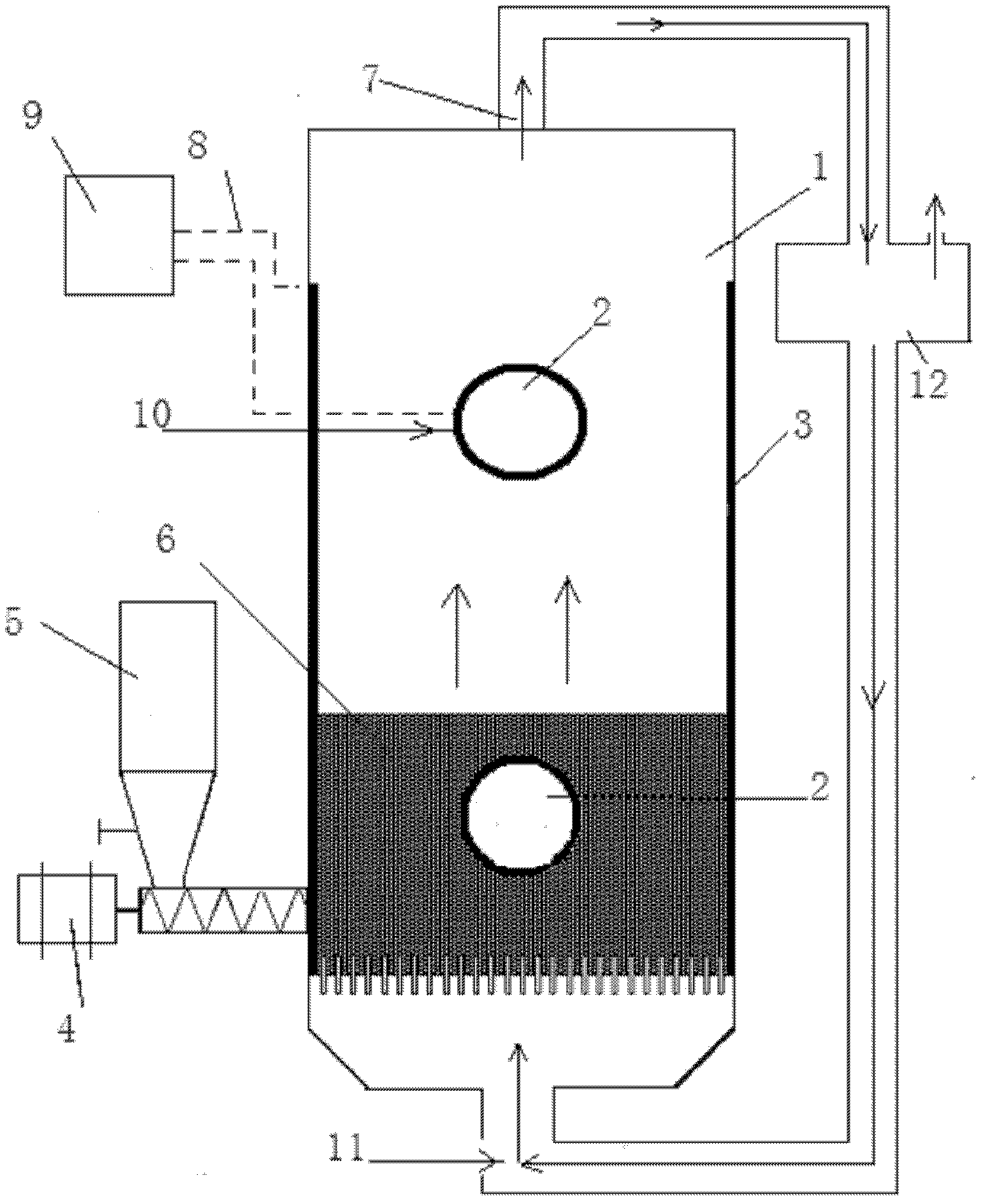

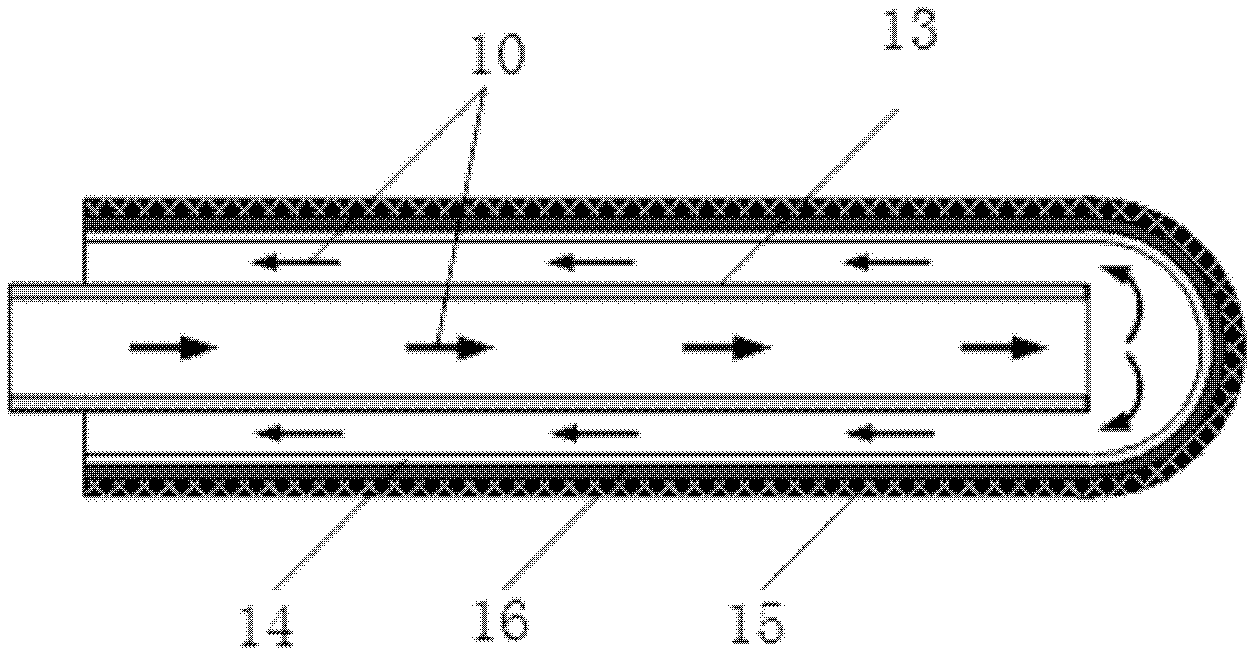

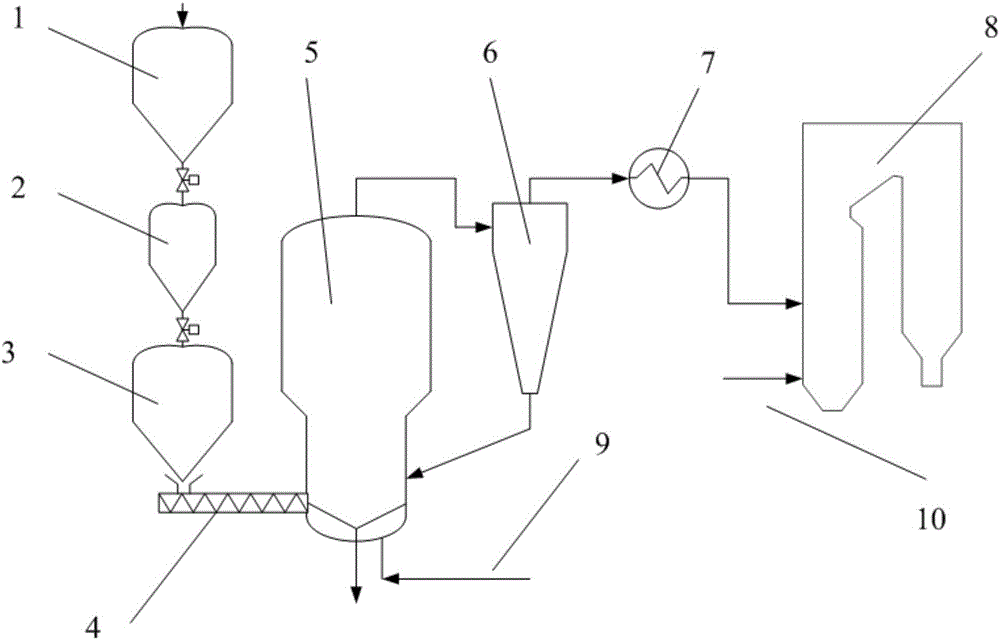

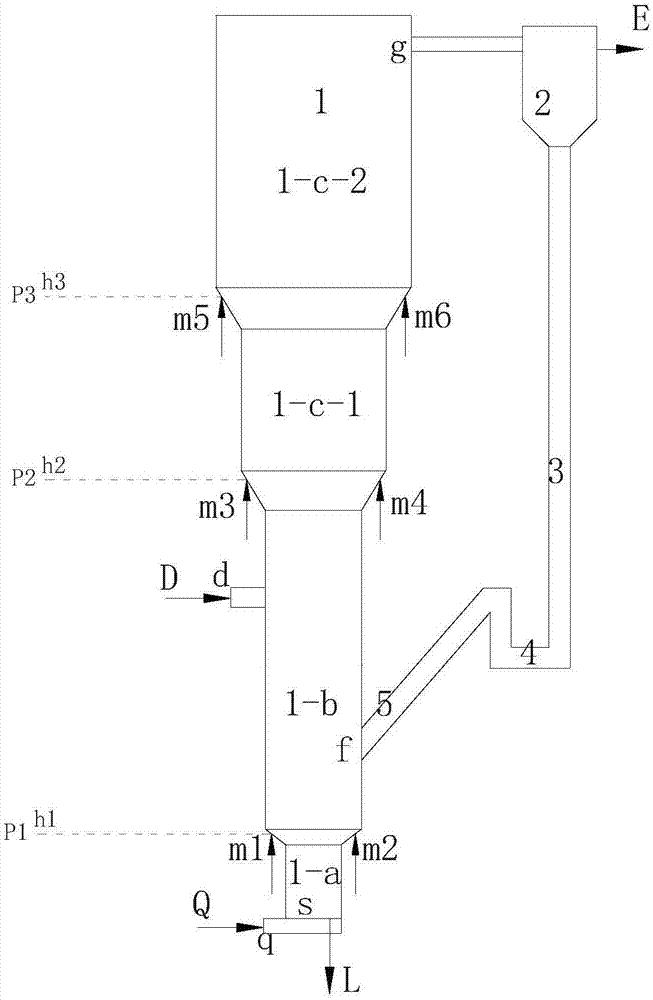

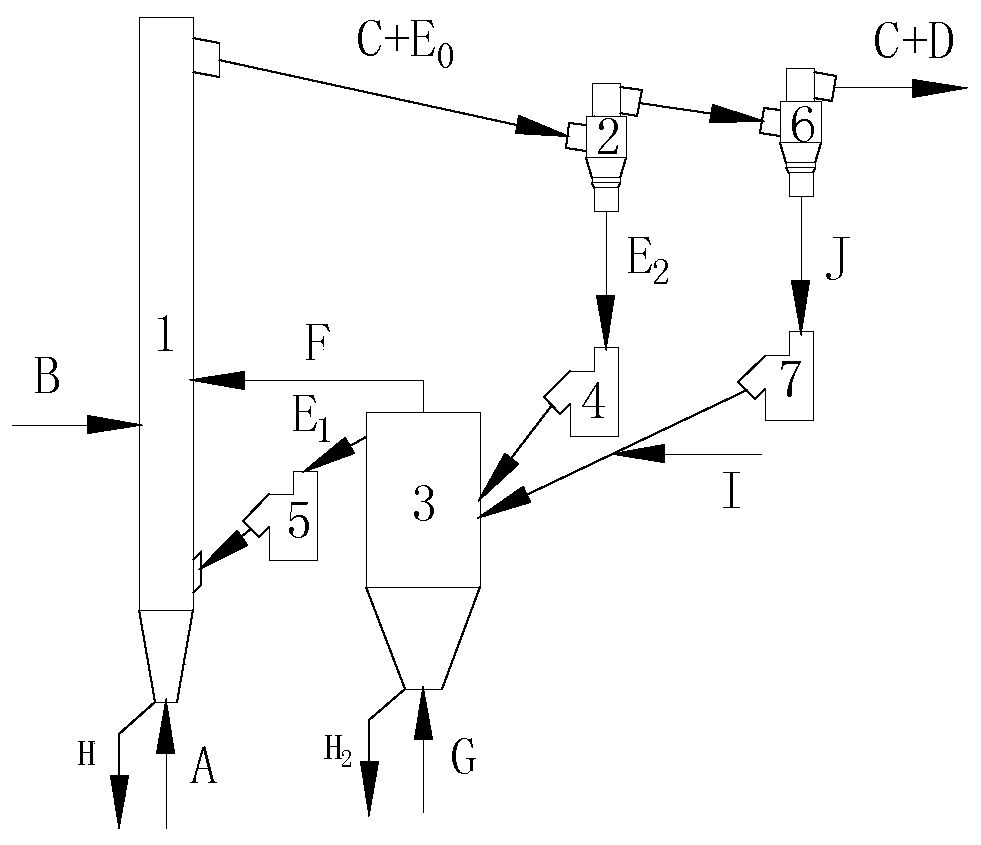

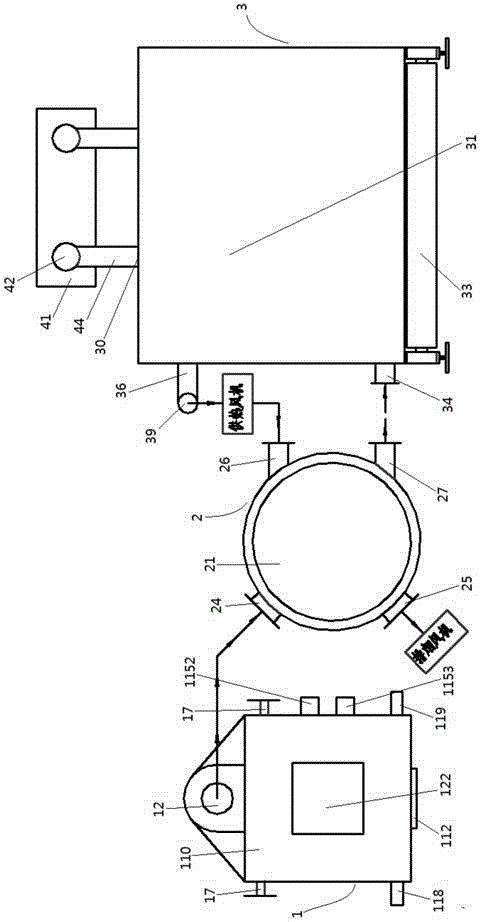

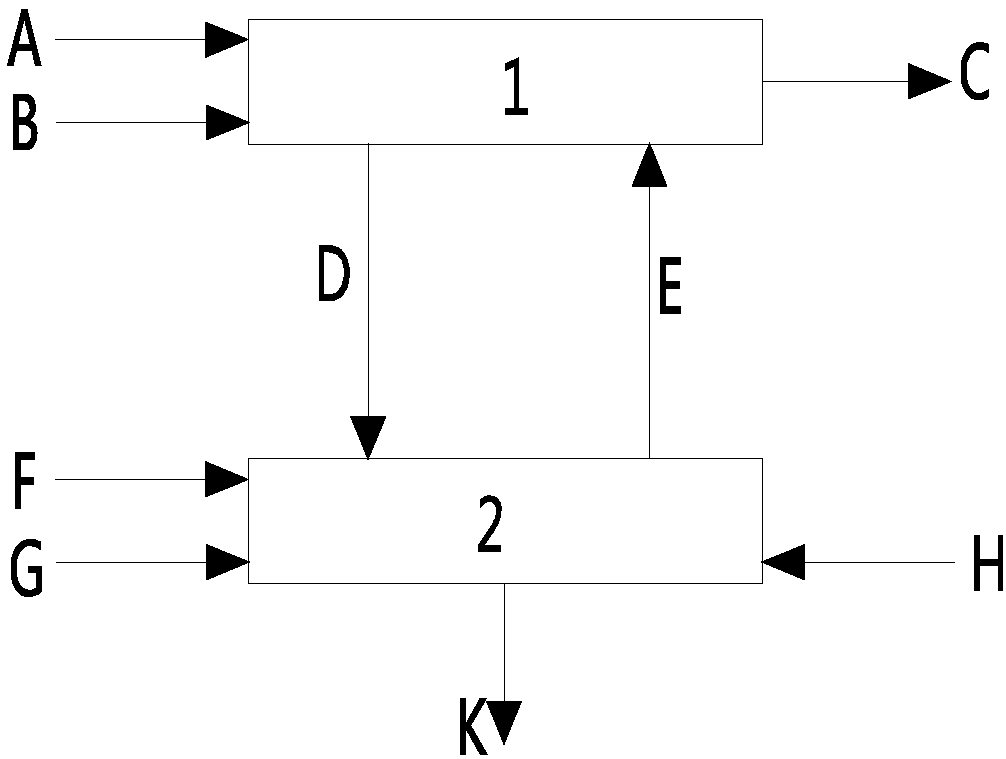

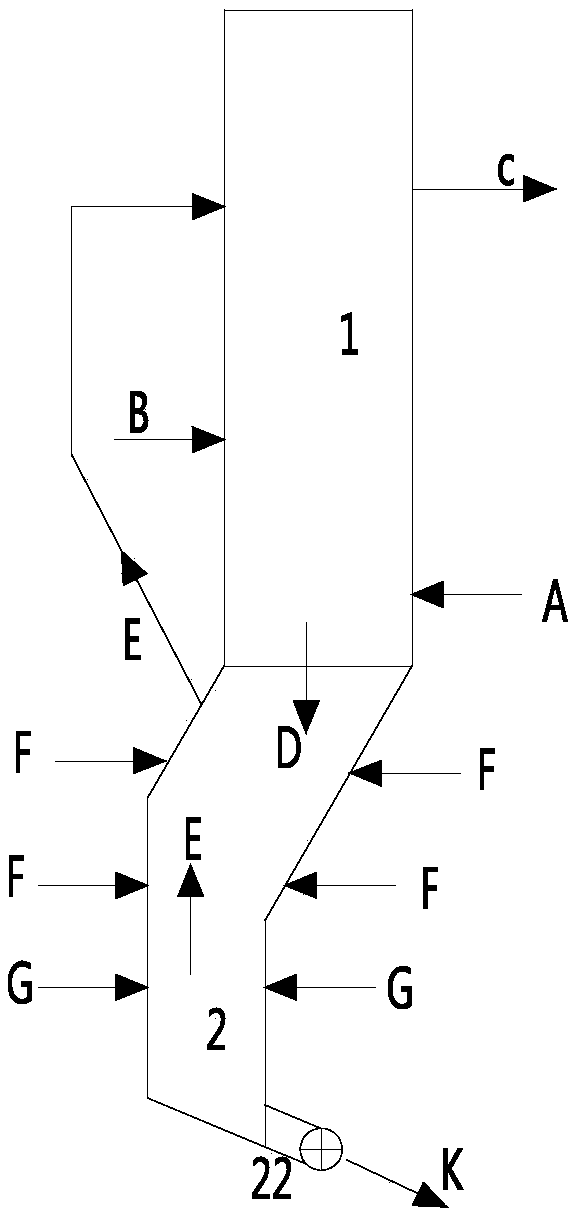

Circulating fluidized bed gasification device with gasification auxiliary bed and gasification method

ActiveCN110791326AImprove carbon conversionPromote gasification reactionGranular/pulverulent flues gasificationGas solidSlag

The invention provides a circulating fluidized bed gasification device with a gasification auxiliary bed and a gasification method. The gasification device includes a gasification furnace (1), a gas-solid separator (2), and the gasification auxiliary bed, wherein a fuel inlet, a gasifying agent inlet, a furnace return gas inlet, a furnace discharge gas outlet, a bottom slag outlet, and a materialreturn opening are formed in the gasification furnace (1); the inlet of the gas-solid separator (2) communicates with the furnace discharge gas outlet of the gasification furnace (1), the gasificationauxiliary bed includes a circulating material inlet, the gasifying agent inlet, the furnace return gas outlet, and a furnace return carbonaceous material outlet, the circulating material inlet of thegasification auxiliary bed communicates with a solid-phase outlet of the gas-solid separator (2), the furnace return gas outlet of the gasification auxiliary bed communicates with the furnace returngas inlet of the gasification furnace (1), and the furnace return carbonaceous material