System for preparing high-caloric-value biomass gasified gas by using high-temperature flue gas of oxygen-enriched combustion boiler

A technology of oxygen-enriched combustion and boiler flue gas, which is applied in granular/powder fuel gasification, combustion equipment, gasification process, etc., can solve the problems of low calorific value of gasification gas and high cost of biomass gasification, and achieve The effect of good applicability, improving energy utilization efficiency and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

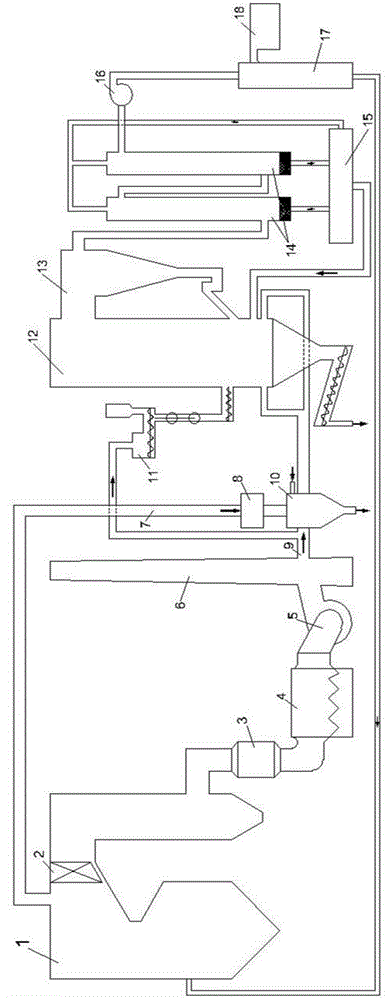

[0036] The high-calorific-value gasification gas production system using high-temperature flue gas from an oxygen-enriched combustion boiler includes a biomass hopper 11 for feeding, a high-temperature dust cover 3 for removing smoke and dust, and high-temperature and low-temperature flue gas pipes 7 for intake air and 9, and binary / ternary gas mixer 10, circulating fluidized bed gasifier 12, cyclone separator 13, the spray tower 14 and sewage treatment device 15, fan 16 and A gas cabinet 17 for storing biomass gasification gas.

[0037] When the system is in operation, firstly, the crushed biomass whose particle size is not greater than 50mm is transported to the biomass hopper 11 with part of the low-temperature flue gas from the low-temperature flue gas pipeline 9, and fed into the middle of the circulating fluidized bed reactor 12. lower part. The high-temperature flue gas from the high-temperature superheater 2 in the furnace 1 of the oxygen-enriched boiler passes throug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com