outlet of the gasification auxiliary bed communicates with the material return opening of the gasification furnace (1). According to the gasification device and the gasification method, the carbon conversion rate of the gasification device can be improved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

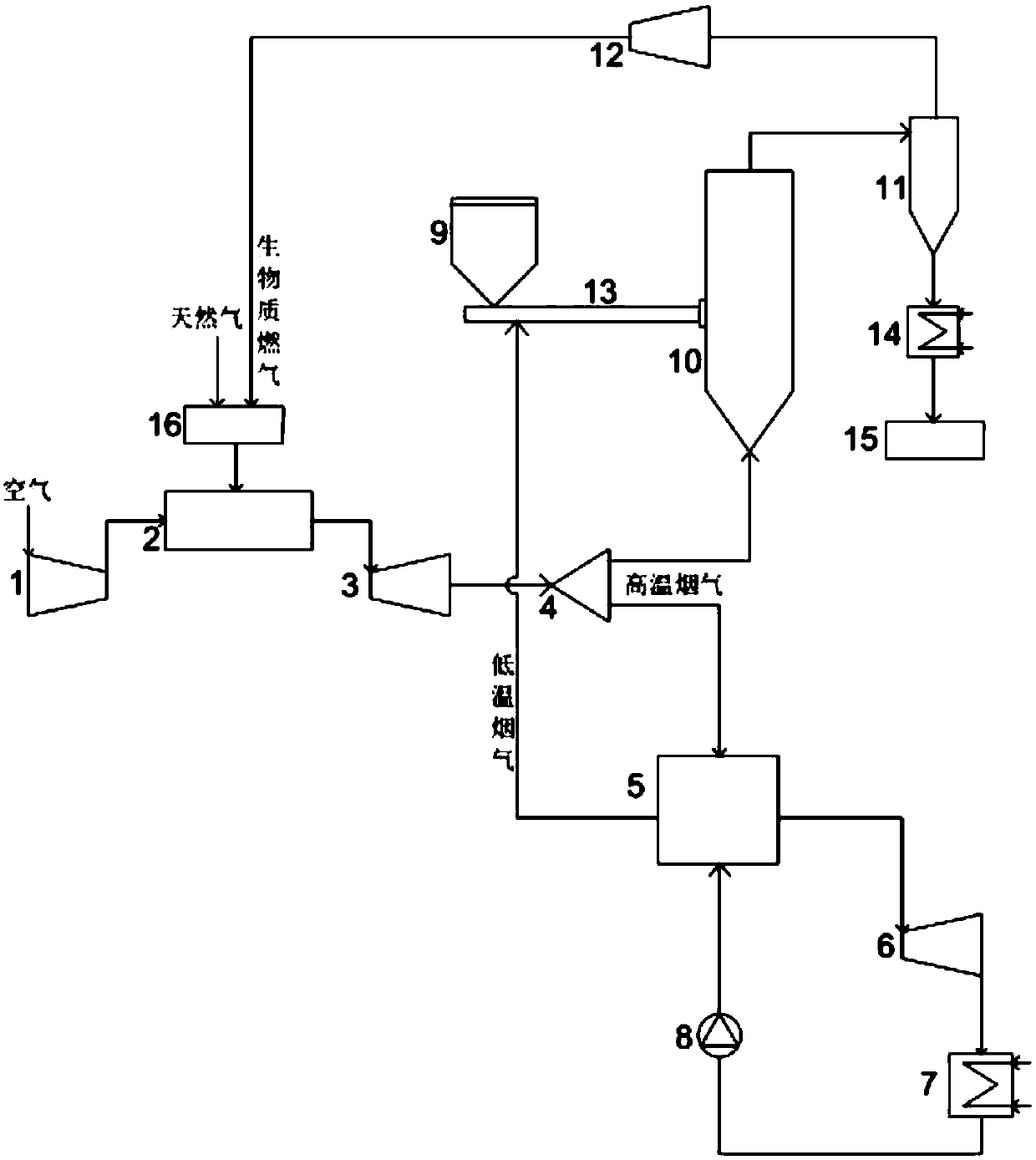

Biomass gas and natural gas coupling power generation device

PendingCN111075566AImprove utilization efficiencyLess investmentProductsReagentsCombustion chamberBoiler (power generation)

The invention discloses a biomass gas and natural gas coupling power generation device, which comprises a combined cycle power generation device and a biomass gasification device, wherein the combinedcycle power generation device comprises a gas compressor, a gas turbine combustion chamber, a gas turbine, a separator, a waste heat boiler, a steam turbine, a condenser and a water pump; and the biomass gasification device comprises a biomass feeding hopper, a biomass gasification furnace, a cyclone separator and a gas compressor. According to the invention, high-temperature flue gas at the outlet of the gas turbine is used as a gasifying agent for biomass gasification, heat is provided for the gasification process, and an external heat source does not need to be used for providing heat forthe biomass gasification process any more, so that the energy consumption of biomass gasification is greatly reduced, the gasified biomass gas and the natural gas are mixed and combusted for combinedcycle power generation, efficient utilization of biomass energy is achieved, and the comprehensive utilization efficiency of energy of a natural gas power plant is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Wood thermal modification treatment method

ActiveCN106182282AWide variety of sourcesLess investmentWood treatment detailsDrying gas arrangementsCombustionPlant Sources

The invention discloses a wood thermal modification treatment method. The method comprises the steps that wood to be subjected to thermal modification treatment is placed in a thermal treatment chamber, and the wood is heated; and when the temperature of the thermal treatment chamber rises to the set thermal modification temperature of the wood through heating, heating to the wood is stopped, and thermal modification of the wood can be conducted conveniently in the environment with the set modification temperature. According to the wood thermal modification treatment method, plant source biomass is used as fuel, the wood is heated in a modification mode through forward combustion type gasification combustion and reverse combustion type gasification combustion at the different stages of wood thermal modification, and the treatment cost can be obviously lowered. The uniformity of the temperature field of the thermal modification wood is guaranteed by adjusting the flowing amount and the flowing speed of thermal modification media, and the quality of the thermal modification wood is improved. Volatile organic compounds (VOC) generated from thermal modification are collected, and emission and thermal pollution of the VOC are reduced. Accordingly, energy is saved, resources are fully utilized, and environmental protection is further facilitated.

Owner:BEIJING FORESTRY UNIVERSITY

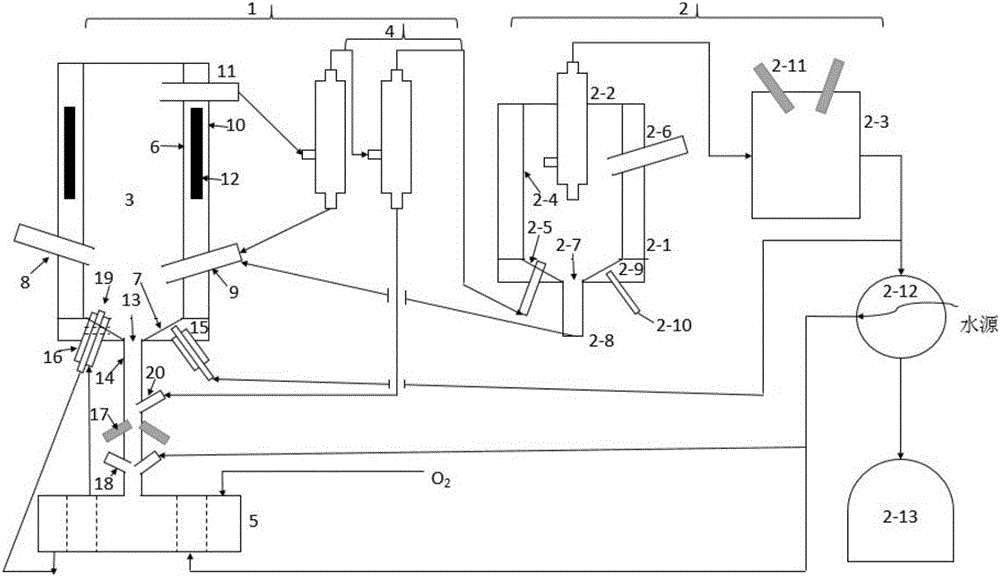

Apparatus for preparing low-tar fuel gas through combining gasification and dry distillation

InactiveCN105925289AEasy to controlSuitable for large-scale productionGasification processes detailsSpecial form destructive distillationSlagCoal conversion

The invention relates to an apparatus for preparing low-tar fuel gas through combining gasification and dry distillation. The apparatus comprises a fluidized bed gasification furnace (3), a cyclone separator (4), a slag collecting device (5), a gasifying agent supply system, microwave heating devices (12), second plasma torches (17), a fluidized bed dry distillation furnace (2-1), a built-in gas-solid separator (2-2), a syngas and coal gas processor (2-3) and first plasma torches (2-11). The apparatus is suitable for preparing coal gas through catalytic conversion and non-catalytic conversion of coal, and has the advantages of high thermal efficiency, easy large-scale formation, long-term stable running, high coal conversion rate, low coke and dust content of fuel gas, and efficient sensible heat recovery of the syngas.

Owner:陕西首信实业有限公司 +1

Gas stove with built-in combustion moving bed

InactiveCN101576252AAccelerate the pyrolysis reactionSolve the problem that hinders the passage of mixed gasCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelReaction layerCombustion

The invention provides a gas stove with a built-in combustion moving bed, which comprises a stove body. The gas stove is characterized in that a coal conveying mechanism which conveys coal from bottom to top is arranged on the lower part of the stove body; a furnace on the upper part of the stove body is a gasification layer; the stove body above the furnace is provided with a flame outlet and a dreg outlet respectively; the coal conveying mechanism comprises a coal conveyor and a spiral material rotary move-up mechanism; and the flame outlet of the stove body is provided with a combustion nozzle. The gas stove has simple and compact structure, small equipment investment and safe and reliable operation, moves the gasification reaction layer of the prior gas stove upwards to the upper part of the gas stove to accelerate the gasification reaction of coal and further improve the temperature of a pyrolytic reaction, and ensures that mixed gas generated by the gasification layer instantly enters the built-in combustion nozzle to react with oxygen, and gas temperature after nozzle combustion can reach 1,400 to 1,500 DEG C. The mode particularly meets the requirement of high temperature heating process.

Owner:淄博禹江实业有限公司

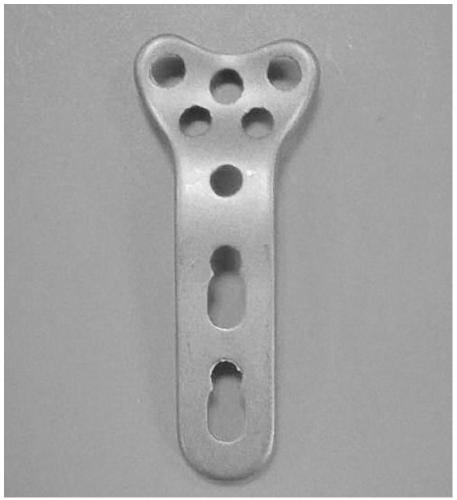

Preparation method of titanium-based tantalum coating biological implant material

ActiveCN109338329AImprove bindingImprove surface roughnessTissue regenerationChemical vapor deposition coatingReaction temperatureBinding force

The invention discloses a preparation method of a titanium-based tantalum coating biological implant material. A titanium-based substrate of which a rough surface is formed by sand blasting treatmentand tantalum metal are placed in a vapor deposition reaction chamber, chlorine and hydrogen are injected to the reaction chamber for a vapor deposition reaction, the vapor deposition time is 7-10 h, and the reaction temperature of vapor deposition is 900-1000 DEG C. According to the preparation method of the titanium-based tantalum coating biological implant material, a tantalum coating obtained by the deposition has good morphology, the thickness of the tantalum coating can be up to 20 microns, and the tantalum coating is uniform and dense; the binding force between the coating and the substrate is greater than 40 Mpa, and the requirements of anti-stripping in the clinical application process can be met; and the prepared titanium-based tantalum coating biological implant material has theaverage compression resistance strength of 611+ / -20.4 Mpa, the yield strength of 508+ / -15.8 Mpa and the elastic modulus of 102+ / -4.1 Gpa, and good bend resistance strength and yield strength are achieved.

Owner:赵德伟 +2

Pyrolyzation, gasification and carbonization device for producing reclaimed oil by utilizing waste

InactiveCN108342226AReduce moisture contentIncrease profitEnergy inputGasification processes detailsWater contentCollection system

The invention discloses a pyrolyzation, gasification and carbonization device for producing reclaimed oil by utilizing waste. The pyrolyzation, gasification and carbonization device comprises a supplysystem, a pretreatment system, a pyrolyzation and carbonization device, a combustion and gasification device, a residual heat recycling system, a carbon recovery system and a reclaimed oil preparation and collection system, wherein the supply system, the pretreatment system, the pyrolyzation and carbonization device, the combustion and gasification device, the residual heat recycling system, thecarbon recovery system and the reclaimed oil preparation and collection system are mutually connected; the reclaimed oil preparation and collection system comprises a quick cooling tower, a reclaimedoil condenser, a reclaimed oil purification tower and a reclaimed oil storage box; the quick cooling tower is communicated with the pyrolyzation and carbonization device; the quick cooling tower is inside communicated with the reclaimed oil condenser; the reclaimed oil condenser and the quick cooling tower are both communicated with the reclaimed oil storage box; the reclaimed oil condenser is communicated with the reclaimed oil purification tower; the purification tower is communicated with the combustion and gasification device and the reclaimed oil storage box. The pyrolyzation, gasification and carbonization device for producing the reclaimed oil by utilizing the waste, which is provided by the invention, is simple in structure, is used for preparing the reclaimed oil by sufficiently utilizing a discarded tire and agricultural waste, is used for effectively decreasing the water content of the waste and circularly utilizing generated heat once again, is used for saving energy, and is used for avoiding ignition and an explosion.

Owner:吴宽永 +6

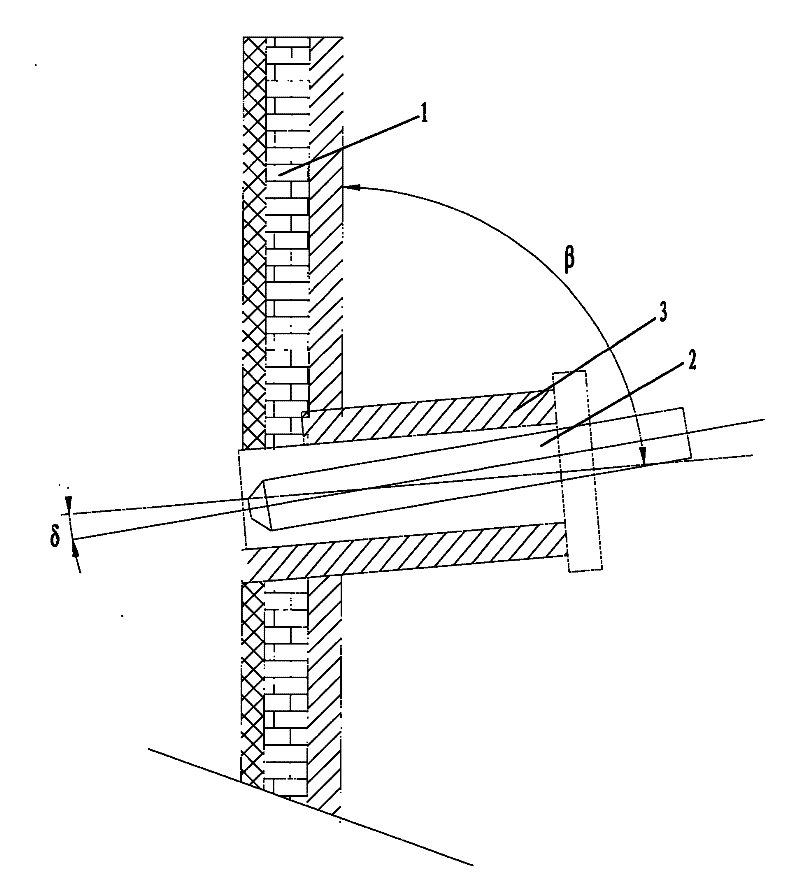

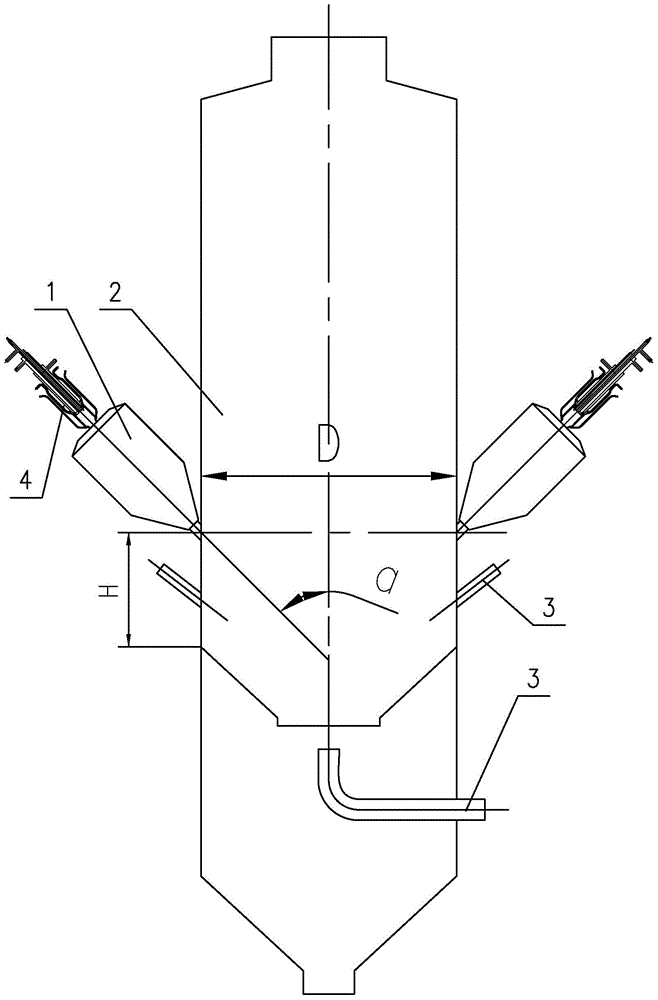

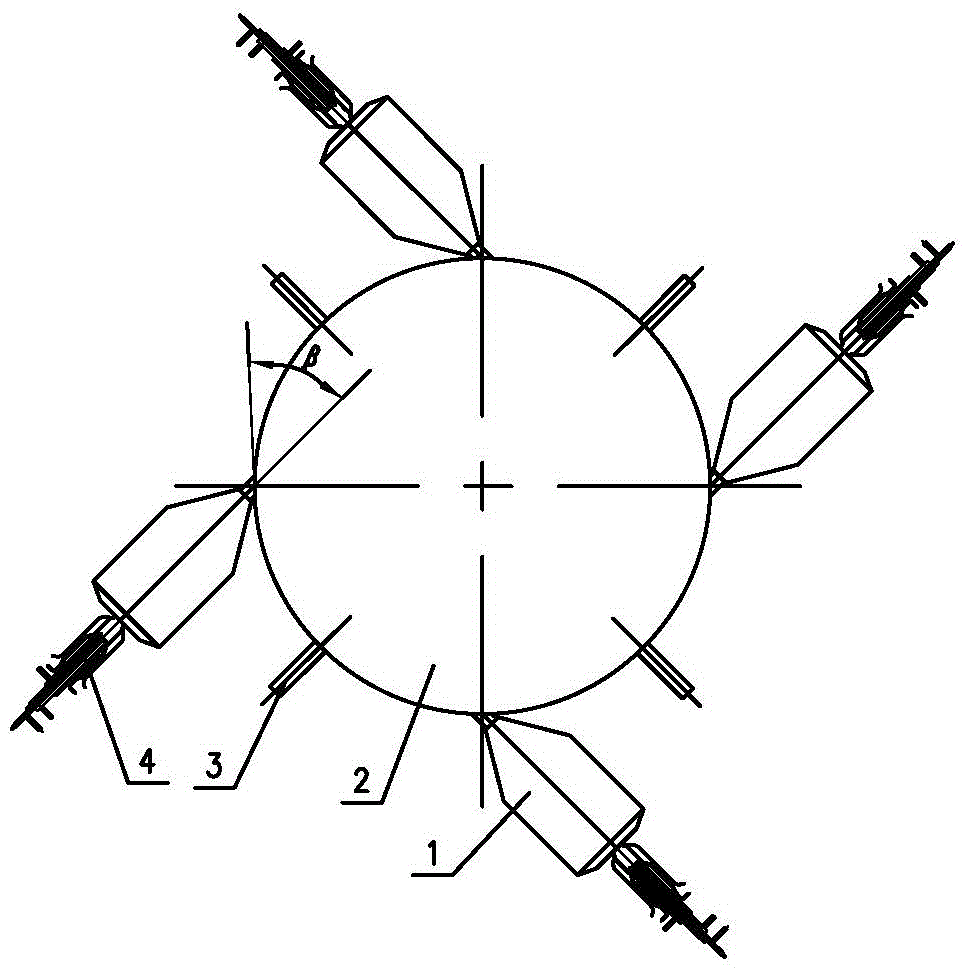

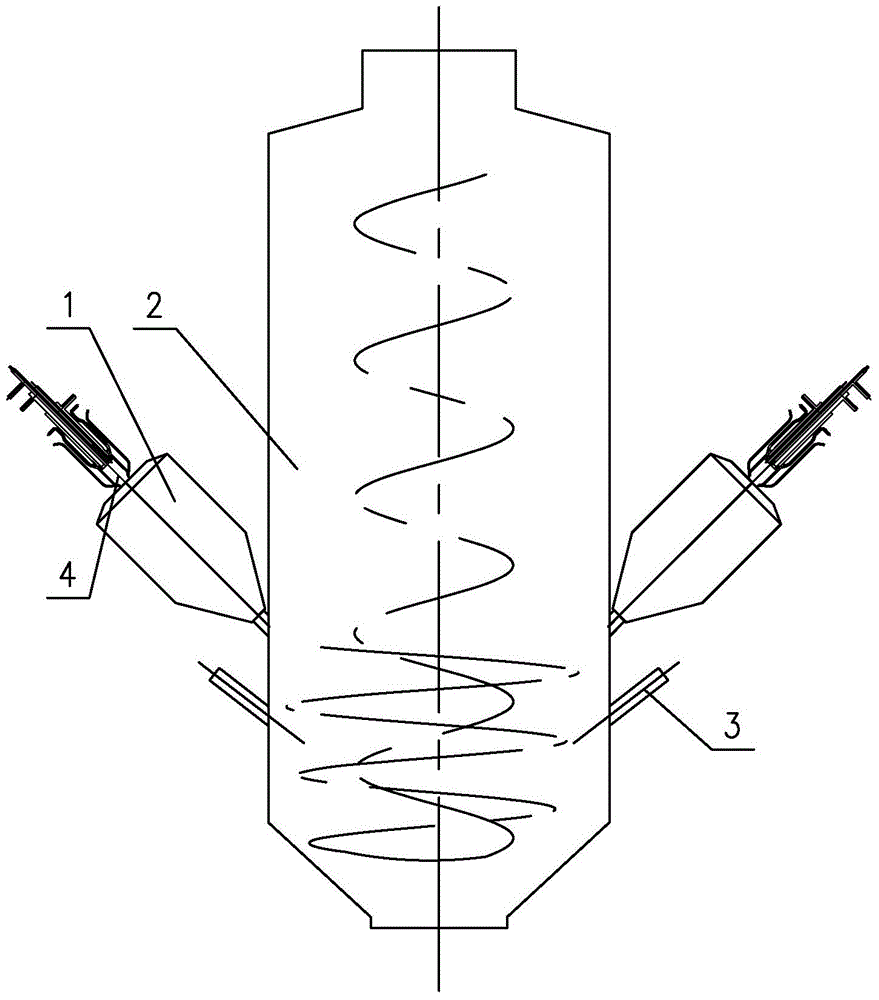

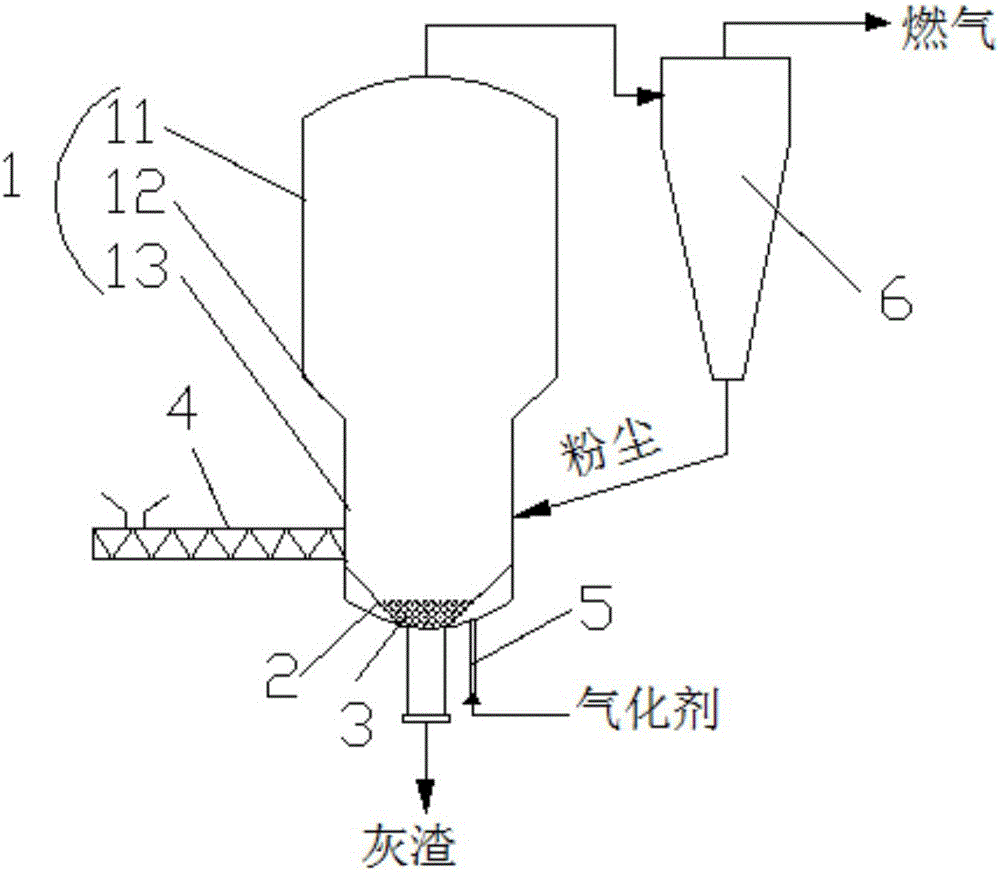

Two-stage type entrained flow gasification furnace

ActiveCN104974796AWork effectively for a long timeReduce volumeGranular/pulverulent flues gasificationSlagEngineering

The present invention discloses a two-stage type entrained flow gasification furnace. In the prior art, under the working condition of dry coal powder entrained flow gasification, the gasification furnace with characteristics of cleaning, long service life, high concern conversion rate and high gasification reaction intensity is required to be developed. The two-stage type entrained flow gasification furnace is characterized in that the outlet of the pre-gasification chamber is obliquely inserted into the main gasification chamber, a ratio of the height from the center of the pre-gasification chamber outlet to the main gasification chamber bottom portion to the diameter of the main gasification chamber is 0.3-2:1, the included angle alpha formed by the axial line of the pre-gasification chamber and the axial line of the main gasification chamber in the vertical cross-section is 30-90 DEG, the included angle beta formed by the axial line of the pre-gasification chamber and the tangent line of the main gasification chamber in the horizontal cross-section is 30-90 DEG, the top portion of the pre-gasification chamber is provided with a coal gasification burner, and the main gasification chamber is provided with a gasification agent spraying nozzle. According to the present invention, the service life of the furnace lining is prolonged, the waste of the fuel due to the falling of the coal powder into the slag pool through the slag discharge port is reduced, and the two-stage type entrained flow gasification furnace is suitable for the occasions using the coal powder to prepare the industrial fuel gas.

Owner:ZHEJIANG ASROAD HIGHWAY CONSTR & MAINTENANCE MACHINERY

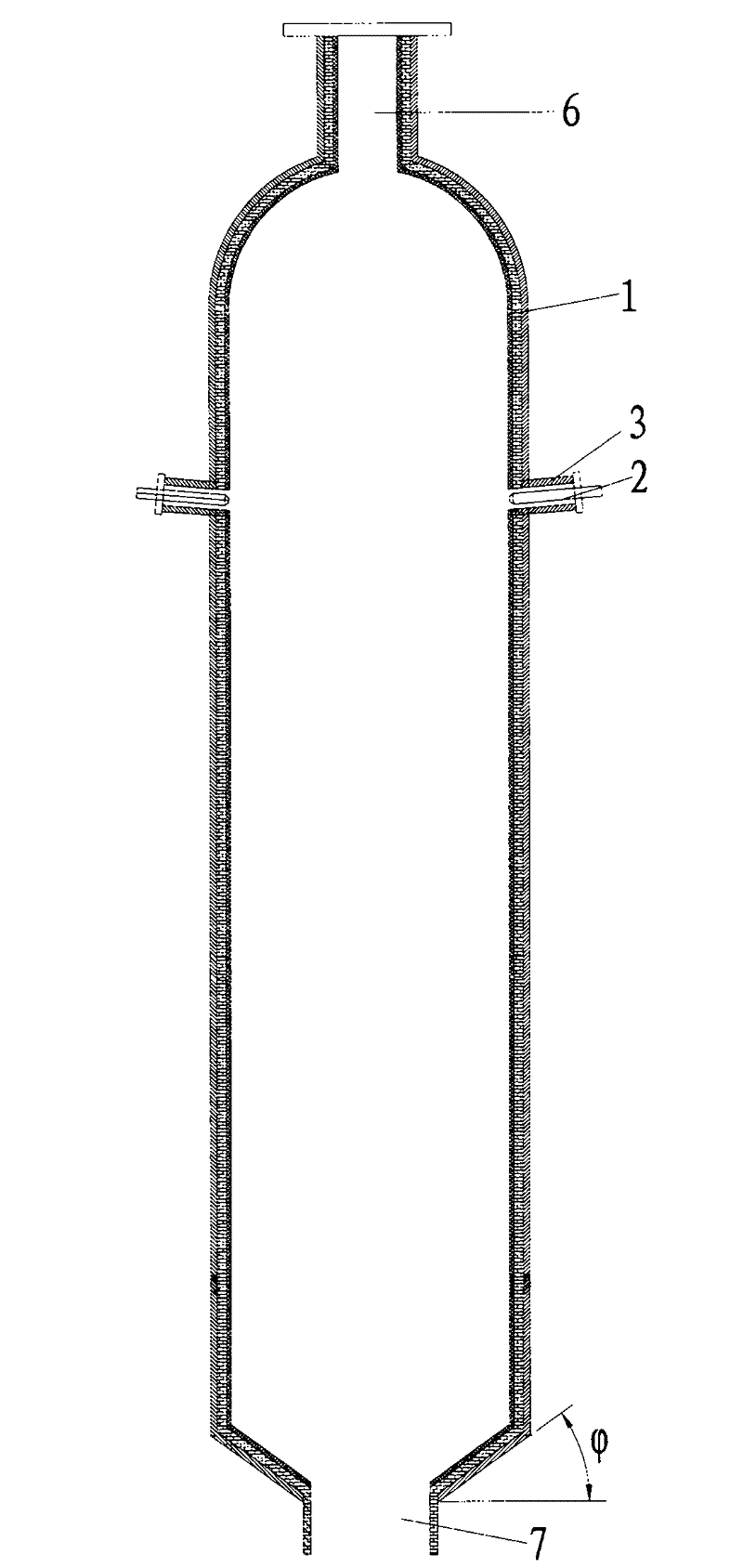

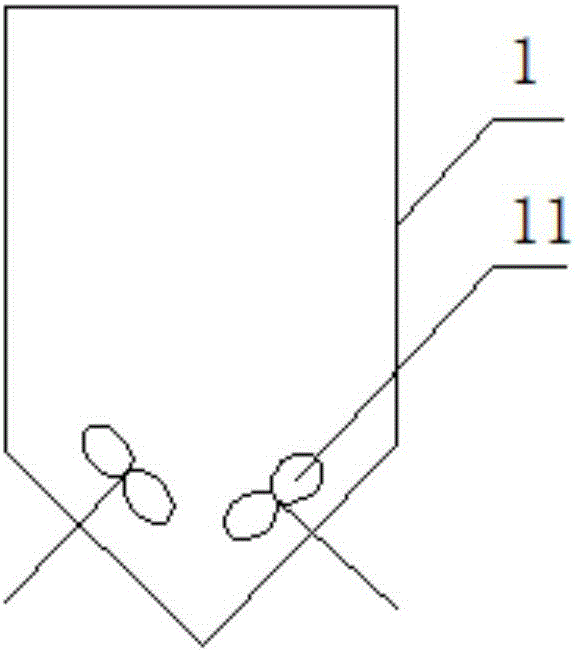

Fluidized-bed gasification furnace for treating biomass

InactiveCN106336905ALight weightSmall specific surface areaGasifier feeding meansGasifier mechanical detailsFluidized bed gasifierRound table

The present invention discloses a fluidized-bed gasification furnace for treating biomass. According to the fluidized-bed gasification furnace, the fluidized-bed gasification furnace body comprises an upper cylinder having a cylindrical structure, a lower cylinder having a cylindrical structure, and a connection section for connecting the upper cylinder and the lower cylinder; and the fluidized-bed gasification furnace is characterized in that the diameter ratio of the upper cylinder to the lower cylinder is 1.5-2:1, the connection section has a top-removing cone structure, the inclination angle of the connection section is 45-75 DEG, the bottom portion of the lower cylinder is provided with a wind distribution plate, the wind distribution plate has a hollow round table structure having the large upper portion and the small lower portion, and the included angle between the wind distribution plate and the bottom portion of the lower cylinder is 20-55 DEG. According to the present invention, the biomass raw material can be subjected to the large-scale treatment with the fluidized-bed gasification furnace, the fluidized-bed gasification furnace has the high energy conversion rate, the tar content in the produced fuel gas is low, and the secondary pollution cannot be generated.

Owner:武汉高斯生态能源技术有限公司

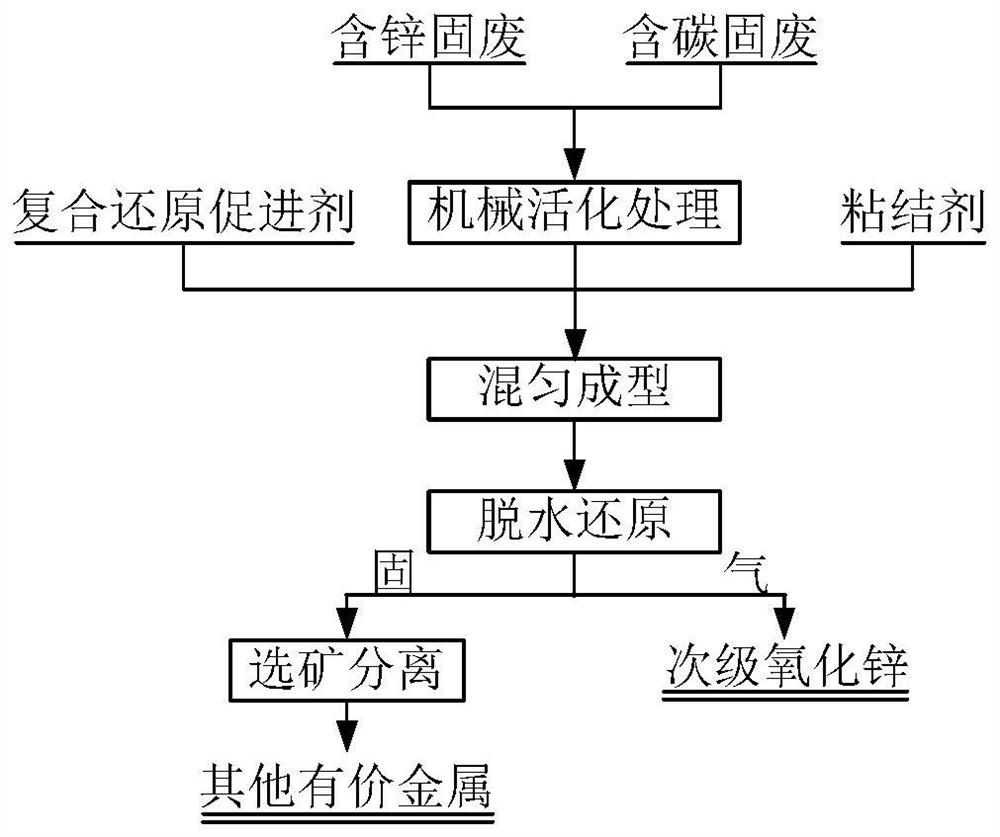

Method for treating zinc-containing and carbon-containing industrial solid waste in steel production process

PendingCN113025813AReduce raw material particle sizeImprove reduction efficiencyFluidised-bed furnacesBriquetteProcess engineering

The invention discloses a method for treating zinc-containing and carbon-containing industrial solid waste in a steel production process. The method comprises the following steps: briquettes containing a composite reduction accelerator, a binder and the zinc-containing and carbon-containing industrial solid waste obtained by mechanical activation treatment in the steel production process are reduced at 950-1050 DEG C for 10-25 minutes; a reduced gas product is recovered through a dust removal system to obtain a secondary zinc oxide product, and residues are separated through mineral separation to extract iron; wherein the briquettes are obtained by uniformly mixing the composite reduction accelerator, the binder, water and the zinc-containing and carbon-containing industrial solid waste in the steel production process and performing compression molding and drying. According to the method, by reducing the reduction temperature and reduction time, the purposes of reducing energy consumption, utilizing carbon resources in solid waste and recycling valuable metals such as zinc and iron are achieved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY +1

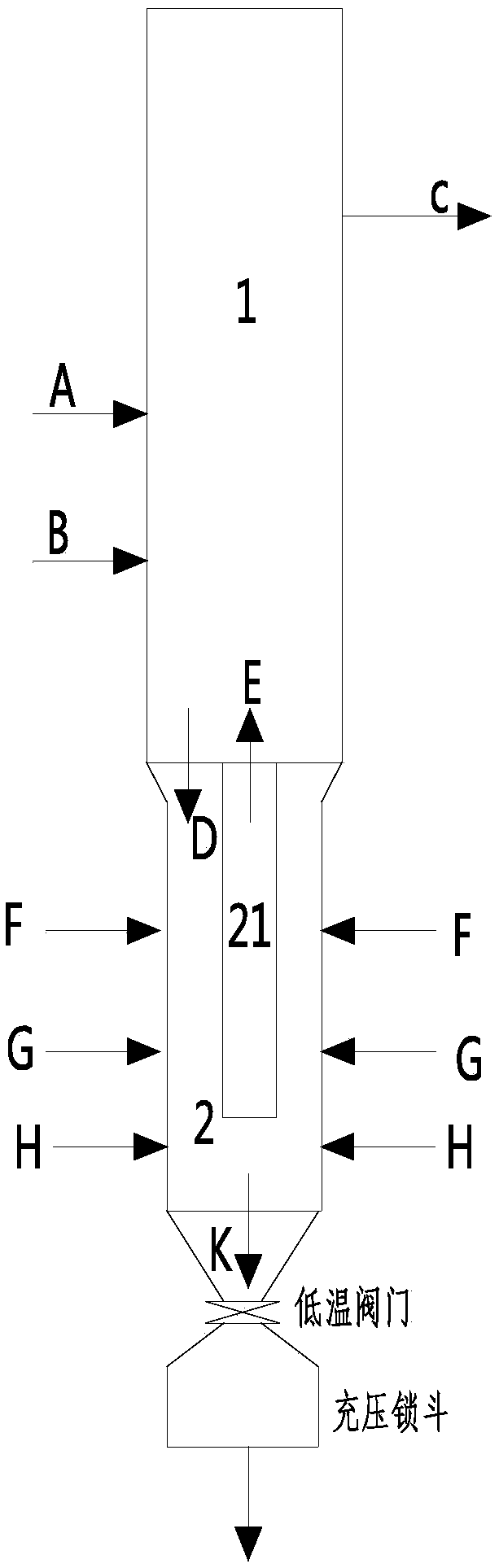

Base slag treatment device and method for fluidized bed gasification furnace

PendingCN110387267AGuaranteed uptimeAvoid prone to slaggingChemical industryGasification processes detailsFluidized bed gasifierSlag

The invention provides a base slag treatment device (2) for a fluidized bed gasification furnace. The base slag treatment device (2) is provided with a hot slag inlet and a cold slag outlet, the hot slag inlet is used for being connected with the gasification furnace (1) to receive hot slag (D), the cold slag outlet is used for discharging cold slag (K), and the base slag treatment device (2) is configured to reignite and cool the hot slag (D). The invention further provides a base slag treatment method for the fluidized bed gasification furnace. According to the base slag treatment device andmethod for the fluidized bed gasification furnace, the base slag is low in carbon content and not prone to slag bonding, the efficiency is high, and energy saving and consumption reducing can be achieved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

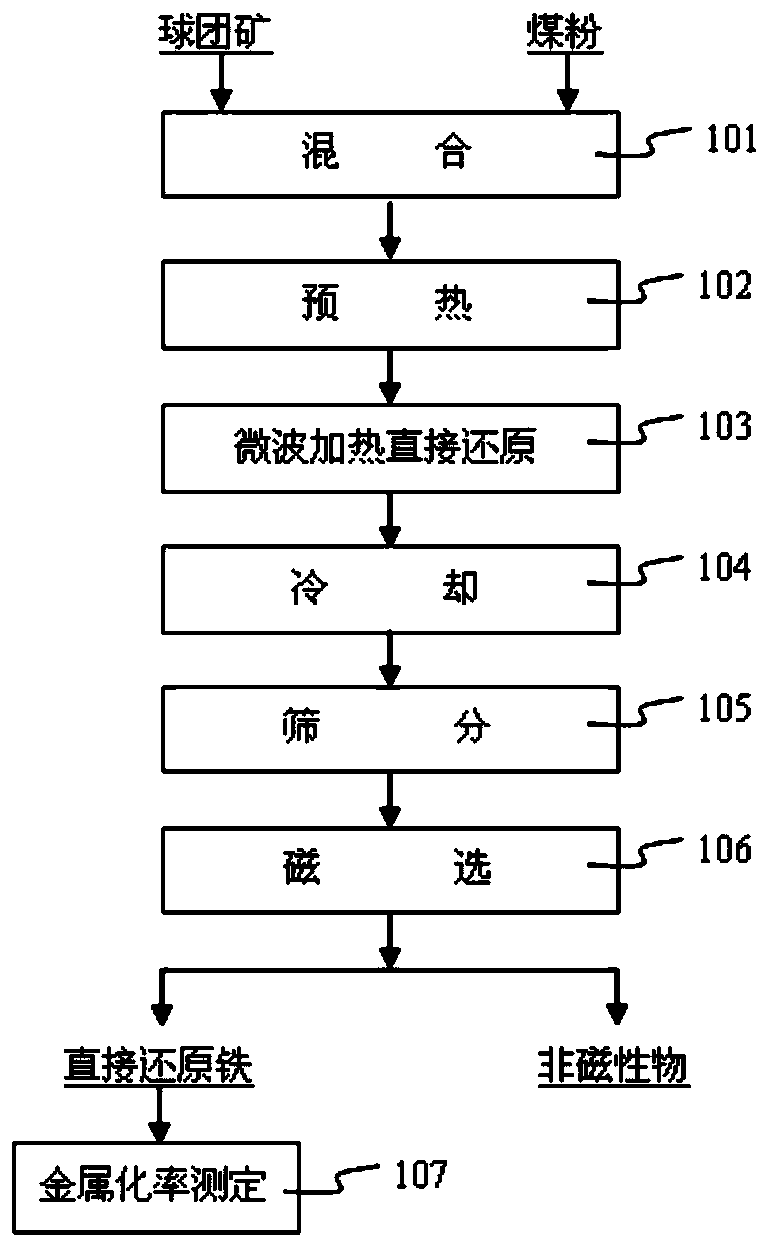

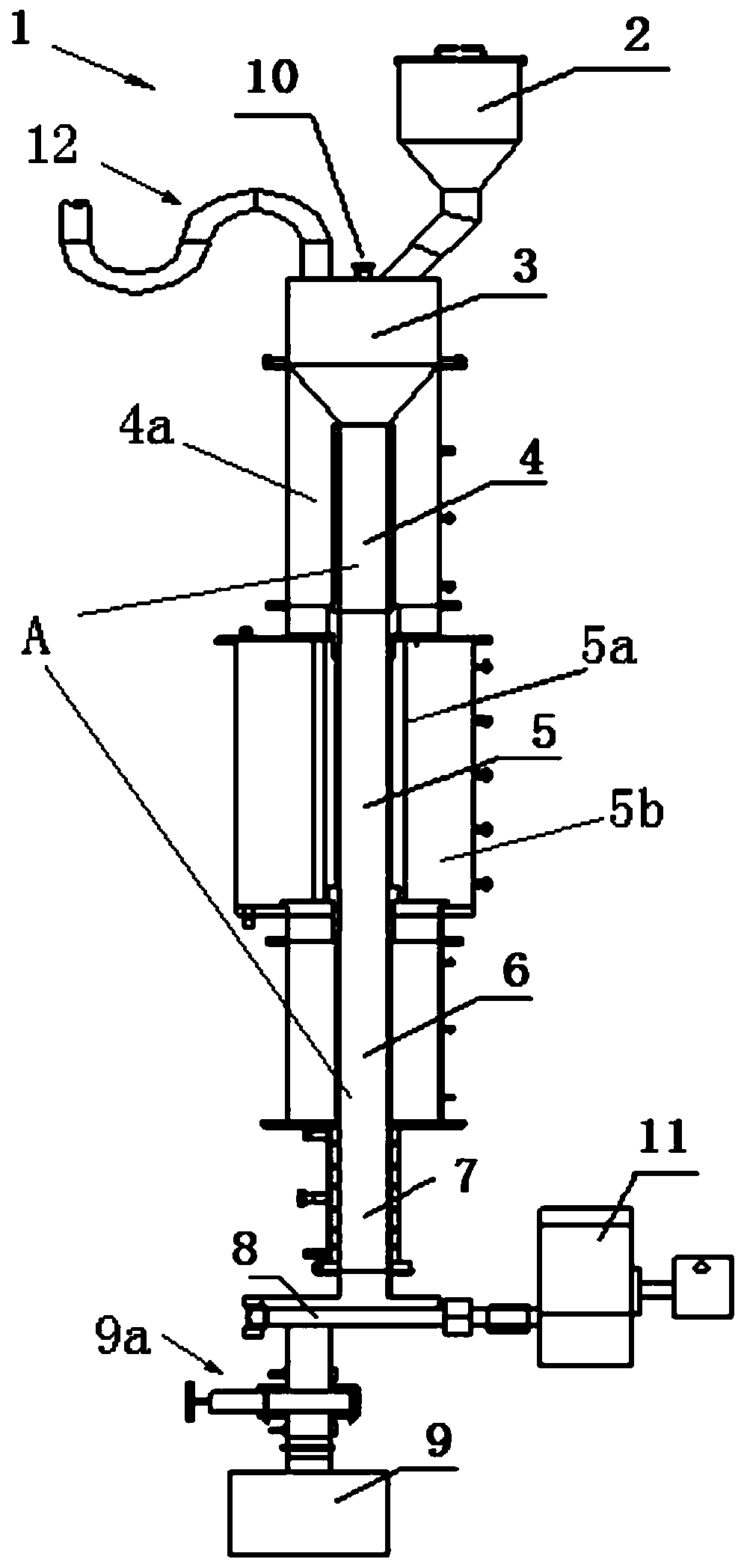

A method and device for producing direct reduced iron

ActiveCN107779536BReduce the temperatureLower requirementShaft furnaceProcess efficiency improvementChemical reactionShaft furnace

The invention relates to a microwave shaft furnace direct reduction process adopting pellets and coal powder. According to the process, direct reduced iron is produced from raw material pellets and external matched material coal powder in a continuous microwave shaft furnace, selection heating, rapid heating, volume heating, activated metallurgical chemical reaction and other features of the microwave are fully utilized, gasification of fixed carbon is accelerated, and iron oxide is further reduced, so that the reduction temperature is lowered and the reaction time is shortened. The coal powder can serve as both a reducing agent and a heating element in the process, a gas-solid-heat exchange step is simplified, energy is saved and emission is reduced. The process contains low free oxygen content, and can produce CO with high purity of 95% or above; and the process is compact in structure, high in metallization degree, which is 94-98%, low in carbon content, which is less than 0.2%, andis low in quality requirements on coal powder, thereby being an environment-friendly iron making process.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com